stop start TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 1869 of 2389

SPEEDOMETER TEST OR OTHER

TESTS (Using Speedometer Tester or

Chassis Dynamometer)

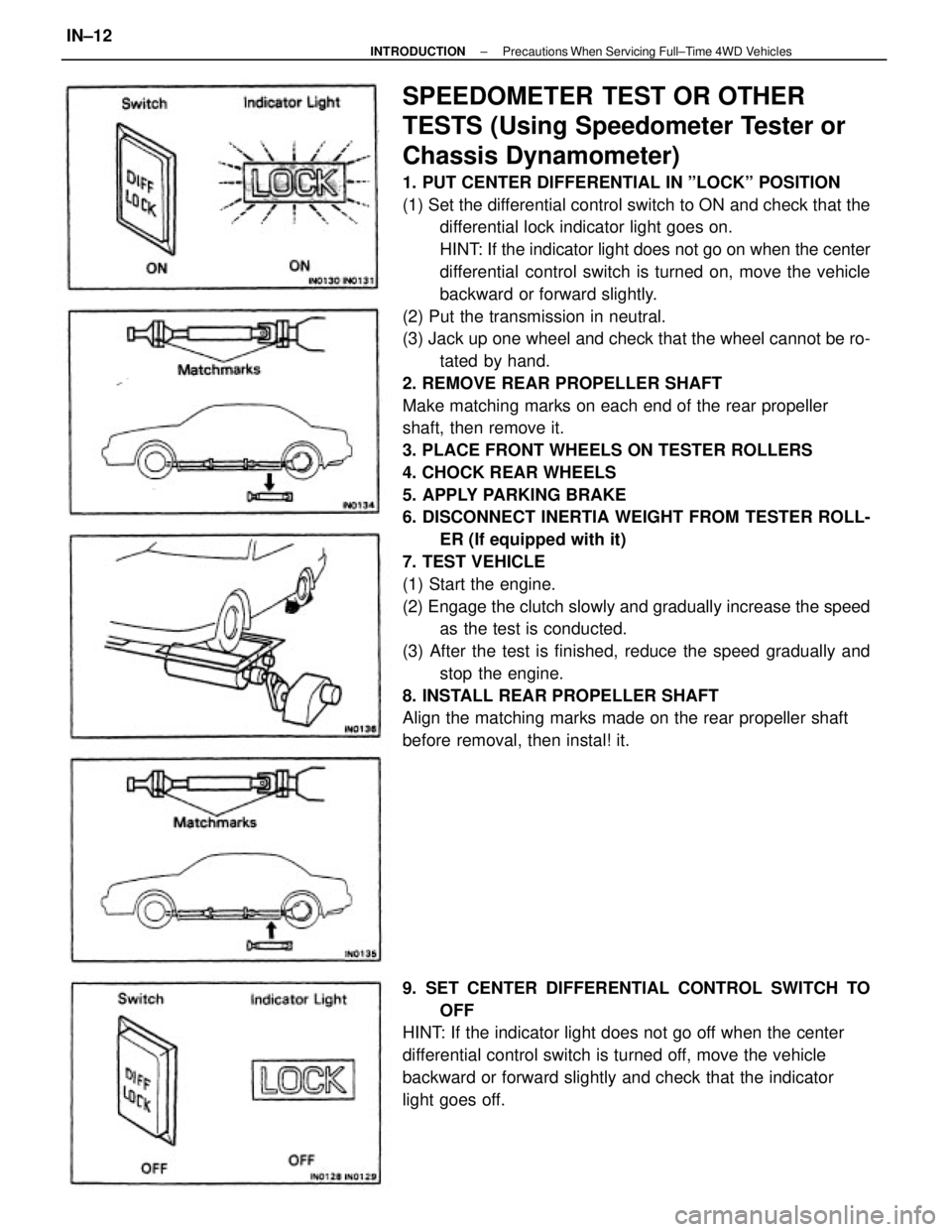

1. PUT CENTER DIFFERENTIAL IN ºLOCKº POSITION

(1) Set the differential control switch to ON and check that the

differential lock indicator light goes on.

HINT: If the indicator light does not go on when the center

differential control switch is turned on, move the vehicle

backward or forward slightly.

(2) Put the transmission in neutral.

(3) Jack up one wheel and check that the wheel cannot be ro-

tated by hand.

