TOYOTA CELICA 1987 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 251 of 346

ENGINE MECHANICAL A Cylinder Block

EM-@-

3.

4.

5. (a)

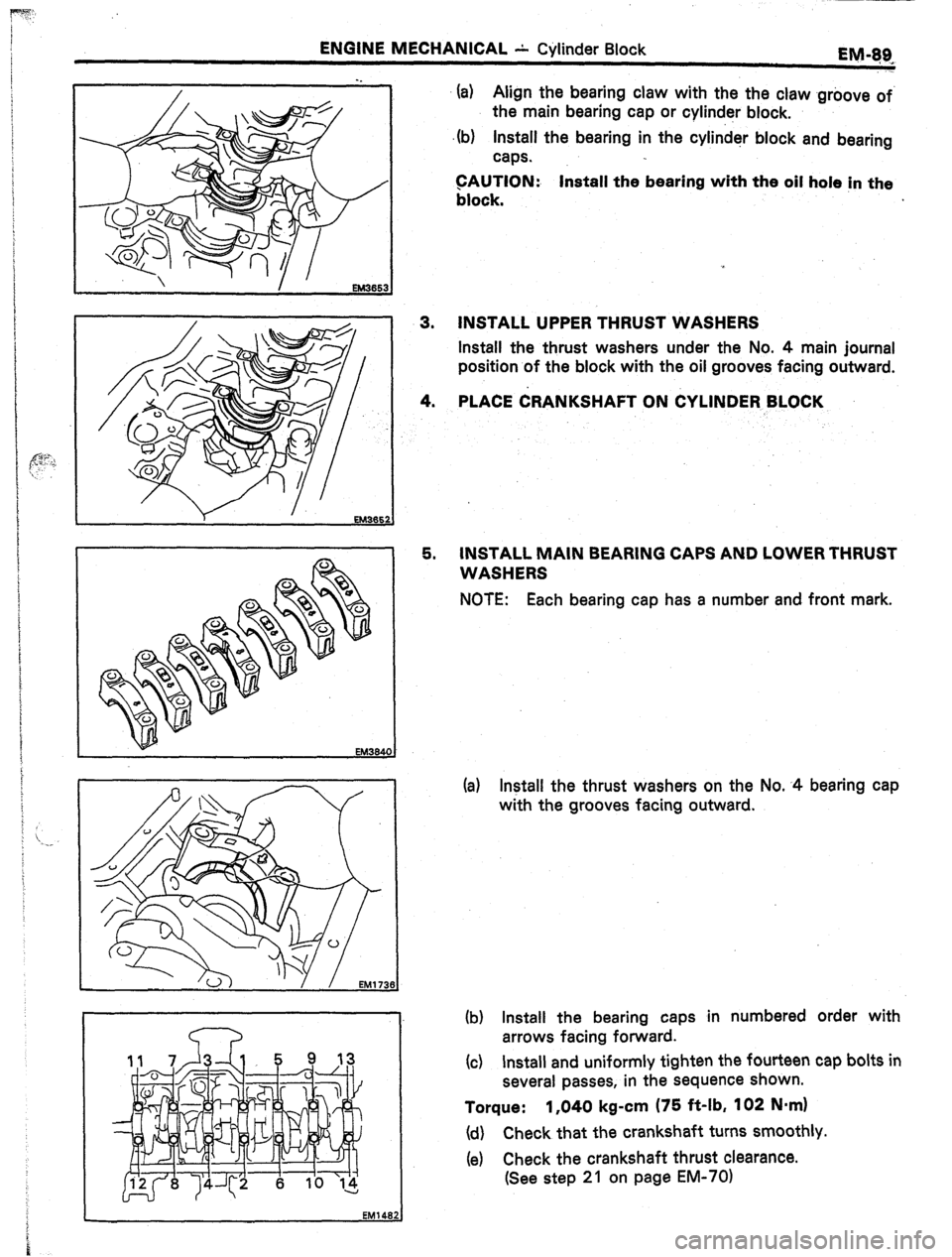

Align the bearing claw with the the claw -groove of.

the main bearing cap or cylind,er block.

(b)

Install the bearing in the cylinder block and bearing

caps.

GAUTION:

Install the bearing with the oil hole in the

block.

INSTALL UPPER THRUST WASHERS

Install the thrust washers under the No. 4 main journal

position of the block with the oil grooves facing outward.

PLACE &ANKSHAFT ON CYLINDER BLOCK

INSTALL MAIN BEARING CAPS AND LOWER THRUST

WASHERS

NOTE: Each bearing cap has a number and front mark.

(a) Install the thrust washers on the No. -4 bearing cap

with the grooves facing outward.

(b) Install the bearing caps in numbered order with

arrows facing forward.

(c) Install and uniformly tighten the fourteen cap bolts in

several passes, in the sequence shown.

Torque: 1,040 kg-cm (75 ft-lb, 102 N.mI

(d) Check that the crankshaft turns smoothly.

(e) Check the crankshaft thrust clearance.

