stop start TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 306 of 2389

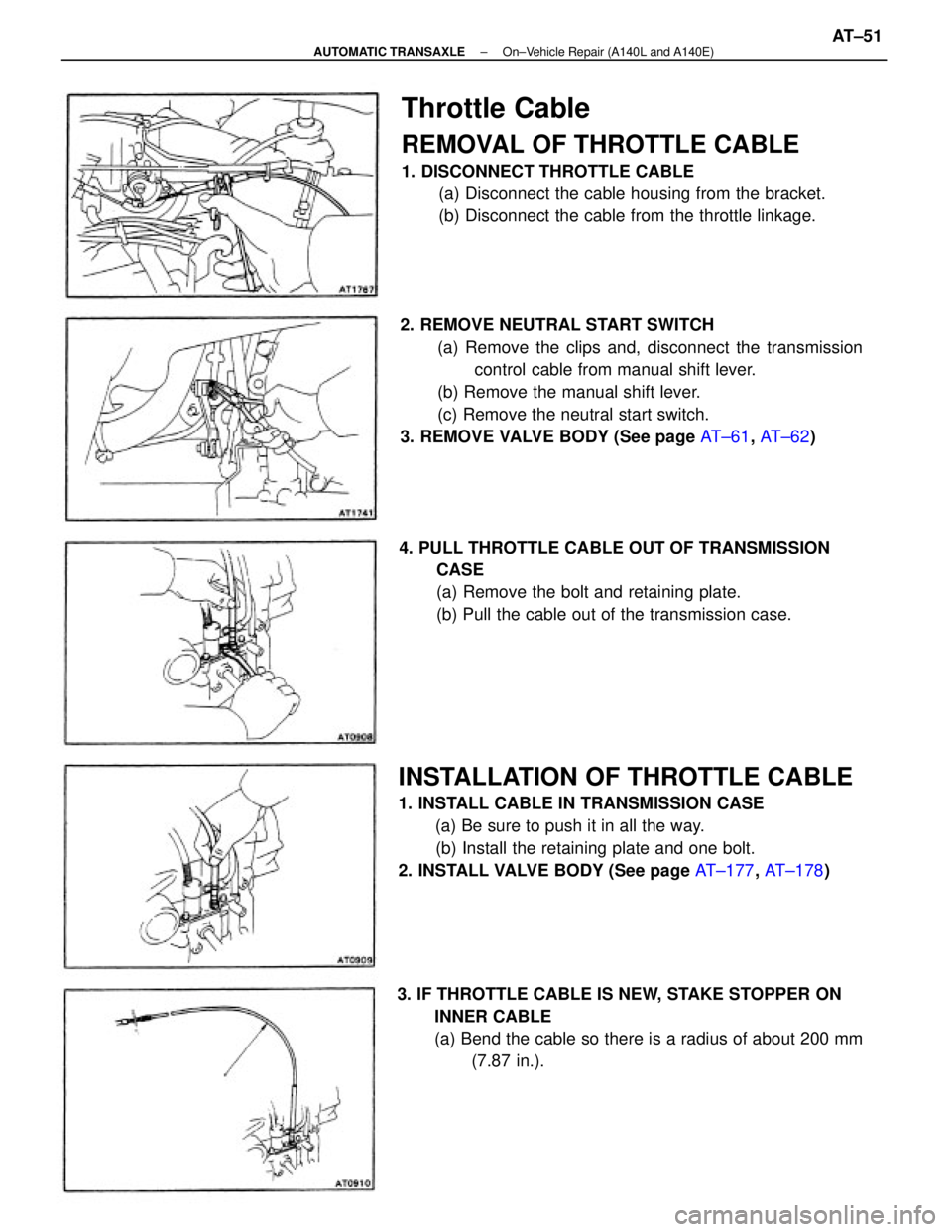

2. REMOVE NEUTRAL START SWITCH

(a) Remove the clips and, disconnect the transmission

control cable from manual shift lever.

(b) Remove the manual shift lever.

(c) Remove the neutral start switch.

3. REMOVE VALVE BODY (See page AT±61, AT±62)

INSTALLATION OF THROTTLE CABLE

1. INSTALL CABLE IN TRANSMISSION CASE

(a) Be sure to push it in all the way.

(b) Install the retaining plate and one bolt.

2. INSTALL VALVE BODY (See page AT±177, AT±178)

Throttle Cable

REMOVAL OF THROTTLE CABLE

1. DISCONNECT THROTTLE CABLE

(a) Disconnect the cable housing from the bracket.

(b) Disconnect the cable from the throttle linkage.

4. PULL THROTTLE CABLE OUT OF TRANSMISSION

CASE

(a) Remove the bolt and retaining plate.

(b) Pull the cable out of the transmission case.

3. IF THROTTLE CABLE IS NEW, STAKE STOPPER ON

INNER CABLE

(a) Bend the cable so there is a radius of about 200 mm

(7.87 in.).

