TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: brake light, hood release, trunk release, key battery, alternator belt, AUX, roof rack

Page 611 of 2389

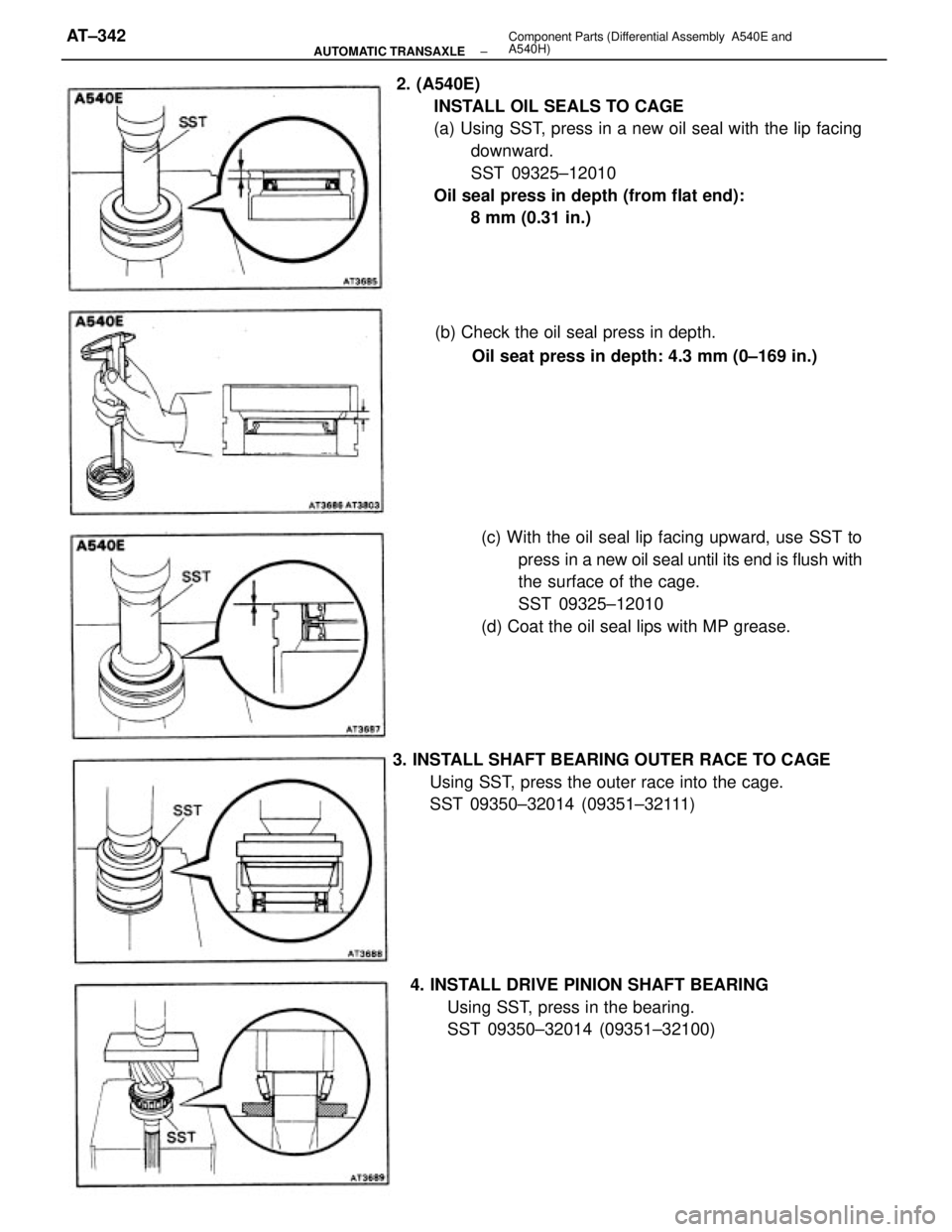

2. (A540E)

INSTALL OIL SEALS TO CAGE

(a) Using SST, press in a new oil seal with the lip facing

downward.

SST 09325±12010

Oil seal press in depth (from flat end):

8 mm (0.31 in.)

(c) With the oil seal lip facing upward, use SST to

press in a new oil seal until its end is flush with

the surface of the cage.

SST 09325±12010

(d) Coat the oil seal lips with MP grease.

3. INSTALL SHAFT BEARING OUTER RACE TO CAGE

Using SST, press the outer race into the cage.

SST 09350±32014 (09351±32111)

4. INSTALL DRIVE PINION SHAFT BEARING

Using SST, press in the bearing.

SST 09350±32014 (09351±32100) (b) Check the oil seal press in depth.

Oil seat press in depth: 4.3 mm (0±169 in.)

