engine mount SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 808 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-160 Automatic Transmission/Transaxle:

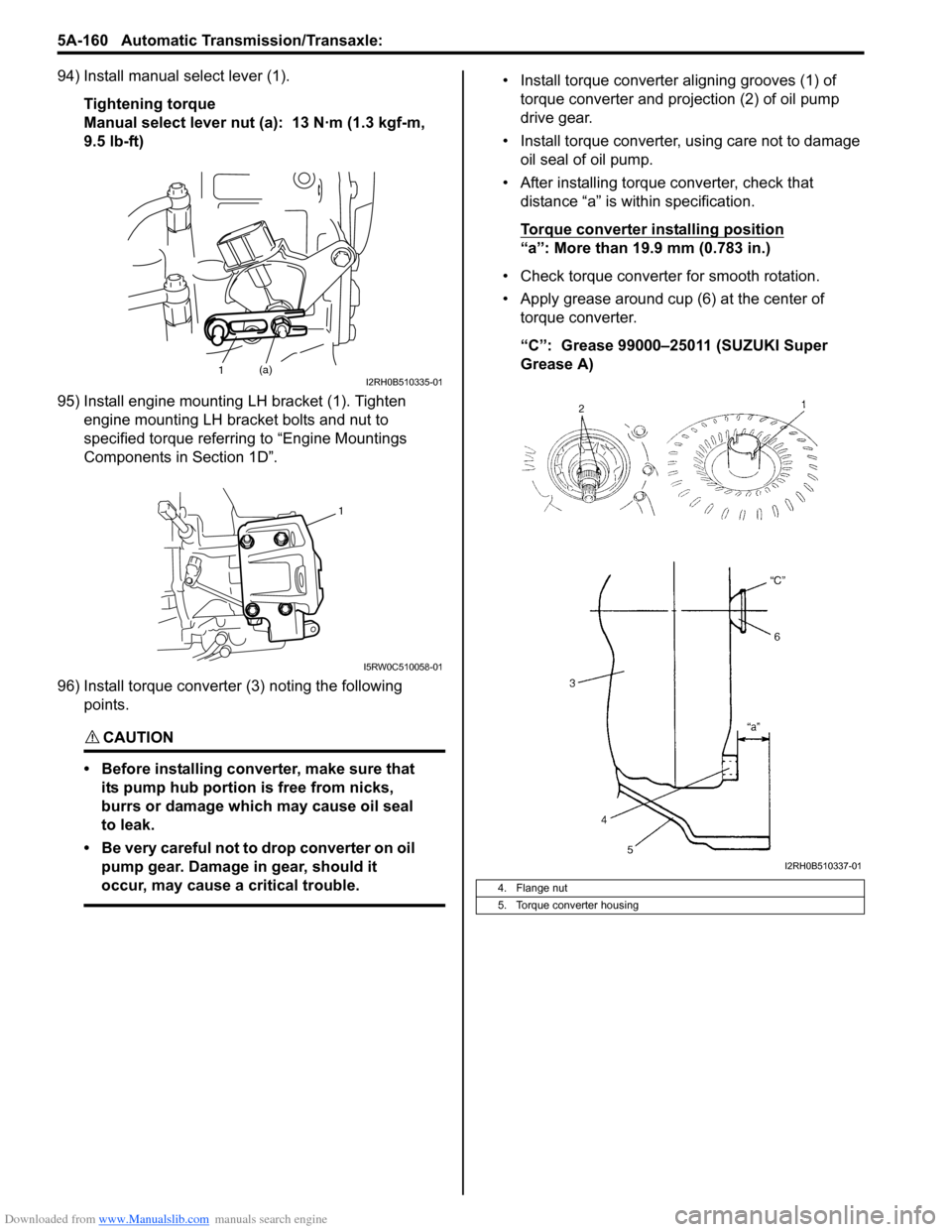

94) Install manual select lever (1).

Tightening torque

Manual select lever nut (a): 13 N·m (1.3 kgf-m,

9.5 lb-ft)

95) Install engine mounting LH bracket (1). Tighten

engine mounting LH bracket bolts and nut to

specified torque referring to “Engine Mountings

Components in Section 1D”.