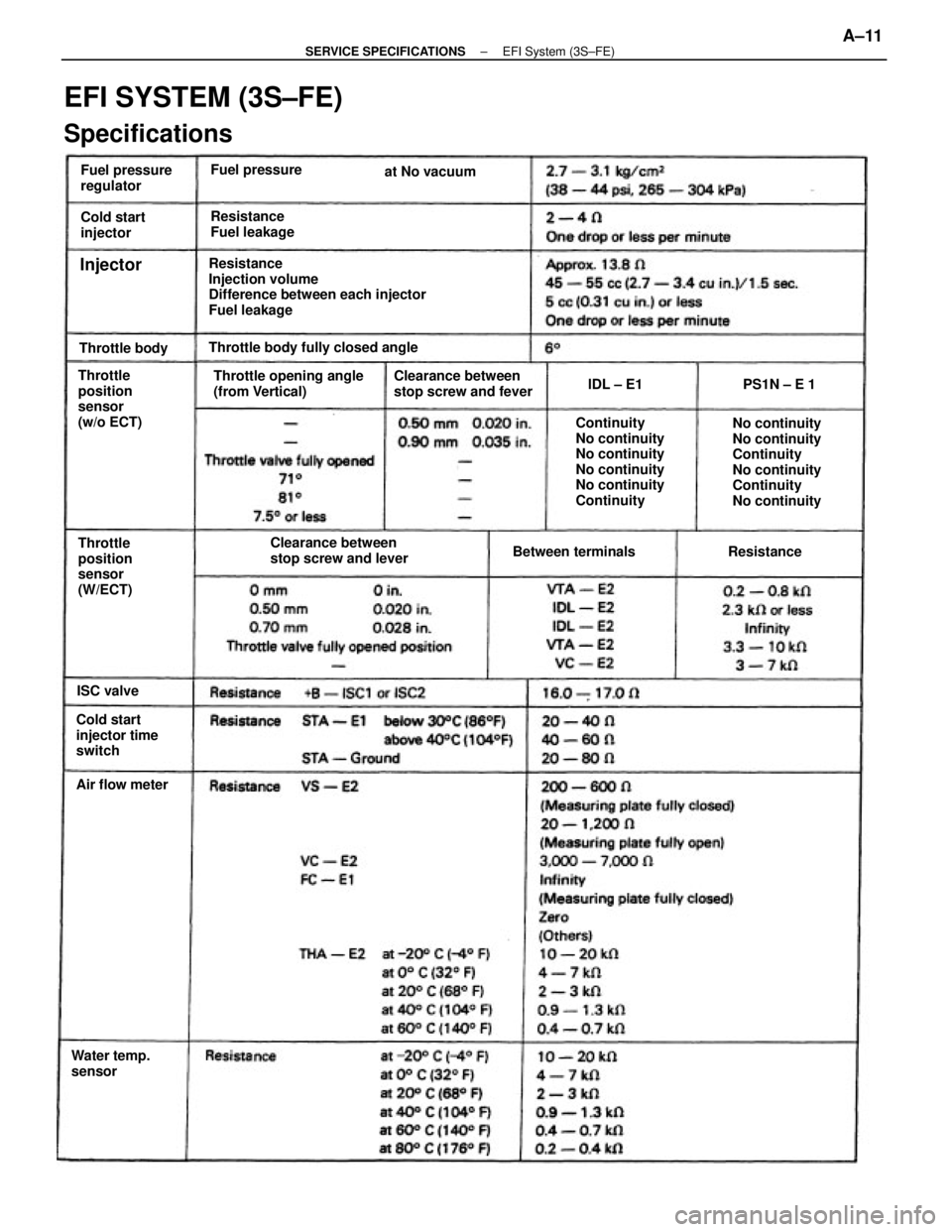

2. REMOVE REAR PROPELLER SHAFT

Make matching marks on each end of the rear propeller

shaft, then remove it.

3. PLACE FRONT WHEELS ON TESTER ROLLERS

4. CHOCK REAR WHEELS

5. APPLY PARKING BRAKE

6. DISCONNECT INERTIA WEIGHT FROM TESTER ROLL-

ER (If equipped with it)

7. TEST VEHICLE

(1) Start the engine.

(2) Engage the clutch slowly and gradually increase the speed

as the test is conducted.

(3) After the test is finished, reduce the speed gradually and

stop the engine.

8. INSTALL REAR PROPELLER SHAFT

Align the matching marks made on the rear propeller shaft

before removal, then instal! it.

9. SET CENTER DIFFERENTIAL CONTROL SWITCH TO

OFF

HINT: If the indicator light does not go off when the center

differential control switch is turned off, move the vehicle

backward or forward slightly and check that the indicator

light goes off.

± INTRODUCTIONPrecautions When Servicing Full±Time 4WD VehiclesIN±12

Page 1878 of 2389

![TOYOTA CAMRY V20 1986 Service Information SPEEDOMETER TEST OR OTHER TESTS

[Using Speedometer Tester or Chassis Dynamometer]

1. SET CENTER DIFFERENTIAL CONTROL SWITCH TO

OFF

(1) Check that the center differential control indicator light

goes TOYOTA CAMRY V20 1986 Service Information SPEEDOMETER TEST OR OTHER TESTS

[Using Speedometer Tester or Chassis Dynamometer]

1. SET CENTER DIFFERENTIAL CONTROL SWITCH TO

OFF

(1) Check that the center differential control indicator light

goes](/img/14/57449/w960_57449-1877.png)

SPEEDOMETER TEST OR OTHER TESTS

[Using Speedometer Tester or Chassis Dynamometer]

1. SET CENTER DIFFERENTIAL CONTROL SWITCH TO

OFF

(1) Check that the center differential control indicator light

goes oft.

