TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: windshield wipers, stop start, tyre pressure, washer fluid, fuel tank removal, service interval, audio

Page 621 of 2389

Torque Converter

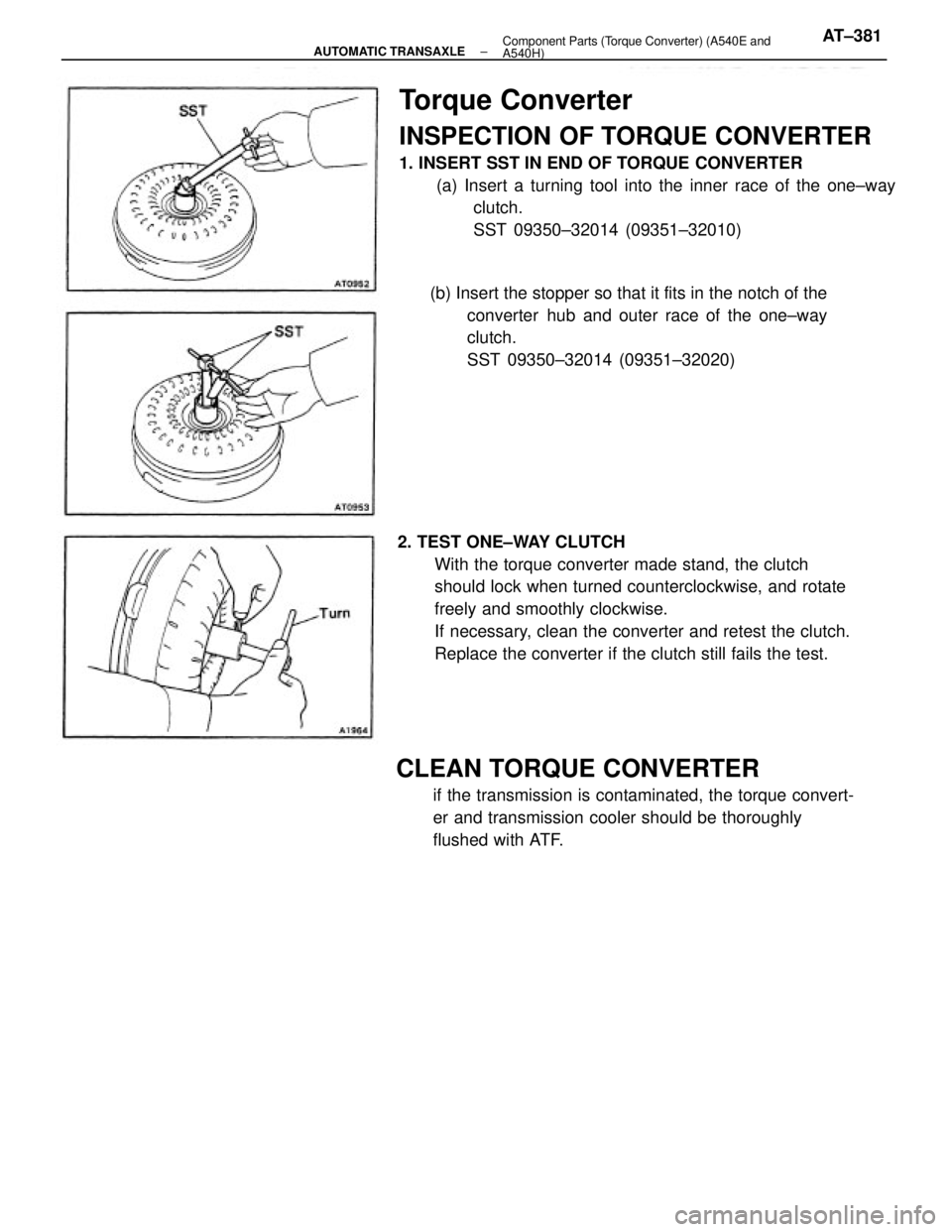

INSPECTION OF TORQUE CONVERTER

1. INSERT SST IN END OF TORQUE CONVERTER

(a) Insert a turning tool into the inner race of the one±way

clutch.

SST 09350±32014 (09351±32010)

2. TEST ONE±WAY CLUTCH

With the torque converter made stand, the clutch

should lock when turned counterclockwise, and rotate

freely and smoothly clockwise.

If necessary, clean the converter and retest the clutch.

Replace the converter if the clutch still fails the test.

CLEAN TORQUE CONVERTER

if the transmission is contaminated, the torque convert-

er and transmission cooler should be thoroughly

flushed with ATF. (b) Insert the stopper so that it fits in the notch of the

converter hub and outer race of the one±way

clutch.

SST 09350±32014 (09351±32020)