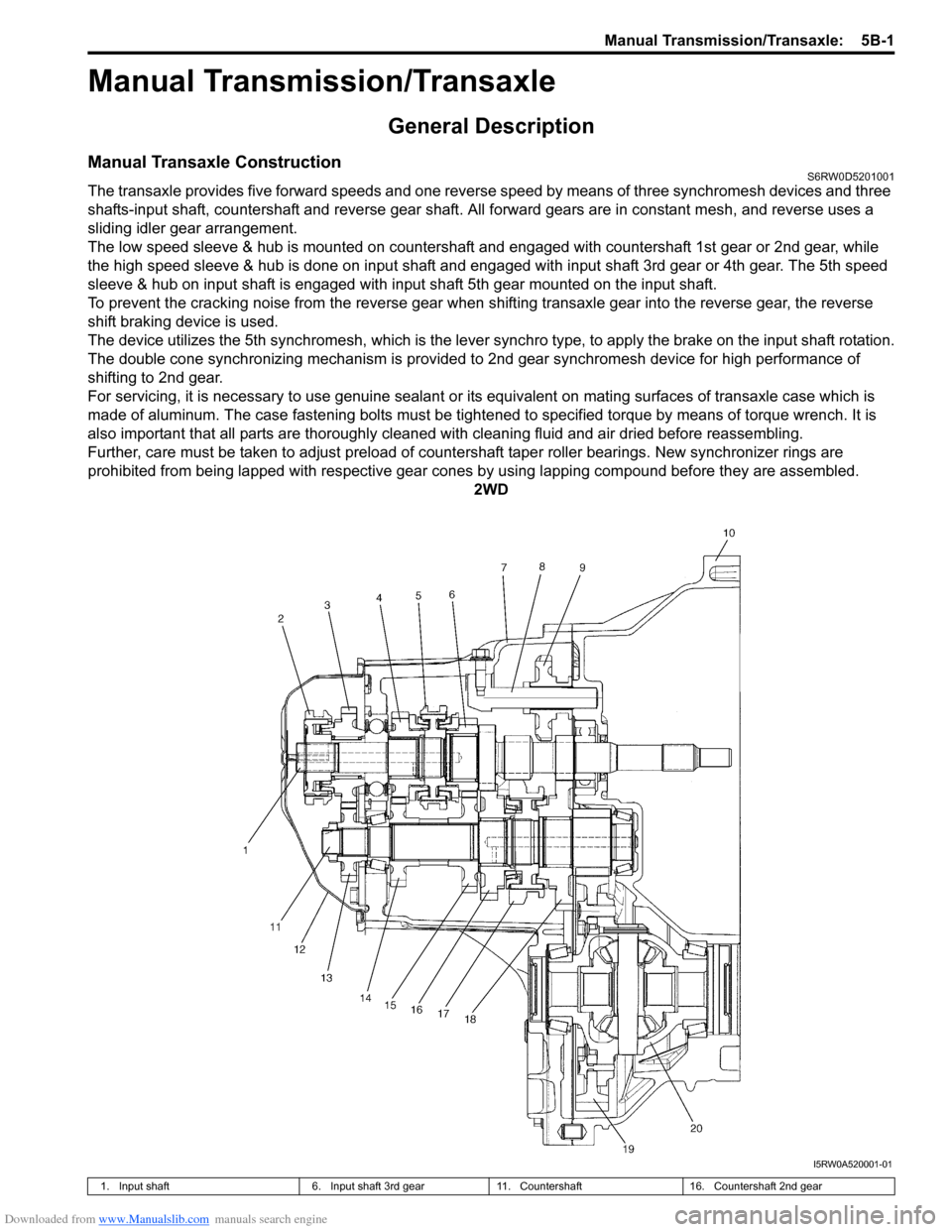

96) Install torque converter (3) noting the following

points.

CAUTION!

• Before installing converter, make sure that

its pump hub portion is free from nicks,

burrs or damage which may cause oil seal

to leak.

• Be very careful not to drop converter on oil

pump gear. Damage in gear, should it

occur, may cause a critical trouble.

• Install torque converter aligning grooves (1) of

torque converter and projection (2) of oil pump

drive gear.

• Install torque converter, using care not to damage

oil seal of oil pump.

• After installing torque converter, check that

distance “a” is within specification.

Torque converter installing position

“a”: More than 19.9 mm (0.783 in.)

• Check torque converter for smooth rotation.

• Apply grease around cup (6) at the center of

torque converter.

“C”: Grease 99000–25011 (SUZUKI Super

Grease A)

1(a)I2RH0B510335-01

1

I5RW0C510058-01

4. Flange nut

5. Torque converter housing

I2RH0B510337-01

Page 813 of 1556

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-1

Transmission / Transaxle

Manual Transmission/Transaxle

General Description

Manual Transaxle ConstructionS6RW0D5201001

The transaxle provides five forward speeds and one reverse speed by means of three synchromesh devices and three

shafts-input shaft, countershaft and reverse gear shaft. All forward gears are in constant mesh, and reverse uses a

sliding idler gear arrangement.

The low speed sleeve & hub is mounted on countershaft and engaged with countershaft 1st gear or 2nd gear, while

the high speed sleeve & hub is done on input shaft and engaged with input shaft 3rd gear or 4th gear. The 5th speed

sleeve & hub on input shaft is engaged with input shaft 5th gear mounted on the input shaft.

To prevent the cracking noise from the reverse gear when shifting transaxle gear into the reverse gear, the reverse

shift braking device is used.

The device utilizes the 5th synchromesh, which is the lever synchro type, to apply the brake on the input shaft rotation.

The double cone synchronizing mechanism is provided to 2nd gear synchromesh device for high performance of

shifting to 2nd gear.

For servicing, it is necessary to use genuine sealant or its equivalent on mating surfaces of transaxle case which is

made of aluminum. The case fastening bolts must be tightened to specified torque by means of torque wrench. It is

also important that all parts are thoroughly cleaned with cleaning fluid and air dried before reassembling.

Further, care must be taken to adjust preload of countershaft taper roller bearings. New synchronizer rings are

prohibited from being lapped with respective gear cones by using lapping compound before they are assembled.

2WD

I5RW0A520001-01

1. Input shaft 6. Input shaft 3rd gear 11. Countershaft 16. Countershaft 2nd gear

Page 820 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-8 Manual Transmission/Transaxle:

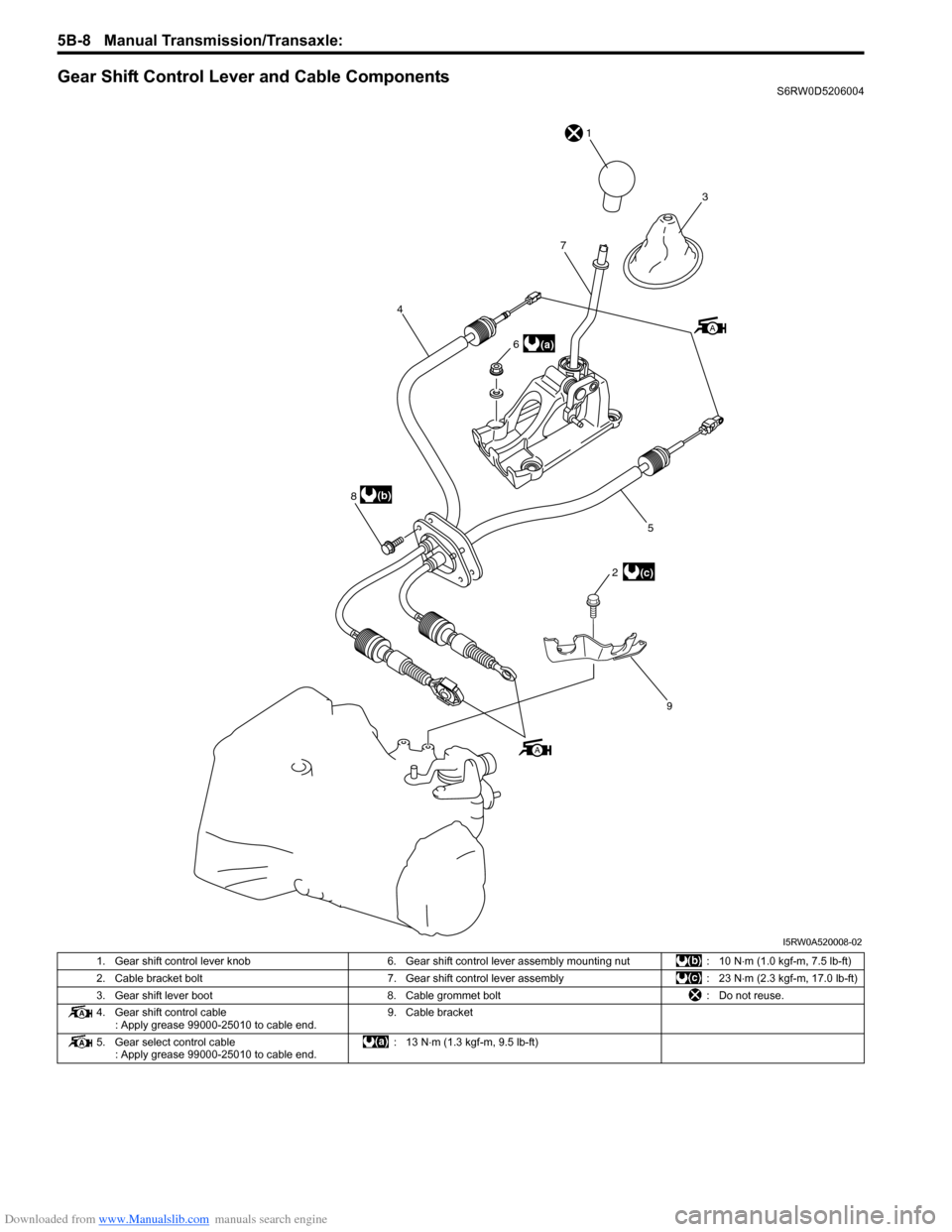

Gear Shift Control Lever and Cable ComponentsS6RW0D5206004

1

7

3

4

(a) 6

A

8(b)

2

(c)

5

9

A

I5RW0A520008-02

1. Gear shift control lever knob 6. Gear shift control lever assembly mounting nut : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

2. Cable bracket bolt 7. Gear shift control lever assembly : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Gear shift lever boot 8. Cable grommet bolt : Do not reuse.

4. Gear shift control cable

: Apply grease 99000-25010 to cable end.9. Cable bracket

5. Gear select control cable

: Apply grease 99000-25010 to cable end.:13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

Page 821 of 1556

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-9

Gear Shift Control Lever and Cable Removal

and Installation

S6RW0D5206005

Removal

1) Remove console box.

2) Disconnect cable ends (5) from pivot (6) of gear shift

control lever assembly by removing clip.

3) Disconnect gear shift and select control cables (1)

from gear shift control lever assembly (2) while

pulling quick joint (4) as shown in figure.

4) Remove gear shift control lever assembly mounting

nuts (3) and gear shift lever assembly from floor

panel.

5) Disconnect gear shift and select control cables from

transaxle.

6) Remove cable grommet bolt, and then remove gear

shift and select control cables from floor panel.

Installation

Reverse removal procedure for installation nothing the

following.

• Tighten each bolts and nuts to specified torque

referring to “Gear Shift Control Lever and Cable

Components”.

• Adjust gear select control cable referring to “Gear

Select Control Cable Adjustment”.