± AUTOMATIC TRANSAXLEComponent Parts (Differential Assembly A540E and

A540H)AT±342

Page 612 of 2389

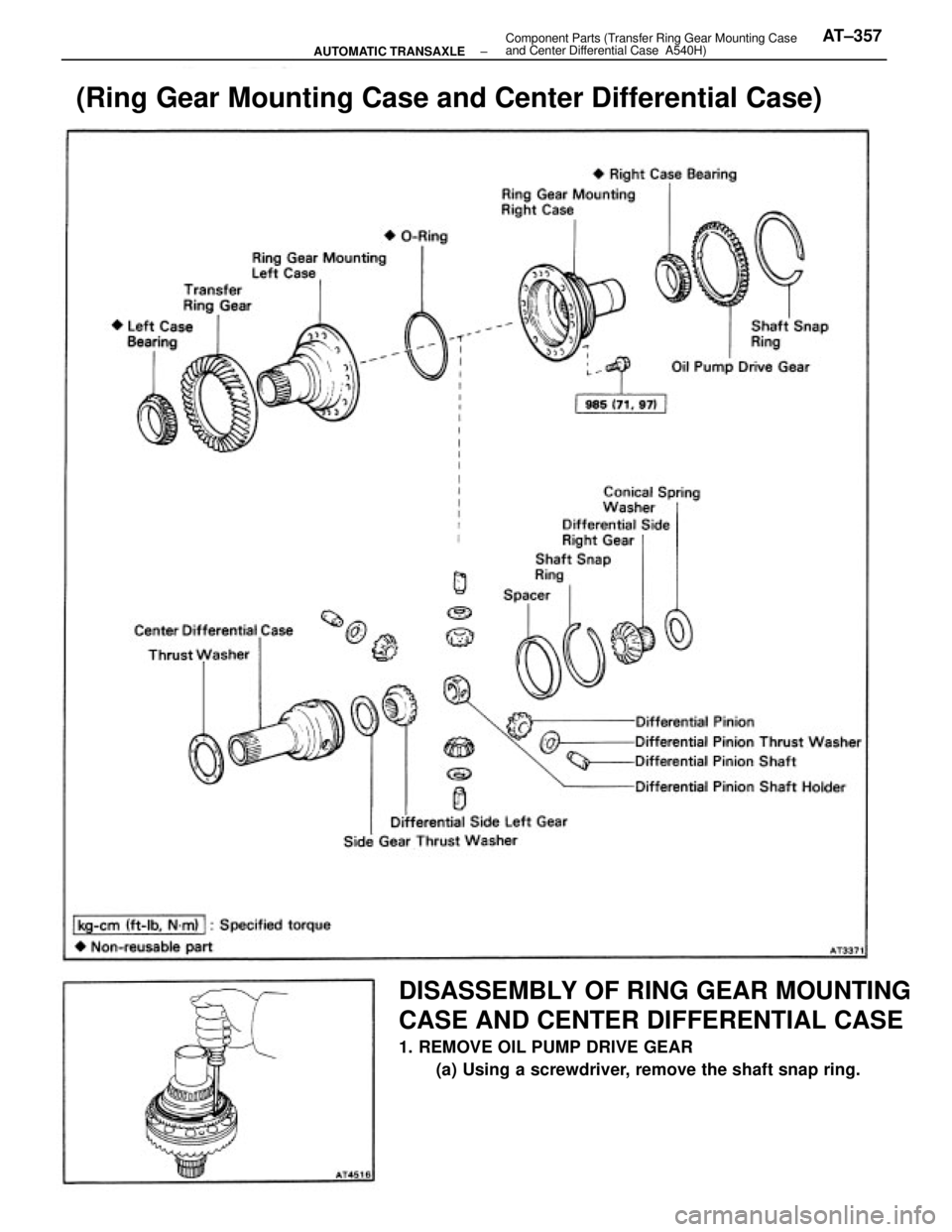

DISASSEMBLY OF RING GEAR MOUNTING

CASE AND CENTER DIFFERENTIAL CASE

1. REMOVE OIL PUMP DRIVE GEAR

(a) Using a screwdriver, remove the shaft snap ring.

(Ring Gear Mounting Case and Center Differential Case)