(2) Further check that the operation of the hydraulic

multiplate clutch control of the center differential is in

OFF condition.

(See page IN±15)

2. MOVE MODE SELECT LEVER ON TRANSAXLE TO ºLOCKº

MODE AND LOCK IT SECURELY WITH BOLT (See page

IN±16)

3. CONFIRM MODE SELECTION

(See page IN±17)

8. DISCONNECT INERTIA WEIGHT FROM TESTER ROLL-

ER (If equipped with it)

9. TEST VEHICLE

(1) Start the engine.

(2) Put the transmission in D range, then gradually in-

crease the speed as the test in conducted.

(3) After the test is finished, reduce the speed gradually

and stop the engine. 4. REMOVE REAR PROPELLER SHAFT

Make matching marks on each end of the rear propeller

shaft, then remove it.

5. PLACE FRONT WHEELS ON TESTER ROLLERS

6. CHOCK REAR WHEELS

7. APPLY PARKING BRAKE

10. AFTER FINISHING TEST, INSTALL REAR PROPELLER

SHAFT

Align the matching marks made on the rear propeller shaft

before removal, then install it.

± INTRODUCTIONPrecautions When Servicing Full±Time 4WD VehiclesIN±21

Page 2222 of 2389

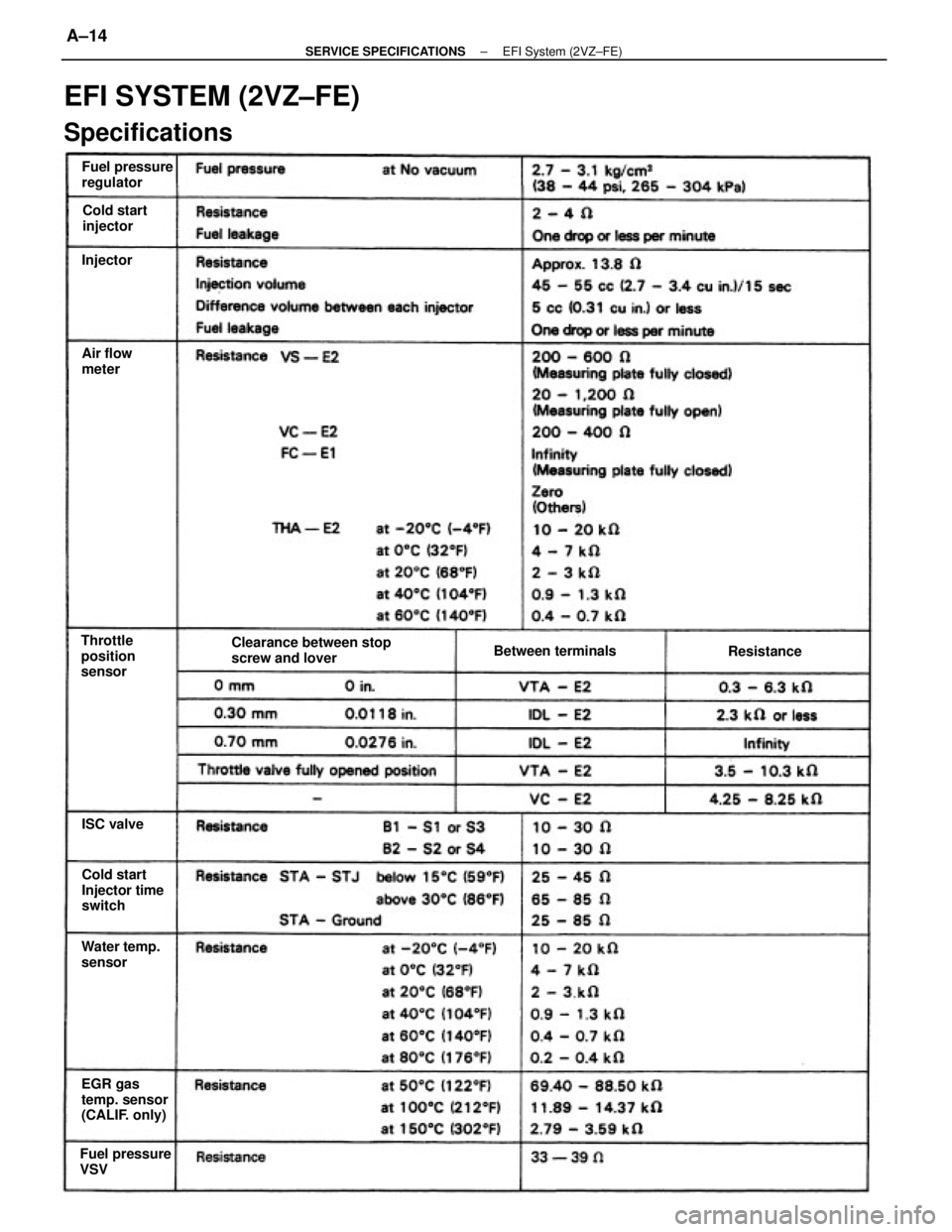

Resistance

Injection volume

Difference between each injector

Fuel leakage

EFI SYSTEM (3S±FE)

