SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 141 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-99

7) Place special tool (C) on soft jawed vise (2) with wider open-

ing (1) facing up.

Special tool

(C) : 09926-26040

8) Place rear clutch assembly (1) on special tool (C).

9) Set dial gauge (2) on the top of clutch flange (3) and mea-

sure clearance by blowing compressed air (4 kg/cm

2, 57 psi)

as shown in figure.

If the clearance is out of specification, replace clutch discs,

plates and flange.

Rear clutch disc clearance

: 0.80 – 1.40 mm (0.031 – 0.055 in.)

10) Attach special tool (B) to dial gauge (4) and set them on the

lowest clutch plate (2).

Special tool

(B) : 09952-06010

11) Measure piston stroke by blowing compressed air (4 kg/cm

2,

57 psi) as shown in figure.

If the piston stroke is out of specification, replace clutch

discs, plates and flange.

Rear clutch piston stroke

: 1.93 – 2.13 mm (0.076 – 0.084 in.)

1. Rear clutch assembly

3. Air gun

Page 142 of 447

7B-100 AUTOMATIC TRANSMISSION (4 A/T)

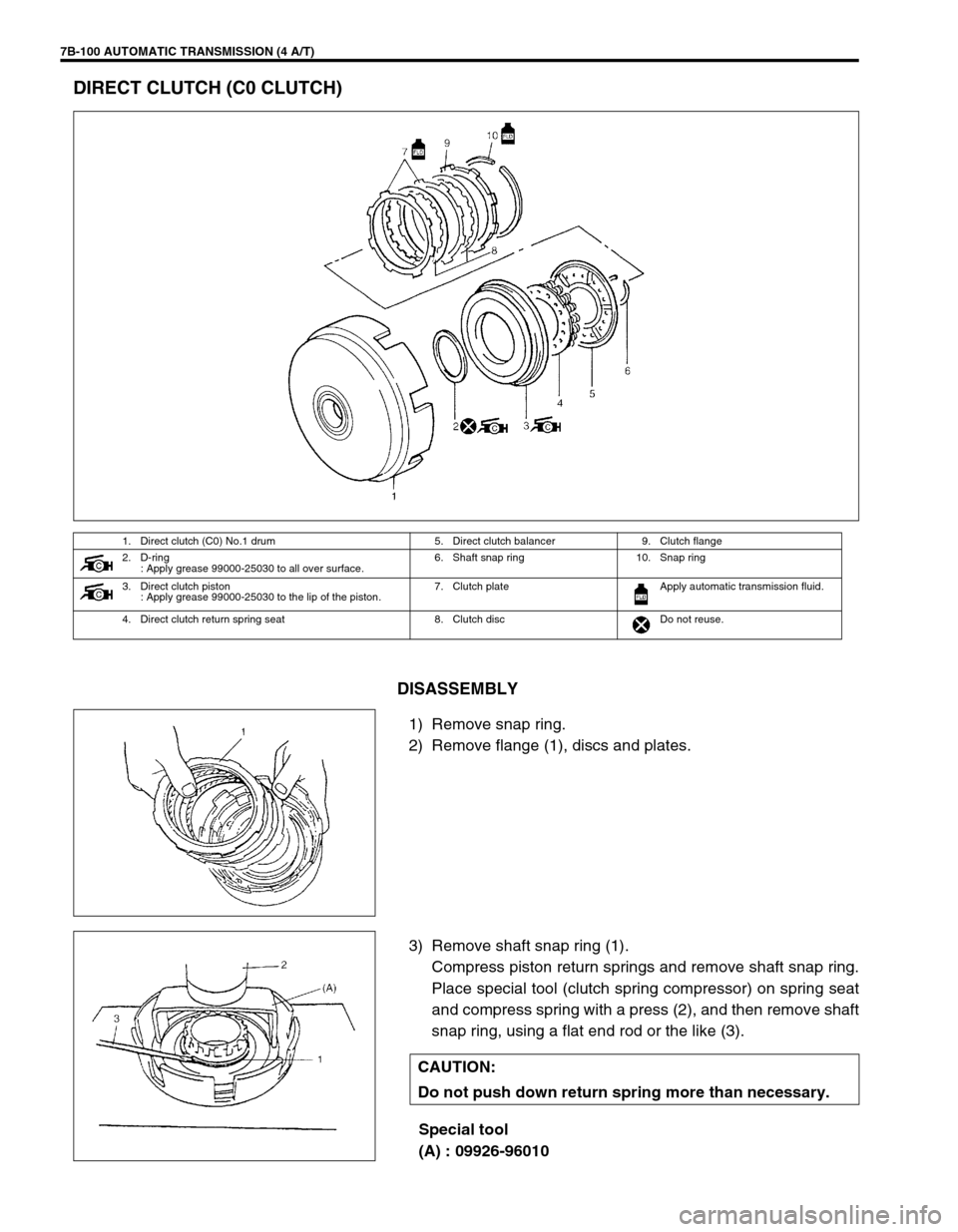

DIRECT CLUTCH (C0 CLUTCH)

DISASSEMBLY

1) Remove snap ring.

2) Remove flange (1), discs and plates.

3) Remove shaft snap ring (1).

Compress piston return springs and remove shaft snap ring.

Place special tool (clutch spring compressor) on spring seat

and compress spring with a press (2), and then remove shaft

snap ring, using a flat end rod or the like (3).

Special tool

(A) : 09926-96010

1. Direct clutch (C0) No.1 drum 5. Direct clutch balancer 9. Clutch flange

2. D-ring

: Apply grease 99000-25030 to all over surface.6. Shaft snap ring 10. Snap ring

3. Direct clutch piston

: Apply grease 99000-25030 to the lip of the piston.7. Clutch plate Apply automatic transmission fluid.

4. Direct clutch return spring seat 8. Clutch disc Do not reuse.

CAUTION:

Do not push down return spring more than necessary.

