TOYOTA CAMRY V20 1986 Service Information

Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 91 of 2389

AT3654

AT3655

AT3656

AT4432 AT4431

(b) Tag the bearings to show the location for reas-

sembly.

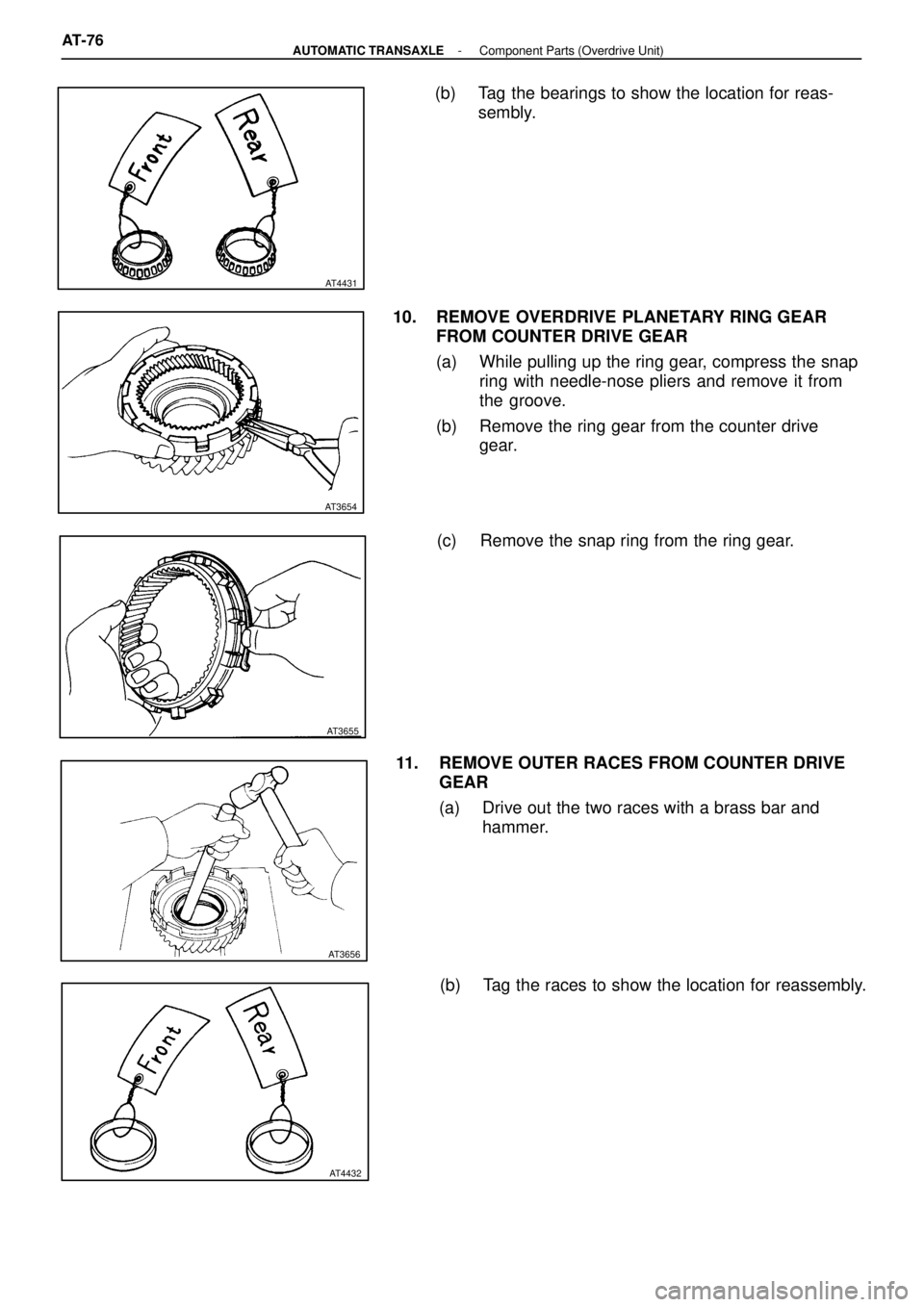

10. REMOVE OVERDRIVE PLANETARY RING GEAR

FROM COUNTER DRIVE GEAR

(a) While pulling up the ring gear, compress the snap

ring with needle-nose pliers and remove it from

the groove.

(b) Remove the ring gear from the counter drive

gear.

(c) Remove the snap ring from the ring gear.

