cruise control TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 17 of 1632

DTC Detecting Condition

Detection of the following condition may set DTC 41:

At vehicle speed of about 2 MPH or more, if voltage at ABS ECU terminal IG1 is less than 9.5 volts for

10 seconds or more, DTC 41 may set.

Diagnostic Procedure

1. Check charging system voltage. If voltage is 10-14 volts, system is okay. Go to next step. If voltage is not

10-14 volts, repair charging system. Ensure system fuses are okay.

2. Turn ignition off. Remove ABS ECU. Do not disconnect electrical connectors. Turn ignition switch to

ON position. Measure voltage between terminals IG1 and GND at ABS ECU harness connector. See Fig.

3 . If voltage is 10-14 volts, turn ignition off. Condition may be intermittent. Check ABS ECU connectors

for poor connection or damage. Repair as necessary. If connectors are okay, replace ABS ECU. If voltage

is not as specified, go to next step.

3. Measure resistance between ground and GND terminals at ABS ECU harness connector. See Fig. 3

. If

resistance is one ohm or less, go to next step. If resistance is more than one ohm, repair ground circuit

wiring. See WIRING DIAGRAMS

.

4. Remove ECU-IG fuse from instrument panel junction block. If fuse is blown, check for short circuit in all

wiring harnesses and components connected to ECU-IG fuse (ECM, A/C, cruise control, deceleration

sensor, combination meter, sun roof, shift lock, transmission pattern select switch). See WIRING

DIAGRAMS . Repair as necessary. If fuse is not blown, check for open circuit in wiring harness between

battery and ABS ECU. Repair as necessary.

DTC 43 & DTC 45: DECELERATION SENSOR MALFUNCTION (4WD MODELS ONLY)

DTC Detecting Conditions

Detection of the following conditions may set DTCs 43 or 45:

On 2-door models, if output voltage from deceleration sensor does not change for 16 consecutive times or

more when vehicle speed is decreased from 19 MPH to zero MPH, DTC 43 will set.

On 4-door models, after battery cables are connected, if input from deceleration sensor does not change at

one cycle (zero MPH to 19 MPH or more, then back to zero) for 16 consecutive times, DTC 43 will set.

When brake pedal is not depressed at vehicle speed of 3 MPH or more, and forward and backward force

(force of more than 0.4 "G") is detected for 30 seconds or more, DTC 43 will set.

On 2-door models, at vehicle speed of 19 MPH or more, if deceleration sensor output and vehicle

acceleration from wheel speed remains abnormally different for one minute or more, DTC 45 will set.

Diagnostic Procedure

1. Check deceleration sensor. See DECELERATION SENSOR CHECK under COMPONENT TESTS.

Replace sensor as necessary. If sensor is okay, go to next step.

2. Check for open or short circuit in wiring harness between deceleration sensor and ABS ECU. See

WIRING DIAGRAMS

. Repair as necessary. If wiring harness is okay, replace ABS ECU.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 113 of 1632

TRANSMISSION SERVICING - A/T

1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal & Installation

REMOVAL & INSTALLATION

MANUAL

AUTOMATIC

Removal (Avalon)

1. Disconnect negative battery cable. Remove battery, battery tray, air cleaner assembly and air cleaner case.

Disconnect throttle valve cable from throttle body. Remove cruise control actuator with mounting

bracket.

2. Raise and support vehicle. Disconnect necessary electrical connectors and ground cables for transaxle

removal. Disconnect shift cable and oil cooler lines at transaxle. Remove shift cable clamp bracket from

transaxle.

3. Remove front (radiator side) engine mount shock absorber-to-lower frame assembly bolts. Remove front

(radiator side) engine mount-to-lower frame assembly bolts/nuts. Remove starter.

4. Remove front (radiator side) exhaust manifold brace from rear of exhaust manifolds. Brace fits between

rear of exhaust manifold and front of transaxle.

5. Remove upper transaxle-to-cylinder block bolts. Support engine with hoist. Steering gear assembly must

be supported in place during transaxle removal. Secure steering gear assembly to the engine hoist using

an attaching strap placed at each end of steering gear assembly.

6. Remove front wheels. Remove front exhaust pipe located between exhaust manifolds and rear exhaust

pipe. Drain transaxle fluid. Remove axle shafts from transaxle. See FWD AXLE SHAFTS article in

DRIVE AXLES.

7. Disconnect shift control cable from mounting bracket. Remove rear (firewall side) engine mount-to-lower

frame assembly bolts/nuts. Remove transaxle mount-to-transaxle bolts at driver's side end of transaxle.

8. Remove stabilizer bar mount bracket-to-lower frame assembly bolts. Remove steering gear assembly-to-

lower frame assembly bolts/nuts. Support lower frame assembly with floor jack. Lower frame assembly is

located below the en

gine and transaxle. NOTE: For manual transmission/transaxle removal and installation procedures, see

appropriate CLUTCHES article.

WARNING:Ensure negative battery cable is disconnected at least 90 seconds before

working on vehicle to prevent air bag deployment.

