valve clearance TOYOTA RAV4 1996 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 718 of 1632

lifted upward as No. 2 camshaft bearing cap bolts are loosened.

4. If intake camshaft is not lifted upward, reinstall all camshaft bearing caps. Reposition intake camshaft so

knock pin is 80-115 degrees from vertical position. See Fig. 19

. Repeat steps 9) and 10) . Remove No. 2

camshaft bearing cap and intake camshaft.

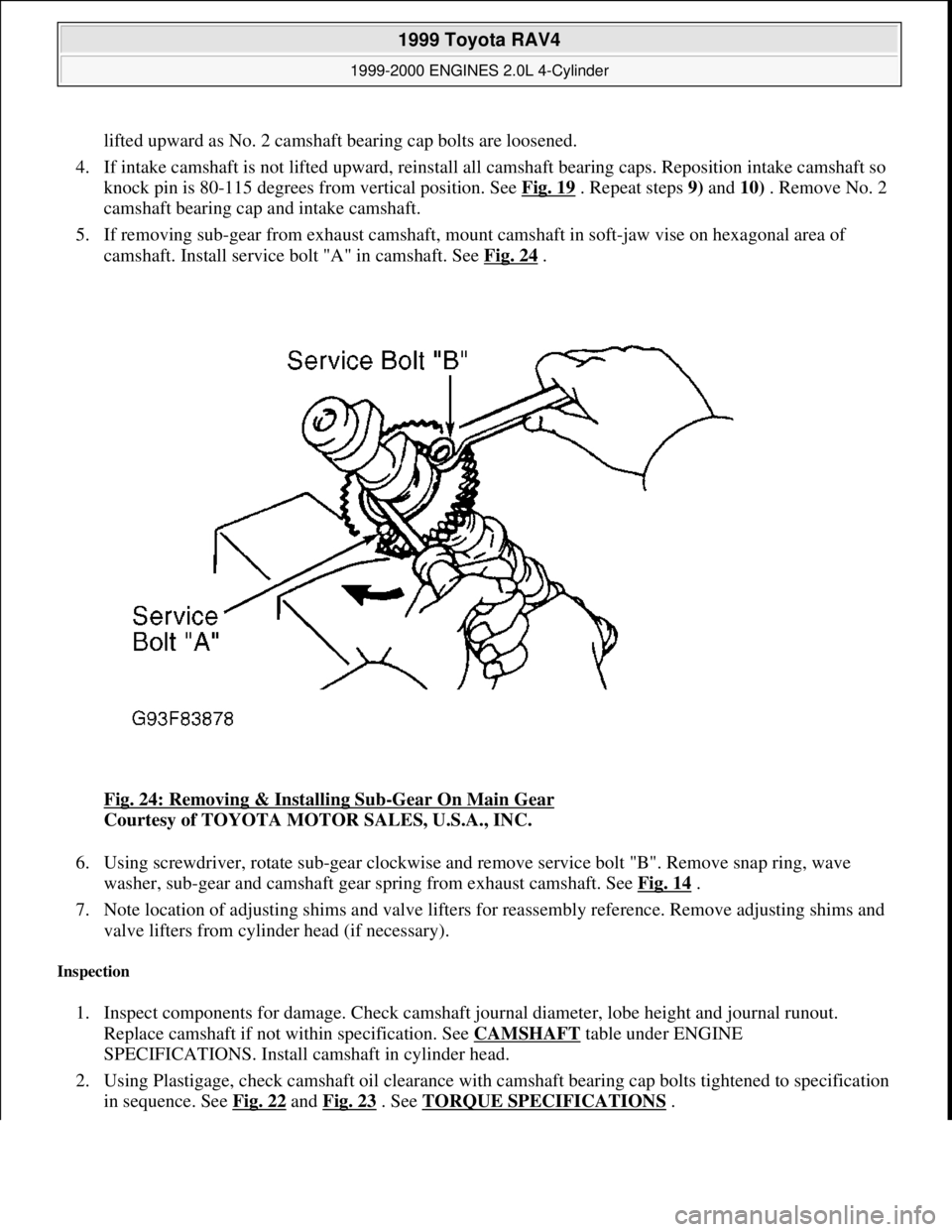

5. If removing sub-gear from exhaust camshaft, mount camshaft in soft-jaw vise on hexagonal area of

camshaft. Install service bolt "A" in camshaft. See Fig. 24

.

Fig. 24: Removing & Installing Sub

-Gear On Main Gear

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

6. Using screwdriver, rotate sub-gear clockwise and remove service bolt "B". Remove snap ring, wave

washer, sub-gear and camshaft gear spring from exhaust camshaft. See Fig. 14

.

7. Note location of adjusting shims and valve lifters for reassembly reference. Remove adjusting shims and

valve lifters from cylinder head (if necessary).

Inspection

1. Inspect components for damage. Check camshaft journal diameter, lobe height and journal runout.

Replace camshaft if not within specification. See CAMSHAFT

table under ENGINE

SPECIFICATIONS. Install camshaft in cylinder head.

2. Using Plastigage, check camshaft oil clearance with camshaft bearing cap bolts tightened to specification

in sequence. See Fig. 22

and Fig. 23 . See TORQUE SPECIFICATIONS.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 35 © 2005 Mitchell Repair Information Company, LLC.

Page 719 of 1632

3. Check camshaft end play with camshaft bearing cap bolts tightened to specification. Replace camshaft

and/or cylinder head if camshaft end play is not within specification. See CAMSHAFT

table under

ENGINE SPECIFICATIONS.

4. Install both camshafts in cylinder head without sub-gear installed on exhaust camshaft. Install and tighten

camshaft bearing cap bolts to specification in sequence. See Fig. 22

and Fig. 23 . See TORQUE

SPECIFICATIONS .

5. Using dial indicator, check gear backlash between gears on camshafts. Replace camshafts if gear backlash

exceeds specification. See CAMSHAFT

table under ENGINE SPECIFICATIONS.

