display TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 485 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–31

ES

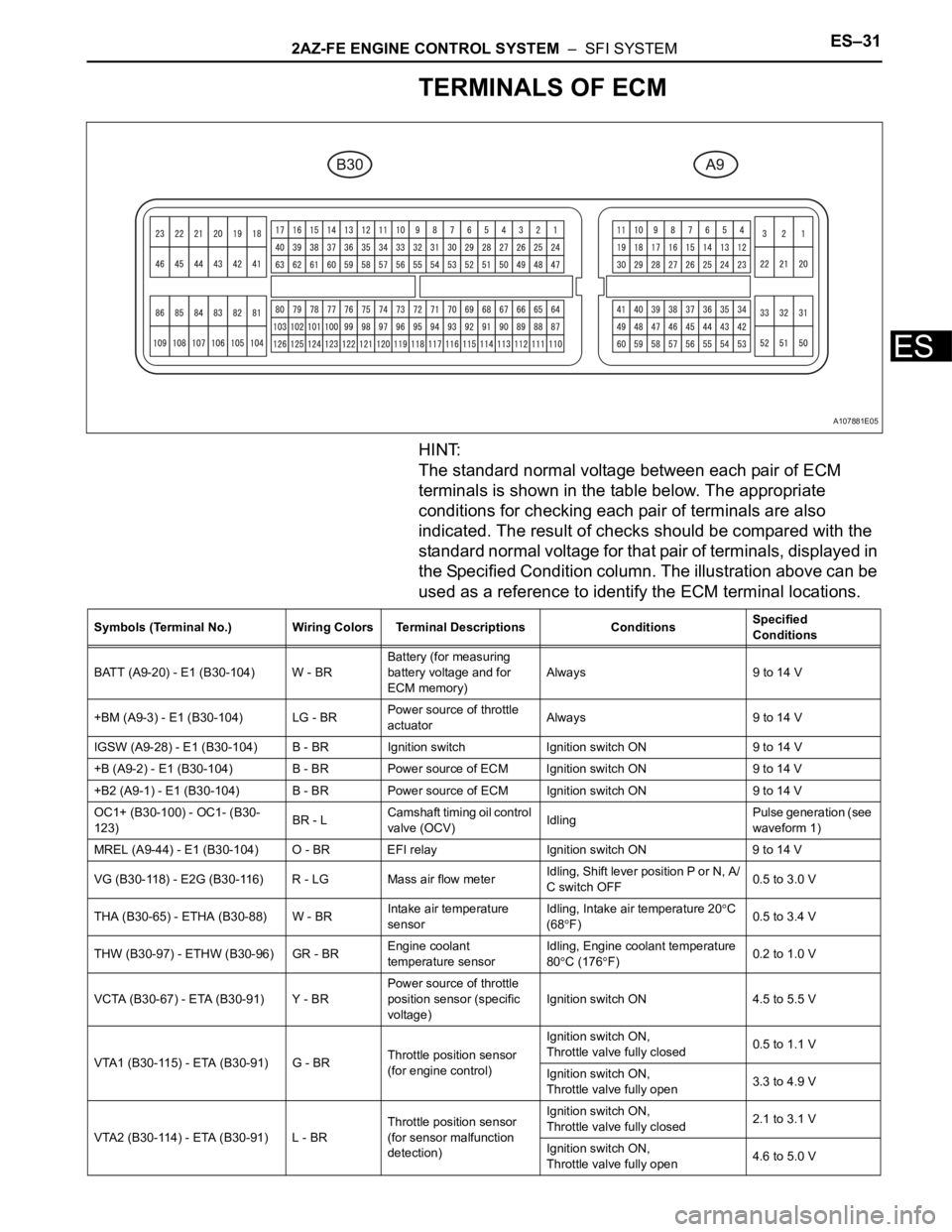

TERMINALS OF ECM

HINT:

The standard normal voltage between each pair of ECM

terminals is shown in the table below. The appropriate

conditions for checking each pair of terminals are also

indicated. The result of checks should be compared with the

standard normal voltage for that pair of terminals, displayed in

the Specified Condition column. The illustration above can be

used as a reference to identify the ECM terminal locations.