(See step 21 on page EM-701

Page 252 of 346

EM-90 ENdIM IV~ECHAN~CAL - Cylinder Block

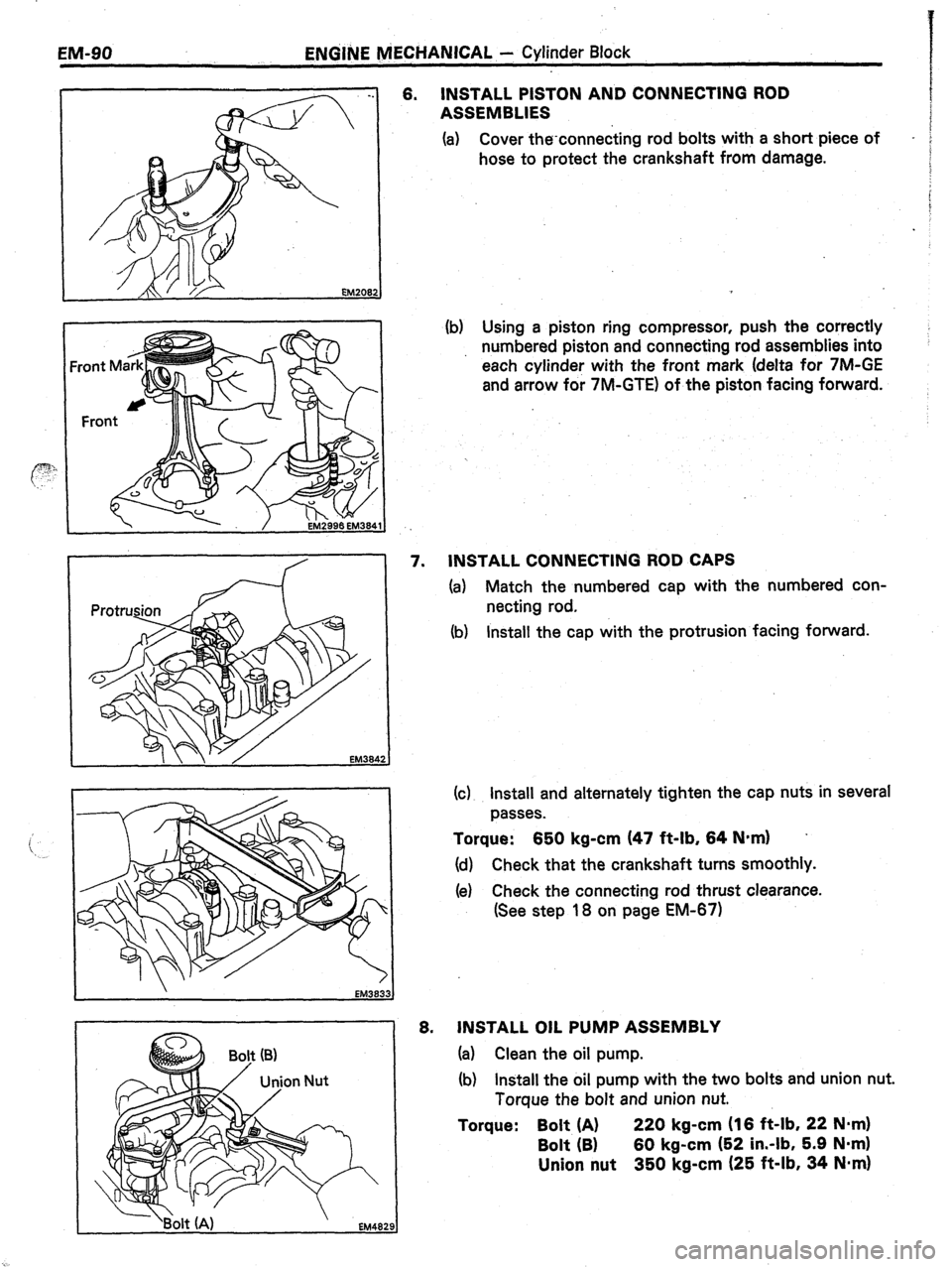

6. INSTALL PISTON AND CONNECTING ROD

ASSEMBLIES

(a) Cover the-connecting rod bolts with a short piece of

-

hose to protect the crankshaft from damage.

(b) Using a piston ring compressor, push the correctly

numbered piston and connecting rod assemblies into

each cylinder with the front mark (delta for 7M-GE

and arrow for 7M-GTE) of the piston facing forward.

EM384

EM383.

EM482

7. INSTALL CONNECTING ROD CAPS

(a) Match the numbered cap with the numbered con-

necting rod.

(b) Install the cap with the protrusion facing forward.

(c) Install and alternately tighten the cap nuts in several

passes.

Torque: 650 kg-cm (47 ft-lb, 64 N-m) .

(d) Check that the crankshaft turns smoothly.

(e) Check the connecting rod thrust clearance.

(See step 18 on page EM-671

6. JNSTALL OIL PUMP ASSEMBLY

(a) Clean the oil pump.

(b) Install the oil pump with the two bolts and union nut.

Torque the bolt and union nut.

Torque: Bolt (A) 220 kg-cm (16 ft-lb, 22 N*m)

Bolt (B) 60 kg-cm (52 in.-lb, 5.9 Nom)

Union nut 350 kg-cm (25 ft-lb, 34 Nmrn)

Page 253 of 346

ENGINE MECHANICAL - Cylinder Block

Qy g&

.