6. Measure length of camshaft gear spring. Replace camshaft gear spring if distance is not within

specification. See CAMSHAFT

table under ENGINE SPECIFICATIONS. Measure valve lifter diameter

and bore diameter. Ensure oil clearance is within specification. Replace components if not within

specification. See VALVE LIFTERS

table under ENGINE SPECIFICATIONS.

Installation

1. If installing sub-gear on exhaust camshaft, install camshaft gear spring, sub-gear, wave washer and snap

ring on exhaust camshaft. Ensure pins on main gear and sub-gear engage with ends of camshaft gear

spring.

2. Install service bolt "A" on sub-gear. See Fig. 24

. Using screwdriver, rotate sub-gear clockwise and align

hole in sub-gear with hole on main gear. Install service bolt "B". Remove service bolt "A".

3. Install adjusting shims and valve lifters in original location on cylinder head (if removed). Ensure valve

lifters rotate smoothly in cylinder head.

4. Coat thrust surfaces of camshafts with multipurpose grease. To install intake camshaft, rotate intake

camshaft so knock pin is at 80-115 degrees from vertical position, and install into cylinder head. See Fig.

19 .

5. Coat seal lip of NEW oil seal for intake camshaft with grease. Install oil seal onto front of intake camshaft

until oil seal is fully seated in cylinder head. Apply sealant to front camshaft bearing cap for intake

camshaft. See Fig. 25

.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 36 © 2005 Mitchell Repair Information Company, LLC.

Page 721 of 1632

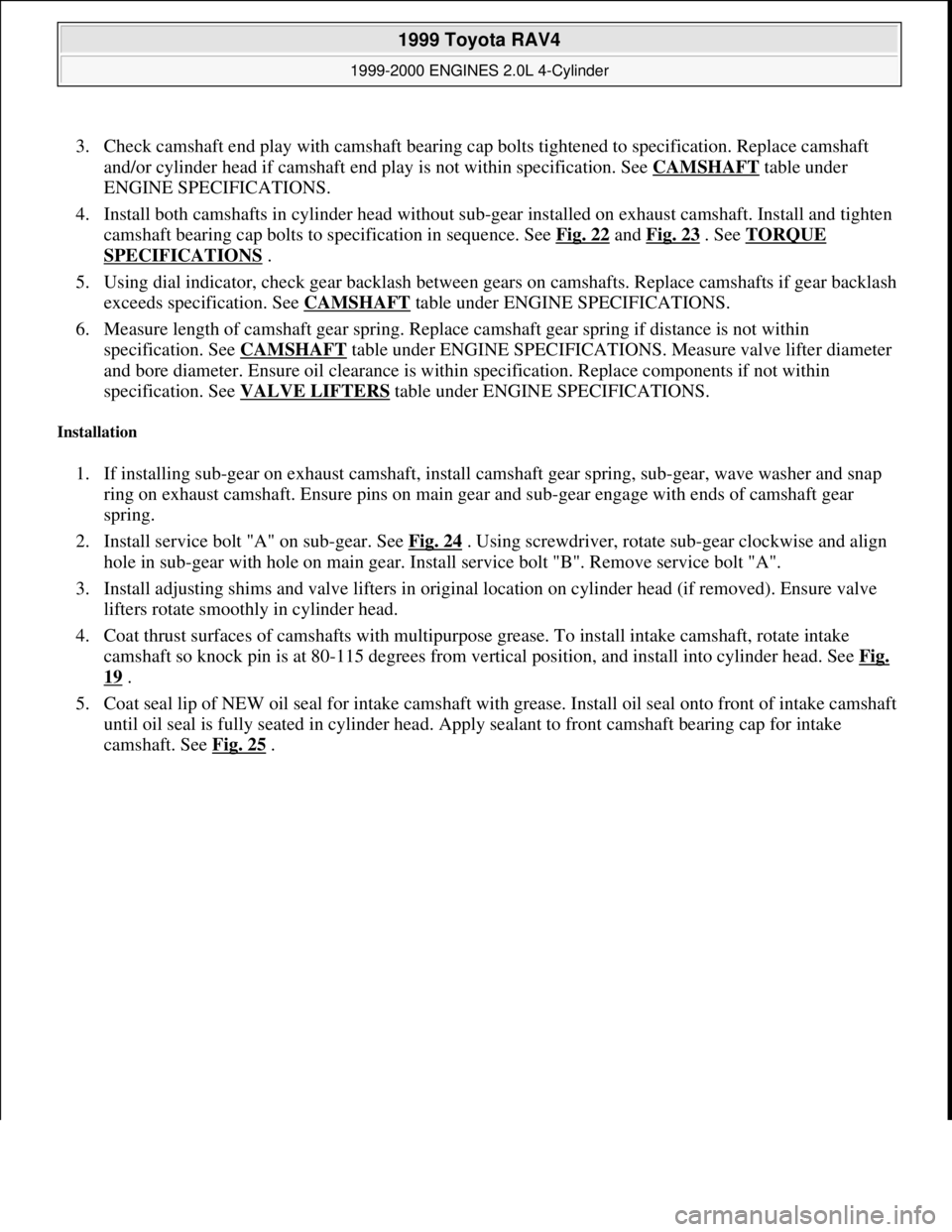

Fig. 26: Aligning Camshaft Timing Marks

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

9. Install camshaft bearing caps for exhaust camshaft on cylinder head in numerical sequence with arrow

pointing toward timing belt end of engine. See Fig. 21

.

10. Coat threads and bolt head-to-camshaft bearing cap contact surfaces of camshaft bearing cap bolts with

engine oil. Install and tighten camshaft bearing cap bolts to specification in sequence using several steps.

See Fig. 22

. See TORQUE SPECIFICATIONS .

11. Remove service bolt "B" from camshaft gear. See Fig. 24

. Install No. 3 timing belt cover. Install and

tighten bolts to specification. See TORQUE SPECIFICATIONS

. Install timing belt using proper

procedure. See TIMING BELT

.