CAUTION: When battery is disconnected, vehicle computer and memory systems

may lose memory data. Driveability problems may exist until computer

systems have completed a relearn cycle.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Helpmelearn

November-03-08 10:30:32 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 115 of 1632

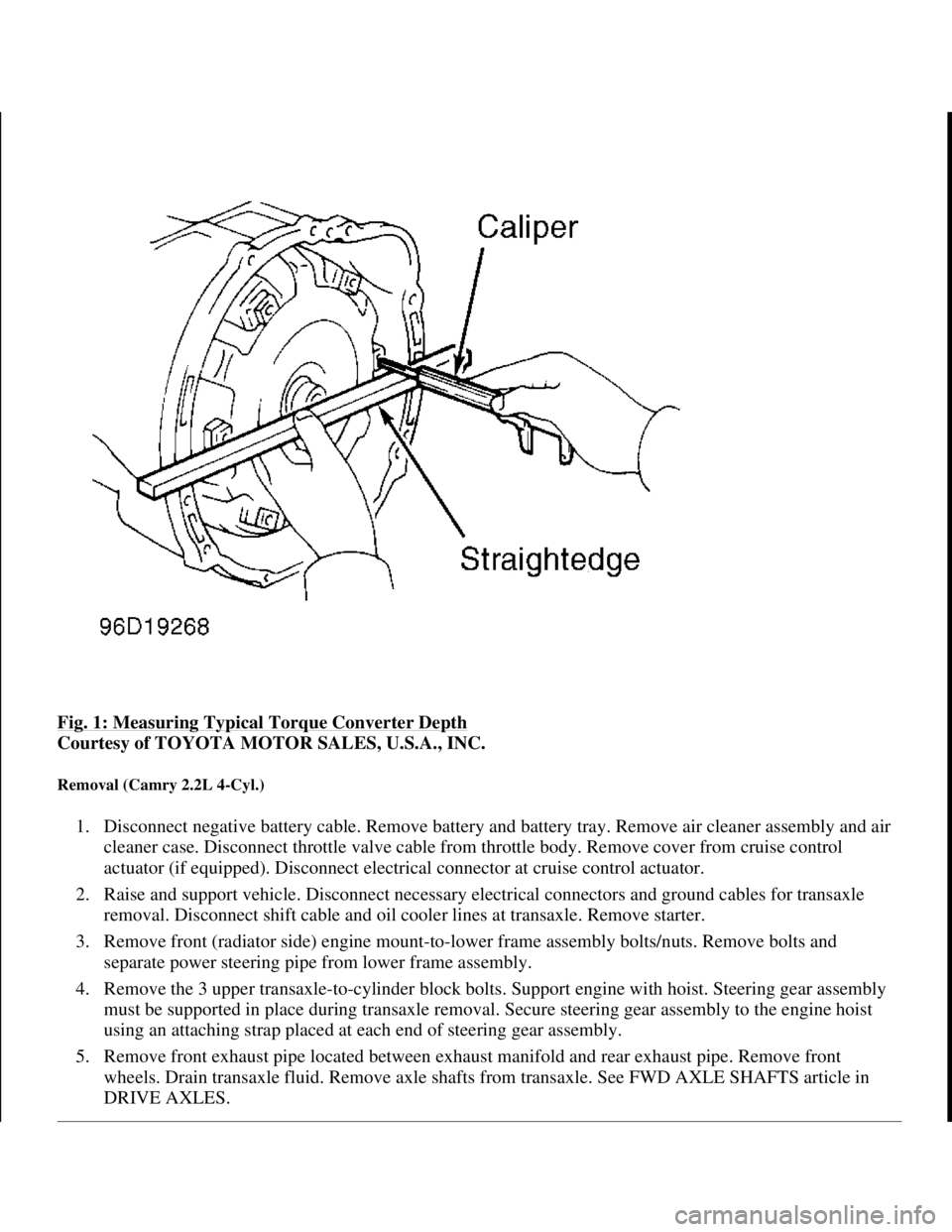

Fig. 1: Measuring Typical Torque Converter Depth

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Removal (Camry 2.2L 4-Cyl.)

1. Disconnect negative battery cable. Remove battery and battery tray. Remove air cleaner assembly and air

cleaner case. Disconnect throttle valve cable from throttle body. Remove cover from cruise control

actuator (if equipped). Disconnect electrical connector at cruise control actuator.

2. Raise and support vehicle. Disconnect necessary electrical connectors and ground cables for transaxle

removal. Disconnect shift cable and oil cooler lines at transaxle. Remove starter.

3. Remove front (radiator side) engine mount-to-lower frame assembly bolts/nuts. Remove bolts and

separate power steering pipe from lower frame assembly.

4. Remove the 3 upper transaxle-to-cylinder block bolts. Support engine with hoist. Steering gear assembly

must be supported in place during transaxle removal. Secure steering gear assembly to the engine hoist

using an attaching strap placed at each end of steering gear assembly.

5. Remove front exhaust pipe located between exhaust manifold and rear exhaust pipe. Remove front

wheels. Drain transaxle fluid. Remove axle shafts from transaxle. See FWD AXLE SHAFTS article in

DRIVE AXLES.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 116 of 1632

6. Remove rear (firewall side) engine mount-to-lower frame assembly nuts. Remove transaxle mount-to-

transaxle bolts at driver's side end of transaxle.

7. Remove stabilizer bar mount bracket-to-lower frame assembly bolts. Remove steering gear assembly-to-

lower frame assembly bolts/nuts. Support lower frame assembly with floor jack. Lower frame assembly is

located below the engine and transaxle.

8. Remove bolts for each fender liner from lower frame assembly. Remove lower frame assembly mounting

brackets. Lower frame assembly mounting brackets are located on the front and rear of lower frame

assembly attaching the lower frame assembly to the body. Remove lower frame assembly.

9. Remove stiffener plates located on each side of cylinder block. Stiffener plate fits between side of

cylinder block and front of transaxle. Support transaxle with transmission jack.

