sensor SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 341 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-59

Main Bearings, Crankshaft and Cylinder Block ComponentsS6RW0D1406037

I6RW0D140003-01

1. CKP sensor

: See “A”11. Rear oil seal 21. Oil filter adapter bolt

2. Knock sensor 12. Input shaft bearing 22. Spring pin

3. Cylinder block 13. Flywheel or drive plate 23. Sensor plate bolt

4. Venturi plug 14. Main bearing cap 24. Oil pressure switch

Page 342 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-60 Engine Mechanical:

Main Bearings, Crankshaft and Cylinder Block

Removal and Installation

S6RW0D1406038

Removal

1) Remove engine assembly from vehicle referring to

“Engine Assembly Removal and Installation”.

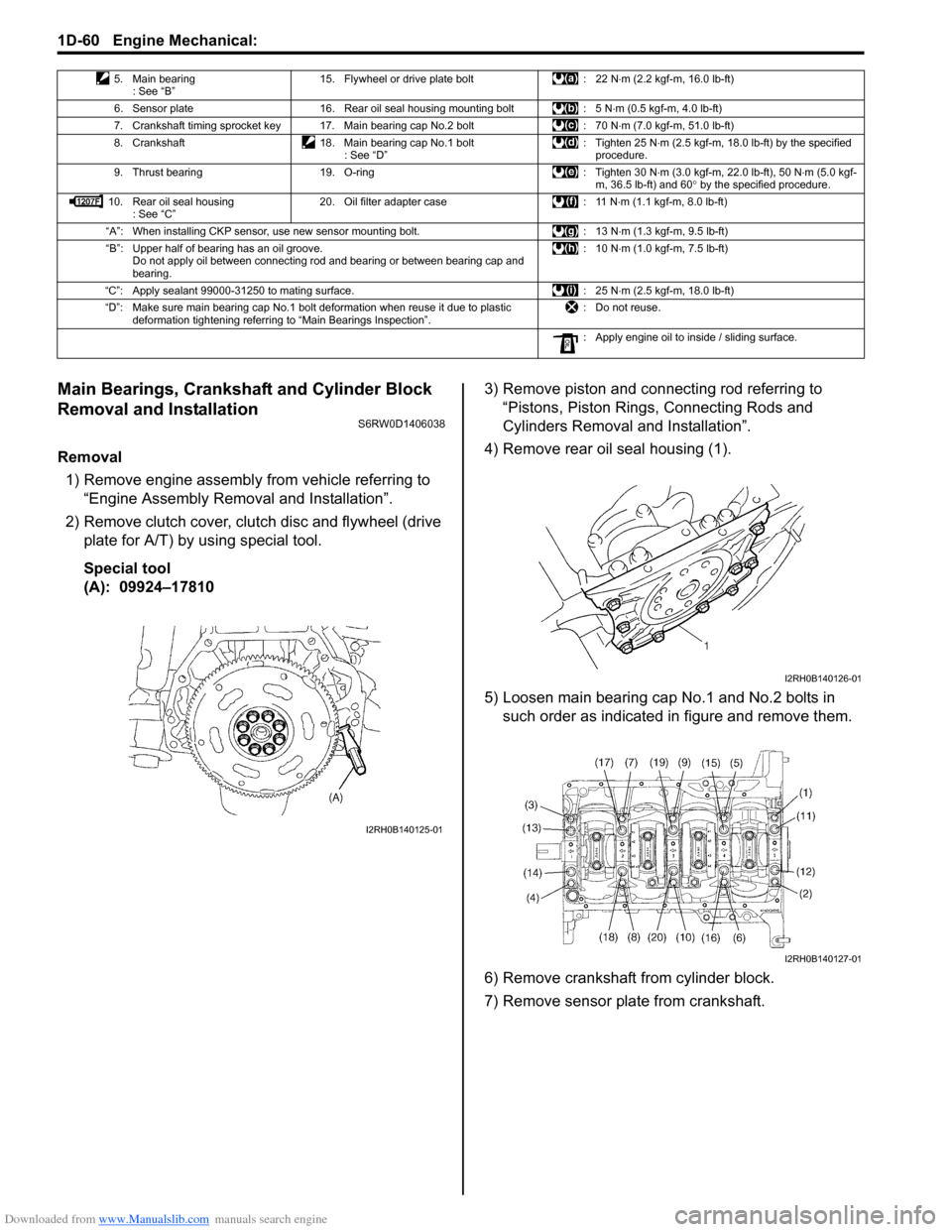

2) Remove clutch cover, clutch disc and flywheel (drive

plate for A/T) by using special tool.

Special tool

(A): 09924–178103) Remove piston and connecting rod referring to

“Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

4) Remove rear oil seal housing (1).