± AUTOMATIC TRANSAXLEOn±Vehicle Repair (A140L and A140E)AT±51

Page 307 of 2389

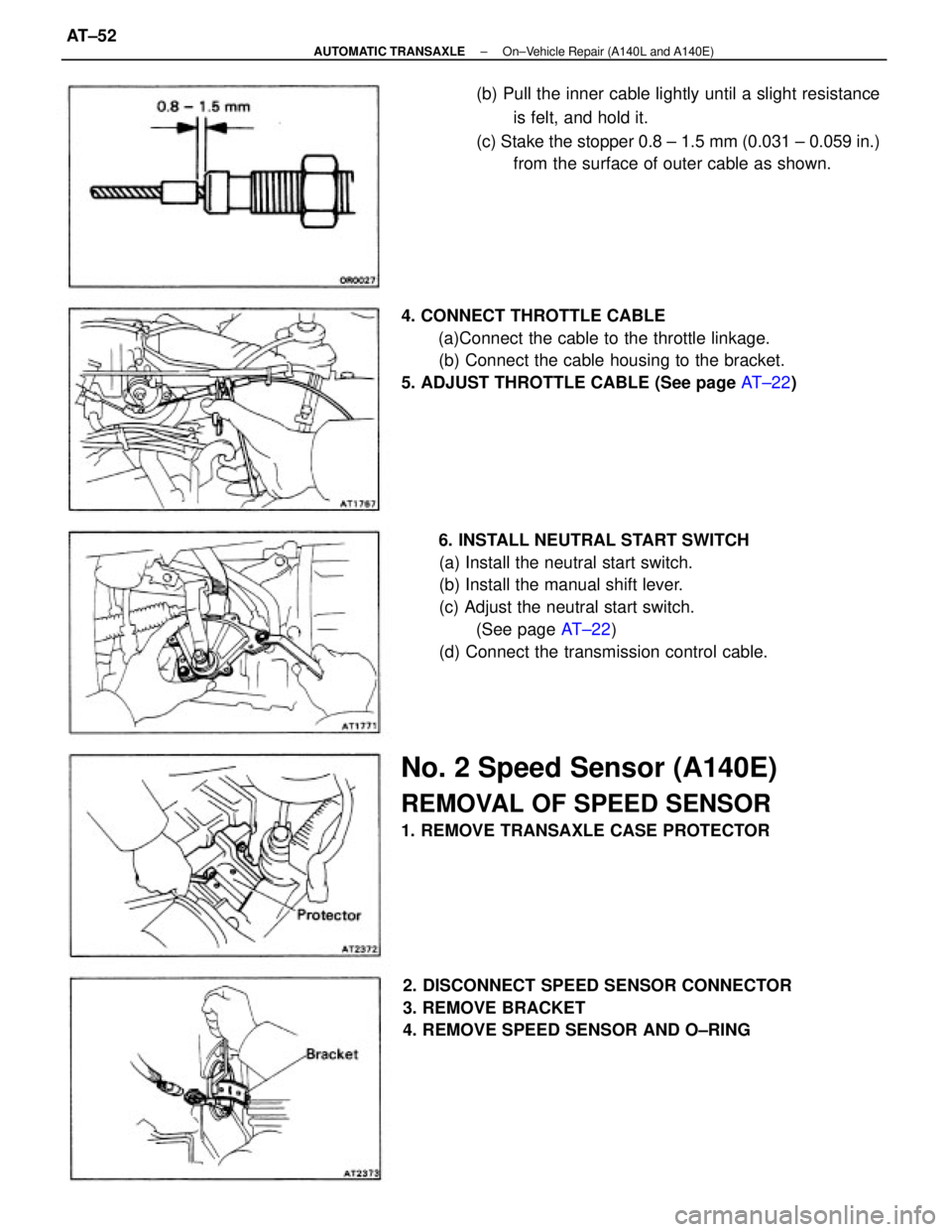

6. INSTALL NEUTRAL START SWITCH

(a) Install the neutral start switch.

(b) Install the manual shift lever.

(c) Adjust the neutral start switch.

(See page AT±22)

(d) Connect the transmission control cable. 4. CONNECT THROTTLE CABLE

(a)Connect the cable to the throttle linkage.

(b) Connect the cable housing to the bracket.

5. ADJUST THROTTLE CABLE (See page AT±22) (b) Pull the inner cable lightly until a slight resistance

is felt, and hold it.

(c) Stake the stopper 0.8 ± 1.5 mm (0.031 ± 0.059 in.)

from the surface of outer cable as shown.

No. 2 Speed Sensor (A140E)

