TOYOTA LAND CRUISER 1996 J80 Workshop Manual

Manufacturer: TOYOTA, Model Year: 1996, Model line: LAND CRUISER, Model: TOYOTA LAND CRUISER 1996 J80Pages: 1399, PDF Size: 41.35 MB

Page 1151 of 1399

SA0510

R08274

R08276

R13246

SA−88

−

SUSPENSION AND AXLE REAR DIFFERENTIAL CARRIER

1996 LAND CRUISER (RM451U)

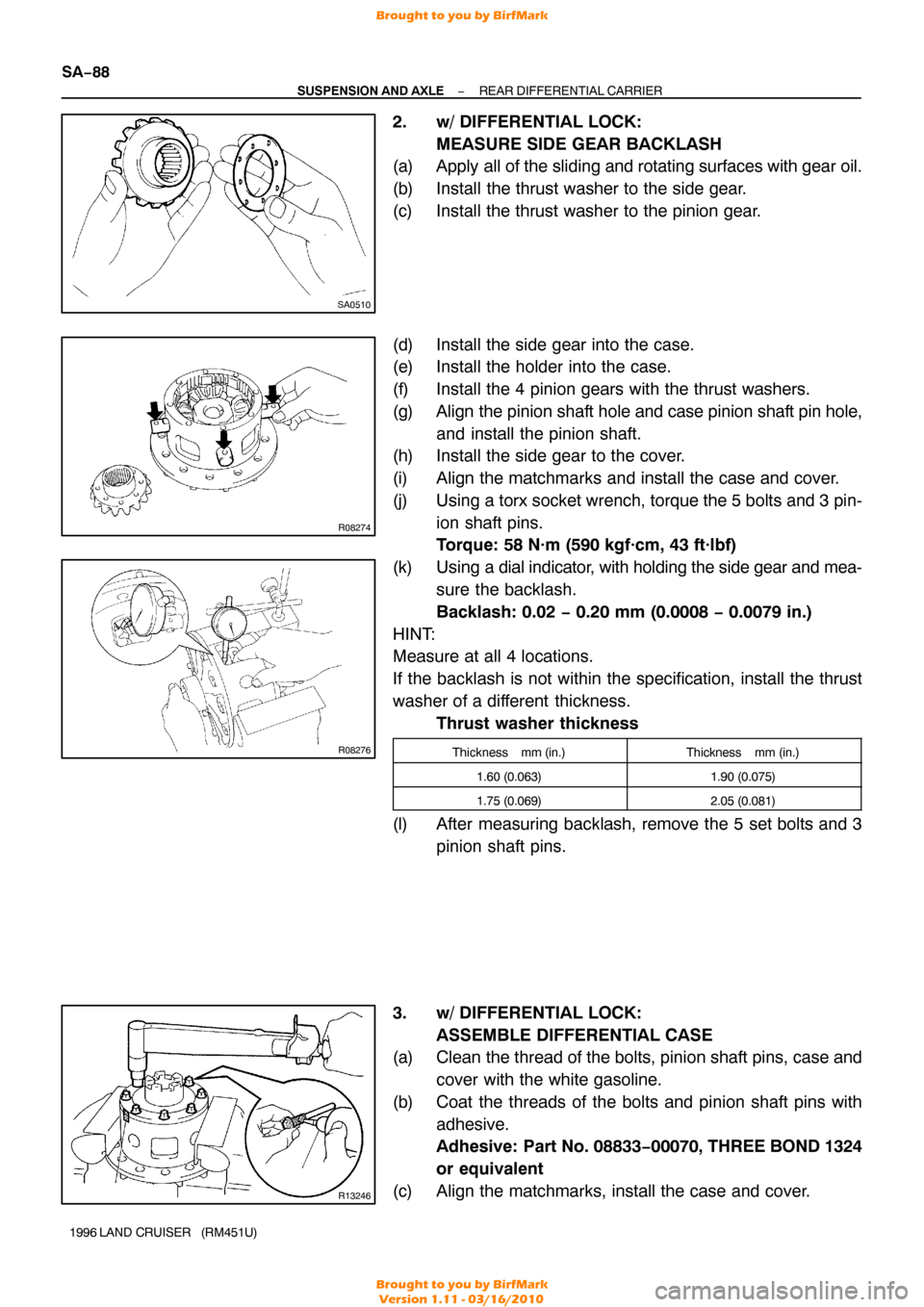

2. w/ DIFFERENTIAL LOCK:

MEASURE SIDE GEAR BACKLASH

(a) Apply all of the sliding and rotating surfaces with gear oil.

(b) Install the thrust washer to the side gear.

(c) Install the thrust washer to the pinion gear.

(d) Install the side gear into the case.

(e) Install the holder into the case.

(f) Install the 4 pinion gears with the thrust washers.

(g) Align the pinion shaft hole and case pinion shaft pin hole,

and install the pinion shaft.

(h) Install the side gear to the cover.

(i) Align the matchmarks and install the case and cover.

(j) Using a torx socket wrench, torque the 5 bolts and 3 pin-

ion shaft pins.

Torque: 58 N·m (590 kgf·cm, 43 ft·lbf)

(k) Using a dial indicator, with holding the side gear and mea- sure the backlash.

Backlash: 0.02 − 0.20 mm (0.0008 − 0.0079 in.)

HINT:

Measure at all 4 locations.

If the backlash is not within the specification, install the thrust

washer of a different thickness. Thrust washer thickness

Thickness mm (in.)Thickness mm (in.)

1.60 (0.063)1.90 (0.075)

1.75 (0.069)2.05 (0.081)

(l) After measuring backlash, remove the 5 set bolts and 3pinion shaft pins.