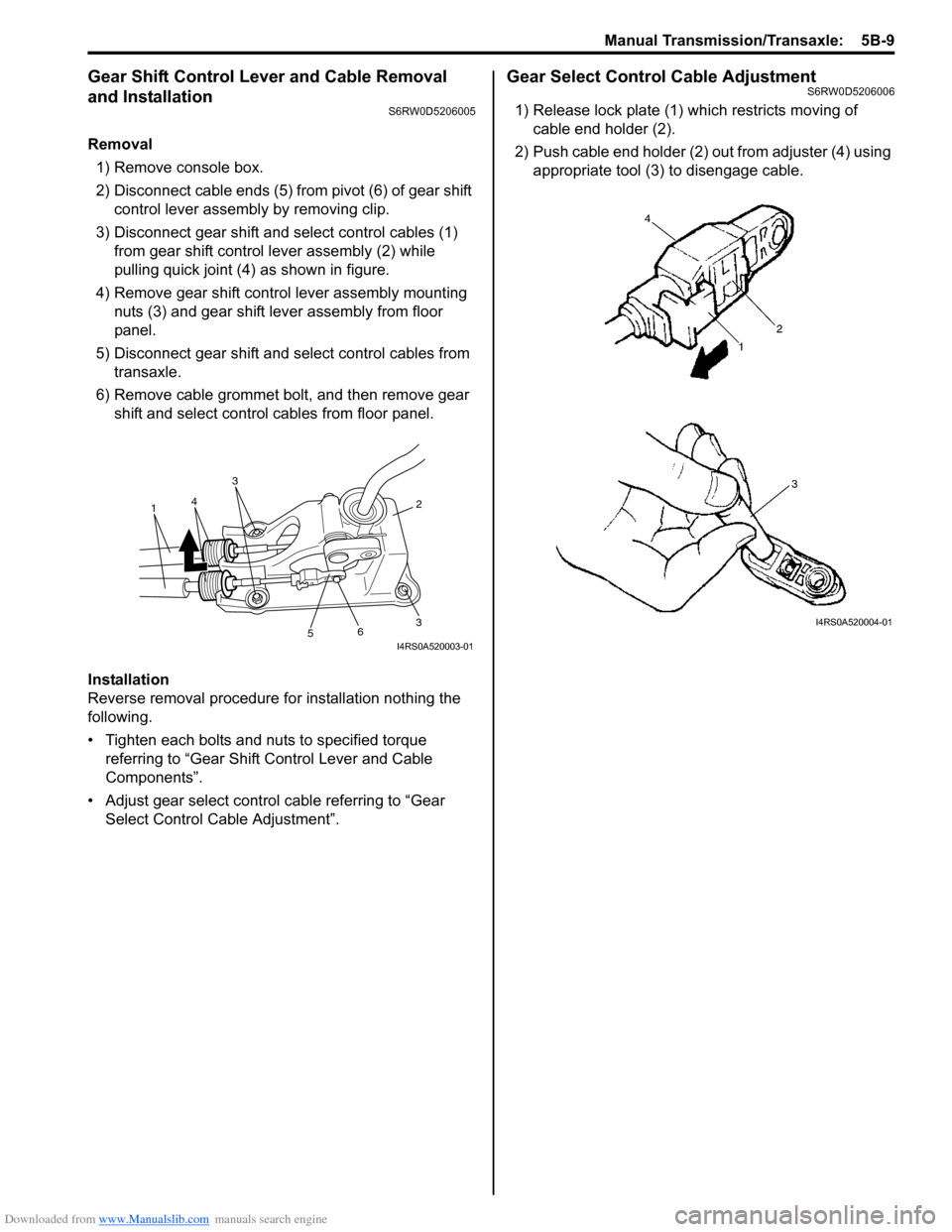

Gear Select Control Cable AdjustmentS6RW0D5206006

1) Release lock plate (1) which restricts moving of

cable end holder (2).

2) Push cable end holder (2) out from adjuster (4) using

appropriate tool (3) to disengage cable.

36

5

2

3

41

I4RS0A520003-01

I4RS0A520004-01

Page 824 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-12 Manual Transmission/Transaxle:

Manual Transaxle Unit Dismounting and

Remounting

S6RW0D5206010

Dismounting

1) Drain coolant.

2) Remove battery and tray with ECM.

3) Remove air cleaner case and resonator.

4) Remove clutch fluid pipe referring to “Clutch Fluid

Pipe Removal and Installation in Section 5C”.

5) Disconnect back up light switch coupler and undo

wiring harness clamps.

