cruise control TOYOTA RAV4 1996 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 912 of 1632

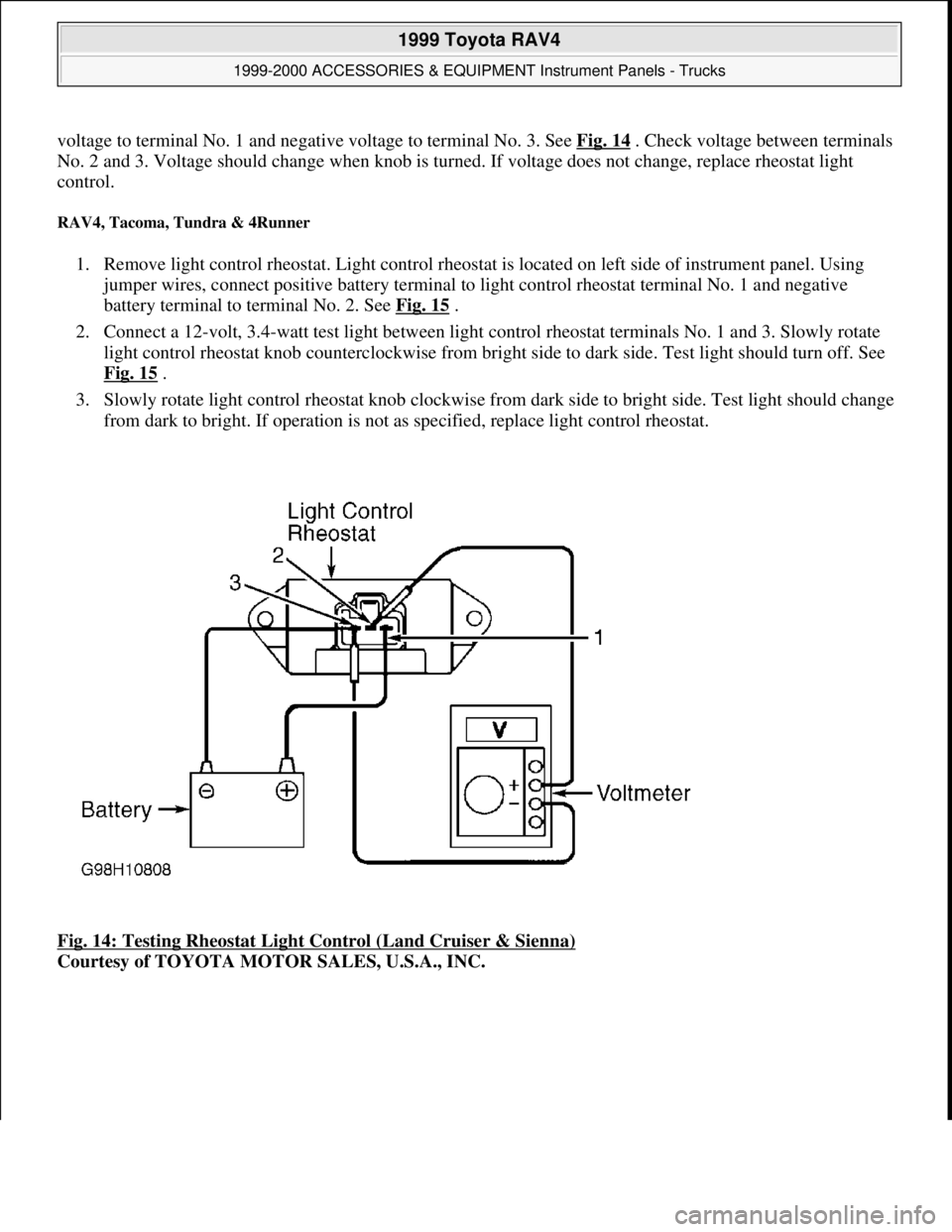

voltage to terminal No. 1 and negative voltage to terminal No. 3. See Fig. 14. Check voltage between terminals

No. 2 and 3. Voltage should change when knob is turned. If voltage does not change, replace rheostat light

control.

RAV4, Tacoma, Tundra & 4Runner

1. Remove light control rheostat. Light control rheostat is located on left side of instrument panel. Using

jumper wires, connect positive battery terminal to light control rheostat terminal No. 1 and negative

battery terminal to terminal No. 2. See Fig. 15

.