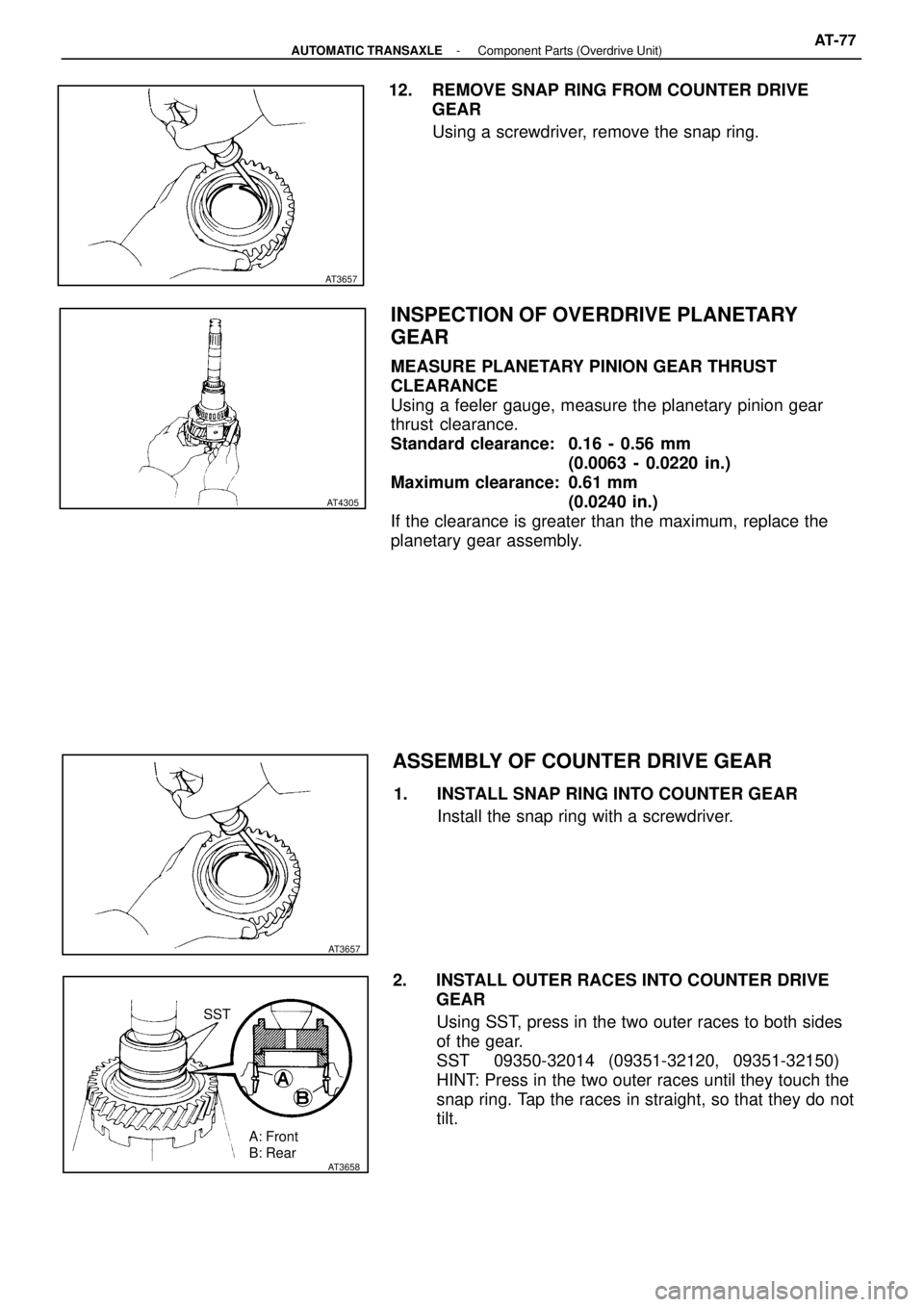

11. REMOVE OUTER RACES FROM COUNTER DRIVE

GEAR

(a) Drive out the two races with a brass bar and

hammer.

(b) Tag the races to show the location for reassembly.

AT-76- AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit)

Page 92 of 2389

AT4305

AT3657

AT3658

A: Front

B: Rear SST

AT3657

12. REMOVE SNAP RING FROM COUNTER DRIVE

GEAR

Using a screwdriver, remove the snap ring.

INSPECTION OF OVERDRIVE PLANETARY

GEAR

MEASURE PLANETARY PINION GEAR THRUST

CLEARANCE

Using a feeler gauge, measure the planetary pinion gear

thrust clearance.

Standard clearance: 0.16 - 0.56 mm

(0.0063 - 0.0220 in.)

Maximum clearance: 0.61 mm

(0.0240 in.)

If the clearance is greater than the maximum, replace the

planetary gear assembly.