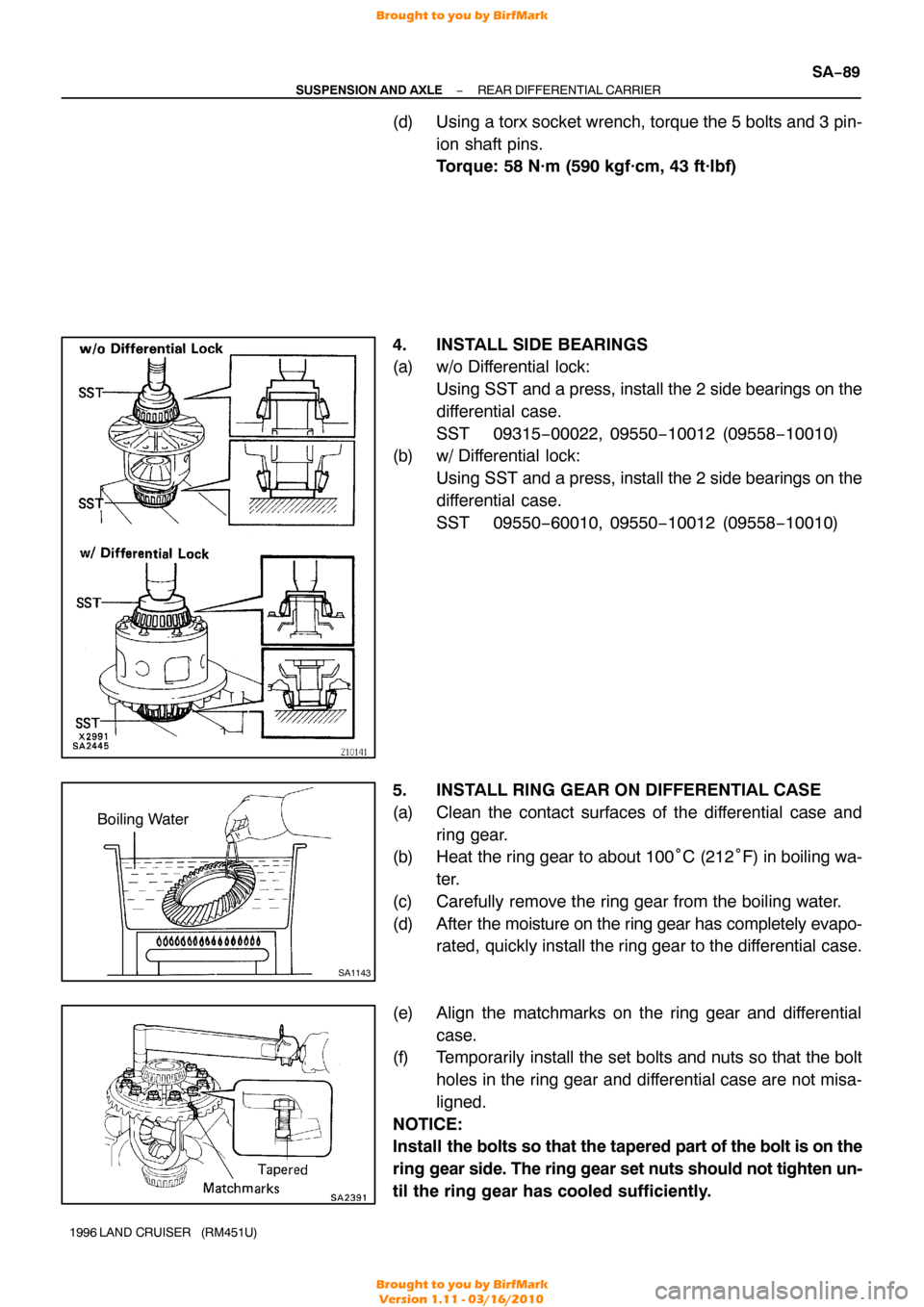

3. w/ DIFFERENTIAL LOCK: ASSEMBLE DIFFERENTIAL CASE

(a) Clean the thread of the bolts, pinion shaft pins, case and

cover with the white gasoline.

(b) Coat the threads of the bolts and pinion shaft pins with adhesive.

Adhesive: Part No. 08833 −00070, THREE BOND 1324

or equivalent

(c) Align the matchmarks, install the case and cover.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 1152 of 1399

SA1143

Boiling Water

−

SUSPENSION AND AXLE REAR DIFFERENTIAL CARRIER

SA−89

1996 LAND CRUISER (RM451U)

(d) Using a torx socket wrench, torque the 5 bolts and 3 pin-

ion shaft pins.

Torque: 58 N·m (590 kgf·cm, 43 ft·lbf)

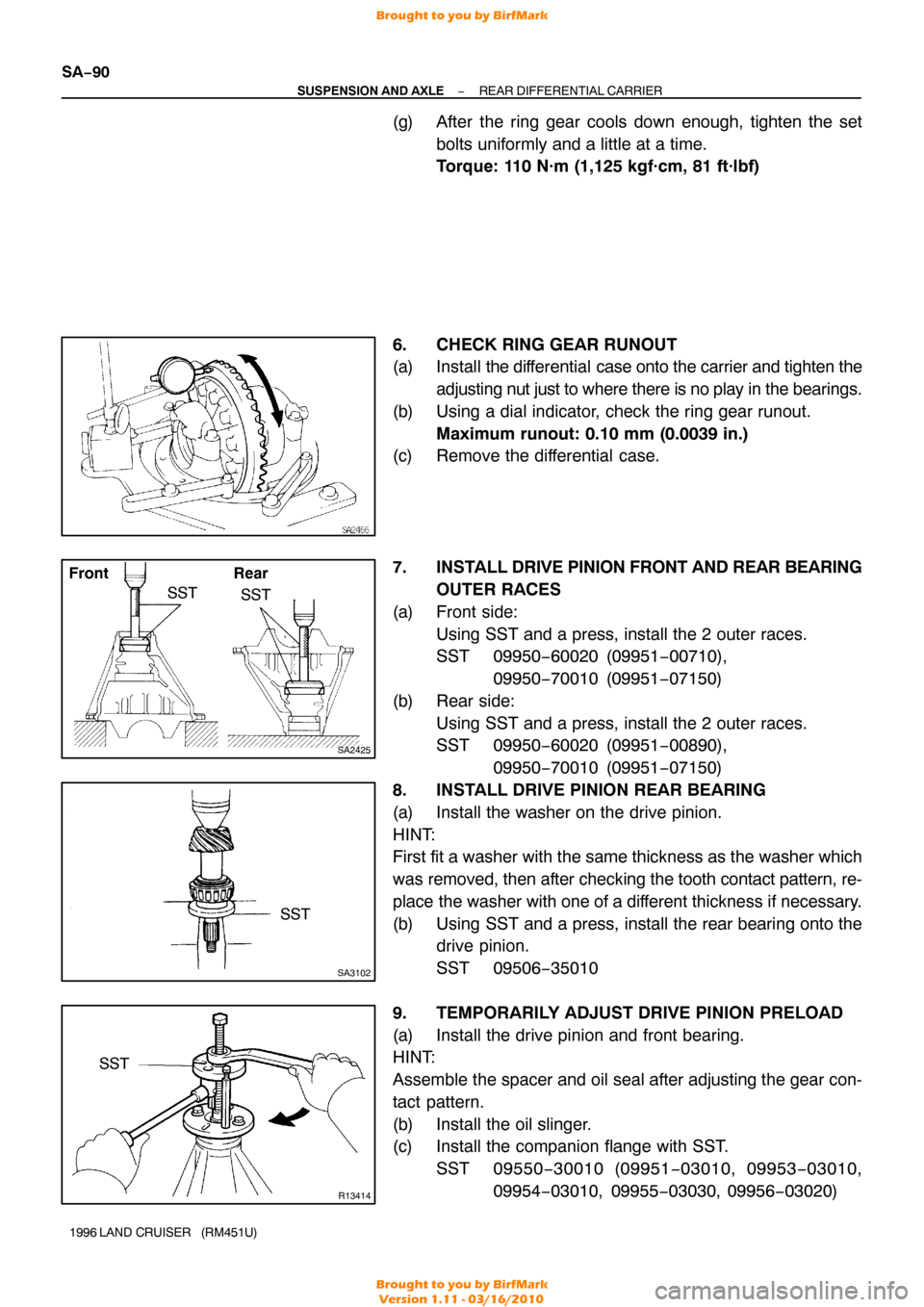

4. INSTALL SIDE BEARINGS

(a) w/o Differential lock: Using SST and a press, install the 2 side bearings on the

differential case.