Specifications

No continuity

No continuity

Continuity

No continuity

Continuity

No continuity Continuity

No continuity

No continuity

No continuity

No continuity

Continuity Throttle opening angle

(from Vertical)Clearance between

stop screw and fever

Clearance between

stop screw and lever Throttle

position

sensor

(w/o ECT)Throttle body fully closed angle

Cold start

injector time

switchThrottle

position

sensor

(W/ECT)Fuel pressure

regulator

Resistance

Fuel leakage

Water temp.

sensorBetween terminals Cold start

injector

Air flow meterFuel pressure

Throttle bodyat No vacuum

ResistancePS1N ± E 1

ISC valvelDL ± E1

Injector

± SERVICE SPECIFICATIONSEFI System (3S±FE)A±11

Page 2226 of 2389

EFI SYSTEM (2VZ±FE)

Specifications

Clearance between stop

screw and lover

EGR gas

temp. sensor

(CALIF. only)Cold start

Injector time

switch Fuel pressure

regulator

Fuel pressure

VSVWater temp.

sensor Throttle

position

sensorBetween terminals Cold start

injector

Air flow

meter

Resistance

ISC valve Injector

± SERVICE SPECIFICATIONSEFI System (2VZ±FE)A±14

Page 2316 of 2389

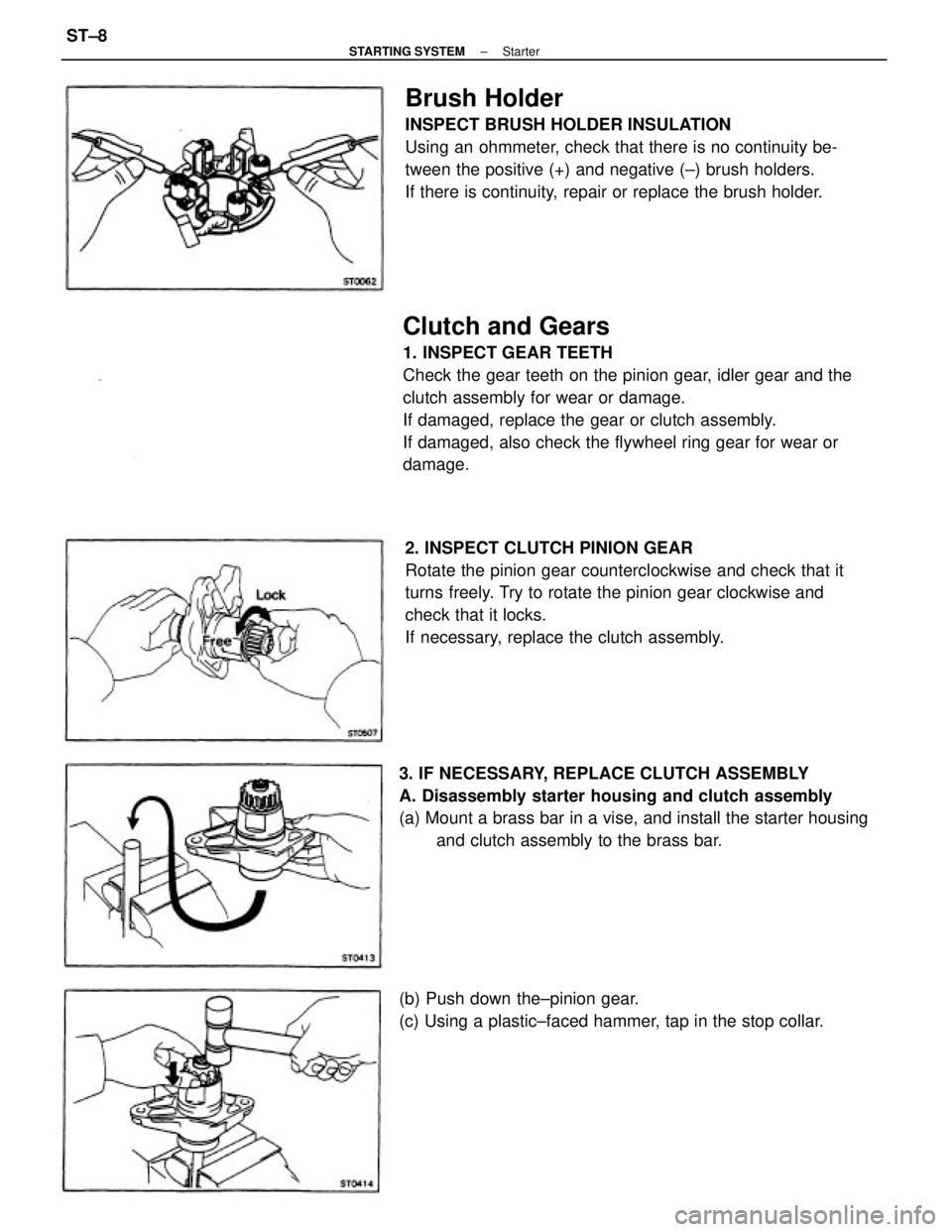

Clutch and Gears

1. INSPECT GEAR TEETH

Check the gear teeth on the pinion gear, idler gear and the

clutch assembly for wear or damage.