A107881E05

Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Conditions

BATT (A9-20) - E1 (B30-104) W - BRBattery (for measuring

battery voltage and for

ECM memory)Always 9 to 14 V

+BM (A9-3) - E1 (B30-104) LG - BRPower source of throttle

actuatorAlways 9 to 14 V

IGSW (A9-28) - E1 (B30-104) B - BR Ignition switch Ignition switch ON 9 to 14 V

+B (A9-2) - E1 (B30-104) B - BR Power source of ECM Ignition switch ON 9 to 14 V

+B2 (A9-1) - E1 (B30-104) B - BR Power source of ECM Ignition switch ON 9 to 14 V

OC1+ (B30-100) - OC1- (B30-

123)BR - LCamshaft timing oil control

valve (OCV)IdlingPulse generation (see

waveform 1)

MREL (A9-44) - E1 (B30-104) O - BR EFI relay Ignition switch ON 9 to 14 V

VG (B30-118) - E2G (B30-116) R - LG Mass air flow meterIdling, Shift lever position P or N, A/

C switch OFF0.5 to 3.0 V

THA (B30-65) - ETHA (B30-88) W - BRIntake air temperature

sensorIdling, Intake air temperature 20

C

(68

F)0.5 to 3.4 V

THW (B30-97) - ETHW (B30-96) GR - BREngine coolant

temperature sensorIdling, Engine coolant temperature

80

C (176F)0.2 to 1.0 V

VCTA (B30-67) - ETA (B30-91) Y - BRPower source of throttle

position sensor (specific

voltage)Ignition switch ON 4.5 to 5.5 V

VTA1 (B30-115) - ETA (B30-91) G - BRThrottle position sensor

(for engine control)Ignition switch ON,

Throttle valve fully closed0.5 to 1.1 V

Ignition switch ON,

Throttle valve fully open3.3 to 4.9 V

VTA2 (B30-114) - ETA (B30-91) L - BRThrottle position sensor

(for sensor malfunction

detection)Ignition switch ON,

Throttle valve fully closed2.1 to 3.1 V

Ignition switch ON,

Throttle valve fully open4.6 to 5.0 V

Page 488 of 2000

ES–342AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

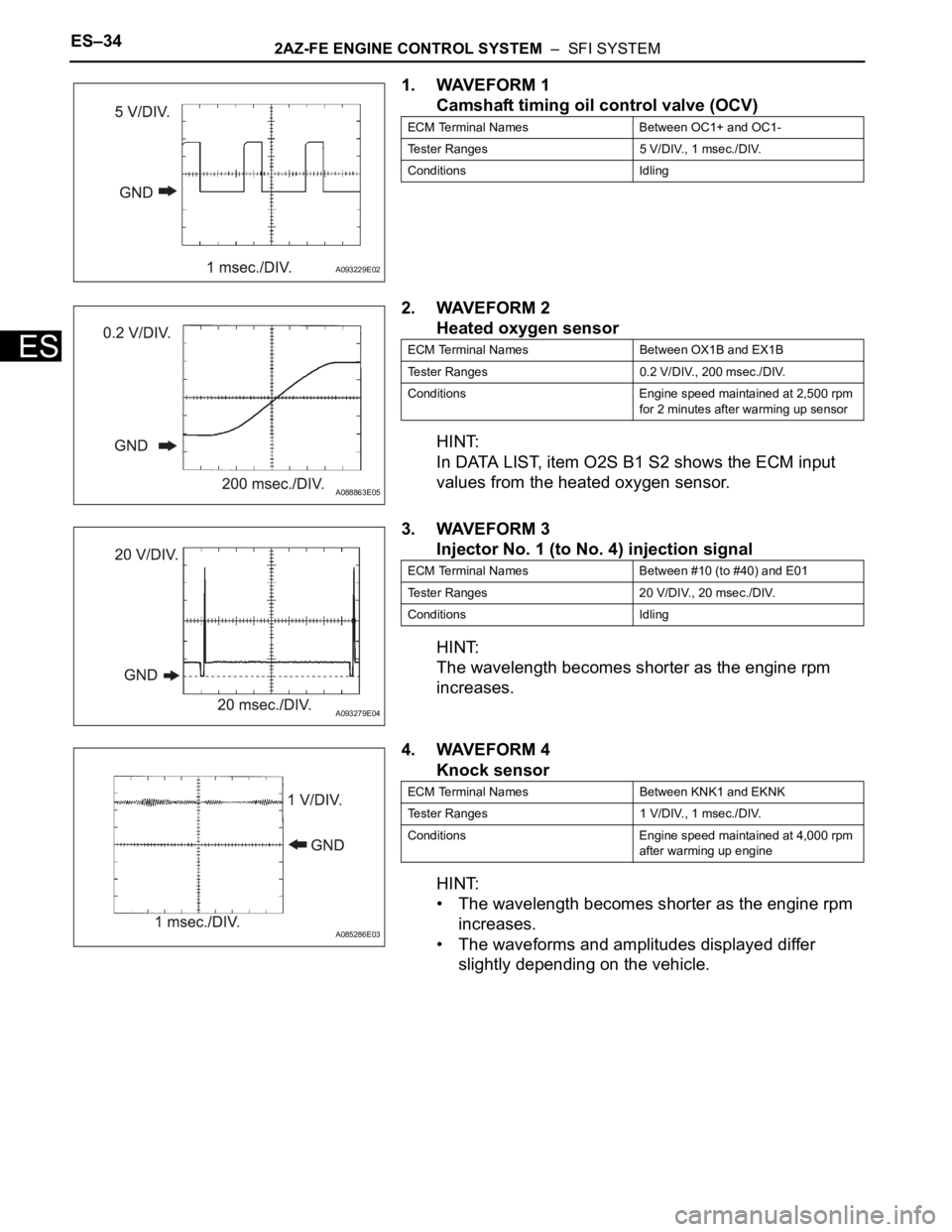

1. WAVEFORM 1

Camshaft timing oil control valve (OCV)

2. WAVEFORM 2

Heated oxygen sensor

HINT:

In DATA LIST, item O2S B1 S2 shows the ECM input

values from the heated oxygen sensor.

3. WAVEFORM 3

Injector No. 1 (to No. 4) injection signal

HINT:

The wavelength becomes shorter as the engine rpm

increases.

4. WAVEFORM 4

Knock sensor

HINT:

• The wavelength becomes shorter as the engine rpm

increases.

• The waveforms and amplitudes displayed differ