6) Disconnect gear shift and gear select control cables

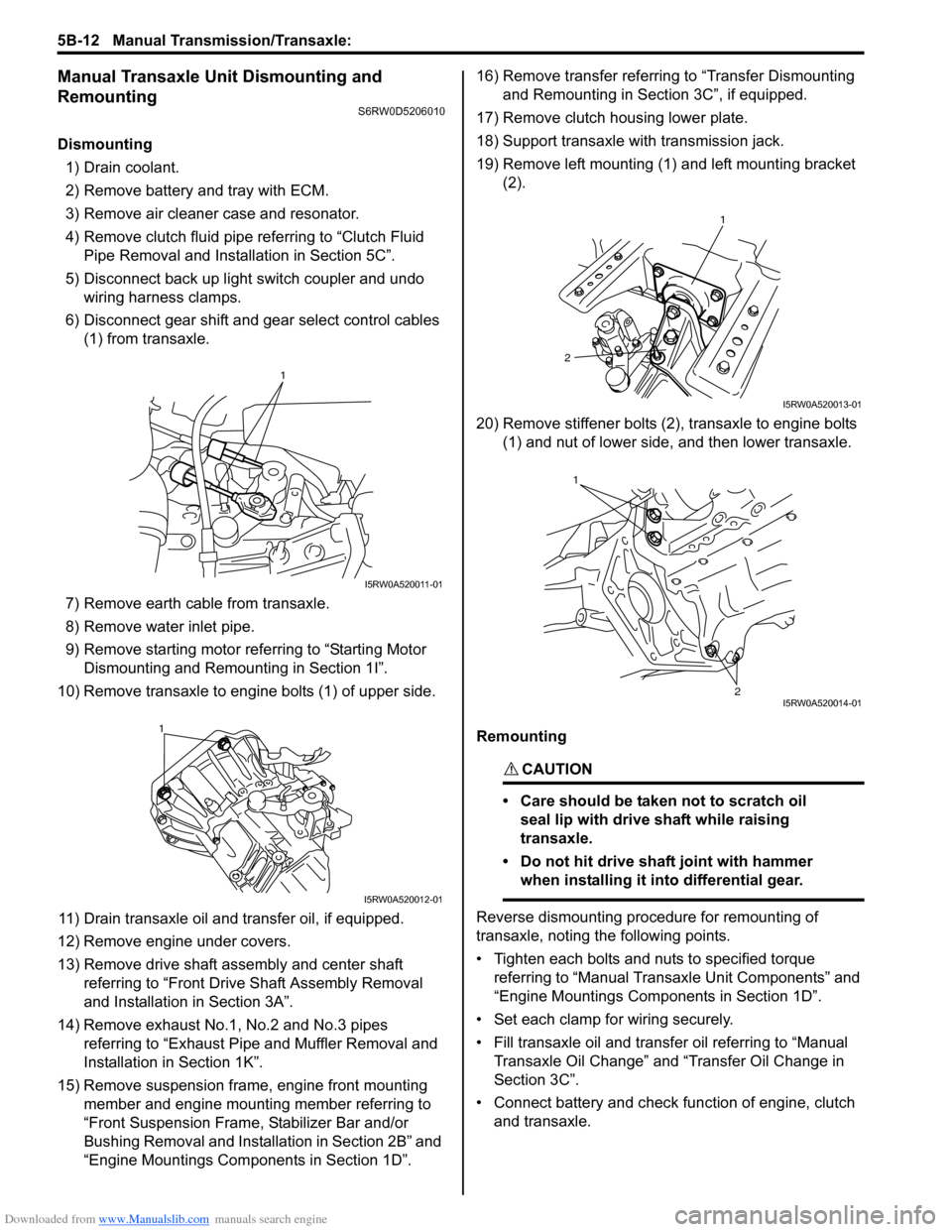

(1) from transaxle.

7) Remove earth cable from transaxle.

8) Remove water inlet pipe.

9) Remove starting motor referring to “Starting Motor

Dismounting and Remounting in Section 1I”.

10) Remove transaxle to engine bolts (1) of upper side.

11) Drain transaxle oil and transfer oil, if equipped.

12) Remove engine under covers.

13) Remove drive shaft assembly and center shaft

referring to “Front Drive Shaft Assembly Removal

and Installation in Section 3A”.

14) Remove exhaust No.1, No.2 and No.3 pipes

referring to “Exhaust Pipe and Muffler Removal and

Installation in Section 1K”.

15) Remove suspension frame, engine front mounting

member and engine mounting member referring to

“Front Suspension Frame, Stabilizer Bar and/or

Bushing Removal and Installation in Section 2B” and

“Engine Mountings Components in Section 1D”.16) Remove transfer referring to “Transfer Dismounting

and Remounting in Section 3C”, if equipped.

17) Remove clutch housing lower plate.

18) Support transaxle with transmission jack.

19) Remove left mounting (1) and left mounting bracket

(2).

20) Remove stiffener bolts (2), transaxle to engine bolts

(1) and nut of lower side, and then lower transaxle.

Remounting

CAUTION!

• Care should be taken not to scratch oil

seal lip with drive shaft while raising

transaxle.

• Do not hit drive shaft joint with hammer

when installing it into differential gear.

Reverse dismounting procedure for remounting of

transaxle, noting the following points.

• Tighten each bolts and nuts to specified torque

referring to “Manual Transaxle Unit Components” and

“Engine Mountings Components in Section 1D”.

• Set each clamp for wiring securely.

• Fill transaxle oil and transfer oil referring to “Manual

Transaxle Oil Change” and “Transfer Oil Change in

Section 3C”.

• Connect battery and check function of engine, clutch

and transaxle.

1

I5RW0A520011-01

1

I5RW0A520012-01

1

2

I5RW0A520013-01

1

2I5RW0A520014-01

Page 826 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-14 Manual Transmission/Transaxle:

Gear Shift and Select Shaft Assembly Removal

and Installation

S6RW0D5206012

Removal

1) Remove battery and tray with ECM.

2) Disconnect gear shift and gear select control cables

from transaxle.

3) Remove gear shift interlock bolt (1) and 5th to

reverse interlock guide bolt (2) from transaxle case.

4) Remove gear shift & select shaft assembly (3).

Installation

1) Clean mating surface of guide case (1) and left case

(5), apply sealant to left case as shown in figure by

such amount that its section is 1.5 mm (0.059 in.) in

diameter, mate guide case with left case.

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

2) Install guide case bolts No.1 to which sealant has

been applied and guide case bolts No.2 (2), and

tighten them to specified torque.

: Sealant 99000–31260 (SUZUKI Bond No.1217G)

Tightening torque

Guide case bolt No.1: 23 N·m (2.3 kgf-m, 17.0 lb-

ft)

Guide case bolt No.2 (a): 23 N·m (2.3 kgf-m, 17.0

lb-ft)3) Install washer and gear shift interlock bolt (3) to

which sealant has been applied and then tighten it to

specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Gear shift interlock bolt (b): 23 N·m (2.3 kgf-m,

17.0 lb-ft)

4) Install washer and 5th to reverse interlock guide bolt

(4) to which sealant has been applied and then

tighten it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

5th to reverse interlock guide bolt (c): 23 N·m (

2.3 kgf-m, 17.0 lb-ft)

5) Connect gear shift and gear select control cables to

transaxle.

6) Install battery and tray with ECM.

7) Check input shaft for rotation in each gear position.

