TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: coolant reservoir, turn signal, tow, coolant capacity, width, tow bar, air suspension

Page 51 of 2389

AT3574

AT3576

AT3577

AT2731

Lock PawlPin

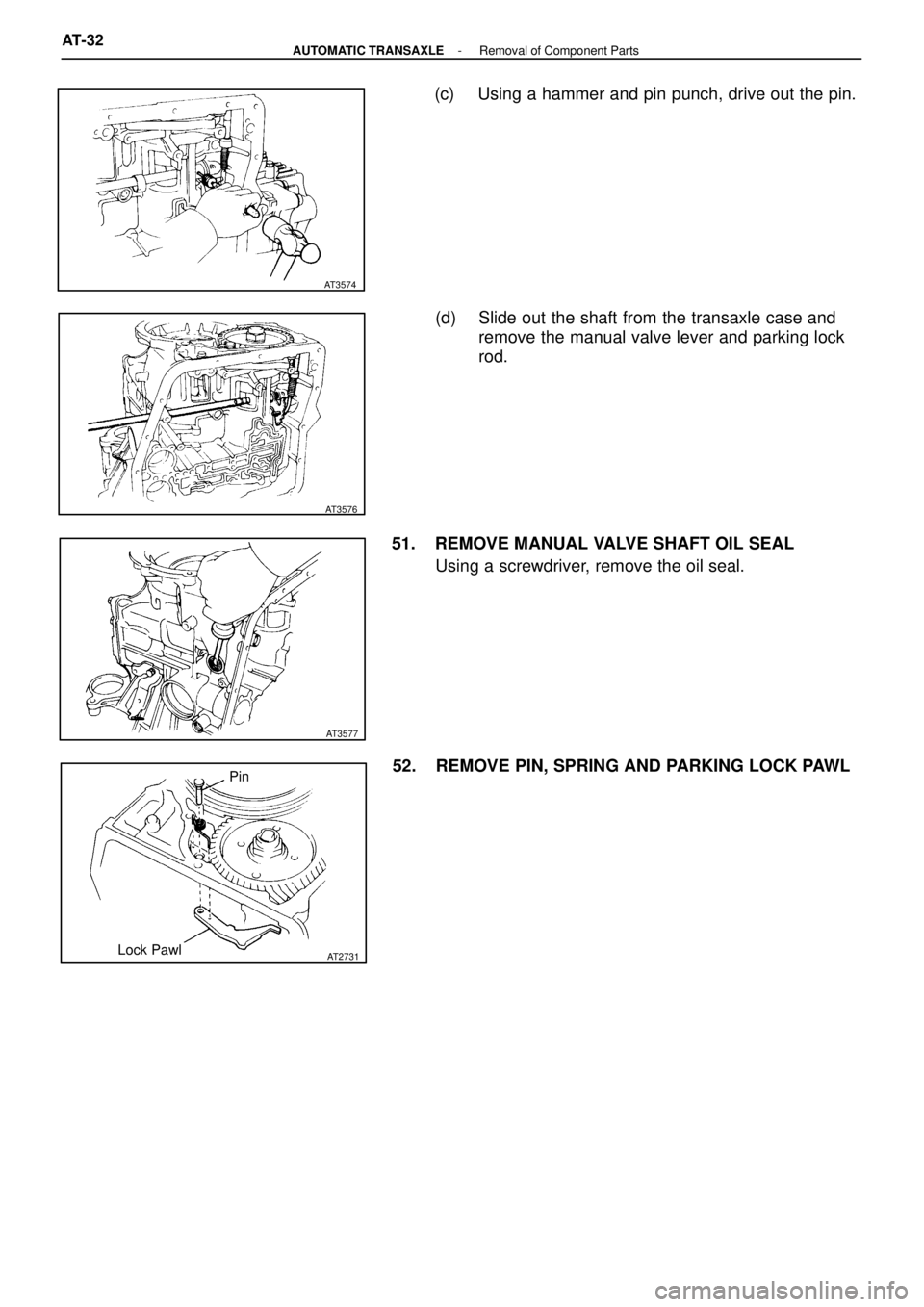

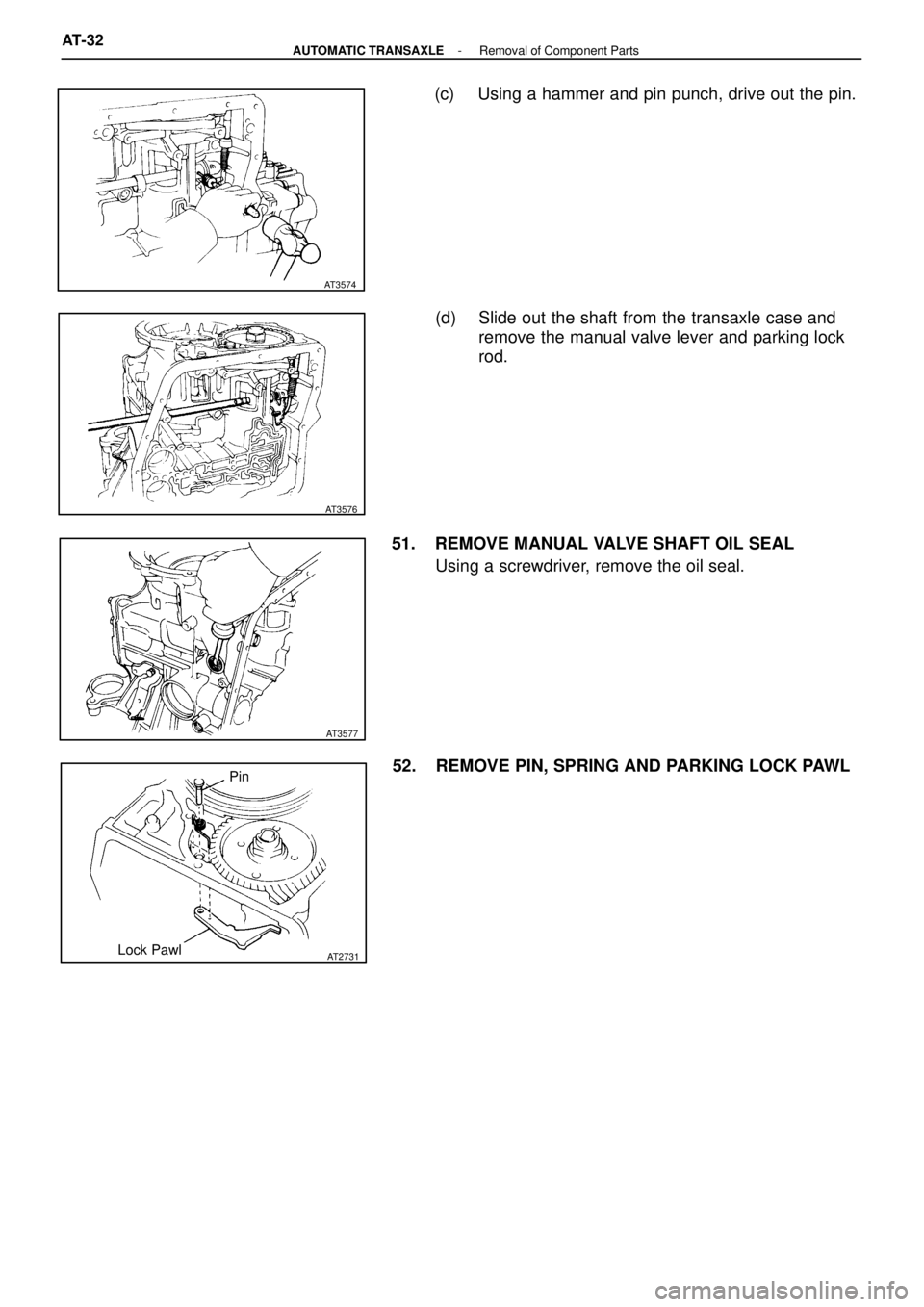

(c) Using a hammer and pin punch, drive out the pin.

(d) Slide out the shaft from the transaxle case and

remove the manual valve lever and parking lock

rod.