2. Connect a 12-volt, 3.4-watt test light between light control rheostat terminals No. 1 and 3. Slowly rotate

light control rheostat knob counterclockwise from bright side to dark side. Test light should turn off. See

Fig. 15

.

3. Slowly rotate light control rheostat knob clockwise from dark side to bright side. Test light should change

from dark to bright. If operation is not as specified, replace light control rheostat.

Fig. 14: Testing Rheostat Light Control (Land Cruiser & Sienna)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 22 © 2005 Mitchell Repair Information Company, LLC.

Page 969 of 1632

35 - HTR 50 Amp Air Conditioning system

36 - ABS 60 Amp Anti-Lock brake system

Fuse & Circuit Breaker Identificatio - 1998

1 - H-LP (LH) 15 Amp Left-Hand Headlight

2 - H-LP (RH) 15 Amp Right-Hand Headlight

3 - SPARE 10 Amp Spare fuse

4 - SPARE 15 Amp Spare fuse

5 - AM2 5 Amp Multiport Fuel Injection System/Sequential Multiport Fuel Injection System, SRS

Airbag System, Seat Belt Pretensioners, Starting System, Discharge Warning Light

6 - ALT-S 5 Amp Charging system

7 - HAZ 10 Amp Emergency Flashers

8 - EFI 20 Amp (USA) or 15 Amp (Canada)Multiport Fuel Injection System/Sequential Multiport Fuel

Injection System

9 - DOME 15 Amp Personal Lights, Open Door Warning Light, Clock

10 - IGN 20 Amp Charging System

11 - H-LP LH-H 10 Amp Left Hand Headlight (High Beam)

12 - H-LP RH-H 10 Amp Right Hand Headlight (High Beam)

13 - H-LP LH-L 10 Amp Left Hand Headlight (Low Beam)

14 - H-LP RH-L 10 Amp Right Hand Headlight (Low Beam)

15 - SEAT-HTR 10 Amp No Circuit

16 - PWR OUTLET 15 Amp Power Outlet

17 - CIG 15 Amp Cigarette Lighter, Clock, Car Audio System, Power Rear View Mirrors, Electronically

Controlled Automatic Transmission

18 - SRS-SCC 10 Amp SRS Airbag System, Seat Belt Pretensioners

19 - WIPER 20 Amp Windshield Wipers And Washer, Rear Window Wiper And Washer

20 - ECU-IG 10 Amp Electronically Controlled Automatic Transmission System, Rear Window

Defogger, Center Differential Lock System, Electric Moon Roof, Multiport Fuel Injection System,

Electric Cooling Fan, Anti-Lock Brake System, Cruise Control System

21 - TURN & GAUGE 10 Amp Turn Signal Lights, Gauges & Meters, Back-Up Lights, Service

Reminder Indicators, Air Conditioning System, Daytime Running Light System

22 - STOP 10 Amp Stop Lights, High Mounted Stop Light, Electronically Controlled Automatic

Transmission System, Anti-Lock Brake System

23 - TAIL 15 Amp Gauges & Meters, Emergency Flashers, Cigarette Lighter, Center Differential Lock

System, Clock, Rear Window Defogger, Air Conditioning System, Electronically Controlled Automatic

Transmission System, Car Audio System, Tail Lights, License Plate Lights, Parking Lights, Instrument

Panel Light Control, Side Marker Lights

24 - OBD 10 Amp On-Board Diagnosis System

25 - SRS-B 10 Amp SRS Air Bag Warning Light

1999 Toyota RAV4

MAINTENANCE INFORMATION 1997-99 MAINTENANCE Toyota Maintenance Information

Microsoft

Sunday, November 22, 2009 10:32:42 AMPage 27 © 2005 Mitchell Repair Information Company, LLC.

Page 1095 of 1632

SYSTEMS TESTS

AIR CONTROL VALVE

Land Cruiser, RAV4, Tacoma & 4Runner

Start and fully warm up engine. Ensure A/C is off. With engine at idle, turn steering wheel to full LOCK

position until test is complete. Ensure engine RPM decreases when air control valve vacuum hose is pinched

shut. When hose is released, engine RPM should increase to normal. If system fails this test, check vacuum

hose, connections, and air control valve.