SST 09315−00022, 09550 −10012 (09558−10010)

(b) w/ Differential lock:

Using SST and a press, install the 2 side bearings on the

differential case.

SST 09550−60010, 09550 −10012 (09558−10010)

5. INSTALL RING GEAR ON DIFFERENTIAL CASE

(a) Clean the contact surfaces of the differential case and ring gear.

(b) Heat the ring gear to about 100° C (212°F) in boiling wa-

ter.

(c) Carefully remove the ring gear from the boiling water.

(d) After the moisture on the ring gear has completely evapo-

rated, quickly install the ring gear to the differential case.

(e) Align the matchmarks on the ring gear and differential case.

(f) Temporarily install the set bolts and nuts so that the bolt

holes in the ring gear and differential case are not misa-

ligned.

NOTICE:

Install the bolts so that the tapered part of the bolt is on the

ring gear side. The ring gear set nuts should not tighten un-

til the ring gear has cooled sufficiently.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 1153 of 1399

SA2425

SSTSST

Front

Rear

SA3102

SST

R13414

SST

SA−90

−

SUSPENSION AND AXLE REAR DIFFERENTIAL CARRIER

1996 LAND CRUISER (RM451U)

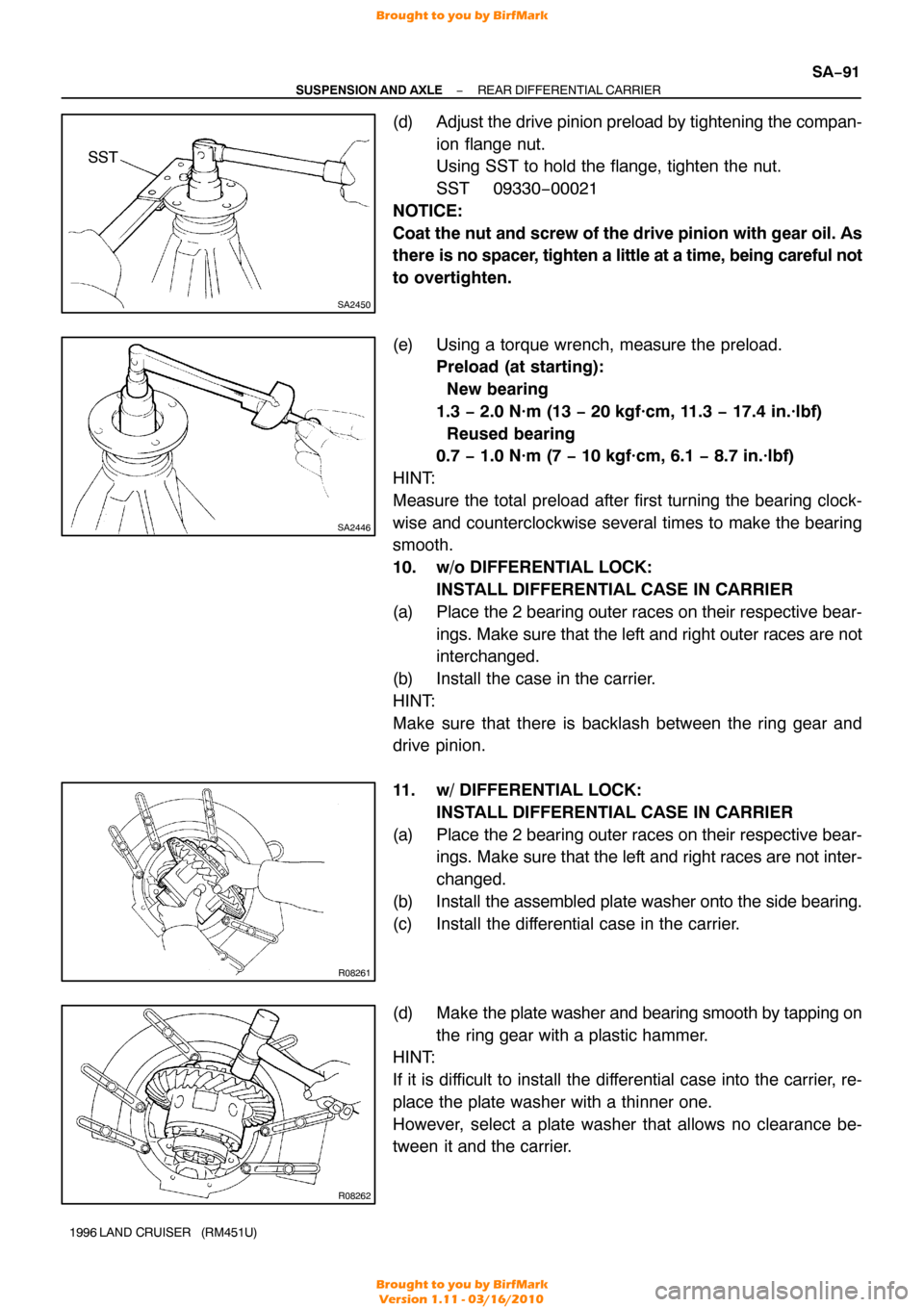

(g) After the ring gear cools down enough, tighten the set

bolts uniformly and a little at a time.

Torque: 110 N·m (1,125 kgf·cm, 81 ft·lbf)

6. CHECK RING GEAR RUNOUT

(a) Install the differential case onto the carrier and tighten the

adjusting nut just to where there is no play in the bearings.

(b) Using a dial indicator, check the ring gear runout. Maximum runout: 0.10 mm (0.0039 in.)

(c) Remove the differential case.

7. INSTALL DRIVE PINION FRONT AND REAR BEARING

OUTER RACES

(a) Front side: Using SST and a press, install the 2 outer races.

SST 09950−60020 (09951 −00710),

09950 −70010 (09951 −07150)

(b) Rear side: Using SST and a press, install the 2 outer races.

SST 09950−60020 (09951 −00890),

09950 −70010 (09951 −07150)

8. INSTALL DRIVE PINION REAR BEARING

(a) Install the washer on the drive pinion.

HINT:

First fit a washer with the same thickness as the washer which

was removed, then after checking the tooth contact pattern, re-

place the washer with one of a different thickne ss if necessary.

(b) Using SST and a press, install the rear bearing onto the drive pinion.

SST 09506−35010

9. TEMPORARILY ADJUST DRIVE PINION PRELOAD

(a) Install the drive pinion and front bearing.