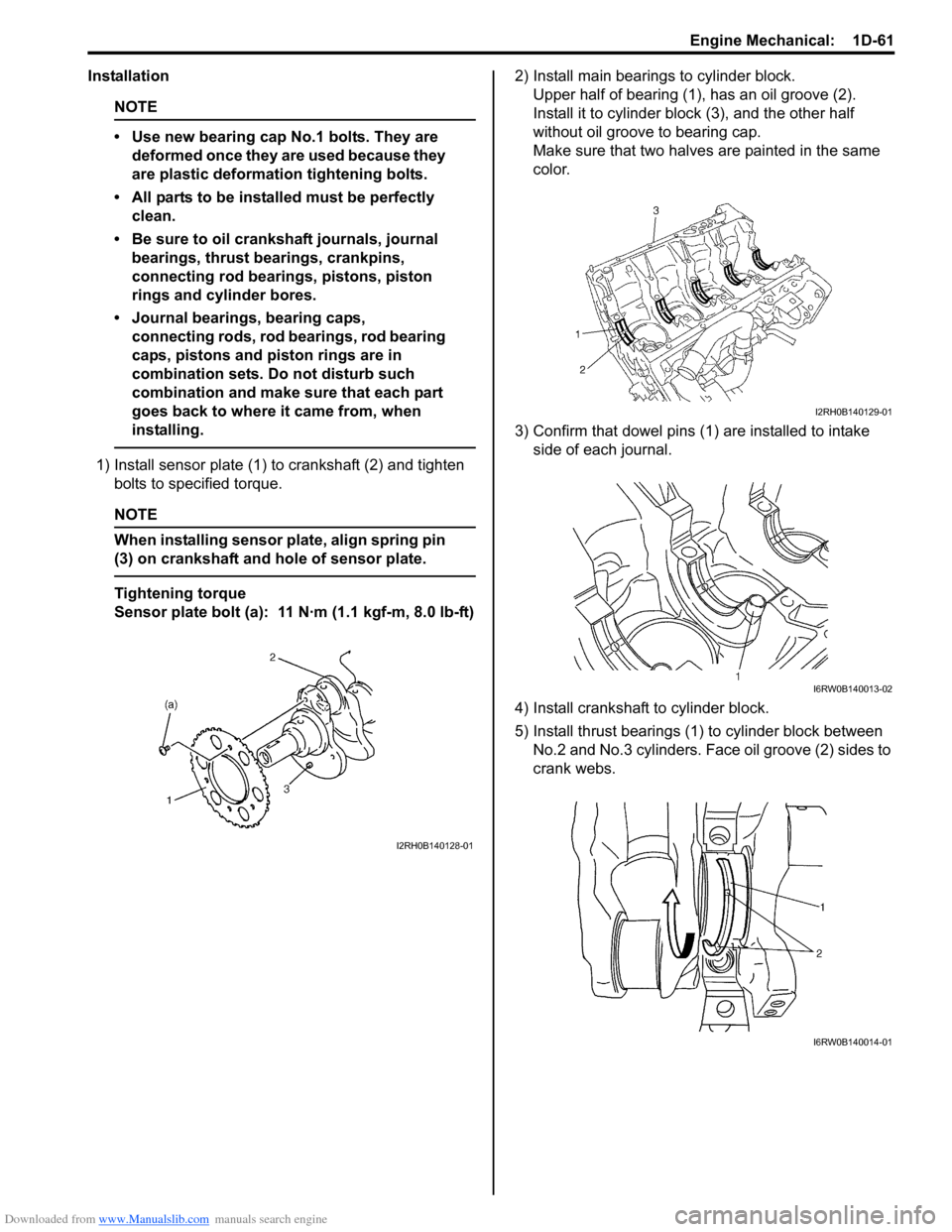

5) Loosen main bearing cap No.1 and No.2 bolts in

such order as indicated in figure and remove them.

6) Remove crankshaft from cylinder block.

7) Remove sensor plate from crankshaft.

5. Main bearing

: See “B”15. Flywheel or drive plate bolt : 22 N⋅m (2.2 kgf-m, 16.0 lb-ft)

6. Sensor plate 16. Rear oil seal housing mounting bolt : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

7. Crankshaft timing sprocket key 17. Main bearing cap No.2 bolt : 70 N⋅m (7.0 kgf-m, 51.0 lb-ft)

8. Crankshaft 18. Main bearing cap No.1 bolt

: See “D”: Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) by the specified

procedure.

9. Thrust bearing 19. O-ring : Tighten 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N⋅m (5.0 kgf-

m, 36.5 lb-ft) and 60° by the specified procedure.

10. Rear oil seal housing

: See “C”20. Oil filter adapter case : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

“A”: When installing CKP sensor, use new sensor mounting bolt. : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

“B”: Upper half of bearing has an oil groove.

Do not apply oil between connecting rod and bearing or between bearing cap and

bearing.:10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

“C”: Apply sealant 99000-31250 to mating surface. : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

“D”: Make sure main bearing cap No.1 bolt deformation when reuse it due to plastic

deformation tightening referring to “Main Bearings Inspection”.: Do not reuse.

: Apply engine oil to inside / sliding surface.

I2RH0B140125-01

I2RH0B140126-01

I2RH0B140127-01

Page 343 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-61

Installation

NOTE

• Use new bearing cap No.1 bolts. They are

deformed once they are used because they

are plastic deformation tightening bolts.

• All parts to be installed must be perfectly

clean.

• Be sure to oil crankshaft journals, journal

bearings, thrust bearings, crankpins,

connecting rod bearings, pistons, piston

rings and cylinder bores.

• Journal bearings, bearing caps,

connecting rods, rod bearings, rod bearing

caps, pistons and piston rings are in

combination sets. Do not disturb such

combination and make sure that each part

goes back to where it came from, when

installing.