HYDRAULIC SYSTEM PRESSURE TEST

Pressure Test

1. Connect pressure to power steering pump high pressure line. Connect pressure gauge according to

manufacturer's instructions. Bleed air from hydraulic system. Check power steering fluid level. With

engine at idle, close pressure gauge valve for 2-3 seconds. DO NOT keep valve closed for more than 10

seconds. Note fluid minimum pressure. See HYDRAULIC PRESSURE

table.

2. Open pressure gauge valve fully. Note pressure with engine at 1000 RPM and at 3000 RPM. DO NOT

turn steering wheel. Pressure difference should be less than 71 psi (5 kg/cm2). If difference is greater than

specified, check flow control valve. If valve is okay, repair or replace power steering pump.

3. When steering wheel at full lock position and pressure valve open, again measure pressure. See

HYDRAULIC PRESSURE

table. If pressure is less than specified, steering gear has an internal leak.

Repair or replace steering gear.

HYDRAULIC PRESSURE

STEERING WHEEL TURNING FORCE

1. Center steering wheel. Check that free play of steering wheel does not exceed 1.58" (40 mm) on Land

Cruiser, or 1.18" (30 mm) on all other models. Remove steering wheel pad.

2. Attach INCH-lb torque wrench to steerin

g wheel nut. Start and idle engine. Using torque wrench, turn

Tacoma, Tundra & 4Runner

New135-180 (61-82)

Used (2) 85-120 (39-54)

(1)Land Cruiser uses automatic belt tensioner.

(2)Belt is used if it has been in operation for longer than 5 minutes.

ApplicationMinimum Pressure - Psi (kg/cm2 )

RAV41067 (75)

Sienna1138 (80)

Land Cruiser, Tacoma, Tundra & 4Runner1209 (85)

1999 Toyota RAV4

1999-2000 STEERING Power Rack & Pinion - Trucks

Microsoft

Sunday, November 22, 2009 10:35:46 AMPage 2 © 2005 Mitchell Repair Information Company, LLC.

Page 1096 of 1632

and measure turning force. See STEERING EFFORT SPECIFICATIONS table. Repair or replace

power steering pump if force exceeds specifications.

STEERING EFFORT SPECIFICATIONS

REMOVAL & INSTALLATION

POWER STEERING PUMP

Removal (Land Cruiser)

1. Raise and support front of vehicle. Remove right and left engine under covers. Disconnect MAF

connector. Remove hose from air cleaner. Remove clamp, bolts and remove air cleaner assembly. Loosen

drive belt tensioner and remove drive belt.

2. Disconnect and plug return hose. Use drain pan to catch power steering fluid when connections are

released. Remove 3 bolts, and remove power steering pump.

Removal (RAV4)

1. Raise and support front of vehicle. Remove right and left engine under covers. Remove front exhaust

pipe. See Fig. 1

.

2. Remove stabilizer bar with link. Disconnect right and left lower control arms. See FRONT

- AVALON,

CAMRY, CAMRY SOLARA, CELICA, COROLLA, ECHO, RAV4 & SIENNA appropriate

FRONT SUSPENSION article in SUSPENSION.

3. Remove 2 power steering gear assembly set bolts and nuts. Remove front suspension crossmember

assembly. See Fig. 1

.

4. Disconnect 2 tube clamps and 2 vacuum hoses. Disconnect and plug return line. Use drain pan to catch

power steering fluid when connections are released.

5. Loosen top and bottom pump bolts and remove drive belt. Disconnect pressure feed tube. Remove 3

power steering pump bracket bolts. Remove pump assembly with bracket.

6. Remove union bolt and

gasket. Remove pressure feed line.

ApplicationINCH Lbs. (N.m)

RAV4 & Sienna52 (5.9)

Land Cruiser, Tacoma, Tundra & 4Runner43 (4.9)

1999 Toyota RAV4

1999-2000 STEERING Power Rack & Pinion - Trucks

Microsoft

Sunday, November 22, 2009 10:35:46 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 1104 of 1632

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Inspection

1. Using micrometer, measure diameter of pump shaft. Using calipers, measure diameter or pump housing

shaft bushing. Determine amount of clearance. Clearance should be .0012-.0020" (.030-.050 mm).

