TOYOTA CAMRY V20 1986 Service Information

Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1391 of 2389

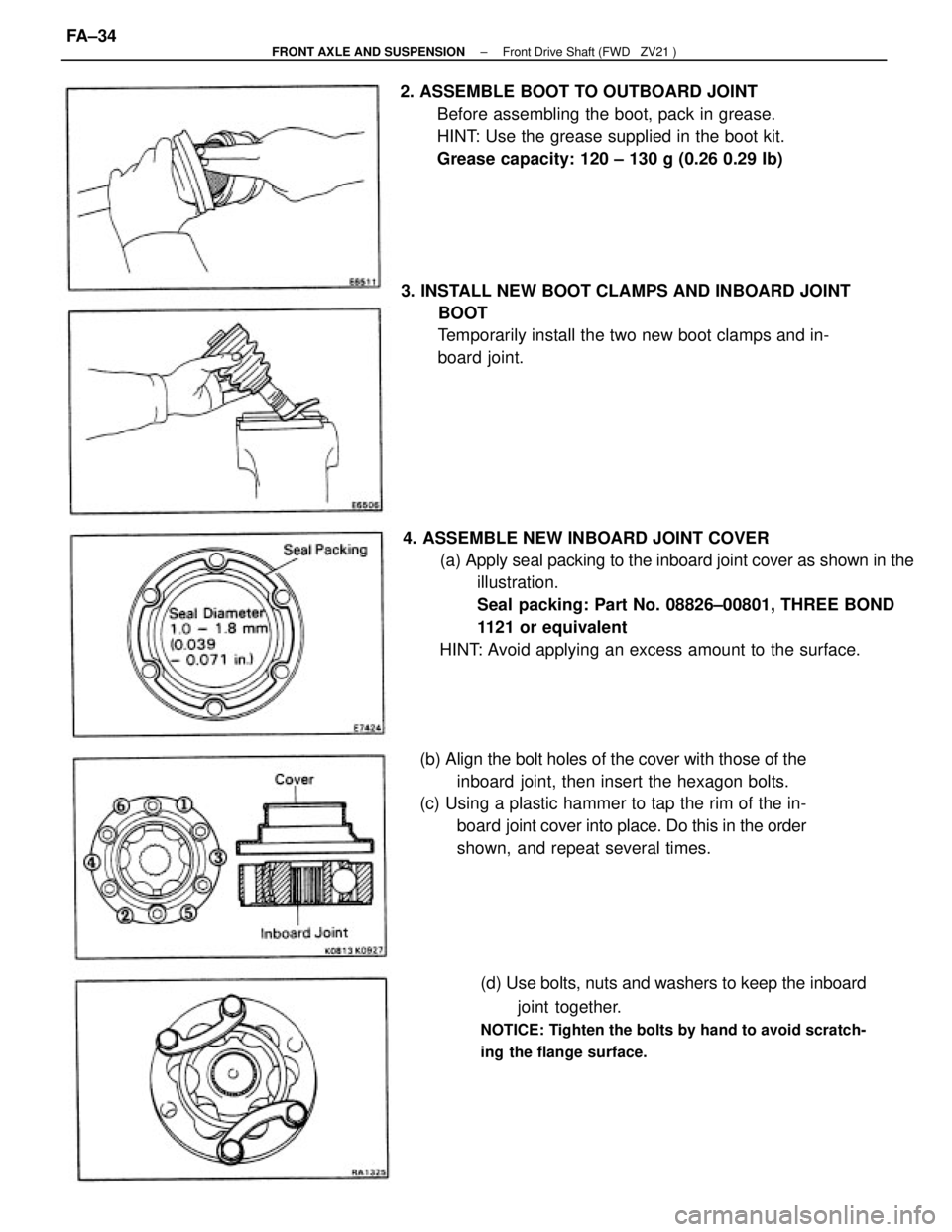

4. ASSEMBLE NEW INBOARD JOINT COVER

(a) Apply seal packing to the inboard joint cover as shown in the

illustration.

Seal packing: Part No. 08826±00801, THREE BOND

1121 or equivalent

HINT: Avoid applying an excess amount to the surface. 3. INSTALL NEW BOOT CLAMPS AND INBOARD JOINT

BOOT

Temporarily install the two new boot clamps and in-

board joint.

(b) Align the bolt holes of the cover with those of the

inboard joint, then insert the hexagon bolts.

(c) Using a plastic hammer to tap the rim of the in-

board joint cover into place. Do this in the order

shown, and repeat several times. 2. ASSEMBLE BOOT TO OUTBOARD JOINT

Before assembling the boot, pack in grease.

HINT: Use the grease supplied in the boot kit.

Grease capacity: 120 ± 130 g (0.26 0.29 Ib)

(d) Use bolts, nuts and washers to keep the inboard

joint together.

NOTICE: Tighten the bolts by hand to avoid scratch-

ing the flange surface.

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD ZV21 )FA±34

Page 1392 of 2389

5. ASSEMBLE INBOARD JOINT

(a) Align the nnatchmarks placed before disassembly.

(b) Using a brass bar and hammer, tap the inboard joint

onto the drive shaft.

NOTICE: Make sure that the brass bar is touching the inner

race, and not the cage.

(c) Remove the bolts, nuts and washers.