slightly depending on the vehicle.

A093229E02

ECM Terminal Names Between OC1+ and OC1-

Tester Ranges 5 V/DIV., 1 msec./DIV.

Conditions Idling

A088863E05

ECM Terminal Names Between OX1B and EX1B

Tester Ranges 0.2 V/DIV., 200 msec./DIV.

Conditions Engine speed maintained at 2,500 rpm

for 2 minutes after warming up sensor

A093279E04

ECM Terminal Names Between #10 (to #40) and E01

Tester Ranges 20 V/DIV., 20 msec./DIV.

Conditions Idling

A085286E03

ECM Terminal Names Between KNK1 and EKNK

Tester Ranges 1 V/DIV., 1 msec./DIV.

Conditions Engine speed maintained at 4,000 rpm

after warming up engine

Page 492 of 2000

ES–382AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

DIAGNOSIS SYSTEM

1. DESCRIPTION

When troubleshooting OBD II (On-Board Diagnostics)

vehicles, the intelligent tester (complying with SAE

J1987) must be connected to the DLC3 (Data Link

Connector 3) of the vehicle. Various data in the vehicle's

ECM (Engine Control Module) can be then read.

OBD II regulations require that the vehicle's on-board

computer illuminate the MIL (Malfunction Indicator

Lamp) on the instrument panel when the computer

detects a malfunction in:

(a) The emission control system components.

(b) The powertrain control components (which affect

vehicle emissions).

(c) The computer itself.

In addition, if the applicable DTCs (Diagnostic Trouble

Codes) prescribed by SAE J2012 are not recorded on 3

consecutive trips, the MIL turns off automatically but the

DTCs remain recorded in the ECM memory.

To check DTCs, connect the intelligent tester to the

DLC3. The tester displays DTCs, freeze frame data, and

a variety of the engine data. The DTCs and freeze frame

data can be erased with the tester (see page ES-35).

In order to enhance OBD function on vehicles and

develop the Off-Board diagnosis system, CAN

(Controller Area Network) communication is introduced

in this system. It minimizes the gap between technician

skills and vehicle technology. CAN is a network, which

uses a pair of data transmission lines, spanning multiple

computers and sensors. It allows high speed

communication between the systems and simplifies the

wire harness connection.

