battery replacement TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 37 of 1632

The air bag sensor, which deploys air bags, contains a back-up power supply, safing sensor and diagnostic code

memory. Spiral cable (clockspring) maintains a complete circuit to the steering wheel pad.

SYSTEM OPERATION CHECK

Turn ignition switch to ACC or ON position. Air bag warning light in instrument cluster should come on for

about 6 seconds and then go out. If light does not respond as specified, SRS is malfunctioning and needs repair.

See DIAGNOSIS

.

SERVICE PRECAUTIONS

Observe the following precautions when working on SRS:

Before servicing any SRS or steering column component, disable SRS. See DISABLING &

ACTIVATING AIR BAG SYSTEM . Failure to disable system could result in accidental air bag

deployment and personal injury.

When diagnosing SRS, always check for diagnostic codes before disconnecting battery.

After ignition switch is turned to LOCK position and negative battery cable is disconnected, wait at least

90 seconds before working on SRS. SRS is equipped with a back-up power source that may allow air bag

to deploy within 90 seconds of disconnecting negative battery cable.

In a minor collision in which air bags do not deploy, steering wheel pad must be inspected.

NEVER use air bag parts from another vehicle. Replace air bag parts with new parts.

Air bag sensor assembly contains mercury. After replacement, DO NOT destroy the old part. When

scrapping vehicle or replacing air bag sensor assembly, remove air bag sensor assembly and dispose of as

toxic waste.

Never disassemble or repair system components. Replace cracked, dented or otherwise damaged system

components.

Remove air bag sensor if shocks are likely to be applied to the sensor during repairs.

When diagnosing electrical circuits, use a Digital Volt/Ohmmeter (DVOM) with high impedance (10,000

ohms minimum).

Information labels are attached to air bag components. Follow all notices on labels.

After servicing SRS, check air bag warning light to ensure system is functioning properly. See SYSTEM

OPERATION CHECK .

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover up, away from

surface. This will reduce motion of module if accidentally deployed.

After deployment, air bag surface may contain deposits of sodium hydroxide which irritates skin. During

clean-up, always wear safety glasses, rubber gloves and long-sleeved shirt. After clean-up, wash hands

using mild soap and water.

When carrying a live air bag module, trim cover must be pointed away from your body to minimize

injury in case of accidental deployment.

If SRS is not fully functional for any reason, vehicle should not be driven until system is repaired and

a

gain becomes operational. DO NOTremove bulbs, modules, sensors or other components or in any way

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 51 of 1632

CLEARING CODES

1. At DLC, connect a jumper wire to terminal Tc, and another jumper wire to terminal AB. See Fig. 12

.

Turn ignition switch to ACC or ON position. Wait about 6 seconds.

2. Starting with terminal Tc, apply body ground alternately to terminal Tc and terminal AB twice each, in

cycles of 1/2 to 1 1/2 seconds. Finally, keep applying body ground to terminal Tc until air bag warning

light flashes quickly, indicating codes are cleared.

DIAGNOSIS

AIR BAG WARNING LIGHT DOES NOT COME ON AT ALL

11Short To Ground In Squib Circuit

12Short To Battery In Squib Circuit

14Open In D Squib Circuit

31Air Bag Sensor Assembly Malfunction

54Open In P Squib Circuit

NOTE: When alternately connecting jumper probes to terminals, simultaneously

release one probe from one terminal while connecting other probe to other

terminal. If time interval between probings is too long, codes will not clear.

WARNING:Failure to follow air bag service precautions may result in air bag

deployment and personal injury. See SERVICE PRECAUTIONS

. After

component replacement, perform system operational check to ensure

proper system operation. See SYSTEM OPERATION CHECK

.

CAUTION: Ensure ignition switch is in LOCK position before disconnecting or

connecting negative battery cable. If ignition switch is in ACC or ON

position when negative battery cable is disconnected or connected, center

air bag sensor may be damaged.