Page 143 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-101

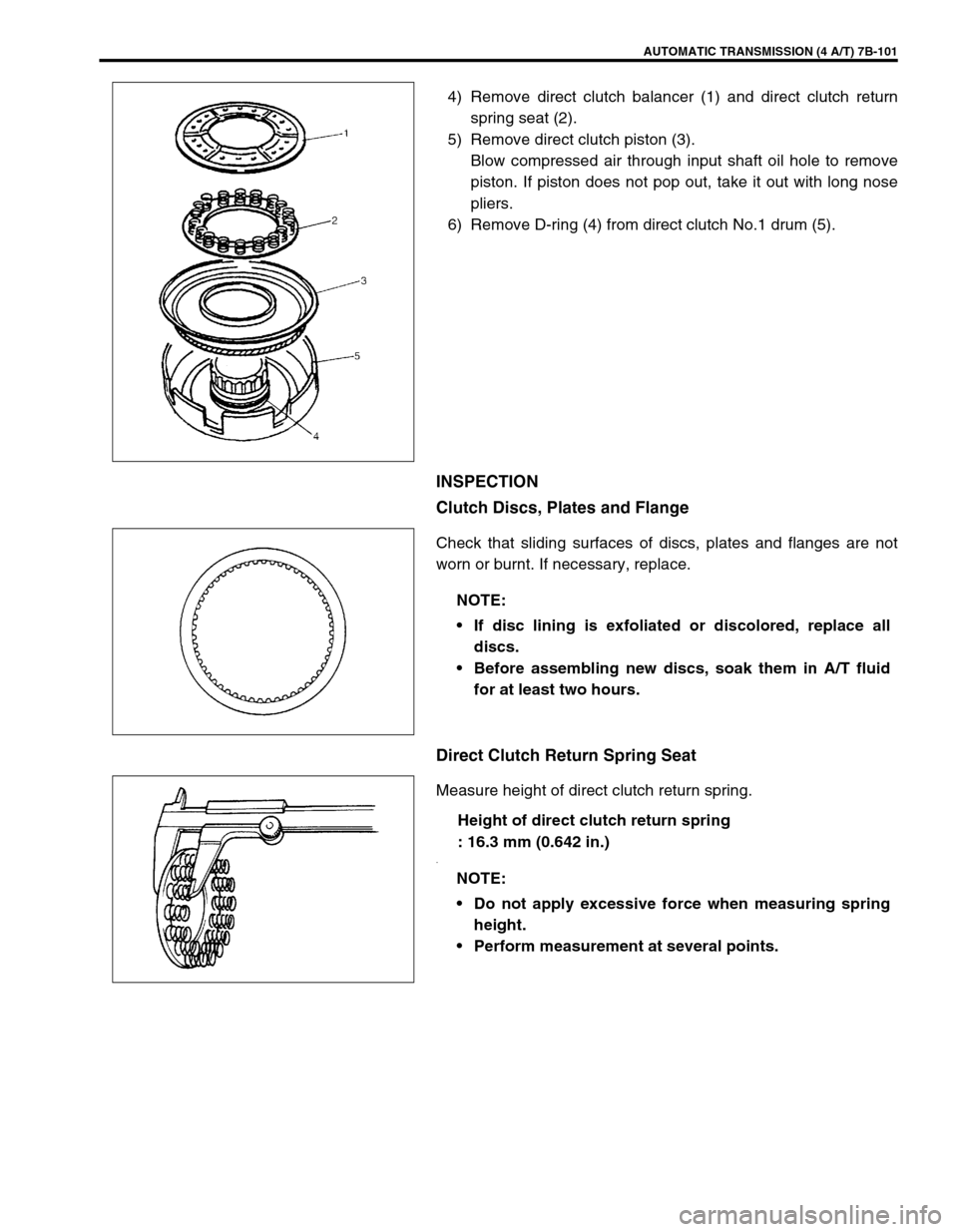

4) Remove direct clutch balancer (1) and direct clutch return

spring seat (2).

5) Remove direct clutch piston (3).

Blow compressed air through input shaft oil hole to remove

piston. If piston does not pop out, take it out with long nose

pliers.

6) Remove D-ring (4) from direct clutch No.1 drum (5).

INSPECTION

Clutch Discs, Plates and Flange

Check that sliding surfaces of discs, plates and flanges are not

worn or burnt. If necessary, replace.

Direct Clutch Return Spring Seat

Measure height of direct clutch return spring.

Height of direct clutch return spring

: 16.3 mm (0.642 in.)

.

NOTE:

If disc lining is exfoliated or discolored, replace all

discs.

Before assembling new discs, soak them in A/T fluid

for at least two hours.

NOTE:

Do not apply excessive force when measuring spring

height.

Perform measurement at several points.

Page 144 of 447

7B-102 AUTOMATIC TRANSMISSION (4 A/T)