If damaged, replace the gear or clutch assembly.

If damaged, also check the flywheel ring gear for wear or

damage.

2. INSPECT CLUTCH PINION GEAR

Rotate the pinion gear counterclockwise and check that it

turns freely. Try to rotate the pinion gear clockwise and

check that it locks.

If necessary, replace the clutch assembly.

Brush Holder

INSPECT BRUSH HOLDER INSULATION

Using an ohmmeter, check that there is no continuity be-

tween the positive (+) and negative (±) brush holders.

If there is continuity, repair or replace the brush holder.

3. IF NECESSARY, REPLACE CLUTCH ASSEMBLY

A. Disassembly starter housing and clutch assembly

(a) Mount a brass bar in a vise, and install the starter housing

and clutch assembly to the brass bar.

(b) Push down the±pinion gear.

(c) Using a plastic±faced hammer, tap in the stop collar.

± STARTING SYSTEMStarterST±8

Page 2317 of 2389

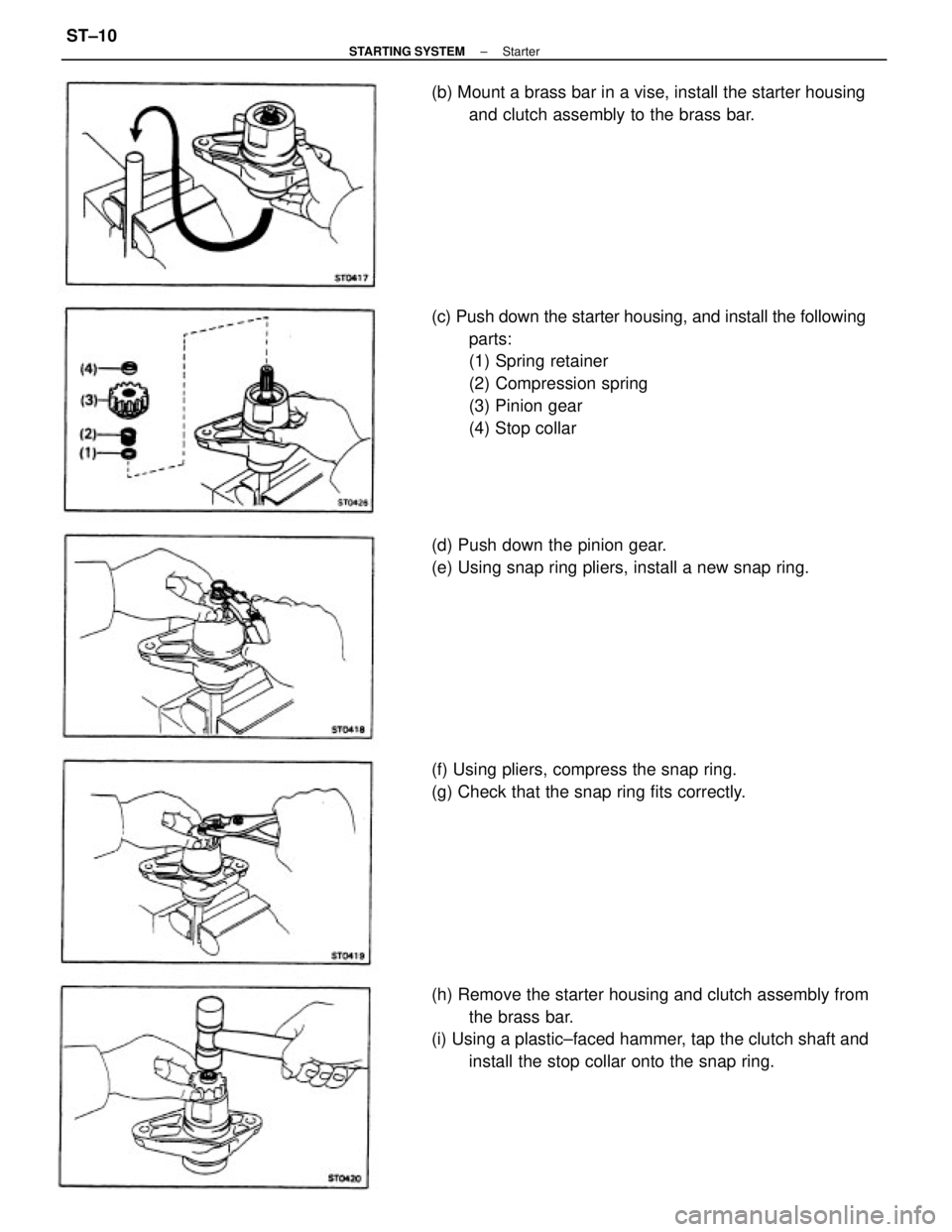

B. Assemble starter housing and clutch assem-

bly

(a) Assembly the following parts:

(1) Starter housing

(2) Bearing retainer

(3) Starter clutch

(4) Compression spring

(5) Clutch shaft (g) Disassemble the following parts:

(1) Starter housing

(2) Bearing retainer.