NOTE: For air bag sensor connector terminal identification, see Fig. 13

.

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 66 of 1632

may allow air bag to deploy until 90 seconds after disconnecting negative battery cable.

If vehicle was in a minor collision but air bags did not deploy, inspect all system components for any sign

of damage, and replace as necessary.

Never use air bag system components from another vehicle. Replace air bag system components with new

parts.

Remove air bag sensor assembly if repairing the vehicle requires impacting (shocking) the vehicle.

Air bag sensor assembly contains mercury. After replacement, DO NOT destroy old part. When

scrapping vehicle or replacing air bag sensor assembly, remove air bag sensor assembly and dispose of it

as toxic waste.

Never disassemble and repair air bag sensor assembly, front air bag sensors, passenger-side or driver-side

air bag modules or seat belt pretensioners.

Replace dropped, cracked, dented or otherwise damaged components.

DO NOT expose air bag sensor assembly, front air bag sensors or air bag modules directly to heat or

flame.

When diagnosing electrical circuits, use a volt/ohm meter with high impedance (10,000 ohms minimum).

Information labels are attached to air bag components. Follow all notices on labels.

After work on air bag system is complete, check AIR BAG warning light to ensure system is functioning

properly. See SYSTEM OPERATION CHECK

.

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover up and away

from surface. This will reduce motion of module if it is accidentally deployed.

After deployment, air bag surface may contain deposits of sodium hydroxide, which irritates skin. Always

wear safety glasses, rubber gloves, and long-sleeved shirt during clean-up. After clean-up, wash hands

using mild soap and water.

Carry a live air bag module with trim cover (air bag) pointed away from your body to minimize injury in

case accidental deployment.

If air bag system is not fully functional for any reason, vehicle should not be driven until system is

repaired and again becomes operational. DO NOT remove bulbs, modules, sensors or other components,

or in any way disable system from operating normally. If air bag system is not functional, park vehicle

until it is repaired and functions properly.