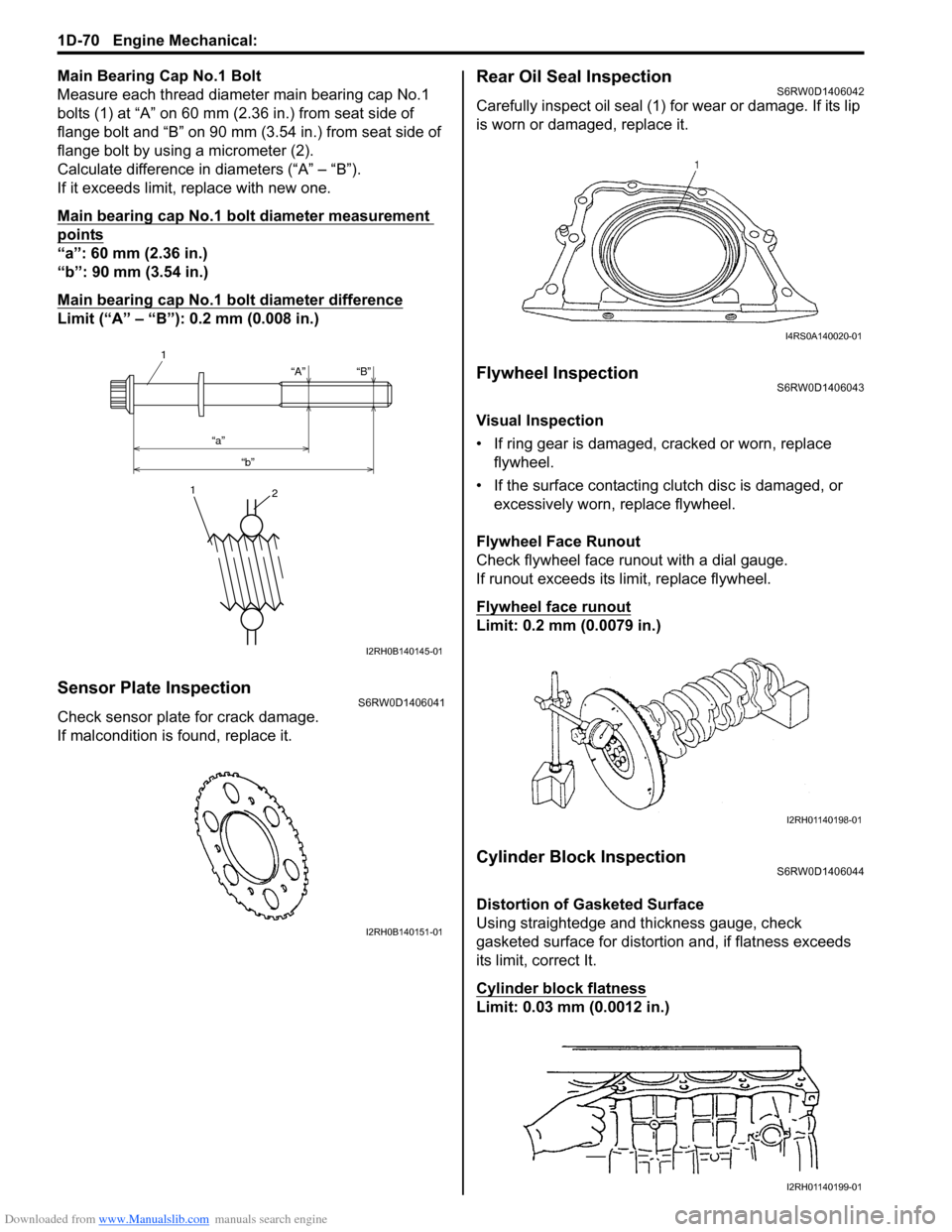

1) Install sensor plate (1) to crankshaft (2) and tighten

bolts to specified torque.

NOTE

When installing sensor plate, align spring pin

(3) on crankshaft and hole of sensor plate.

Tightening torque

Sensor plate bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)2) Install main bearings to cylinder block.

Upper half of bearing (1), has an oil groove (2).

Install it to cylinder block (3), and the other half

without oil groove to bearing cap.

Make sure that two halves are painted in the same

color.

3) Confirm that dowel pins (1) are installed to intake

side of each journal.

4) Install crankshaft to cylinder block.

5) Install thrust bearings (1) to cylinder block between

No.2 and No.3 cylinders. Face oil groove (2) sides to

crank webs.

I2RH0B140128-01

I2RH0B140129-01

I6RW0B140013-02

I6RW0B140014-01

Page 352 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-70 Engine Mechanical:

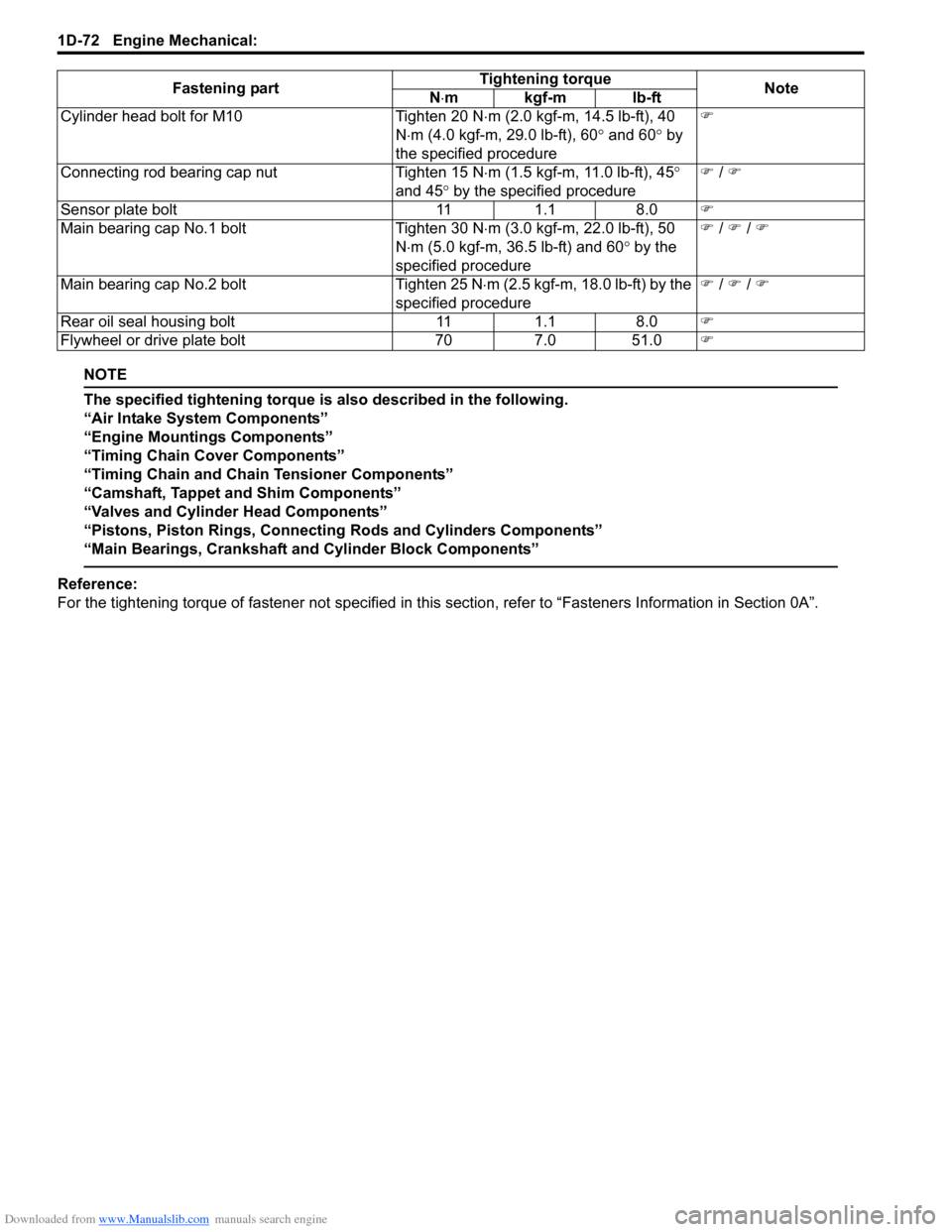

Main Bearing Cap No.1 Bolt

Measure each thread diameter main bearing cap No.1

bolts (1) at “A” on 60 mm (2.36 in.) from seat side of

flange bolt and “B” on 90 mm (3.54 in.) from seat side of

flange bolt by using a micrometer (2).

Calculate difference in diameters (“A” – “B”).

If it exceeds limit, replace with new one.

Main bearing cap No.1 bolt diameter measurement

points

“a”: 60 mm (2.36 in.)

“b”: 90 mm (3.54 in.)

Main bearing cap No.1 bolt diameter difference

Limit (“A” – “B”): 0.2 mm (0.008 in.)

Sensor Plate InspectionS6RW0D1406041

Check sensor plate for crack damage.

If malcondition is found, replace it.

Rear Oil Seal InspectionS6RW0D1406042

Carefully inspect oil seal (1) for wear or damage. If its lip

is worn or damaged, replace it.

Flywheel InspectionS6RW0D1406043

Visual Inspection

• If ring gear is damaged, cracked or worn, replace

flywheel.

• If the surface contacting clutch disc is damaged, or

excessively worn, replace flywheel.

Flywheel Face Runout

Check flywheel face runout with a dial gauge.

If runout exceeds its limit, replace flywheel.

Flywheel face runout

Limit: 0.2 mm (0.0079 in.)

Cylinder Block InspectionS6RW0D1406044

Distortion of Gasketed Surface

Using straightedge and thickness gauge, check

gasketed surface for distortion and, if flatness exceeds

its limit, correct It.

Cylinder block flatness

Limit: 0.03 mm (0.0012 in.)

“A”

“a”

“b”“B”

1

1

2

I2RH0B140145-01

I2RH0B140151-01

I4RS0A140020-01

I2RH01140198-01

I2RH01140199-01

Page 354 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-72 Engine Mechanical:

NOTE

The specified tightening torque is also described in the following.

“Air Intake System Components”

“Engine Mountings Components”

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”. Cylinder head bolt for M10 Tighten 20 N⋅m (2.0 kgf-m, 14.5 lb-ft), 40

N⋅m (4.0 kgf-m, 29.0 lb-ft), 60° and 60° by

the specified procedure�)

Connecting rod bearing cap nut Tighten 15 N⋅m (1.5 kgf-m, 11.0 lb-ft), 45°

and 45° by the specified procedure�) / �)

Sensor plate bolt 11 1.1 8.0�)

Main bearing cap No.1 bolt Tighten 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50

N⋅m (5.0 kgf-m, 36.5 lb-ft) and 60° by the

specified procedure�) / �) / �)

Main bearing cap No.2 bolt Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) by the

specified procedure�) / �) / �)

Rear oil seal housing bolt 11 1.1 8.0�)

Flywheel or drive plate bolt 70 7.0 51.0�) Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Page 368 of 1556

Downloaded from www.Manualslib.com manuals search engine 1F-3 Engine Cooling System:

Diagnostic Information and Procedures

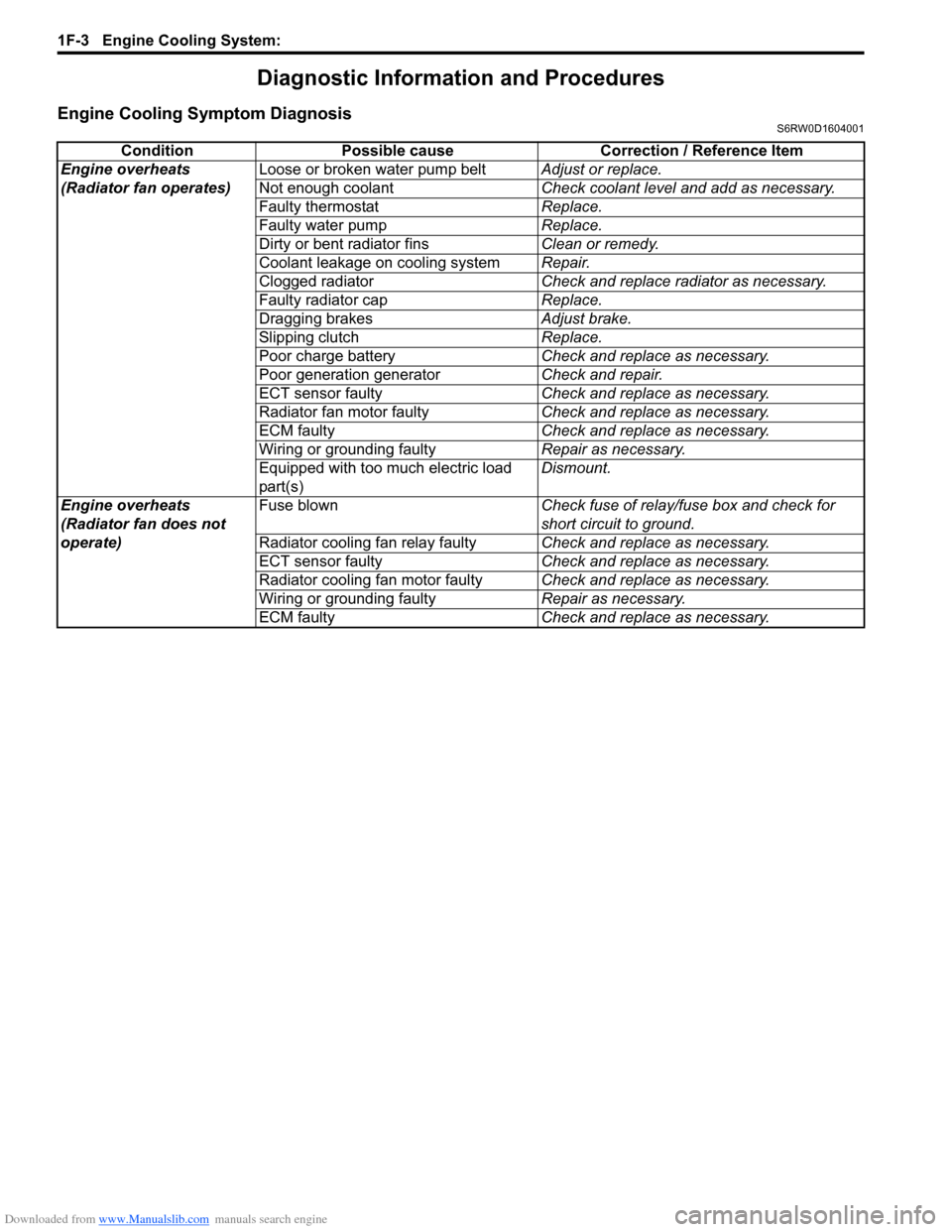

Engine Cooling Symptom DiagnosisS6RW0D1604001

Condition Possible cause Correction / Reference Item

Engine overheats

(Radiator fan operates)Loose or broken water pump beltAdjust or replace.

Not enough coolantCheck coolant level and add as necessary.

Faulty thermostatReplace.

Faulty water pumpReplace.

Dirty or bent radiator finsClean or remedy.

Coolant leakage on cooling systemRepair.

Clogged radiatorCheck and replace radiator as necessary.

Faulty radiator capReplace.

Dragging brakesAdjust brake.

Slipping clutchReplace.

Poor charge batteryCheck and replace as necessary.

Poor generation generatorCheck and repair.

ECT sensor faultyCheck and replace as necessary.

Radiator fan motor faultyCheck and replace as necessary.

ECM faultyCheck and replace as necessary.

Wiring or grounding faultyRepair as necessary.

Equipped with too much electric load

part(s)Dismount.

Engine overheats

(Radiator fan does not

operate)Fuse blownCheck fuse of relay/fuse box and check for

short circuit to ground.

Radiator cooling fan relay faultyCheck and replace as necessary.

ECT sensor faultyCheck and replace as necessary.

Radiator cooling fan motor faultyCheck and replace as necessary.

Wiring or grounding faultyRepair as necessary.

ECM faultyCheck and replace as necessary.

