TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: checking oil, instrument, parking brake, wipers, low oil pressure, timing belt, engine oil

Page 591 of 2389

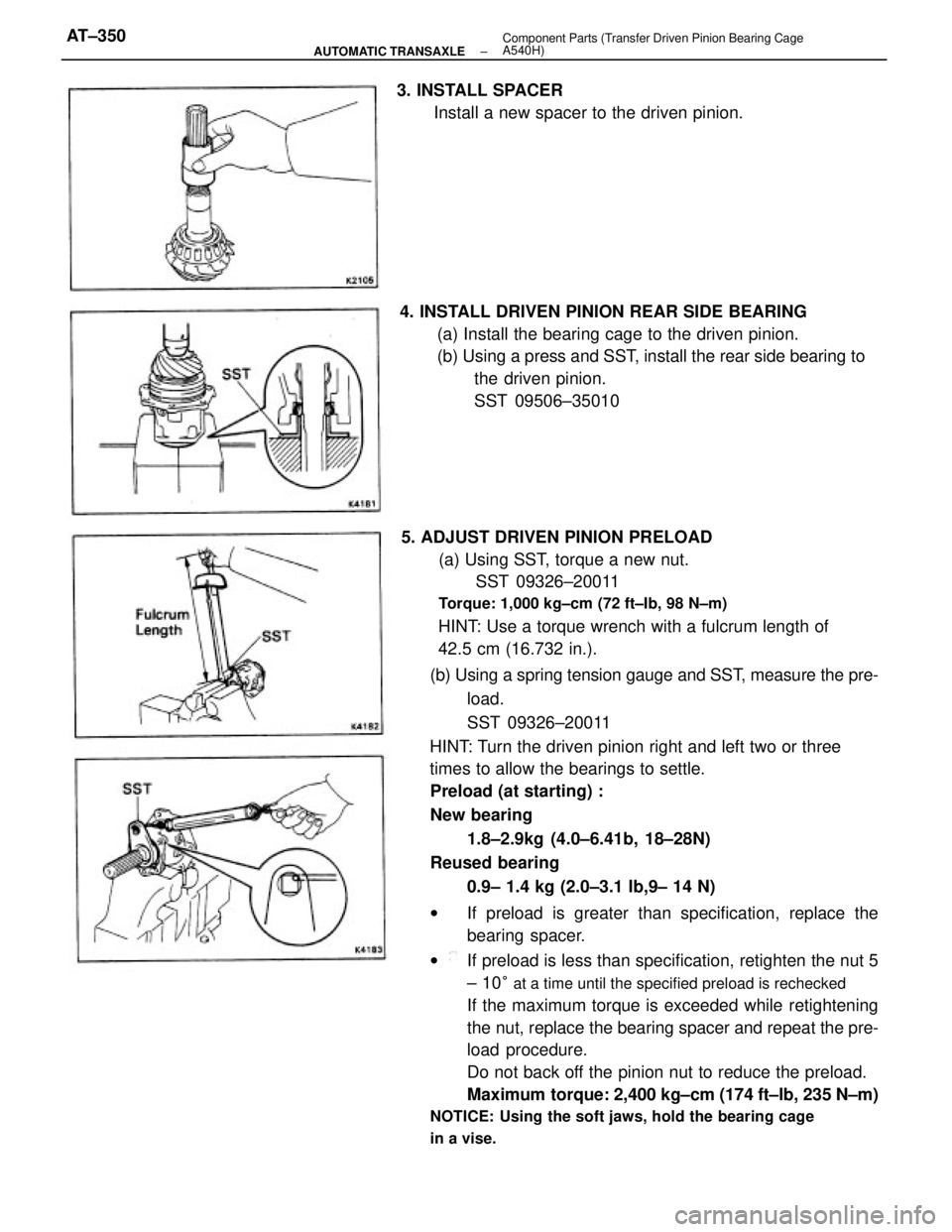

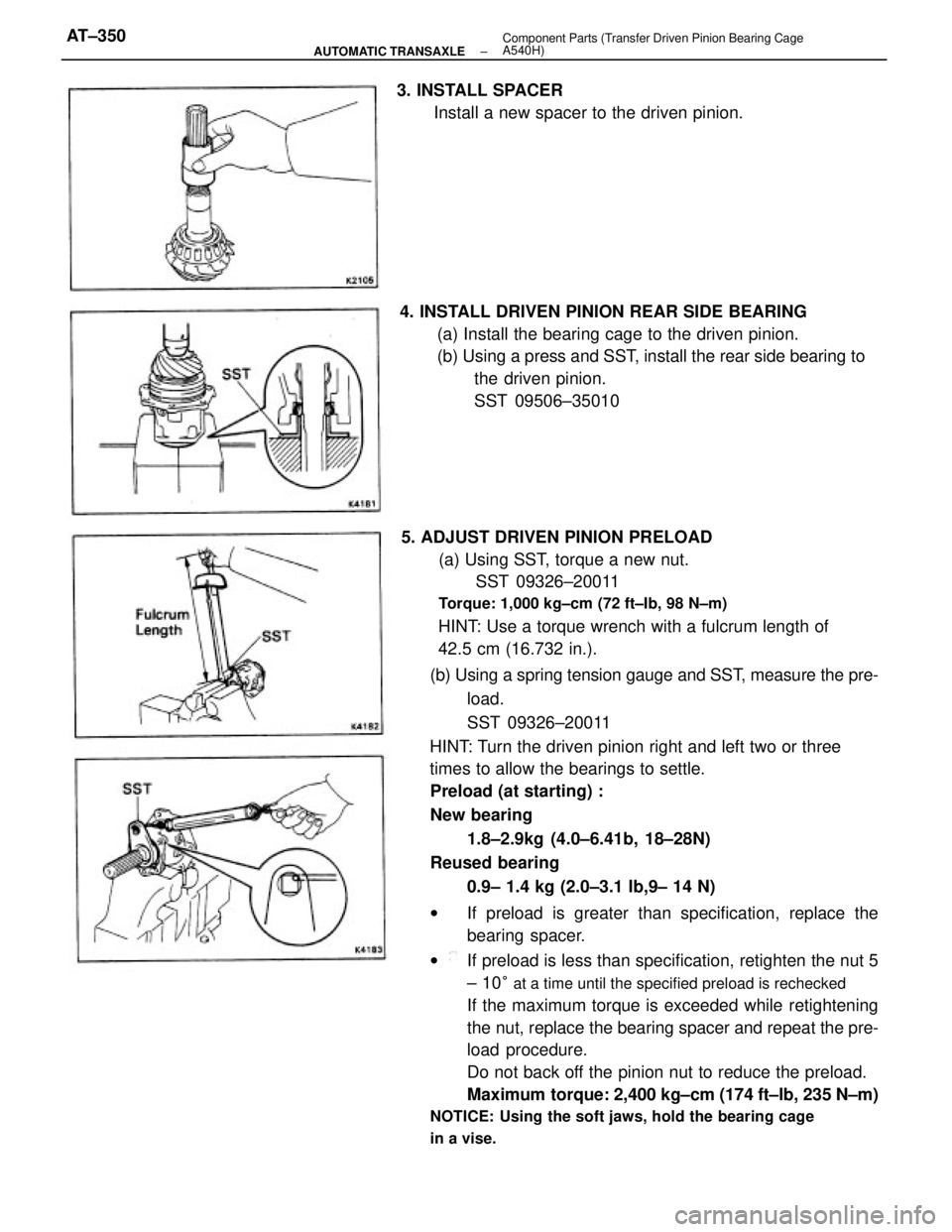

(b) Using a spring tension gauge and SST, measure the pre-

load.

SST 09326±20011

HINT: Turn the driven pinion right and left two or three

times to allow the bearings to settle.

Preload (at starting) :

New bearing

1.8±2.9kg (4.0±6.41b, 18±28N)

Reused bearing

0.9± 1.4 kg (2.0±3.1 Ib,9± 14 N)

wIf preload is greater than specification, replace the

bearing spacer.

wIf preload is less than specification, retighten the nut 5

± 10

° at a time until the specified preload is rechecked

If the maximum torque is exceeded while retightening

the nut, replace the bearing spacer and repeat the pre-

load procedure.

Do not back off the pinion nut to reduce the preload.

Maximum torque: 2,400 kg±cm (174 ft±Ib, 235 N±m)

NOTICE: Using the soft jaws, hold the bearing cage

in a vise.

5. ADJUST DRIVEN PINION PRELOAD

(a) Using SST, torque a new nut.

SST 09326±20011

Torque: 1,000 kg±cm (72 ft±Ib, 98 N±m)

HINT: Use a torque wrench with a fulcrum length of

42.5 cm (16.732 in.). 4. INSTALL DRIVEN PINION REAR SIDE BEARING

(a) Install the bearing cage to the driven pinion.

(b) Using a press and SST, install the rear side bearing to

the driven pinion.

SST 09506±35010 3. INSTALL SPACER

Install a new spacer to the driven pinion.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Driven Pinion Bearing Cage