ADJUSTMENTS

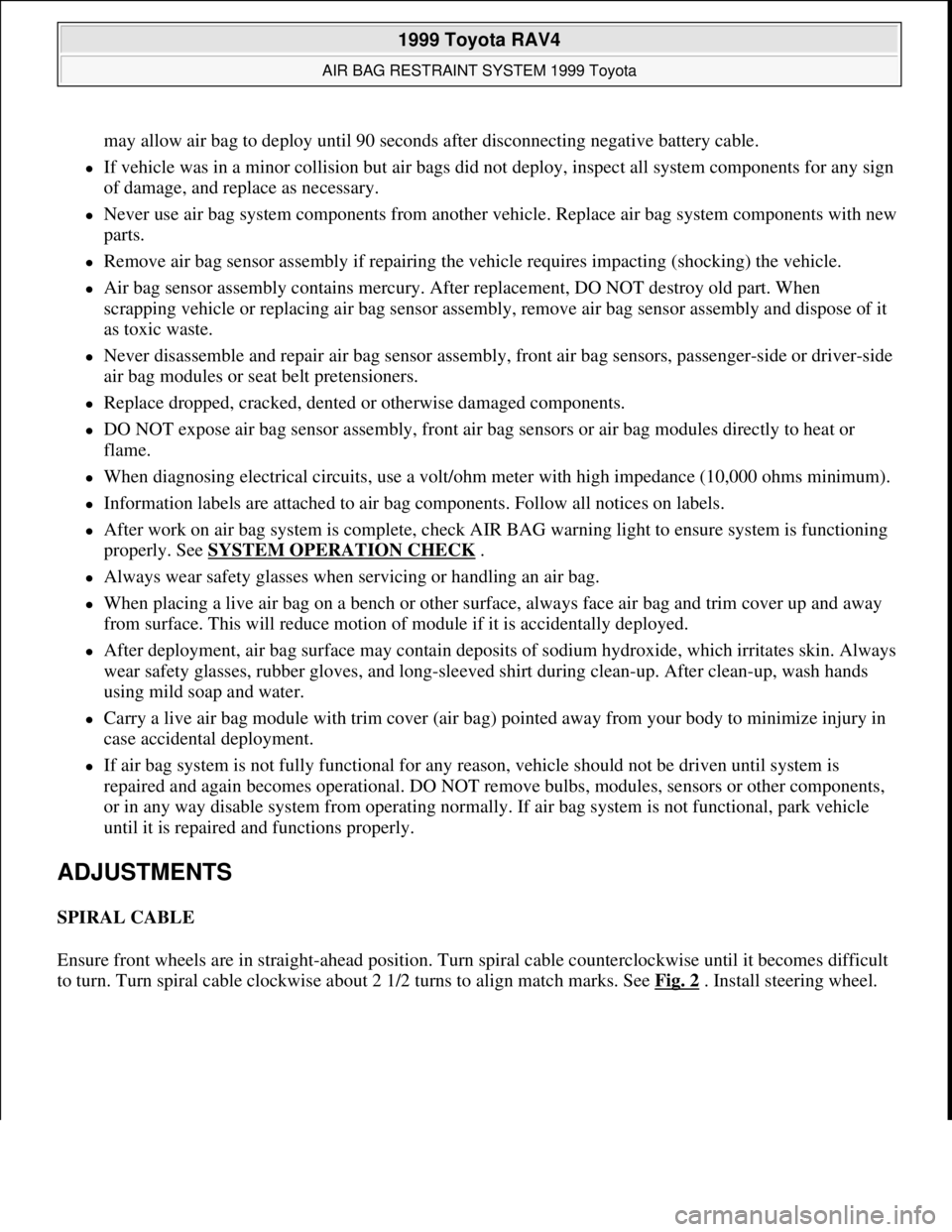

SPIRAL CABLE

Ensure front wheels are in straight-ahead position. Turn spiral cable counterclockwise until it becomes difficult

to turn. Turn spiral cable clockwise about 2 1/2 turns to align match marks. See Fig. 2

. Install steering wheel.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 67 of 1632

Fig. 2: Adjusting Spiral Cable

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DISABLING & ACTIVATING AIR BAG SYSTEM

DISABLING SYSTEM

For Component Replacement

Turn ignition switch to LOCK position. Disconnect and shield negative battery cable. Wait at least 90 seconds

before starting any work on vehicle.

WARNING:Back-up power supply maintains air bag system voltage for about 90

seconds after battery is disconnected. After disabling air bag system, wait

at least 90 seconds before servicing air bag system to prevent accidental

air bag deployment and possible personal injury.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 69 of 1632