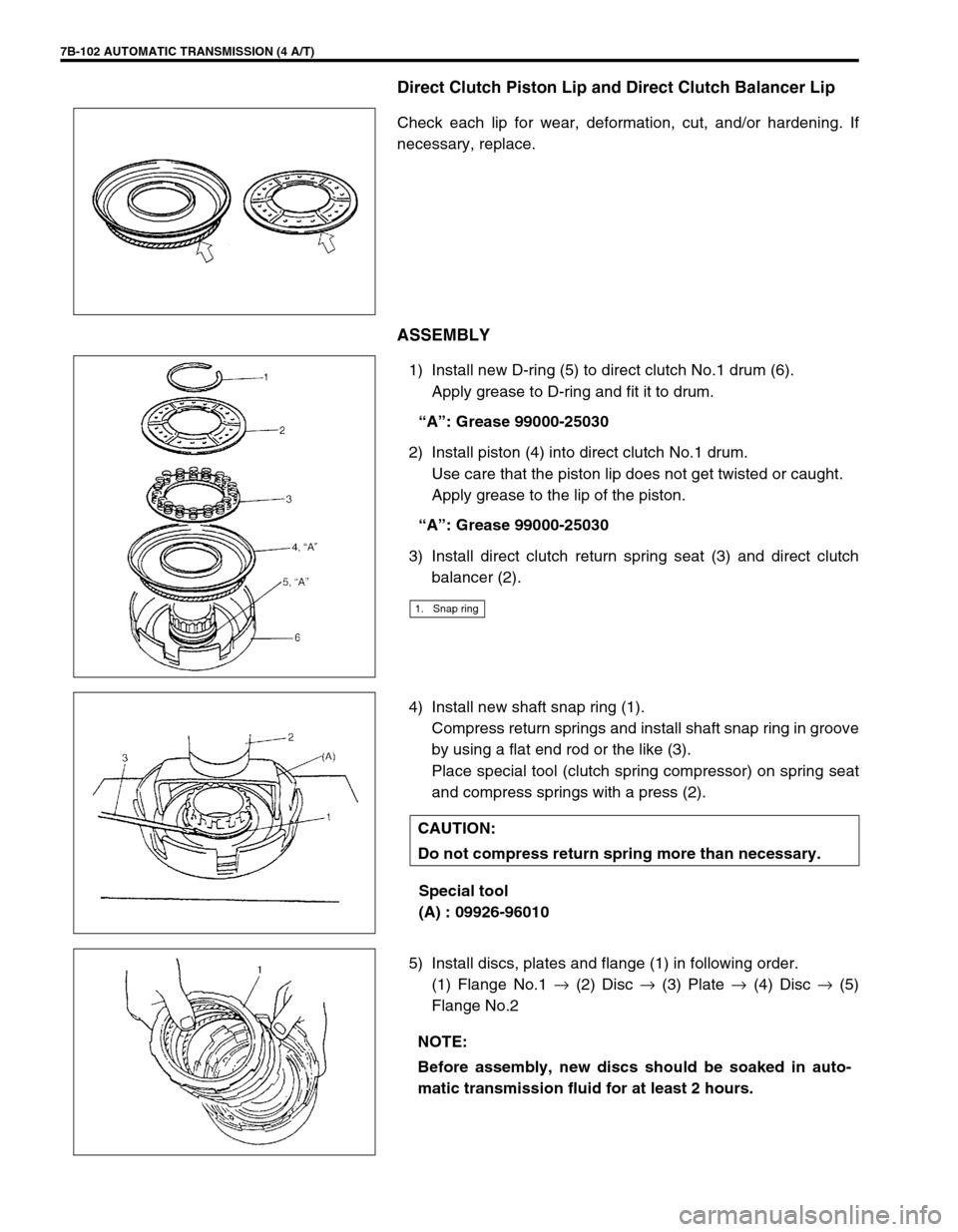

Direct Clutch Piston Lip and Direct Clutch Balancer Lip

Check each lip for wear, deformation, cut, and/or hardening. If

necessary, replace.

ASSEMBLY

1) Install new D-ring (5) to direct clutch No.1 drum (6).

Apply grease to D-ring and fit it to drum.

“A”: Grease 99000-25030

2) Install piston (4) into direct clutch No.1 drum.

Use care that the piston lip does not get twisted or caught.

Apply grease to the lip of the piston.

“A”: Grease 99000-25030

3) Install direct clutch return spring seat (3) and direct clutch

balancer (2).

4) Install new shaft snap ring (1).

Compress return springs and install shaft snap ring in groove

by using a flat end rod or the like (3).

Place special tool (clutch spring compressor) on spring seat

and compress springs with a press (2).

Special tool

(A) : 09926-96010

5) Install discs, plates and flange (1) in following order.

(1) Flange No.1 →

(2) Disc →

(3) Plate →

(4) Disc →

(5)

Flange No.2

1. Snap ring

CAUTION:

Do not compress return spring more than necessary.

NOTE:

Before assembly, new discs should be soaked in auto-

matic transmission fluid for at least 2 hours.

Page 145 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-103

6) Install snap ring (1).

7) Place special tool (A) on soft jawed vise (1) and install 2 oil

seal rings on special tool.

Special tool

(A) : 09926-26050

(B) : Rear cover seal ring 24742-78F10 SUZUKI GENUINE

PARTS

8) Place direct clutch assembly (1) on special tool (A).

9) Set dial gauge (4) on the top of clutch flange (2) and mea-

sure clearance by blowing compressed air (4 kg/cm

2, 57 psi)

as shown in figure.

If the clearance is out of specification, replace clutch discs,

plates and flange.

Direct clutch disc clearance

: 0.50 – 1.04 mm (0.0197 – 0.0409 in.) NOTE:

Make sure that the ends of the snap ring do not come to

the opening of the front clutch No.1 drum.