A540H)AT±350

Page 592 of 2389

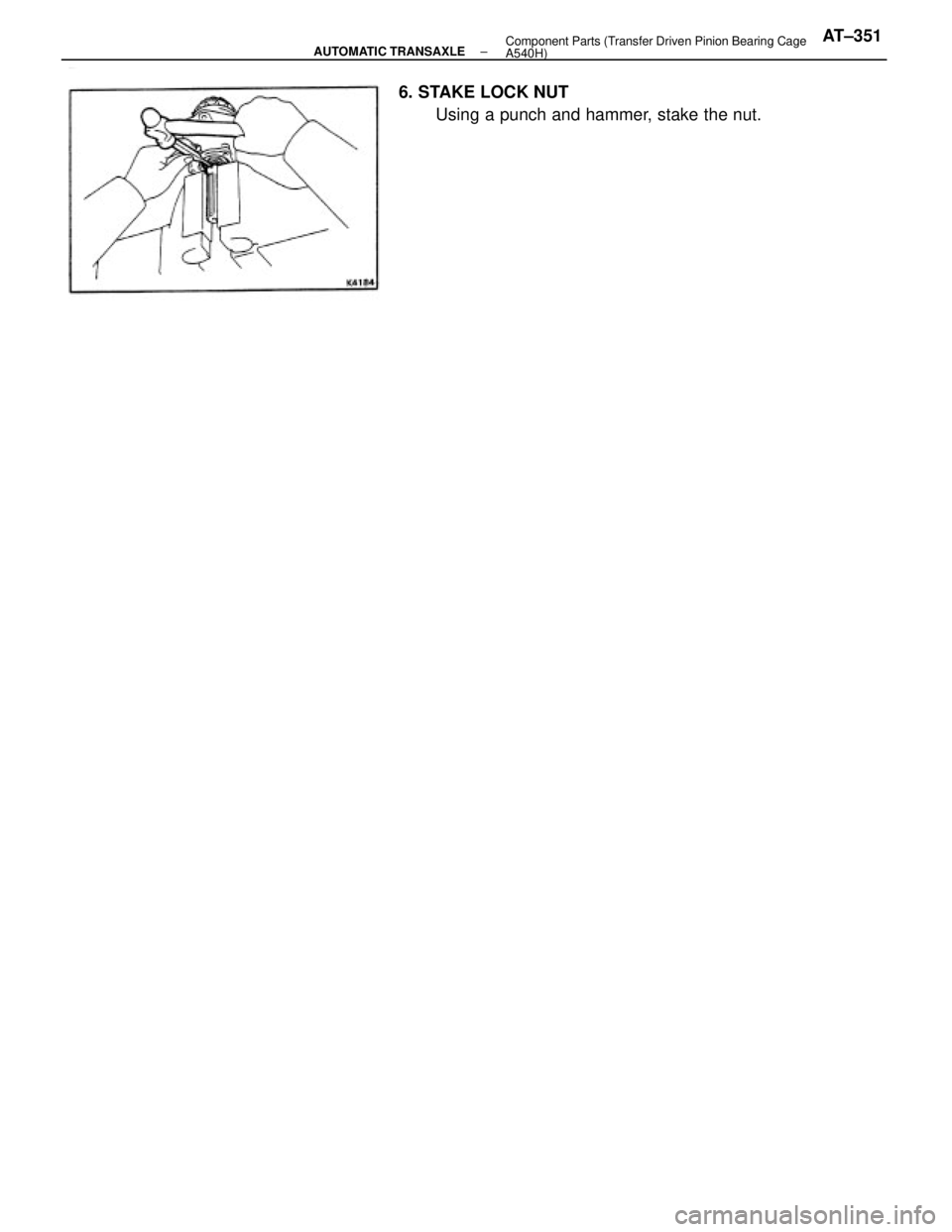

6. STAKE LOCK NUT

Using a punch and hammer, stake the nut.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Driven Pinion Bearing Cage

A540H)AT±351

Page 593 of 2389

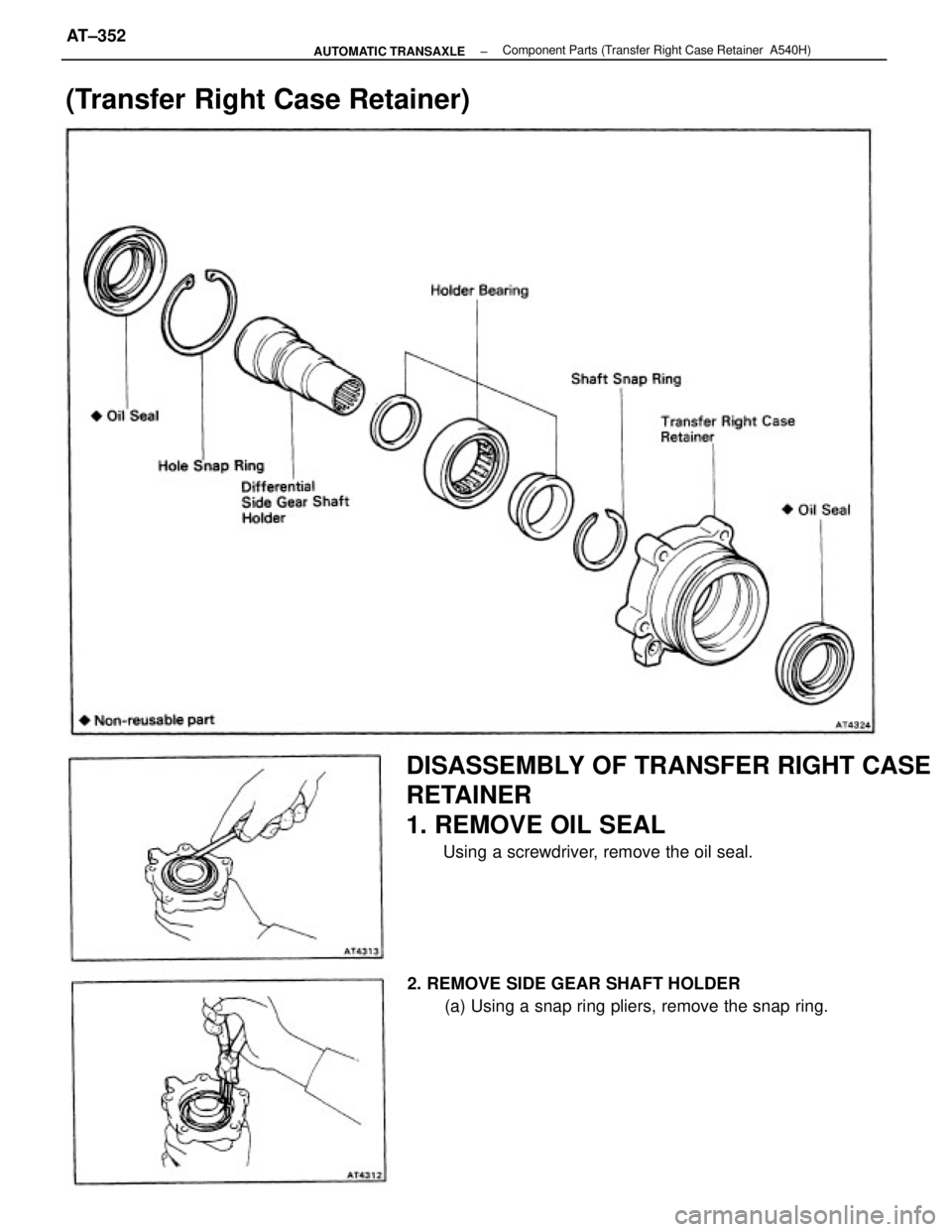

DISASSEMBLY OF TRANSFER RIGHT CASE

RETAINER

1. REMOVE OIL SEAL

Using a screwdriver, remove the oil seal.

2. REMOVE SIDE GEAR SHAFT HOLDER

(a) Using a snap ring pliers, remove the snap ring.