10. Remove torque converter cover from front of transaxle. Remove Black torque converter bolt first and

then the remaining torque converter bolts. Remove remaining transaxle-to-cylinder block bolts. Lower

transaxle from vehicle.

Installation

1. Before installing transaxle, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transaxle. To ensure torque converter is fully seated, torque converter depth

should be checked. Using straightedge and caliper, measure torque converter depth from torque converter

bolt lug on torque converter to the surface on transaxle. See Fig. 1

.

3. Torque converter depth should be more than .510" (13.00 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. Ensure the Black torque converter bolt is installed first before installing the

remaining torque converter bolts. Adjust all cables and fill with ATF. See appropriate TRANSMISSION

SERVICING article.

Removal (Camry 3.0L V6)

1. Disconnect negative battery cable. Remove battery, air cleaner assembly and air cleaner case. Disconnect

throttle valve cable from throttle body. Remove cruise control actuator with mounting bracket from the

body.

2. Raise and support vehicle. Disconnect necessary electrical connectors and ground cables for transaxle

removal. Disconnect shift cable and oil cooler lines at transaxle. Remove shift cable clamp bracket from

transaxle.

3. Remove front (radiator side) engine mount shock absorber-to-lower frame assembly bolts. Remove front

(radiator side) engine mount-to-lower frame assembly bolts/nuts. Remove starter.

4. Remove the 5 upper transaxle-to-cylinder block bolts. Support engine with hoist. Steering gear assembly

must be supported in place during transaxle removal. Secure steering gear assembly to the engine hoist

using an attaching strap placed at each end of steering gear assembly.

5. Remove front wheels. Remove front exhaust pipe located between exhaust manifolds and rear exhaust

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 121 of 1632

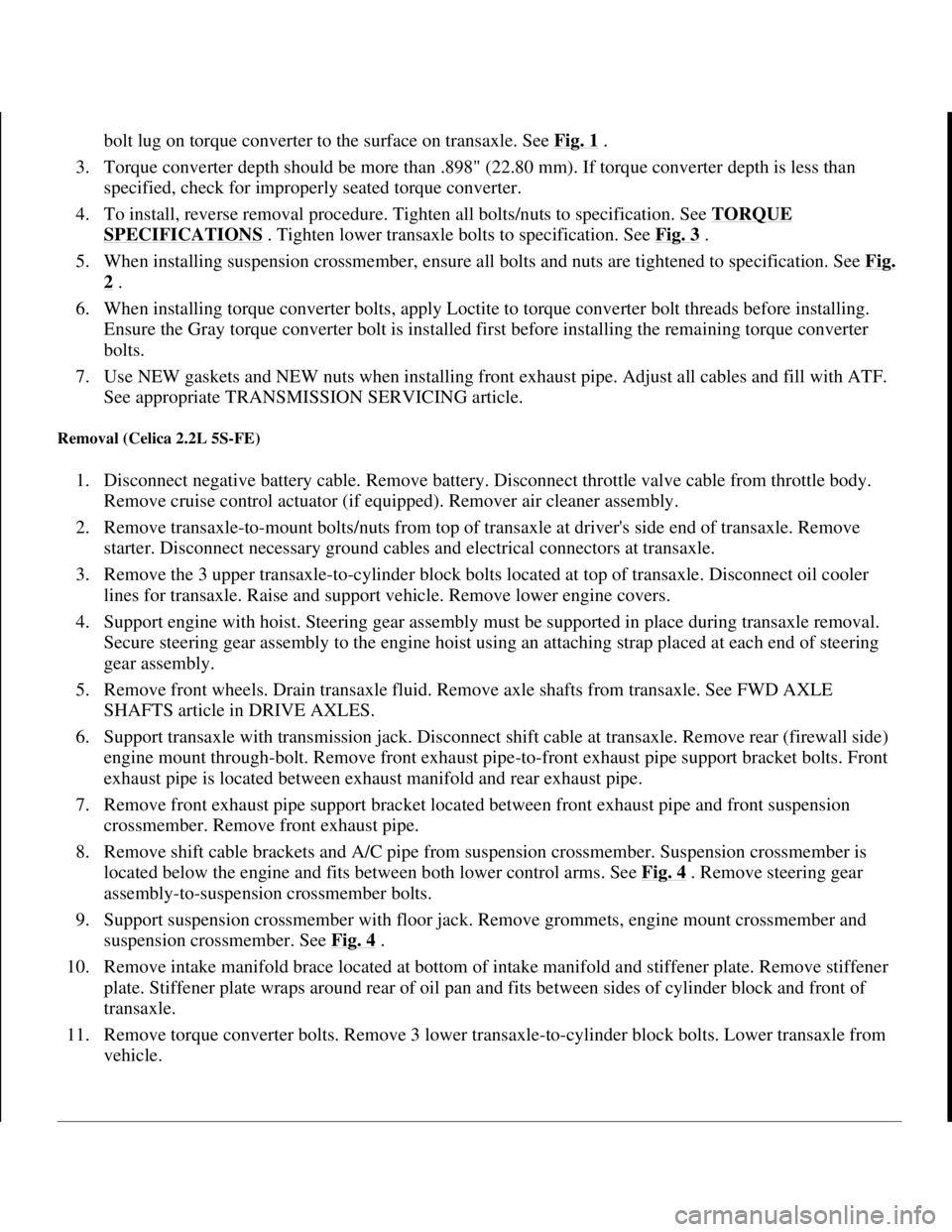

bolt lug on torque converter to the surface on transaxle. See Fig. 1.

3. Torque converter depth should be more than .898" (22.80 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . Tighten lower transaxle bolts to specification. See Fig. 3 .