4. Transaxle side cover

3

1

2

4

I5RW0A520016-01

I5RW0A520017-02

Page 831 of 1556

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-19

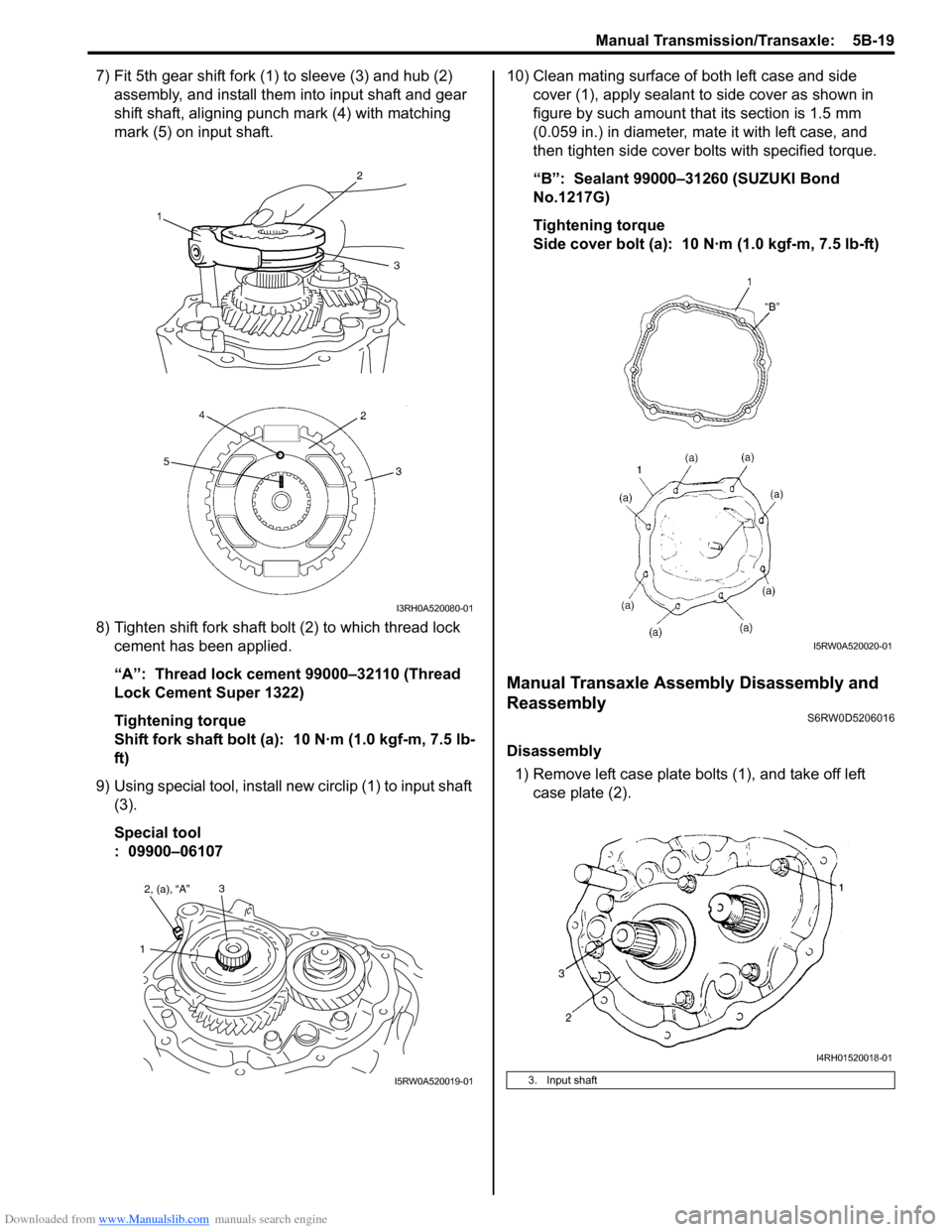

7) Fit 5th gear shift fork (1) to sleeve (3) and hub (2)

assembly, and install them into input shaft and gear

shift shaft, aligning punch mark (4) with matching

mark (5) on input shaft.

8) Tighten shift fork shaft bolt (2) to which thread lock

cement has been applied.

“A”: Thread lock cement 99000–32110 (Thread

Lock Cement Super 1322)

Tightening torque

Shift fork shaft bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-

ft)

9) Using special tool, install new circlip (1) to input shaft

(3).

Special tool

: 09900–0610710) Clean mating surface of both left case and side

cover (1), apply sealant to side cover as shown in

figure by such amount that its section is 1.5 mm

(0.059 in.) in diameter, mate it with left case, and

then tighten side cover bolts with specified torque.

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Side cover bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

Manual Transaxle Assembly Disassembly and

Reassembly

S6RW0D5206016

Disassembly

1) Remove left case plate bolts (1), and take off left

case plate (2).

I3RH0A520080-01

2, (a), “A”

13

I5RW0A520019-013. Input shaft

I5RW0A520020-01

I4RH01520018-01

Page 834 of 1556

Downloaded from www.Manualslib.com manuals search engine 5B-22 Manual Transmission/Transaxle:

6) Clean mating surfaces of both right and left cases,

apply sealant to left case (2) as shown in the figure

by such amount that its section is 1.5 mm (0.059 in.)

in diameter then mate it with right case (1).

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

7) Tighten case bolts (3) from outside and tighten

another case bolts from clutch housing side to

specified torque.

Tightening torque

Transaxle case bolt (a): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

8) Install reverse shaft bolt (4) to which thread lock

cement has been applied, with aluminum washer

and tighten it to specified torque.

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Reverse shaft bolt (b): 23 N·m (2.3 kgf-m, 17.0

lb-ft)9) Check locating springs (2, 4 and 5) for deterioration

and replace with new ones as necessary.

Locating spring

10) Install steel balls (3) and locating springs (2, 4 and 5)

for respective gear shift shaft and tighten bolts (1) to

which thread lock cement has been applied.

“A”: Thread lock cement 99000–32110 (Thread

Lock Cement Super 1322)

Tightening torque

Gear shift locating bolt (a): 13 N·m (1.3 kgf-m,

9.5 lb-ft)

11) Install new snap ring (1) using special tool.

Special tool

(A): 09900–06107

I5RW0A520023-01

Locating spring free length Standard Service limit

Low speed (2)53.1 mm

(2.091 in.)47.8 mm

(1.881 in.)

High speed (4)45.9 mm

(1.807 in.)41.4 mm

(1.629 in.)

5th & reverse (5)29.9 mm

(1.777 in.)27.0 mm

(1.062 in.)