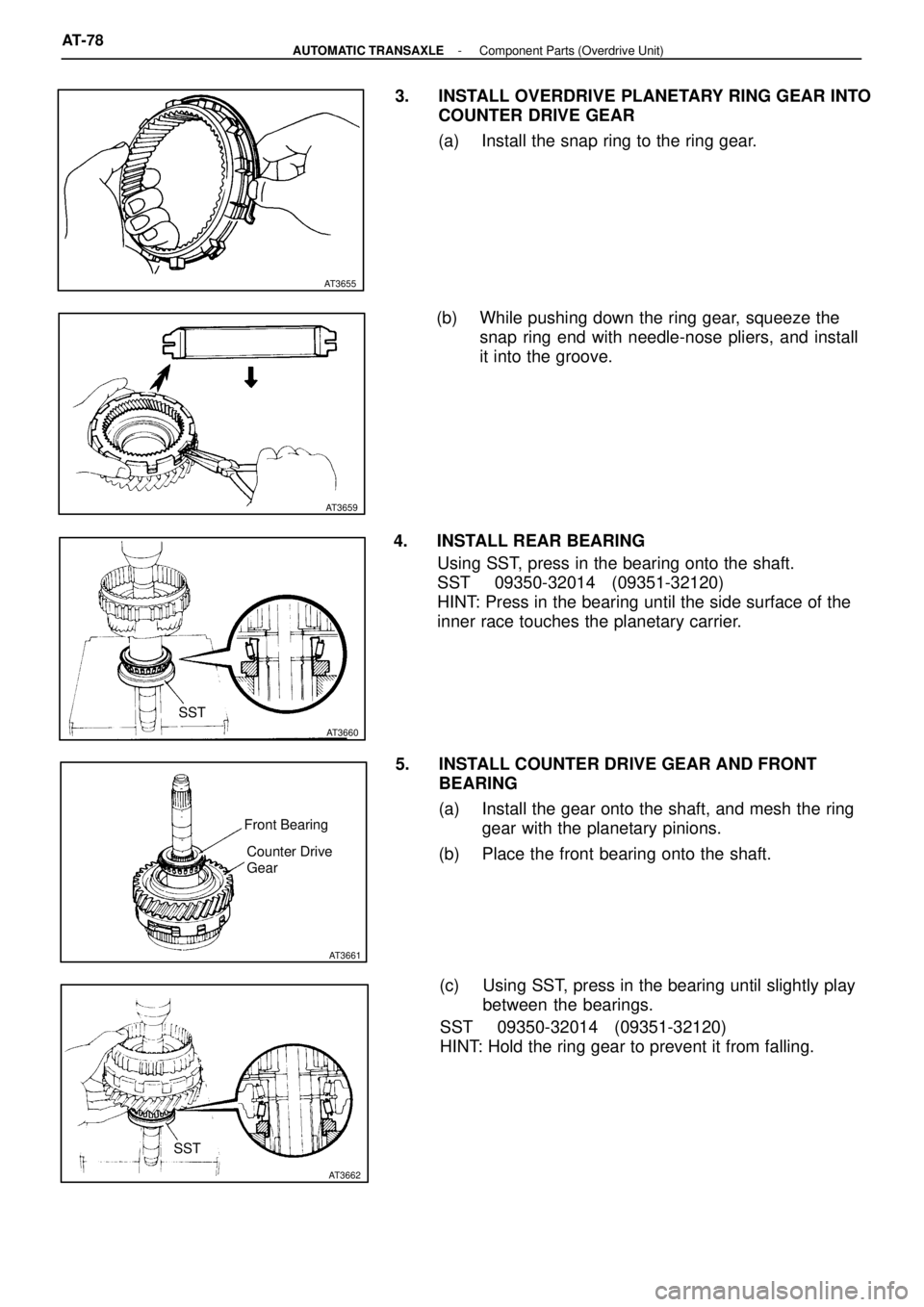

ASSEMBLY OF COUNTER DRIVE GEAR

1. INSTALL SNAP RING INTO COUNTER GEAR

Install the snap ring with a screwdriver.

2. INSTALL OUTER RACES INTO COUNTER DRIVE

GEAR

Using SST, press in the two outer races to both sides

of the gear.

SST 09350-32014 (09351-32120, 09351-32150)

HINT: Press in the two outer races until they touch the

snap ring. Tap the races in straight, so that they do not

tilt.

- AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit)AT-77

Page 93 of 2389

AT3659

AT3660

SST

AT3661

Counter Drive

Gear Front Bearing

AT3662

SST

AT3655

3. INSTALL OVERDRIVE PLANETARY RING GEAR INTO

COUNTER DRIVE GEAR

(a) Install the snap ring to the ring gear.

(b) While pushing down the ring gear, squeeze the

snap ring end with needle-nose pliers, and install

it into the groove.

4. INSTALL REAR BEARING

Using SST, press in the bearing onto the shaft.

SST 09350-32014 (09351-32120)

HINT: Press in the bearing until the side surface of the

inner race touches the planetary carrier.

5. INSTALL COUNTER DRIVE GEAR AND FRONT

BEARING

(a) Install the gear onto the shaft, and mesh the ring

gear with the planetary pinions.

(b) Place the front bearing onto the shaft.

(c) Using SST, press in the bearing until slightly play

between the bearings.

SST 09350-32014 (09351-32120)

HINT: Hold the ring gear to prevent it from falling.

AT-78- AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit)

Page 94 of 2389

AT3665

Washer

AT3666

Adjusting Nut

AT3667

Adjusting

Nut

AT5052 AT3663

SST

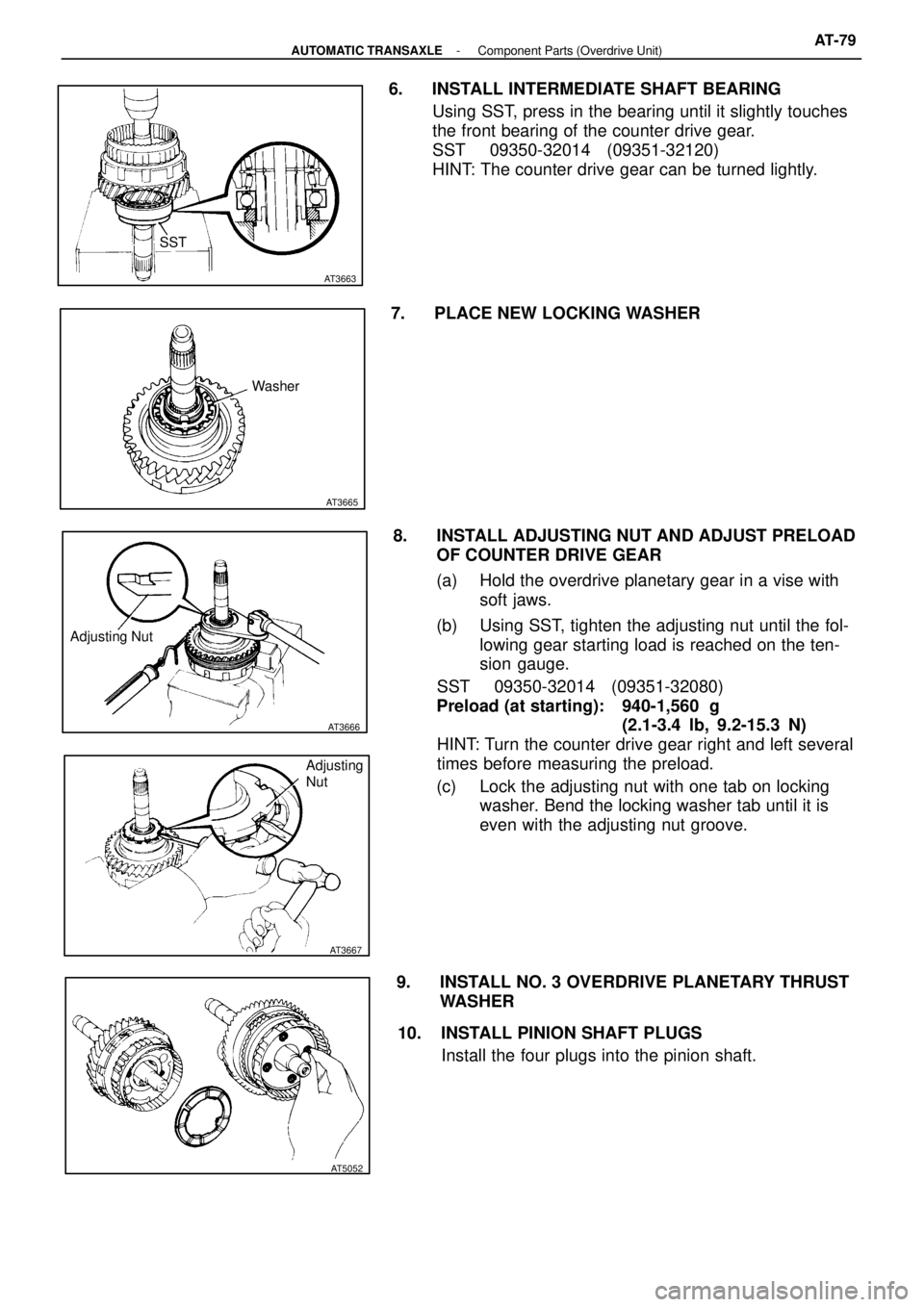

6. INSTALL INTERMEDIATE SHAFT BEARING

Using SST, press in the bearing until it slightly touches

the front bearing of the counter drive gear.