5. When installing suspension crossmember, ensure all bolts and nuts are tightened to specification. See Fi

g.

2 .

6. When installing torque converter bolts, apply Loctite to torque converter bolt threads before installing.

Ensure the Gray torque converter bolt is installed first before installing the remaining torque converter

bolts.

7. Use NEW gaskets and NEW nuts when installing front exhaust pipe. Adjust all cables and fill with ATF.

See appropriate TRANSMISSION SERVICING article.

Removal (Celica 2.2L 5S-FE)

1. Disconnect negative battery cable. Remove battery. Disconnect throttle valve cable from throttle body.

Remove cruise control actuator (if equipped). Remover air cleaner assembly.

2. Remove transaxle-to-mount bolts/nuts from top of transaxle at driver's side end of transaxle. Remove

starter. Disconnect necessary ground cables and electrical connectors at transaxle.

3. Remove the 3 upper transaxle-to-cylinder block bolts located at top of transaxle. Disconnect oil cooler

lines for transaxle. Raise and support vehicle. Remove lower engine covers.

4. Support engine with hoist. Steering gear assembly must be supported in place during transaxle removal.

Secure steering gear assembly to the engine hoist using an attaching strap placed at each end of steering

gear assembly.

5. Remove front wheels. Drain transaxle fluid. Remove axle shafts from transaxle. See FWD AXLE

SHAFTS article in DRIVE AXLES.

6. Support transaxle with transmission jack. Disconnect shift cable at transaxle. Remove rear (firewall side)

engine mount through-bolt. Remove front exhaust pipe-to-front exhaust pipe support bracket bolts. Front

exhaust pipe is located between exhaust manifold and rear exhaust pipe.

7. Remove front exhaust pipe support bracket located between front exhaust pipe and front suspension

crossmember. Remove front exhaust pipe.

8. Remove shift cable brackets and A/C pipe from suspension crossmember. Suspension crossmember is

located below the engine and fits between both lower control arms. See Fig. 4

. Remove steering gear

assembly-to-suspension crossmember bolts.

9. Support suspension crossmember with floor jack. Remove grommets, engine mount crossmember and

suspension crossmember. See Fig. 4

.

10. Remove intake manifold brace located at bottom of intake manifold and stiffener plate. Remove stiffener

plate. Stiffener plate wraps around rear of oil pan and fits between sides of cylinder block and front of

transaxle.

11. Remove torque converter bolts. Remove 3 lower transaxle-to-cylinder block bolts. Lower transaxle from

vehicle.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 9 © 2005 Mitchell Repair Information Company, LLC.