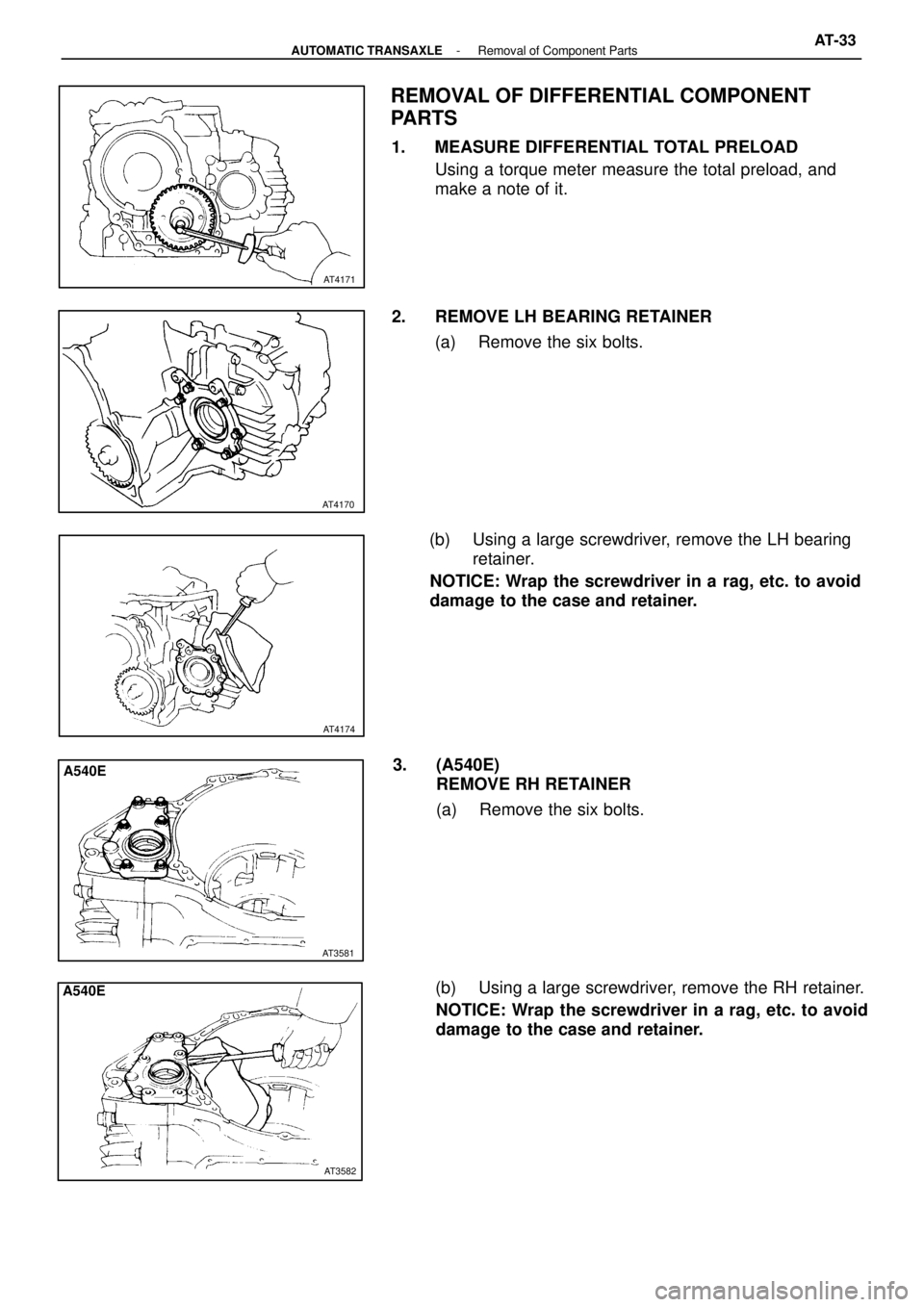

51. REMOVE MANUAL VALVE SHAFT OIL SEAL

Using a screwdriver, remove the oil seal.