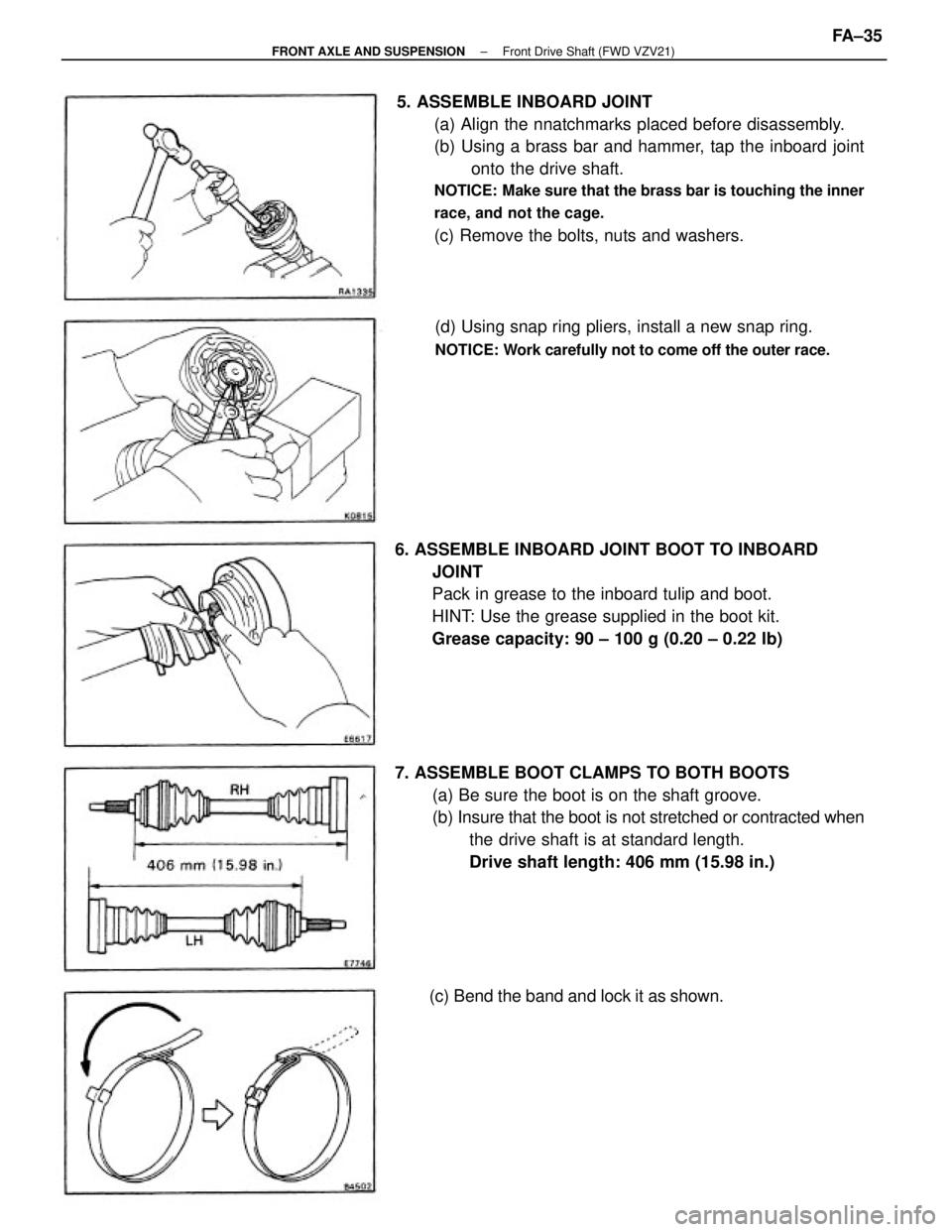

7. ASSEMBLE BOOT CLAMPS TO BOTH BOOTS

(a) Be sure the boot is on the shaft groove.

(b) Insure that the boot is not stretched or contracted when

the drive shaft is at standard length.

Drive shaft length: 406 mm (15.98 in.) 6. ASSEMBLE INBOARD JOINT BOOT TO INBOARD

JOINT

Pack in grease to the inboard tulip and boot.

HINT: Use the grease supplied in the boot kit.

Grease capacity: 90 ± 100 g (0.20 ± 0.22 Ib)(d) Using snap ring pliers, install a new snap ring.

NOTICE: Work carefully not to come off the outer race.

(c) Bend the band and lock it as shown.

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD VZV21)FA±35

Page 1393 of 2389

8. CHECK DRIVE SHAFT

(a) Check to see that there is no play in the inboard joint

and outboard joint.

(b) Check to see that the inboard joint slides smoothly in

the thrust direction.

DISASSEMBLY OF CENTER DRIVE

SHAFT

1. REMOVE DUST COVERS

(a) Using a press, press out the transaxle side dust cover.