(3) Starter clutch

(4) Compression spring

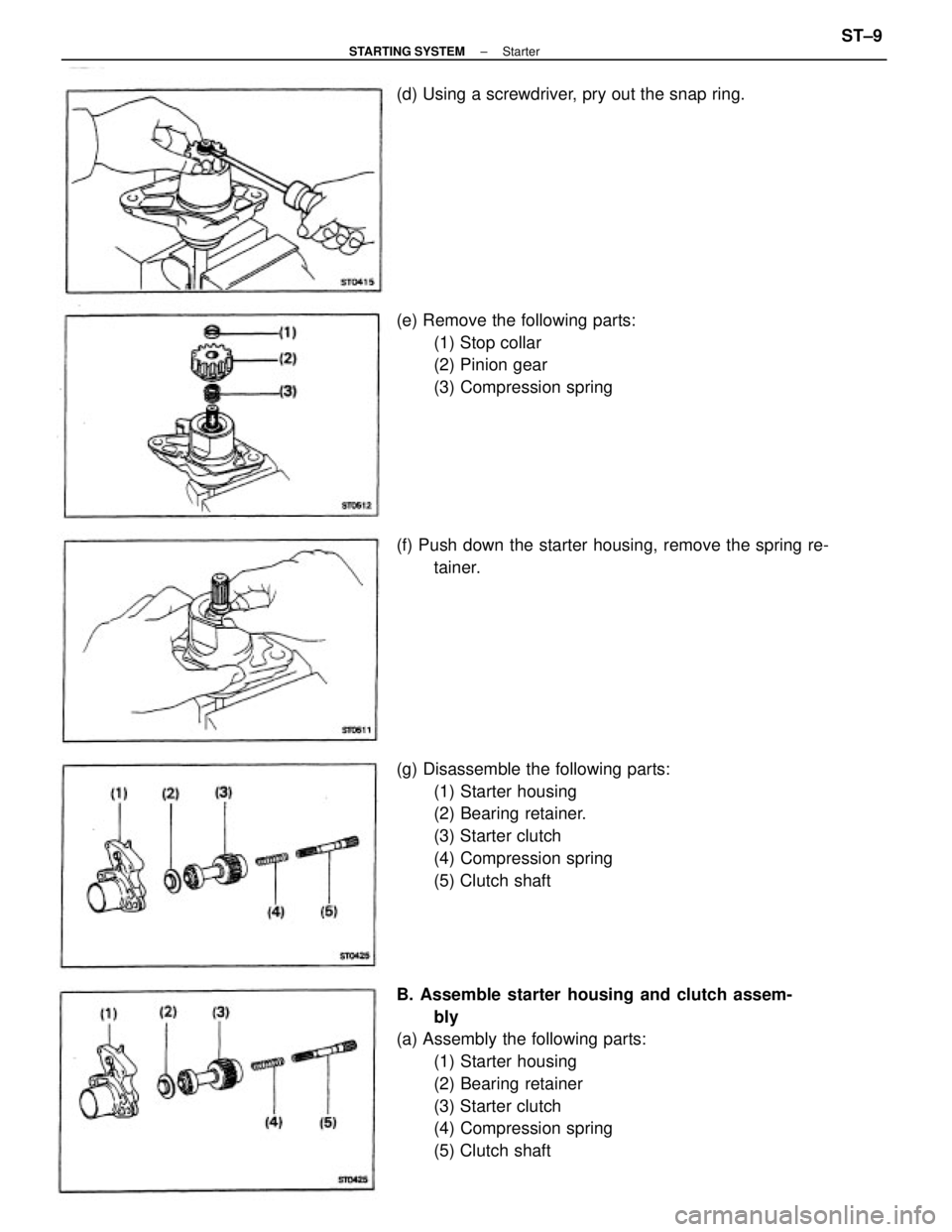

(5) Clutch shaft (e) Remove the following parts:

(1) Stop collar

(2) Pinion gear

(3) Compression spring

(f) Push down the starter housing, remove the spring re-

tainer. (d) Using a screwdriver, pry out the snap ring.

± STARTING SYSTEMStarterST±9

Page 2318 of 2389

(c) Push down the starter housing, and install the following

parts:

(1) Spring retainer

(2) Compression spring

(3) Pinion gear

(4) Stop collar

(h) Remove the starter housing and clutch assembly from

the brass bar.

(i) Using a plastic±faced hammer, tap the clutch shaft and

install the stop collar onto the snap ring. (d) Push down the pinion gear.

(e) Using snap ring pliers, install a new snap ring. (b) Mount a brass bar in a vise, install the starter housing

and clutch assembly to the brass bar.

(f) Using pliers, compress the snap ring.