(Transfer Right Case Retainer)

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Right Case Retainer A540H)AT±352

Page 594 of 2389

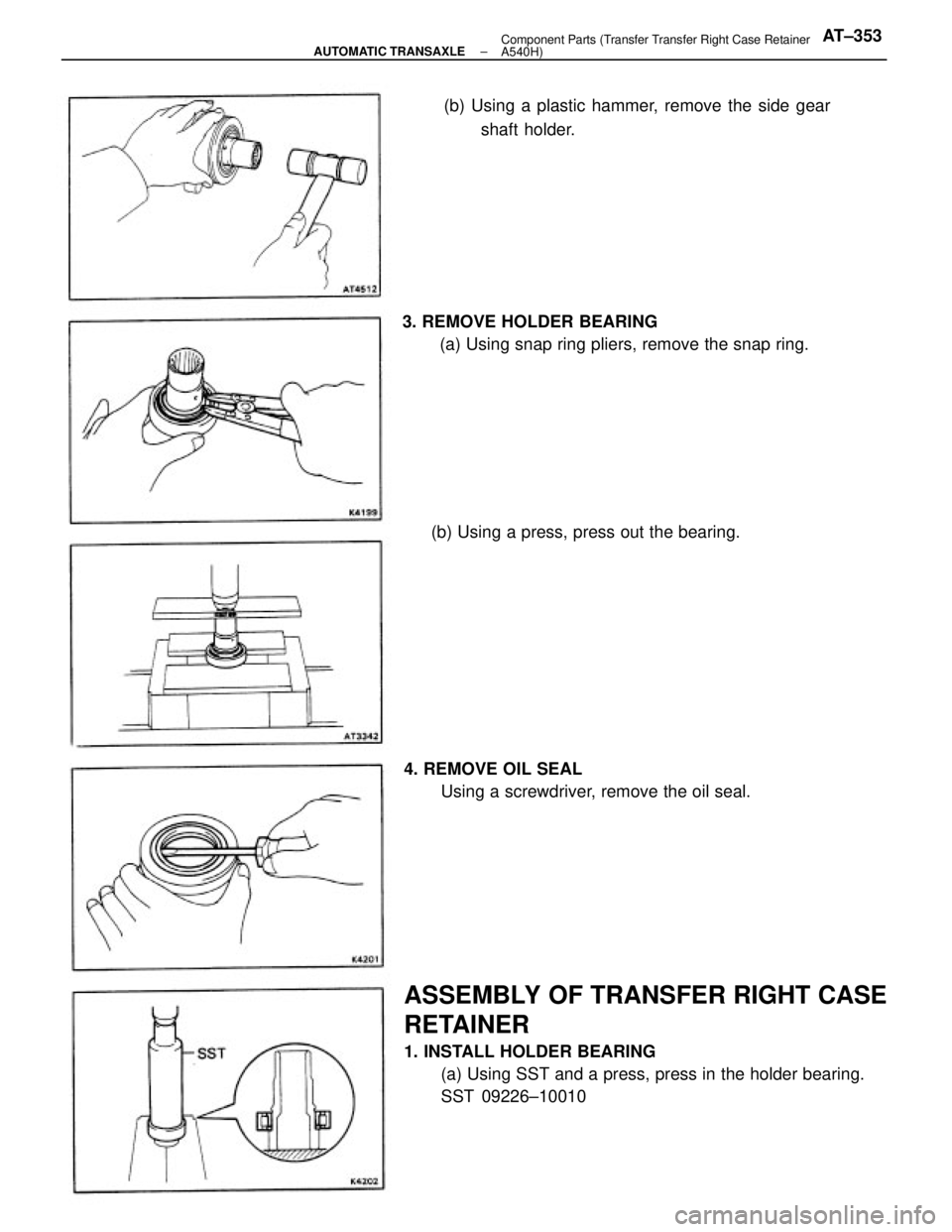

ASSEMBLY OF TRANSFER RIGHT CASE

RETAINER

1. INSTALL HOLDER BEARING

(a) Using SST and a press, press in the holder bearing.

SST 09226±10010 3. REMOVE HOLDER BEARING

(a) Using snap ring pliers, remove the snap ring.(b) Using a plastic hammer, remove the side gear

shaft holder.

4. REMOVE OIL SEAL

Using a screwdriver, remove the oil seal. (b) Using a press, press out the bearing.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Right Case Retainer