Page 126 of 1632

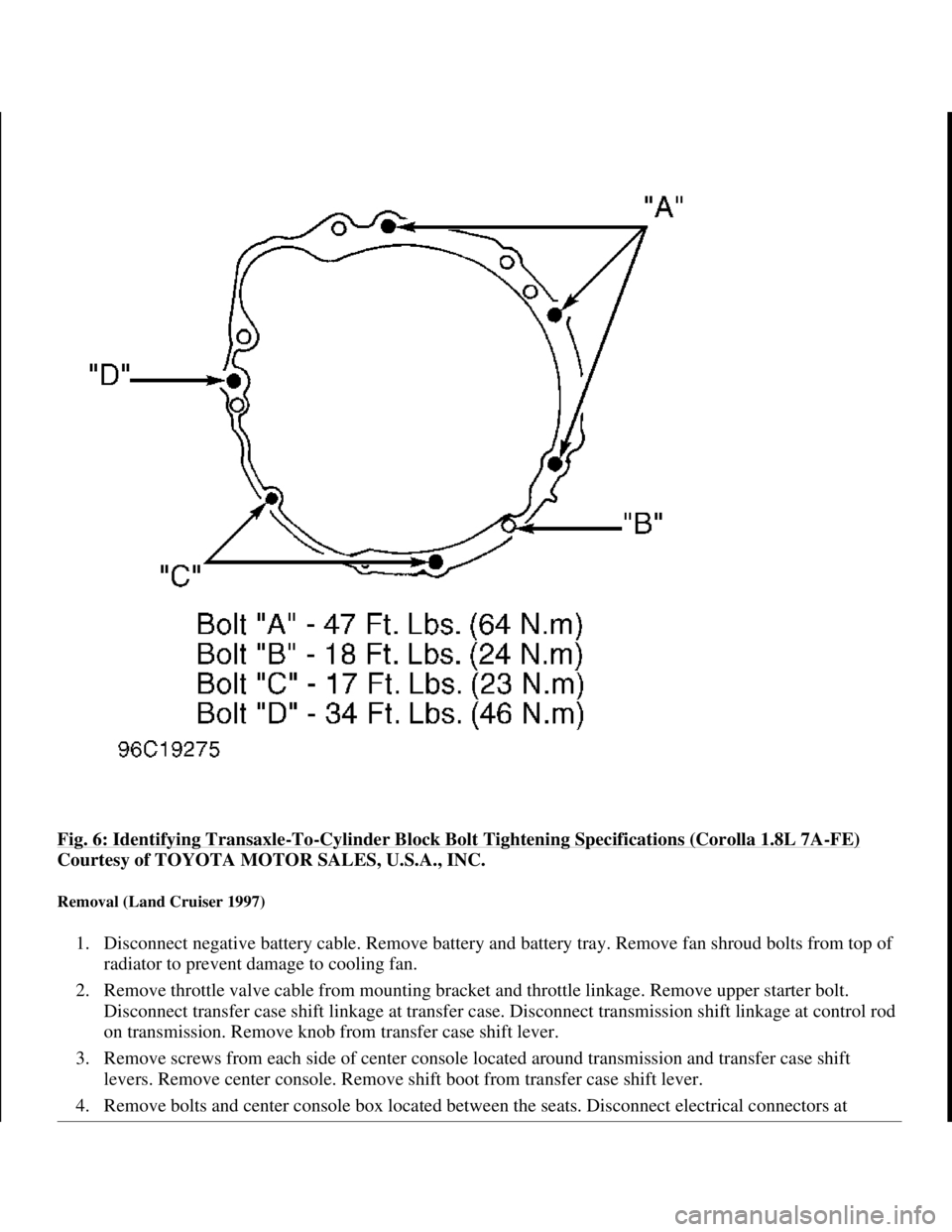

Fig. 6: Identifying Transaxle-To-Cylinder Block Bolt Tightening Specifications (Corolla 1.8L 7A-FE)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Removal (Land Cruiser 1997)

1. Disconnect negative battery cable. Remove battery and battery tray. Remove fan shroud bolts from top of

radiator to prevent damage to cooling fan.

2. Remove throttle valve cable from mounting bracket and throttle linkage. Remove upper starter bolt.

Disconnect transfer case shift linkage at transfer case. Disconnect transmission shift linkage at control rod

on transmission. Remove knob from transfer case shift lever.

3. Remove screws from each side of center console located around transmission and transfer case shift

levers. Remove center console. Remove shift boot from transfer case shift lever.

4. Remove bolts and center console box located between the seats. Disconnect electrical connectors at

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 14 © 2005 Mitchell Repair Information Company, LLC.

Page 134 of 1632

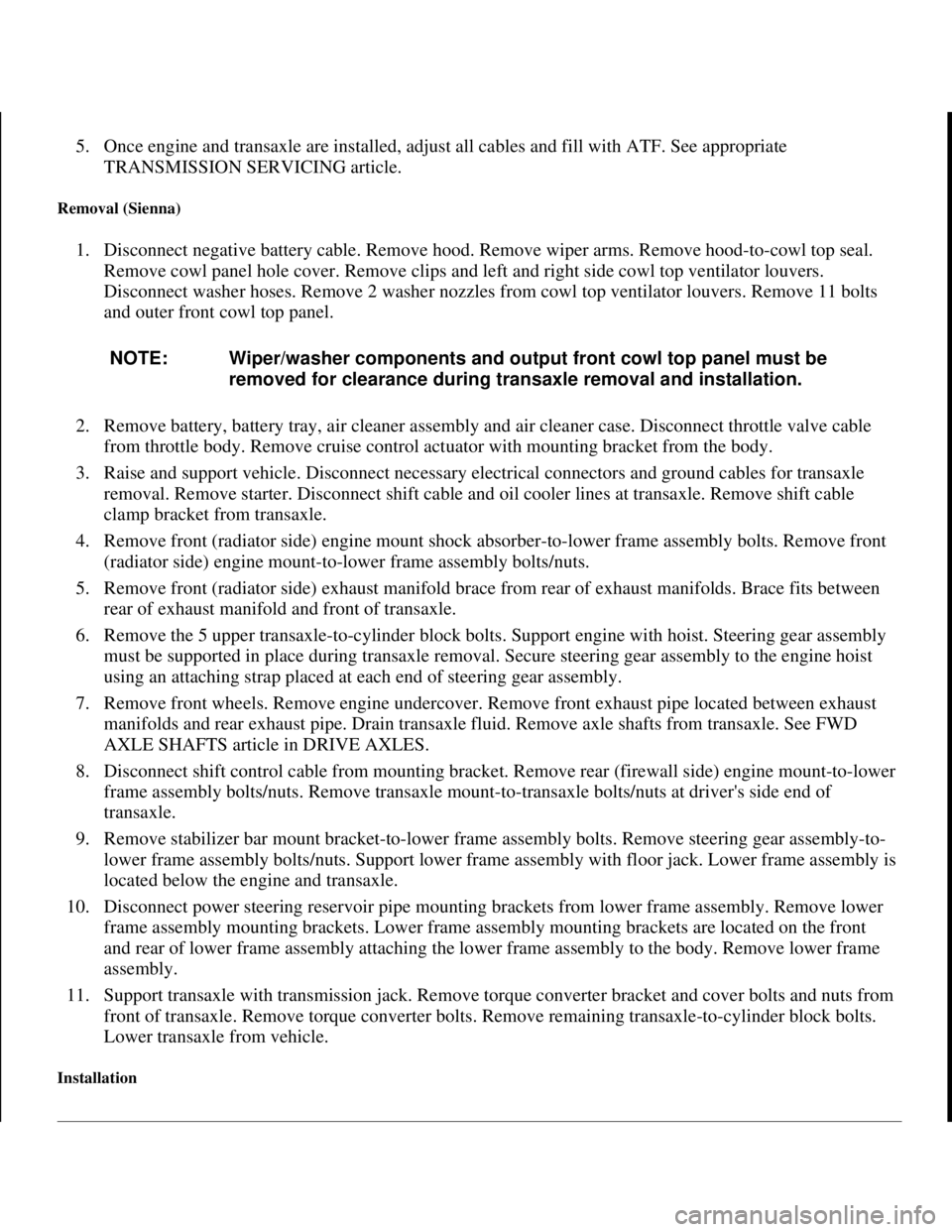

5. Once engine and transaxle are installed, adjust all cables and fill with ATF. See appropriate

TRANSMISSION SERVICING article.