12. Check valve clearance. See VALVE CLEARANCE ADJUSTMENT

under ADJUSTMENTS. Apply

sealant in grooves on rear side of semi-circular plugs located on exhaust camshaft side of cylinder head.

Install semi-circular plugs in cylinder head.

13. Before installing gasket and valve cover, apply sealant at front and rear valve cover areas on cylinder

head. See Fig. 6

.

14. Using NEW gasket, install valve cover. Install grommets in original location with marking on grommet

aligned in designated area. See Fig. 7

. Install and tighten valve cover nuts to specification. See

TORQUE SPECIFICATIONS

.

15. If installing distributor, install NEW "O" ring on distributor. Coat "O" ring with engine oil.

16. Rotate crankshaft clockwise, as viewed from timing belt end of engine, so cylinder No. 1 is at TDC on

compression stroke and timing mark on crankshaft pulley aligns with "0" mark on timing belt cover.

C

ylinder No. 1 is front cylinder at timing belt end of engine.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:26 AMPage 38 © 2005 Mitchell Repair Information Company, LLC.

Page 726 of 1632

4. Ensure valve lifter bore diameter in cylinder head is within specification. See VALVE LIFTERS table

under ENGINE SPECIFICATIONS.

Valve Springs

Ensure valve spring free length, pressure and out-of-square are within specification. See VALVES & VALVE

SPRINGS table under ENGINE SPECIFICATIONS.

Valve Stem Oil Seals

Intake valve stem oil seal is Brown. Exhaust valve stem oil seal is Black. Ensure proper valve stem oil seal is

installed. Lubricate valve stem oil seal with engine oil. Install valve stem oil seal using Oil Seal Installer (SST

09201-41020).

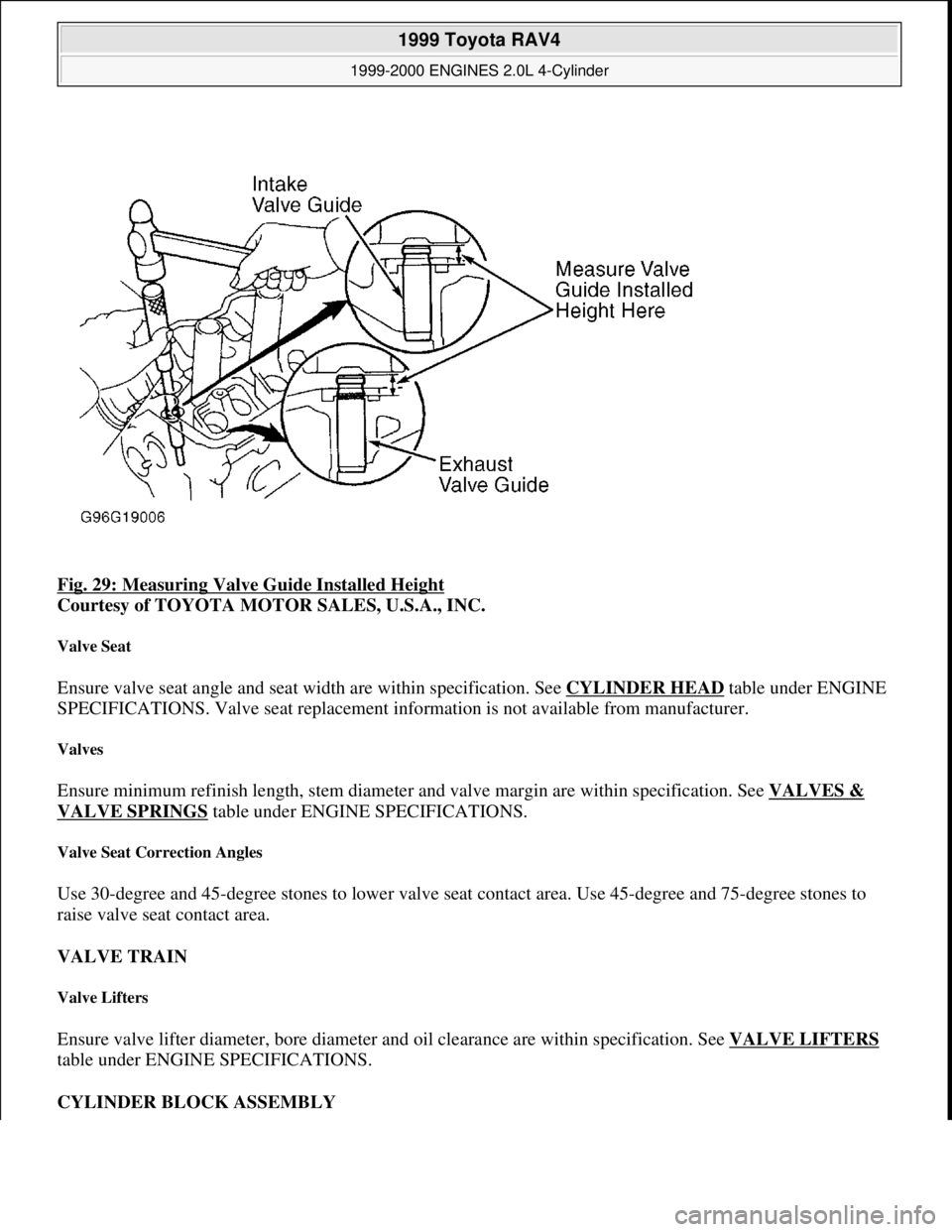

Valve Guides

1. Ensure valve guide inside diameter is within specification. See CYLINDER HEAD table under ENGINE

SPECIFICATIONS. Replace valve guide if inside diameter exceeds specification.

2. To replace valve guide, heat cylinder head to 176-212°F (80-100°C). Using a hammer and Valve Guide

Remover/Installer (SST 09201-01060), drive valve guide from camshaft side of cylinder head.

3. Measure cylinder head valve guide bore inside diameter. If bore inside diameter is .4325-.4335" (10.985-

11.012 mm), use standard valve guide. If bore inside diameter is .4344-.4355" (11.035-11.062 mm), use

oversize valve guide.