± AUTOMATIC TRANSAXLEComponent Parts (Torque Converter) (A540E and

A540H)AT±381

Page 622 of 2389

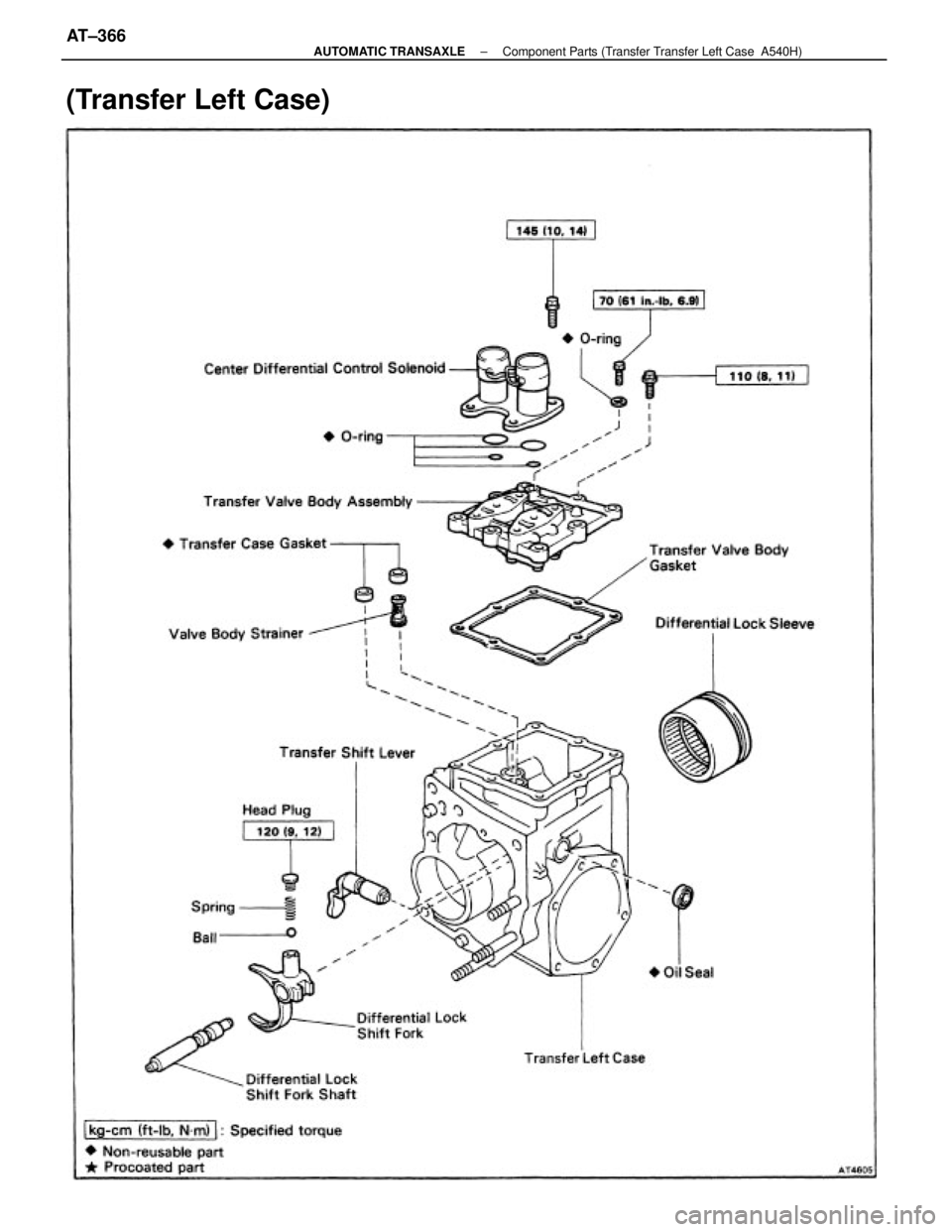

(Transfer Left Case)

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Left Case A540H)AT±366

Page 623 of 2389

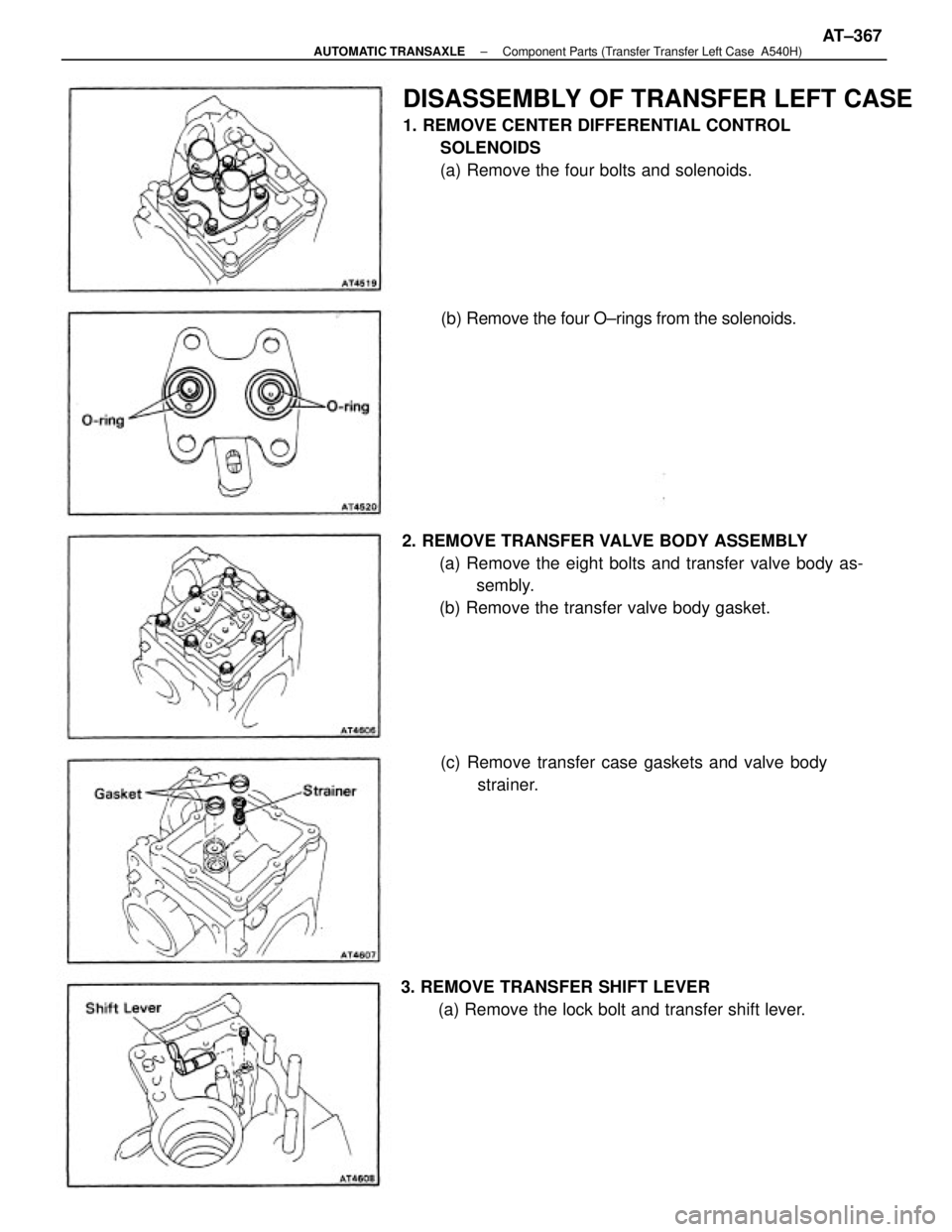

2. REMOVE TRANSFER VALVE BODY ASSEMBLY

(a) Remove the eight bolts and transfer valve body as-

sembly.

(b) Remove the transfer valve body gasket.

DISASSEMBLY OF TRANSFER LEFT CASE

1. REMOVE CENTER DIFFERENTIAL CONTROL

SOLENOIDS

(a) Remove the four bolts and solenoids.