HINT:

Assemble the spacer and oil seal after adjusting the gear con-

tact pattern.

(b) Install the oil slinger.

(c) Install the companion flange with SST. SST 09550 −30010 (09951 −03010, 09953 −03010,

09954 −03010, 09955 −03030, 09956−03020)

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 1154 of 1399

SA2450

SST

SA2446

R08261

R08262

−

SUSPENSION AND AXLE REAR DIFFERENTIAL CARRIER

SA−91

1996 LAND CRUISER (RM451U)

(d) Adjust the drive pinion preload by tightening the compan-

ion flange nut.

Using SST to hold the flange, tighten the nut.

SST 09330−00021

NOTICE:

Coat the nut and screw of the drive pinion with gear oil. As

there is no spacer, tighten a little at a time, being careful not

to overtighten.

(e) Using a torque wrench, measure the preload. Preload (at starting):

New bearing

1.3 − 2.0 N·m (13 − 20 kgf·cm, 11.3 − 17.4 in.·lbf)

Reused bearing

0.7 − 1.0 N·m (7 − 10 kgf·cm, 6.1 − 8.7 in.·lbf)

HINT:

Measure the total preload after first turning the bearing clock-

wise and counterclockwise several times to make the bearing

smooth.

10. w/o DIFFERENTIAL LOCK: INSTALL DIFFERENTIAL CASE IN CARRIER

(a) Place the 2 bearing outer races on their respective bear- ings. Make sure that the left and right outer races are not

interchanged.

(b) Install the case in the carrier.

HINT:

Make sure that there is backlash between the ring gear and

drive pinion.

11. w/ DIFFERENTIAL LOCK: INSTALL DIFFERENTIAL CASE IN CARRIER

(a) Place the 2 bearing outer races on their respective bear- ings. Make sure that the left and right races are not inter-

changed.

(b) Install the assembled plate washer onto the side bearing.

(c) Install the differential case in the carrier.

(d) Make the plate washer and bearing smooth by tapping on

the ring gear with a plastic hammer.

HINT:

If it is difficult to install the differential case into the carrier, re-

place the plate washer with a thinner one.

However, select a plate washer that allows no clearance be-

tween it and the carrier.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 1155 of 1399

R08263

R08264

R08265

SA−92

−

SUSPENSION AND AXLE REAR DIFFERENTIAL CARRIER

1996 LAND CRUISER (RM451U)

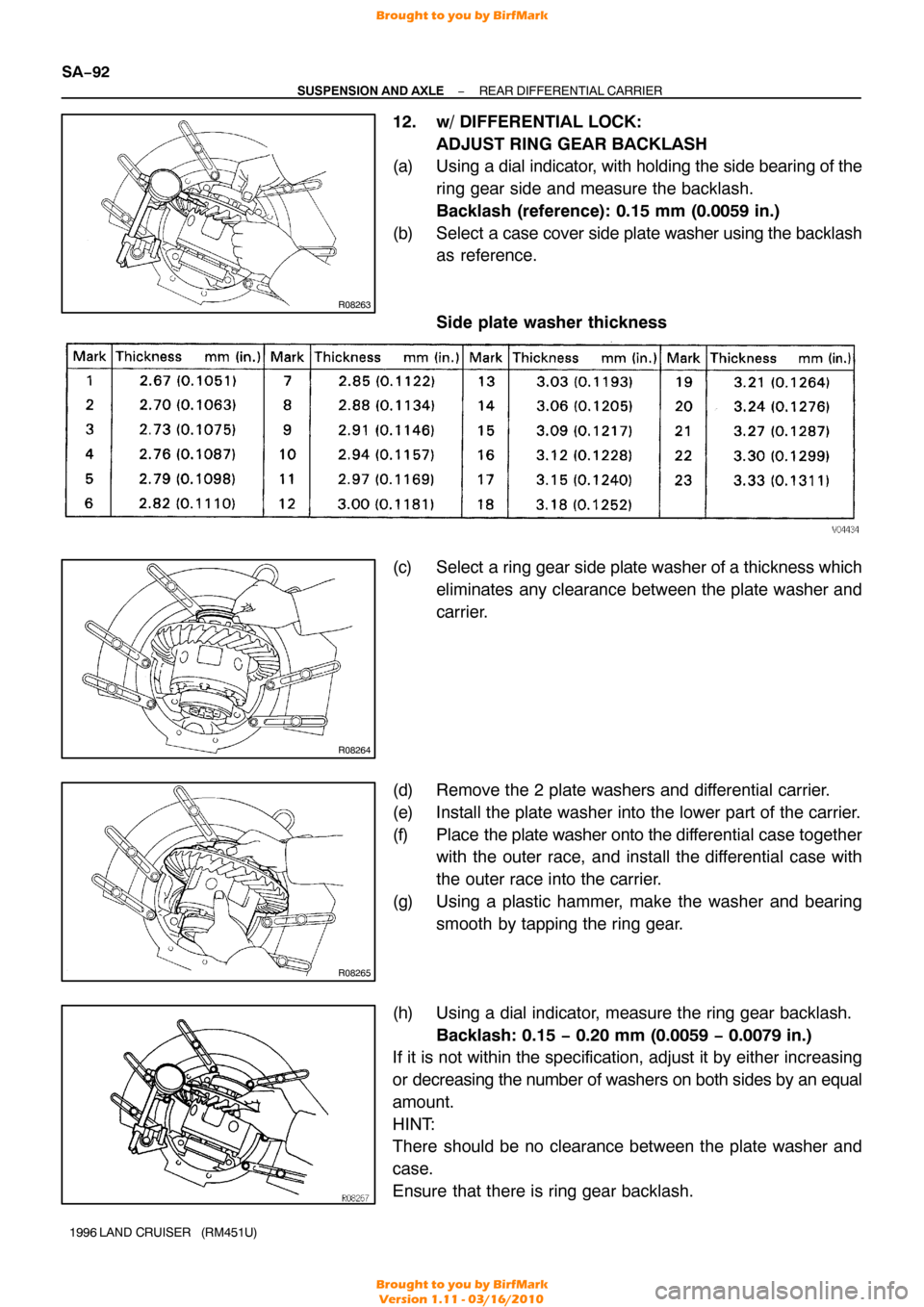

12. w/ DIFFERENTIAL LOCK:

ADJUST RING GEAR BACKLASH

(a) Using a dial indicator, with holding the side bearing of the

ring gear side and measure the backlash.

Backlash (reference): 0.15 mm (0.0059 in.)

(b) Select a case cover side plate washer using the backlash

as reference.

Side plate washer thickness

(c) Select a ring gear side plate washer of a thickness which

eliminates any clearance between the plate washer and

carrier.

(d) Remove the 2 plate washers and differential carrier.

(e) Install the plate washer into the lower part of the carrier.

(f) Place the plate washer onto the dif ferential case together

with the outer race, and install the differential case with

the outer race into the carrier.