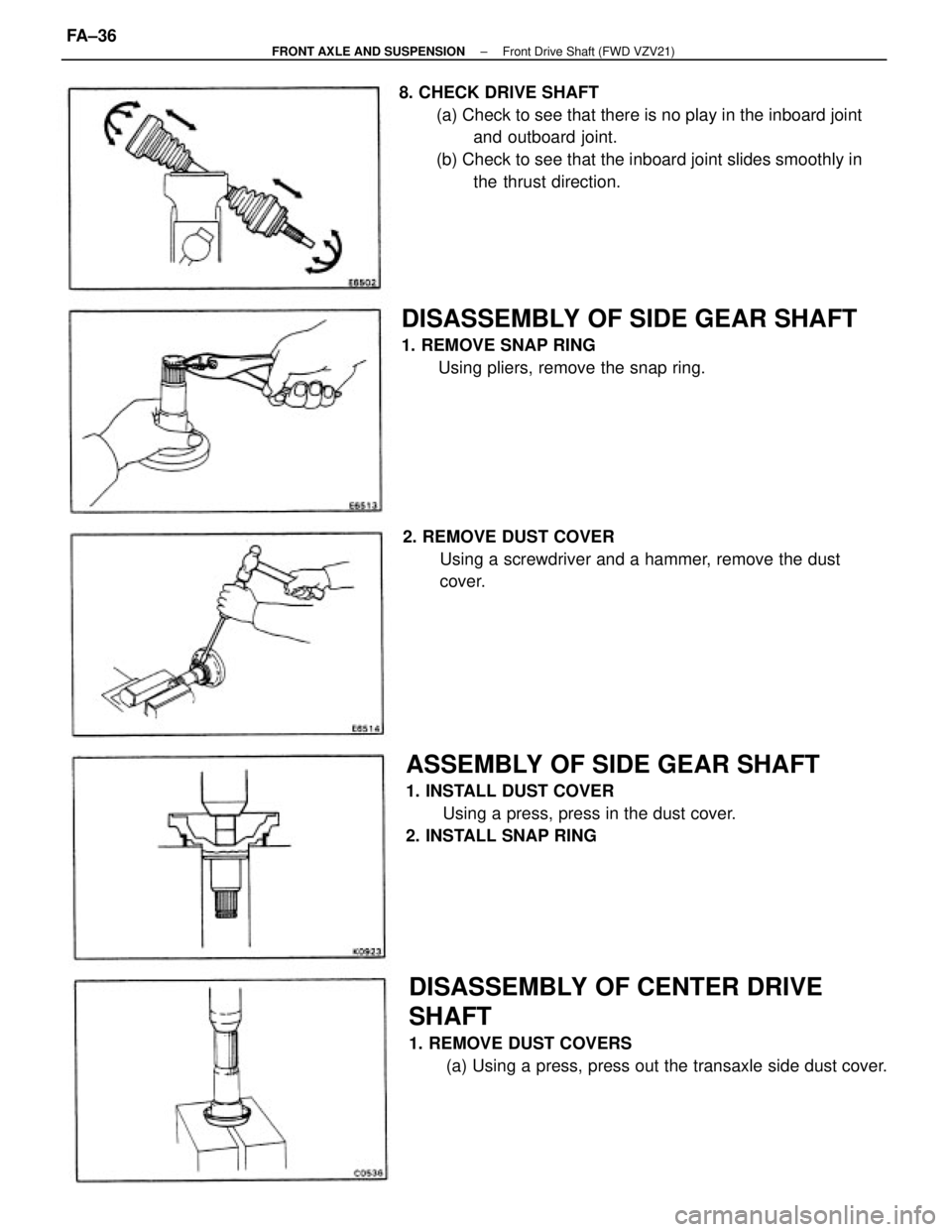

ASSEMBLY OF SIDE GEAR SHAFT

1. INSTALL DUST COVER

Using a press, press in the dust cover.

2. INSTALL SNAP RING

DISASSEMBLY OF SIDE GEAR SHAFT

1. REMOVE SNAP RING

Using pliers, remove the snap ring.

2. REMOVE DUST COVER

Using a screwdriver and a hammer, remove the dust

cover.

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD VZV21)FA±36

Page 1394 of 2389

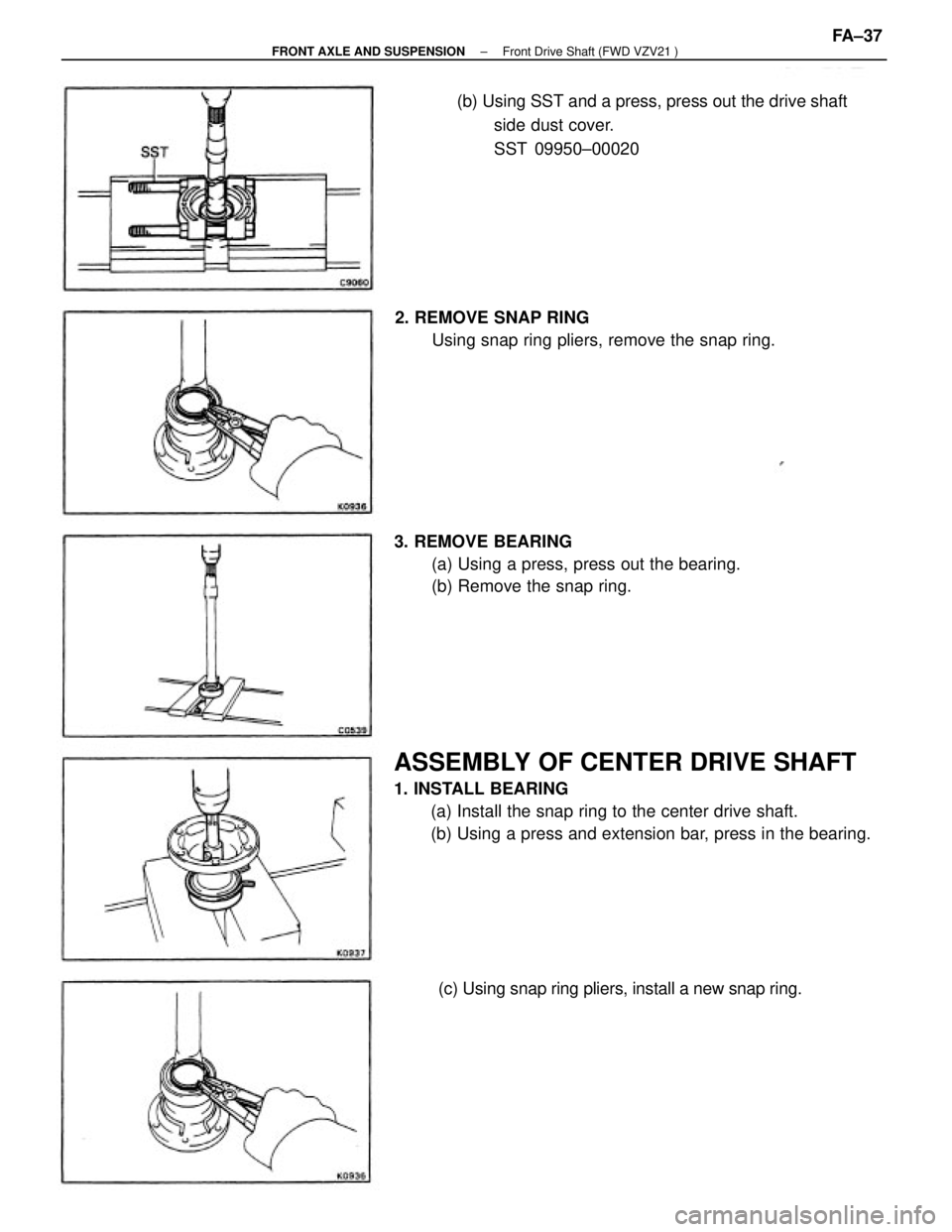

ASSEMBLY OF CENTER DRIVE SHAFT

1. INSTALL BEARING

(a) Install the snap ring to the center drive shaft.