52. REMOVE PIN, SPRING AND PARKING LOCK PAWL

AT-32- AUTOMATIC TRANSAXLERemoval of Component Parts

Page 52 of 2389

AT4170

AT4174

AT3581

A540E

AT3582

A540E

AT4171

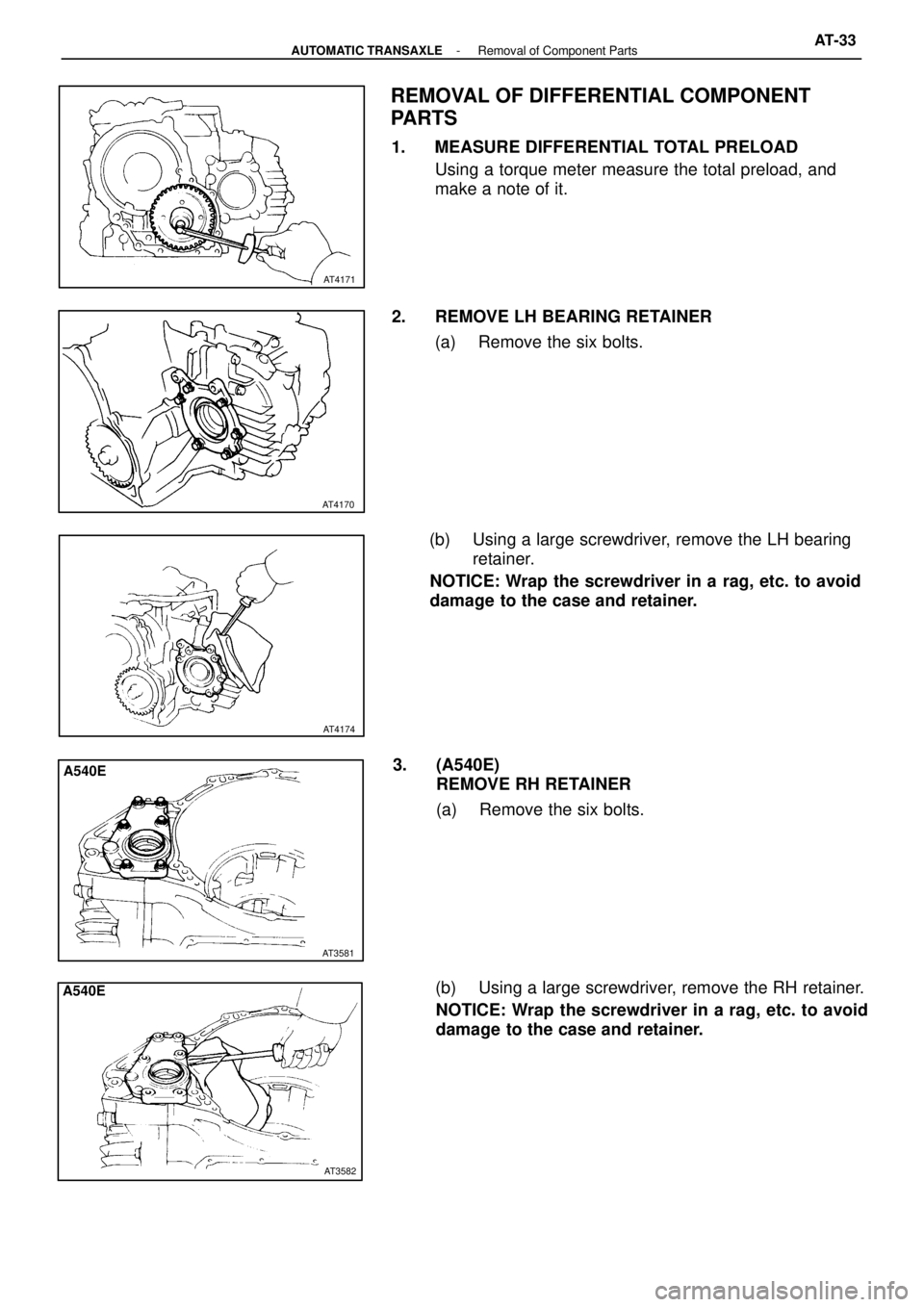

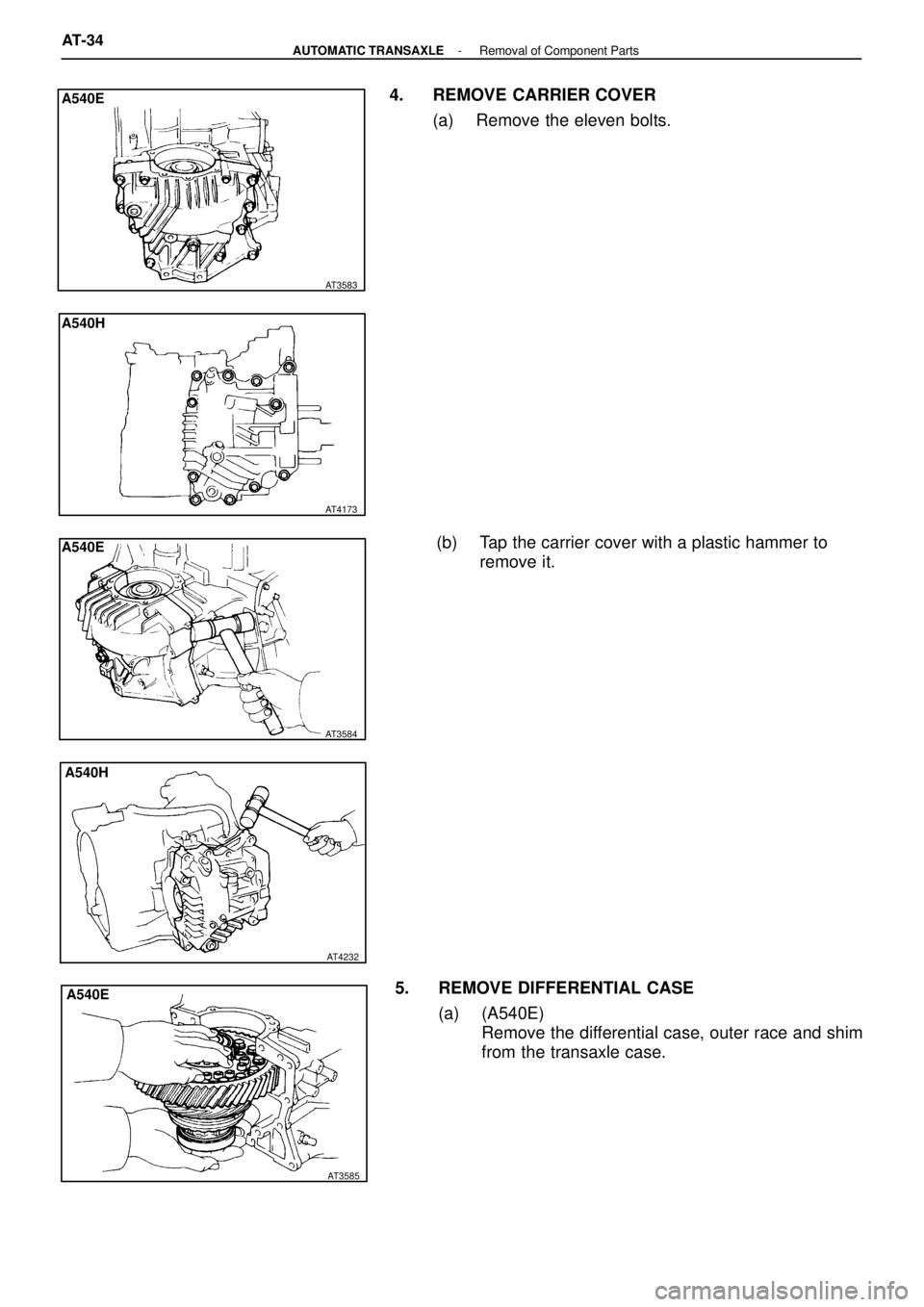

REMOVAL OF DIFFERENTIAL COMPONENT

PARTS

1. MEASURE DIFFERENTIAL TOTAL PRELOAD

Using a torque meter measure the total preload, and

make a note of it.

2. REMOVE LH BEARING RETAINER

(a) Remove the six bolts.

(b) Using a large screwdriver, remove the LH bearing

retainer.

NOTICE: Wrap the screwdriver in a rag, etc. to avoid

damage to the case and retainer.

3. (A540E)

REMOVE RH RETAINER

(a) Remove the six bolts.

(b) Using a large screwdriver, remove the RH retainer.

NOTICE: Wrap the screwdriver in a rag, etc. to avoid

damage to the case and retainer.