3. REMOVE TRANSFER SHIFT LEVER

(a) Remove the lock bolt and transfer shift lever.(c) Remove transfer case gaskets and valve body

strainer. (b) Remove the four O±rings from the solenoids.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Left Case A540H)AT±367

Page 624 of 2389

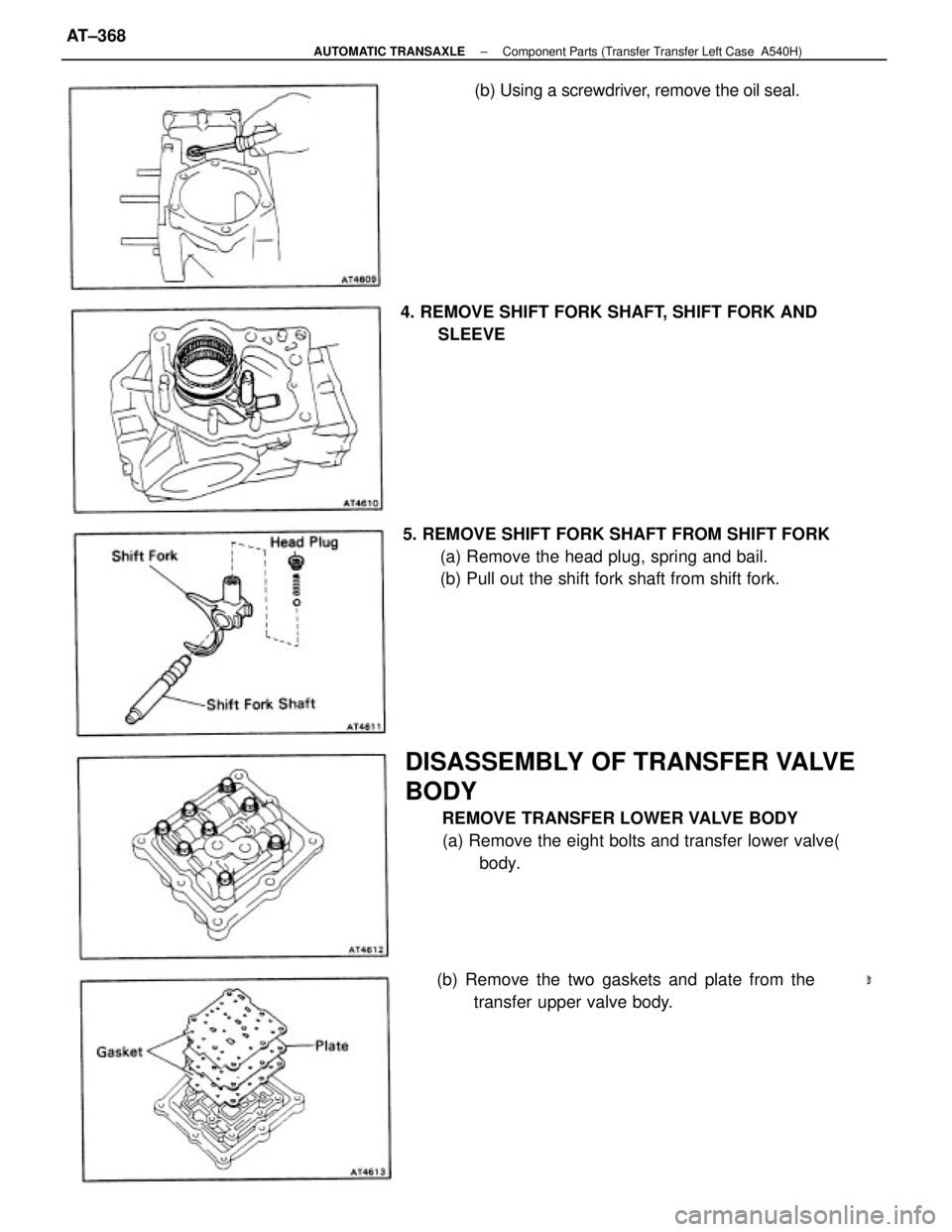

DISASSEMBLY OF TRANSFER VALVE

BODY

REMOVE TRANSFER LOWER VALVE BODY

(a) Remove the eight bolts and transfer lower valve(

body. 5. REMOVE SHIFT FORK SHAFT FROM SHIFT FORK

(a) Remove the head plug, spring and bail.

(b) Pull out the shift fork shaft from shift fork.

(b) Remove the two gaskets and plate from the

transfer upper valve body. 4. REMOVE SHIFT FORK SHAFT, SHIFT FORK AND

SLEEVE(b) Using a screwdriver, remove the oil seal.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Left Case A540H)AT±368