(b) Using a press and extension bar, press in the bearing.(b) Using SST and a press, press out the drive shaft

side dust cover.

SST 09950±00020

3. REMOVE BEARING

(a) Using a press, press out the bearing.

(b) Remove the snap ring. 2. REMOVE SNAP RING

Using snap ring pliers, remove the snap ring.

(c) Using snap ring pliers, install a new snap ring.

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD VZV21 )FA±37

Page 1395 of 2389

INSTALLATION OF DRIVE SHAFT

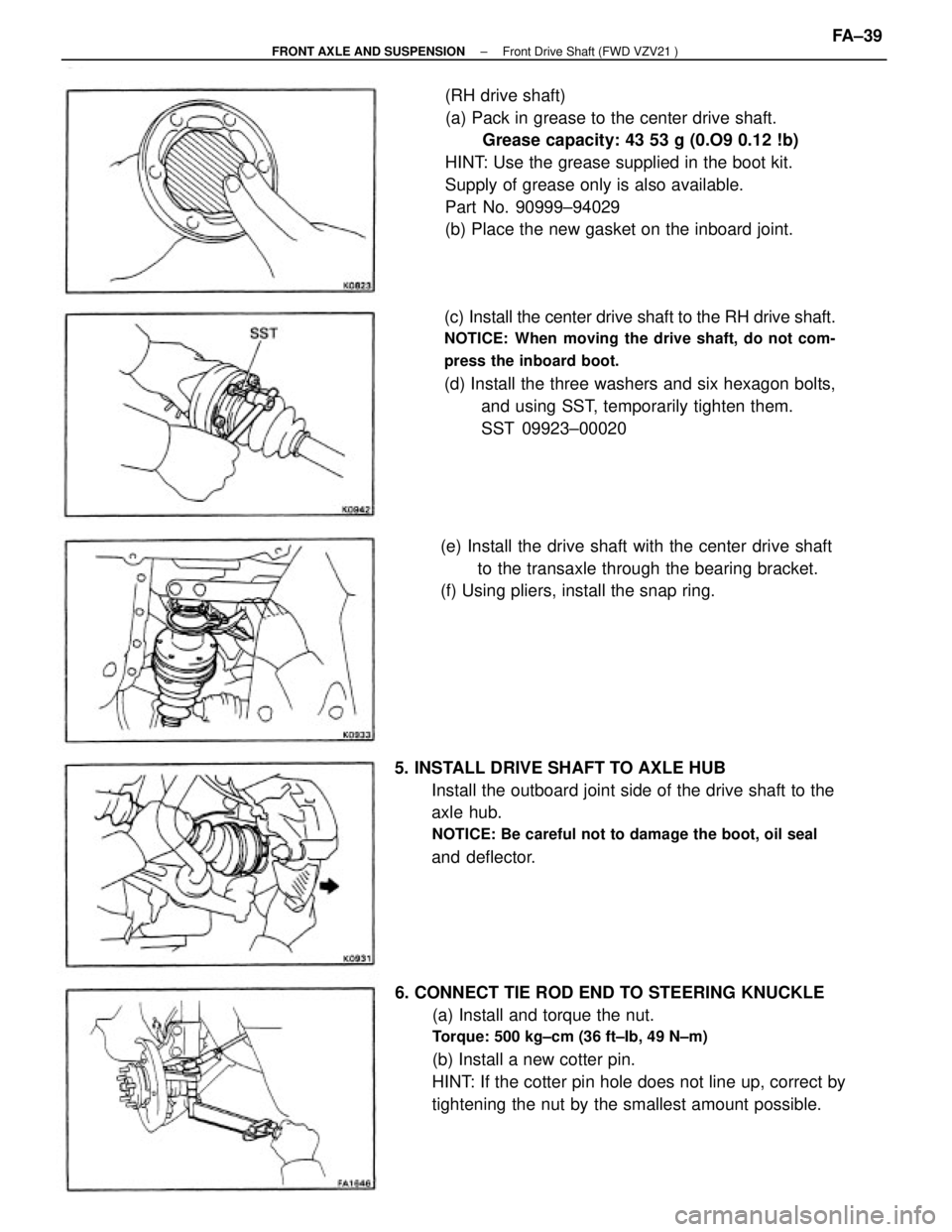

1. INSTALL SIDE GEAR SHAFT

(a) Insure that a new snap ring is positioned securely in the

groove of the side gear shaft.

(b) Using a brass bar and hammer, tap in the drive shaft

until it makes contact with the pinion shaft.

HINT:

wBefore installing the drive shaft, set the snap ring

opening side facing downward.

wWhether or not the side gear shaft is making contact

with the pinion shaft can be known by the sound or

feeling when driving it in.

2. CHECK INSTALLATION OF SIDE GEAR SHAFT

(a) Check that the side gear shaft will not come out by try-

ing to pull it completely out by hand.

(b) Push the side gear shaft to the differential and measure

the distance between the side gear shaft and the

transaxle case. Check that the distance between the

two is the same as the measurement taken before re-

moving the side gear shaft.