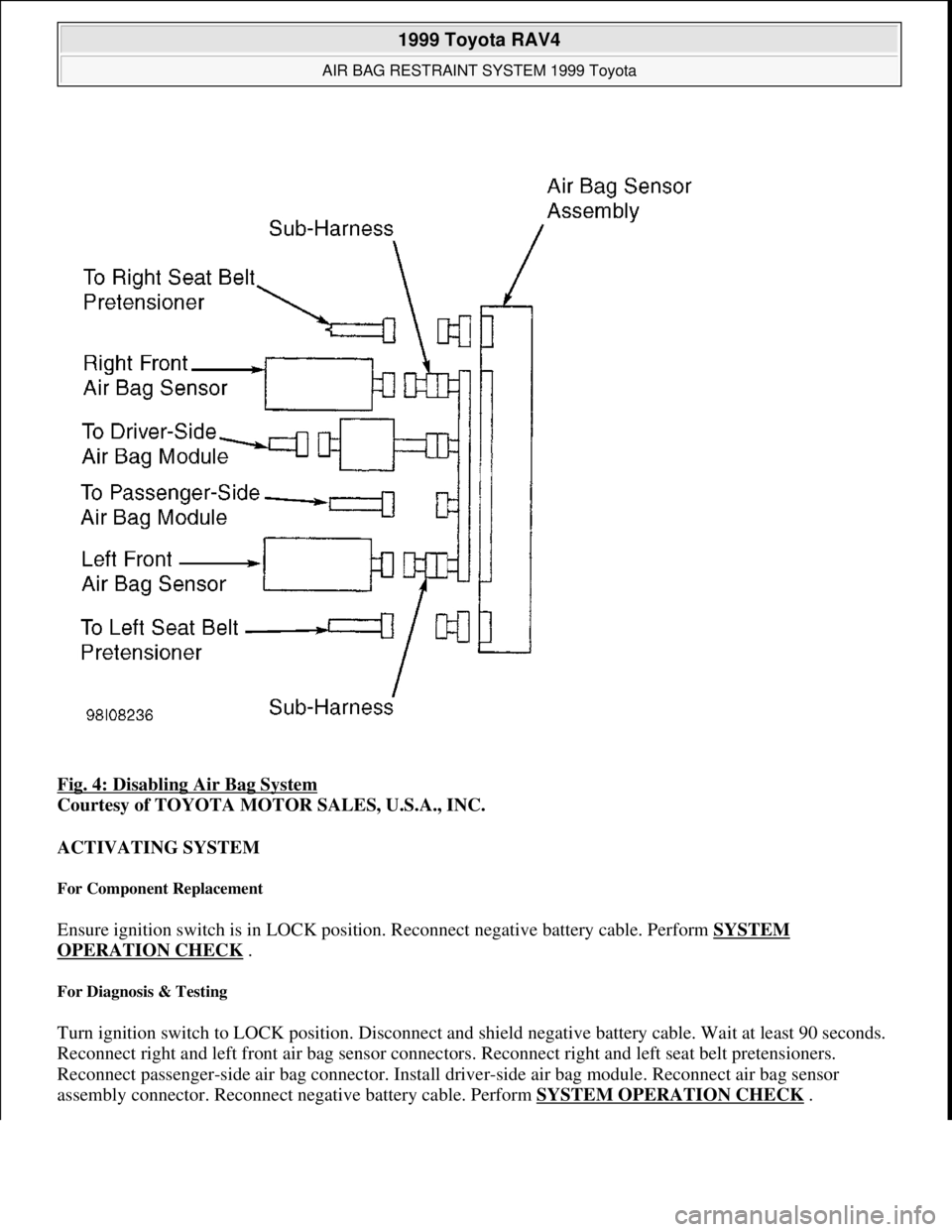

Fig. 4: Disabling Air Bag System

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

ACTIVATING SYSTEM

For Component Replacement

Ensure ignition switch is in LOCK position. Reconnect negative battery cable. Perform SYSTEM

OPERATION CHECK .

For Diagnosis & Testing

Turn ignition switch to LOCK position. Disconnect and shield negative battery cable. Wait at least 90 seconds.

Reconnect right and left front air bag sensor connectors. Reconnect right and left seat belt pretensioners.

Reconnect passenger-side air bag connector. Install driver-side air bag module. Reconnect air bag sensor

assembl

y connector. Reconnect negative battery cable. Perform SYSTEM OPERATION CHECK.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 76 of 1632

REMOVAL & INSTALLATION

AIR BAG SENSOR ASSEMBLY

Removal & Installation

1. Before proceeding, see SERVICE PRECAUTIONS . Air bag sensor assembly is located on the floor

inside center console box. See Fig. 10

. Turn ignition switch to LOCK position. Disconnect negative

battery cable. Wait at least 90 seconds.

2. Remove shift lever and boot. Ash tray and console box hole cover. Remove console box. Remove 4 Torx

screws retaining air bag sensor assembly. Remove air bag sensor assembly.