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Ring Gear Mounting Case

and Center Differential Case A540H)AT±357

Page 613 of 2389

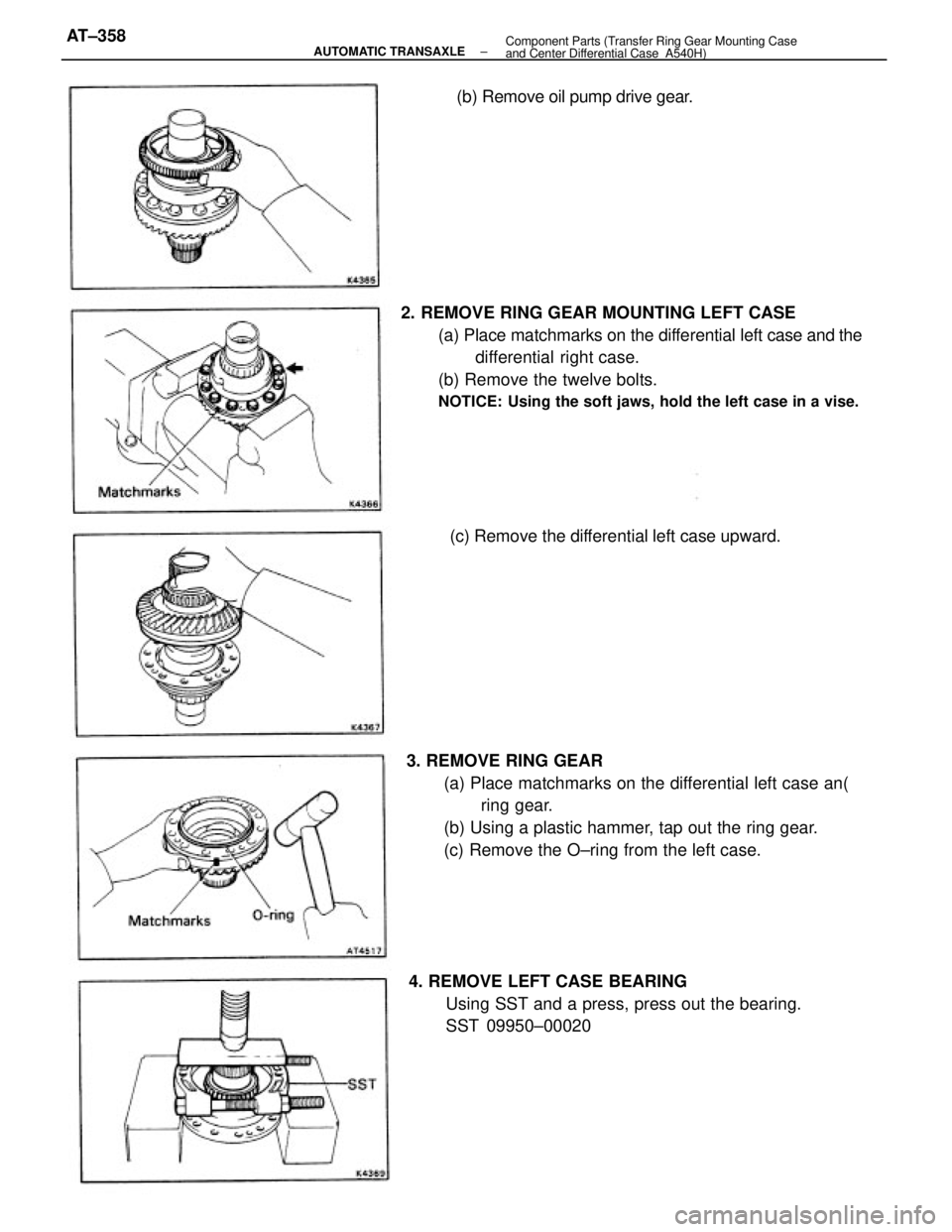

2. REMOVE RING GEAR MOUNTING LEFT CASE

(a) Place matchmarks on the differential left case and the

differential right case.

(b) Remove the twelve bolts.

NOTICE: Using the soft jaws, hold the left case in a vise.

3. REMOVE RING GEAR

(a) Place matchmarks on the differential left case an(

ring gear.

(b) Using a plastic hammer, tap out the ring gear.

(c) Remove the O±ring from the left case.

4. REMOVE LEFT CASE BEARING

Using SST and a press, press out the bearing.

SST 09950±00020(c) Remove the differential left case upward.(b) Remove oil pump drive gear.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Ring Gear Mounting Case

and Center Differential Case A540H)AT±358

Page 614 of 2389

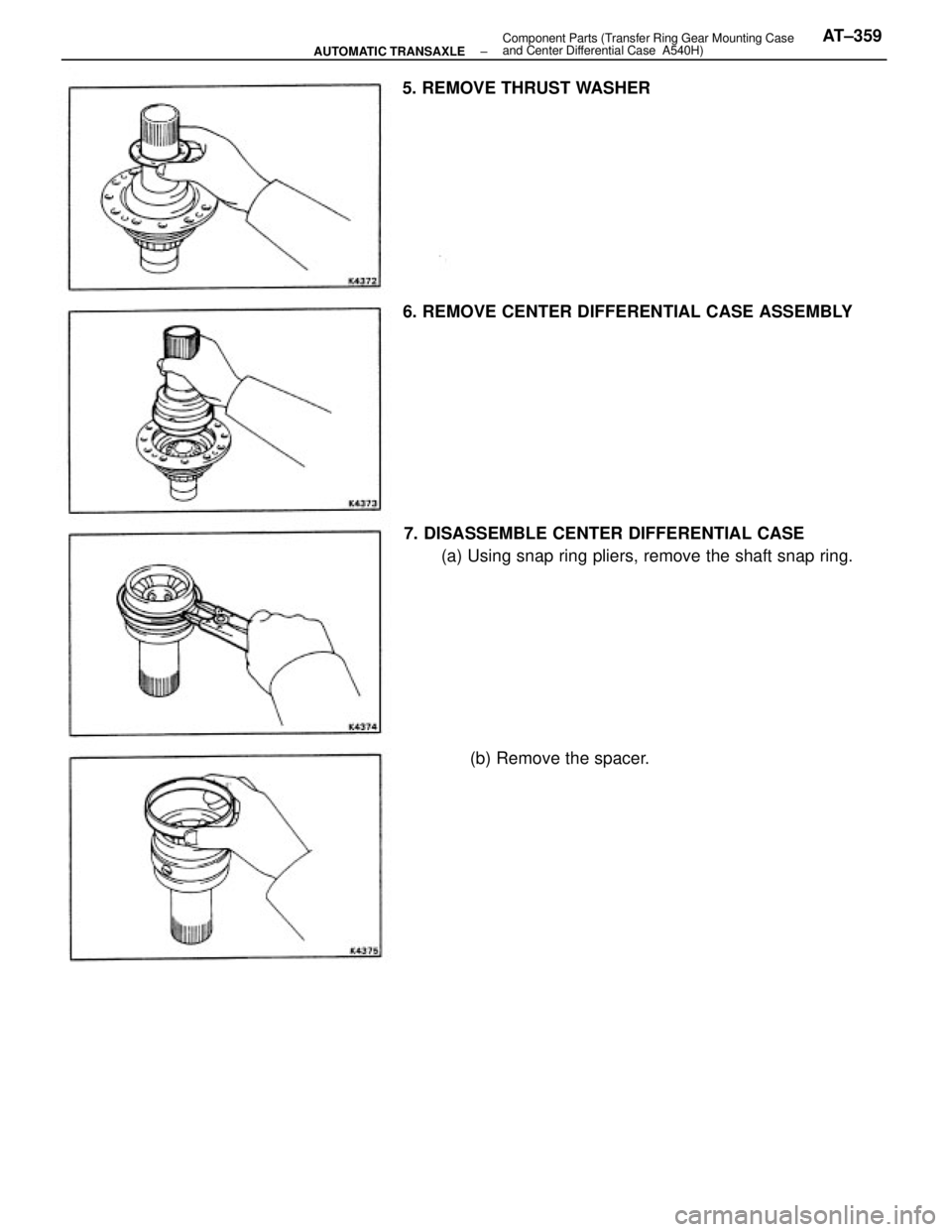

7. DISASSEMBLE CENTER DIFFERENTIAL CASE

(a) Using snap ring pliers, remove the shaft snap ring. 6. REMOVE CENTER DIFFERENTIAL CASE ASSEMBLY 5. REMOVE THRUST WASHER