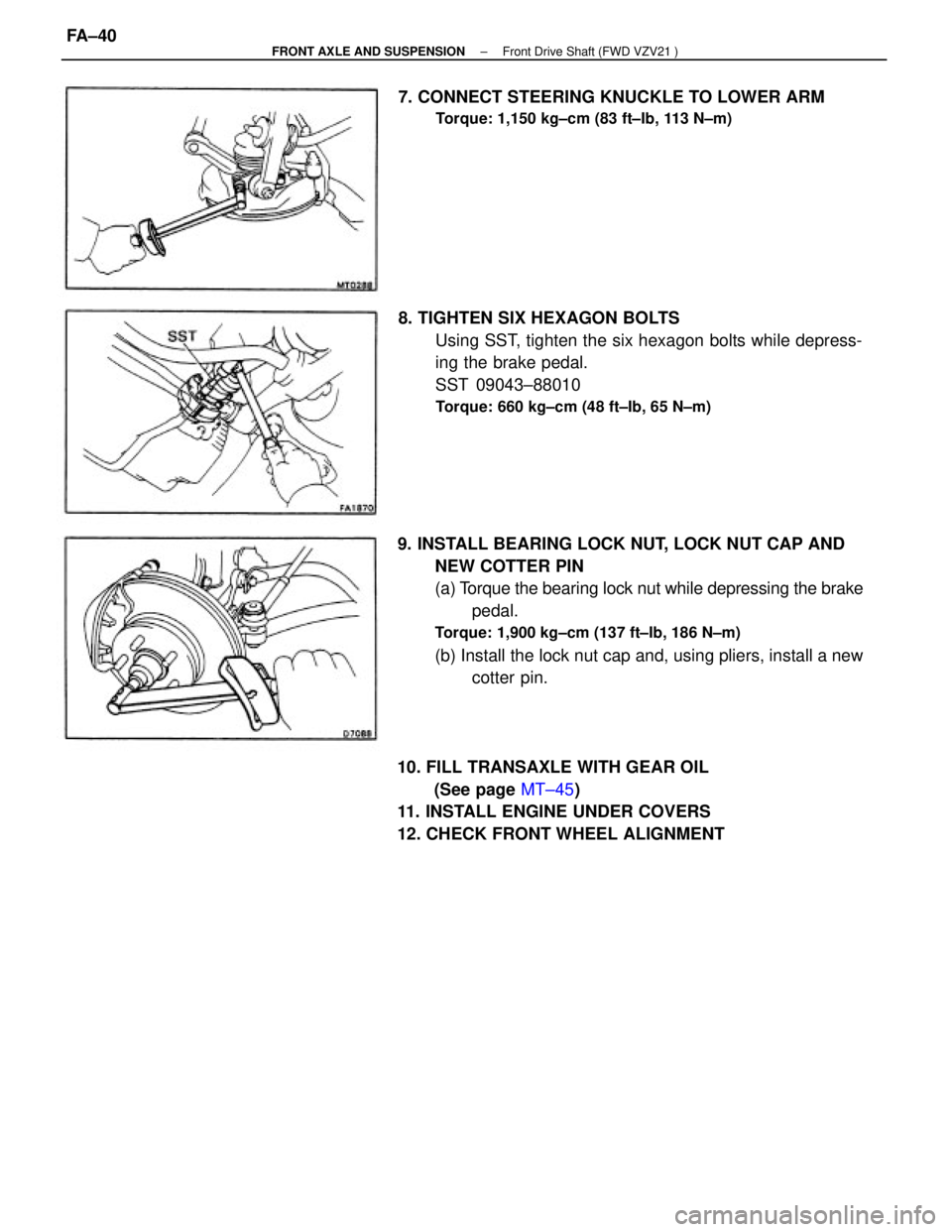

3. PACK IN GREASE TO SIDE GEAR SHAFT

Pack in grease to the side gear shaft.

Grease capacity: 43 ± 53 g (0.09 ± 0.12 Ib)

HINT: Use the grease supplied in the boot kit.

Supply of grease only is also available.

Part No. 90999±94029

4. INSTALL DRIVE SHAFT

(LH drive shaft)

(a) Place the new gasket on the inboard joint.

(b) Align the matchmarks on the side gear shaft and in-

board joint.

NOTICE: When moving the drive shaft, do not compress the

inboard boot.