Clearance should not exceed .0028" (.071 mm). If clearance exceeds maximum specification, replace

front housing and pump shaft.

2. Using micrometer, measure height, thickness and length of 10 vane plates. See VANE PLATE

SPECIFICATIONS table. Use feeler gauge to measure clearance between rotor groove and plate.

Maximum clearance is .0012" (.030 mm). If clearance exceeds maximum, replace plate and/or rotor with

one having same mark stamp of "1", "2", "3", "4" or no marking.

3. Coat flow control valve with power steering fluid and check that it falls smoothly into valve hole on its

own weight.

4. Check flow control valve for leakage by closing one hose and applying 57-71 psi (4-5 kg/cm2) air

pressure to opposite hole. Air should NOT come out hole on end of valve. If valve does not respond as

indicated, replace valve with one having same letter mark as on front housing and/or on valve.

5. Using calipers, measure free length of flow control valve spring. Minimum free length is 1.42" (36.0

mm). If not within specification, replace spring.

6. If necessary, replace oil seal. Coat NEW seal lip with power steering fluid and carefully press NEW oil

seal into position. Ensure seal is in same direction as removed.

VANE PLATE SPECIFICATIONS

Reassembly

1. Coat all internal components with power steering fluid. Install long straight pin into front housing and

short straight pin into side front plate.

2. Install 2 NEW "O" rings to side front plate. Coat "O" rings with power steering fluid. Install front plate to

pump shaft. Install rotor to pump shaft with mark facing outward. Install NEW snap ring to pump shaft.

3. Align hole of plate and longer straight pin, and tap shaft into place with soft-face hammer. Use care not to

damage oil seal and "O" rings. Align holes of cam ring and 2 straight pins, and install cam ring with mark

facing outward. Install 10 vane plates, with round end facing outward.

4. Coat a NEW "O" ring with power steering fluid. Install "O" ring to side rear plate. Align holes on plate

and 2 straight pins, and install plate. Install wave washer so protrusions fit into slots in side rear plate.

ApplicationIn. (mm)

RAV4

Height.319 (8.1)

Length.59008 (14.988)

Thickness.0707 (1.796)

Land Cruiser, Sienna, Tacoma, Tundra & 4Runner

Height.339 (8.6)

Length.5902 (14.991)

Thickness.0550 (1.397)

1999 Toyota RAV4

1999-2000 STEERING Power Rack & Pinion - Trucks

Microsoft

Sunday, November 22, 2009 10:35:46 AMPage 11 © 2005 Mitchell Repair Information Company, LLC.

Page 1110 of 1632

1. Using micrometer, measure diameter of pump shaft. Using calipers, measure diameter or pump housing

shaft bushing. Determine amount of clearance. Clearance should be .0012-.0020" (.030-.050 mm).

Clearance should not exceed .0028" (.071 mm). If clearance exceeds maximum specification, replace

front housing and pump shaft.

2. Using micrometer, measure height, thickness and length of 10 vane plates. See VANE PLATE

SPECIFICATIONS table. Use feeler gauge to measure clearance between rotor groove and plate.

Maximum clearance is .0014" (.035 mm). If clearance exceeds maximum, replace plate and/or rotor with

one having same mark stamp of "1", "2", "3", "4" or no marking.

3. Coat flow control valve with power steering fluid, and check that it falls smoothly into valve hole on its

own weight.

4. Check flow control valve for leakage by closing one hose and applying 57-71 psi (4-5 kg/cm2) air

pressure to opposite hole. Air should NOT come out hole on end of valve. If valve does not respond as

indicated, replace valve with one having same letter mark as on front housing and/or on valve.

5. Using calipers, measure free length of flow control valve spring. Minimum free length is 1.307" (33.2

mm). If not within specification, replace spring.

6. If necessary, replace oil seal in front housing. Coat NEW seal lip with power steering fluid and carefully

press NEW oil seal into position. Ensure seal is in same direction as removed.

7. If necessary, replace pump shaft bearing. Press old bearing off of shaft. Remove snap ring. Install NEW

snap ring. Coat NEW bearing with power steering fluid. Press bearing onto shaft.