REMOVAL OF SPEED SENSOR

1. REMOVE TRANSAXLE CASE PROTECTOR

2. DISCONNECT SPEED SENSOR CONNECTOR

3. REMOVE BRACKET

4. REMOVE SPEED SENSOR AND O±RING

± AUTOMATIC TRANSAXLEOn±Vehicle Repair (A140L and A140E)AT±52

Page 456 of 2389

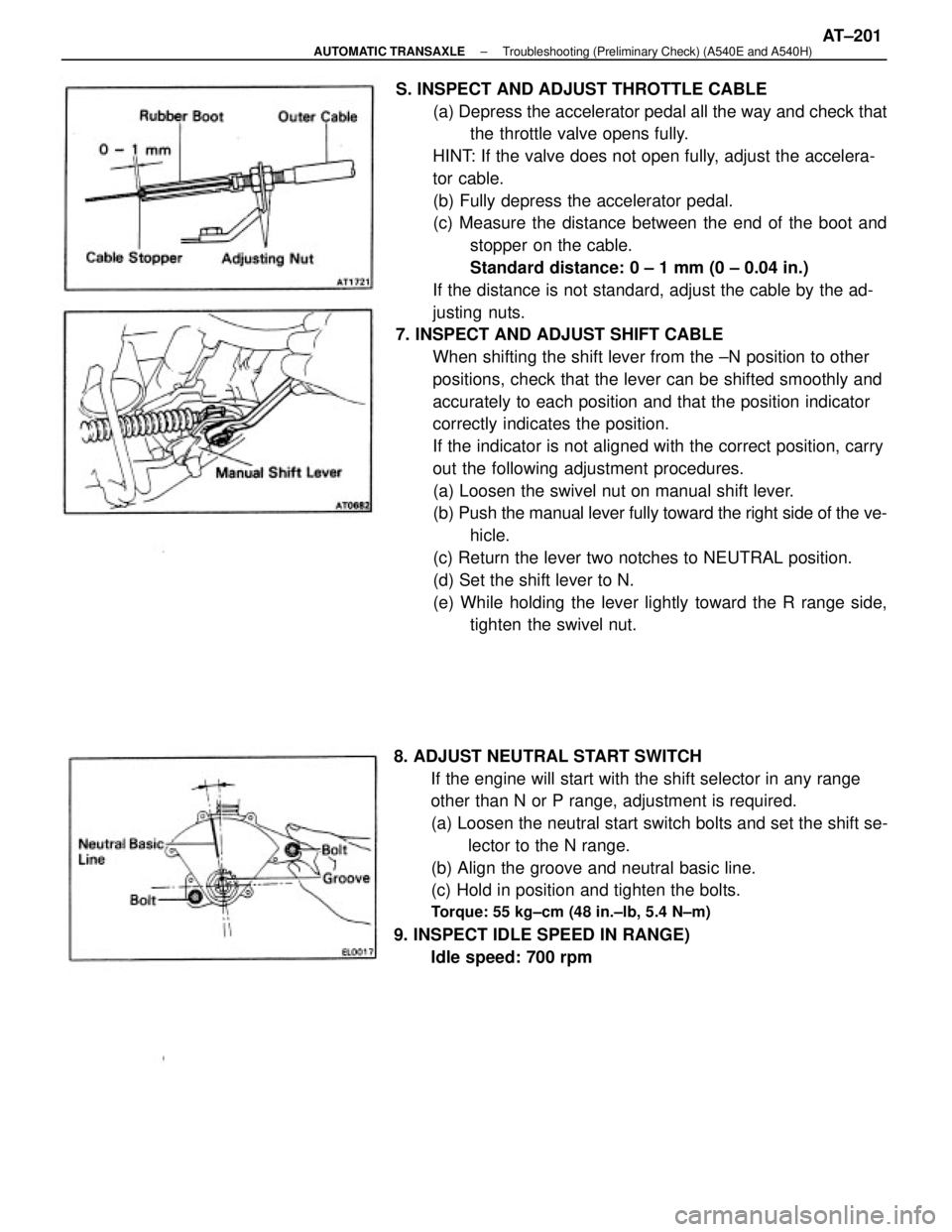

S. INSPECT AND ADJUST THROTTLE CABLE

(a) Depress the accelerator pedal all the way and check that

the throttle valve opens fully.

HINT: If the valve does not open fully, adjust the accelera-

tor cable.

(b) Fully depress the accelerator pedal.

(c) Measure the distance between the end of the boot and

stopper on the cable.

Standard distance: 0 ± 1 mm (0 ± 0.04 in.)

If the distance is not standard, adjust the cable by the ad-

justing nuts.

7. INSPECT AND ADJUST SHIFT CABLE

When shifting the shift lever from the ±N position to other

positions, check that the lever can be shifted smoothly and

accurately to each position and that the position indicator

correctly indicates the position.

If the indicator is not aligned with the correct position, carry

out the following adjustment procedures.

(a) Loosen the swivel nut on manual shift lever.

(b) Push the manual lever fully toward the right side of the ve-

hicle.

(c) Return the lever two notches to NEUTRAL position.

(d) Set the shift lever to N.

(e) While holding the lever lightly toward the R range side,

tighten the swivel nut.

8. ADJUST NEUTRAL START SWITCH

If the engine will start with the shift selector in any range

other than N or P range, adjustment is required.

(a) Loosen the neutral start switch bolts and set the shift se-

lector to the N range.

(b) Align the groove and neutral basic line.

(c) Hold in position and tighten the bolts.

Torque: 55 kg±cm (48 in.±lb, 5.4 N±m)