(b) Remove the spacer.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Ring Gear Mounting Case

and Center Differential Case A540H)AT±359

Page 615 of 2389

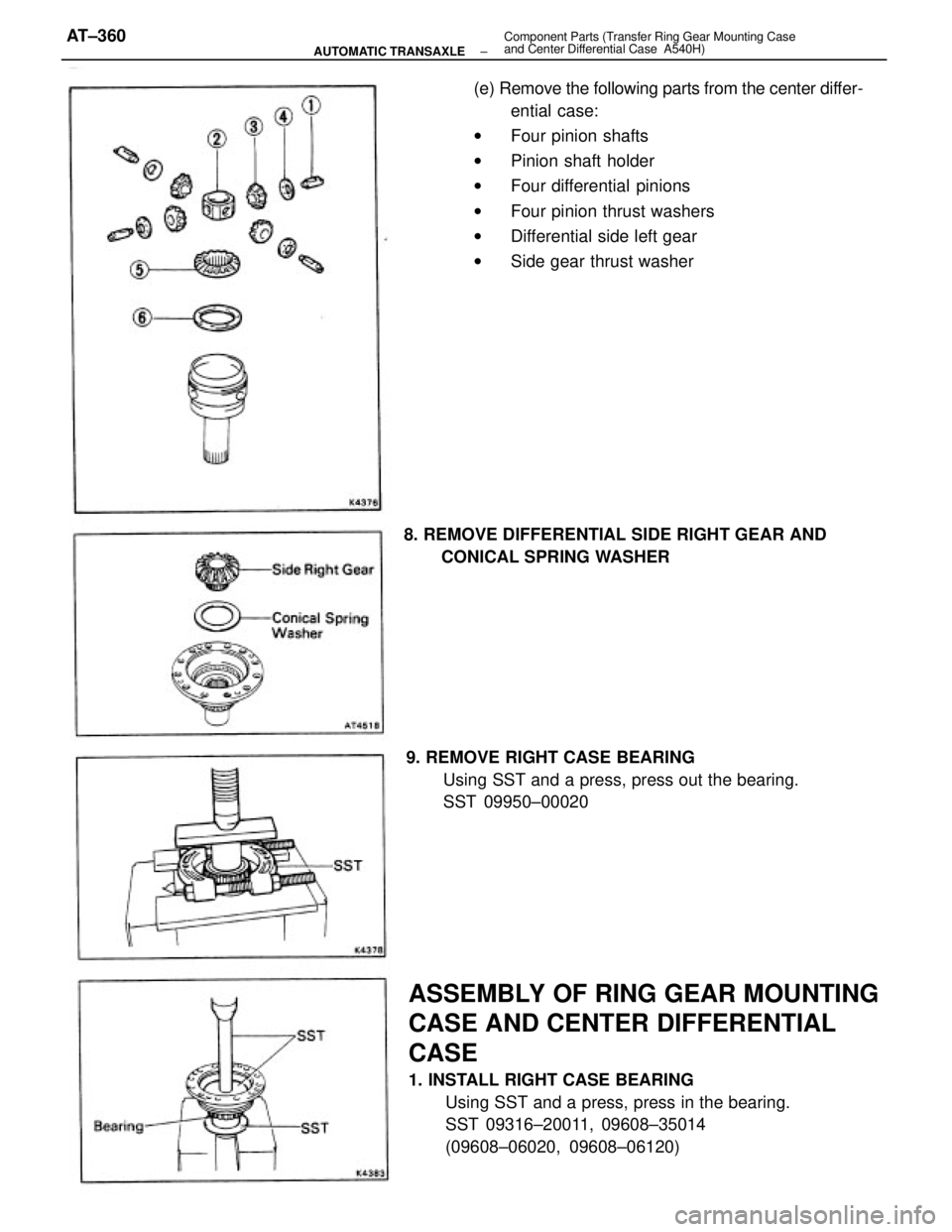

(e) Remove the following parts from the center differ-

ential case:

wFour pinion shafts

wPinion shaft holder

wFour differential pinions

wFour pinion thrust washers

wDifferential side left gear

wSide gear thrust washer

ASSEMBLY OF RING GEAR MOUNTING

CASE AND CENTER DIFFERENTIAL

CASE

1. INSTALL RIGHT CASE BEARING

Using SST and a press, press in the bearing.

SST 09316±20011, 09608±35014

(09608±06020, 09608±06120) 9. REMOVE RIGHT CASE BEARING

Using SST and a press, press out the bearing.