Since this system is equipped with the CAN

communication, connecting the CAN VIM (Vehicle

Interface Module) to the intelligent tester is necessary to

display any information from the ECM. (Also the

communication between the intelligent tester and the

ECM uses CAN communication signals.) When

confirming the DTCs and any data of the ECM, connect

the CAN VIM between the DLC3 and the intelligent

tester.

2. NORMAL MODE AND CHECK MODE

The diagnosis system operates in normal mode during

normal vehicle use. In normal mode, 2 trip detection

logic is used to ensure accurate detection of

malfunctions. Check mode is also available as an option

for technicians. In check mode, 1 trip detection logic is

used for simulating malfunction symptoms and

increasing the system's ability to detect malfunctions,

including intermittent problems (intelligent tester only)

(see page ES-38).

FI00534

B127989E01

Page 493 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–39

ES

3. 2 TRIP DETECTION LOGIC

When a malfunction is first detected, the malfunction is

temporarily stored in the ECM memory (1st trip). If the

same malfunction is detected during the next

subsequent drive cycle, the MIL is illuminated (2nd trip).

4. FREEZE FRAME DATA

Freeze frame data records the engine conditions (fuel

system, calculated engine load, engine coolant

temperature, fuel trim, engine speed, vehicle speed,

etc.) when malfunctions are detected. When

troubleshooting, freeze frame data can help determine if

the vehicle was moving or stationary, if the engine was

warmed up or not, if the air-fuel ratio was lean or rich,

and other data from the time the malfunction occurred.