- AUTOMATIC TRANSAXLERemoval of Component PartsAT-33

Page 53 of 2389

AT3583

A540E

AT4173

A540H

AT3584

A540E

AT3585

A540E

AT4232

A540H

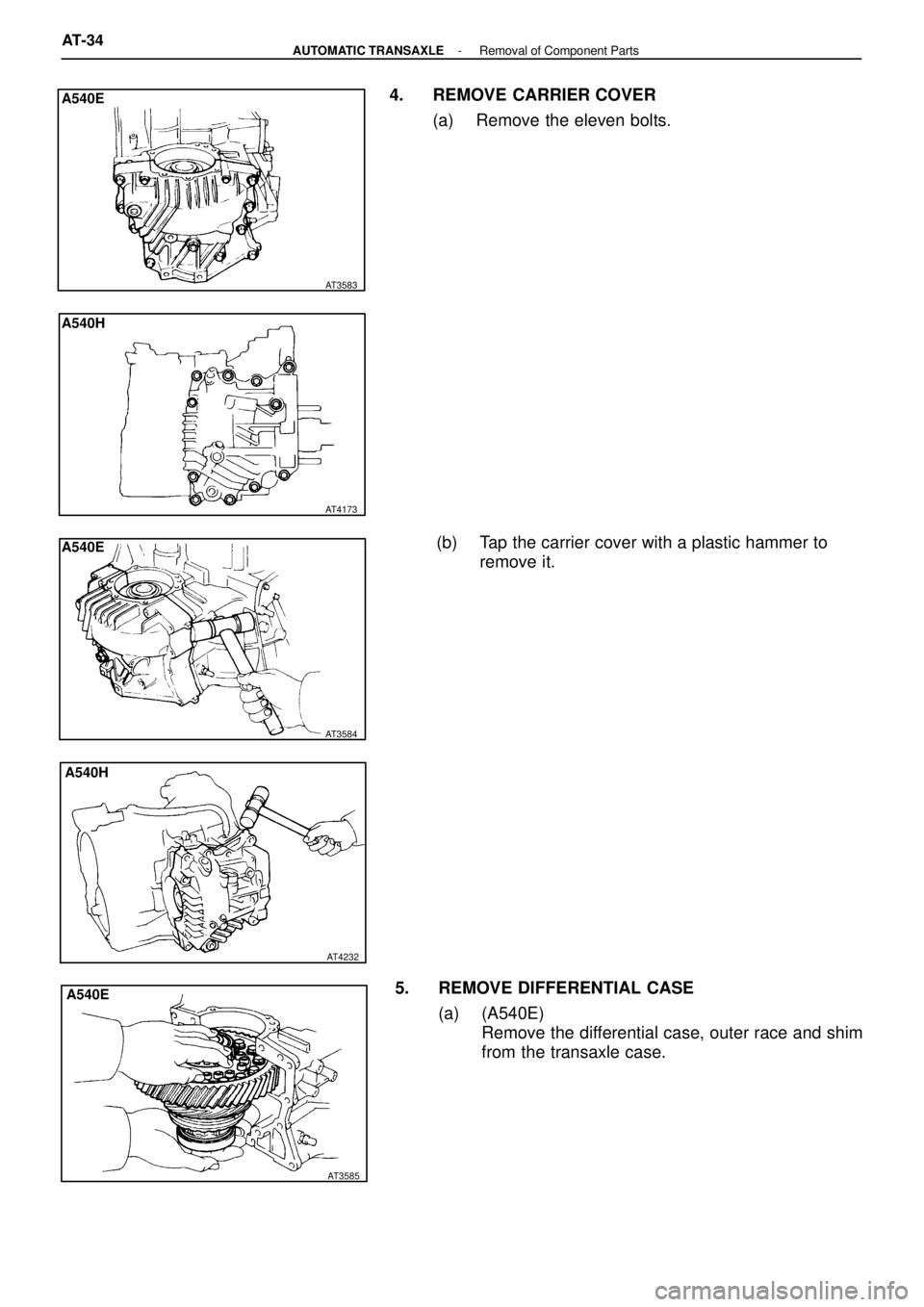

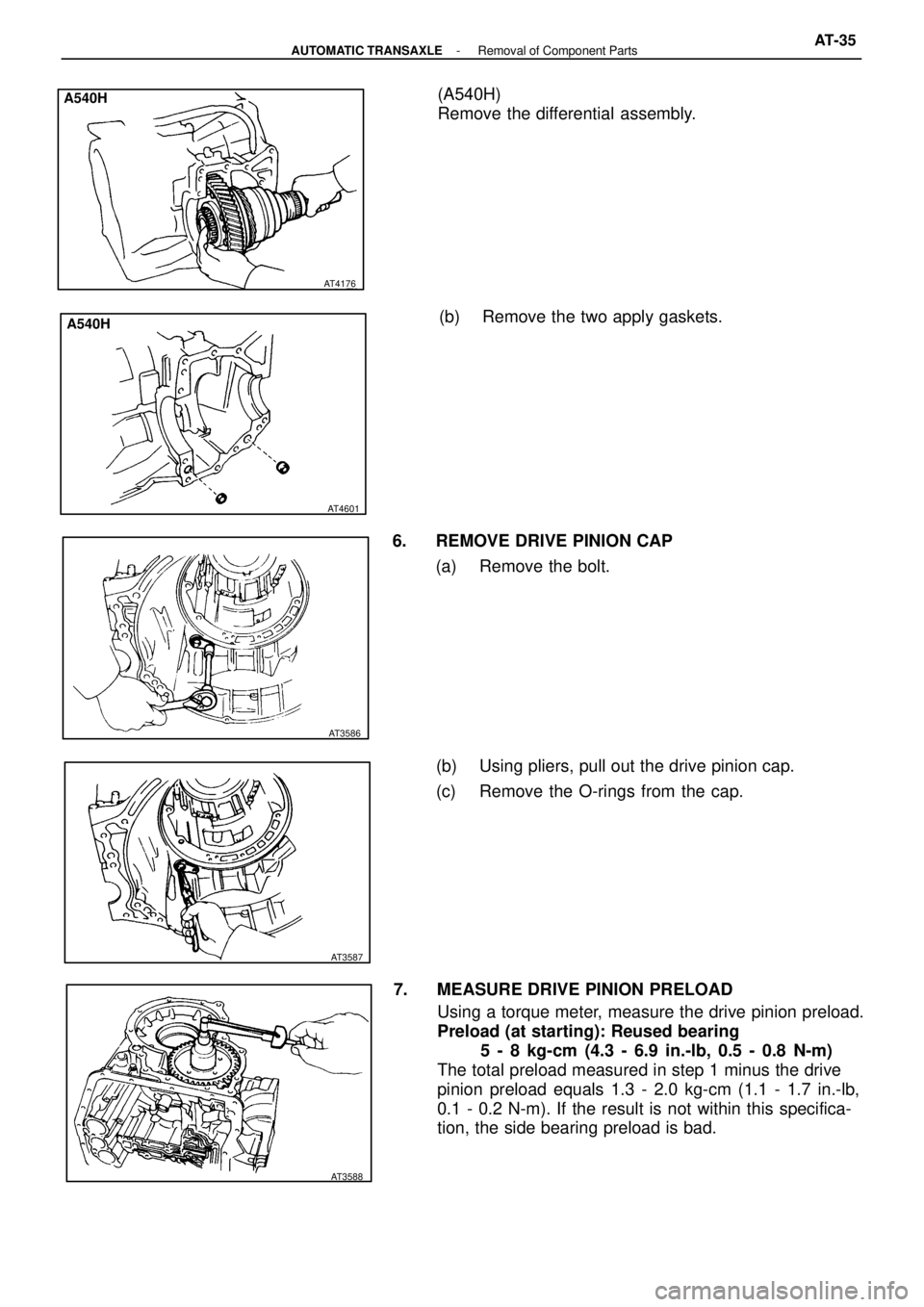

4. REMOVE CARRIER COVER

(a) Remove the eleven bolts.

(b) Tap the carrier cover with a plastic hammer to

remove it.

5. REMOVE DIFFERENTIAL CASE

(a) (A540E)

Remove the differential case, outer race and shim

from the transaxle case.

AT-34- AUTOMATIC TRANSAXLERemoval of Component Parts

Page 54 of 2389

AT4601

A540H

AT3586

AT3587

AT3588 AT4176

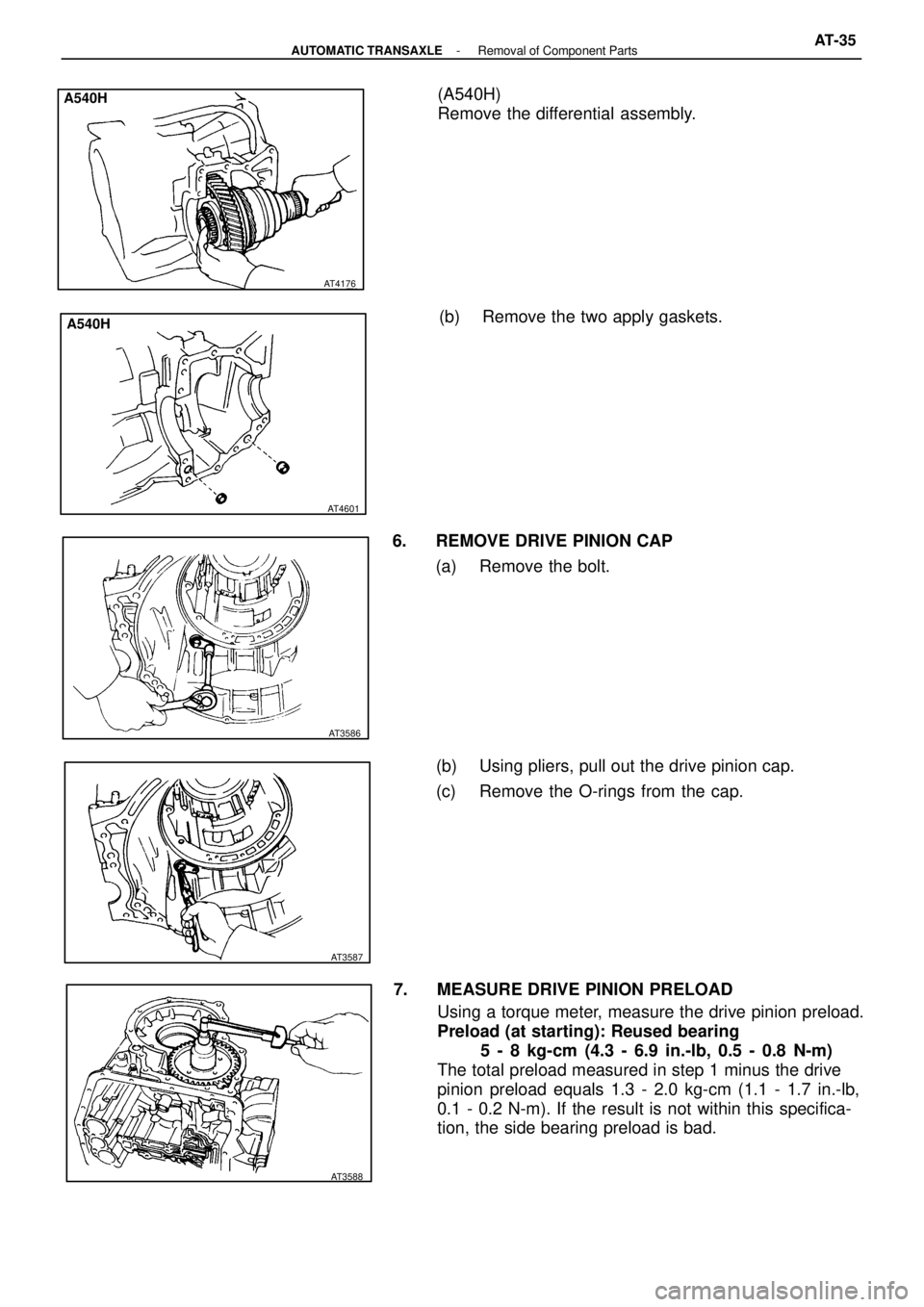

A540H(A540H)

Remove the differential assembly.

(b) Remove the two apply gaskets.

6. REMOVE DRIVE PINION CAP

(a) Remove the bolt.

(b) Using pliers, pull out the drive pinion cap.

(c) Remove the O-rings from the cap.

7. MEASURE DRIVE PINION PRELOAD

Using a torque meter, measure the drive pinion preload.

Preload (at starting): Reused bearing

5 - 8 kg-cm (4.3 - 6.9 in.-lb, 0.5 - 0.8 N-m)

The total preload measured in step 1 minus the drive

pinion preload equals 1.3 - 2.0 kg-cm (1.1 - 1.7 in.-lb,

0.1 - 0.2 N-m). If the result is not within this specifica-

tion, the side bearing preload is bad.