4. If bore inside diameter exceeds .4335" (11.012 mm), machine valve guide bore to .4344-.4355" (11.035-

11.062 mm) for oversize valve guide. If bore inside diameter exceeds .4355" (11.062 mm), replace

cylinder head.

5. Intake valve guide is 1.516" (38.50 mm) long. Exhaust valve guide is 1.594" (40.50 mm) long. Ensure

proper valve guide is installed.

6. To install valve guide, heat cylinder head to 176-212°F (80-100°C). Using hammer and valve guide

remover/installer, drive valve guide in from camshaft side of cylinder head until valve guide installed

height is .315-.346" (8.00-8.80 mm). Valve guide installed height is measured from top of valve guide to

cylinder head surface. See Fig. 29

.

7. On all valve guide applications, use .236" (6.00 mm) reamer to ream valve guide to obtain correct valve

stem-to-guide oil clearance. See CYLINDER HEAD

table under ENGINE SPECIFICATIONS. CAUTION: Valve stems oil seals are painted a different color on top of oil seal for

specified valve application. Intake valve stem oil seal is Brown and

exhaust valve stem oil seal is Black. Ensure valve stem oil seal is installed

in proper location.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 43 © 2005 Mitchell Repair Information Company, LLC.

Page 727 of 1632

Fig. 29: Measuring Valve Guide Installed Height

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Valve Seat

Ensure valve seat angle and seat width are within specification. See CYLINDER HEAD table under ENGINE

SPECIFICATIONS. Valve seat replacement information is not available from manufacturer.

Valves

Ensure minimum refinish length, stem diameter and valve margin are within specification. See VALVES &

VALVE SPRINGS table under ENGINE SPECIFICATIONS.

Valve Seat Correction Angles

Use 30-degree and 45-degree stones to lower valve seat contact area. Use 45-degree and 75-degree stones to

raise valve seat contact area.

VALVE TRAIN

Valve Lifters

Ensure valve lifter diameter, bore diameter and oil clearance are within specification. See VALVE LIFTERS

table under ENGINE SPECIFICATIONS.

CYLINDER BLOCK ASSEMBLY

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 44 © 2005 Mitchell Repair Information Company, LLC.

Page 738 of 1632

under REMOVAL & INSTALLATION. Remove oil pan. See OIL PANunder REMOVAL &

INSTALLATION.

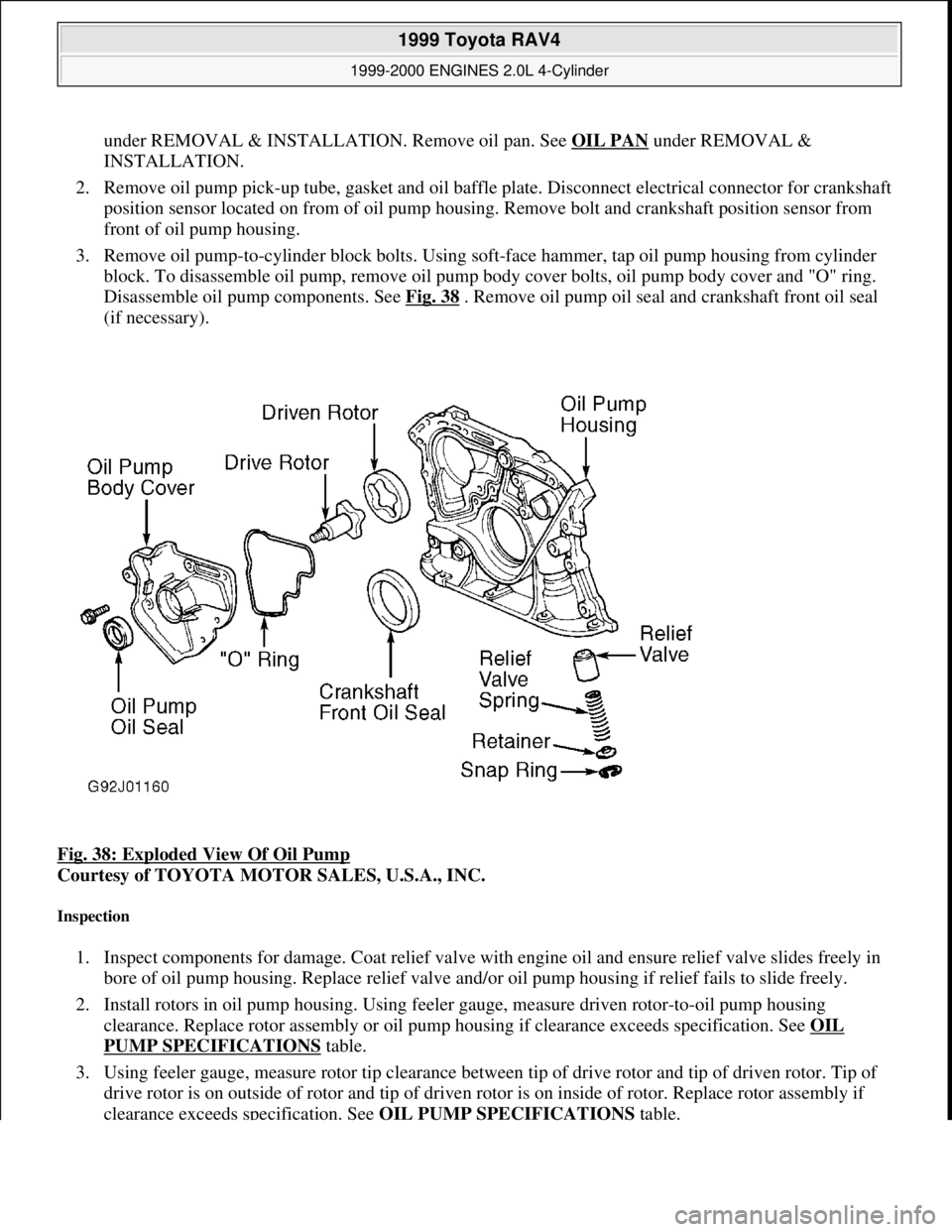

2. Remove oil pump pick-up tube, gasket and oil baffle plate. Disconnect electrical connector for crankshaft

position sensor located on from of oil pump housing. Remove bolt and crankshaft position sensor from

front of oil pump housing.