9. INSPECT IDLE SPEED IN RANGE)

Idle speed: 700 rpm

± AUTOMATIC TRANSAXLETroubleshooting (Preliminary Check) (A540E and A540H)AT±201

Page 458 of 2389

Mechanical System Tests

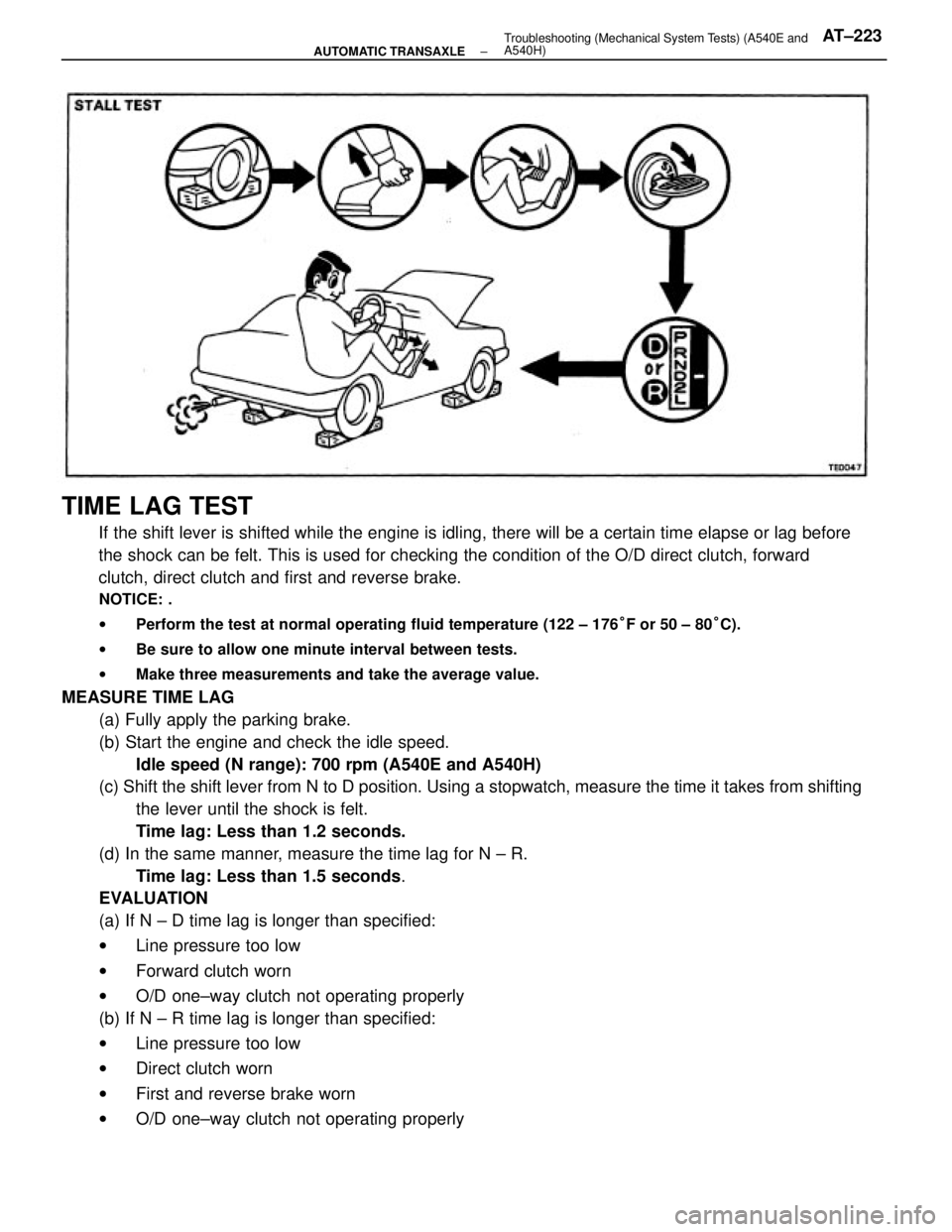

STALL TEST

The object of this test is to check the overall performance of the transaxle and engine by measuring

the stall speeds in the D and R ranges.

CAUTION:

wPerform the test at normal operation fluid temperature (122 ± 176°F or 50 ± 80°C).

wDo not continuously run this test longer than 5 seconds.

wTo ensure safety, conduct this test in a wide, clear, level area, which provides good traction.

wThe stall test should always be carried out in pairs. One should observe the conditions of wheels

or wheel stoppers outside the vehicle while the other is performing the test.

MEASURE STALL SPEED

(a) Chock the front and rear wheels.

(b) Connect a tachometer to the engine.

(c) Fully apply the parking brake.

(d) Step down strongly on the brake pedal with your left foot.

(e) Start the engine.

(f) Shift into the D range. Step all the way down on the accelerator pedal with your right foot. Quickly

read the stall speed at this time.

Stall speed: A540E (2VZ±FE) 2,450

+150 rpm

A540H (3S±FE) 2,320

+150 rpm

(g) Perform the same test in R range.

EVALUATION

(a) If the stall speed is the same for both ranges without the rear wheels rotating but lower than specified

value:

wEngine output may be insufficient

wStartor one±way clutch is not operating properly

(b) If the stall speed in D range is higher than specified:

wLine pressure too low

wForward clutch slipping

wNo. 2 one±way clutch not operating properly

wO/D one±way clutch not operating properly

(e) If the stall speed in R range is higher than specified:

wLine pressure too low

wDirect clutch slipping

wFirst and reverse brake slipping

wO/D one±way clutch not operating properly

(d) If the stall speed in both R and D ranges are higher than specified:

wLine pressure too low

wImproper fluid level

wO/D one±way clutch not operating properly

± AUTOMATIC TRANSAXLETroubleshooting (Mechanical System Tests) (A540E and

A540H)AT±222

Page 459 of 2389

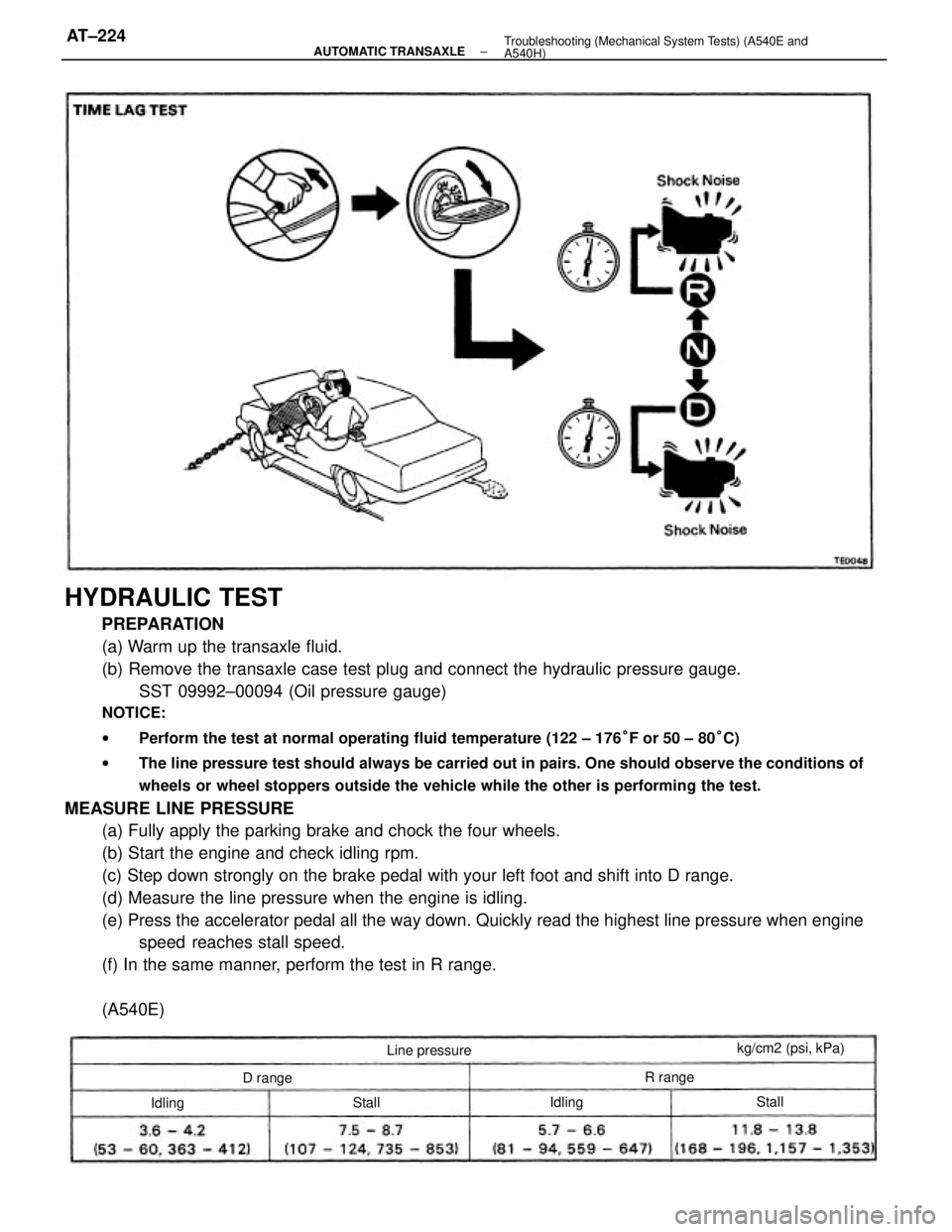

TIME LAG TEST

If the shift lever is shifted while the engine is idling, there will be a certain time elapse or lag before

the shock can be felt. This is used for checking the condition of the O/D direct clutch, forward

clutch, direct clutch and first and reverse brake.

NOTICE: .

wPerform the test at normal operating fluid temperature (122 ± 176°F or 50 ± 80°C).

wBe sure to allow one minute interval between tests.

wMake three measurements and take the average value.

MEASURE TIME LAG

(a) Fully apply the parking brake.

(b) Start the engine and check the idle speed.

Idle speed (N range): 700 rpm (A540E and A540H)

(c) Shift the shift lever from N to D position. Using a stopwatch, measure the time it takes from shifting

the lever until the shock is felt.

Time lag: Less than 1.2 seconds.

(d) In the same manner, measure the time lag for N ± R.

Time lag: Less than 1.5 seconds.

EVALUATION

(a) If N ± D time lag is longer than specified:

wLine pressure too low

wForward clutch worn

wO/D one±way clutch not operating properly

(b) If N ± R time lag is longer than specified:

wLine pressure too low

wDirect clutch worn

wFirst and reverse brake worn

wO/D one±way clutch not operating properly

± AUTOMATIC TRANSAXLETroubleshooting (Mechanical System Tests) (A540E and

A540H)AT±223

Page 460 of 2389

HYDRAULIC TEST

PREPARATION

(a) Warm up the transaxle fluid.

(b) Remove the transaxle case test plug and connect the hydraulic pressure gauge.

SST 09992±00094 (Oil pressure gauge)

NOTICE:

wPerform the test at normal operating fluid temperature (122 ± 176°F or 50 ± 80°C)

wThe line pressure test should always be carried out in pairs. One should observe the conditions of

wheels or wheel stoppers outside the vehicle while the other is performing the test.

MEASURE LINE PRESSURE

(a) Fully apply the parking brake and chock the four wheels.

(b) Start the engine and check idling rpm.

(c) Step down strongly on the brake pedal with your left foot and shift into D range.

(d) Measure the line pressure when the engine is idling.

(e) Press the accelerator pedal all the way down. Quickly read the highest line pressure when engine

speed reaches stall speed.

(f) In the same manner, perform the test in R range.

(A540E)

kg/cm2 (psi, kPa)