(g) Using a plastic hammer, make the washer and bearing smooth by tapping the ring gear.

(h) Using a dial indicator, measure the ring gear backlash. Backlash: 0.15 − 0.20 mm (0.0059 − 0.0079 in.)

If it is not within the specification, adjust it by either increasing

or decreasing the number of washers on both sides by an equal

amount.

HINT:

There should be no clearance between the plate washer and

case.

Ensure that there is ring gear backlash.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 1156 of 1399

RA0090

R08269

SST

−

SUSPENSION AND AXLE REAR DIFFERENTIAL CARRIER

SA−93

1996 LAND CRUISER (RM451U)

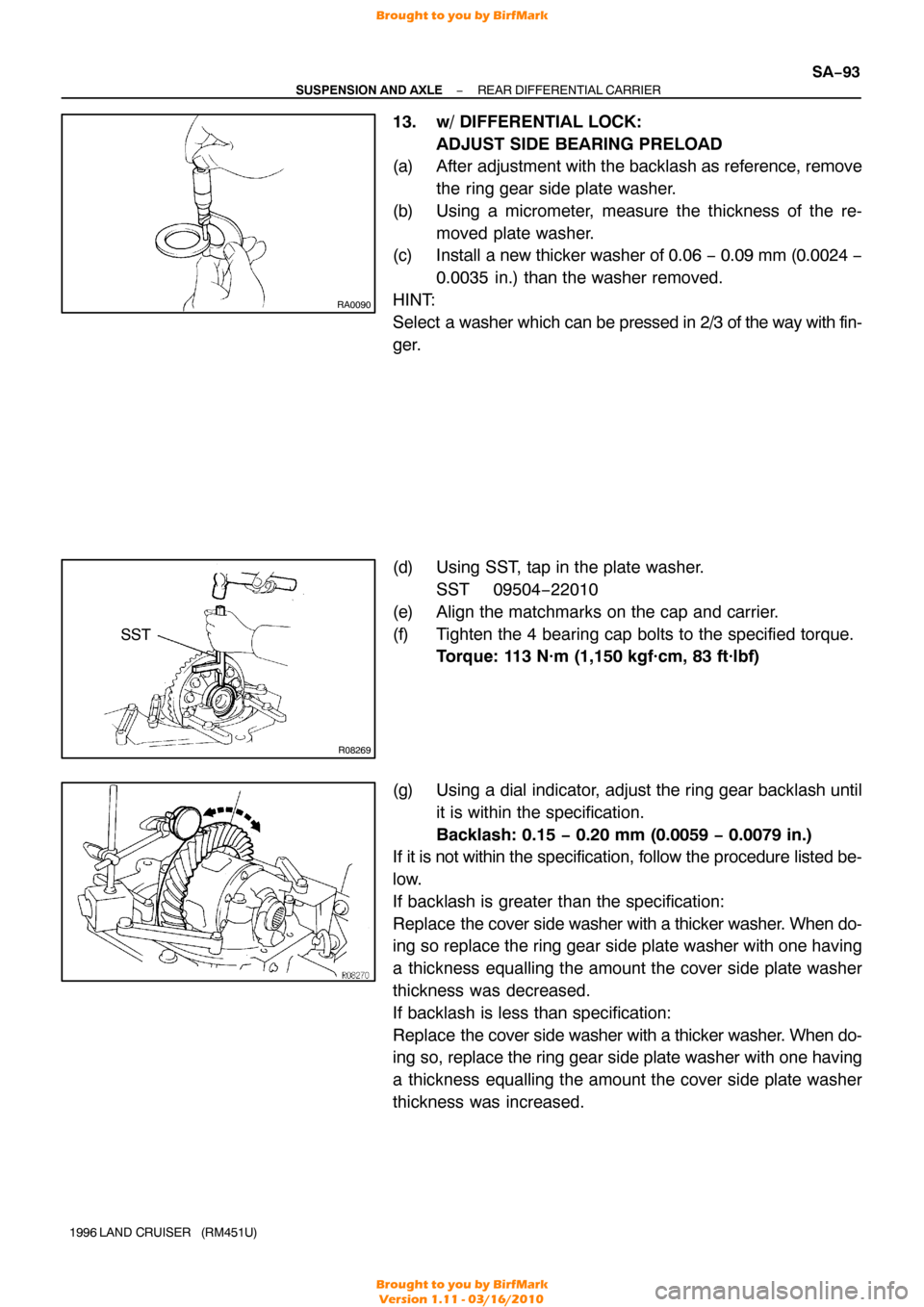

13. w/ DIFFERENTIAL LOCK:

ADJUST SIDE BEARING PRELOAD

(a) After adjustment with the backlash as reference, remove

the ring gear side plate washer.

(b) Using a micrometer, measure the thickness of the re- moved plate washer.

(c) Install a new thicker washer of 0.06 − 0.09 mm (0.0024 −

0.0035 in.) than the washer removed.

HINT:

Select a washer which can be pressed in 2/3 of the way with fin-

ger.

(d) Using SST, tap in the plate washer. SST 09504−22010

(e) Align the matchmarks on the cap and carrier.

(f) Tighten the 4 bearing cap bolts to the specified torque. Torque: 113 N·m (1,150 kgf·cm, 83 ft·lbf)

(g) Using a dial indicator, adjust the ring gear backlash until it is within the specification.

Backlash: 0.15 − 0.20 mm (0.0059 − 0.0079 in.)

If it is not within the specification, follow the procedure listed be-

low.

If backlash is greater than the specification:

Replace the cover side washer with a thicker washer. When do-

ing so replace the ring gear side plate washer with one having

a thickness equalling the amount the cover side plate washer

thickness was decreased.

If backlash is less than specification:

Replace the cover side washer with a thicker washer. When do-

ing so, replace the ring gear side plate washer with one having

a thickness equalling the amount the cover side plate washer

thickness was increased.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 1157 of 1399