A540H)AT±353

Page 595 of 2389

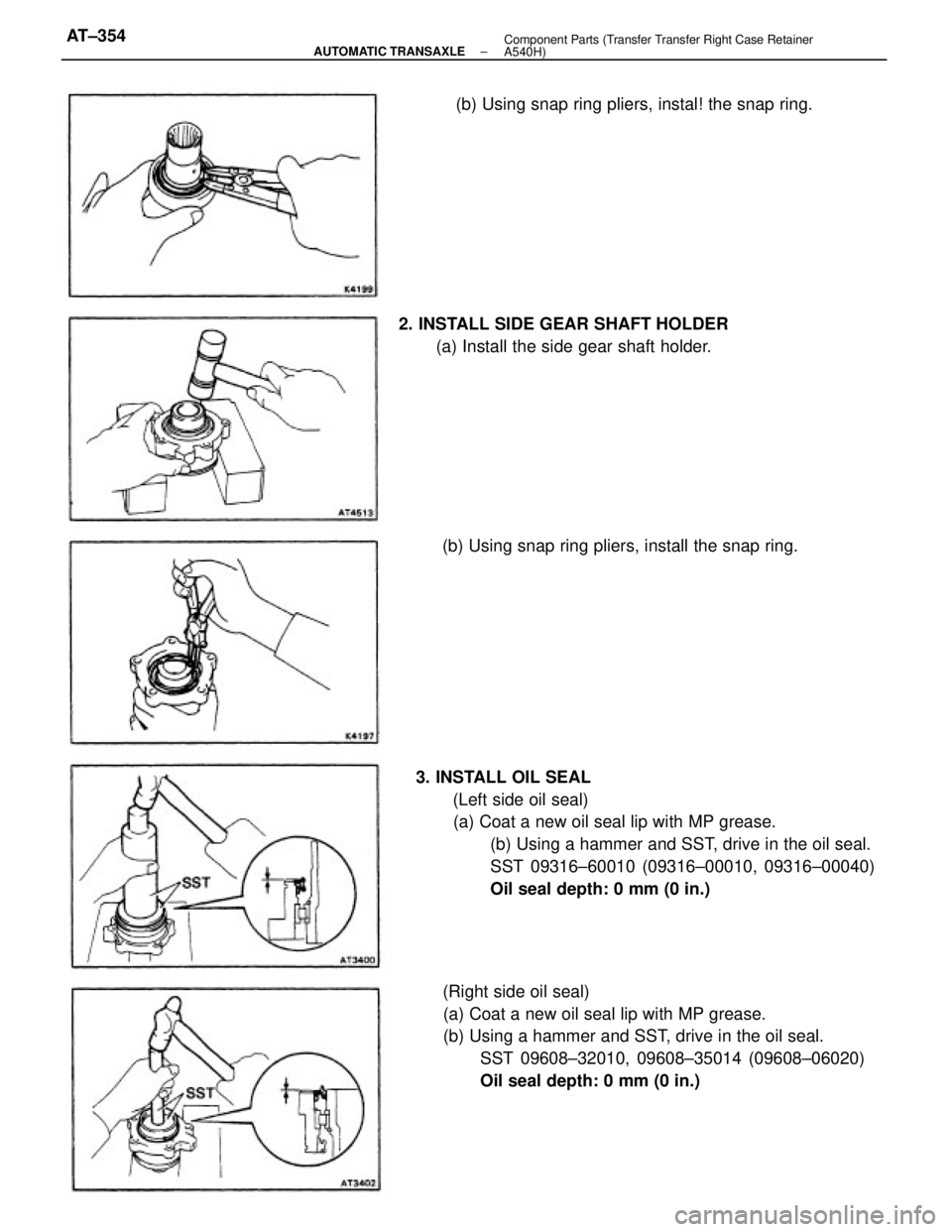

3. INSTALL OIL SEAL

(Left side oil seal)

(a) Coat a new oil seal lip with MP grease.

(b) Using a hammer and SST, drive in the oil seal.

SST 09316±60010 (09316±00010, 09316±00040)

Oil seal depth: 0 mm (0 in.)

(Right side oil seal)

(a) Coat a new oil seal lip with MP grease.

(b) Using a hammer and SST, drive in the oil seal.

SST 09608±32010, 09608±35014 (09608±06020)

Oil seal depth: 0 mm (0 in.) (b) Using snap ring pliers, instal! the snap ring.

2. INSTALL SIDE GEAR SHAFT HOLDER

(a) Install the side gear shaft holder.

(b) Using snap ring pliers, install the snap ring.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Right Case Retainer

A540H)AT±354

Page 596 of 2389

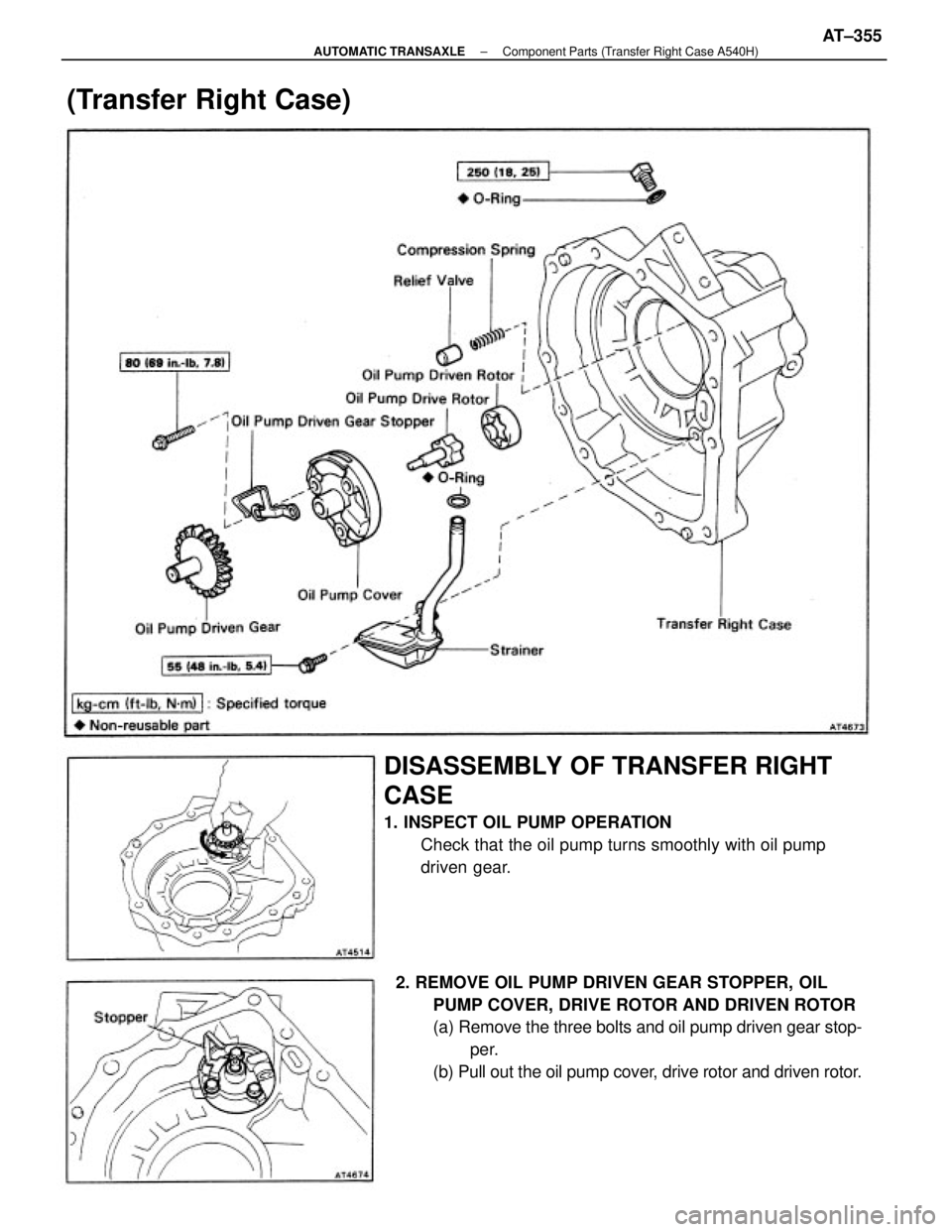

2. REMOVE OIL PUMP DRIVEN GEAR STOPPER, OIL

PUMP COVER, DRIVE ROTOR AND DRIVEN ROTOR

(a) Remove the three bolts and oil pump driven gear stop-

per.