Page 369 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-4

Repair Instructions

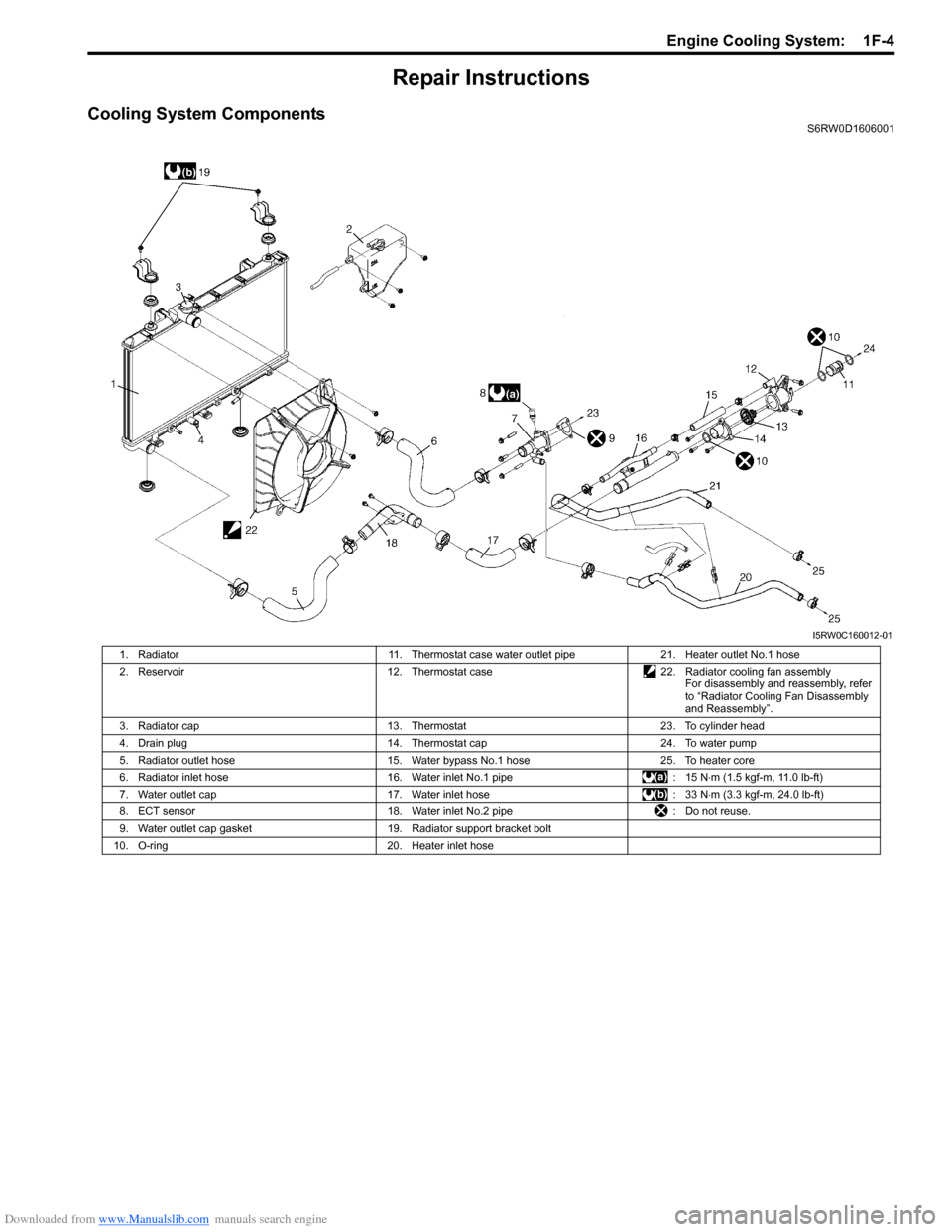

Cooling System ComponentsS6RW0D1606001

I5RW0C160012-01

1. Radiator 11. Thermostat case water outlet pipe 21. Heater outlet No.1 hose

2. Reservoir 12. Thermostat case 22. Radiator cooling fan assembly

For disassembly and reassembly, refer

to “Radiator Cooling Fan Disassembly

and Reassembly”.

3. Radiator cap 13. Thermostat 23. To cylinder head

4. Drain plug 14. Thermostat cap 24. To water pump

5. Radiator outlet hose 15. Water bypass No.1 hose 25. To heater core

6. Radiator inlet hose 16. Water inlet No.1 pipe : 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

7. Water outlet cap 17. Water inlet hose : 33 N⋅m (3.3 kgf-m, 24.0 lb-ft)

8. ECT sensor 18. Water inlet No.2 pipe : Do not reuse.

9. Water outlet cap gasket 19. Radiator support bracket bolt

10. O-ring 20. Heater inlet hose

Page 379 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-2

General Description

Fuel System DescriptionS6RW0D1701001

CAUTION!

This engine requires the unleaded fuel only.

The leaded and/or low lead fuel can result in

engine damage and reduce the effectiveness

of the emission control system.

The main components of the fuel system are fuel tank,

fuel pump assembly (with fuel filter, fuel level gauge, fuel

pressure regulator), fuel feed line and fuel vapor line.

For the details of fuel flow, refer to “Fuel Delivery System

Diagram”.

Fuel Delivery System DescriptionS6RW0D1701002

The fuel delivery system consists of the fuel tank, fuel

pump assembly (with built-in fuel filter and fuel pressure

regulator), delivery pipe, injectors and fuel feed line.

The fuel in the fuel tank is pumped up by the fuel pump,

sent into delivery pipe and injected by the injectors.

As the fuel pump assembly is equipped with built-in fuel

filter and fuel pressure regulator, the fuel is filtered and

its pressure is regulated before being sent to the feed

pipe.

The excess fuel at fuel pressure regulation process is

returned back into the fuel tank.

Also, fuel vapor generated in fuel tank is led through the

fuel vapor line into the EVAP canister.

For system diagram, refer to “Fuel Delivery System

Diagram”.