- AUTOMATIC TRANSAXLERemoval of Component PartsAT-35

Page 55 of 2389

AT3590SST

AT3591

SST

AT3592

SST

AT3593

Oil Slinger Spacer

AT3589

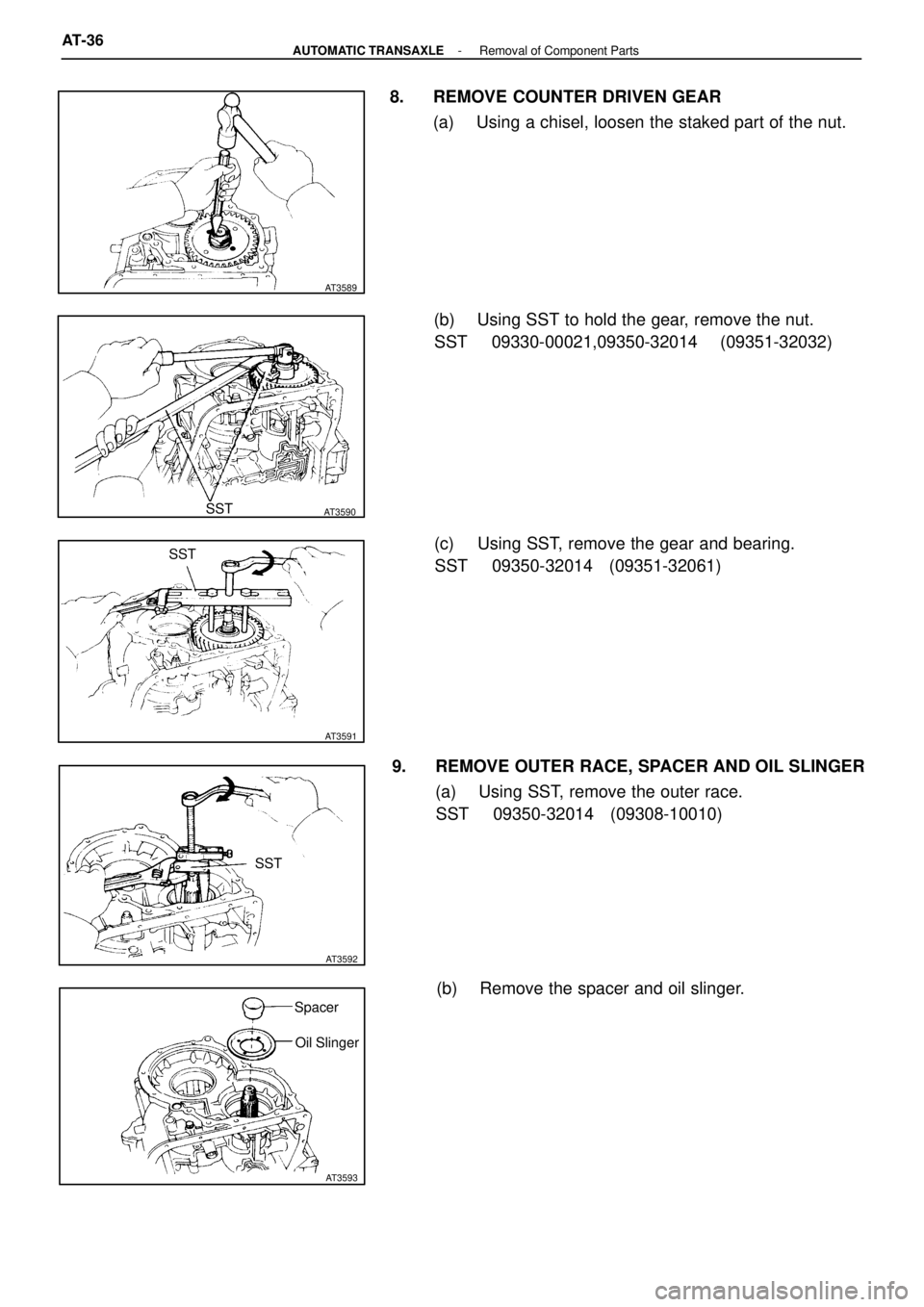

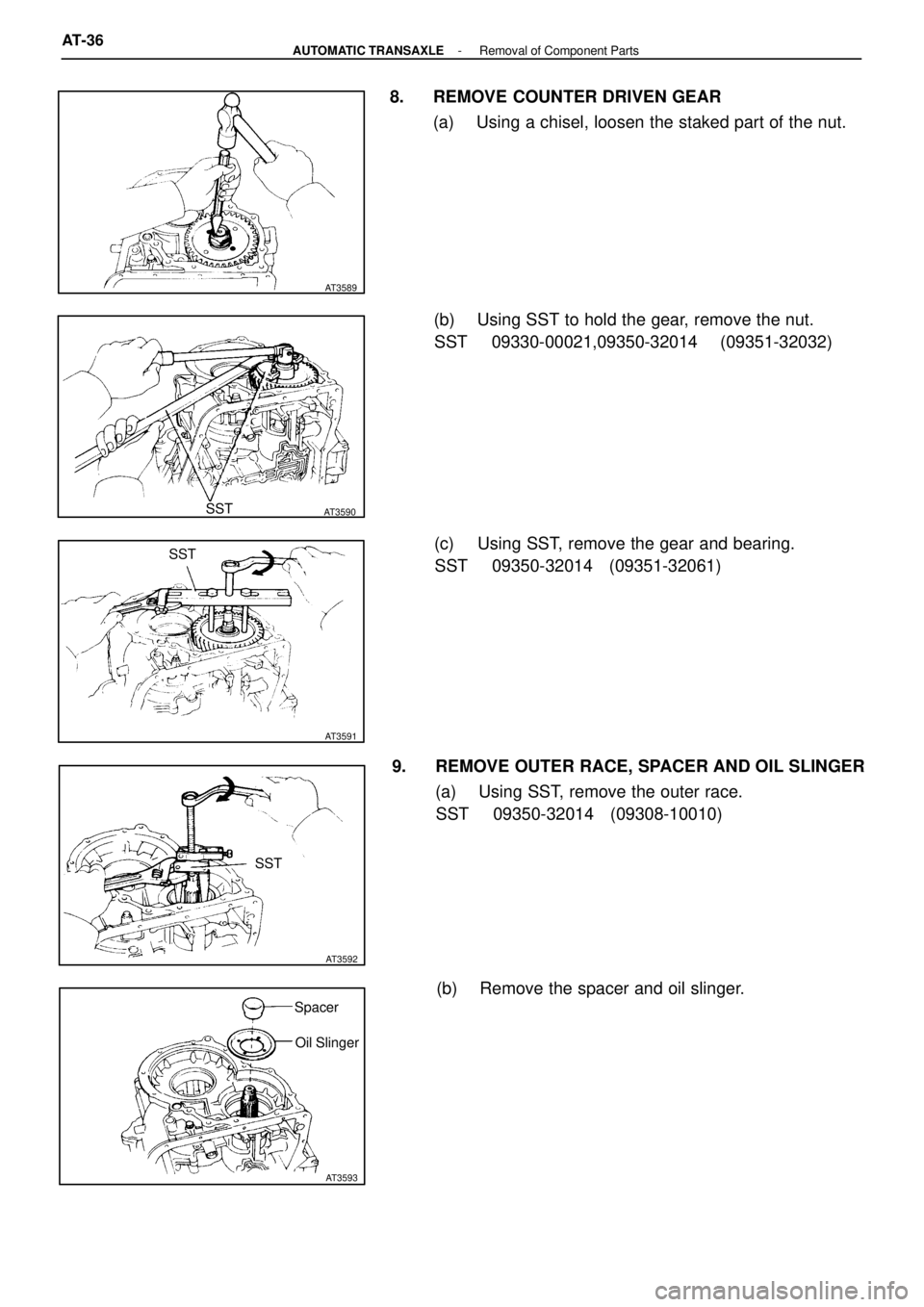

8. REMOVE COUNTER DRIVEN GEAR

(a) Using a chisel, loosen the staked part of the nut.

(b) Using SST to hold the gear, remove the nut.

SST 09330-00021,09350-32014 (09351-32032)

(c) Using SST, remove the gear and bearing.

SST 09350-32014 (09351-32061)

9. REMOVE OUTER RACE, SPACER AND OIL SLINGER

(a) Using SST, remove the outer race.

SST 09350-32014 (09308-10010)

(b) Remove the spacer and oil slinger.