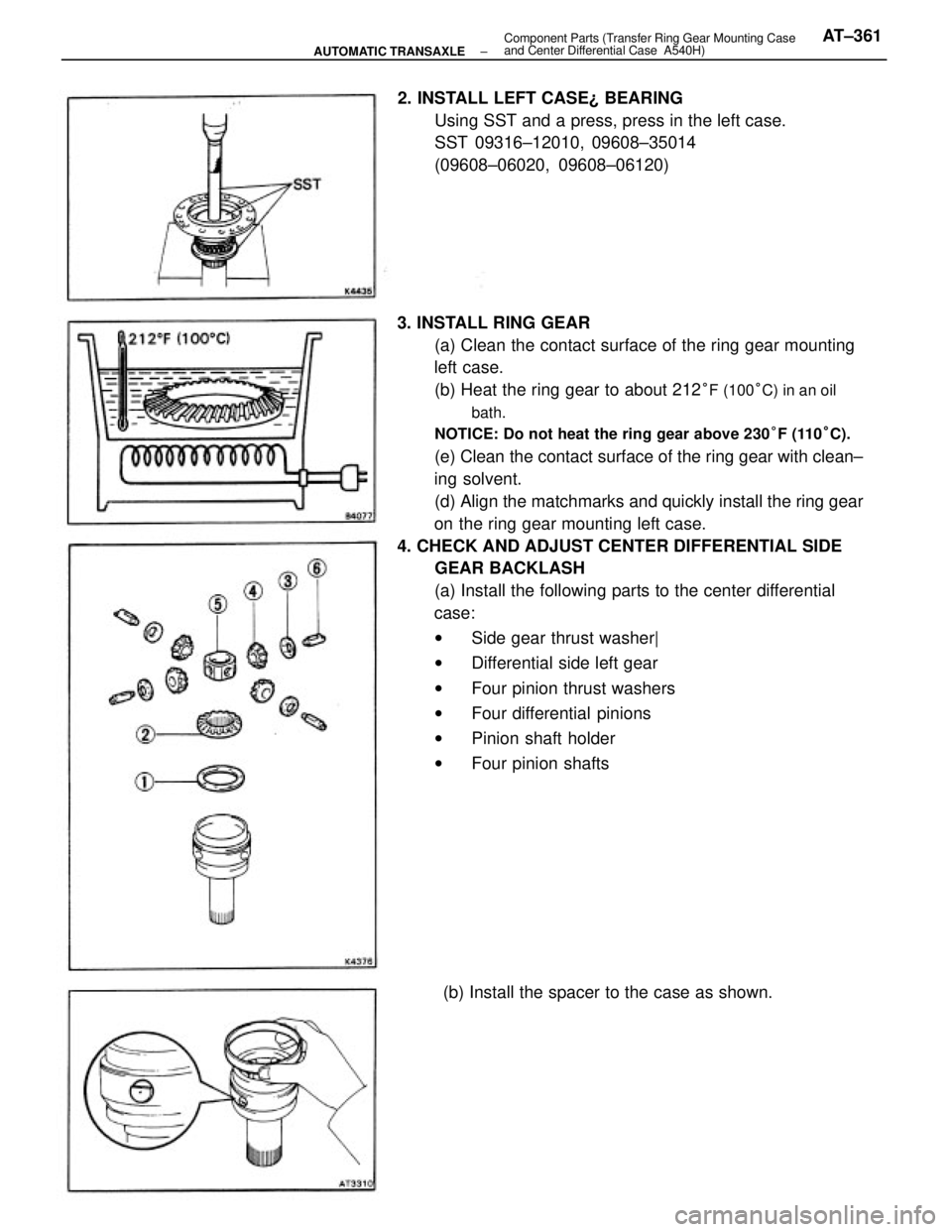

SST 09950±00020 8. REMOVE DIFFERENTIAL SIDE RIGHT GEAR AND

CONICAL SPRING WASHER

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Ring Gear Mounting Case

and Center Differential Case A540H)AT±360

Page 616 of 2389

3. INSTALL RING GEAR

(a) Clean the contact surface of the ring gear mounting

left case.

(b) Heat the ring gear to about 212

°F (100°C) in an oil

bath.

NOTICE: Do not heat the ring gear above 230°F (110°C).

(e) Clean the contact surface of the ring gear with clean±

ing solvent.

(d) Align the matchmarks and quickly install the ring gear

on the ring gear mounting left case.

4. CHECK AND ADJUST CENTER DIFFERENTIAL SIDE

GEAR BACKLASH

(a) Install the following parts to the center differential

case:

wSide gear thrust washer|

wDifferential side left gear

wFour pinion thrust washers

wFour differential pinions

wPinion shaft holder

wFour pinion shafts 2. INSTALL LEFT CASE¿ BEARING

Using SST and a press, press in the left case.

SST 09316±12010, 09608±35014

(09608±06020, 09608±06120)

(b) Install the spacer to the case as shown.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Ring Gear Mounting Case