Page 625 of 2389

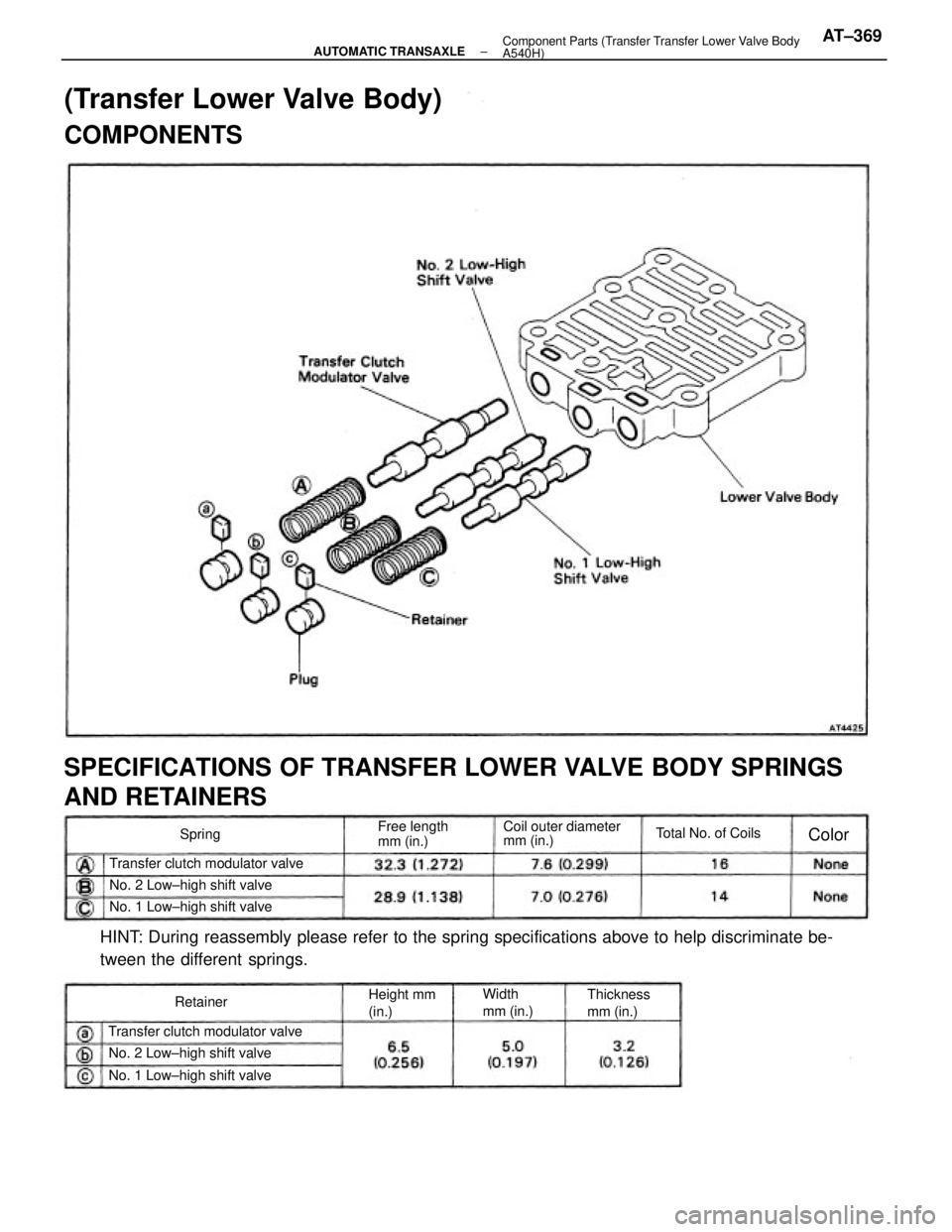

HINT: During reassembly please refer to the spring specifications above to help discriminate be-

tween the different springs.

SPECIFICATIONS OF TRANSFER LOWER VALVE BODY SPRINGS

AND RETAINERS

(Transfer Lower Valve Body)

COMPONENTS

Transfer clutch modulator valveTransfer clutch modulator valveCoil outer diameter

mm (in.)