SST 09350-32014 (09351-32120)

HINT: The counter drive gear can be turned lightly.

7. PLACE NEW LOCKING WASHER

8. INSTALL ADJUSTING NUT AND ADJUST PRELOAD

OF COUNTER DRIVE GEAR

(a) Hold the overdrive planetary gear in a vise with

soft jaws.

(b) Using SST, tighten the adjusting nut until the fol-

lowing gear starting load is reached on the ten-

sion gauge.

SST 09350-32014 (09351-32080)

Preload (at starting): 940-1,560 g

(2.1-3.4 lb, 9.2-15.3 N)

HINT: Turn the counter drive gear right and left several

times before measuring the preload.

(c) Lock the adjusting nut with one tab on locking

washer. Bend the locking washer tab until it is

even with the adjusting nut groove.

9. INSTALL NO. 3 OVERDRIVE PLANETARY THRUST

WASHER

10. INSTALL PINION SHAFT PLUGS

Install the four plugs into the pinion shaft.

- AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit)AT-79

Page 95 of 2389

AT3645HoldLockFreeTurn

AT0426

AT3649

AT3748

AT3647

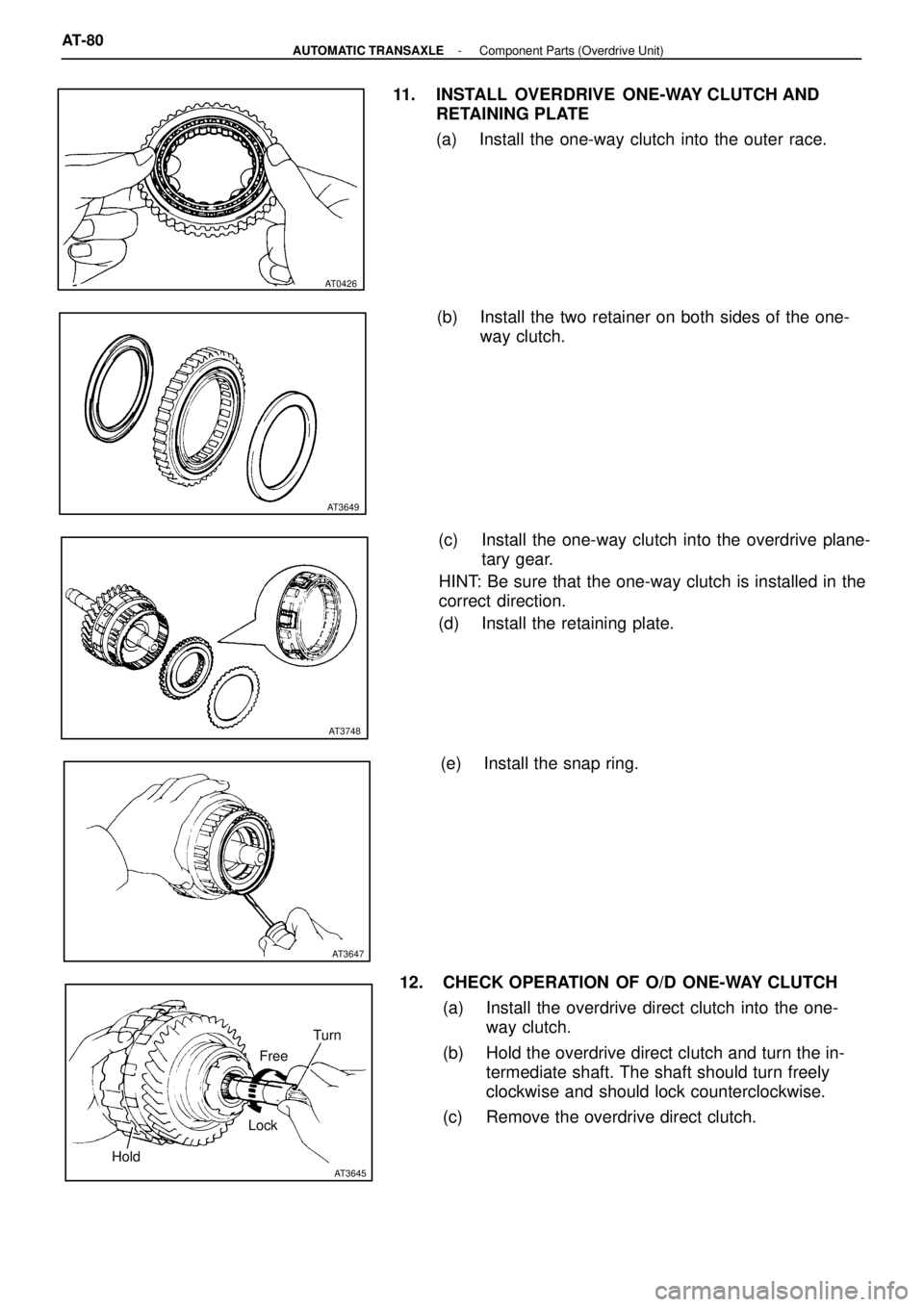

11. INSTALL OVERDRIVE ONE-WAY CLUTCH AND

RETAINING PLATE

(a) Install the one-way clutch into the outer race.