Line pressure

D rangeR range

Idling

IdlingStallStall

± AUTOMATIC TRANSAXLETroubleshooting (Mechanical System Tests) (A540E and

A540H)AT±224

Page 465 of 2389

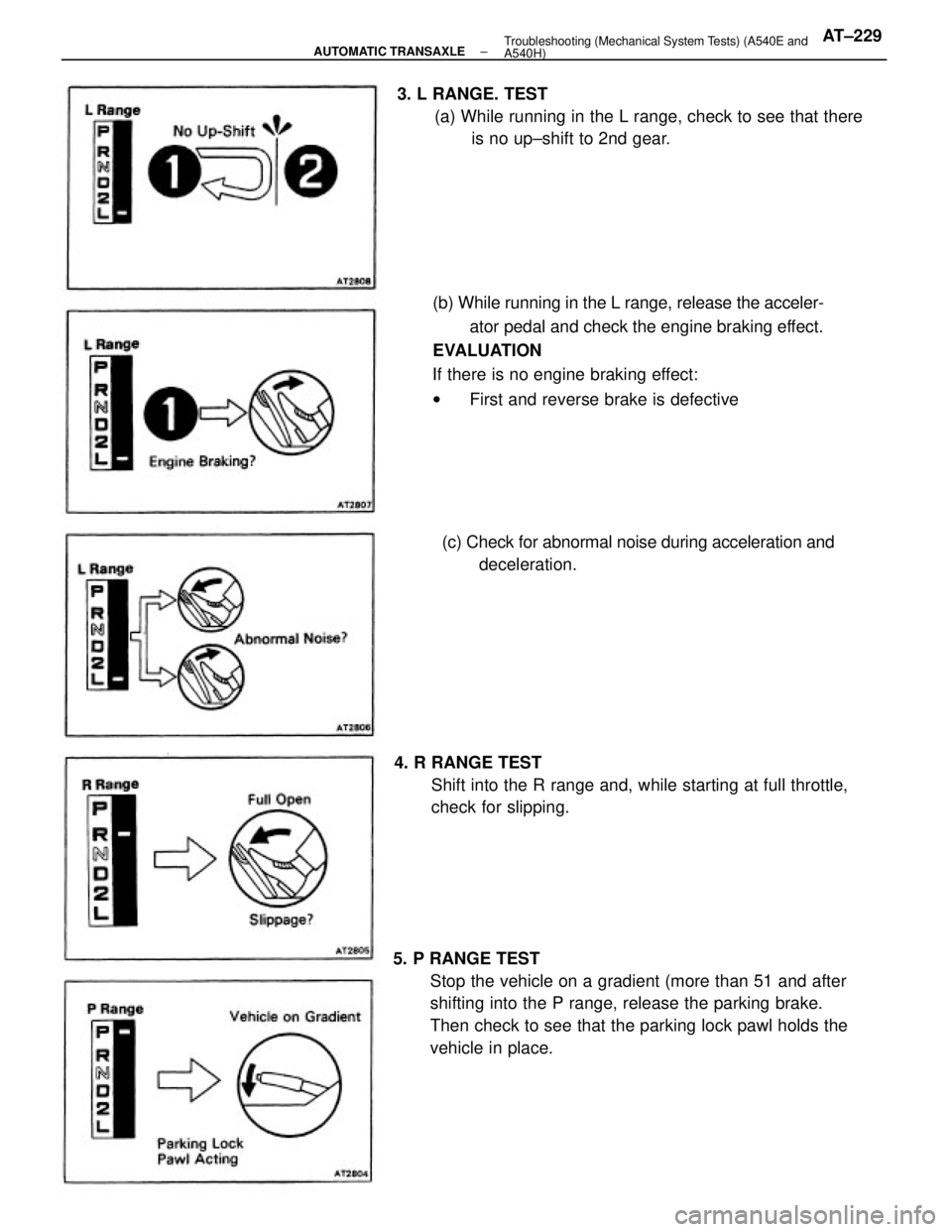

5. P RANGE TEST

Stop the vehicle on a gradient (more than 51 and after

shifting into the P range, release the parking brake.

Then check to see that the parking lock pawl holds the

vehicle in place.(b) While running in the L range, release the acceler-

ator pedal and check the engine braking effect.

EVALUATION

If there is no engine braking effect:

wFirst and reverse brake is defective 3. L RANGE. TEST

(a) While running in the L range, check to see that there

is no up±shift to 2nd gear.

4. R RANGE TEST

Shift into the R range and, while starting at full throttle,

check for slipping.(c) Check for abnormal noise during acceleration and

deceleration.