(b) Pull out the oil pump cover, drive rotor and driven rotor.

DISASSEMBLY OF TRANSFER RIGHT

CASE

1. INSPECT OIL PUMP OPERATION

Check that the oil pump turns smoothly with oil pump

driven gear.

(Transfer Right Case)

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Right Case A540H)AT±355

Page 597 of 2389

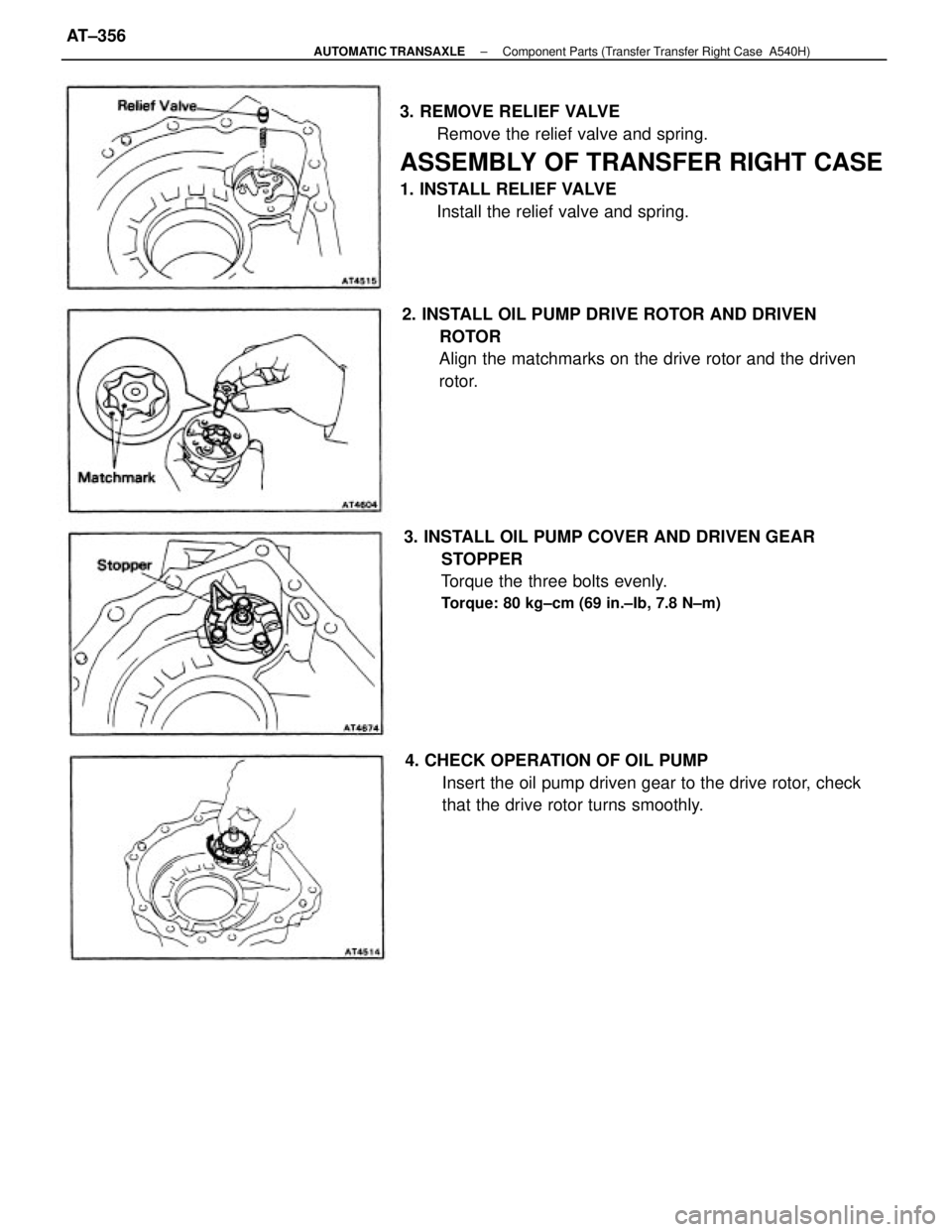

3. REMOVE RELIEF VALVE

Remove the relief valve and spring.

ASSEMBLY OF TRANSFER RIGHT CASE

1. INSTALL RELIEF VALVE

Install the relief valve and spring.

3. INSTALL OIL PUMP COVER AND DRIVEN GEAR

STOPPER

Torque the three bolts evenly.

Torque: 80 kg±cm (69 in.±Ib, 7.8 N±m)

2. INSTALL OIL PUMP DRIVE ROTOR AND DRIVEN

ROTOR

Align the matchmarks on the drive rotor and the driven

rotor.

4. CHECK OPERATION OF OIL PUMP

Insert the oil pump driven gear to the drive rotor, check

that the drive rotor turns smoothly.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Right Case A540H)AT±356