NOTE:

Rear cover seal set has two seal rings in a set.

Do not use the seal rings removed from rear cover. It is

not necessary to remove seal rings from special tool

once installed.

3. Air gun

Page 146 of 447

7B-104 AUTOMATIC TRANSMISSION (4 A/T)

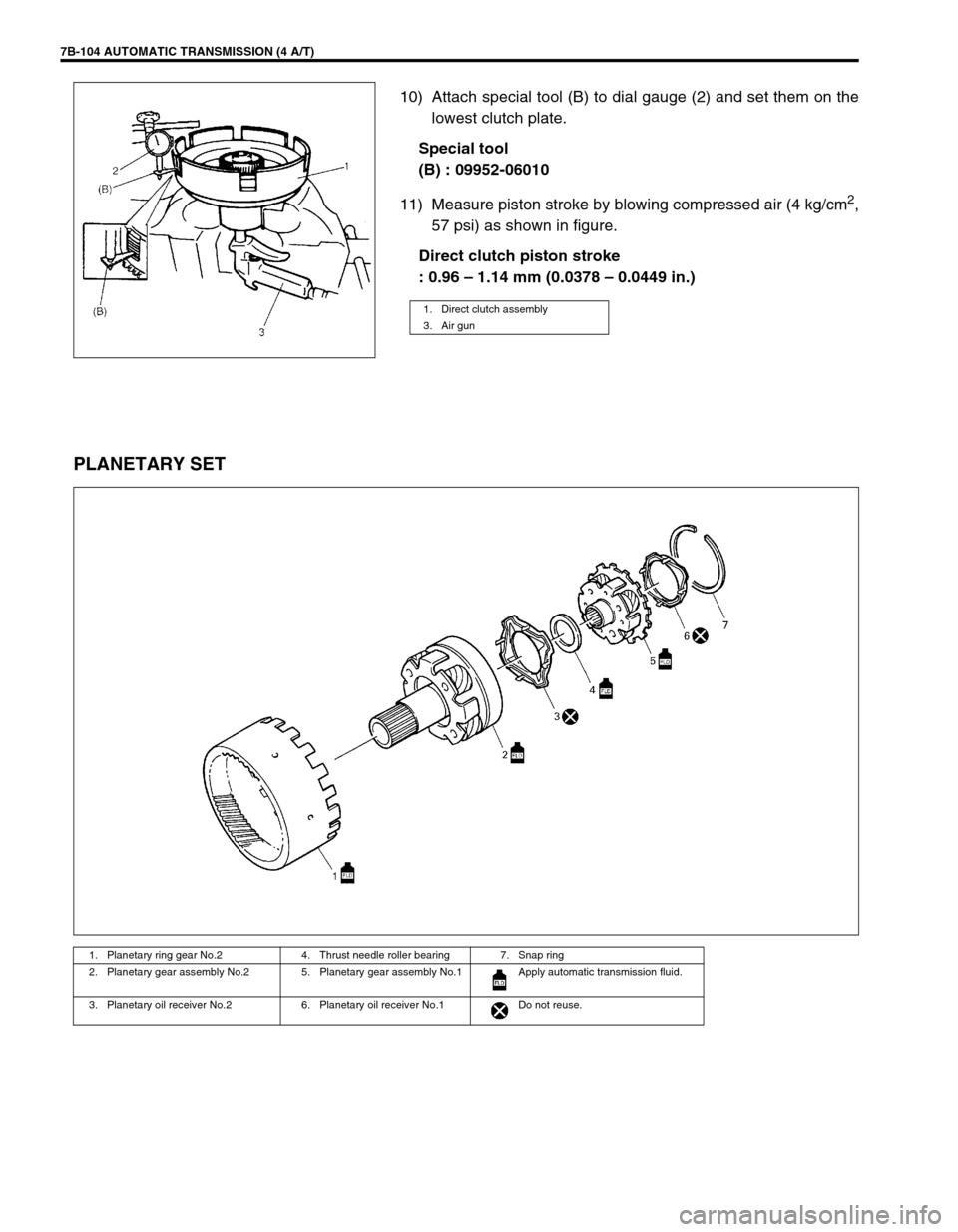

10) Attach special tool (B) to dial gauge (2) and set them on the

lowest clutch plate.