e. .-. .a ,j .a. VI ,... :~.~.**-.-. ),

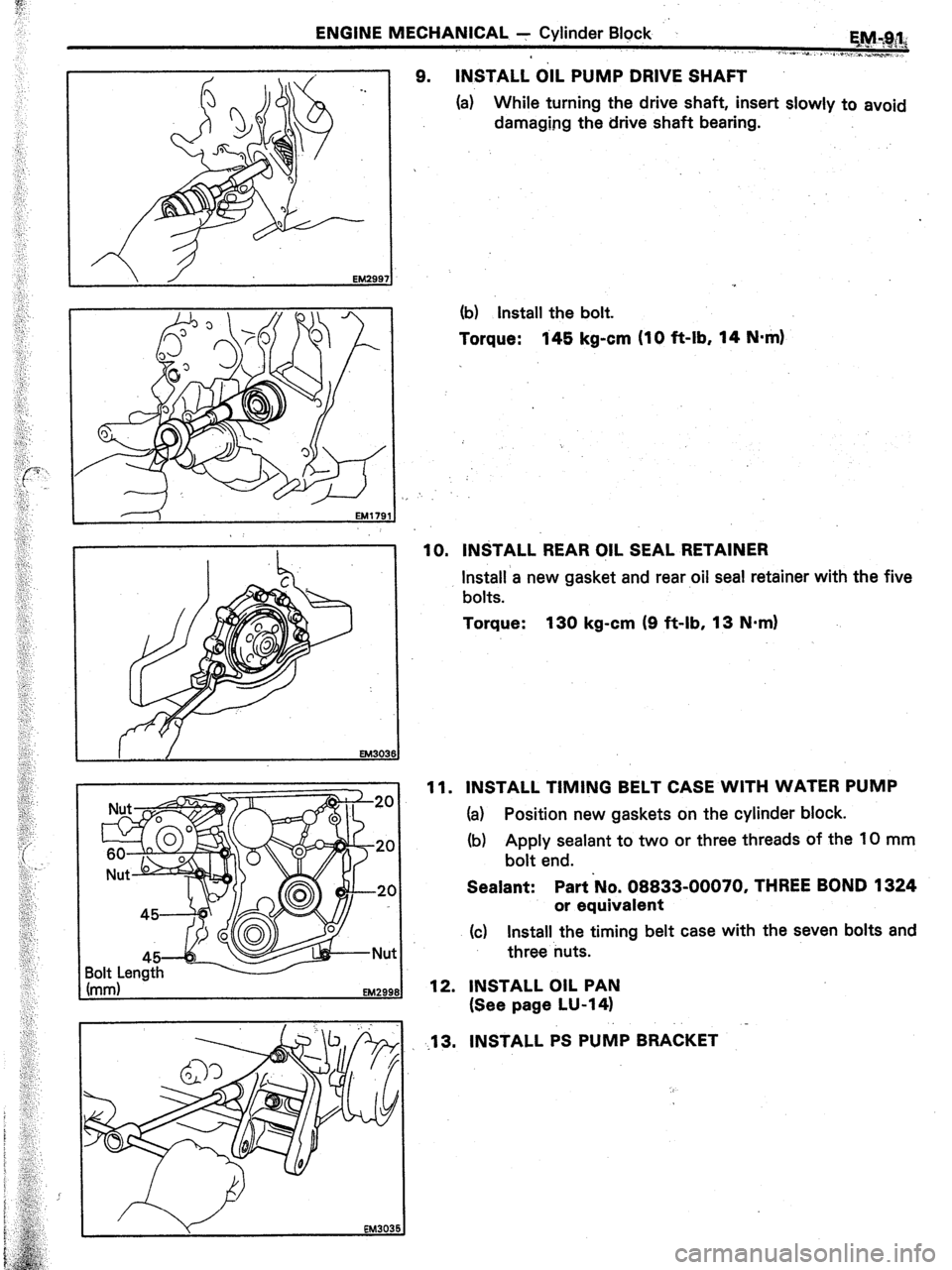

9. INSTALL OIL PUMP DRIVE SHAFT

(a) While turning the drive shaft, insert slowly to avoid

damaging the drive shaft bearing.

(b) Install the bolt.

Torque:

145 kg-cm (10 ft-lb, 14 N*m)

10. INSTALL REAR OIL SEAL RETAINER

Install

a new gasket and rear oil seal retainer with the five

bolts.

Torque: 130 kg-cm (9 ft-lb, 13 N.m)

11. INSTALL TIMING BELT CASE WITH WATER PUMP

(a) Position new

gaskets on the cylinder block.

(b) Apply sealant to two or three threads of the 10 mm

bolt end.

Sealant: Part No. 08833-00070, THREE BOND 1324

or equivalent

(c) Install the timing belt case with the seven bolts and

three nuts.

12. INSTALL OIL PAN

(See page LU-14)

.13. INSTALL PS PUMP BRACKET

Page 254 of 346

EM-92 _. ENGINE MECHANICAL +’ Cylinder Block

-..

: .

;,,

“.’