Page 598 of 2389

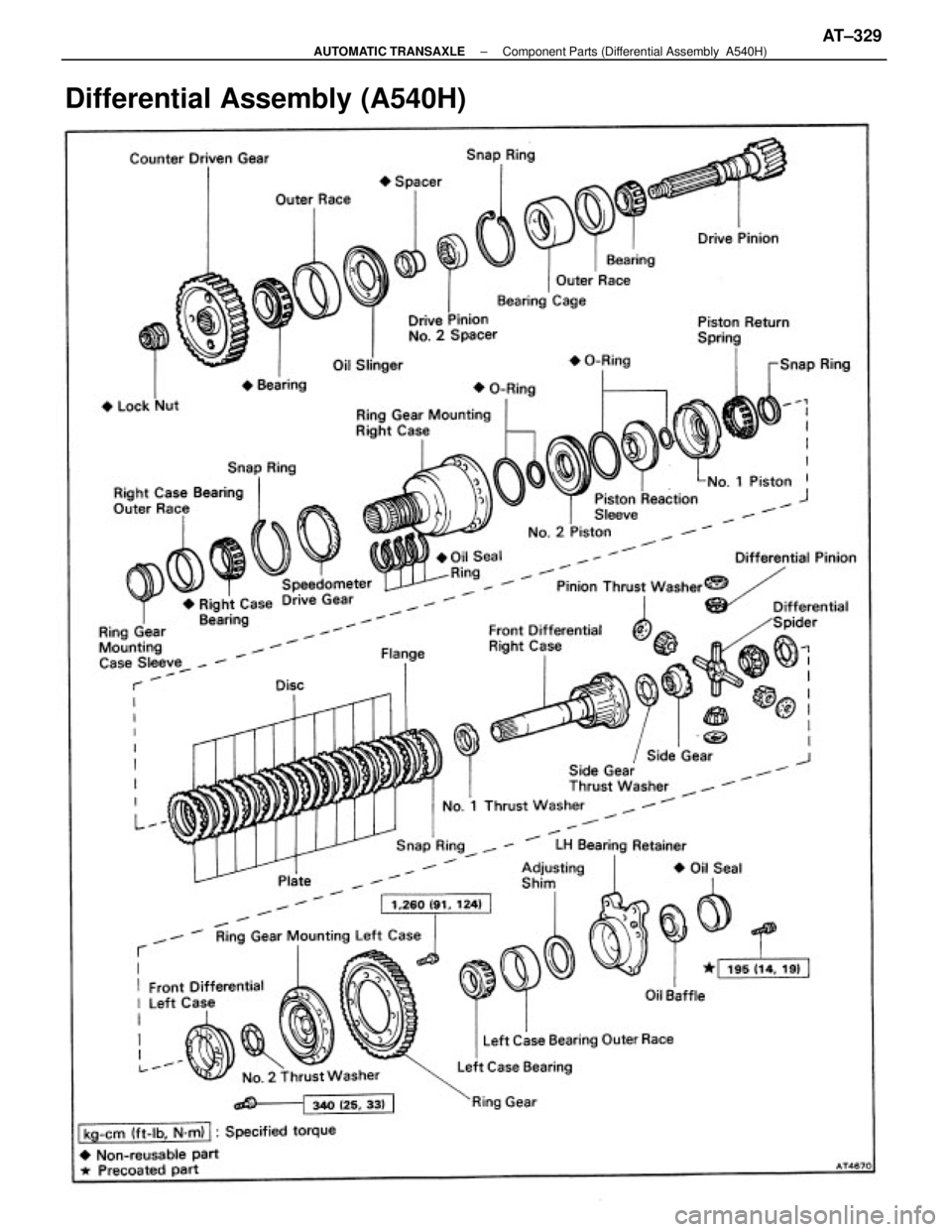

Differential Assembly (A540H)

± AUTOMATIC TRANSAXLEComponent Parts (Differential Assembly A540H)AT±329

Page 599 of 2389

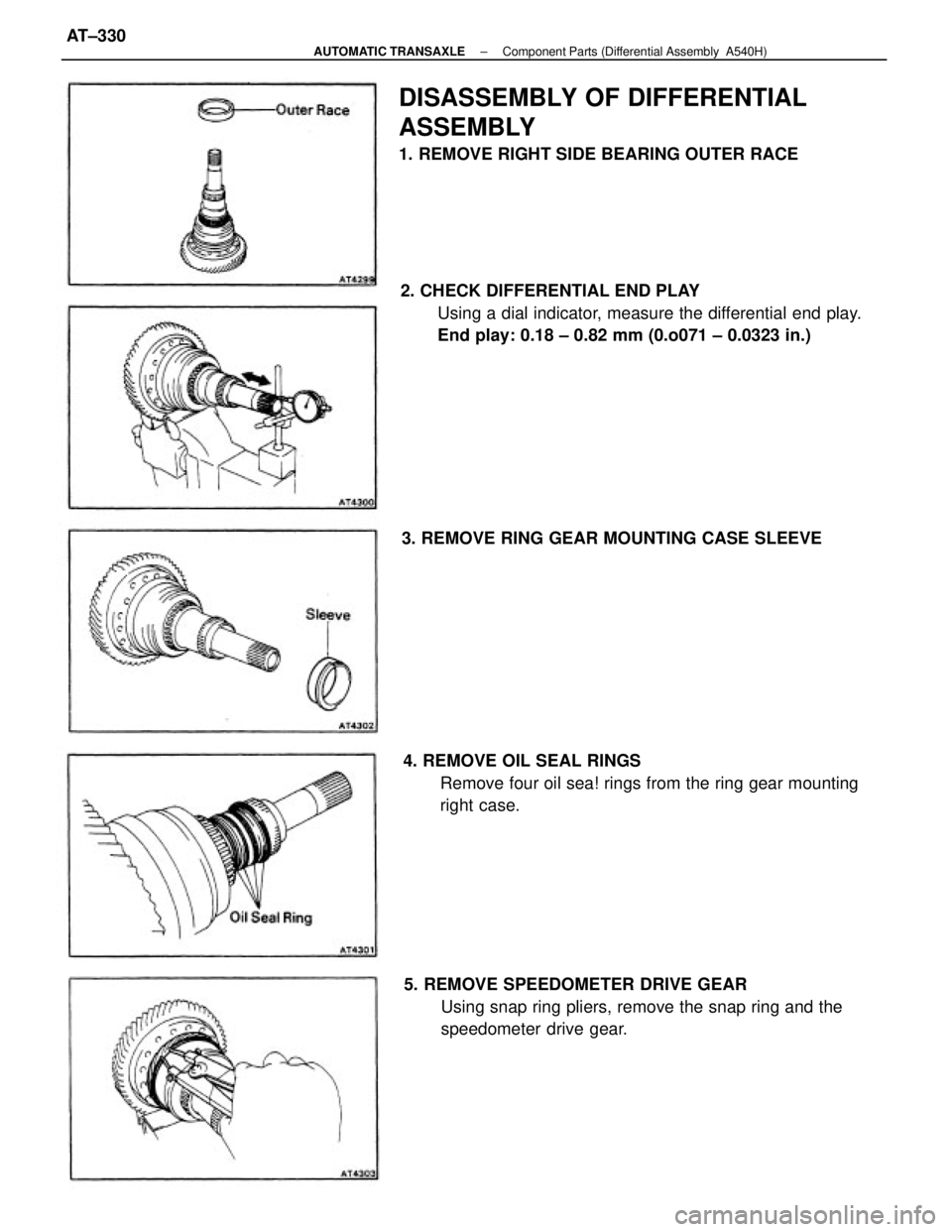

2. CHECK DIFFERENTIAL END PLAY

Using a dial indicator, measure the differential end play.