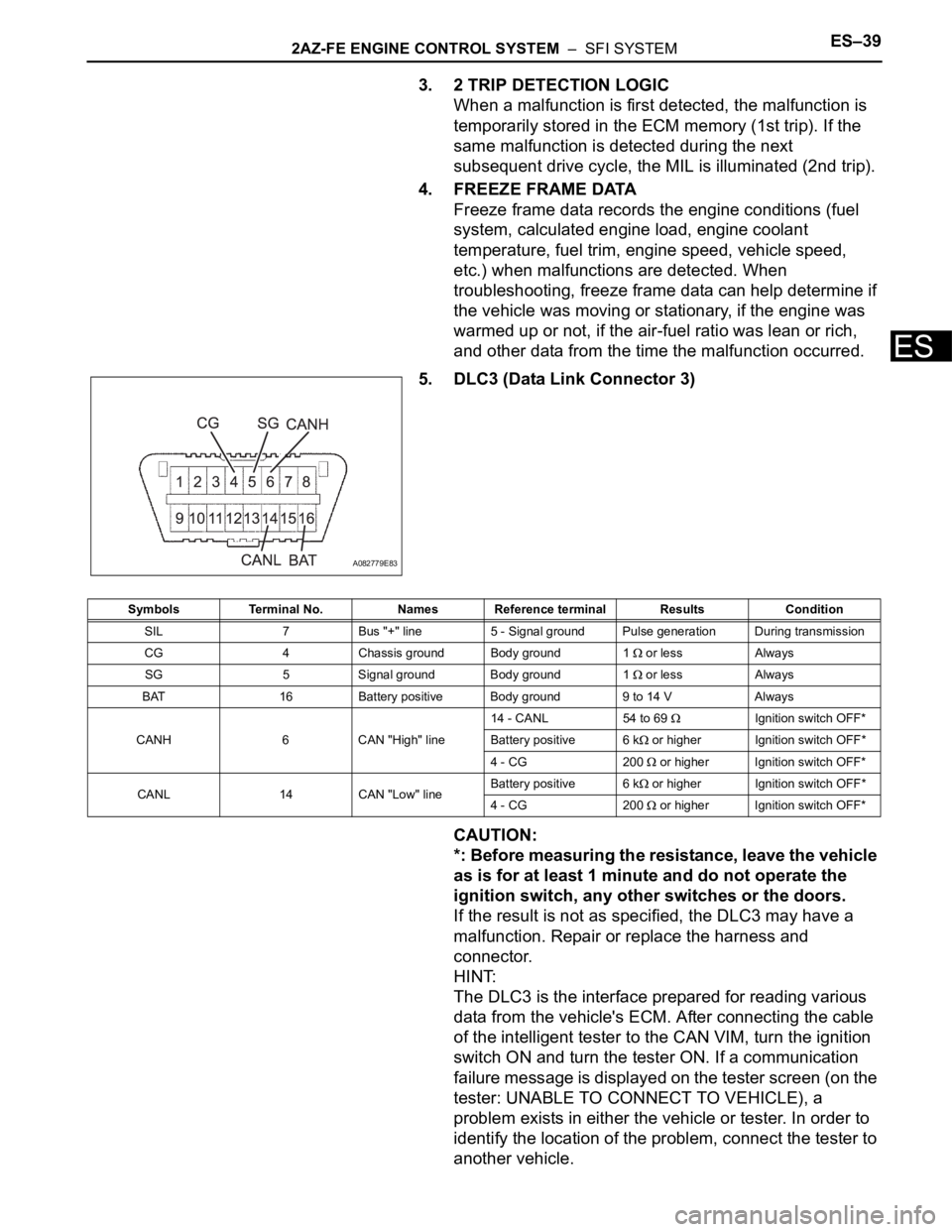

5. DLC3 (Data Link Connector 3)

CAUTION:

*: Before measuring the resistance, leave the vehicle

as is for at least 1 minute and do not operate the

ignition switch, any other switches or the doors.

If the result is not as specified, the DLC3 may have a

malfunction. Repair or replace the harness and

connector.

HINT:

The DLC3 is the interface prepared for reading various

data from the vehicle's ECM. After connecting the cable

of the intelligent tester to the CAN VIM, turn the ignition

switch ON and turn the tester ON. If a communication

failure message is displayed on the tester screen (on the

tester: UNABLE TO CONNECT TO VEHICLE), a

problem exists in either the vehicle or tester. In order to

identify the location of the problem, connect the tester to

another vehicle.

A082779E83

Symbols Terminal No. Names Reference terminal Results Condition

SIL 7 Bus "+" line 5 - Signal ground Pulse generation During transmission

CG 4 Chassis ground Body ground 1

or less Always

SG 5 Signal ground Body ground 1

or less Always

BAT 16 Battery positive Body ground 9 to 14 V Always

CANH 6 CAN "High" line14 - CANL 54 to 69

Ignition switch OFF*

Battery positive 6 k

or higher Ignition switch OFF*

4 - CG 200

or higher Ignition switch OFF*

CANL 14 CAN "Low" lineBattery positive 6 k

or higher Ignition switch OFF*

4 - CG 200

or higher Ignition switch OFF*

Page 495 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–41

ES

DTC CHECK / CLEAR

NOTICE:

When the diagnosis system is changed from normal

mode to check mode or vice versa, all DTCs and freeze

frame data recorded in normal mode are erased. Before

changing modes, always check and make a note of any

DTCs and freeze frame data.

HINT:

• DTCs which are stored in the ECM can be displayed on

the intelligent tester. The intelligent tester can display

current and pending DTCs.

• Some DTCs are not set if the ECM does not detect the

same malfunction again during a second consecutive

driving cycle. However, such malfunctions, detected on

only one occasion, are stored as pending DTCs.

1. CHECK DTC (Using intelligent tester)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch ON.

(c) Turn the tester ON.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT

CODES or PENDING CODES.

(e) Check the DTC(s) and freeze frame data, and then

write them down.

(f) Check the details of the DTC(s) (see page ES-51).

2. CLEAR DTC (Using intelligent tester)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch ON.

(c) Turn the tester ON.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CLEAR CODES.

(e) Press the YES button.

3. CLEAR DTC (Without using intelligent tester)

(a) Perform either of the following operations.

(1) Disconnect the cable from the negative (-)

battery terminal for more than 1 minute.

(2) Remove the EFI and ETCS fuses from the

engine room relay block (located inside the

engine compartment) for more than 1 minute.