2. Input shaft

3. Input shaft left bearing

1, (a), “A”

2

3

4

5

I5RW0A520024-02

1 (A)

2

3

I3RH0A520016-01

Page 855 of 1556

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-2

Diagnostic Information and Procedures

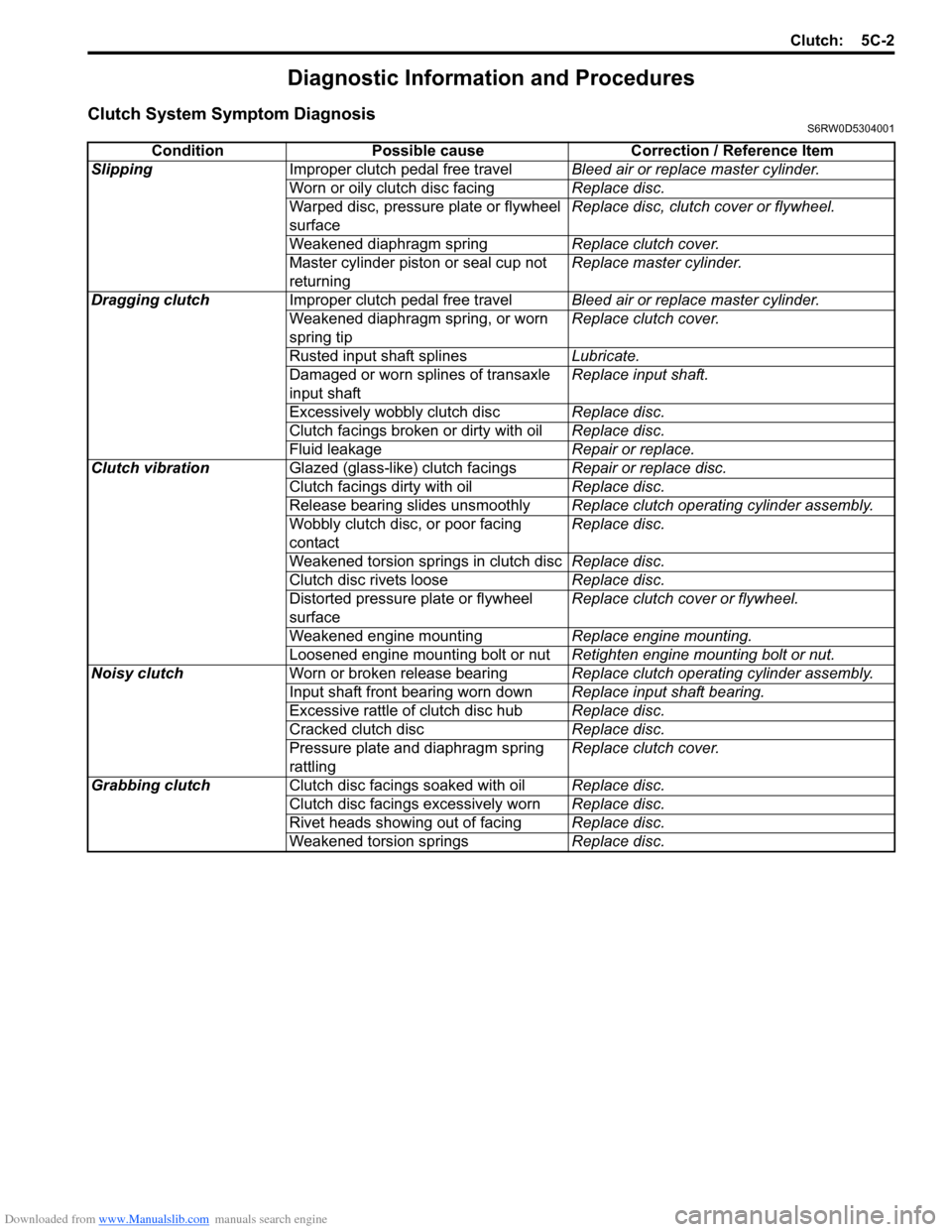

Clutch System Symptom DiagnosisS6RW0D5304001

Condition Possible cause Correction / Reference Item

SlippingImproper clutch pedal free travelBleed air or replace master cylinder.

Worn or oily clutch disc facingReplace disc.

Warped disc, pressure plate or flywheel

surfaceReplace disc, clutch cover or flywheel.

Weakened diaphragm springReplace clutch cover.

Master cylinder piston or seal cup not

returningReplace master cylinder.

Dragging clutchImproper clutch pedal free travelBleed air or replace master cylinder.

Weakened diaphragm spring, or worn

spring tipReplace clutch cover.

Rusted input shaft splinesLubricate.

Damaged or worn splines of transaxle

input shaftReplace input shaft.

Excessively wobbly clutch discReplace disc.

Clutch facings broken or dirty with oilReplace disc.

Fluid leakageRepair or replace.

Clutch vibrationGlazed (glass-like) clutch facingsRepair or replace disc.

Clutch facings dirty with oilReplace disc.

Release bearing slides unsmoothlyReplace clutch operating cylinder assembly.

Wobbly clutch disc, or poor facing

contactReplace disc.

Weakened torsion springs in clutch discReplace disc.

Clutch disc rivets looseReplace disc.

Distorted pressure plate or flywheel

surfaceReplace clutch cover or flywheel.

Weakened engine mountingReplace engine mounting.

Loosened engine mounting bolt or nutRetighten engine mounting bolt or nut.

Noisy clutchWorn or broken release bearingReplace clutch operating cylinder assembly.

Input shaft front bearing worn downReplace input shaft bearing.

Excessive rattle of clutch disc hubReplace disc.

Cracked clutch discReplace disc.

Pressure plate and diaphragm spring

rattlingReplace clutch cover.

Grabbing clutchClutch disc facings soaked with oilReplace disc.