End play: 0.18 ± 0.82 mm (0.o071 ± 0.0323 in.)

DISASSEMBLY OF DIFFERENTIAL

ASSEMBLY

1. REMOVE RIGHT SIDE BEARING OUTER RACE

4. REMOVE OIL SEAL RINGS

Remove four oil sea! rings from the ring gear mounting

right case.

5. REMOVE SPEEDOMETER DRIVE GEAR

Using snap ring pliers, remove the snap ring and the

speedometer drive gear. 3. REMOVE RING GEAR MOUNTING CASE SLEEVE

± AUTOMATIC TRANSAXLEComponent Parts (Differential Assembly A540H)AT±330

Page 600 of 2389

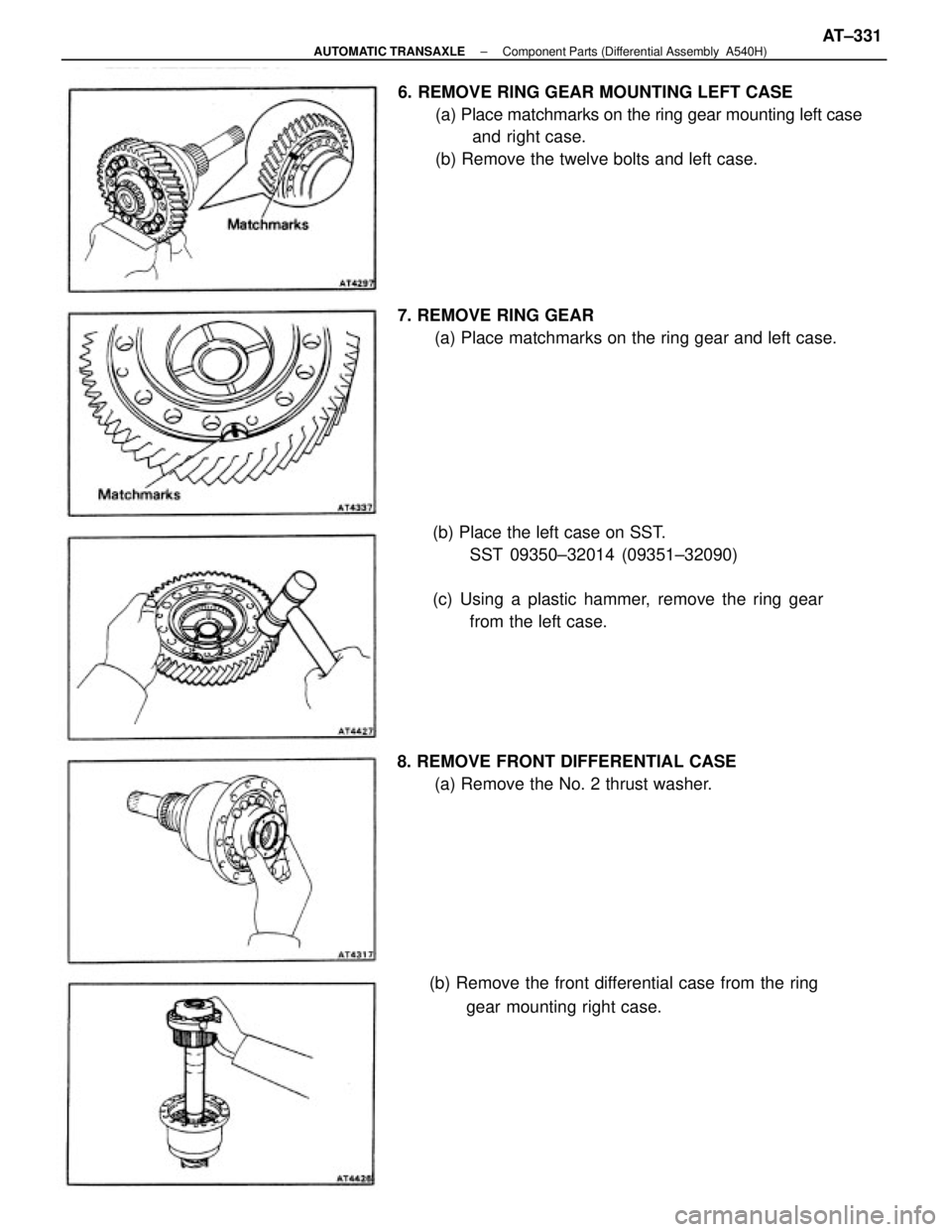

6. REMOVE RING GEAR MOUNTING LEFT CASE

(a) Place matchmarks on the ring gear mounting left case

and right case.

(b) Remove the twelve bolts and left case.

(b) Place the left case on SST.

SST 09350±32014 (09351±32090)

(c) Using a plastic hammer, remove the ring gear

from the left case. 7. REMOVE RING GEAR

(a) Place matchmarks on the ring gear and left case.

(b) Remove the front differential case from the ring

gear mounting right case. 8. REMOVE FRONT DIFFERENTIAL CASE

(a) Remove the No. 2 thrust washer.

± AUTOMATIC TRANSAXLEComponent Parts (Differential Assembly A540H)AT±331

Trending: ESP, air conditioning relay, battery location, service interval, electrical, length, fuse diagram