Special tool

(B) : 09952-06010

11) Measure piston stroke by blowing compressed air (4 kg/cm

2,

57 psi) as shown in figure.

Direct clutch piston stroke

: 0.96 – 1.14 mm (0.0378 – 0.0449 in.)

PLANETARY SET

1. Direct clutch assembly

3. Air gun

1. Planetary ring gear No.2 4. Thrust needle roller bearing 7. Snap ring

2. Planetary gear assembly No.2 5. Planetary gear assembly No.1 Apply automatic transmission fluid.

3. Planetary oil receiver No.2 6. Planetary oil receiver No.1 Do not reuse.

Page 147 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-105

DISASSEMBLY

1) Remove snap ring.

Remove planetary ring gear No.2.

2) Remove planetary oil receiver No.1 (1) and planetary gear

assembly No.1 (2) from planetary gear assembly No.2 (5).

3) Remove needle roller bearing (3) and planetary oil receiver

No.2 (4) from planetary gear assembly No.2.

ASSEMBLY

1) Install new planetary oil receiver No.2 (4) and needle roller

bearing (3) to planetary gear assembly No.2 (5).

2) Install planetary gear assembly No.1 (2) to planetary gear

assembly No.2 (5).

3) Install new planetary oil receiver No.1 (1).

4) Assemble planetary ring gear No.2 and planetary gear

assembly No.2.

5) Install snap ring (1).

.

NOTE:

Do not reuse oil receivers (1 and 4).

NOTE:

Note the direction of needle roller bearing.

Take care not to break the claw of oil receiver.

NOTE:

Take care not to break the claw of oil receiver.

NOTE:

Note the location of the ends of the snap ring.

2. Planetary ring gear No.2

Page 148 of 447

7B-106 AUTOMATIC TRANSMISSION (4 A/T)