3. Remove oil pump-to-cylinder block bolts. Using soft-face hammer, tap oil pump housing from cylinder

block. To disassemble oil pump, remove oil pump body cover bolts, oil pump body cover and "O" ring.

Disassemble oil pump components. See Fig. 38

. Remove oil pump oil seal and crankshaft front oil seal

(if necessary).

Fig. 38: Exploded View Of Oil Pump

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Inspection

1. Inspect components for damage. Coat relief valve with engine oil and ensure relief valve slides freely in

bore of oil pump housing. Replace relief valve and/or oil pump housing if relief fails to slide freely.

2. Install rotors in oil pump housing. Using feeler gauge, measure driven rotor-to-oil pump housing

clearance. Replace rotor assembly or oil pump housing if clearance exceeds specification. See OIL

PUMP SPECIFICATIONS table.

3. Using feeler gauge, measure rotor tip clearance between tip of drive rotor and tip of driven rotor. Tip of

drive rotor is on outside of rotor and tip of driven rotor is on inside of rotor. Replace rotor assembly if

clearance exceeds specification. See OIL PUMP SPECIFICATIONS

table.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 55 © 2005 Mitchell Repair Information Company, LLC.

Page 739 of 1632

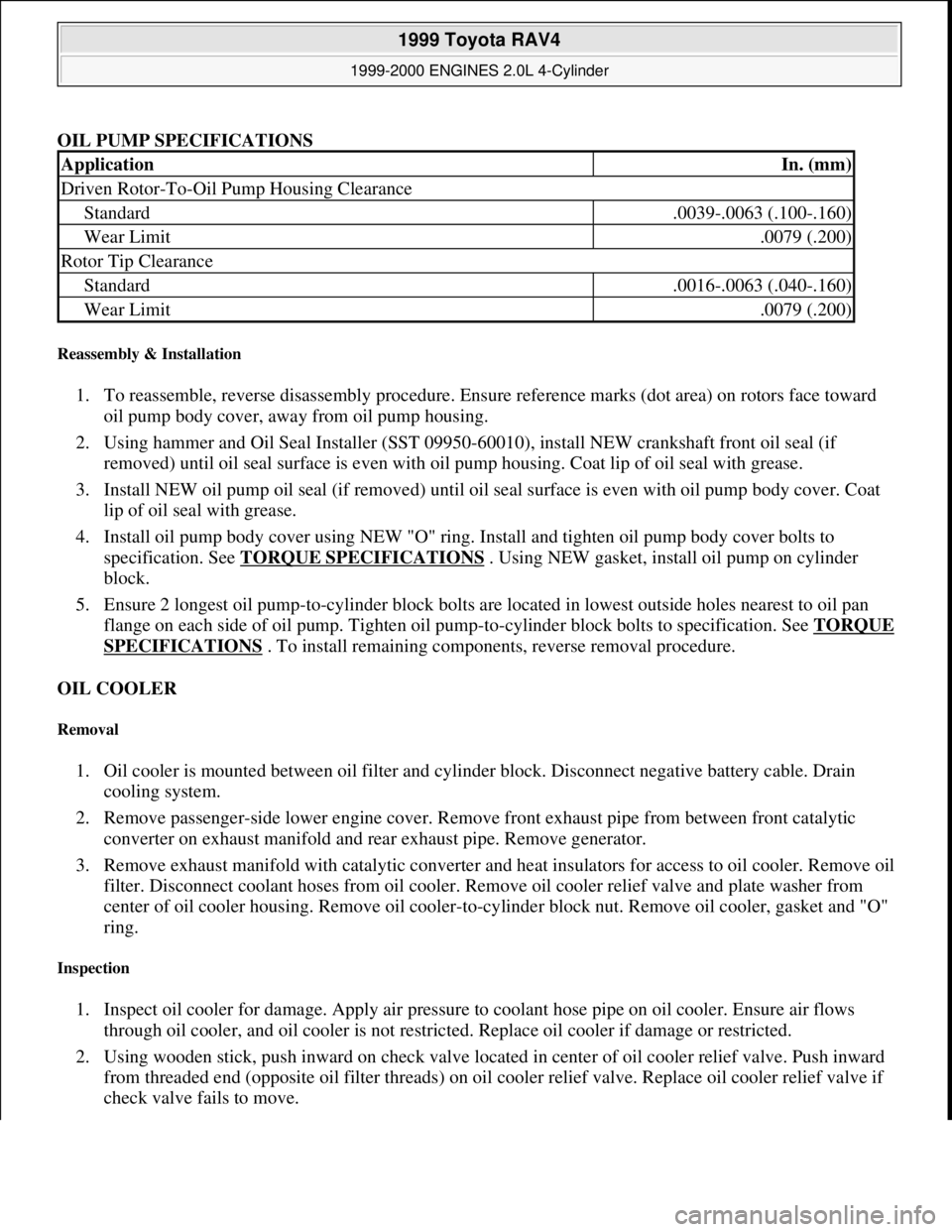

OIL PUMP SPECIFICATIONS

Reassembly & Installation

1. To reassemble, reverse disassembly procedure. Ensure reference marks (dot area) on rotors face toward

oil pump body cover, away from oil pump housing.

2. Using hammer and Oil Seal Installer (SST 09950-60010), install NEW crankshaft front oil seal (if

removed) until oil seal surface is even with oil pump housing. Coat lip of oil seal with grease.

3. Install NEW oil pump oil seal (if removed) until oil seal surface is even with oil pump body cover. Coat

lip of oil seal with grease.