(c) Insert and finger tighten the six hexagon bolts and the

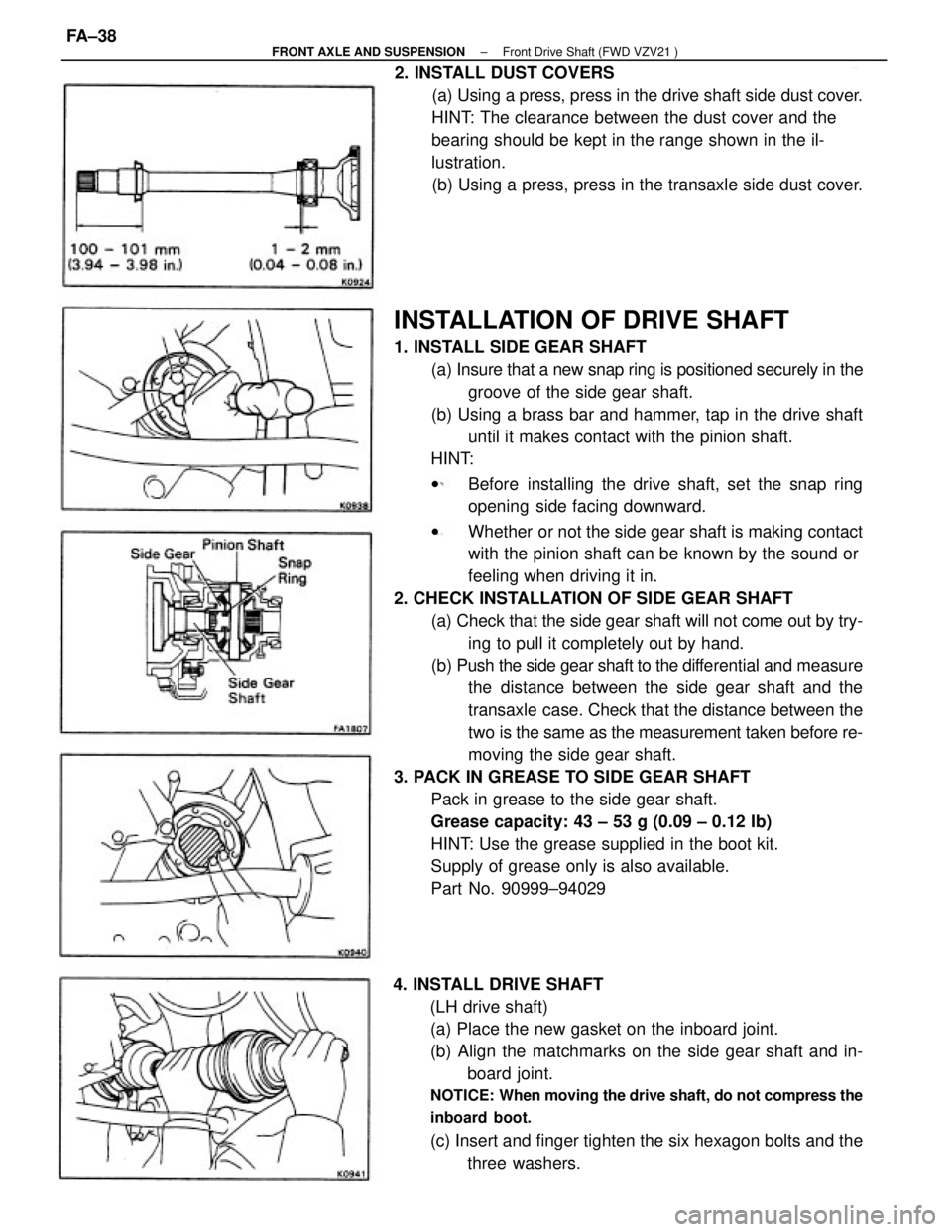

three washers. 2. INSTALL DUST COVERS

(a) Using a press, press in the drive shaft side dust cover.

HINT: The clearance between the dust cover and the

bearing should be kept in the range shown in the il-

lustration.

(b) Using a press, press in the transaxle side dust cover.

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD VZV21 )FA±38

Page 1396 of 2389

(RH drive shaft)

(a) Pack in grease to the center drive shaft.

Grease capacity: 43 53 g (0.O9 0.12 !b)

HINT: Use the grease supplied in the boot kit.

Supply of grease only is also available.

Part No. 90999±94029

(b) Place the new gasket on the inboard joint.

6. CONNECT TIE ROD END TO STEERING KNUCKLE

(a) Install and torque the nut.

Torque: 500 kg±cm (36 ft±Ib, 49 N±m)

(b) Install a new cotter pin.

HINT: If the cotter pin hole does not line up, correct by

tightening the nut by the smallest amount possible.(c) Install the center drive shaft to the RH drive shaft.

NOTICE: When moving the drive shaft, do not com-

press the inboard boot.

(d) Install the three washers and six hexagon bolts,

and using SST, temporarily tighten them.

SST 09923±00020

5. INSTALL DRIVE SHAFT TO AXLE HUB

Install the outboard joint side of the drive shaft to the

axle hub.

NOTICE: Be careful not to damage the boot, oil seal

and deflector.(e) Install the drive shaft with the center drive shaft

to the transaxle through the bearing bracket.

(f) Using pliers, install the snap ring.

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD VZV21 )FA±39

Page 1397 of 2389

9. INSTALL BEARING LOCK NUT, LOCK NUT CAP AND

NEW COTTER PIN

(a) Torque the bearing lock nut while depressing the brake

pedal.

Torque: 1,900 kg±cm (137 ft±Ib, 186 N±m)

(b) Install the lock nut cap and, using pliers, install a new

cotter pin. 8. TIGHTEN SIX HEXAGON BOLTS

Using SST, tighten the six hexagon bolts while depress-

ing the brake pedal.

SST 09043±88010

Torque: 660 kg±cm (48 ft±Ib, 65 N±m)

10. FILL TRANSAXLE WITH GEAR OIL

(See page MT±45)

11. INSTALL ENGINE UNDER COVERS

12. CHECK FRONT WHEEL ALIGNMENT7. CONNECT STEERING KNUCKLE TO LOWER ARM

Torque: 1,150 kg±cm (83 ft±Ib, 113 N±m)