No. 2 Low±high shift valveNo. 2 Low±high shift valve

No. 1 Low±high shift valveNo. 1 Low±high shift valveFree length

mm (in.)Total No. of Coils

Thickness

mm (in.) Height mm

(in.)Width

mm (in.) RetainerSpring

Color

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Lower Valve Body

A540H)AT±369

Page 626 of 2389

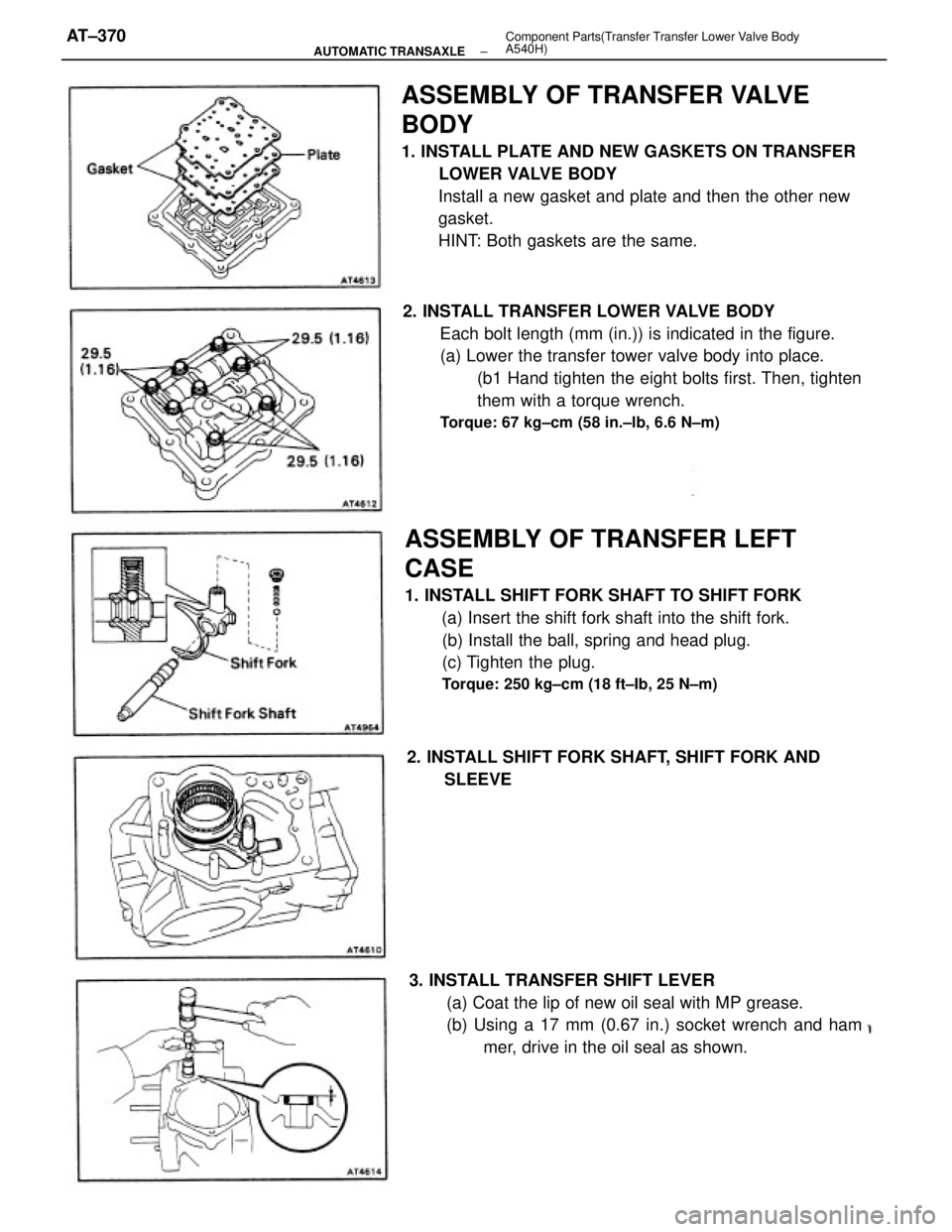

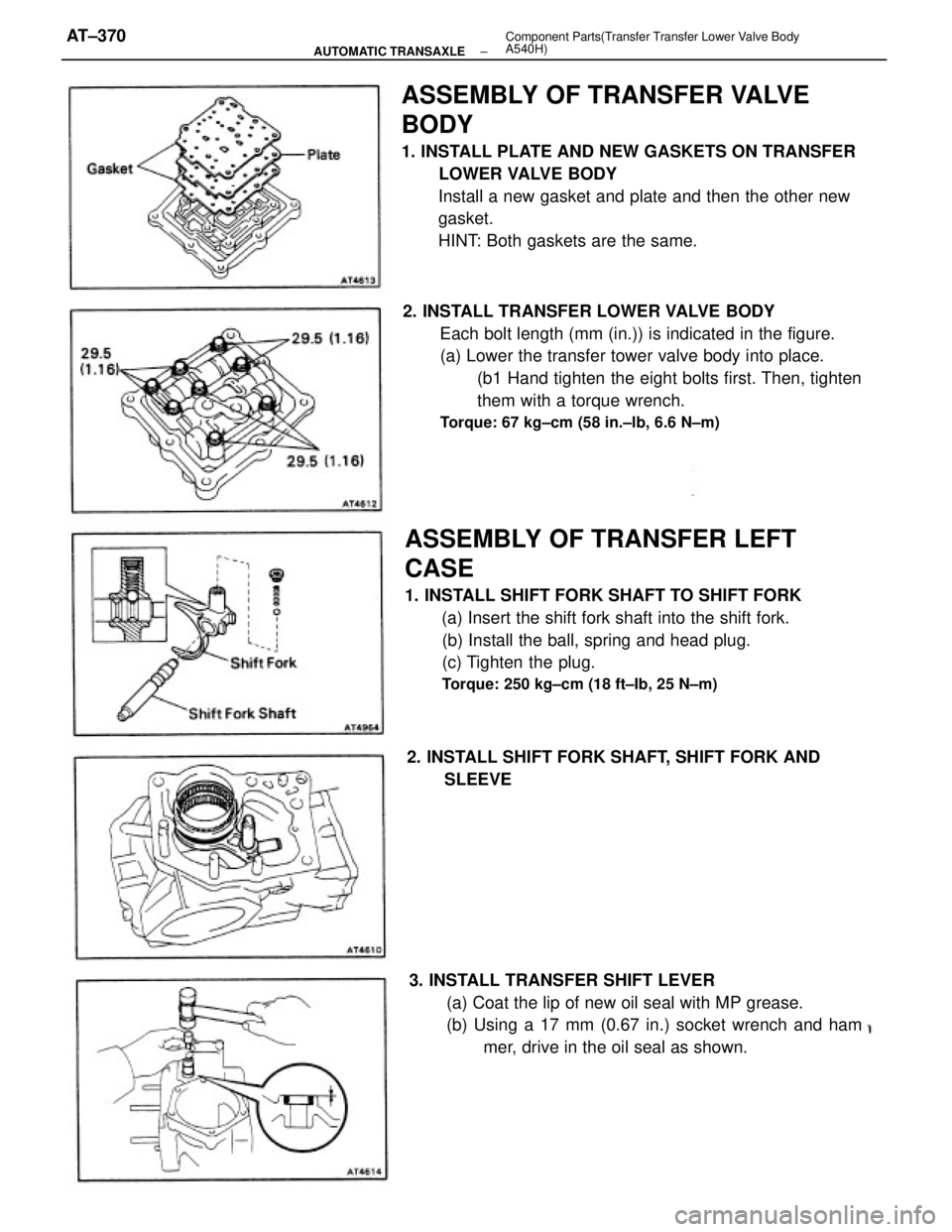

ASSEMBLY OF TRANSFER VALVE

BODY

1. INSTALL PLATE AND NEW GASKETS ON TRANSFER

LOWER VALVE BODY

Install a new gasket and plate and then the other new

gasket.

HINT: Both gaskets are the same.

2. INSTALL TRANSFER LOWER VALVE BODY

Each bolt length (mm (in.)) is indicated in the figure.

(a) Lower the transfer tower valve body into place.

(b1 Hand tighten the eight bolts first. Then, tighten

them with a torque wrench.

Torque: 67 kg±cm (58 in.±lb, 6.6 N±m)

ASSEMBLY OF TRANSFER LEFT

CASE

1. INSTALL SHIFT FORK SHAFT TO SHIFT FORK

(a) Insert the shift fork shaft into the shift fork.

(b) Install the ball, spring and head plug.

(c) Tighten the plug.

Torque: 250 kg±cm (18 ft±Ib, 25 N±m)

3. INSTALL TRANSFER SHIFT LEVER

(a) Coat the lip of new oil seal with MP grease.