Page 496 of 2000

ES–422AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

FREEZE FRAME DATA

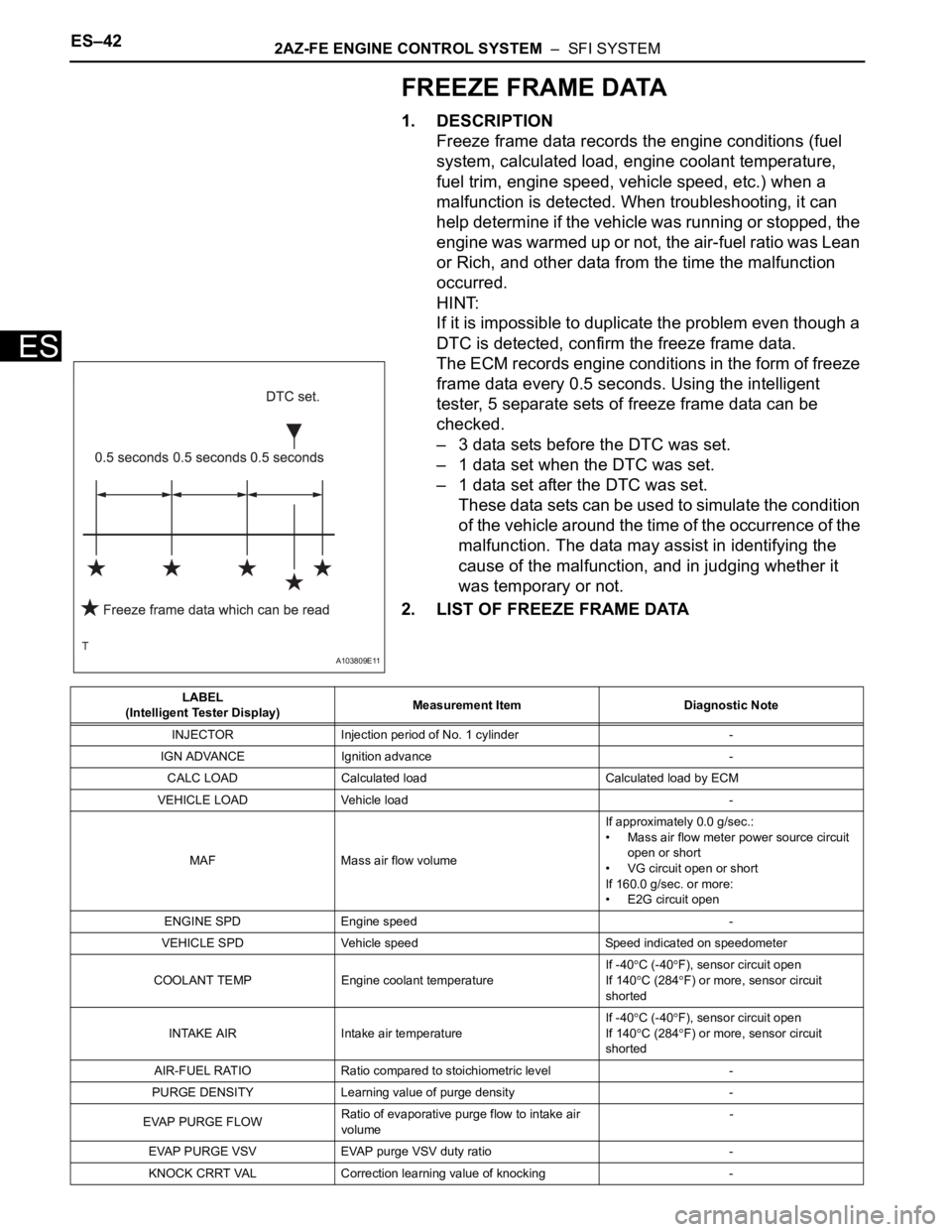

1. DESCRIPTION

Freeze frame data records the engine conditions (fuel

system, calculated load, engine coolant temperature,

fuel trim, engine speed, vehicle speed, etc.) when a

malfunction is detected. When troubleshooting, it can

help determine if the vehicle was running or stopped, the

engine was warmed up or not, the air-fuel ratio was Lean

or Rich, and other data from the time the malfunction

occurred.

HINT:

If it is impossible to duplicate the problem even though a

DTC is detected, confirm the freeze frame data.

The ECM records engine conditions in the form of freeze

frame data every 0.5 seconds. Using the intelligent

tester, 5 separate sets of freeze frame data can be

checked.

– 3 data sets before the DTC was set.

– 1 data set when the DTC was set.

– 1 data set after the DTC was set.

These data sets can be used to simulate the condition

of the vehicle around the time of the occurrence of the

malfunction. The data may assist in identifying the

cause of the malfunction, and in judging whether it

was temporary or not.