Reassembly

1. Coat all internal components with power steering fluid. Cover serrated part of shaft with vinyl tape. Press

pump shaft with bearing into housing. Install NEW snap ring in front housing. Install 2 NEW straight

pins into front housing.

2. Align holes of cam ring and 2 straight pins, and install cam ring with mark facing outward. Install pump

rotor with mark facing outward. Install NEW snap ring on pump shaft. Install 10 vane plates, with round

end facing outward.

3. Install a NEW gasket on front housing. Install side plate, aligning holes with straight pins. Install wave

washer so protrusions fit into slots in side plate.

4. Coat 2 NEW "O" rings with power steering fluid. Install "O" rings into pump rear housing. Install rear

housing and tighten bolts to specification. See TORQUE SPECIFICATIONS

.

5. Install flow control spring and valve. Ensure valve is facing correct direction. Coat a NEW "O" ring with

power steering fluid. Install "O" ring to pressure port union. Tighten union to specification. See

TORQUE SPECIFICATIONS

.

6. Install fluid reservoir with NEW "O" ring. Tighten bolts to specification. See TORQUE

SPECIFICATIONS .

7. Position and hold pump pulley, and install nut. Tighten nut to specification. See TORQUE

SPECIFICATIONS . Measure pump rotating torque. Using a torque wrench, check pump rotating

torque. Rotating torque should be 2.4 INCH lbs. (.3 N.m) or less.

Disassembly (Land Cruiser, Tacoma & 4Runner V6 & Tundra V6 & V8)

1. Mount pump assembly in soft-jaw vise. Ensure pump rotates smoothly. Using a torque wrench, check

1999 Toyota RAV4

1999-2000 STEERING Power Rack & Pinion - Trucks

Microsoft

Sunday, November 22, 2009 10:35:47 AMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 1130 of 1632

with power steering fluid.

7. Place NEW gasket on rack housing. Position control valve housing. Install and tighten mounting bolt. See

TORQUE SPECIFICATIONS

. Hold control valve shaft from turning, and install NEW self-locking

nut on lower end of shaft. Install dust cover.

8. Apply thread lock sealant to 2-3 threads of rack housing cap. Install and tighten cap to specification. See

TORQUE SPECIFICATIONS

. Stake cap in 2 places.

9. Install rack guide seat to guide. Apply thread lock sealant to 2-3 threads of rack guide spring cap. Install

guide, spring, washer and cap. Temporarily tighten cap.

10. Temporarily install both rack ends. Using 21-mm wrench, tighten rack guide spring cap to 18 ft. lbs. (24

N.m). Loosen cap by 12 degrees. Using torque wrench on top end of control valve stem, turn stem right

and left 1-2 times. Loosen rack guide spring cap until rack guide spring is not functioning. Tighten rack

guide spring cap until preload is within 7.8-13.0 INCH lbs. (0.9-1.5 N.m), measured with torque wrench

on control valve stem. See Fig. 11

.

11. Apply thread lock sealant to rack guide spring cap lock nut. Hold spring cap from rotating, use torque

wrench to tighten lock nut to specification. See TORQUE SPECIFICATIONS

. Recheck preload.

12. Remove both rack ends. Install No. 2 rack housing bracket and grommet. Align reference marks. Install

and tighten bolt. See TORQUE SPECIFICATIONS

.

13. Install NEW claw washers on each end of rack. Align claws with grooves in rack. Install rack ends. Hold

rack from turning, and tighten rack ends to 44 ft. lbs. (60 N.m). Stake claw washers.

14. Ensure steering rack hole (next to rack end) is not clogged with grease. Clean as necessary. Install boots,

clamps and clips. Pinch clamp until there is .08" (2.0 mm) or less clearance between clamp ends.

15. Screw tie rod end lock nut onto tie rod until reference marks are aligned. Install left and right tie rod ends.

After adjusting toe-in, tighten lock nuts to specification. See TORQUE SPECIFICATIONS

.

16. Install 2 turn pressure tubes. Use NEW "O" rings coated with power steering fluid. Tighten fittings to

specification. See TORQUE SPECIFICATIONS

.

Disassembly (Land Cruiser, Tacoma 4WD, Tundra & 4Runner)

1. Secure rack and pinion housing in soft-jaw vise (DO NOT over-tighten vise). Remove 2 turn pressure

tubes. Remove union seats from fittings. See Fig. 17

.