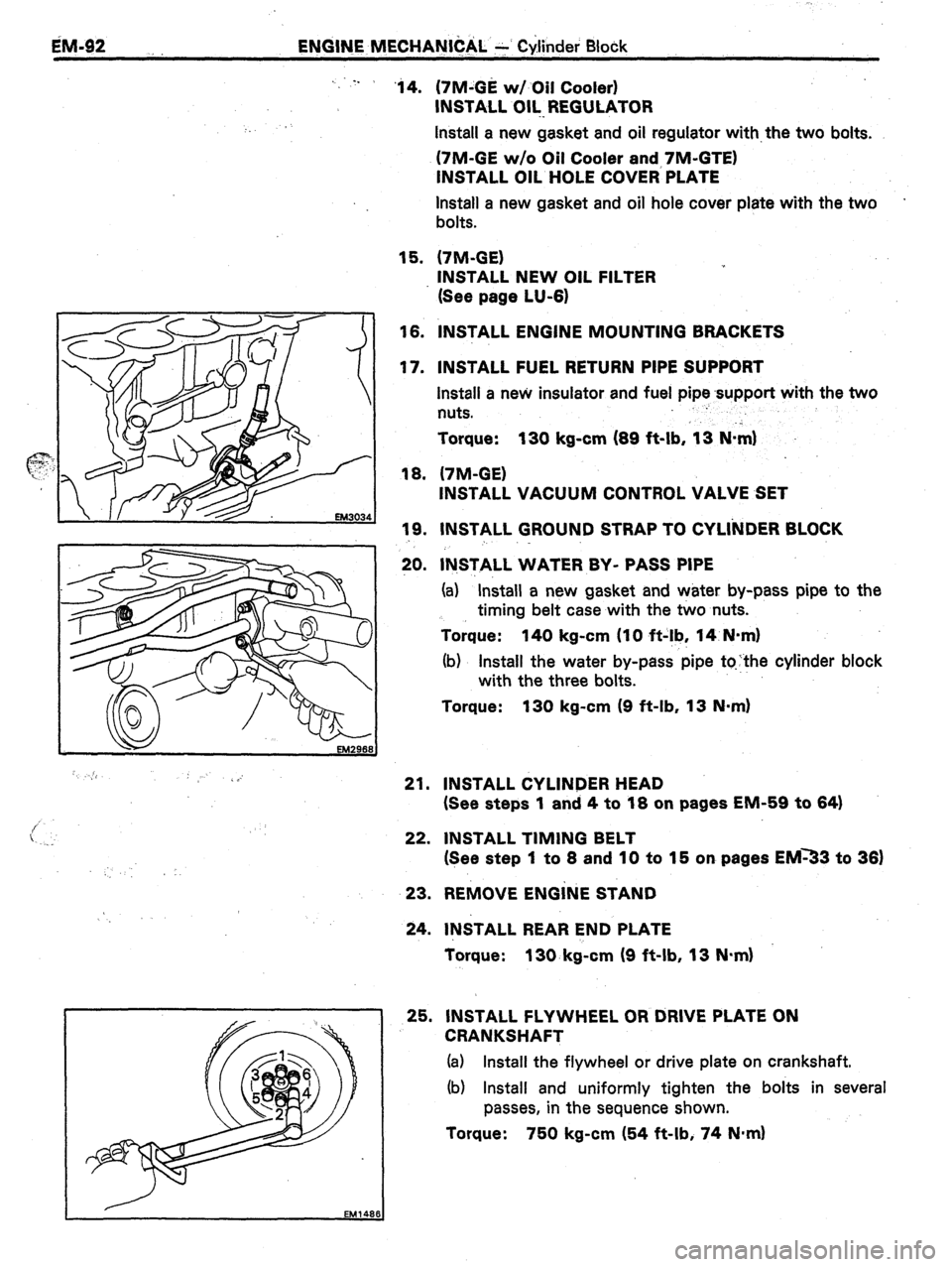

‘i4. (7M-GE w/ Oil Cooler)

INSTALL Oil.. REGULATOR

Install a new gasket and oil regulator with. the two bolts.

(7M-GE w/o Oil Cooler and.7M-GTE)

INSTALL OIL HOLE COVER PLATE

Install a new gasket and oil hole cover plate with the two .

bolts.

15. (7M-GE)

INSTALL NEW OIL FILTER

(See page LU-6)

16. INSTALL ENGlNE MOUNTING BRACKETS

17. INSTALL FUEL RETURN PIPE SUPPORT

Install a new insulator and fuel pipe support with the two

nuts. :

Torque: 130 kg-cm (69 ft-lb, ‘1.3 N&l

18. (7M-GE)

INSTALL VACUUM CONTROL VALVE SET

19. INSTALL GROUND STRAP TO CYLI’NDER BLOCK

20. lN,STALL WATER BY- PASS PIPE

(a) “Install a new gasket and water by-pass pipe to the

timing belt case with the two nuts.

Torque: 140 kg-cm (IO ft-!b, 14 N-m)

(b) Install the water by-pass pipe tqthe cylinder block

with the three bolts.

Torque: 130 kg-cm (9 ft-lb, 13 N-m)

21. INSTALL CYLINDER HEAD

(See steps 1 and 4 to 18 on pages EM-59 to 64)

22. INSTALL TIMING BELT

(See step 1 to 8 and 10 to 15 on pages EM33 to 36)

23. REMOVE ENGiNE STAND

24. INSTALL REAR END PLATE

Torque: 130. kg-cm (9 ft-lb, 13 N.m)

25. INSTALL FLYWHEEL OR DRIVE PLATE ON

CRANKSHAFT

(a) Install the flywheel or drive plate on crankshaft.

(b) Install and uniformly tighten the bolts in several

passes, in the sequence shown.

Torque: 750 kg-cm (54 ft-lb, 74 N*m)

Page 255 of 346

. .

-.

.’ .,

-.. . . t .’

. . . ,..

1.1 .I.. -I ““... _.. ____ ,,_

_ ..I,. ..-. It

_-

IGNiiid’N SYSTEM

PRECAUTIONS Page

................................

16-2

TROUBLESHOOTING

............................

IG-3

IGNITION SYSTEM CIRCUIT

....................

ON-VEHICLE INSPkTlON (7M-GE) IO-4

............. IO-5

ON-VEHICLE INSPECTION (7M-GTE)

............ IO-1 2

DISTRIBUTOR (7M-GE)

.........................

IO-19

CAM POSITION SENSOR (7M-GTE)

............. 16-23

Page 256 of 346

16-2 IGNITION SYSTEM - precautions

-.