(b) Install the two retainer on both sides of the one-

way clutch.

(c) Install the one-way clutch into the overdrive plane-

tary gear.

HINT: Be sure that the one-way clutch is installed in the

correct direction.

(d) Install the retaining plate.

(e) Install the snap ring.

12. CHECK OPERATION OF O/D ONE-WAY CLUTCH

(a) Install the overdrive direct clutch into the one-

way clutch.

(b) Hold the overdrive direct clutch and turn the in-

termediate shaft. The shaft should turn freely

clockwise and should lock counterclockwise.

(c) Remove the overdrive direct clutch.

AT-80- AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit)

Page 96 of 2389

AT3668

AT3669

Piston Plate

AT3670

AT0441

AT7728

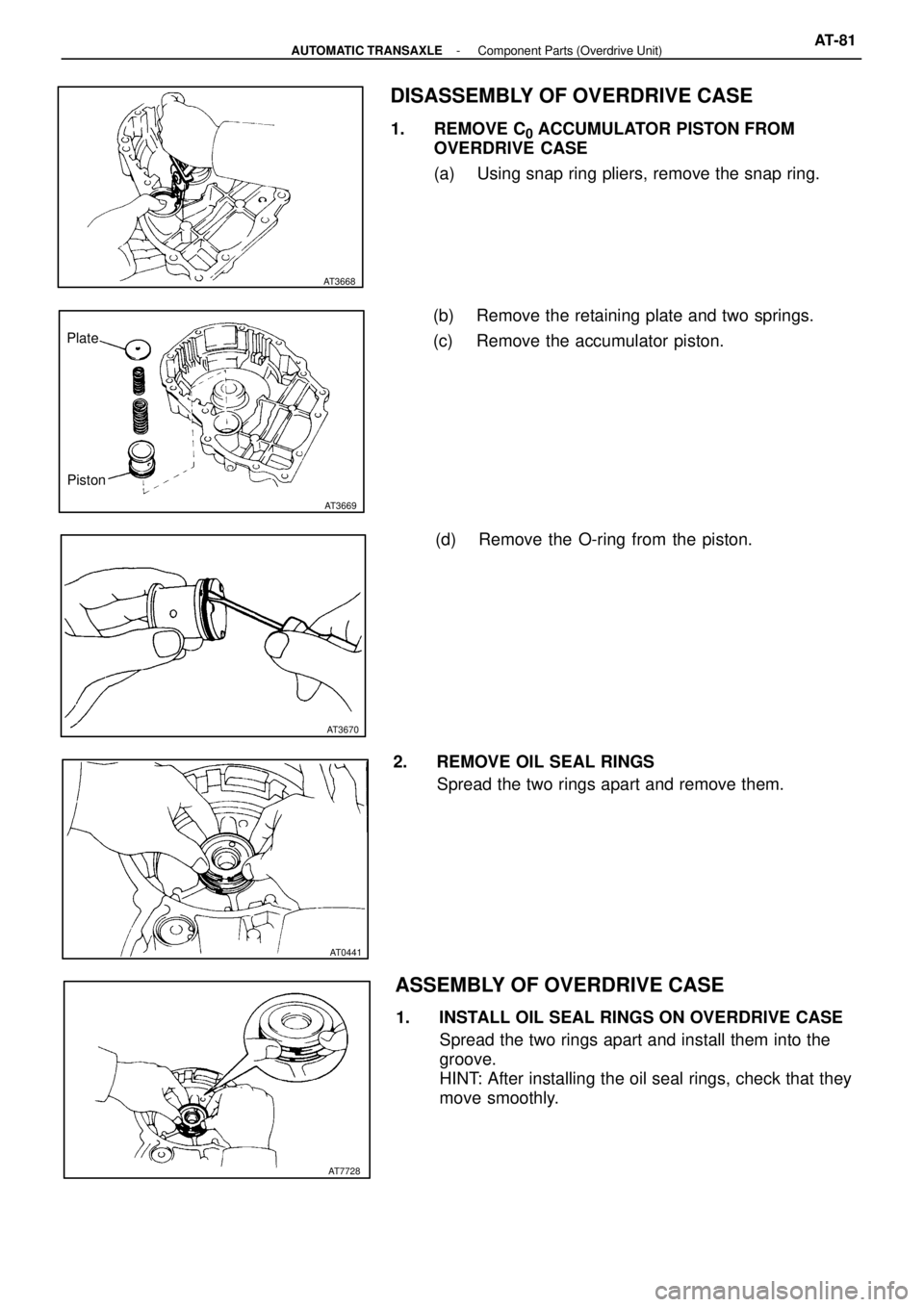

DISASSEMBLY OF OVERDRIVE CASE

1. REMOVE C0 ACCUMULATOR PISTON FROM

OVERDRIVE CASE

(a) Using snap ring pliers, remove the snap ring.

(b) Remove the retaining plate and two springs.

(c) Remove the accumulator piston.

(d) Remove the O-ring from the piston.

2. REMOVE OIL SEAL RINGS

Spread the two rings apart and remove them.

ASSEMBLY OF OVERDRIVE CASE

1. INSTALL OIL SEAL RINGS ON OVERDRIVE CASE

Spread the two rings apart and install them into the

groove.

HINT: After installing the oil seal rings, check that they

move smoothly.

- AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit)AT-81

Page 97 of 2389

AT3669

Piston Plate

AT3668

AT2756

AT7729

DrumPiston

AT3671

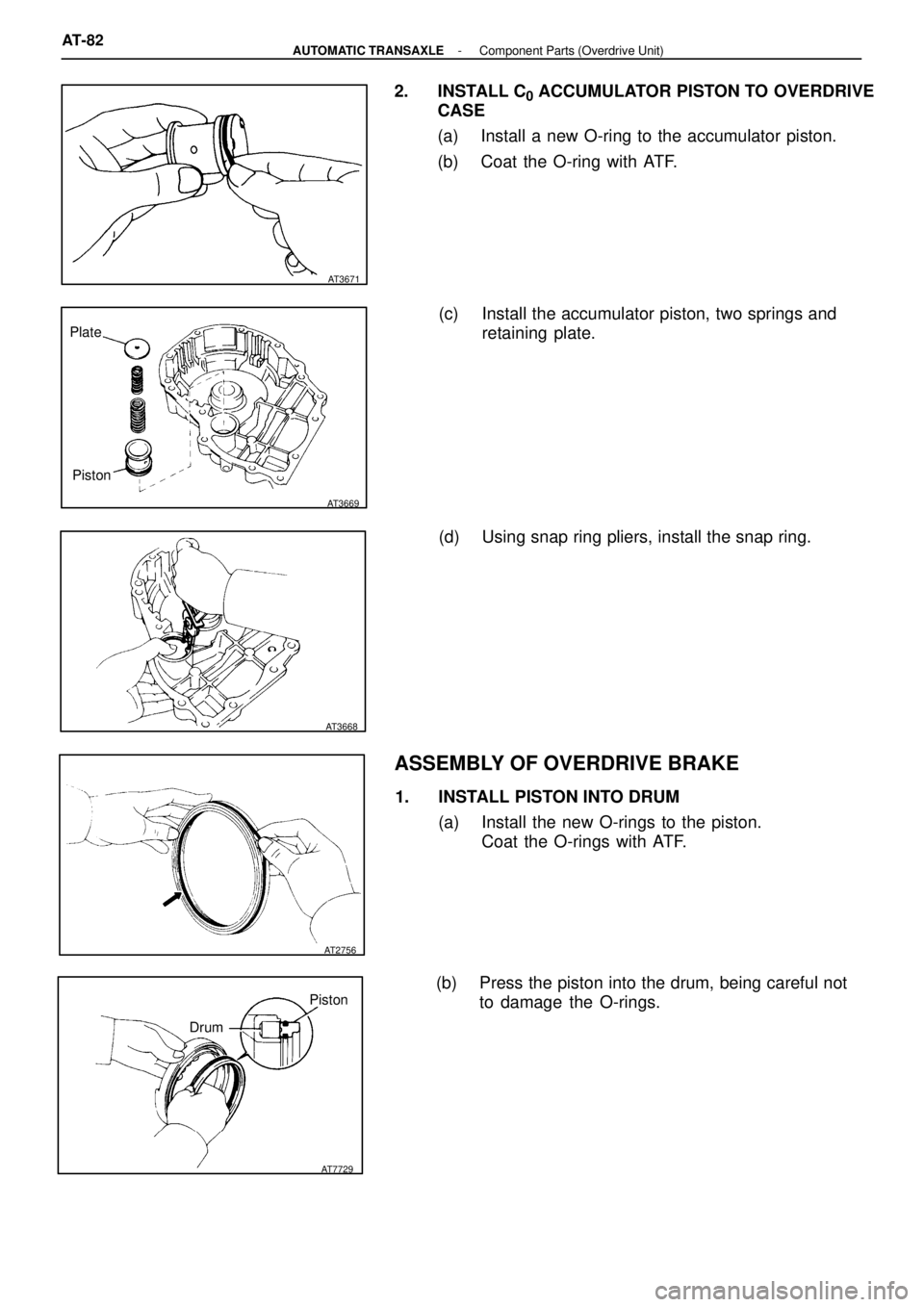

2. INSTALL C0 ACCUMULATOR PISTON TO OVERDRIVE

CASE

(a) Install a new O-ring to the accumulator piston.

(b) Coat the O-ring with ATF.

(c) Install the accumulator piston, two springs and

retaining plate.

(d) Using snap ring pliers, install the snap ring.

ASSEMBLY OF OVERDRIVE BRAKE

1. INSTALL PISTON INTO DRUM

(a) Install the new O-rings to the piston.

Coat the O-rings with ATF.

(b) Press the piston into the drum, being careful not

to damage the O-rings.

AT-82- AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit)