Z06953SST

SA2444

SA−94

−

SUSPENSION AND AXLE REAR DIFFERENTIAL CARRIER

1996 LAND CRUISER (RM451U)

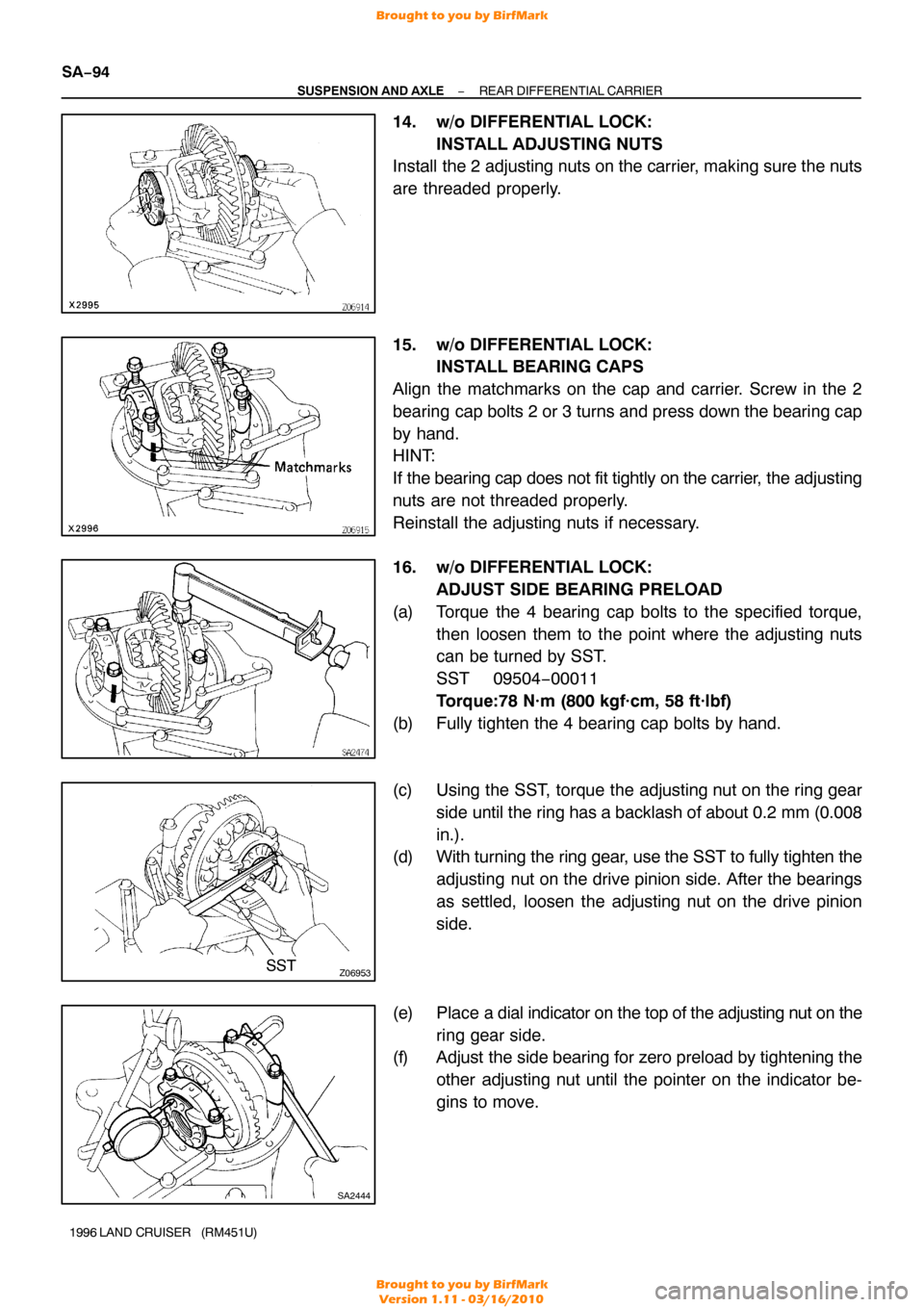

14. w/o DIFFERENTIAL LOCK:

INSTALL ADJUSTING NUTS

Install the 2 adjusting nuts on the carrier, making sure the nuts

are threaded properly.

15. w/o DIFFERENTIAL LOCK: INSTALL BEARING CAPS

Align the matchmarks on the cap and carrier. Screw in the 2

bearing cap bolts 2 or 3 turns and press down the bearing cap

by hand.

HINT:

If the bearing cap does not fit tightly on the carrier , the adjusting

nuts are not threaded properly.

Reinstall the adjusting nuts if necessary.

16. w/o DIFFERENTIAL LOCK: ADJUST SIDE BEARING PRELOAD

(a) Torque the 4 bearing cap bolts to the specified torque, then loosen them to the point where the adjusting nuts

can be turned by SST.

SST 09504−00011

Torque:78 N·m (800 kgf·cm, 58 ft·lbf)

(b) Fully tighten the 4 bearing cap bolts by hand.

(c) Using the SST, torque the adjusting nut on the ring gear side until the ring has a backlash of about 0.2 mm (0.008

in.).

(d) With turning the ring gear, use the SST to fully tighten the

adjusting nut on the drive pinion side. After the bearings

as settled, loosen the adjusting nut on the drive pinion

side.

(e) Place a dial indicator on the top of the adjusting nut on the ring gear side.