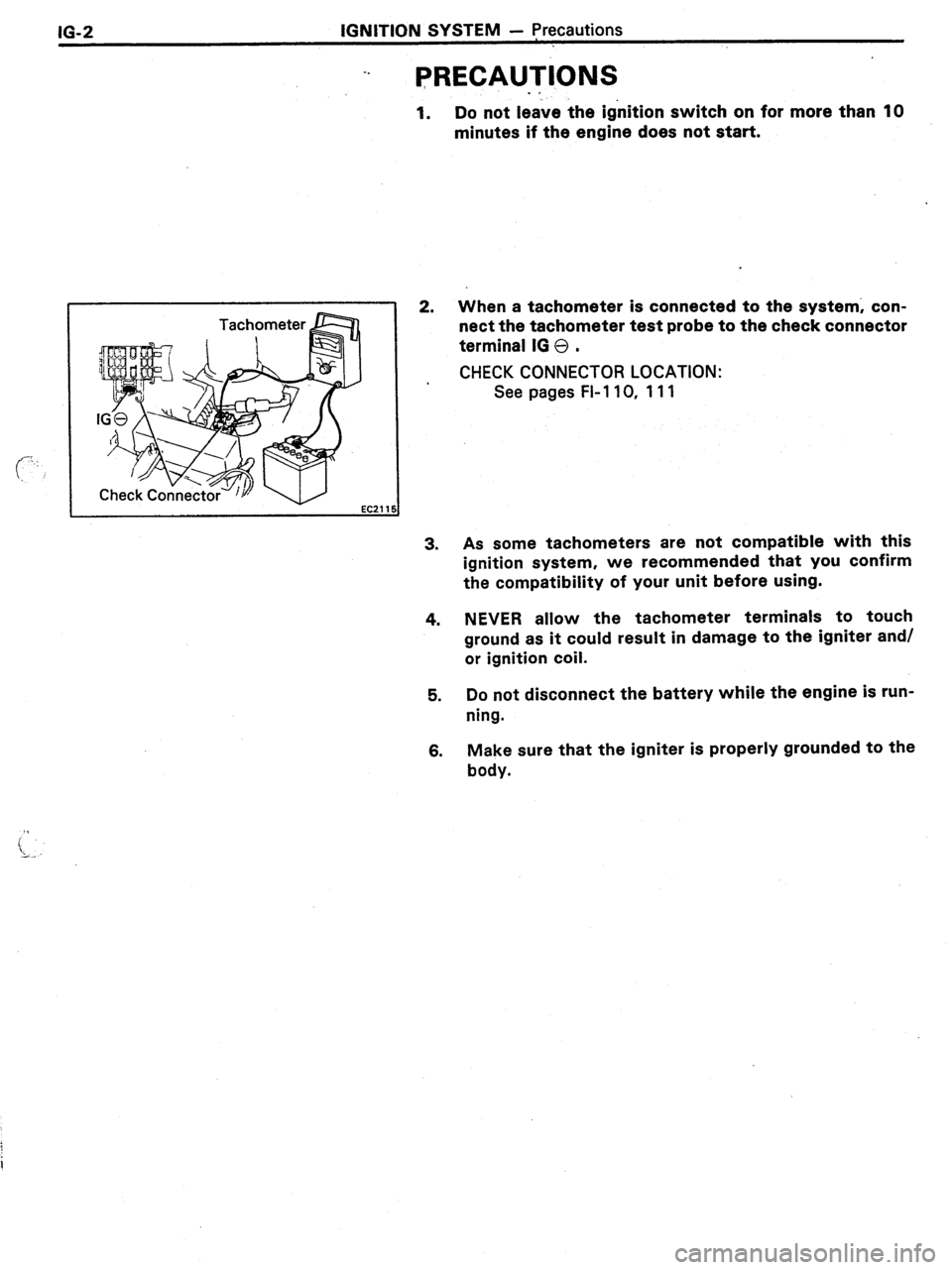

PRECAUTIONS

1.

2.

3.

4.

5.

6.

. *

Do not leave the ignition switch on for more than 10

minutes if the engine does not start.

When a tachometer is connected to the system; con-

nect the tachometer test probe to the check connector

terminal IG 0 .

CHECK CONNECTOR LOCATION:

See pages FI-110, 111

As some tachometers are not compatible with this

ignition system, we recommended that you confirm

the compatibility of your unit before using.

NEVER allow the tachometer terminals to touch

ground as it could result in damage to the igniter and/

or ignition coil.

Do not disconnect the battery while the engine is run-

ning.

Make sure that the igniter is properly grounded to the

body.

Page 257 of 346

:on-

ztor

thi

‘irr

‘UC

mc

WI

tf

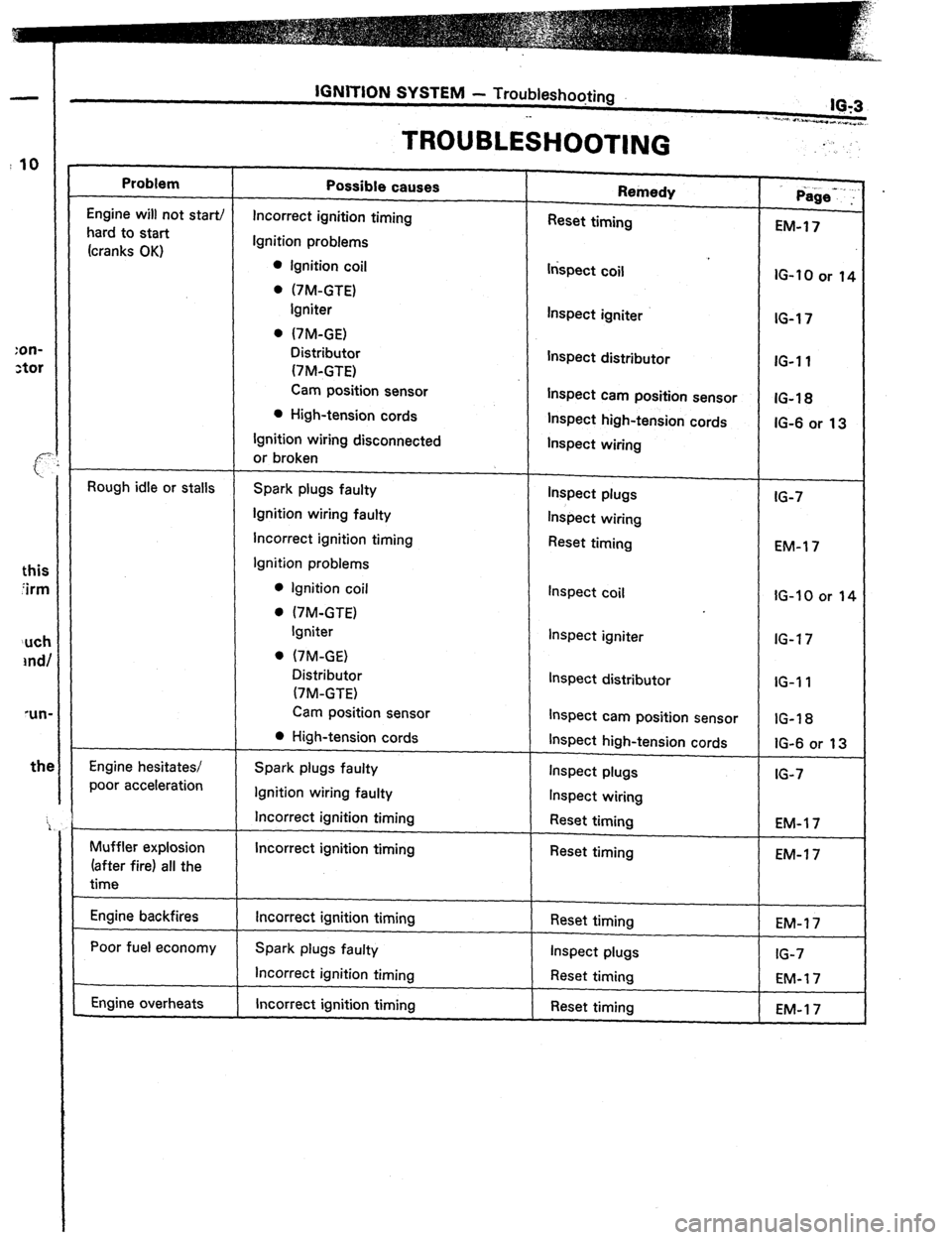

Problem

Engine will not star-t/

hard to start

(cranks OK)