4. Install oil pump body cover using NEW "O" ring. Install and tighten oil pump body cover bolts to

specification. See TORQUE SPECIFICATIONS

. Using NEW gasket, install oil pump on cylinder

block.

5. Ensure 2 longest oil pump-to-cylinder block bolts are located in lowest outside holes nearest to oil pan

flange on each side of oil pump. Tighten oil pump-to-cylinder block bolts to specification. See TORQUE

SPECIFICATIONS . To install remaining components, reverse removal procedure.

OIL COOLER

Removal

1. Oil cooler is mounted between oil filter and cylinder block. Disconnect negative battery cable. Drain

cooling system.

2. Remove passenger-side lower engine cover. Remove front exhaust pipe from between front catalytic

converter on exhaust manifold and rear exhaust pipe. Remove generator.

3. Remove exhaust manifold with catalytic converter and heat insulators for access to oil cooler. Remove oil

filter. Disconnect coolant hoses from oil cooler. Remove oil cooler relief valve and plate washer from

center of oil cooler housing. Remove oil cooler-to-cylinder block nut. Remove oil cooler, gasket and "O"

ring.

Inspection

1. Inspect oil cooler for damage. Apply air pressure to coolant hose pipe on oil cooler. Ensure air flows

through oil cooler, and oil cooler is not restricted. Replace oil cooler if damage or restricted.

2. Using wooden stick, push inward on check valve located in center of oil cooler relief valve. Push inward

from threaded end (opposite oil filter threads) on oil cooler relief valve. Replace oil cooler relief valve if

check valve fails to move.

ApplicationIn. (mm)

Driven Rotor-To-Oil Pump Housing Clearance

Standard.0039-.0063 (.100-.160)

Wear Limit.0079 (.200)

Rotor Tip Clearance

Standard.0016-.0063 (.040-.160)

Wear Limit.0079 (.200)

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 56 © 2005 Mitchell Repair Information Company, LLC.

Page 747 of 1632

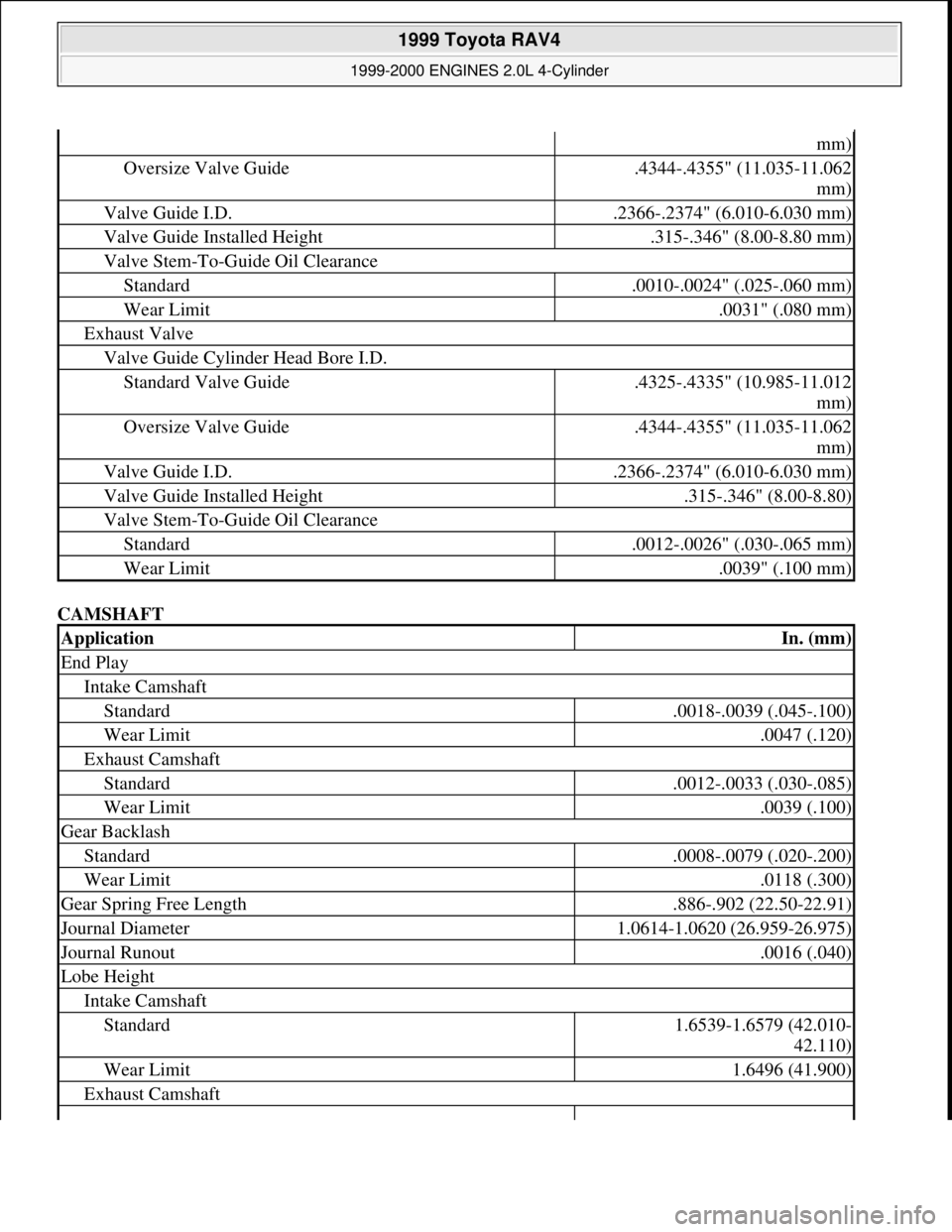

CAMSHAFT

mm)

Oversize Valve Guide.4344-.4355" (11.035-11.062

mm)

Valve Guide I.D..2366-.2374" (6.010-6.030 mm)

Valve Guide Installed Height.315-.346" (8.00-8.80 mm)

Valve Stem-To-Guide Oil Clearance

Standard.0010-.0024" (.025-.060 mm)

Wear Limit.0031" (.080 mm)

Exhaust Valve

Valve Guide Cylinder Head Bore I.D.