(f) Adjust the side bearing for zero preload by tightening the

other adjusting nut until the pointer on the indicator be-

gins to move.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 1158 of 1399

Z06918

−

SUSPENSION AND AXLE REAR DIFFERENTIAL CARRIER

SA−95

1996 LAND CRUISER (RM451U)

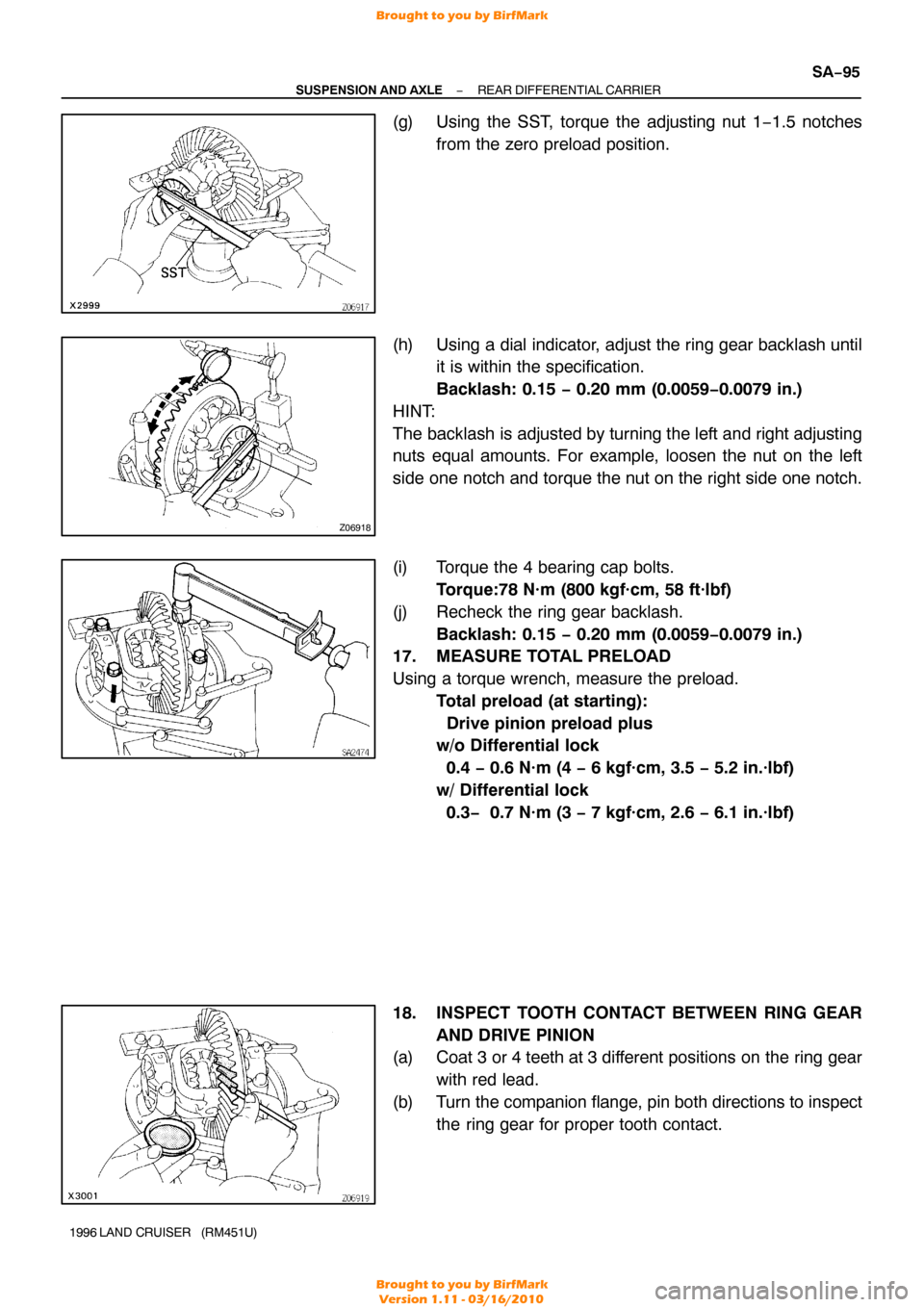

(g) Using the SST, torque the adjusting nut 1−1.5 notches

from the zero preload position.

(h) Using a dial indicator, adjust the ring gear backlash until it is within the specification.

Backlash: 0.15 − 0.20 mm (0.0059−0.0079 in.)

HINT:

The backlash is adjusted by turning the left and right adjusting

nuts equal amounts. For example, loosen the nut on the left

side one notch and torque the nut on the right side one notch.

(i) Torque the 4 bearing cap bolts. Torque:78 N·m (800 kgf·cm, 58 ft·lbf)

(j) Recheck the ring gear backlash. Backlash: 0.15 − 0.20 mm (0.0059−0.0079 in.)

17. MEASURE TOTAL PRELOAD

Using a torque wrench, measure the preload.

Total preload (at starting):

Drive pinion preload plus

w/o Differential lock

0.4 − 0.6 N·m (4 − 6 kgf·cm, 3.5 − 5.2 in.·lbf)

w/ Differential lock

0.3− 0.7 N·m (3 − 7 kgf·cm, 2.6 − 6.1 in.·lbf)

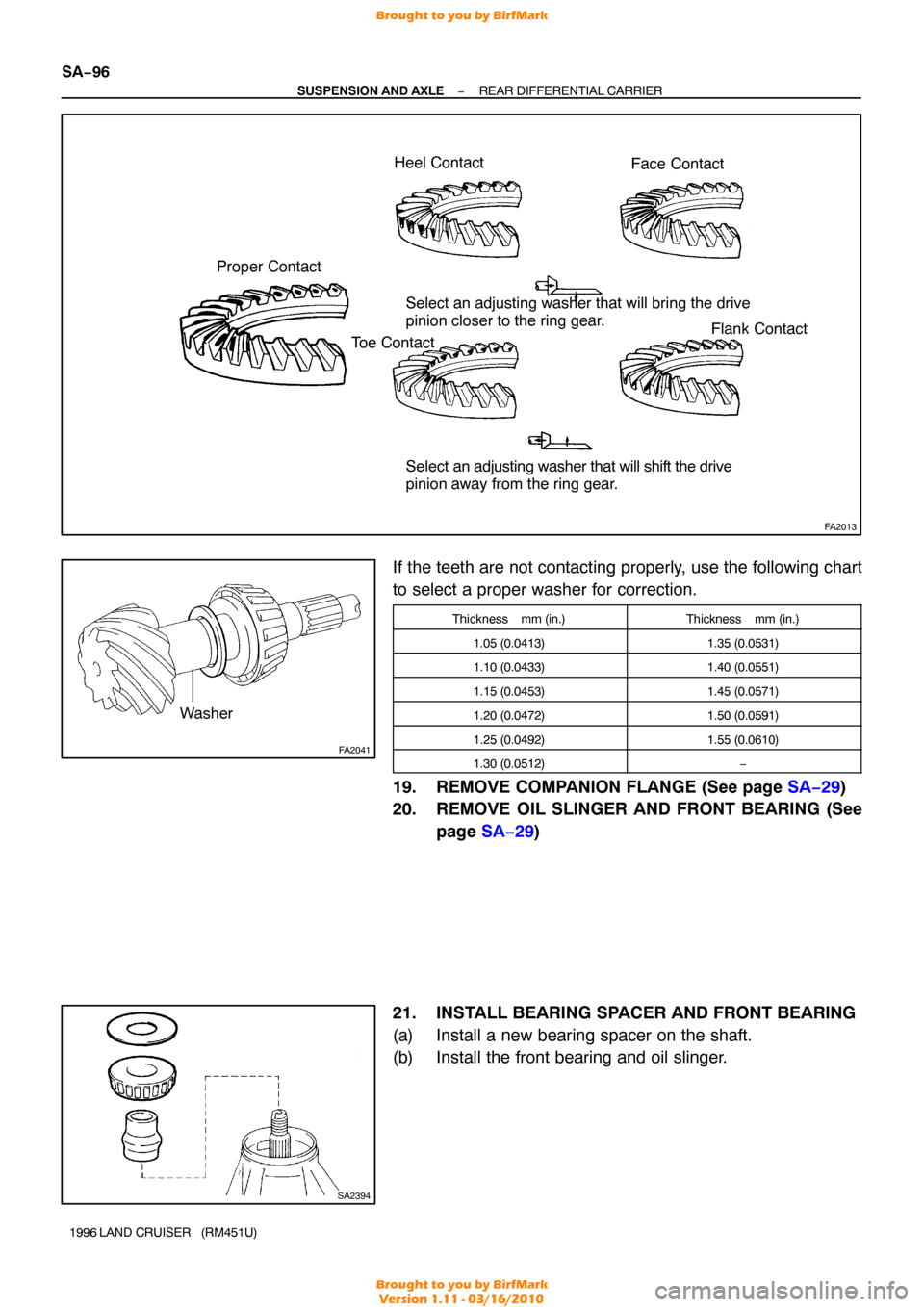

18. INSPECT TOOTH CONTACT BETWEEN RING GEAR AND DRIVE PINION

(a) Coat 3 or 4 teeth at 3 different positions on the ring gear

with red lead.

(b) Turn the companion flange, pin both directions to inspect the ring gear for proper tooth contact.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 1159 of 1399

FA2013

Proper ContactHeel Contact

Face Contact

Select an adjusting washer that will bring the drive

pinion closer to the ring gear.