Removal (Sienna)

1. Disconnect negative battery cable. Remove hood. Remove wiper arms. Remove hood-to-cowl top seal.

Remove cowl panel hole cover. Remove clips and left and right side cowl top ventilator louvers.

Disconnect washer hoses. Remove 2 washer nozzles from cowl top ventilator louvers. Remove 11 bolts

and outer front cowl top panel.

2. Remove battery, battery tray, air cleaner assembly and air cleaner case. Disconnect throttle valve cable

from throttle body. Remove cruise control actuator with mounting bracket from the body.

3. Raise and support vehicle. Disconnect necessary electrical connectors and ground cables for transaxle

removal. Remove starter. Disconnect shift cable and oil cooler lines at transaxle. Remove shift cable

clamp bracket from transaxle.

4. Remove front (radiator side) engine mount shock absorber-to-lower frame assembly bolts. Remove front

(radiator side) engine mount-to-lower frame assembly bolts/nuts.

5. Remove front (radiator side) exhaust manifold brace from rear of exhaust manifolds. Brace fits between

rear of exhaust manifold and front of transaxle.

6. Remove the 5 upper transaxle-to-cylinder block bolts. Support engine with hoist. Steering gear assembly

must be supported in place during transaxle removal. Secure steering gear assembly to the engine hoist

using an attaching strap placed at each end of steering gear assembly.

7. Remove front wheels. Remove engine undercover. Remove front exhaust pipe located between exhaust

manifolds and rear exhaust pipe. Drain transaxle fluid. Remove axle shafts from transaxle. See FWD

AXLE SHAFTS article in DRIVE AXLES.

8. Disconnect shift control cable from mounting bracket. Remove rear (firewall side) engine mount-to-lower

frame assembly bolts/nuts. Remove transaxle mount-to-transaxle bolts/nuts at driver's side end of

transaxle.

9. Remove stabilizer bar mount bracket-to-lower frame assembly bolts. Remove steering gear assembly-to-

lower frame assembly bolts/nuts. Support lower frame assembly with floor jack. Lower frame assembly is

located below the engine and transaxle.

10. Disconnect power steering reservoir pipe mounting brackets from lower frame assembly. Remove lower

frame assembly mounting brackets. Lower frame assembly mounting brackets are located on the front

and rear of lower frame assembly attaching the lower frame assembly to the body. Remove lower frame

assembly.

11. Support transaxle with transmission jack. Remove torque converter bracket and cover bolts and nuts from

front of transaxle. Remove torque converter bolts. Remove remaining transaxle-to-cylinder block bolts.

Lower transaxle from vehicle.

Installation

NOTE: Wiper/washer components and output front cowl top panel must be

removed for clearance during transaxle removal and installation.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 22 © 2005 Mitchell Repair Information Company, LLC.

Page 164 of 1632

1. If shift lever is actuated with engine idling, a time lag will be noted before shock can be felt. This test is

used for checking condition of OD direct clutch, forward clutch, direct clutch, and 1st and reverse brake.

2. Apply parking brake. Start engine. On RAV4, ensure idle speed is 700-800 RPM. On all other models,

ensure idle speed is 650-750 RPM. Shift transaxle from "N" into "D" range. Use a stop watch to measure

elapsed time between shifting of lever until shock is felt. Standard time lag is less than 1.2 seconds.

3. Repeat procedure outlined in step 2) to measure time lag for "N" to "R". Standard lag time is less than 1.5

seconds.

4. If "N" to "D" time lag is longer than specification, line pressure is too low, forward clutch may be worn,

or OD one-way clutch is not operating properly.

5. If "N" to "R" time lag is longer than specified, direct clutch may be worn, 1st and reverse brake may be

worn, line pressure is too low or OD one-way clutch is not operating properly.

ROAD TEST

"D" Range Test In NORM & PWR Pattern Ranges

1. Shift into "D" range. Hold accelerator pedal constant at full throttle. Place shift mode button in NORM or

PWR position. Check 1-2, 2-3, and 3-OD lock-up and upshift points. See appropriate table under SHIFT

SPEED SPECIFICATIONS .

�zIf no 1-2 upshift occurs, check 1-2 shift valve or solenoid.

�zIf no 2-3 upshift occurs, check 2-3 shift valve or solenoid.

�zIf no 3-OD upshift occurs, check 3-OD shift valve.

�zIf all shift points are incorrect, check throttle valve, 1-2 shift valve, 2-3 shift valve and 3-OD shift

valve.

�zIf all lock-up points are incorrect, check lock-up relay valve or shift solenoid valve SL.

2. Use procedure outlined in step 1) to check for shock and slip between 1-2, 2-3, and 3-OD upshifts. If

shock is harsh, line pressure may be too high. Check accumulator or check ball.

3. Run vehicle in "D" range lock-up or overdrive gear. Check for abnormal noise and vibration.

4. While running in "D" range, confirm correct kickdown vehicle speed limits for 2-1, 3-2, OD-3 shift

points. Check for abnormal shock and slip at kickdown.

5. Check loc

k-up function. Drive vehicle in OD gear of "D" range with lock-up on. Hold vehicle speed NOTE: Perform test at normal operating fluid temperature of 122-176°F (50-80°C).

NOTE: There is no overdrive upshift when coolant temperature is below 140°F

(60°C). There is no lock-up when vehicle speed is 6 MPH less than the set

cruise control speed.

NOTE: Check for cause of abnormal noise and vibration must be made with

extreme care as problem could be due to an unbalanced drive shaft,

differential, tire, torque converter, etc.