AT-36- AUTOMATIC TRANSAXLERemoval of Component Parts

Page 56 of 2389

AT4175

A540H

AT3595

SST

AT3596

AT3597

O-Ring

AT3594

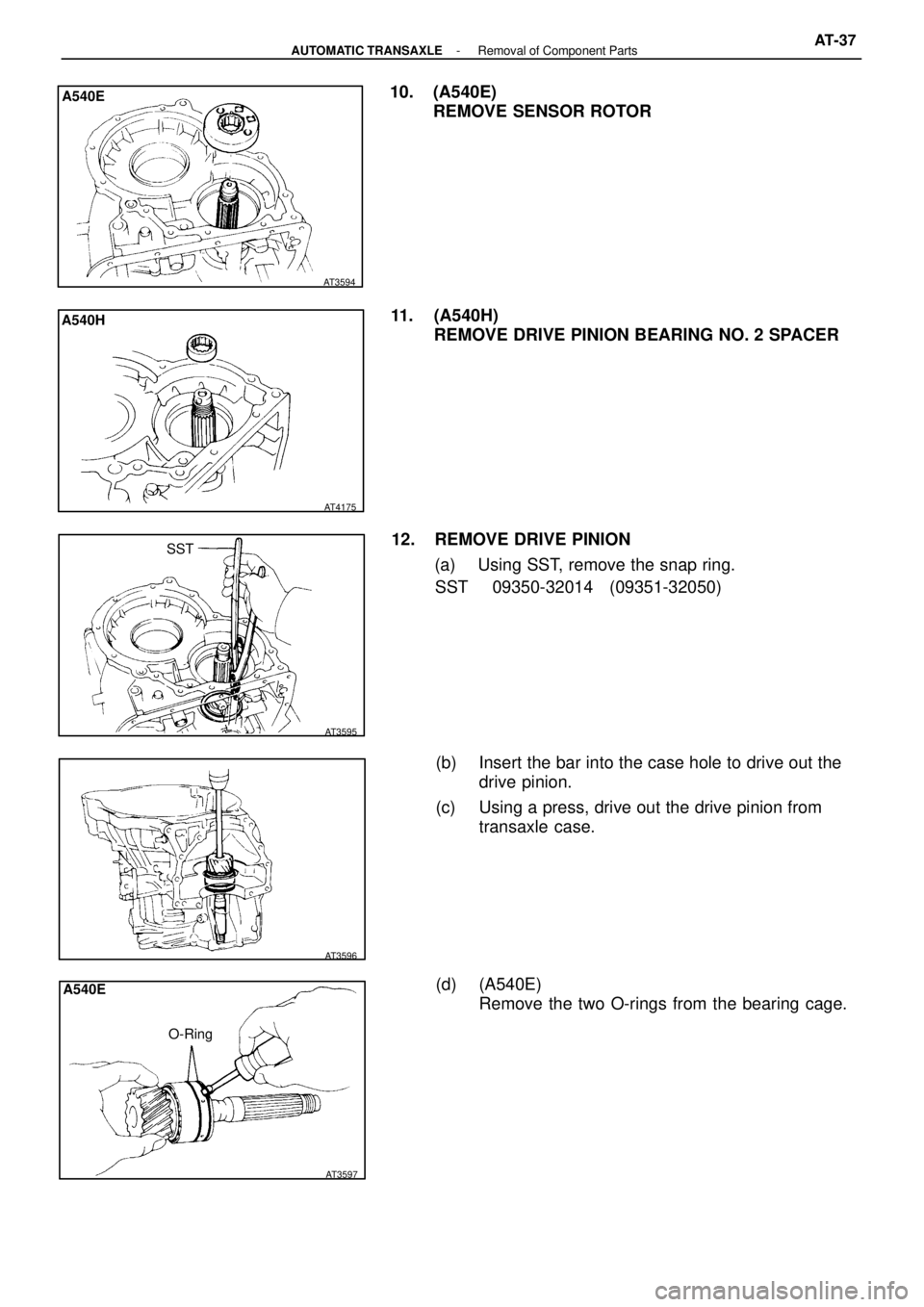

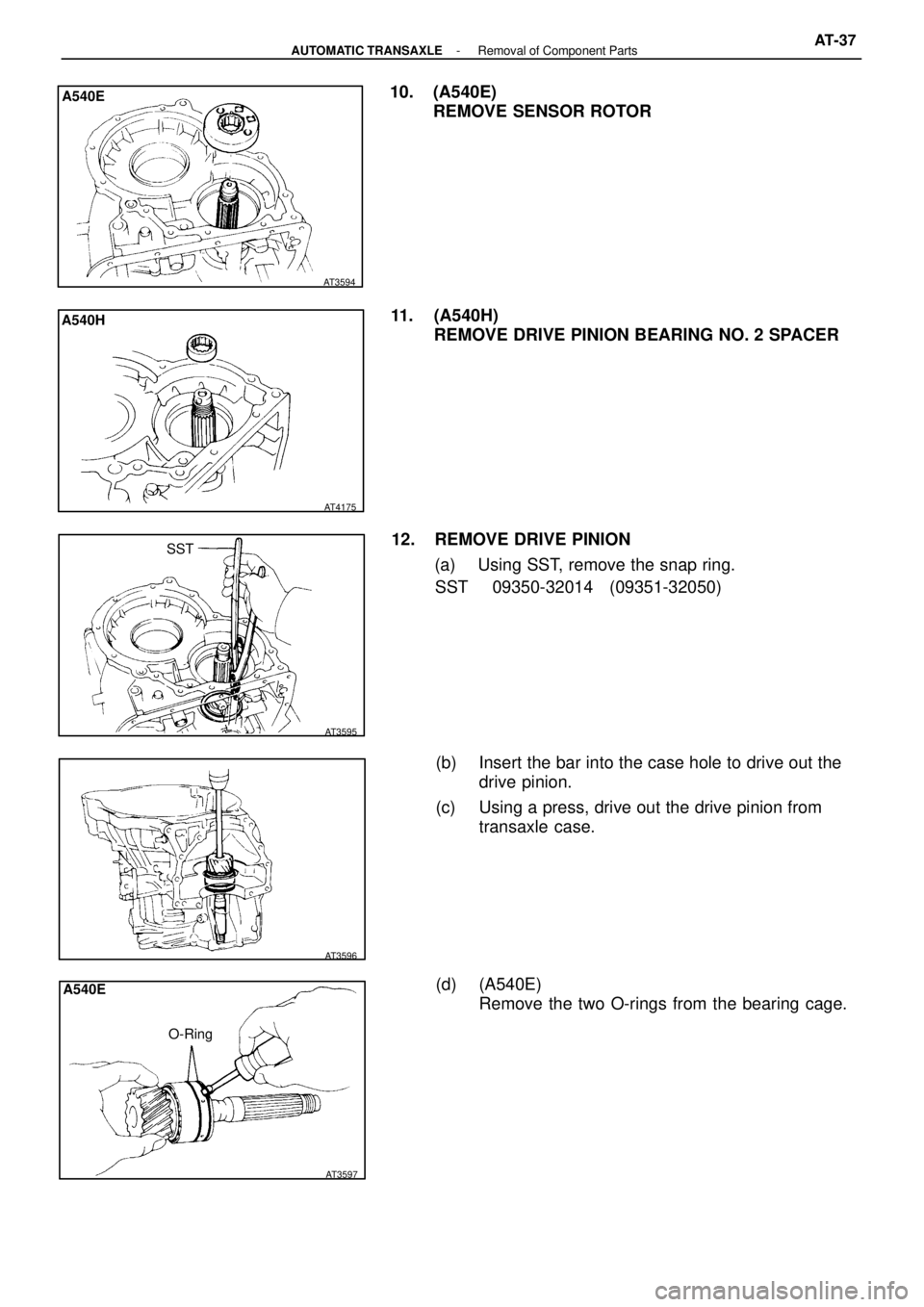

A540E10. (A540E)

REMOVE SENSOR ROTOR

11. (A540H)

REMOVE DRIVE PINION BEARING NO. 2 SPACER

12. REMOVE DRIVE PINION

(a) Using SST, remove the snap ring.

SST 09350-32014 (09351-32050)

(b) Insert the bar into the case hole to drive out the

drive pinion.

(c) Using a press, drive out the drive pinion from

transaxle case.

(d) (A540E)

Remove the two O-rings from the bearing cage.