Rough idle or stalls

Engine hesitates/

poor acceleration

Muffler explosion

(after fire) all the

time

Engine backfires

Poor fuel economy

Engine overheats

TROUBLESHOOTING

Possible causes

Incorrect ignition timing

Ignition problems

0 Ignition coil

. (7M-GTE)

Igniter

. (7M-GE)

Distributor

(7M-GTE)

Cam position sensor

l High-tension cords

Ignition wiring disconnected

or broken

Spark plugs faulty

Ignition wiring faulty

Incorrect ignition timing

Ignition problems

0 Ignition coil

. I7M-GTE)

Igniter

. (7M-GE)

Distributor

(7M-GTE)

Cam position sensor

0 High-tension cords

Spark plugs faulty

Ignition wiring faulty

Incorrect ignition timing

Incorrect ignition timing

Incorrect ignition timing

Spark plugs faulty

Incorrect ignition timing

Incorrect ignition timing Remedy

Reset timing

lrkpect coil

Inspect igniter

Inspect distributor

Inspect cam position sensor

Inspect high-tension cords

Inspect wiring

Inspect plugs

Inspect wiring

Reset timing

Inspect coil

Inspect igniter

Inspect distributor

Inspect cam position sensor

Inspect high-tension cords

Inspect plugs

Inspect wiring

Reset timing

Reset timing

Reset timing

Inspect plugs

Reset timing

Reset timing =

Page-.. :

-

EM-17

IG-10 or 14

IG-17

IG-11

IG-1%

IG-6 or 13

IG-7

EM-l 7

IG-10 or 11

IG-17

IG-I 1

IG-18

IG-6 or 13

IG-7

EM-l 7

EM-1 7

Page 258 of 346

IQ-4

IGNITION SYSTEM - Ignition System Circuit

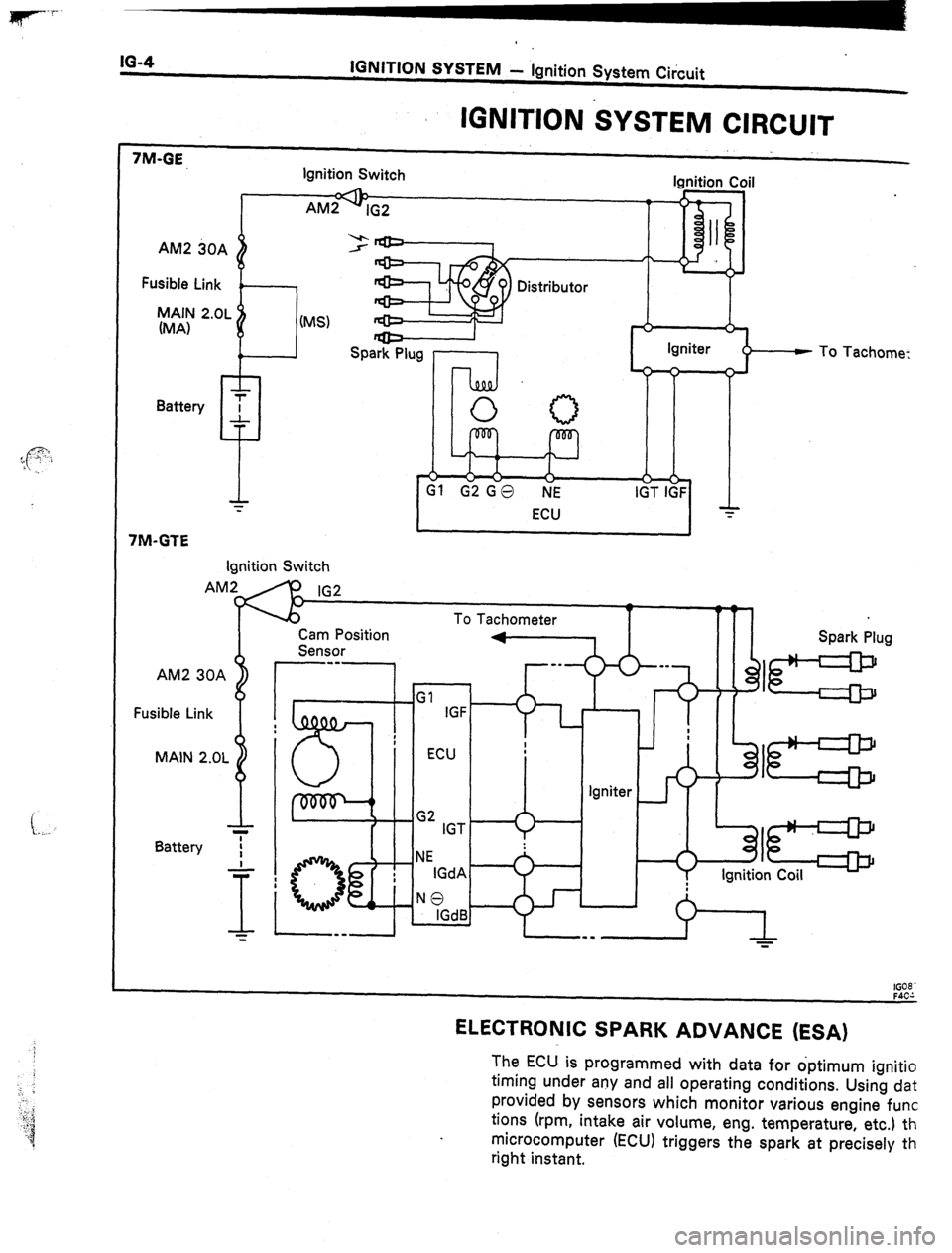

IGNlTlON SYSTEM CIRCUIT

7M-GE, Ignition Switch lanitian Cnil

AM2 30A

Fusible Link

MAIN 2.OL

(MA)

~“. _._. _ _..