2. Place reference marks on tie rod ends and rack ends, across lock nuts. Remove lock nuts and tie rod ends.

Remove boot clips and clamps. Mark and remove left and right side rack boots.

3. Unstake claw washer on both rack ends. See Fig. 18

. Holding steering rack, use appropriate removal tool

to remove rack ends. Mark left and right sides for proper reinstallation.

4. Remove rack guide spring cap lock nut. See Fig. 17

. Remove rack guide spring cap, spring and rack

guide. Remove dust cover.

5. Place reference marks on valve housing and rack housing. Remove mounting bolts, and pull control valve

assembly and housing from rack housing. Remove "O" ring from rack housing.

6. Loosen bearing guide nut. See Fig. 17

. Tape serrated end of control valve shaft. Tap control valve

assembly and bearing guide nut from housing. Remove nut. Remove "O" ring from nut. NOTE: When removing oil seals, be sure to note direction seals are facing for

reinstallation in same direction.

1999 Toyota RAV4

1999-2000 STEERING Power Rack & Pinion - Trucks

Microsoft

Sunday, November 22, 2009 10:35:47 AMPage 37 © 2005 Mitchell Repair Information Company, LLC.

Page 1133 of 1632

Fig. 18: Exploded View Of Power Rack & Pinion Steering Gear Assembly (Tacoma 4WD &

4Runner Shown; Land Cruiser & Tundra Are Similar - 2 Of 2)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Inspection

1. With rack mounted horizontally on "V" blocks, use dial indicator to measure rack runout. Runout should

not exceed .012" (.30 mm). Check rack and teeth for wear and damage. Replace rack if necessary.

2. If necessary, press oil seal and bearing from control valve housing. Coat NEW seal lip with power

steering fluid. Press seal into place. Ensure oil seal is facing same direction as removed.

3. Coat NEW bushing with molybdenum disulfide lithium-base grease. Using press, install bushing against

oil seal in rack housing.

4. If necessary, press oil seal from bearing guide nut. Coat NEW oil seal with power steering fluid and press

into bearing guide nut.

5. Check needle bearing of rack housing for pitting or wear. If faulty, replace rack housing. If okay, coat

inside of bearing with molybdenum disulfide lithium-base grease.

6. Inspect condition of control valve bearing. If worn or damaged, replace control valve assembly. If okay,

coat inside of bearing with molybdenum disulfide lithium-base grease.

7. Check inside of cylinder end stopper bushing. If faulty, replace bushing. If okay, coat inside of bearing

with molybdenum disulfide lithium-base grease.

8. If necessary, use screwdriver to remove Teflon ring and "O" ring from steering rack. Coat NEW "O" ring

with power steering fluid. Install "O" ring. Carefully expand NEW Teflon ring by hand, only enough to

accommodate installation. Coat Teflon ring with power steering fluid. Press ring firmly into rack groove.

9. If necessary, use screwdriver to remove 4 Teflon rings from control valve assembly. Coat NEW rings

with power steering fluid. Slightly expand rings by hand, and install in each groove. Use installer tool to

slide over rings and fully seat them.

10. If necessary, use screw extractor to remove union seats from side of control valve housing. Carefully tap

NEW seats into place.

Reassembly

1. With rack housing mounted vertically in soft-jaw vise, coat NEW seal lip with power steering fluid. Press

seal and spacer into rack housing from end opposite control valve housing portion. See Fig. 18

. Ensure

oil seal faces in proper direction.

2. Mount rack housing horizontally in vise. Clean rack teeth of any burrs. Place protective sleeve end piece

on steering rack teeth end. Coat protective sleeve with power steering fluid. Install steering rack into rack

housing. Remove protective sleeve.

3. Coat NEW rack housing oil seal lip with power steering fluid. Install seal into rack housing.

4. Coat NEW cylinder end stopper "O" ring with power steering fluid. Install cylinder end stopper and

tighten to specification. See TORQUE SPECIFICATIONS

. Stake rack housing at end stopper.

5. Install special connectors onto union fittings of rack housing and attach hand vacuum pump. Apply

15.75" Hg for about 30 seconds. Ensure there is no vacuum leak. If there is a leak, check installation of

oil seals at each end of housing. See Fig. 9

.