and Center Differential Case A540H)AT±361

Page 617 of 2389

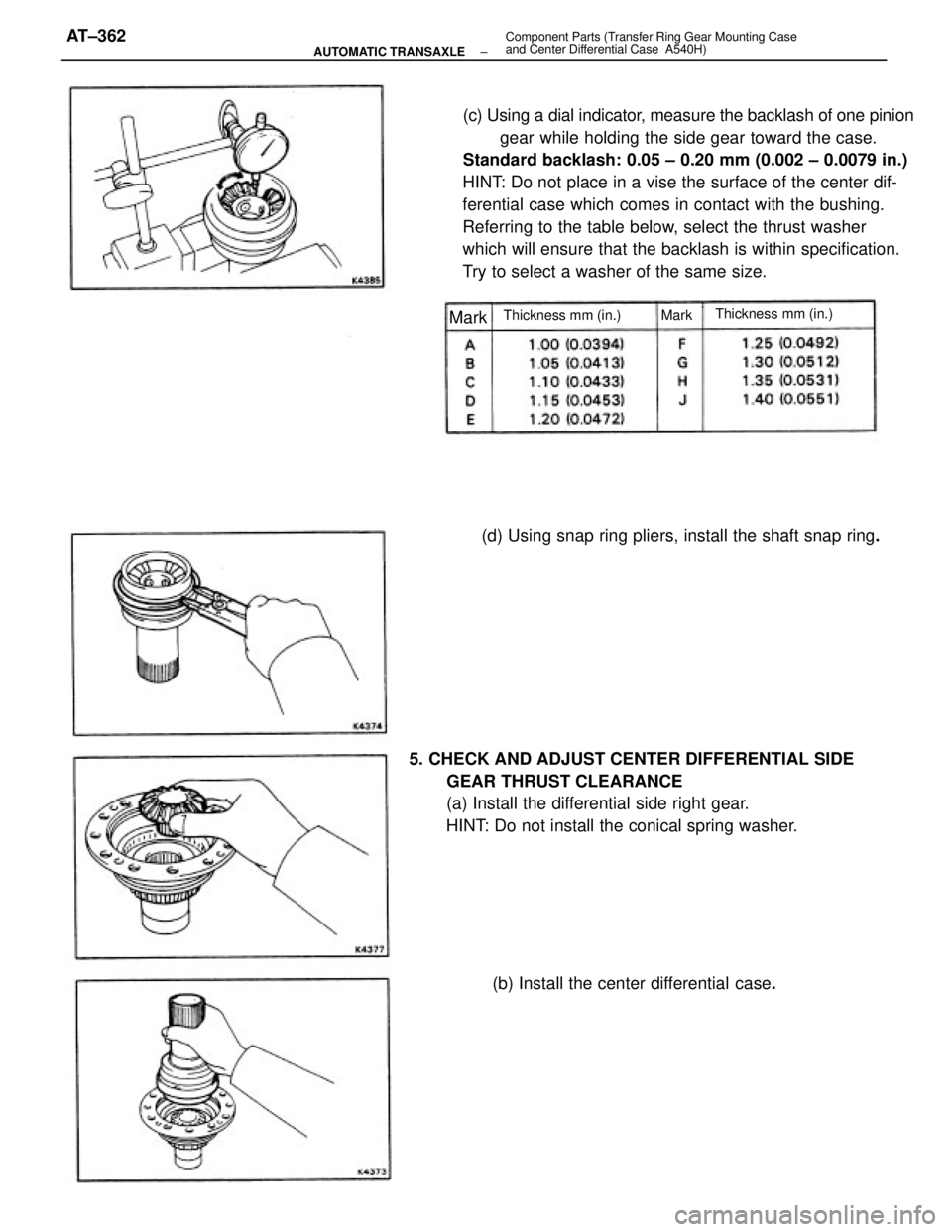

(c) Using a dial indicator, measure the backlash of one pinion

gear while holding the side gear toward the case.

Standard backlash: 0.05 ± 0.20 mm (0.002 ± 0.0079 in.)

HINT: Do not place in a vise the surface of the center dif-

ferential case which comes in contact with the bushing.

Referring to the table below, select the thrust washer

which will ensure that the backlash is within specification.

Try to select a washer of the same size.