A540E

- AUTOMATIC TRANSAXLERemoval of Component PartsAT-37

Page 57 of 2389

AT3605

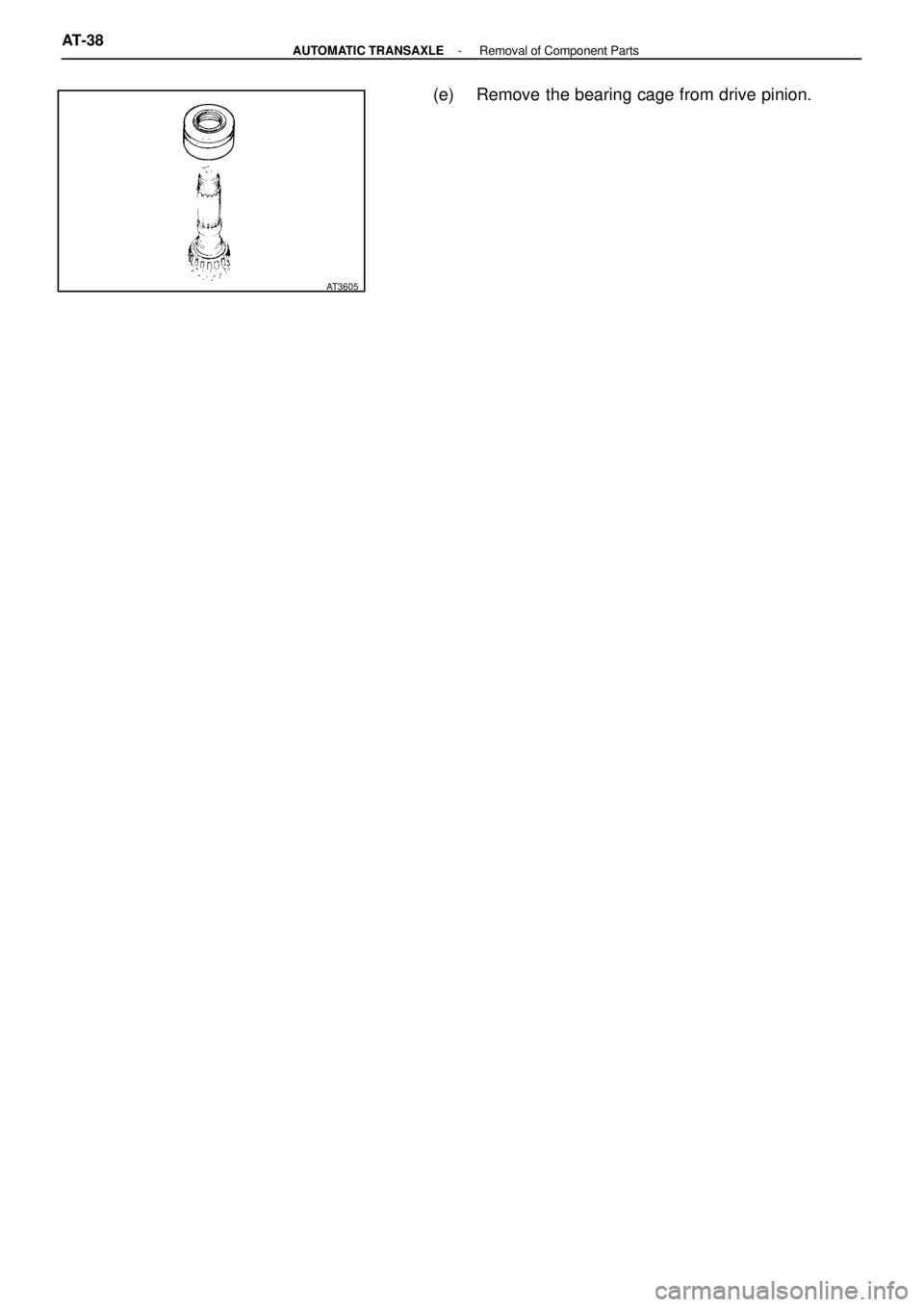

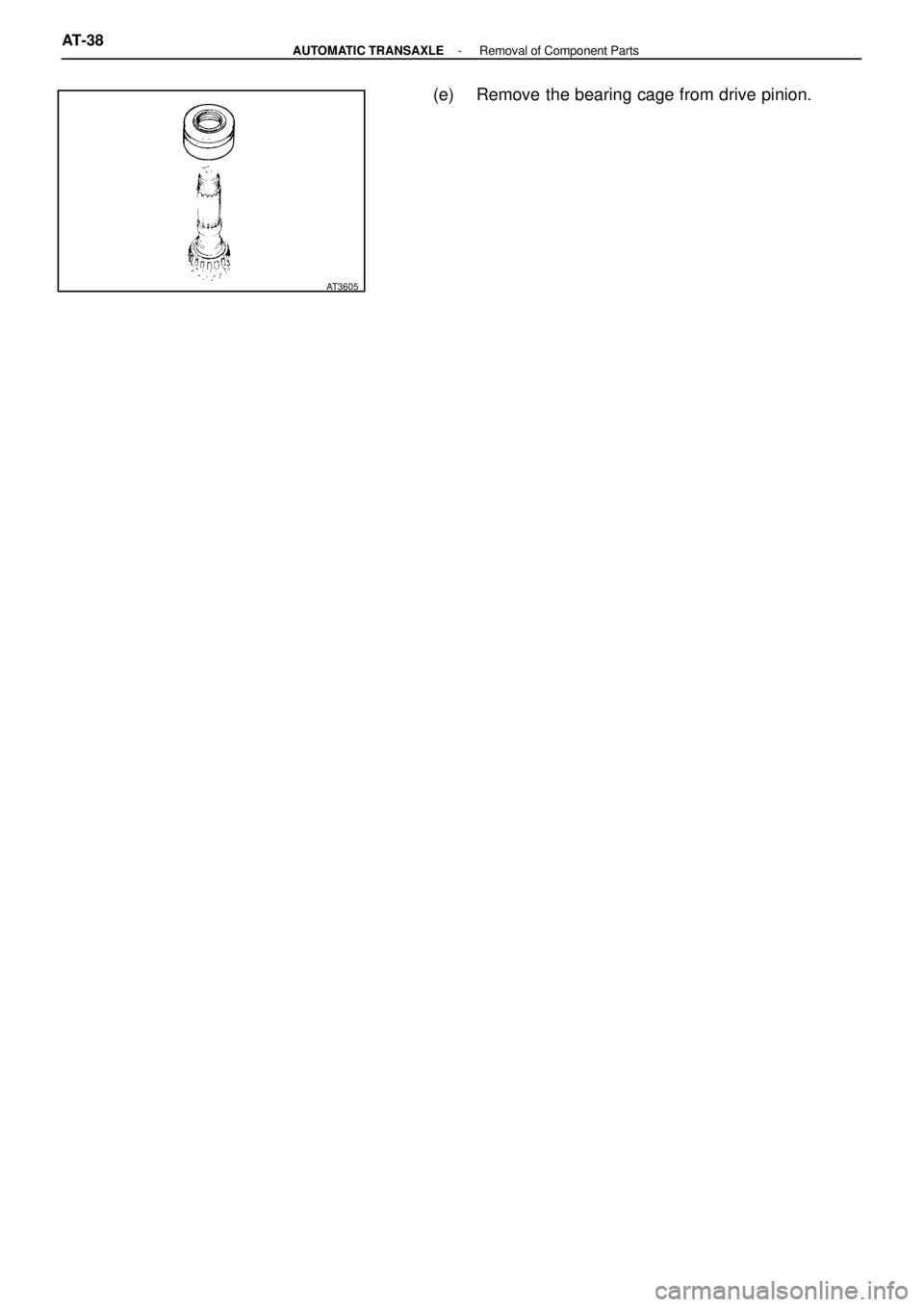

(e) Remove the bearing cage from drive pinion.

AT-38- AUTOMATIC TRANSAXLERemoval of Component Parts

Page 58 of 2389

AT3608r Non-reusable part

: Specified torque kg-cm (ft-lb, N-m)