6. Coat Teflon rin

gs of control valve assembly with power steering fluid. Wrap serrated end of control valve

1999 Toyota RAV4

1999-2000 STEERING Power Rack & Pinion - Trucks

Microsoft

Sunday, November 22, 2009 10:35:47 AMPage 40 © 2005 Mitchell Repair Information Company, LLC.

Page 1134 of 1632

shaft with tape. Push control valve assembly into housing. Coat NEW "O" ring with power steering fluid

and install into bearing guide nut. Install and tighten nut. See TORQUE SPECIFICATIONS

. Stake

guide nut.

7. Coat NEW control valve "O" ring with power steering fluid. Install into control valve housing. Align

reference marks for housings. Position control valve housing. Install and tighten mounting bolts. See

TORQUE SPECIFICATIONS

. Install dust cover.

8. Install rack guide, spring and rack guide spring cap. Apply thread lock sealant to cap threads.

Temporarily install cap.

9. Temporarily install both rack ends. Using a 21-mm wrench, tighten rack guide spring cap to 18 ft. lbs. (24

N.m). Loosen cap by 12 degrees on Tundra, or 19 degrees on all other models. With torque wrench on top

end of control valve stem, turn stem right and left 1-2 times. Loosen rack guide spring cap until rack

guide spring is not functioning. Tighten rack guide spring cap until preload is within 11.5-16 INCH lbs.

(1.3-1.8 N.m) on Land Cruiser, 10.4-13.9 INCH lbs. (1.2-1.6 N.m) on Tundra, or 4.1-14.9 INCH lbs.

(0.5-1.7 N.m) on all other models, measured with torque wrench on control valve stem. See Fig. 11

.

10. Apply thread lock sealant to rack guide spring cap lock nut. Hold spring cap from rotating, use torque

wrench to tighten lock nut to specification. See TORQUE SPECIFICATIONS

. Recheck preload.

11. Remove both rack ends. Install NEW claw washers on each end of rack. Align claws with grooves in

rack. Install rack ends. Hold rack from turning and tighten rack ends to 56 ft. lbs. (76 N.m). Stake claw

washers.

12. Ensure steering rack hole (next to rack end) is not clogged with grease. Clean as necessary. Install boots,

clamps and clips. Pinch clamp until there is .08" (2.0 mm) or less clearance between clamp ends.

13. Screw tie rod end lock nut onto tie rod until reference marks are aligned. Install left and right tie rod ends.

After adjusting toe-in, tighten lock nuts to specification. See TORQUE SPECIFICATIONS

.

14. Install NEW union seats into housing fittings. Install 2 turn pressure tubes. Tighten fittings to

specification. See TORQUE SPECIFICATIONS

.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS (LAND CRUISER)

ApplicationFt. Lbs. (N.m)

Power Steering Pump

Mounting Bolts/Nut13 (17)

Power Steering Pulley Nut32 (43)

Pressure Feed Tube Union Bolt42 (56)

Pressure Port Union61 (83)

Rear Housing Bolts17 (23)

Rack & Pinion

Assembly Mounting Bolts/Nuts74 (100)

Bearing Guide Nut19 (25)

Control Valve Housing-To-Rack Housing Bolts13 (18)

Control Valve Housing-To-Pressure Feed Tube36 (49)

Control Valve Stem-To-Intermediate Shaft Clamp Bolt26 (35)

Cylinder End Stopper49 (65)

1999 Toyota RAV4

1999-2000 STEERING Power Rack & Pinion - Trucks

Microsoft

Sunday, November 22, 2009 10:35:47 AMPage 41 © 2005 Mitchell Repair Information Company, LLC.