(b) Using a 17 mm (0.67 in.) socket wrench and ham

mer, drive in the oil seal as shown. 2. INSTALL SHIFT FORK SHAFT, SHIFT FORK AND

SLEEVE

± AUTOMATIC TRANSAXLEComponent Parts(Transfer Transfer Lower Valve Body

A540H)AT±370

Page 627 of 2389

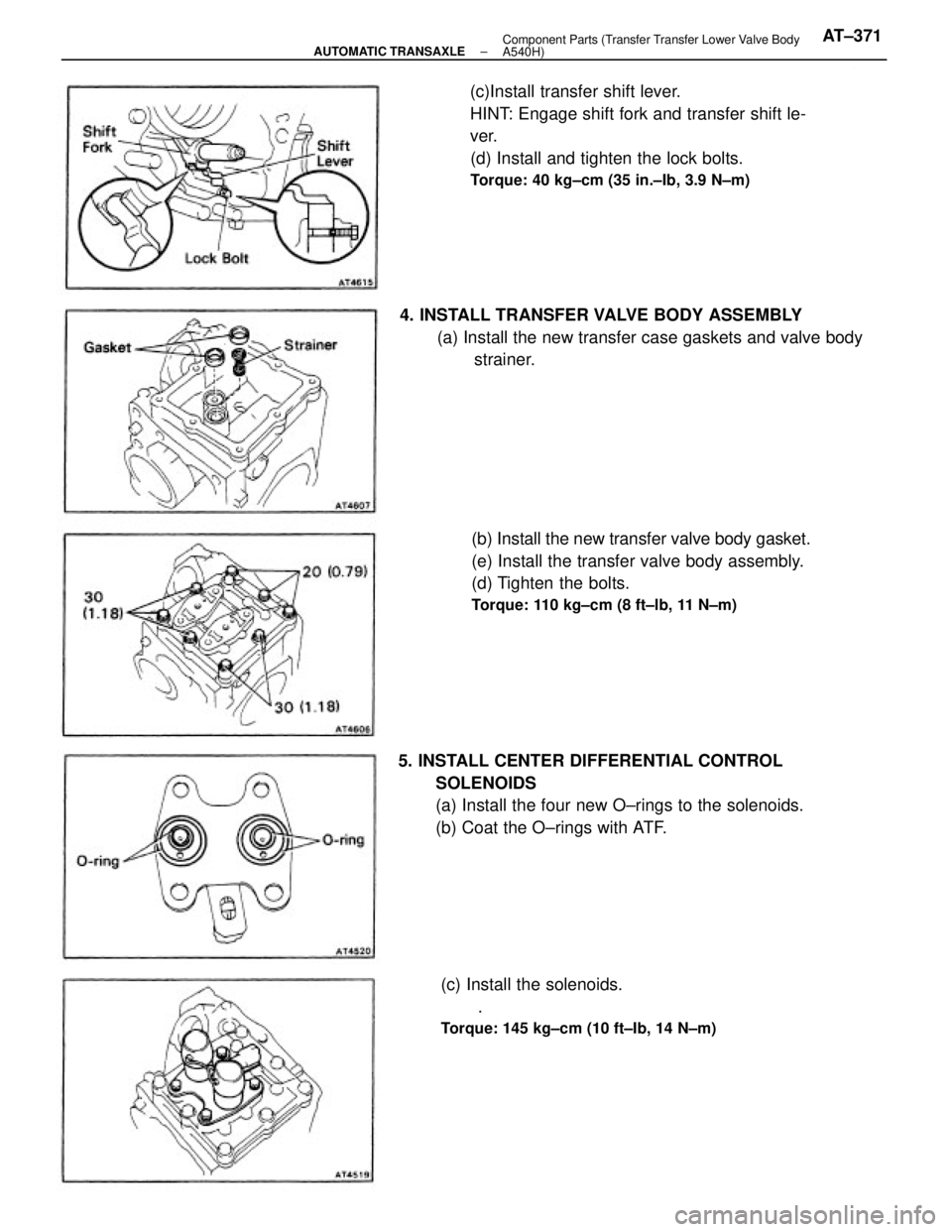

5. INSTALL CENTER DIFFERENTIAL CONTROL

SOLENOIDS

(a) Install the four new O±rings to the solenoids.

(b) Coat the O±rings with ATF.(c)Install transfer shift lever.

HINT: Engage shift fork and transfer shift le-

ver.

(d) Install and tighten the lock bolts.

Torque: 40 kg±cm (35 in.±Ib, 3.9 N±m)

(b) Install the new transfer valve body gasket.

(e) Install the transfer valve body assembly.

(d) Tighten the bolts.

Torque: 110 kg±cm (8 ft±lb, 11 N±m)

4. INSTALL TRANSFER VALVE BODY ASSEMBLY

(a) Install the new transfer case gaskets and valve body

strainer.

(c) Install the solenoids.

.

Torque: 145 kg±cm (10 ft±Ib, 14 N±m)

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Lower Valve Body

A540H)AT±371

Page 628 of 2389

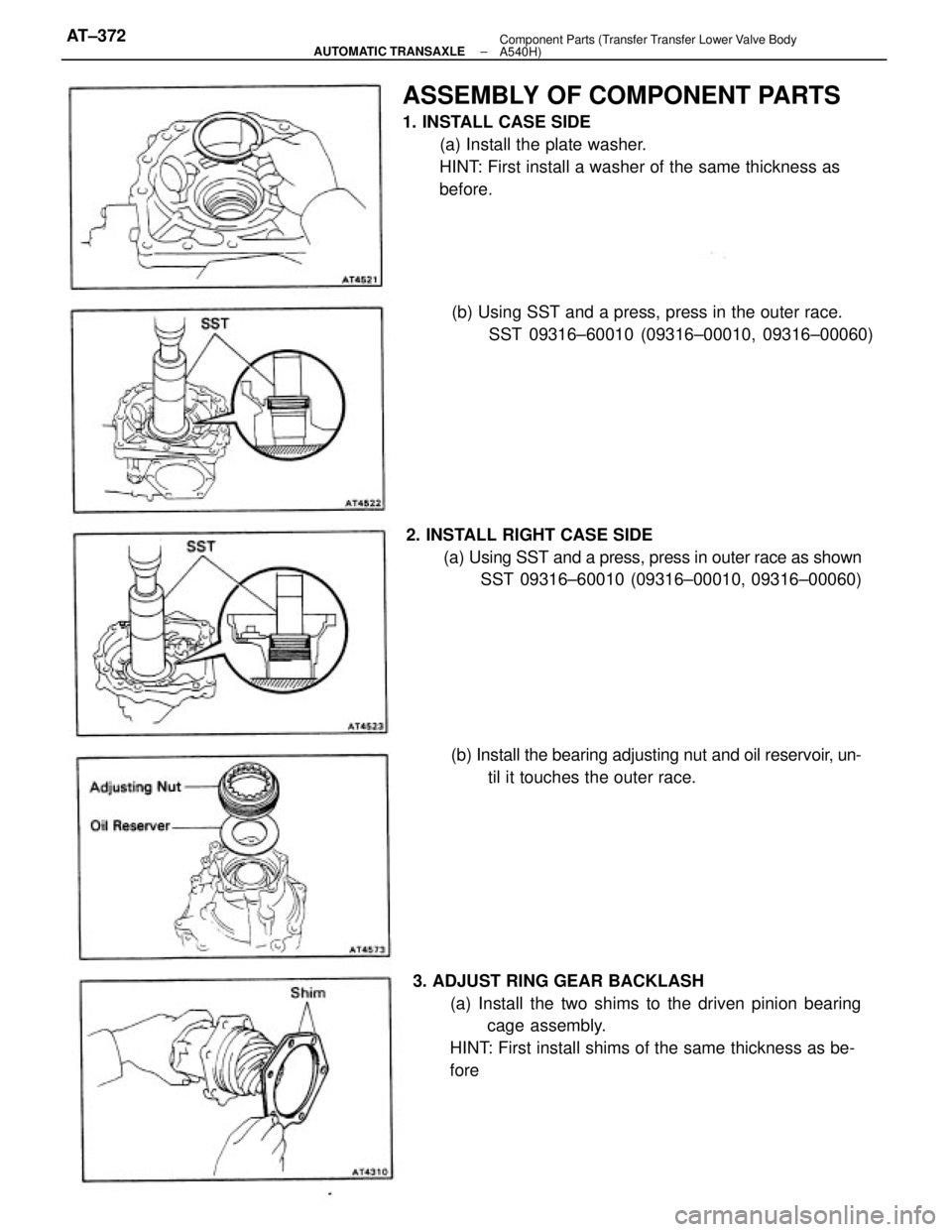

ASSEMBLY OF COMPONENT PARTS

1. INSTALL CASE SIDE

(a) Install the plate washer.

HINT: First install a washer of the same thickness as

before.