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD VZV21 )FA±40

Page 1398 of 2389

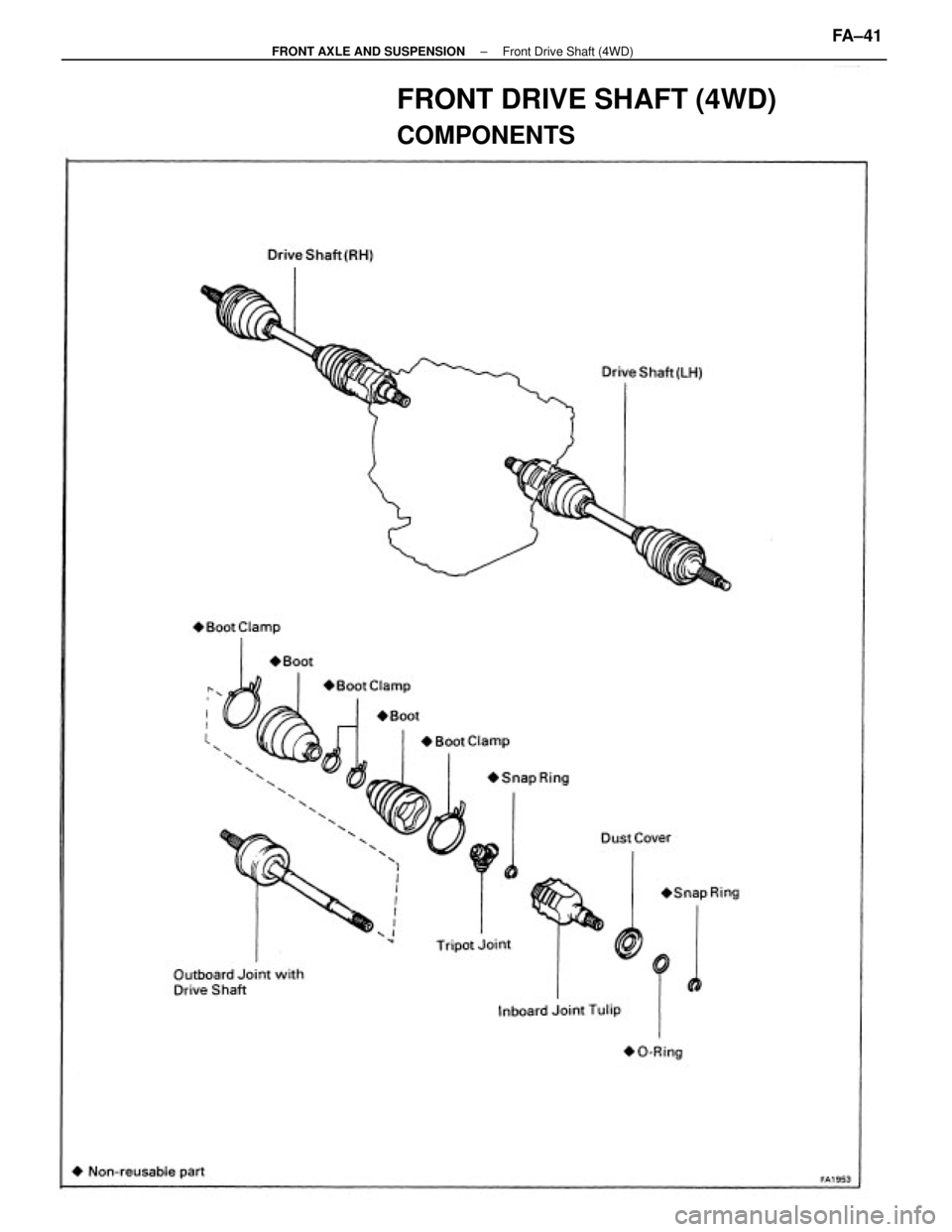

FRONT DRIVE SHAFT (4WD)

COMPONENTS

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (4WD)FA±41

Page 1399 of 2389

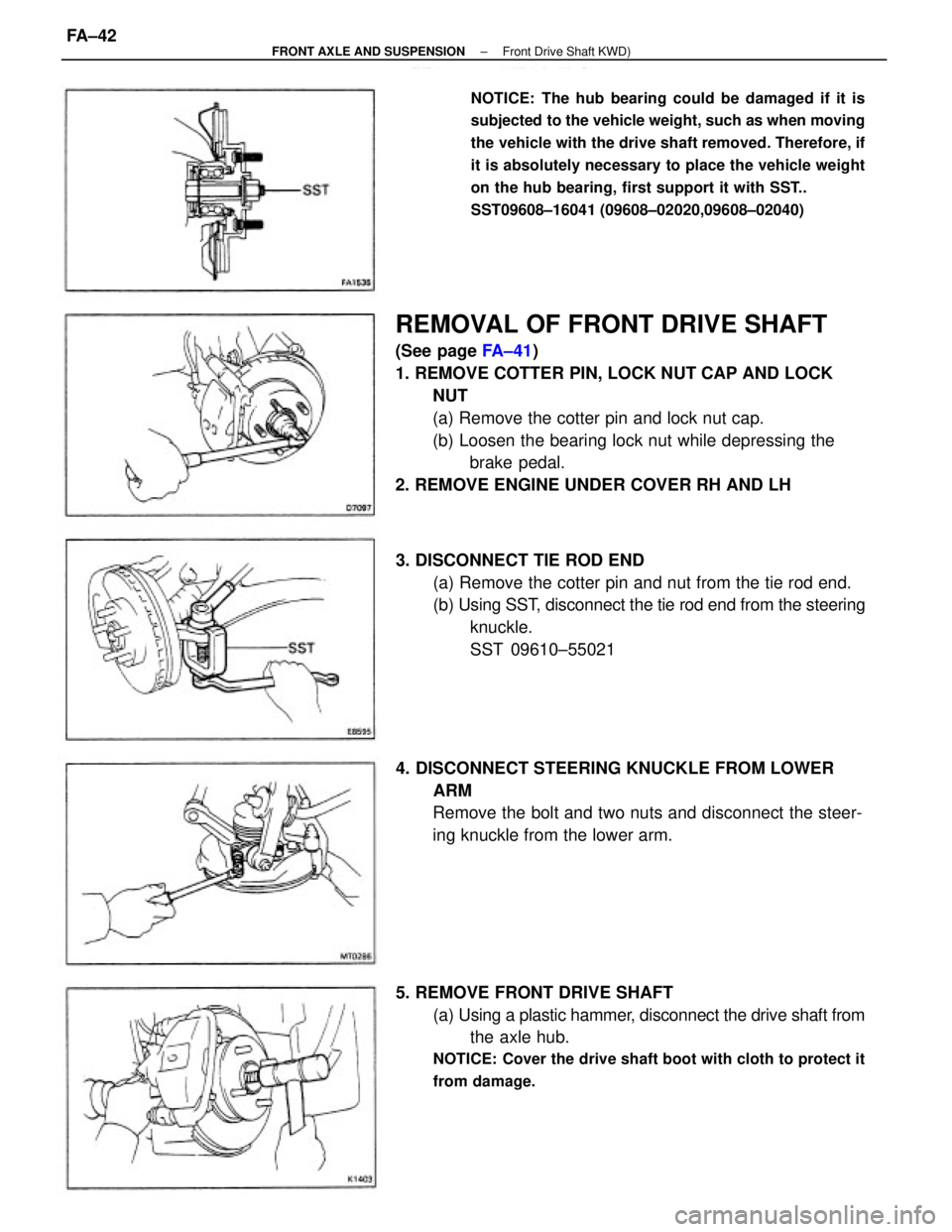

REMOVAL OF FRONT DRIVE SHAFT

(See page FA±41)

1. REMOVE COTTER PIN, LOCK NUT CAP AND LOCK

NUT

(a) Remove the cotter pin and lock nut cap.