Page 1174 of 1632

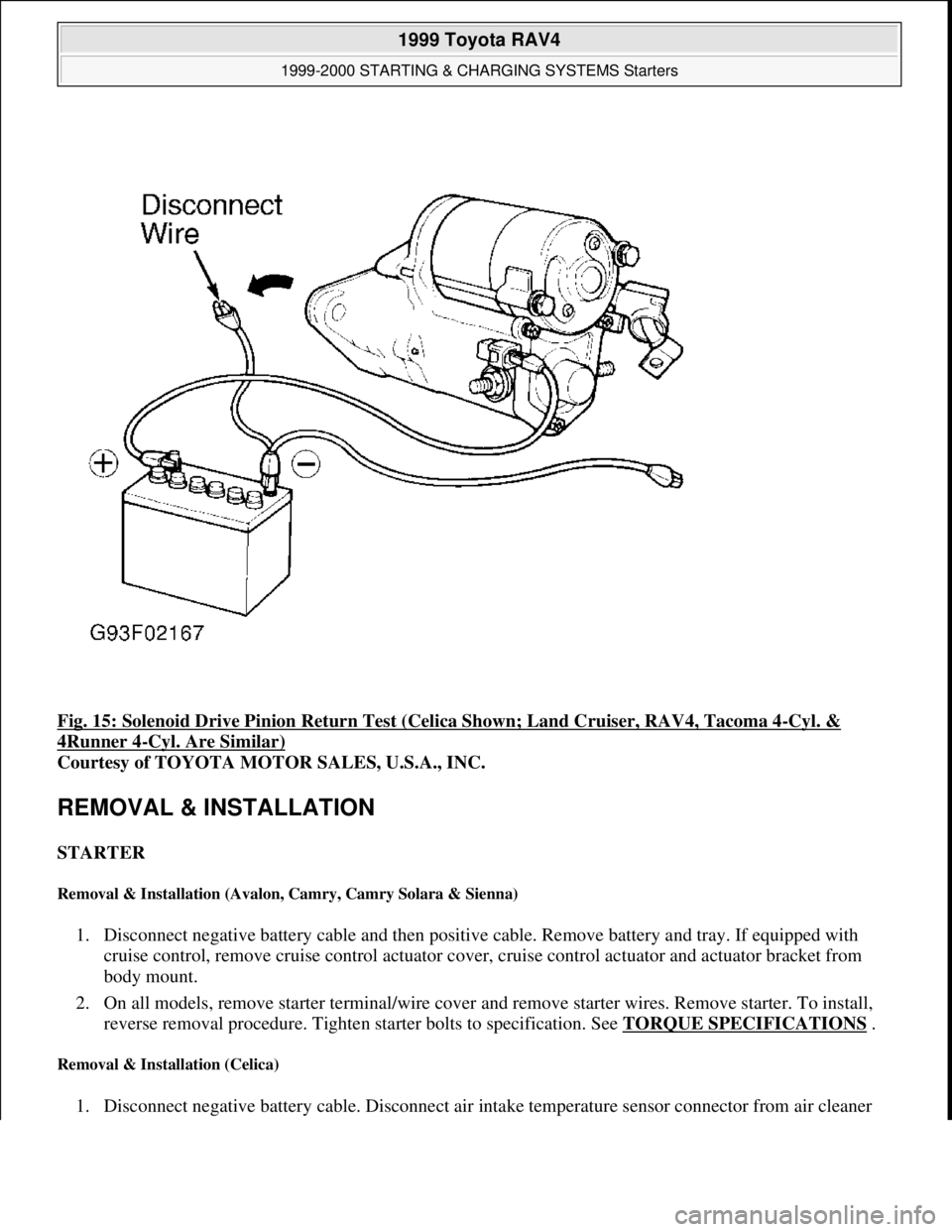

Fig. 15: Solenoid Drive Pinion Return Test (Celica Shown; Land Cruiser, RAV4, Tacoma 4-Cyl. &

4Runner 4-Cyl. Are Similar)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

REMOVAL & INSTALLATION

STARTER

Removal & Installation (Avalon, Camry, Camry Solara & Sienna)

1. Disconnect negative battery cable and then positive cable. Remove battery and tray. If equipped with

cruise control, remove cruise control actuator cover, cruise control actuator and actuator bracket from

body mount.

2. On all models, remove starter terminal/wire cover and remove starter wires. Remove starter. To install,

reverse removal procedure. Tighten starter bolts to specification. See TORQUE SPECIFICATIONS

.

Removal & Installation (Celica)

1. Disconnect negative battery cable. Disconnect air intake temperature sensor connector from air cleaner

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Starters

Microsoft

Sunday, November 22, 2009 10:19:18 AMPage 19 © 2005 Mitchell Repair Information Company, LLC.