VALVE BODY

1. Upper valve body 12. Lock-up control valve 23. Fail valve No.1

2. Upper valve body gasket 13. Lock-up control valve spring 24. Fail valve No.1 sleeve

3. Valve body plate 14. Lock-up signal valve plug 25. Key (short)

4. Lower valve body gasket 15. Lock-up signal valve 26. Key (long)

5. Lower valve body 16. Lock-up signal valve spring 27. Oil strainer

6. Primary regulator valve sleeve 17. Fail valve No.2 sleeve 28. Cooler by-pass valve

7. Primary regulator valve plunger 18. Fail valve No.2 29. Cooler by-pass valve spring

8. Primary regulator valve spring 19. Secondary regulator valve plug 30. Steel ball

9. Washer 20. Secondary regulator valve spring 31. Lock-up control valve

10. Primary regulator valve 21. Secondary regulator valve Apply automatic transmission fluid.

11. Lock-up control valve sleeve 22. Manual valve Do not reuse.

Page 149 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-107

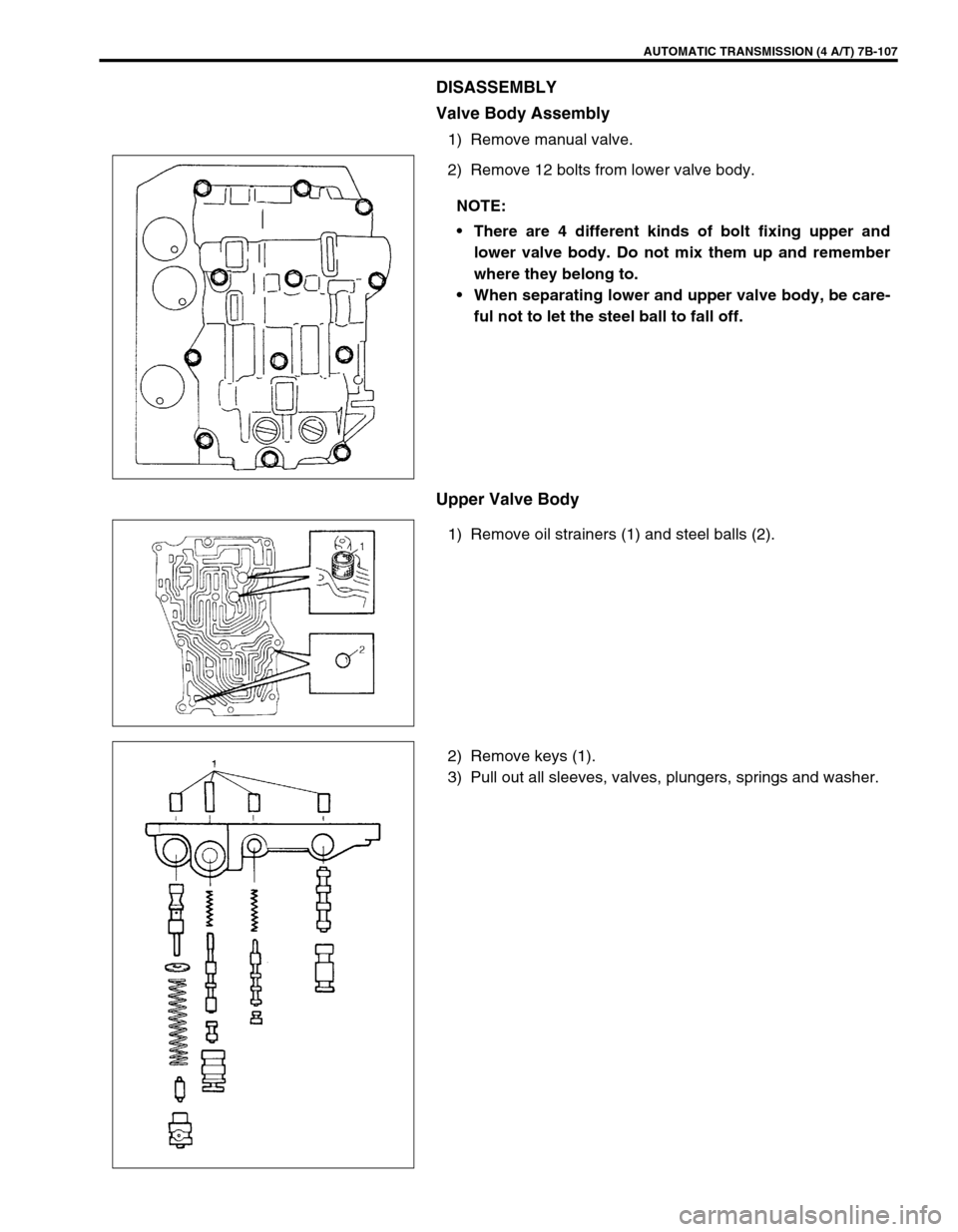

DISASSEMBLY

Valve Body Assembly

1) Remove manual valve.

2) Remove 12 bolts from lower valve body.

Upper Valve Body

1) Remove oil strainers (1) and steel balls (2).