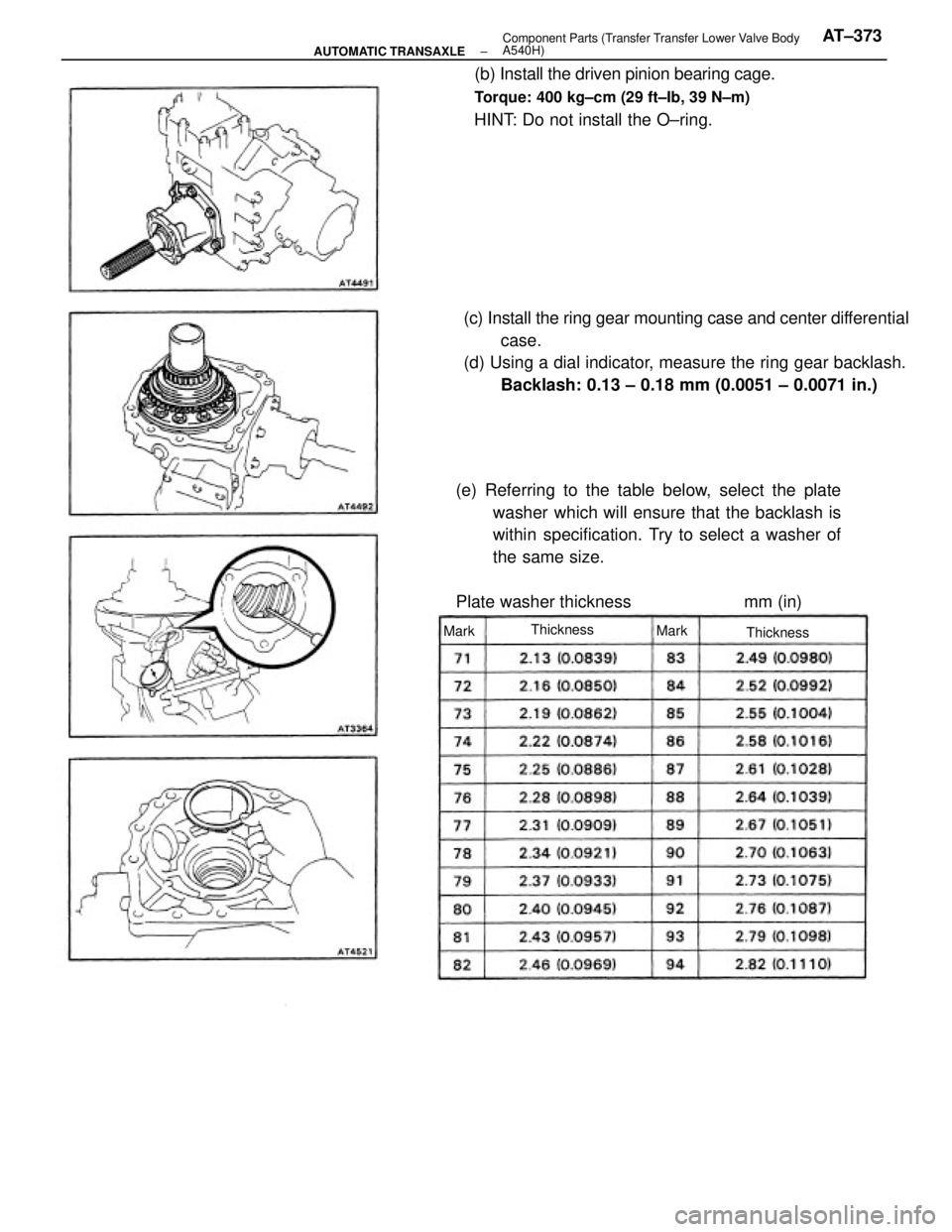

3. ADJUST RING GEAR BACKLASH

(a) Install the two shims to the driven pinion bearing

cage assembly.

HINT: First install shims of the same thickness as be-

fore 2. INSTALL RIGHT CASE SIDE

(a) Using SST and a press, press in outer race as shown

SST 09316±60010 (09316±00010, 09316±00060)

(b) Install the bearing adjusting nut and oil reservoir, un-

til it touches the outer race. (b) Using SST and a press, press in the outer race.

SST 09316±60010 (09316±00010, 09316±00060)

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Lower Valve Body

A540H)AT±372

Page 629 of 2389

(c) Install the ring gear mounting case and center differential

case.

(d) Using a dial indicator, measure the ring gear backlash.

Backlash: 0.13 ± 0.18 mm (0.0051 ± 0.0071 in.)

(e) Referring to the table below, select the plate

washer which will ensure that the backlash is

within specification. Try to select a washer of

the same size.

Plate washer thickness mm (in)(b) Install the driven pinion bearing cage.

Torque: 400 kg±cm (29 ft±Ib, 39 N±m)

HINT: Do not install the O±ring.