± AUTOMATIC TRANSAXLETroubleshooting (Mechanical System Tests) (A540E and

A540H)AT±229

Page 479 of 2389

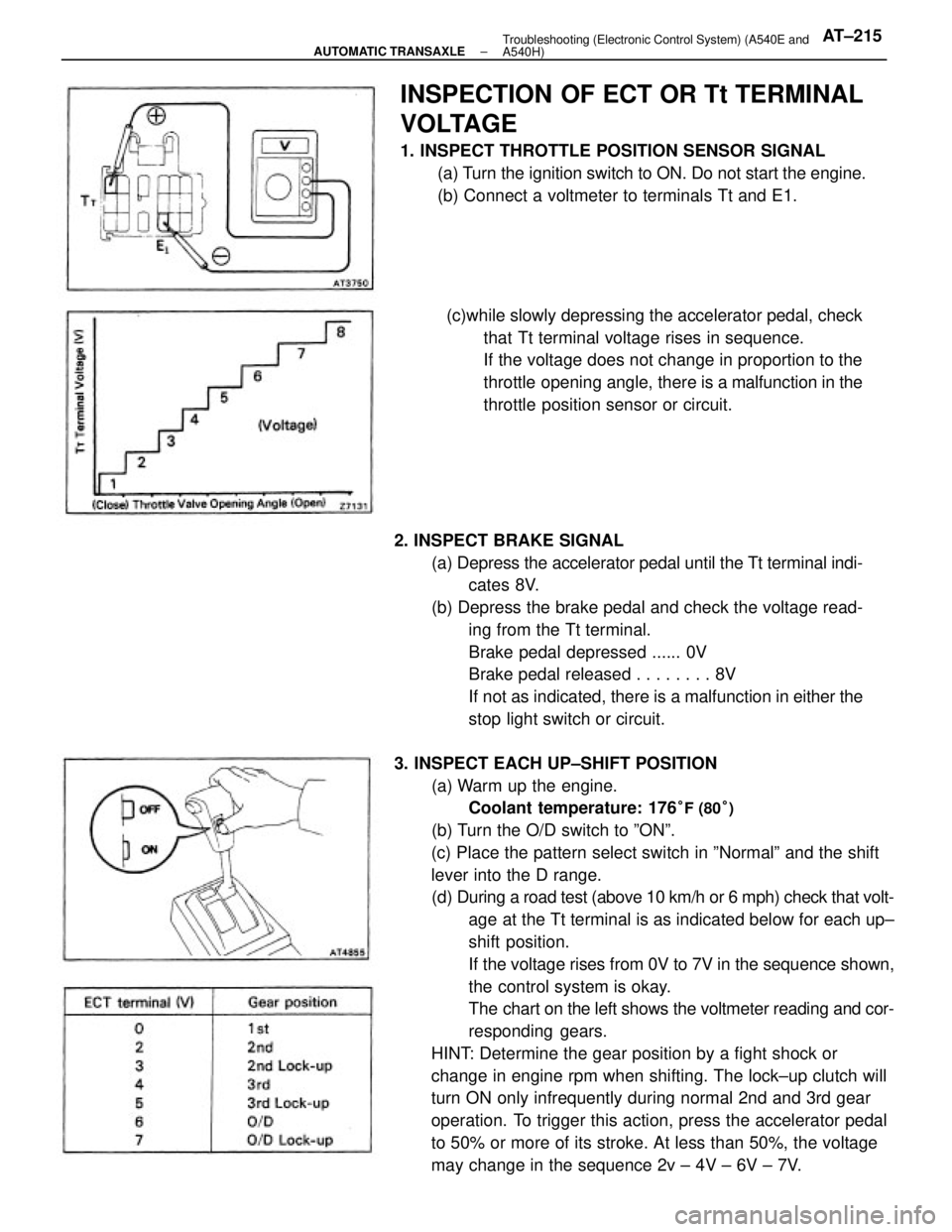

3. INSPECT EACH UP±SHIFT POSITION

(a) Warm up the engine.

Coolant temperature: 176

°F (80°)

(b) Turn the O/D switch to ºONº.

(c) Place the pattern select switch in ºNormalº and the shift

lever into the D range.

(d) During a road test (above 10 km/h or 6 mph) check that volt-

age at the Tt terminal is as indicated below for each up±

shift position.

If the voltage rises from 0V to 7V in the sequence shown,

the control system is okay.

The chart on the left shows the voltmeter reading and cor-

responding gears.

HINT: Determine the gear position by a fight shock or

change in engine rpm when shifting. The lock±up clutch will

turn ON only infrequently during normal 2nd and 3rd gear

operation. To trigger this action, press the accelerator pedal

to 50% or more of its stroke. At less than 50%, the voltage

may change in the sequence 2v ± 4V ± 6V ± 7V. 2. INSPECT BRAKE SIGNAL

(a) Depress the accelerator pedal until the Tt terminal indi-

cates 8V.

(b) Depress the brake pedal and check the voltage read-

ing from the Tt terminal.

Brake pedal depressed ...... 0V

Brake pedal released . . . . . . . . 8V

If not as indicated, there is a malfunction in either the

stop light switch or circuit.

INSPECTION OF ECT OR Tt TERMINAL

VOLTAGE

1. INSPECT THROTTLE POSITION SENSOR SIGNAL

(a) Turn the ignition switch to ON. Do not start the engine.

(b) Connect a voltmeter to terminals Tt and E1.

(c)while slowly depressing the accelerator pedal, check

that Tt terminal voltage rises in sequence.

If the voltage does not change in proportion to the

throttle opening angle, there is a malfunction in the

throttle position sensor or circuit.

± AUTOMATIC TRANSAXLETroubleshooting (Electronic Control System) (A540E and

A540H)AT±215

Page 486 of 2389

INSTALLATION OF THROTTLE CABLE

1. INSTALL CABLE INTO TRANSMISSION CASE

2. INSTALL VALVE BODY

3. IF THROTTLE CABLE IS NEW, STAKE STOPPER OR

PAINT MARK ON INNER CABLE

HINT: New cable do not have a cable stopper staked.

(a) Bend the cable so there is a radius of about 200 mm(7.87 in.).

(b) Pull the inner cable lightly until a slight resistance is felt, and hold

it.

(e) Stake the stopper, 0.8 ± 1.5 mm (0.031 ± 0.059 in.)

from the end of outer cable.

4. CONNECT THROTTLE CABLE TO ENGINE

5. ADJUST THROTTLE CABLE (See page AT±201)

6. INSTALL AND ADJUST NEUTRAL START SWITCH

7. TEST DRIVE VEHICLE

Throttle Cable

REMOVAL OF THROTTLE CABLE

1. DISCONNECT THROTTLE CABLE FROM ENGINE

2. REMOVE NEUTRAL START SWITCH

3. REMOVE VALVE BODY

4. REMOVE THROTTLE CABLE

ON±VEHICLE REPAIR

HINT: The components mentioned below can be replaced on the vehicle without any necessity for

removal of the transaxle. For the respective operating procedures refer to the following pages:

Speedometer driven gear oil

seal

Extension housing oil

seal Side gear

shaft oil sealAT±232 and AT±233 AT±242 to AT±244

Throttle cable

Only A540H Components

Valve bodyInstallation

RemovalRemarks

AT±231AT±231

AT±233AT±232

AT±233AT±232

AT±232

± AUTOMATIC TRANSAXLEOn±Vehicle Repair (A540E and A540H)AT±231

Page 720 of 2389

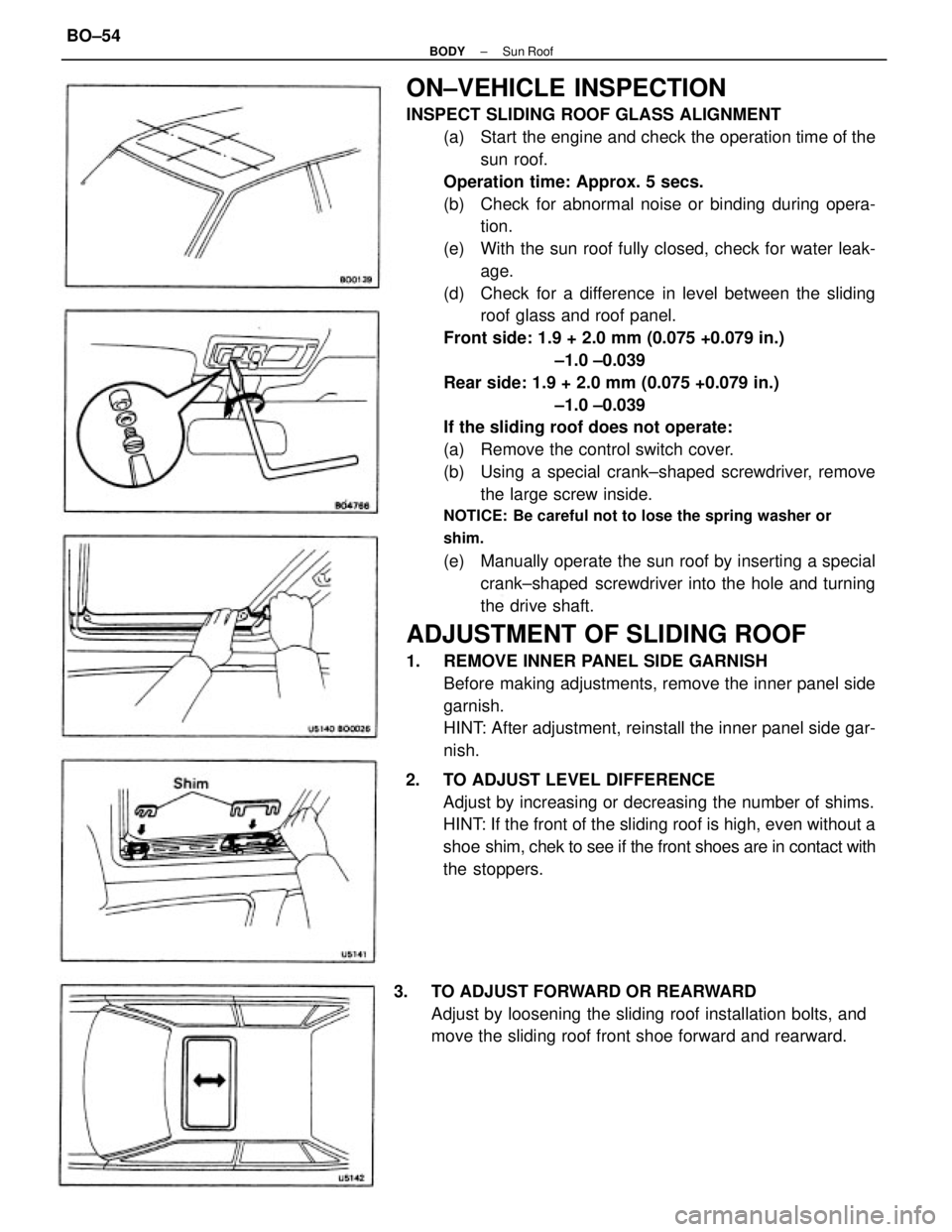

ON±VEHICLE INSPECTION

INSPECT SLIDING ROOF GLASS ALIGNMENT

(a) Start the engine and check the operation time of the

sun roof.

Operation time: Approx. 5 secs.

(b) Check for abnormal noise or binding during opera-

tion.

(e) With the sun roof fully closed, check for water leak-

age.

(d) Check for a difference in level between the sliding

roof glass and roof panel.

Front side: 1.9 + 2.0 mm (0.075 +0.079 in.)

±1.0 ±0.039

Rear side: 1.9 + 2.0 mm (0.075 +0.079 in.)

±1.0 ±0.039

If the sliding roof does not operate:

(a) Remove the control switch cover.

(b) Using a special crank±shaped screwdriver, remove

the large screw inside.

NOTICE: Be careful not to lose the spring washer or

shim.

(e) Manually operate the sun roof by inserting a special

crank±shaped screwdriver into the hole and turning

the drive shaft.

ADJUSTMENT OF SLIDING ROOF

1. REMOVE INNER PANEL SIDE GARNISH

Before making adjustments, remove the inner panel side

garnish.

HINT: After adjustment, reinstall the inner panel side gar-

nish.

2. TO ADJUST LEVEL DIFFERENCE

Adjust by increasing or decreasing the number of shims.

HINT: If the front of the sliding roof is high, even without a

shoe shim, chek to see if the front shoes are in contact with

the stoppers.

3. TO ADJUST FORWARD OR REARWARD

Adjust by loosening the sliding roof installation bolts, and

move the sliding roof front shoe forward and rearward.

± BODYSun RoofBO±54