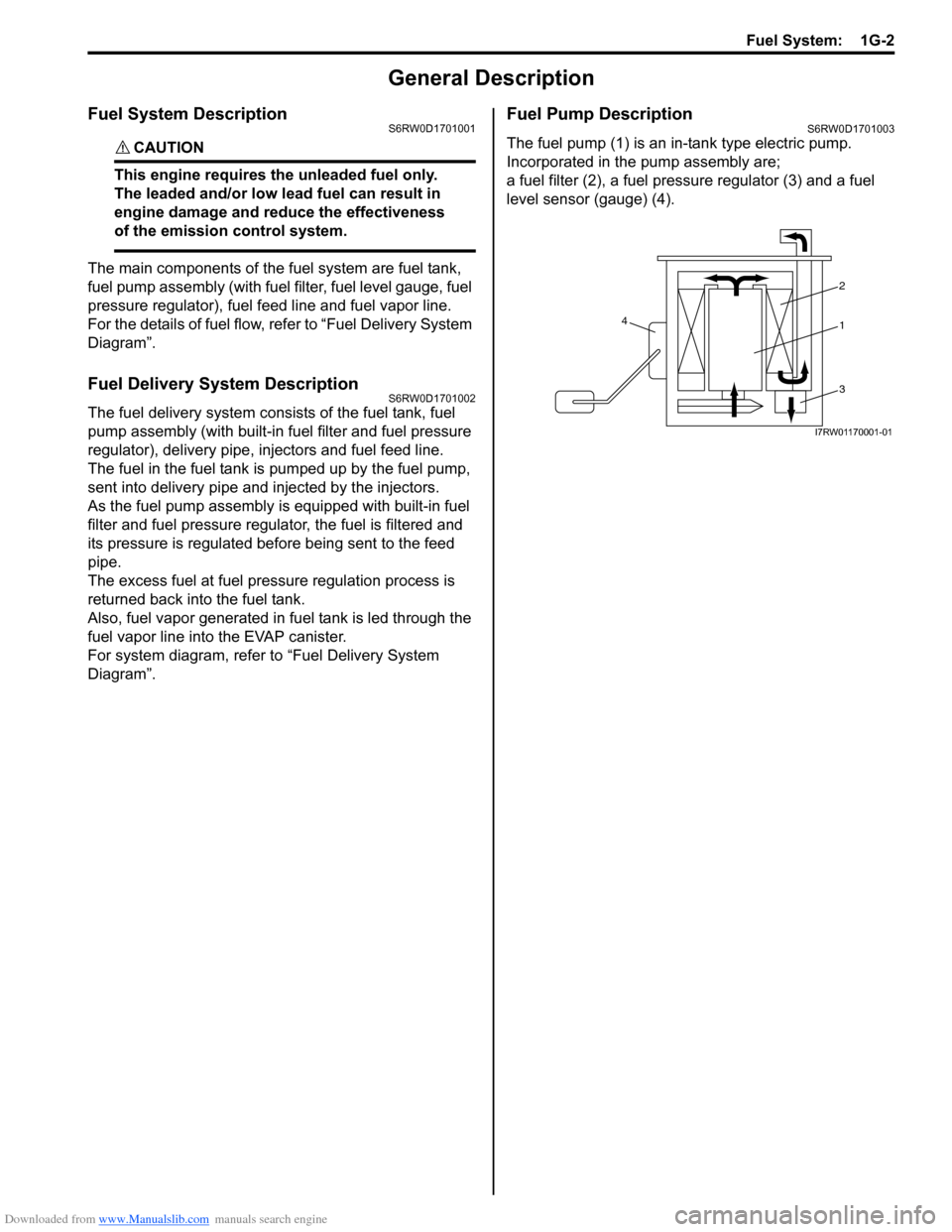

Fuel Pump DescriptionS6RW0D1701003

The fuel pump (1) is an in-tank type electric pump.

Incorporated in the pump assembly are;

a fuel filter (2), a fuel pressure regulator (3) and a fuel

level sensor (gauge) (4).

2

41

3

I7RW01170001-01

Page 380 of 1556

Downloaded from www.Manualslib.com manuals search engine 1G-3 Fuel System:

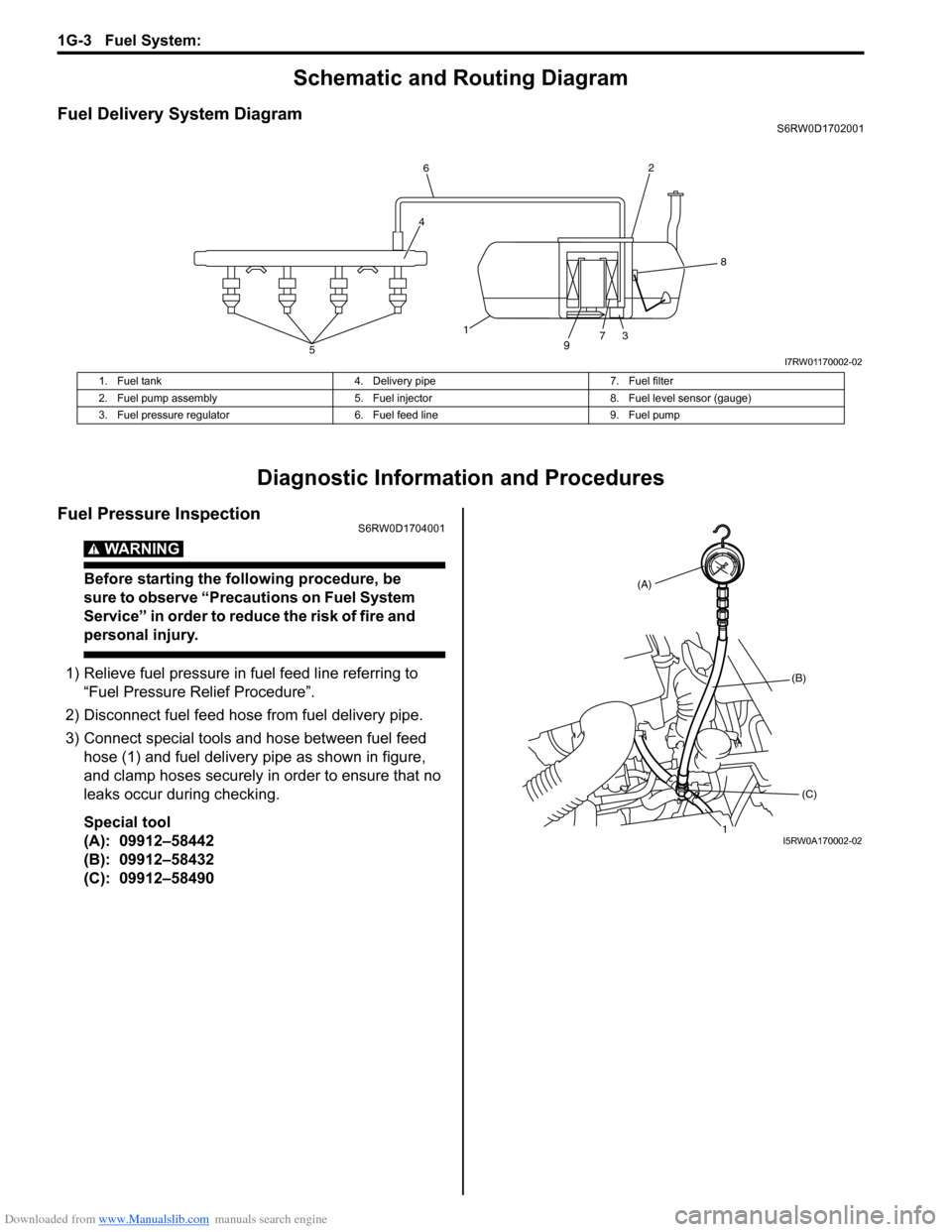

Schematic and Routing Diagram

Fuel Delivery System DiagramS6RW0D1702001

Diagnostic Information and Procedures

Fuel Pressure InspectionS6RW0D1704001

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk of fire and

personal injury.

1) Relieve fuel pressure in fuel feed line referring to

“Fuel Pressure Relief Procedure”.