3. To install, reverse removal procedure. Tighten air bag sensor assembly Torx screws to specification. See

TORQUE SPECIFICATIONS

. Check AIR BAG warning light to ensure system is functioning

properl

y. See SYSTEM OPERATION CHECK. WARNING:Failure to follow service precautions may result in air bag deployment and

personal injury. See SERVICE PRECAUTIONS

. After component

replacement, check system operation. See SYSTEM OPERATION CHECK

.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 88 of 1632

Fig. 15: Releasing Shorting Spring

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DIAGNOSTIC TESTS

AIR BAG WARNING LIGHT DOES NOT ILLUMINATE

Description

AIR BAG warning light is located in instrument cluster. When air bag system is normal, AIR BAG warning

light illuminates for about 6 seconds after ignition switch is turned from LOCK to ACC or ON position, and

turns off automatically. If a malfunction is present in air bag system, AIR BAG warning light illuminates to

inform operator of malfunction. When Data Link Connector 1 (DLC1) terminals Tc and E1 are connected

together, a Diagnostic Trouble Code (DTC) is displayed by flashing AIR BAG warning light.

Diagnostic Procedure

1. Remove SRS-B fuse and check continuity across fuse blades. SRS-B fuse is located in instrument panel

fuse block under left side of instrument panel. If fuse is faulty, go to step 4). If fuse is okay, reinstall fuse

and go to next step.

2. Disable air bag system. See DISABLING SYSTEM

under DISABLING & ACTIVATING AIR BAG

SYSTEM. Reconnect negative battery cable. Turn ignition switch to ACC or ON position. Measure

voltage between ground and harness side of air bag sensor assembly connector C20, terminal No. 3

(circuit LA, Black/Yellow wire). See Fig. 16

. If 10-14 volts is not present, repair AIR BAG warning

light bulb or circuit. If 10-14 volts is present, go to next step.

3. Turn ignition switch to LOCK position. Disconnect negative battery cable. Reconnect 3 air bag sensor

assembly connectors. Leave air bag modules, pretensioners and front air bag sensors disconnected.

Reconnect negative battery cable and wait at least 2 seconds. Turn ignition switch to ACC or ON

position. If AIR BAG warning light illuminates, system operation is normal. If AIR BAG warning light

does not come on, check for poor connection at air bag sensor assembly connector C20, terminal No. 3

(Black/Yellow wire). If connection is oka

y, replace air bag sensor assembly. WARNING:Failure to follow service precautions may result in air bag deployment and

personal injury. See SERVICE PRECAUTIONS

. After component

replacement, check system operation. See SYSTEM OPERATION CHECK

.

CAUTION: Ensure ignition switch is in LOCK position before disconnecting or

connecting negative battery cable. If ignition switch is in ACC or ON

position when negative battery cable is disconnected or connected, air

bag sensor may be damaged. To prevent damage to connector terminals,

DO NOT probe terminal ends. Instead, backprobe terminals (probe

terminal where wire enters harness connector).

NOTE: In the following tests, the term squib connector and module connector may be

used interchangeably.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:23 AMPage 25 © 2005 Mitchell Repair Information Company, LLC.

Page 950 of 1632

On models equipped with anti-lock brake systems, ALWAYS observe the following cautions:

DO NOT attempt to bleed hydraulic system without first referring to the appropriate ANTI-LOCK

BRAKE SYSTEM article in the BRAKES Section.

DO NOT mix tire sizes. As long as tires remain close to the original diameter, increasing the width is

acceptable. Rolling diameter must be identical for all 4 tires. Some manufacturers recommend tires of the

same brand, style and type. Failure to follow this precaution may cause inaccurate wheel speed readings.

Use ONLY recommended brake fluids. DO NOT use silicone brake fluids in an ABS-equipped vehicle.

BATTERY WARNING

REPLACING BLOWN FUSES

BRAKE PAD WEAR INDICATOR

Indicator will cause a squealing or scraping noise, warning that brake pads need replacement.