Clutch disc facings excessively wornReplace disc.

Rivet heads showing out of facingReplace disc.

Weakened torsion springsReplace disc.

Page 858 of 1556

Downloaded from www.Manualslib.com manuals search engine 5C-5 Clutch:

Clutch Master Cylinder Removal and

Installation

S6RW0D5306007

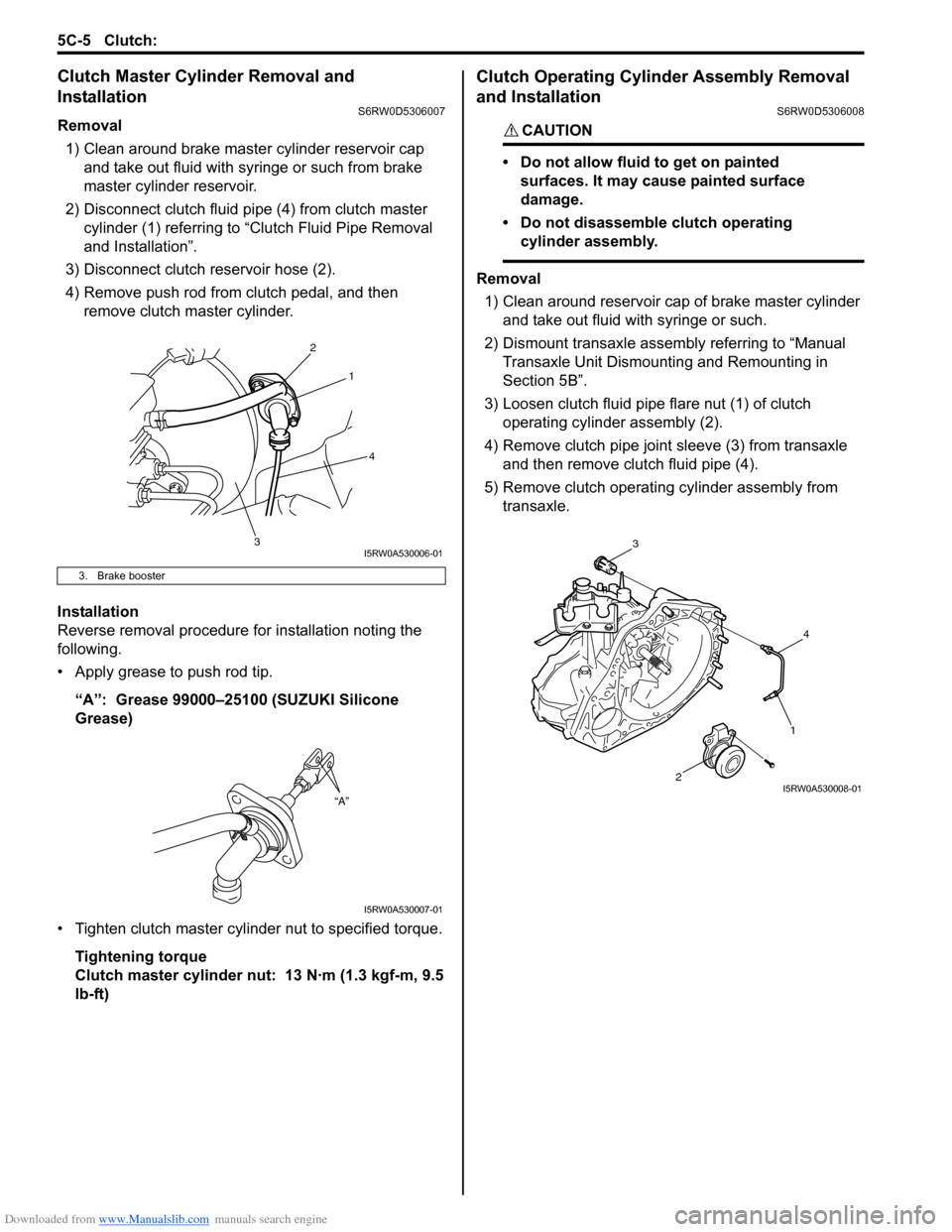

Removal

1) Clean around brake master cylinder reservoir cap

and take out fluid with syringe or such from brake

master cylinder reservoir.

2) Disconnect clutch fluid pipe (4) from clutch master

cylinder (1) referring to “Clutch Fluid Pipe Removal

and Installation”.

3) Disconnect clutch reservoir hose (2).

4) Remove push rod from clutch pedal, and then

remove clutch master cylinder.

Installation

Reverse removal procedure for installation noting the

following.

• Apply grease to push rod tip.

“A”: Grease 99000–25100 (SUZUKI Silicone

Grease)

• Tighten clutch master cylinder nut to specified torque.

Tightening torque

Clutch master cylinder nut: 13 N·m (1.3 kgf-m, 9.5

lb-ft)

Clutch Operating Cylinder Assembly Removal

and Installation

S6RW0D5306008

CAUTION!

• Do not allow fluid to get on painted

surfaces. It may cause painted surface

damage.

• Do not disassemble clutch operating

cylinder assembly.

Removal

1) Clean around reservoir cap of brake master cylinder

and take out fluid with syringe or such.

2) Dismount transaxle assembly referring to “Manual

Transaxle Unit Dismounting and Remounting in

Section 5B”.

3) Loosen clutch fluid pipe flare nut (1) of clutch

operating cylinder assembly (2).

4) Remove clutch pipe joint sleeve (3) from transaxle

and then remove clutch fluid pipe (4).

5) Remove clutch operating cylinder assembly from

transaxle.

3. Brake booster

1

3

2

4

I5RW0A530006-01

“A”

I5RW0A530007-01

3

4

2

1

I5RW0A530008-01