Standard Valve Guide.4325-.4335" (10.985-11.012

mm)

Oversize Valve Guide.4344-.4355" (11.035-11.062

mm)

Valve Guide I.D..2366-.2374" (6.010-6.030 mm)

Valve Guide Installed Height.315-.346" (8.00-8.80)

Valve Stem-To-Guide Oil Clearance

Standard.0012-.0026" (.030-.065 mm)

Wear Limit.0039" (.100 mm)

ApplicationIn. (mm)

End Play

Intake Camshaft

Standard.0018-.0039 (.045-.100)

Wear Limit.0047 (.120)

Exhaust Camshaft

Standard.0012-.0033 (.030-.085)

Wear Limit.0039 (.100)

Gear Backlash

Standard.0008-.0079 (.020-.200)

Wear Limit.0118 (.300)

Gear Spring Free Length.886-.902 (22.50-22.91)

Journal Diameter1.0614-1.0620 (26.959-26.975)

Journal Runout.0016 (.040)

Lobe Height

Intake Camshaft

Standard1.6539-1.6579 (42.010-

42.110)

Wear Limit1.6496 (41.900)

Exhaust Camshaft

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 64 © 2005 Mitchell Repair Information Company, LLC.

Page 748 of 1632

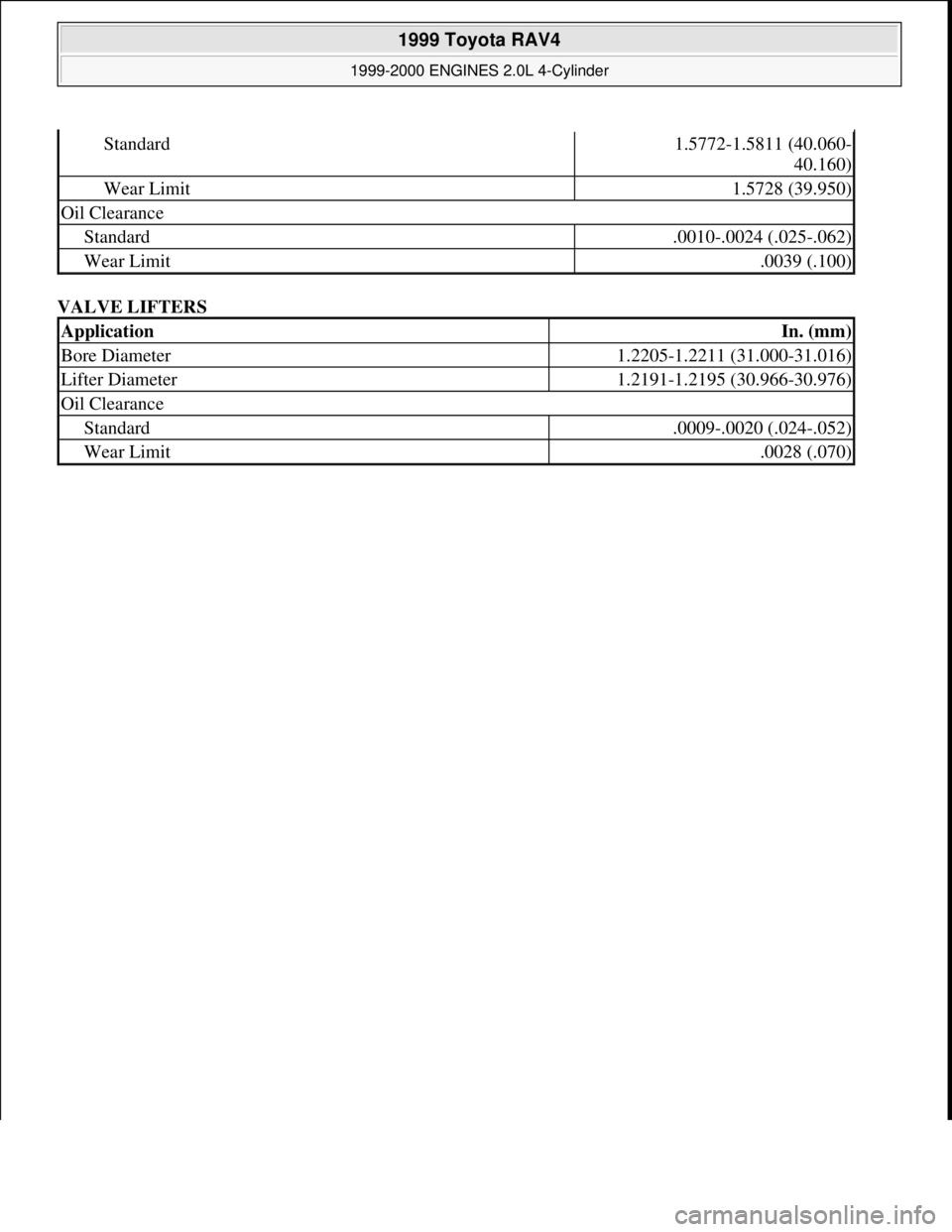

VALVE LIFTERS

Standard1.5772-1.5811 (40.060-

40.160)

Wear Limit1.5728 (39.950)

Oil Clearance

Standard.0010-.0024 (.025-.062)

Wear Limit.0039 (.100)

ApplicationIn. (mm)

Bore Diameter1.2205-1.2211 (31.000-31.016)

Lifter Diameter1.2191-1.2195 (30.966-30.976)

Oil Clearance

Standard.0009-.0020 (.024-.052)

Wear Limit.0028 (.070)

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 65 © 2005 Mitchell Repair Information Company, LLC.