AM29~2

I “i!l A II

I

(MS)

I

Spark Plug l-1 II

R Igniter

1

7M-GTE

I

Ignition Switch

AM2 30A

Fusible Link

MAIN 2.OL

Battery IG2

To Tachometer

1 f

Cam Position

Sensor

r--1

G2 IGT

NE

IGdA

NO

IGdB f

To Tachome:

n Spark Plug

Igniter

: I=

B

I=

Ignition Coil

It08

ELECTRONIC SPARK ADVANCE (ESA)

The ECU is programmed with data for optimum ignitio

timing under any and all operating conditions. Using dat

provided by sensors which monitor various engine func

tions (rpm,

intake air volume, eng. temperature, etc.) th

microcomputer (ECU) triggers the spark at precisely th

right instant.

Page 259 of 346

IGNITION SYSTEM - On-Vehicle Inspection (7M-GE)

IO-6 *

-. ON-VEHICLE INSPECTION (7M43E)‘;

SPARK TEST --

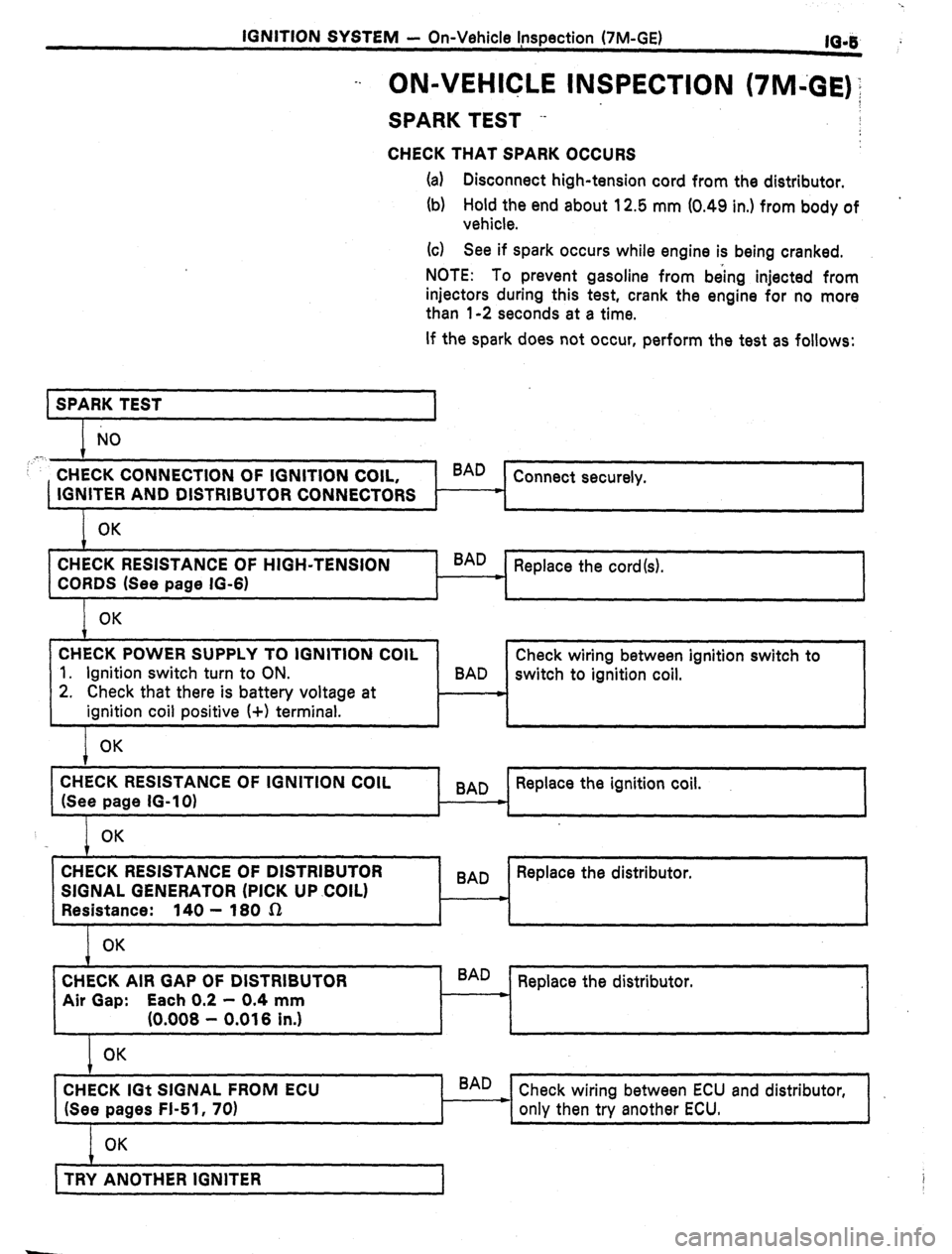

CHECK THAT SPARK OCCURS

(a) Disconnect high-tension cord from the distributor.

(b) Hold the end about 12.5 mm (0.49 in.) from body of

vehicle.

(G) See if spark occurs while engine is being cranked.

NOTE: To prevent gasoline from being injected from

injectors during this test, crank the engine for no more

than l-2 seconds at a time.

If the spark does not occur, perform the test as follows:

SPARK TEST

1

NO

,‘.

CHECK CONNECTION OF IGNITION COIL, BAD

Connect securely.

IGNITER AND DISTRIBUTOR CONNECTORS c

OK

CHECK RESISTANCE OF HIGH-TENSION

CORDS (See page IG-6) ’ BAD

Replace the cord(s).

OK

CHECK POWER SUPPLY TO IGNITION COIL

1. Ignition switch turn to ON.

2. Check that there is battery voltage at

ignition coil positive I+) terminal. Check wiring between ignition switch to

BAD

switch to ignition coil.