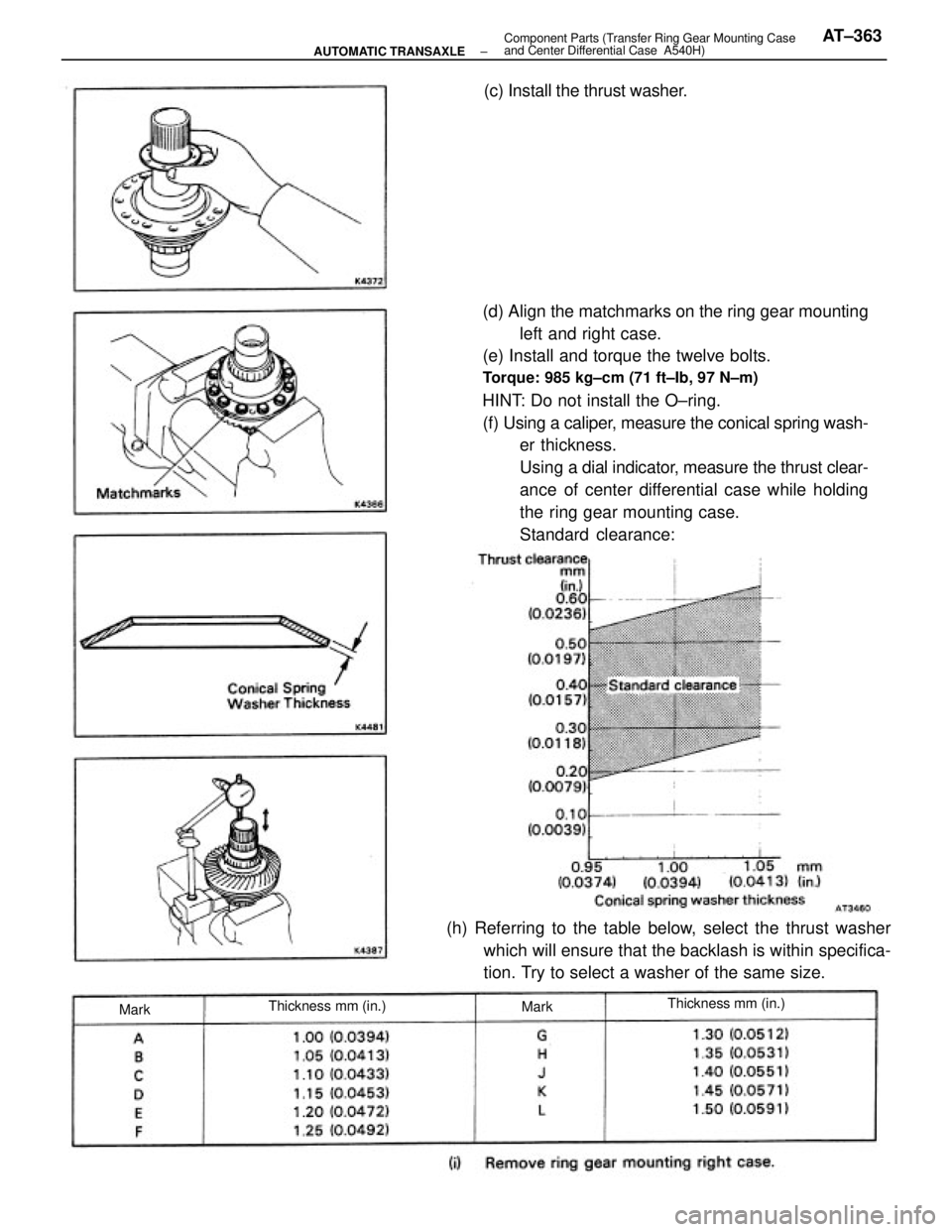

5. CHECK AND ADJUST CENTER DIFFERENTIAL SIDE

GEAR THRUST CLEARANCE

(a) Install the differential side right gear.

HINT: Do not install the conical spring washer.(d) Using snap ring pliers, install the shaft snap ring.

(b) Install the center differential case.

Thickness mm (in.)

Thickness mm (in.) MarkMark

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Ring Gear Mounting Case

and Center Differential Case A540H)AT±362

Page 618 of 2389

(d) Align the matchmarks on the ring gear mounting

left and right case.

(e) Install and torque the twelve bolts.

Torque: 985 kg±cm (71 ft±Ib, 97 N±m)

HINT: Do not install the O±ring.

(f) Using a caliper, measure the conical spring wash-

er thickness.

Using a dial indicator, measure the thrust clear-

ance of center differential case while holding

the ring gear mounting case.

Standard clearance:

(h) Referring to the table below, select the thrust washer

which will ensure that the backlash is within specifica-

tion. Try to select a washer of the same size.(c) Install the thrust washer.

Thickness mm (in.)Thickness mm (in.)