(b) Loosen the bearing lock nut while depressing the

brake pedal.

2. REMOVE ENGINE UNDER COVER RH AND LH

3. DISCONNECT TIE ROD END

(a) Remove the cotter pin and nut from the tie rod end.

(b) Using SST, disconnect the tie rod end from the steering

knuckle.

SST 09610±55021

NOTICE: The hub bearing could be damaged if it is

subjected to the vehicle weight, such as when moving

the vehicle with the drive shaft removed. Therefore, if

it is absolutely necessary to place the vehicle weight

on the hub bearing, first support it with SST..

SST09608±16041 (09608±02020,09608±02040)

5. REMOVE FRONT DRIVE SHAFT

(a) Using a plastic hammer, disconnect the drive shaft from

the axle hub.

NOTICE: Cover the drive shaft boot with cloth to protect it

from damage.

4. DISCONNECT STEERING KNUCKLE FROM LOWER

ARM

Remove the bolt and two nuts and disconnect the steer-

ing knuckle from the lower arm.

± FRONT AXLE AND SUSPENSIONFront Drive Shaft KWD)FA±42

Page 1400 of 2389

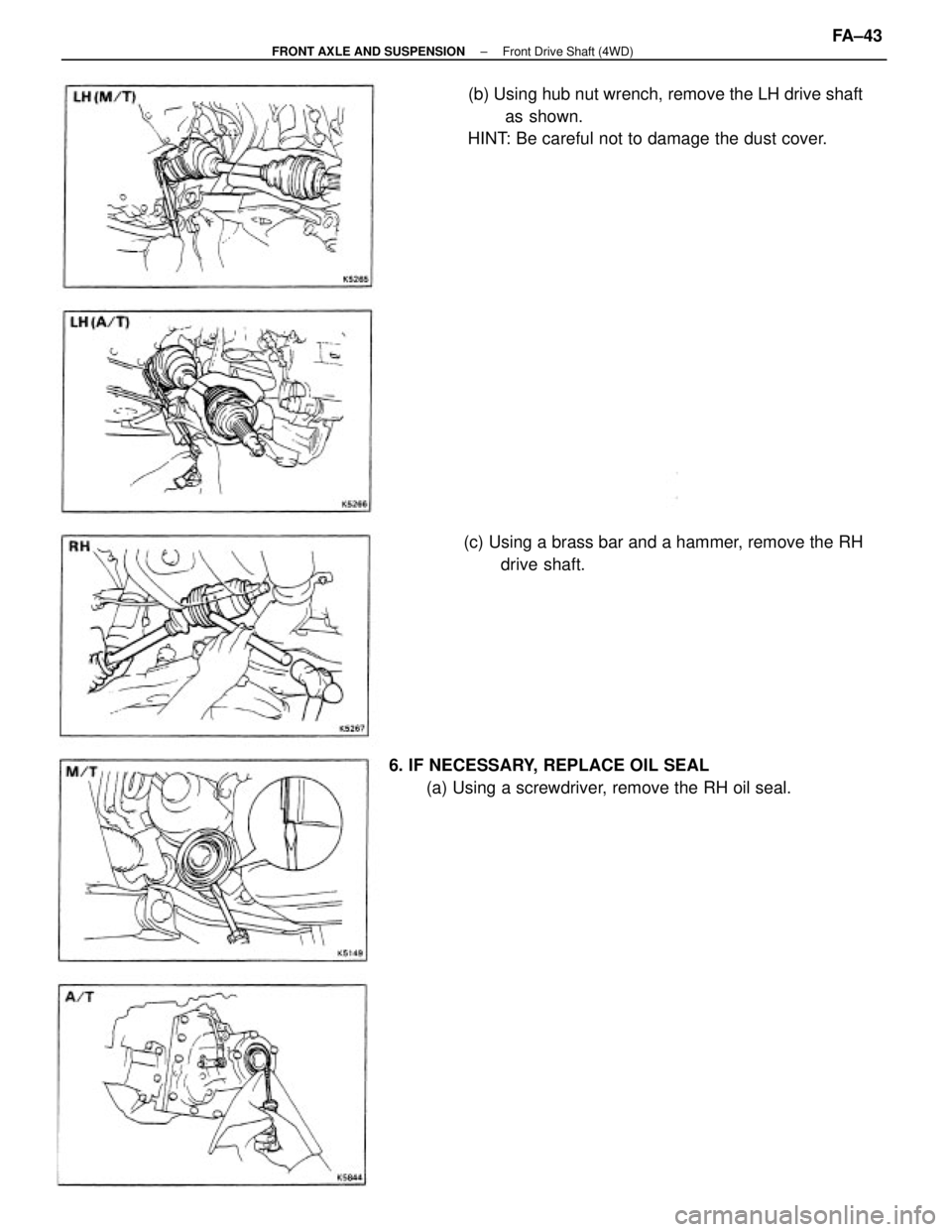

(b) Using hub nut wrench, remove the LH drive shaft

as shown.

HINT: Be careful not to damage the dust cover.

6. IF NECESSARY, REPLACE OIL SEAL

(a) Using a screwdriver, remove the RH oil seal.(c) Using a brass bar and a hammer, remove the RH

drive shaft.

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (4WD)FA±43