Page 750 of 1632

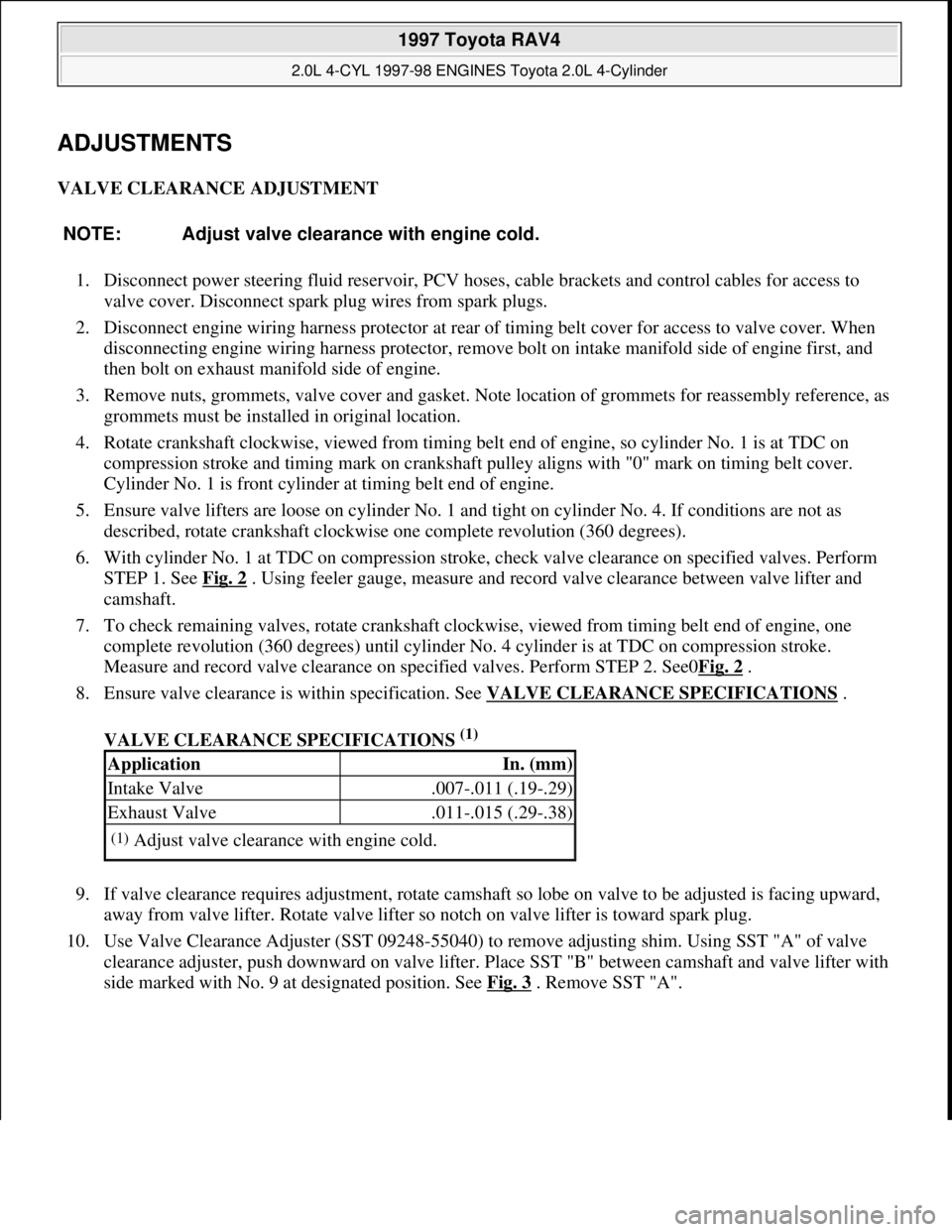

ADJUSTMENTS

VALVE CLEARANCE ADJUSTMENT

1. Disconnect power steering fluid reservoir, PCV hoses, cable brackets and control cables for access to

valve cover. Disconnect spark plug wires from spark plugs.

2. Disconnect engine wiring harness protector at rear of timing belt cover for access to valve cover. When

disconnecting engine wiring harness protector, remove bolt on intake manifold side of engine first, and

then bolt on exhaust manifold side of engine.

3. Remove nuts, grommets, valve cover and gasket. Note location of grommets for reassembly reference, as

grommets must be installed in original location.

4. Rotate crankshaft clockwise, viewed from timing belt end of engine, so cylinder No. 1 is at TDC on

compression stroke and timing mark on crankshaft pulley aligns with "0" mark on timing belt cover.

Cylinder No. 1 is front cylinder at timing belt end of engine.

5. Ensure valve lifters are loose on cylinder No. 1 and tight on cylinder No. 4. If conditions are not as

described, rotate crankshaft clockwise one complete revolution (360 degrees).

6. With cylinder No. 1 at TDC on compression stroke, check valve clearance on specified valves. Perform

STEP 1. See Fig. 2

. Using feeler gauge, measure and record valve clearance between valve lifter and

camshaft.

7. To check remaining valves, rotate crankshaft clockwise, viewed from timing belt end of engine, one

complete revolution (360 degrees) until cylinder No. 4 cylinder is at TDC on compression stroke.

Measure and record valve clearance on specified valves. Perform STEP 2. See0Fig. 2

.

8. Ensure valve clearance is within specification. See VALVE CLEARANCE SPECIFICATIONS

.

VALVE CLEARANCE SPECIFICATIONS

(1)

9. If valve clearance requires adjustment, rotate camshaft so lobe on valve to be adjusted is facing upward,

away from valve lifter. Rotate valve lifter so notch on valve lifter is toward spark plug.

10. Use Valve Clearance Adjuster (SST 09248-55040) to remove adjusting shim. Using SST "A" of valve

clearance adjuster, push downward on valve lifter. Place SST "B" between camshaft and valve lifter with

side marked with No. 9 at desi

gnated position. See Fig. 3. Remove SST "A". NOTE: Adjust valve clearance with engine cold.

ApplicationIn. (mm)

Intake Valve.007-.011 (.19-.29)

Exhaust Valve.011-.015 (.29-.38)

(1)Adjust valve clearance with engine cold.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:30 AMPage 2 © 2005 Mitchell Repair Information Company, LLC.