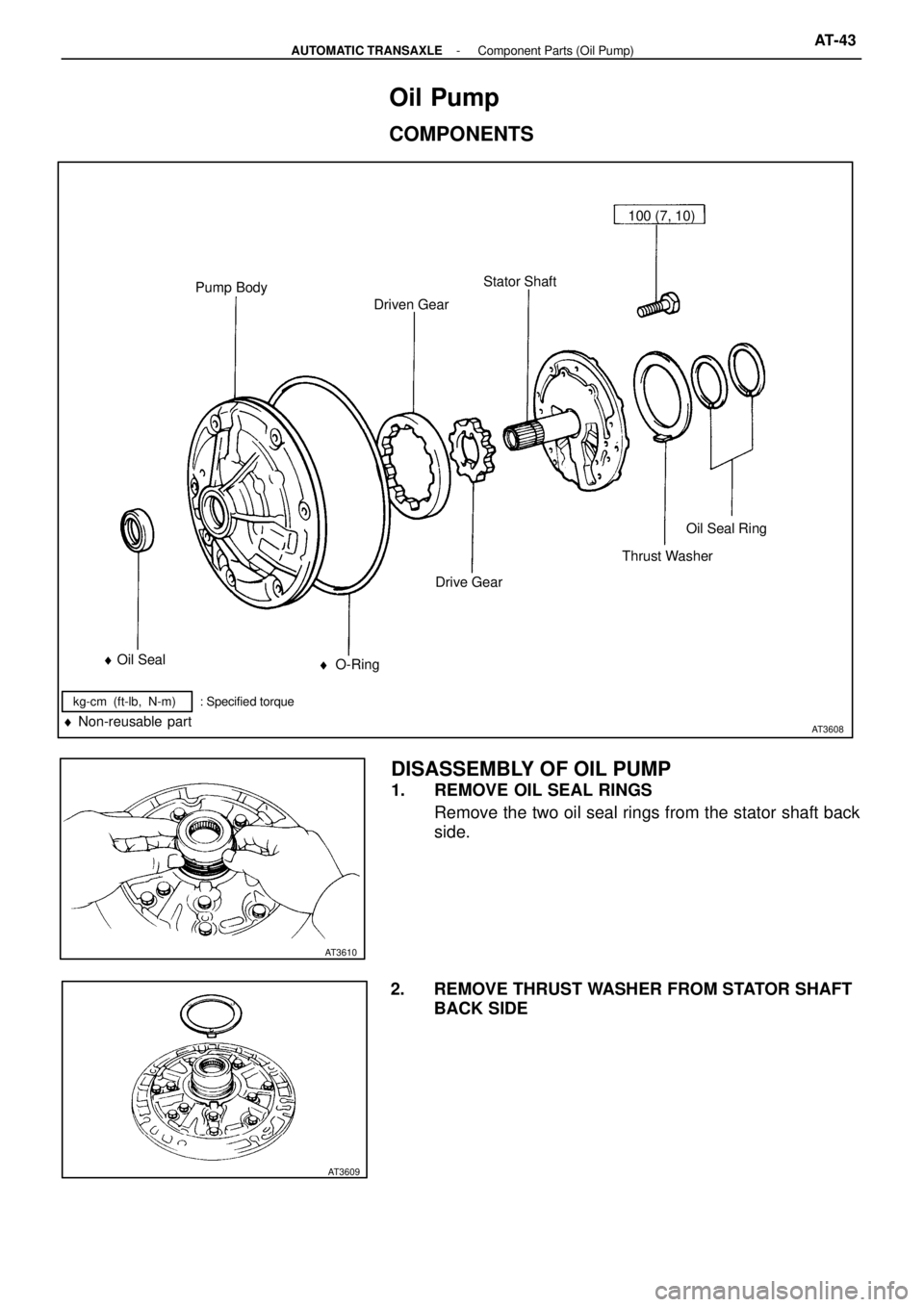

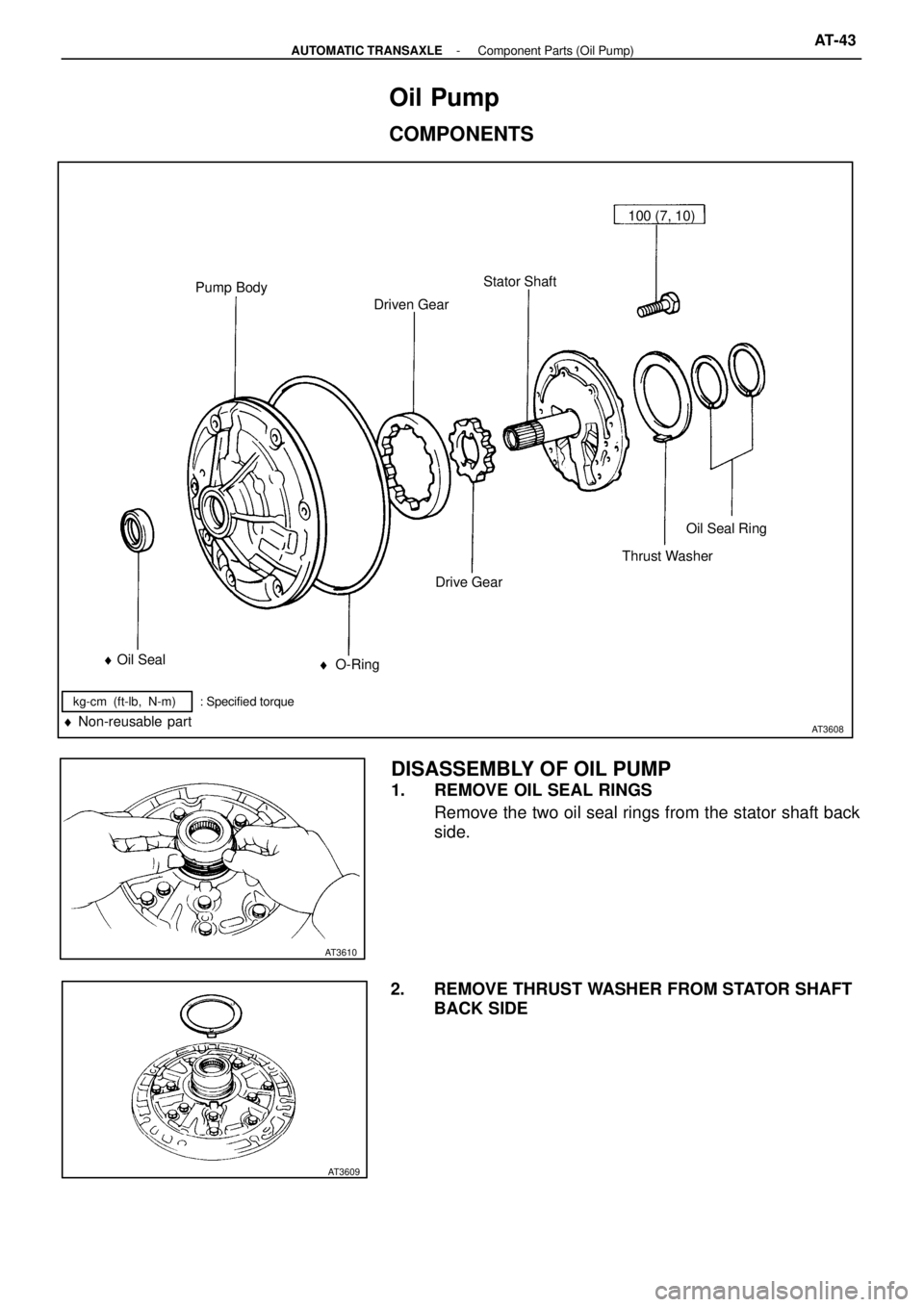

r O-Ring r Oil SealDrive GearThrust WasherOil Seal Ring Driven Gear Pump BodyStator Shaft100 (7, 10)

AT3609 AT3610

Oil Pump

COMPONENTS

DISASSEMBLY OF OIL PUMP

1. REMOVE OIL SEAL RINGS

Remove the two oil seal rings from the stator shaft back

side.

2. REMOVE THRUST WASHER FROM STATOR SHAFT

BACK SIDE

- AUTOMATIC TRANSAXLEComponent Parts (Oil Pump)AT-43

Page 59 of 2389

AT2732

AT0153

AT0154

AT0155 AT3611

3. REMOVE STATOR SHAFT

Remove the eleven bolts and stator shaft.

HINT: Keep the gears in assembly order.

4. REMOVE FRONT OIL SEAL

Pry off the oil seal with a screwdriver.

INSPECTION OF OIL PUMP

1. CHECK BODY CLEARANCE OF DRIVEN GEAR

Push the driven gear to one side of the body.

Using a feeler gauge, measure the clearance.

Standard body clearance: 0.07 - 0.15 mm

(0.0028 - 0.0059 in.)

Maximum body clearance: 0.3 mm (0.012 in.)

If the body clearance is greater than the maximum, re-

place the oil pump body subassembly.

2. CHECK TIP CLEARANCE OF DRIVEN GEAR

Measure between the driven gear teeth and the cres-

cent-shaped part of the pump body.

Standard tip clearance: 0.11 - 0.14 mm

(0.0043 - 0.0055 in.)

Maximum tip clearance: 0.3 mm (0.012 in.)

If the tip clearance is greater than the maximum, replace

the oil pump body subassembly.

3. CHECK SIDE CLEARANCE OF BOTH GEARS

Using a steel straightedge and a feeler gauge, measure

the side clearance of both gears.

Standard side clearance: 0.002 - 0.005 mm

(0.0008 - 0.0020 in.)

Maximum side clearance: 0.1 mm (0.004 in.)

AT-44- AUTOMATIC TRANSAXLEComponent Parts (Oil Pump)

Page 60 of 2389

AT3612

AT0156

SST

AT0157AT7708

There are three different thicknesses for drive and driven

gears.

Drive and driven gear thickness

Mark Thickness

A 9.440 - 9.456 mm (0.3717 - 0.3723 in.)

B 9.456 - 9.474 mm (0.3723 - 0.3730 in.)

C 9.474 - 9.490 mm (0.3730 - 0.3736 in.)

If the thickest gear can not make the side clearance

within standard specification, replace the oil pump body

subassembly.

4. CHECK OIL PUMP BODY BUSHING

Using a dial indicator, measure the inside diameter of

the oil pump body bushing.

Maximum inside diameter: 38.18 mm (1.5031 in.)

If the inside diameter is greater than the maximum, re-

place the oil pump body subassembly.

5. CHECK STATOR SHAFT BUSHING

Using a dial indicator, measure the inside diameter stator

shaft bushing.

Maximum inside diameter: 21.57 mm (0.8492 in.)

If the inside diameter is greater than the maximum, re-

place the stator shaft.

ASSEMBLY OF OIL PUMP

1. INSTALL FRONT OIL SEAL

Using SST and a hammer, install a new oil seal. The

seal end should be flush with the outer edge of the

pump body.

SST 09350-32014 (09351-32140)

2. INSTALL DRIVEN GEAR AND DRIVE GEAR

Make sure the top of the gears are facing upward.

- AUTOMATIC TRANSAXLEComponent Parts (Oil Pump)AT-45

Trending: interior, seat adjustment, warning light, child lock, fuse, drain bolt, suspension