(g) Check that the snap ring fits correctly.

± STARTING SYSTEMStarterST±10

Page 2349 of 2389

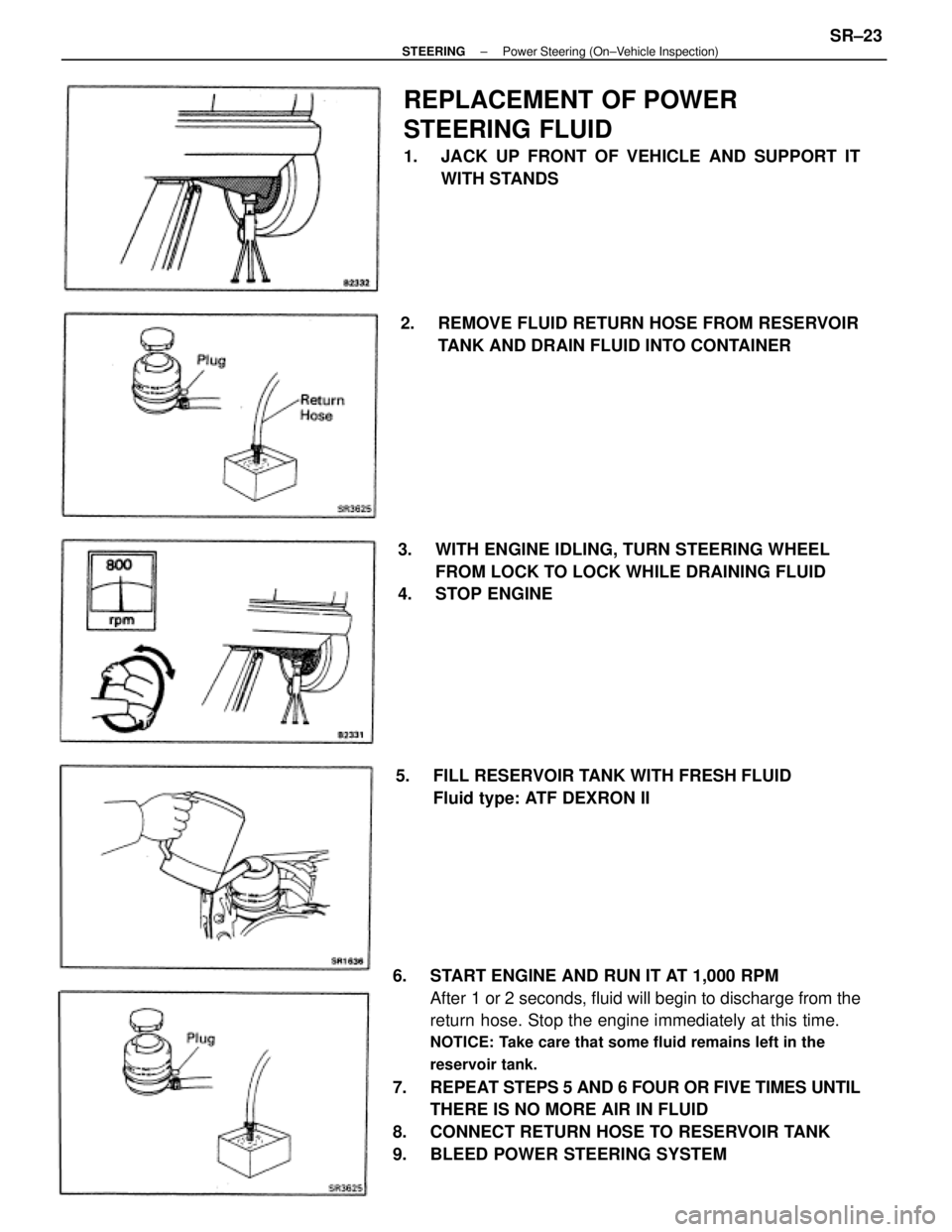

6. START ENGINE AND RUN IT AT 1,000 RPM

After 1 or 2 seconds, fluid will begin to discharge from the

return hose. Stop the engine immediately at this time.

NOTICE: Take care that some fluid remains left in the

reservoir tank.