OK

CHECK RESISTANCE OF IGNITION COIL

(See page IG-10) 9

BAD Replace the ignition coil.

*

OK

1 , , 1

CHECK RESISTANCE OF DISTRIBUTOR

SIGNAL GENERATOR (PICK UP .COIL)

Resistance: 140 - 180 sz

OK BAD Replace the distributor.

m

CHECK AIR GAP OF DISTRIBUTOR

Air Gap: Each 0.2 - 0.4 mm

(0.008 - 0.016 in.) BAD

Replace the distributor.

L

OK

CHECK IGt SIGNAL FROM ECU

(See pages FI-51, 70) BAD

Check wiring between ECU and distributor,

only then try another ECU.

OK

t ,

TRY ANOTHER IGNITER

1 i

Page 260 of 346

IGNlTliiN SYSTEM - On-Vehicle Inspection (7M-GE)

It059 ‘6

IG059

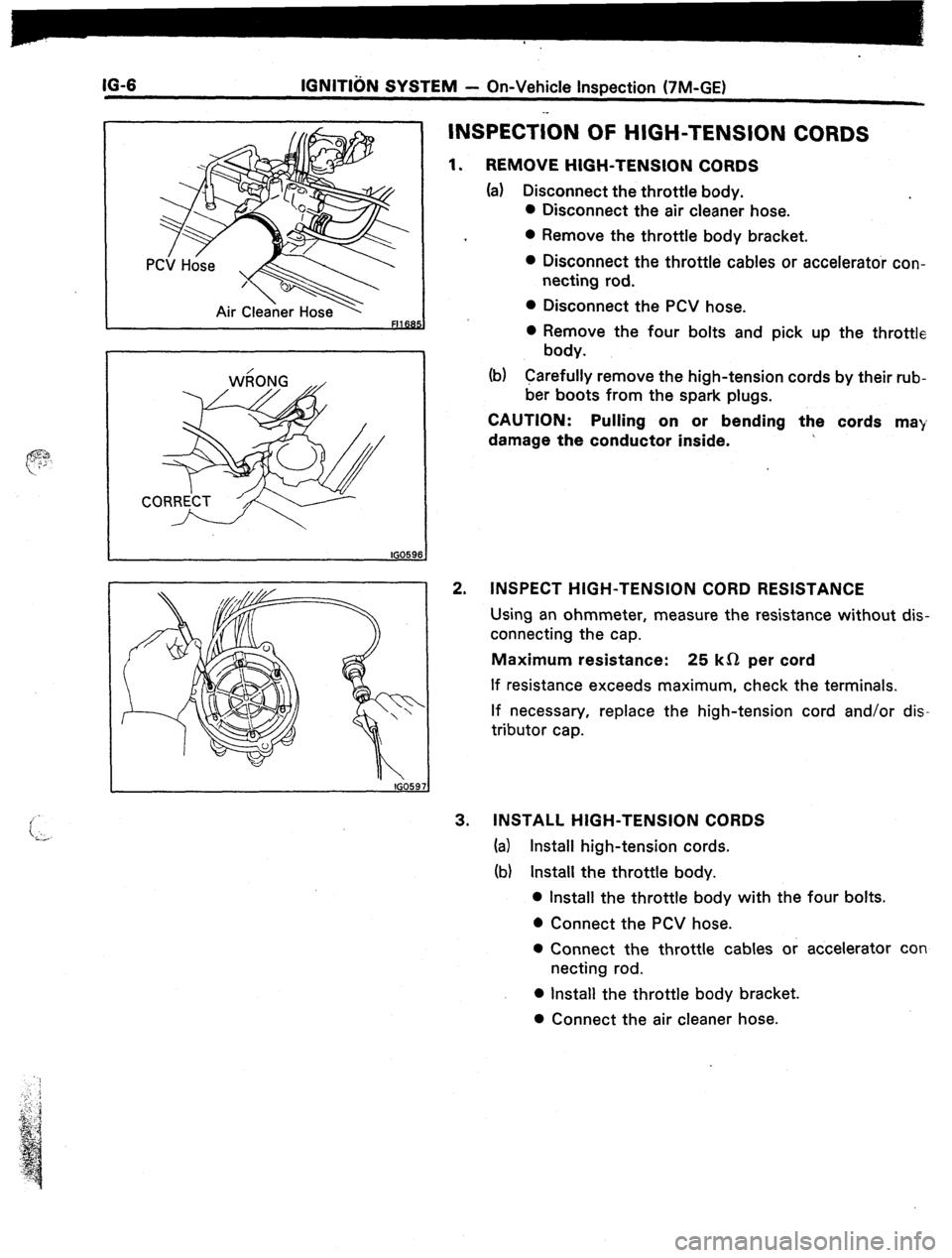

INSPECTiON OF HIGH-TENSION CORDS

1. REMOVE HIGH-TENSION CORDS

(a) Disconnect the throttle body.

l Disconnect the air cleaner hose.

l Remove the throttle body bracket.

0 Disconnect the throttle cables or accelerator con-

necting rod.

l Disconnect the PCV hose.

0 Remove the four bolts and pick up the throttle

body.

(b) Carefully remove the high-tension cords by their rub-

ber boots from the spark plugs.

CAUTION: Pulling on or bending the cords ma)

damage the conductor inside.

2. INSPECT HIGH-TENSION CORD RESISTANCE

Using an ohmmeter, measure the resistance without dis-

connecting the cap.

Maximum resistance: 25 kS2 per cord

If resistance exceeds maximum, check the terminals.

If necessary, replace the high-tension cord and/or dis-

tributor cap.

3. INSTALL HIGH-TENSION CORDS

(a) Install high-tension cords.

(b) Install the throttle body.

l Install the throttle body with the four bolts.

l Connect the PCV hose.

0 Connect the throttle cables or accelerator con

netting rod.

l Install the throttle body bracket.

0 Connect the air cleaner hose.