Page 98 of 2389

AT1905

AT2823

AT7730

AT3673 AT3672

FlangeDisc Plate

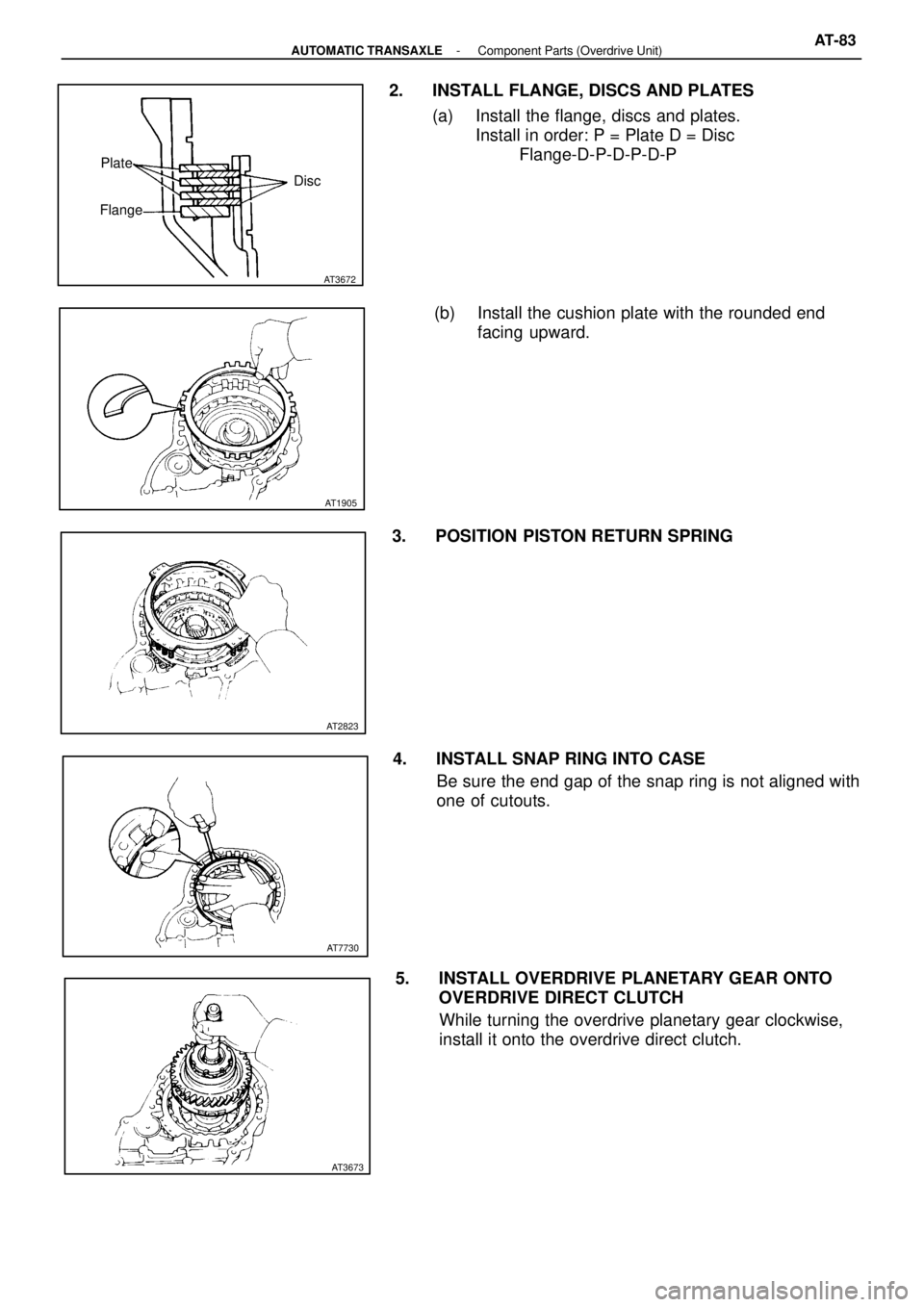

2. INSTALL FLANGE, DISCS AND PLATES

(a) Install the flange, discs and plates.

Install in order: P = Plate D = Disc

Flange-D-P-D-P-D-P

(b) Install the cushion plate with the rounded end

facing upward.

3. POSITION PISTON RETURN SPRING

4. INSTALL SNAP RING INTO CASE

Be sure the end gap of the snap ring is not aligned with

one of cutouts.

5. INSTALL OVERDRIVE PLANETARY GEAR ONTO

OVERDRIVE DIRECT CLUTCH

While turning the overdrive planetary gear clockwise,

install it onto the overdrive direct clutch.

- AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit)AT-83

Page 99 of 2389

AT7731

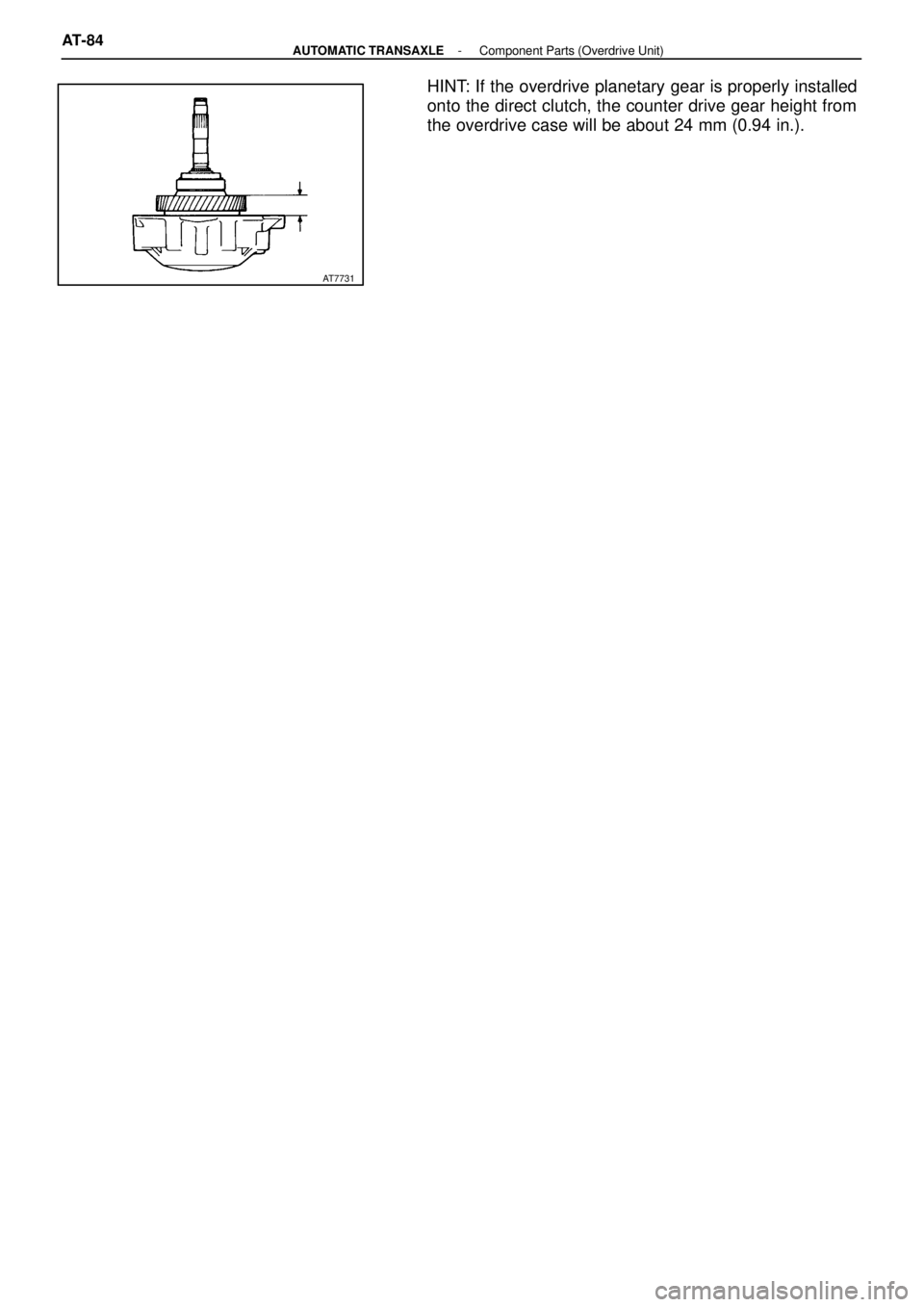

HINT: If the overdrive planetary gear is properly installed

onto the direct clutch, the counter drive gear height from

the overdrive case will be about 24 mm (0.94 in.).