2) Disconnect fuel feed hose from fuel delivery pipe.

3) Connect special tools and hose between fuel feed

hose (1) and fuel delivery pipe as shown in figure,

and clamp hoses securely in order to ensure that no

leaks occur during checking.

Special tool

(A): 09912–58442

(B): 09912–58432

(C): 09912–58490

73 6

1 4

5

8

9

2

I7RW01170002-02

1. Fuel tank 4. Delivery pipe 7. Fuel filter

2. Fuel pump assembly 5. Fuel injector 8. Fuel level sensor (gauge)

3. Fuel pressure regulator 6. Fuel feed line 9. Fuel pump

(C) (B)

(A)

1I5RW0A170002-02

Page 391 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-14

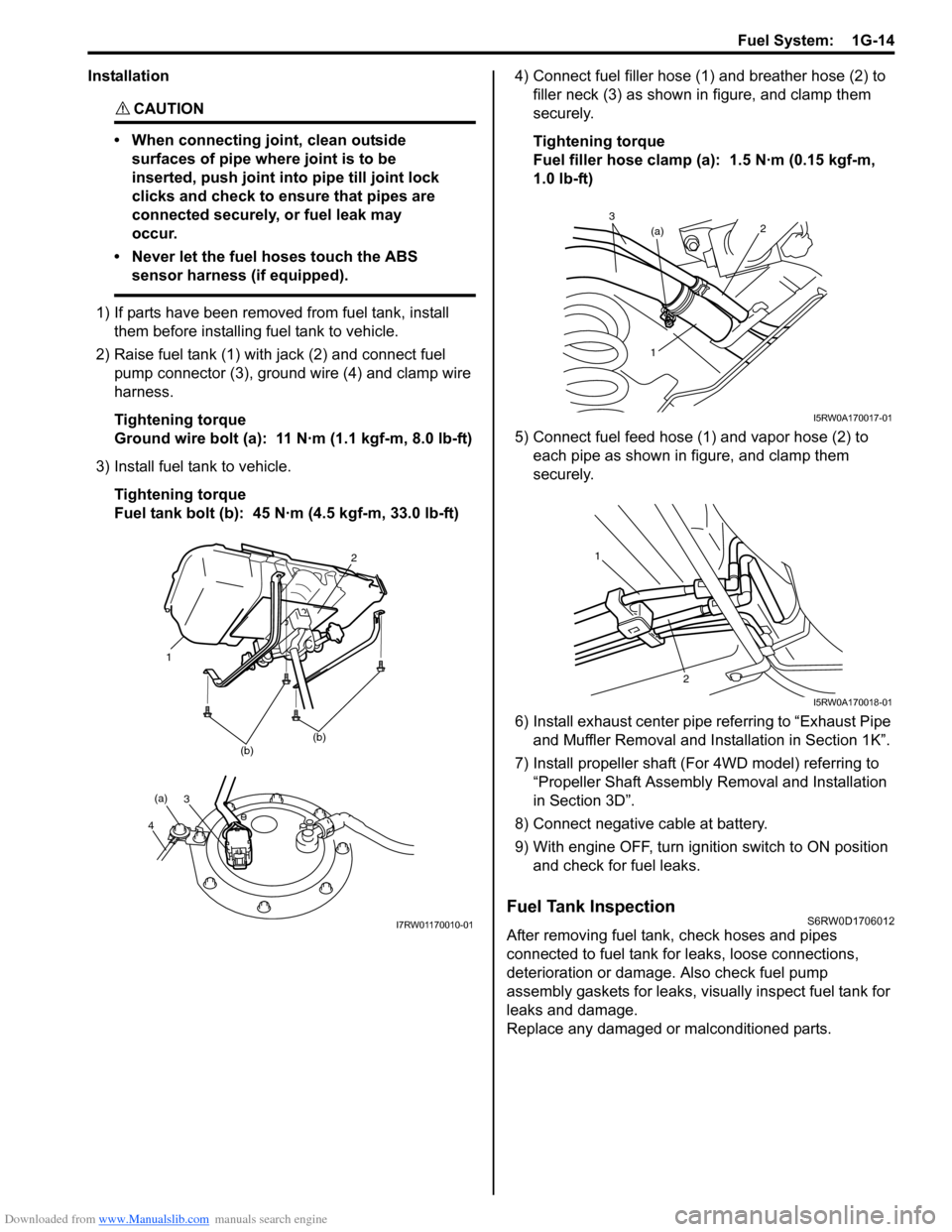

Installation

CAUTION!

• When connecting joint, clean outside

surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS

sensor harness (if equipped).

1) If parts have been removed from fuel tank, install

them before installing fuel tank to vehicle.

2) Raise fuel tank (1) with jack (2) and connect fuel

pump connector (3), ground wire (4) and clamp wire

harness.

Tightening torque

Ground wire bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install fuel tank to vehicle.

Tightening torque

Fuel tank bolt (b): 45 N·m (4.5 kgf-m, 33.0 lb-ft)4) Connect fuel filler hose (1) and breather hose (2) to

filler neck (3) as shown in figure, and clamp them

securely.

Tightening torque

Fuel filler hose clamp (a): 1.5 N·m (0.15 kgf-m,

1.0 lb-ft)

5) Connect fuel feed hose (1) and vapor hose (2) to

each pipe as shown in figure, and clamp them

securely.

6) Install exhaust center pipe referring to “Exhaust Pipe

and Muffler Removal and Installation in Section 1K”.

7) Install propeller shaft (For 4WD model) referring to

“Propeller Shaft Assembly Removal and Installation

in Section 3D”.

8) Connect negative cable at battery.

9) With engine OFF, turn ignition switch to ON position

and check for fuel leaks.

Fuel Tank InspectionS6RW0D1706012

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

(b)(b)

1

2

3

4

(a)

I7RW01170010-01

1(a)2

3

I5RW0A170017-01

1

2

I5RW0A170018-01