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:17 AMPage 10 © 2005 Mitchell Repair Information Company, LLC.

Page 269 of 1632

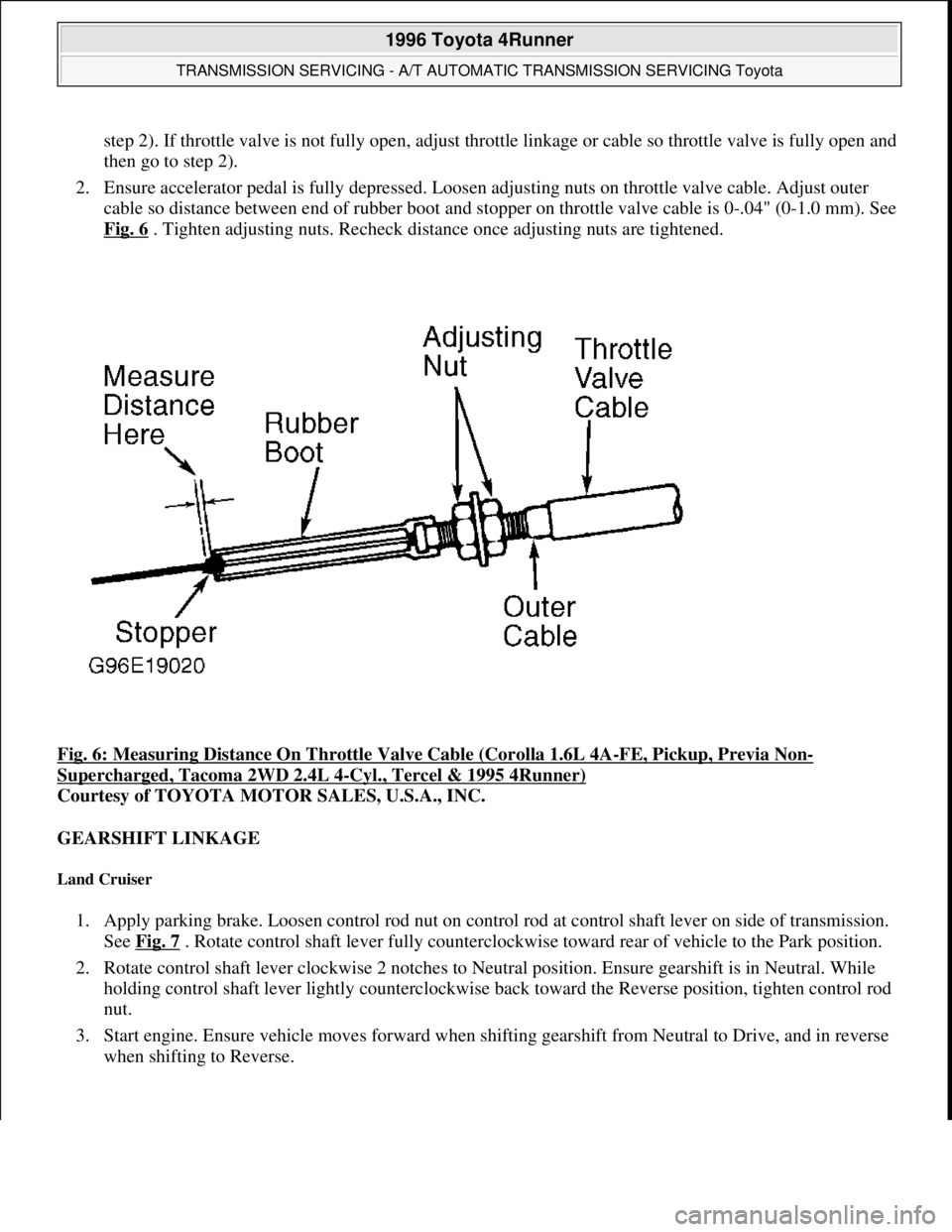

step 2). If throttle valve is not fully open, adjust throttle linkage or cable so throttle valve is fully open and

then go to step 2).

2. Ensure accelerator pedal is fully depressed. Loosen adjusting nuts on throttle valve cable. Adjust outer

cable so distance between end of rubber boot and stopper on throttle valve cable is 0-.04" (0-1.0 mm). See

Fig. 6

. Tighten adjusting nuts. Recheck distance once adjusting nuts are tightened.

Fig. 6: Measuring Distance On Throttle Valve Cable (Corolla 1.6L 4A

-FE, Pickup, Previa Non-

Supercharged, Tacoma 2WD 2.4L 4-Cyl., Tercel & 1995 4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