CATALYTIC CONVERTER CAUTION: The anti-lock brake system contains electronic equipment that can be

susceptible to interference caused by improperly installed or high output

radio transmitting equipment. Since this interference could cause the

possible loss of the anti-lock braking capability, such equipment should

be installed by qualified professionals.

WARNING:When battery is disconnected, vehicles equipped with computers may

lose memory data. When battery power is restored, driveability problems

may exist on some vehicles. These vehicles may require a relearn

procedure. See COMPUTER RELEARN PROCEDURES article in GENERAL

INFORMATION section.

CAUTION: Before replacing a blown fuse, remove ignition key, turn off all lights and

accessories to avoid damaging the electrical system. Be sure to use fuse

with the correct indicated amperage rating. The use of an incorrect

amperage rating fuse may result in a dangerous electrical system

overload.

CAUTION: Continued operation of vehicle with a severe malfunction could cause

converter to overheat, resulting in possible damage to converter and

vehicle.

CAUTION: Any modification to the exhaust system on turbo models, which reduces

exhaust backpressure, will lead to lean fuel mixtures and excessive spark

advance. This could cause serious engine damage.

1999 Toyota RAV4

MAINTENANCE INFORMATION 1997-99 MAINTENANCE Toyota Maintenance Information

Microsoft

Sunday, November 22, 2009 10:32:42 AMPage 8 © 2005 Mitchell Repair Information Company, LLC.

Page 952 of 1632

Covers any repair or replacement of parts which becomes necessary due to defects in materials or workmanship

under normal use for 36 months or 36,000 miles from in-service date.

The items specified below are covered for a period different from the basic coverage:

Air Conditioner

The air conditioner refrigerant charge is covered for the first 12 months, regardless of mileage, unless done as

part of a warranty repair.

Adjustments

Service adjustment (minor repairs not usually associated with the replacement of parts) are covered for the first

12 months or 12,500 miles, whichever occurs first.

POWERTRAIN WARRANTY

Engine, transmission, front wheel drive, rear wheel drive and restraint system are warranted against defects in

materials or workmanship under normal use for 5 years or 60,000 miles, whichever occurs first. See copy of

warranty for specific components covered.

CORROSION PERFORATION WARRANTY

Covers any repair or replacement to body sheet metal which develops corrosion perforation (hole through

panel), in normal use, due to defects in material or workmanship for a period of 5 years, regardless of mileage.

BATTERY WARRANTY

Covers replacement of defective original battery for first 12 months or 12,000 miles. After the first 12 months

or 12,000 miles, warranty covers a pro-rated amount based on months in service, up to a maximum of 36

months.

EMISSION SYSTEM DEFECT WARRANTY (EXCEPT CALIFORNIA)

Warrants to the retail purchaser, and subsequent purchaser that vehicle was designed, built, and equipped so as

to conform at the time of sale with applicable emission regulations and that it is free from defects in materials or

workmanship which may cause the vehicle to fail to conform with applicable regulations for 5 years or 50,000

miles, whichever occurs first.

EMISSION SYSTEM PERFORMANCE WARRANTY (EXCEPT CALIFORNIA)

Covers all repairs, adjustments, or replacements if vehicle fails to conform to applicable emission standards and

such failure results in the vehicle owner having to bear a penalty or other sanction under local, state or federal

law for 5 years or 50,000 miles, whichever comes first. If the vehicle has been in use for more than 24 months

or 24,000 miles, the manufacturer will make the necessary adjustments, repairs or replacements at no cost to the

owner only when noncompliance is caused by failure of components which have been installed in the vehicle

for the sole or primary purpose of reducing vehicle emissions. See copy of warranty for specific components

1999 Toyota RAV4

MAINTENANCE INFORMATION 1997-99 MAINTENANCE Toyota Maintenance Information

Microsoft

Sunday, November 22, 2009 10:32:42 AMPage 10 © 2005 Mitchell Repair Information Company, LLC.