AT-84- AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit)

Page 100 of 2389

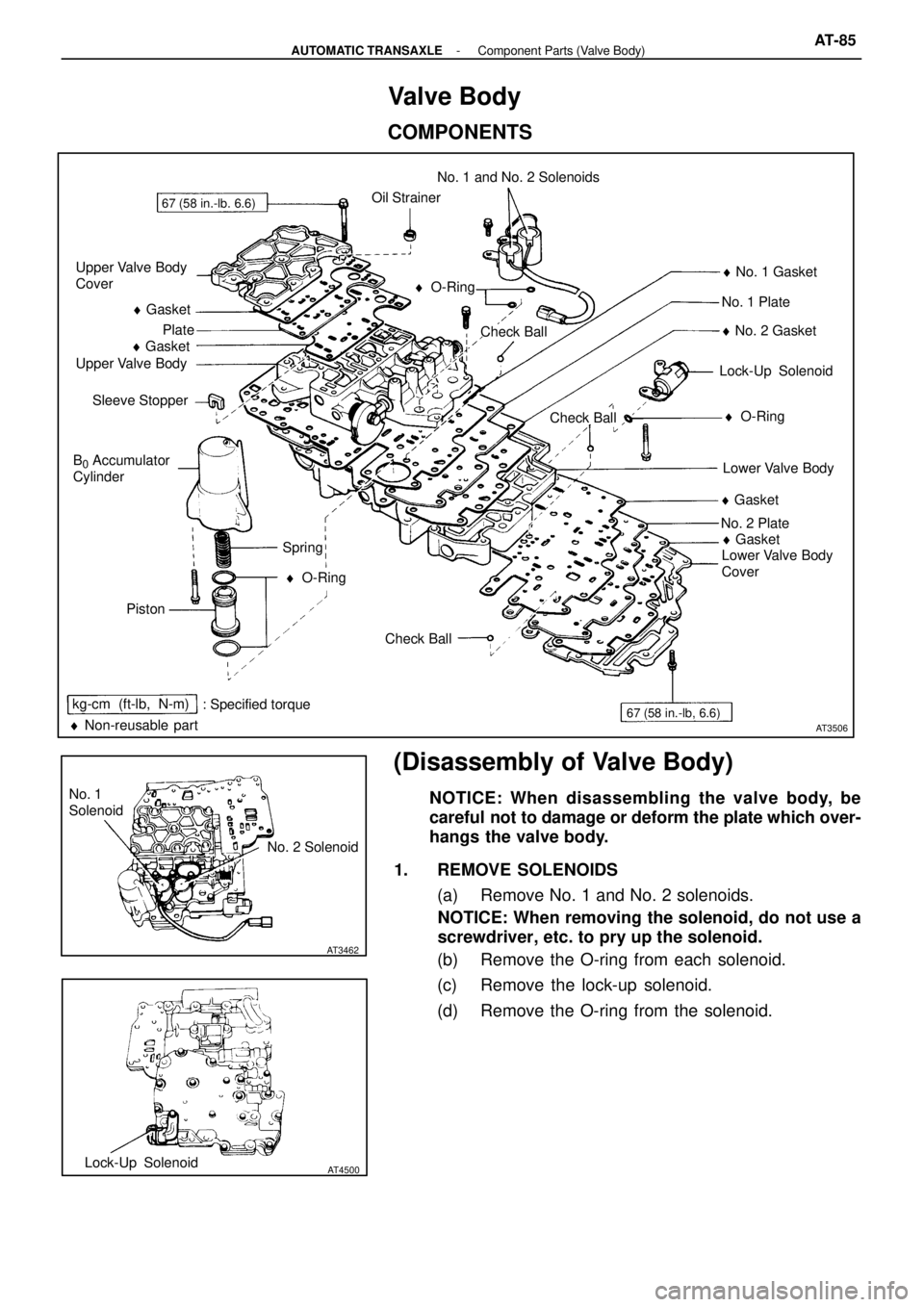

AT3462

No. 2 Solenoid No. 1

Solenoid

AT4500Lock-Up Solenoid

AT3506r Non-reusable part67 (58 in.-lb, 6.6)kg-cm (ft-lb, N-m)

: Specified torqueCheck Ball Pistonr Gasket B

0 Accumulator

CylinderLower Valve Bodyr O-Ring

Check BallLock-Up Solenoid Check Ballr No. 2 Gasket r GasketNo. 1 Plate Upper Valve Body

Cover

r O-Ringr No. 1 Gasket Oil Strainer

67 (58 in.-lb. 6.6)

No. 1 and No. 2 Solenoids

Lower Valve Body

Cover r Gasket No. 2 Plate Plate

r Gasket

Upper Valve Body

Sleeve Stopper

Spring

r O-Ring

Valve Body

COMPONENTS

(Disassembly of Valve Body)

NOTICE: When disassembling the valve body, be

careful not to damage or deform the plate which over-

hangs the valve body.

1. REMOVE SOLENOIDS

(a) Remove No. 1 and No. 2 solenoids.

NOTICE: When removing the solenoid, do not use a

screwdriver, etc. to pry up the solenoid.

(b) Remove the O-ring from each solenoid.

(c) Remove the lock-up solenoid.

(d) Remove the O-ring from the solenoid.

- AUTOMATIC TRANSAXLEComponent Parts (Valve Body)AT-85