GEARSHIFT LINKAGE

Land Cruiser

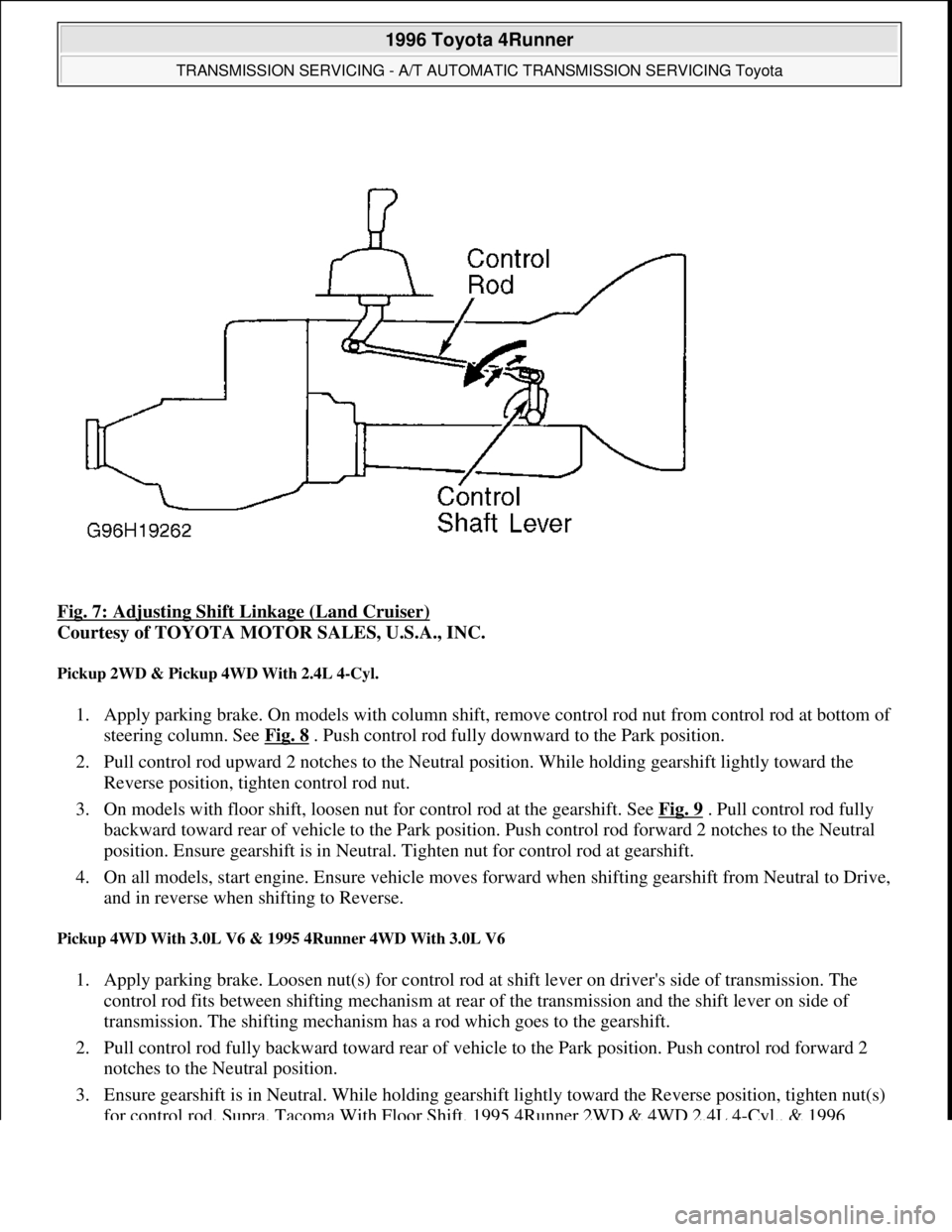

1. Apply parking brake. Loosen control rod nut on control rod at control shaft lever on side of transmission.

See Fig. 7

. Rotate control shaft lever fully counterclockwise toward rear of vehicle to the Park position.

2. Rotate control shaft lever clockwise 2 notches to Neutral position. Ensure gearshift is in Neutral. While

holding control shaft lever lightly counterclockwise back toward the Reverse position, tighten control rod

nut.

3. Start engine. Ensure vehicle moves forward when shifting gearshift from Neutral to Drive, and in reverse

when shiftin

g to Reverse.

1996 Toyota 4Runner

TRANSMISSION SERVICING - A/T AUTOMATIC TRANSMISSION SERVICING Toyota

Microsoft

Tuesday, August 18, 2009 7:18:46 PMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 270 of 1632

Fig. 7: Adjusting Shift Linkage (Land Cruiser)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Pickup 2WD & Pickup 4WD With 2.4L 4-Cyl.

1. Apply parking brake. On models with column shift, remove control rod nut from control rod at bottom of

steering column. See Fig. 8

. Push control rod fully downward to the Park position.

2. Pull control rod upward 2 notches to the Neutral position. While holding gearshift lightly toward the

Reverse position, tighten control rod nut.

3. On models with floor shift, loosen nut for control rod at the gearshift. See Fig. 9

. Pull control rod fully

backward toward rear of vehicle to the Park position. Push control rod forward 2 notches to the Neutral

position. Ensure gearshift is in Neutral. Tighten nut for control rod at gearshift.

4. On all models, start engine. Ensure vehicle moves forward when shifting gearshift from Neutral to Drive,

and in reverse when shifting to Reverse.

Pickup 4WD With 3.0L V6 & 1995 4Runner 4WD With 3.0L V6

1. Apply parking brake. Loosen nut(s) for control rod at shift lever on driver's side of transmission. The

control rod fits between shifting mechanism at rear of the transmission and the shift lever on side of

transmission. The shifting mechanism has a rod which goes to the gearshift.

2. Pull control rod fully backward toward rear of vehicle to the Park position. Push control rod forward 2

notches to the Neutral position.

3. Ensure gearshift is in Neutral. While holding gearshift lightly toward the Reverse position, tighten nut(s)

for control rod. Supra, Tacoma With Floor Shift, 1995 4Runner 2WD & 4WD 2.4L 4-C

yl., & 1996

1996 Toyota 4Runner

TRANSMISSION SERVICING - A/T AUTOMATIC TRANSMISSION SERVICING Toyota

Microsoft

Tuesday, August 18, 2009 7:18:46 PMPage 14 © 2005 Mitchell Repair Information Company, LLC.