2) Remove keys (1).

3) Pull out all sleeves, valves, plungers, springs and washer.NOTE:

There are 4 different kinds of bolt fixing upper and

lower valve body. Do not mix them up and remember

where they belong to.

When separating lower and upper valve body, be care-

ful not to let the steel ball to fall off.

Page 150 of 447

7B-108 AUTOMATIC TRANSMISSION (4 A/T)

Valve spring dimensions (Reference)

Lower Valve Body

1) Remove oil strainers (1).

2) Remove solenoid valves, if still attached.

3) Remove keys (2) and pull out all sleeve, plug, spring and

valves.

Valve spring dimensions (Reference)Spring Free length

“a” (mm)Outside diameter

“b” (mm)

Primary regula-

tor valve spring79.2 18.0

Lock-up control

valve spring31.1 8.5

Lock-up signal

valve spring36.1 8.5

3. Fail valve No.1 sleeve

4. Fail valve No.1

5. Cooler by-pass valve

6. Cooler by-pass valve spring

7. Manual valve

8. Secondary regulator valve

9. Secondary regulator valve spring

10. Secondary regulator valve plug

Spring Free length

“a” (mm)Outside diame-

ter “b” (mm)

Secondary regula-

tor valve spring38.7 8.8

Cooler by-pass

valve spring22.8 8.0