7. REPEAT STEPS 5 AND 6 FOUR OR FIVE TIMES UNTIL

THERE IS NO MORE AIR IN FLUID

8. CONNECT RETURN HOSE TO RESERVOIR TANK

9. BLEED POWER STEERING SYSTEM

REPLACEMENT OF POWER

STEERING FLUID

1. JACK UP FRONT OF VEHICLE AND SUPPORT IT

WITH STANDS

3. WITH ENGINE IDLING, TURN STEERING WHEEL

FROM LOCK TO LOCK WHILE DRAINING FLUID

4. STOP ENGINE2. REMOVE FLUID RETURN HOSE FROM RESERVOIR

TANK AND DRAIN FLUID INTO CONTAINER

5. FILL RESERVOIR TANK WITH FRESH FLUID

Fluid type: ATF DEXRON II

± STEERINGPower Steering (On±Vehicle Inspection)SR±23

Page 2350 of 2389

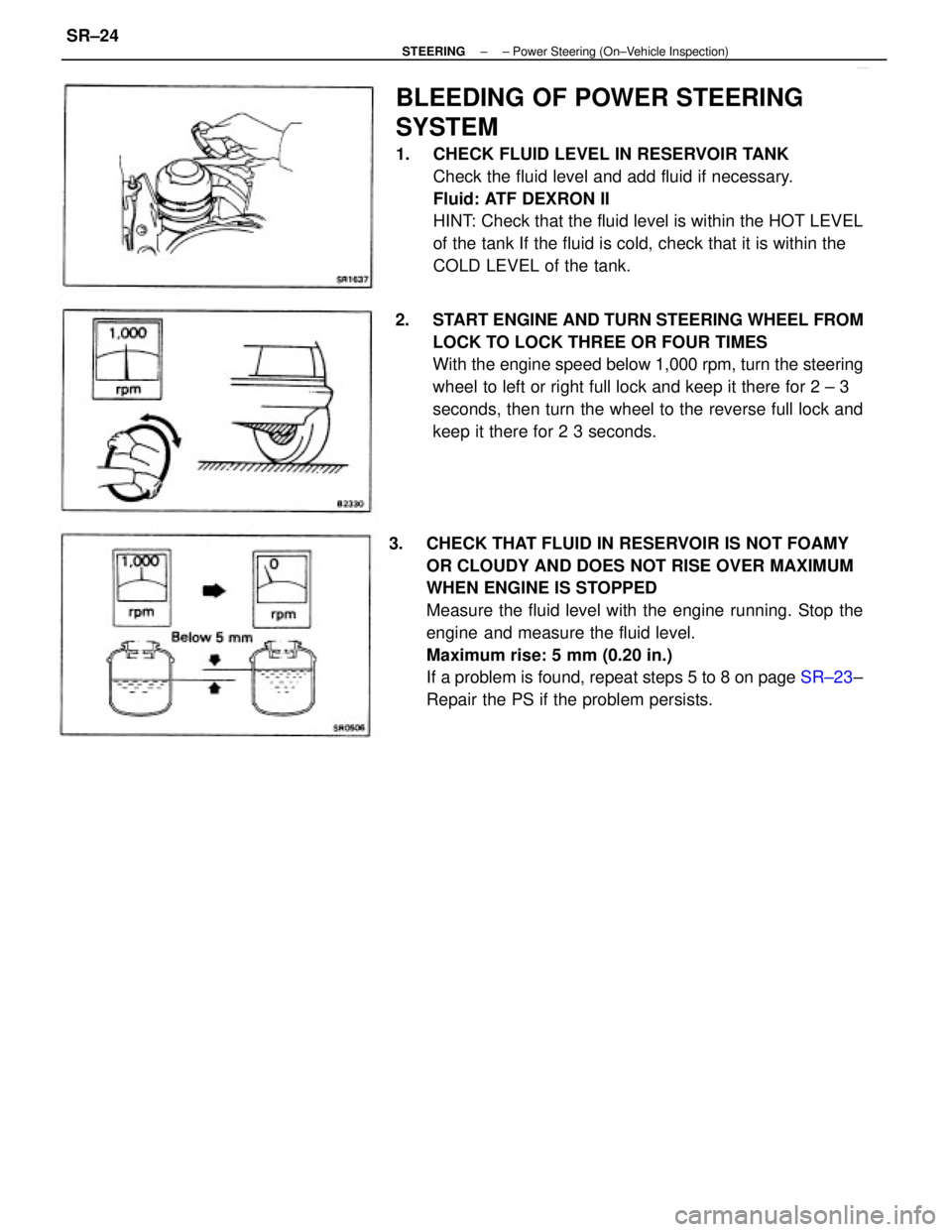

3. CHECK THAT FLUID IN RESERVOIR IS NOT FOAMY

OR CLOUDY AND DOES NOT RISE OVER MAXIMUM

WHEN ENGINE IS STOPPED

Measure the fluid level with the engine running. Stop the

engine and measure the fluid level.

Maximum rise: 5 mm (0.20 in.)

If a problem is found, repeat steps 5 to 8 on page SR±23±

Repair the PS if the problem persists.

BLEEDING OF POWER STEERING

SYSTEM

1. CHECK FLUID LEVEL IN RESERVOIR TANK

Check the fluid level and add fluid if necessary.

Fluid: ATF DEXRON II

HINT: Check that the fluid level is within the HOT LEVEL

of the tank If the fluid is cold, check that it is within the

COLD LEVEL of the tank.

2. START ENGINE AND TURN STEERING WHEEL FROM

LOCK TO LOCK THREE OR FOUR TIMES

With the engine speed below 1,000 rpm, turn the steering

wheel to left or right full lock and keep it there for 2 ± 3

seconds, then turn the wheel to the reverse full lock and

keep it there for 2 3 seconds.

± STEERING± Power Steering (On±Vehicle Inspection)SR±24