Select an adjusting washer that will shift the drive

pinion away from the ring gear.

Toe Contact

Flank Contact

FA2041

Washer

SA2394

SA−96

−

SUSPENSION AND AXLE REAR DIFFERENTIAL CARRIER

1996 LAND CRUISER (RM451U)

If the teeth are not contacting properly, use the following chart

to select a proper washer for correction.

Thickness mm (in.)Thickness mm (in.)

1.05 (0.0413)1.35 (0.0531)

1.10 (0.0433)1.40 (0.0551)

1.15 (0.0453)1.45 (0.0571)

1.20 (0.0472)1.50 (0.0591)

1.25 (0.0492)1.55 (0.0610)

1.30 (0.0512)−

19. REMOVE COMPANION FLANGE (See page SA−29)

20. REMOVE OIL SLINGER AND FRONT BEARING (See

page SA−29 )

21. INSTALL BEARING SPACER AND FRONT BEARING

(a) Install a new bearing spacer on the shaft.

(b) Install the front bearing and oil slinger.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010

Page 1160 of 1399

SA2454

SST

R13414

SST

SA2351

SST

SA2446

−

SUSPENSION AND AXLE REAR DIFFERENTIAL CARRIER

SA−97

1996 LAND CRUISER (RM451U)

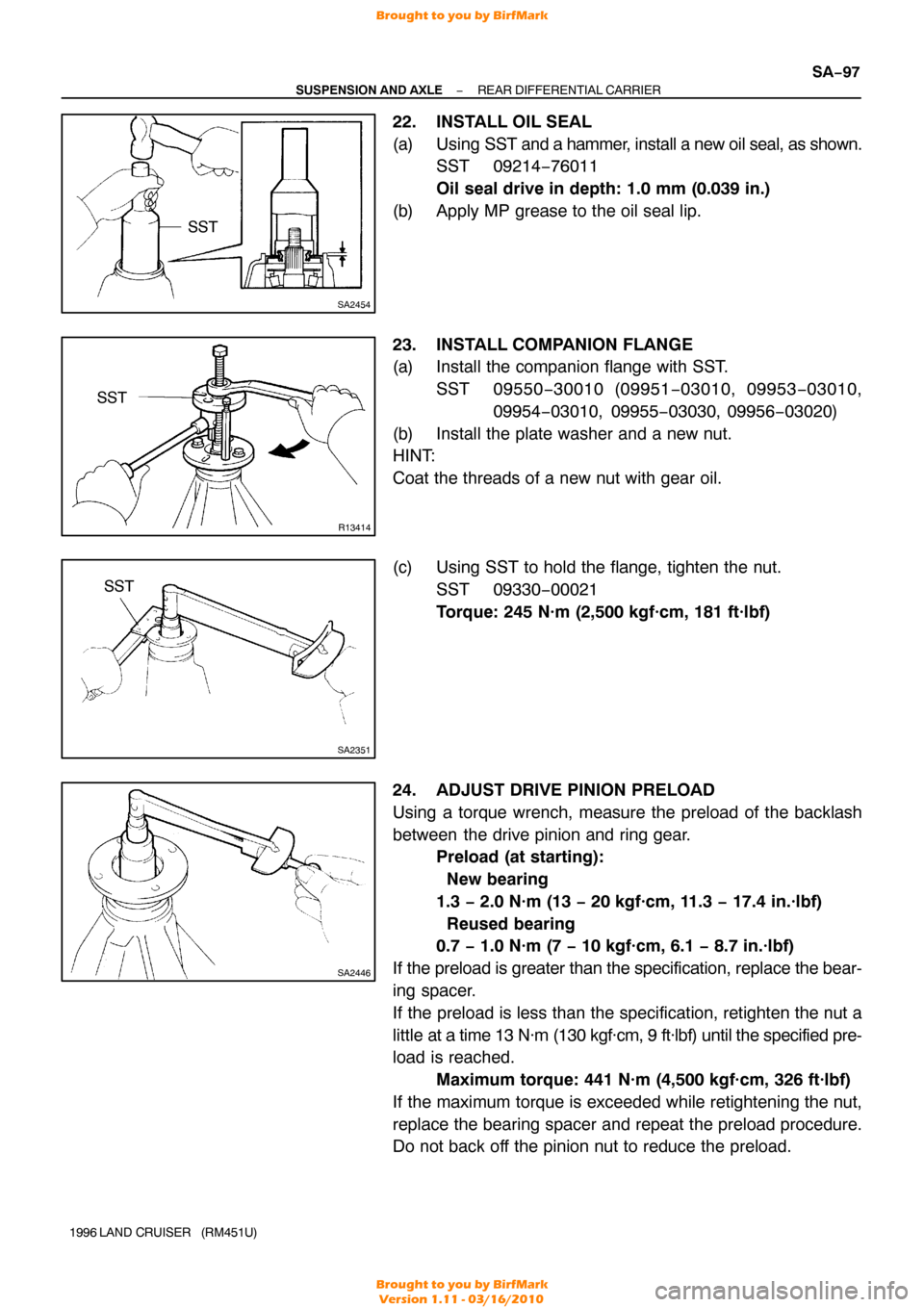

22. INSTALL OIL SEAL

(a) Using SST and a hammer, install a new oil seal, as shown.

SST 09214−76011

Oil seal drive in depth: 1.0 mm (0.039 in.)

(b) Apply MP grease to the oil seal lip.

23. INSTALL COMPANION FLANGE

(a) Install the companion flange with SST. SST 09550 −30010 (09951 −03010, 09953 −03010,

09954 −03010, 09955 −03030, 09956−03020)

(b) Install the plate washer and a new nut.

HINT:

Coat the threads of a new nut with gear oil.

(c) Using SST to hold the flange, tighten the nut. SST 09330−00021

Torque: 245 N·m (2,500 kgf·cm, 181 ft·lbf)

24. ADJUST DRIVE PINION PRELOAD

Using a torque wrench, measure the preload of the backlash

between the drive pinion and ring gear. Preload (at starting):

New bearing

1.3 − 2.0 N·m (13 − 20 kgf·cm, 11.3 − 17.4 in.·lbf)

Reused bearing

0.7 − 1.0 N·m (7 − 10 kgf·cm, 6.1 − 8.7 in.·lbf)

If the preload is greater than the specification, replace the bear-

ing spacer.

If the preload is less than the specification, retighten the nut a

little at a time 13 N·m (130 kgf·cm, 9 ft·lbf) until the specified pre-

load is reached. Maximum torque: 441 N·m (4,500 kgf·cm, 326 ft·lbf)

If the maximum torque is exceeded while retightening the nut,

replace the bearing spacer and repeat the preload procedure.

Do not back off the pinion nut to reduce the preload.

Brought to you by BirfMark

Brought to you by BirfMark

Version 1.11 - 03/16/2010