Thickness

Thickness Mark

Mark

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Lower Valve Body

A540H)AT±373

Page 630 of 2389

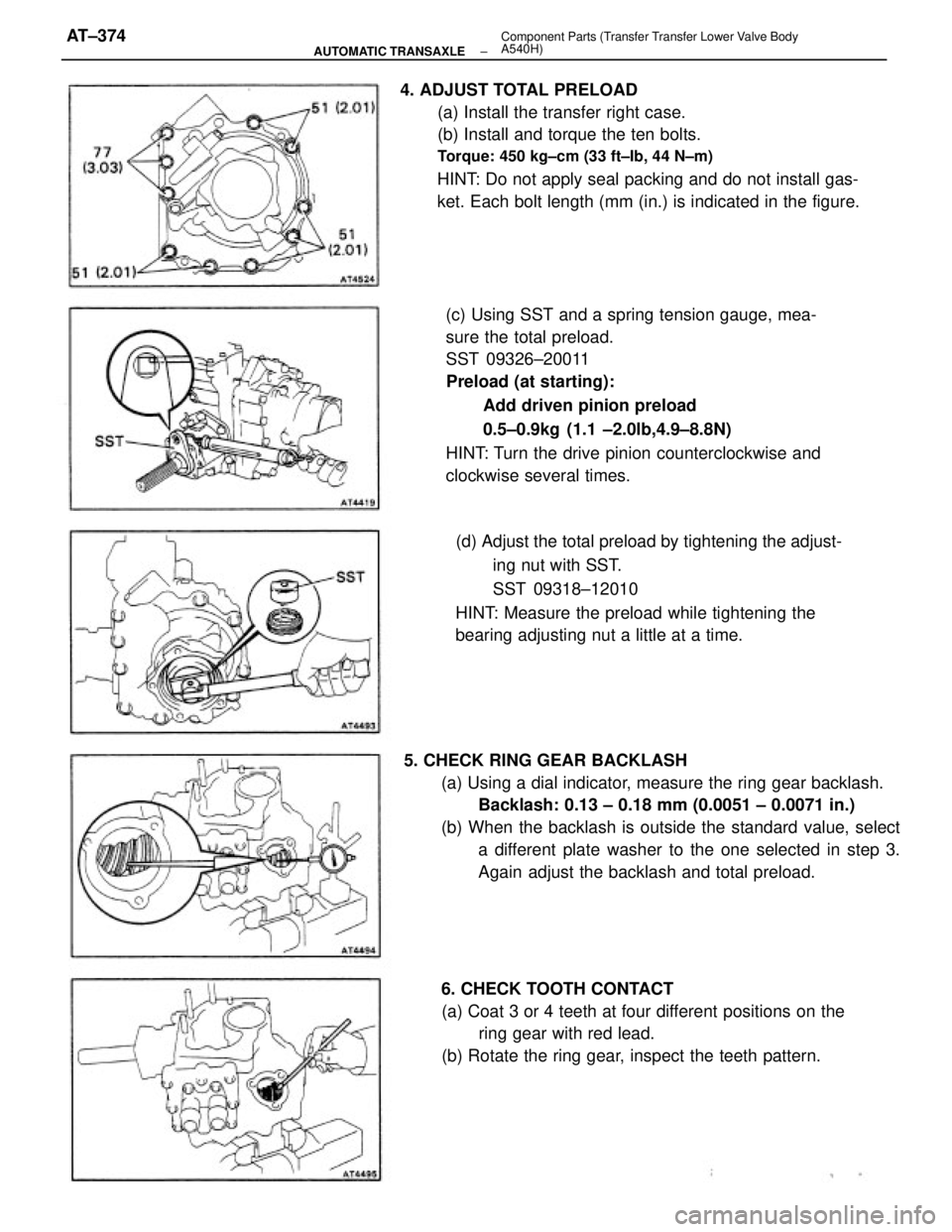

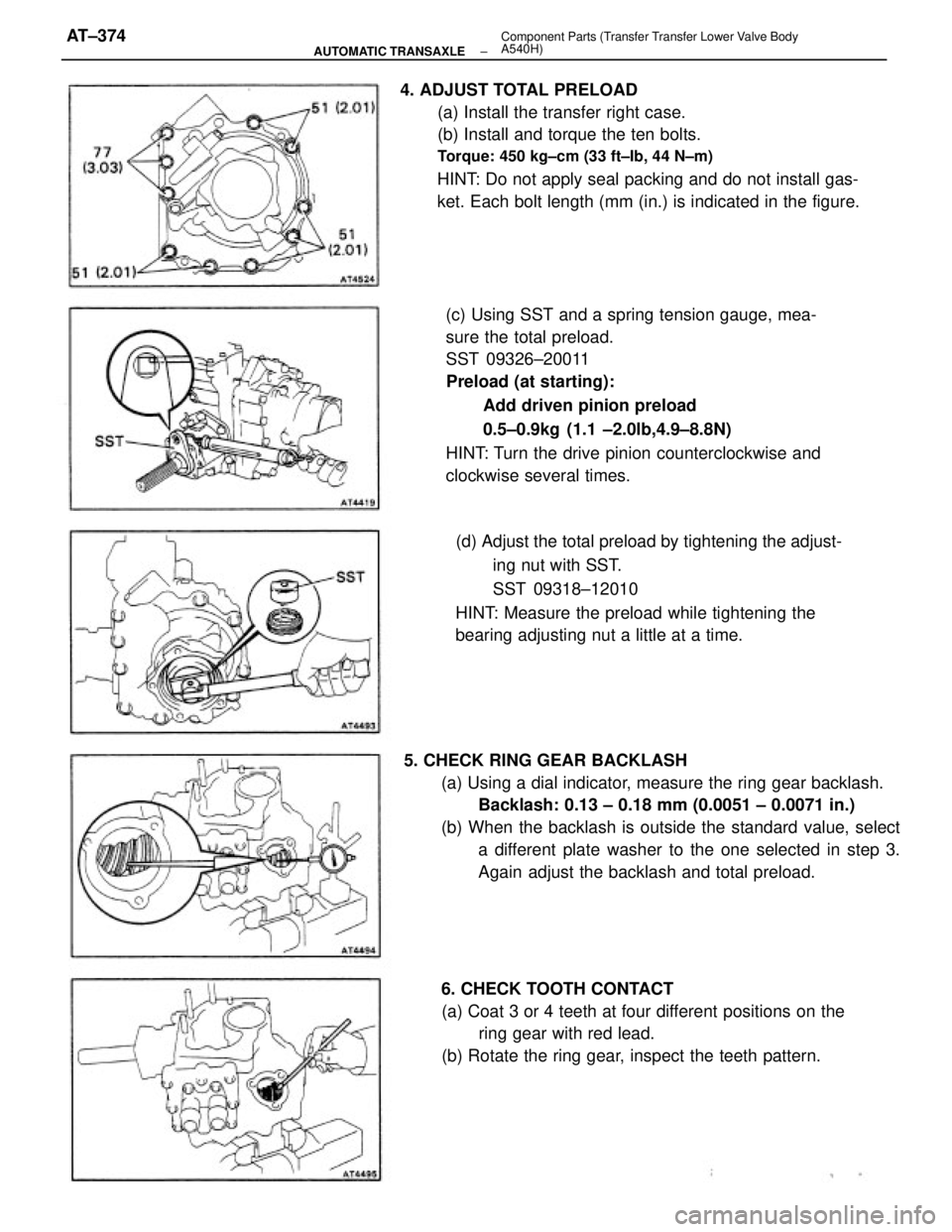

4. ADJUST TOTAL PRELOAD

(a) Install the transfer right case.

(b) Install and torque the ten bolts.

Torque: 450 kg±cm (33 ft±Ib, 44 N±m)

HINT: Do not apply seal packing and do not install gas-

ket. Each bolt length (mm (in.) is indicated in the figure.

(c) Using SST and a spring tension gauge, mea-

sure the total preload.

SST 09326±20011

Preload (at starting):

Add driven pinion preload

0.5±0.9kg (1.1 ±2.0lb,4.9±8.8N)

HINT: Turn the drive pinion counterclockwise and

clockwise several times.

5. CHECK RING GEAR BACKLASH

(a) Using a dial indicator, measure the ring gear backlash.

Backlash: 0.13 ± 0.18 mm (0.0051 ± 0.0071 in.)

(b) When the backlash is outside the standard value, select

a different plate washer to the one selected in step 3.

Again adjust the backlash and total preload. (d) Adjust the total preload by tightening the adjust-

ing nut with SST.

SST 09318±12010

HINT: Measure the preload while tightening the

bearing adjusting nut a little at a time.

6. CHECK TOOTH CONTACT

(a) Coat 3 or 4 teeth at four different positions on the

ring gear with red lead.

(b) Rotate the ring gear, inspect the teeth pattern.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Lower Valve Body

A540H)AT±374

Trending: bolt pattern, fog light, fuel pump, fuse, lock, wiper blades, horn