MarkMark

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Ring Gear Mounting Case

and Center Differential Case A540H)AT±363

Page 619 of 2389

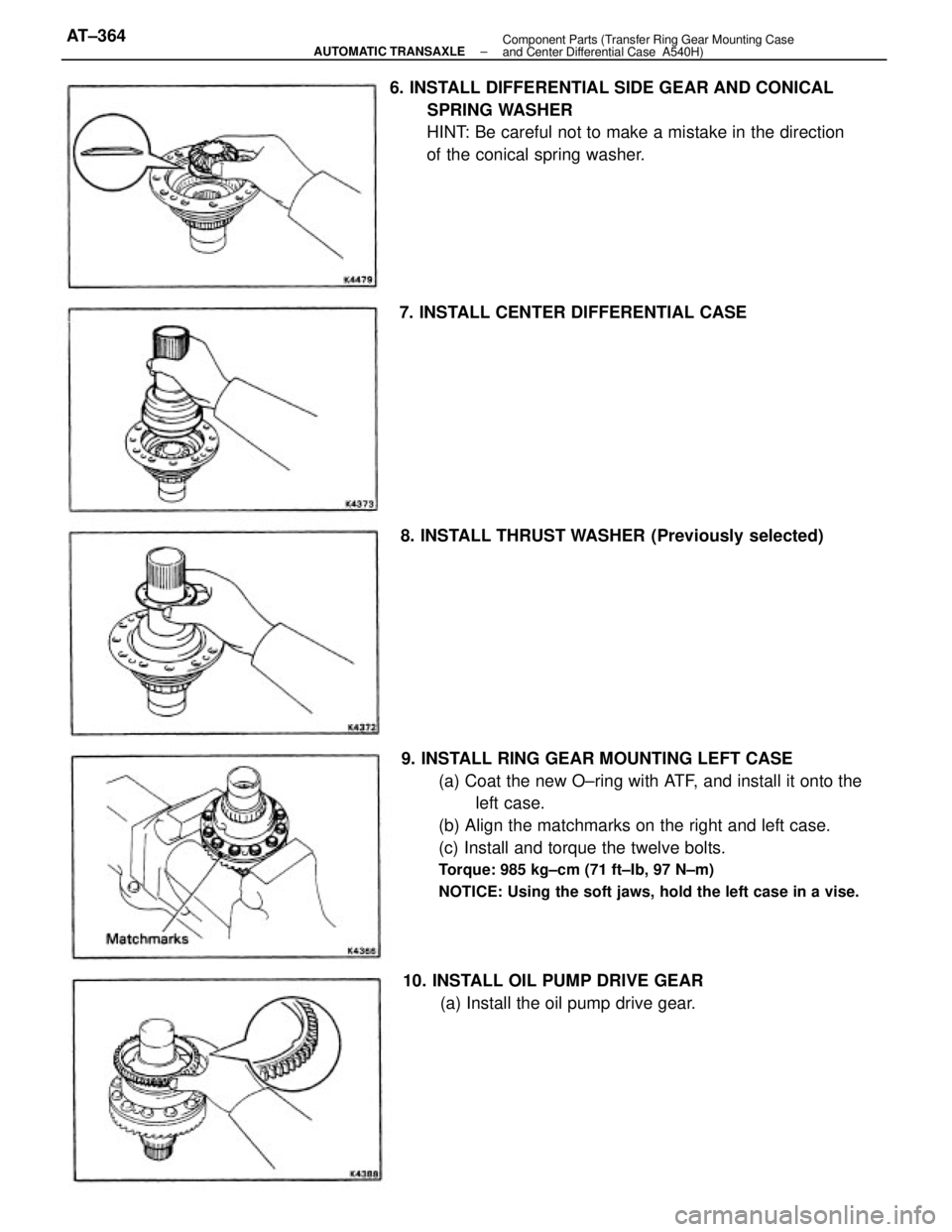

9. INSTALL RING GEAR MOUNTING LEFT CASE

(a) Coat the new O±ring with ATF, and install it onto the

left case.

(b) Align the matchmarks on the right and left case.

(c) Install and torque the twelve bolts.

Torque: 985 kg±cm (71 ft±Ib, 97 N±m)

NOTICE: Using the soft jaws, hold the left case in a vise.

6. INSTALL DIFFERENTIAL SIDE GEAR AND CONICAL

SPRING WASHER

HINT: Be careful not to make a mistake in the direction

of the conical spring washer.

10. INSTALL OIL PUMP DRIVE GEAR

(a) Install the oil pump drive gear. 7. INSTALL CENTER DIFFERENTIAL CASE

8. INSTALL THRUST WASHER (Previously selected)

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Ring Gear Mounting Case

and Center Differential Case A540H)AT±364

Page 620 of 2389

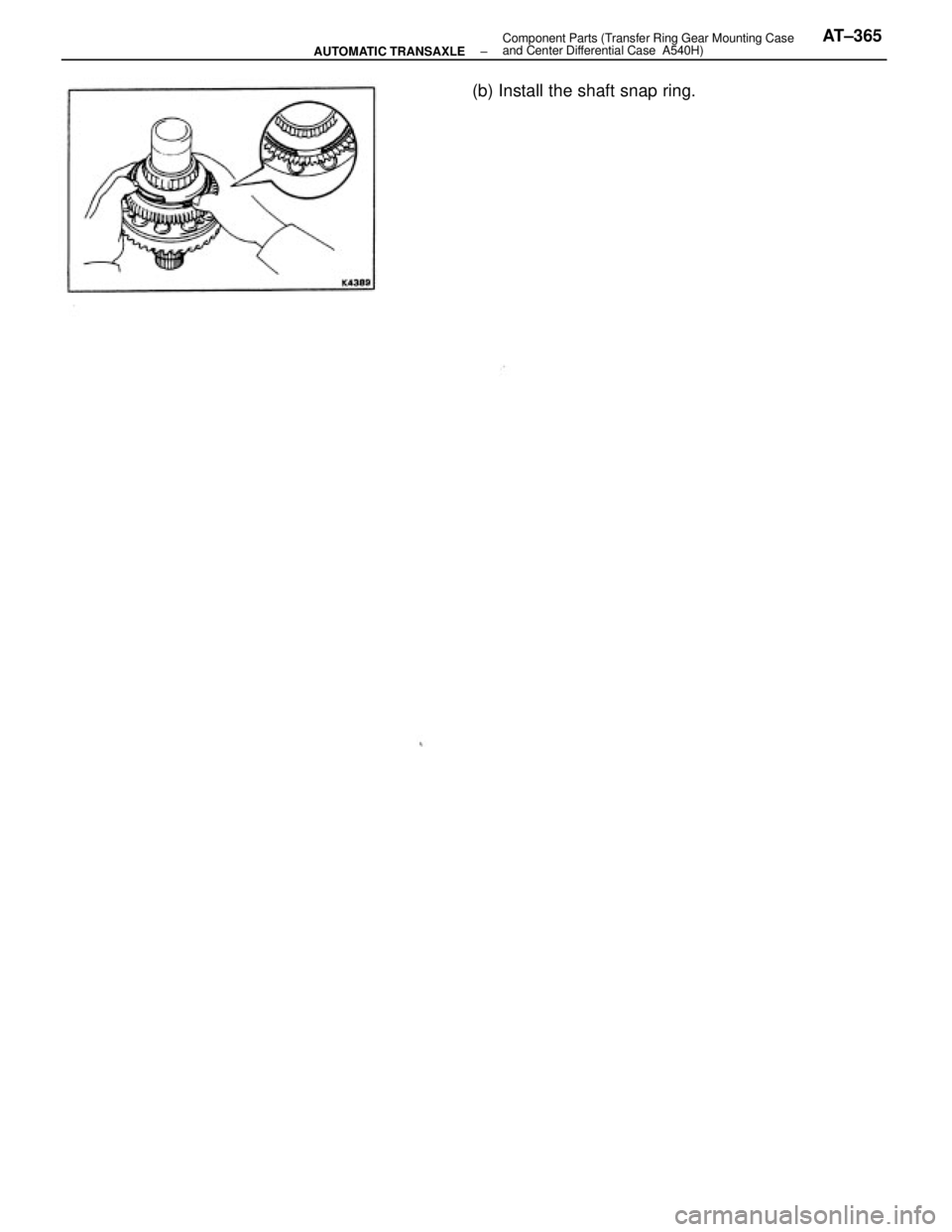

(b) Install the shaft snap ring.

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Ring Gear Mounting Case

and Center Differential Case A540H)AT±365

Trending: fuel tank removal, lights, clock reset, torque, headlight bulb, washer fluid, low oil pressure