2. LIST OF FREEZE FRAME DATA

A103809E11

LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

INJECTOR Injection period of No. 1 cylinder -

IGN ADVANCE Ignition advance -

CALC LOAD Calculated load Calculated load by ECM

VEHICLE LOAD Vehicle load -

MAF Mass air flow volumeIf approximately 0.0 g/sec.:

• Mass air flow meter power source circuit

open or short

• VG circuit open or short

If 160.0 g/sec. or more:

• E2G circuit open

ENGINE SPD Engine speed -

VEHICLE SPD Vehicle speed Speed indicated on speedometer

COOLANT TEMP Engine coolant temperatureIf -40

C (-40F), sensor circuit open

If 140

C (284F) or more, sensor circuit

shorted

INTAKE AIR Intake air temperature If -40

C (-40F), sensor circuit open

If 140

C (284F) or more, sensor circuit

shorted

AIR-FUEL RATIO Ratio compared to stoichiometric level -

PURGE DENSITY Learning value of purge density -

EVAP PURGE FLOWRatio of evaporative purge flow to intake air

volume-

EVAP PURGE VSV EVAP purge VSV duty ratio -

KNOCK CRRT VAL Correction learning value of knocking -

Page 497 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–43

ES

KNOCK FB VAL Feedback value of knocking -

ACCEL POS #1Absolute Accelerator Pedal Position (APP)

No.1-

ACCEL POS #2 Absolute APP No. 2 -

THROTTLE POS Throttle sensor positioning -

THROTTLE POS Throttle position -

THROTTLE POS #2 Throttle sensor positioning #2 -

THROTTLE MOT Throttle motor -

O2S B1 S2 Heated oxygen sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check output voltage of sensor

AFS B1 S1 A/F sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check output voltage of sensor

TOTAL FT #1 Total fuel trim -

SHORT FT #1 Short-term fuel trimShort-term fuel compensation used to

maintain air-fuel ratio at stoichiometric air-fuel

ratio

LONG FT #1 Long-term fuel trimOverall fuel compensation carried out in long-

term to compensate a continual deviation of

short-term fuel trim from central valve

FUEL SYS #1 Fuel system status• OL (Open Loop): Has not yet satisfied

conditions to go closed loop

• CL (Closed Loop): Using A/F sensor as

feedback for fuel control

• OL DRIVE: Open loop due to driving

conditions (fuel enrichment)

• OL FAULT: Open loop due to detected

system fault

• CL FAULT: Closed loop but A/F sensor,

which used for fuel control malfunctioning

O2FT B1 S2 Fuel trim at heated oxygen sensor -

AF FT B1 S1 Fuel trim at A/F sensor -

AFS B1 S1 A/F sensor current -

CAT TEMP B1S1 Estimated catalyst temperature (sensor 1) -

CAT TEMP B1S2 Estimated catalyst temperature (sensor 2) -

S O2S B1S2Sub heated oxygen sensor impedance

(sensor 2)-

INI COOL TEMP Engine coolant temperature at engine start -

INI INTAKE TEMP Intake air temperature at engine start -

INJ VOL Injection volume -

STARTER SIG Starter switch (STSW) signal -

PS SW Power steering signal -

PS SIGNAL Power steering signal (history)Signal status usually ON until ignition switch

turned OFF

CTP SW Closed throttle position switch -

A/C SIGNAL A/C signal -

PNP SW (NSW) Park/Neutral Position (PNP) switch signal -

ELECT LOAD SIG Electrical load signal -

STOP LIGHT SW Stop light switch -

BATTERY VOLTAGE Battery voltage -

ATM PRESSURE Atmosphere pressure -

EVAP (Purge) VSV EVAP Purge VSV -

FUEL PUMP/SPD Fuel pump/speed status -LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 498 of 2000

ES–442AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

VVT CTRL B1 VVT control status -

VA C U U M P U M PKey-off EVAP system leak detection pump

status(see page ES-333)

EVAP VENT VAL Key-off EVAP system vent valve status -

FAN MOTOR Electric fan motor -

TC/TE1 TC and CG (TE1) terminals of DLC3 -

ENG SPEED #1 Engine rpm during No. 1 cylinder fuel cutOutput only when FUEL CUT #1 is performed

using ACTIVE TEST

ENG SPEED #2 Engine rpm during No. 2 cylinder fuel cutOutput only when FUEL CUT #2 is performed

using ACTIVE TEST

ENG SPEED #3 Engine rpm during No. 3 cylinder fuel cutOutput only when FUEL CUT #3 is performed

using ACTIVE TEST

ENG SPEED #4 Engine rpm during No. 4 cylinder fuel cutOutput only when FUEL CUT #4 is performed

using ACTIVE TEST

ENG SPEED ALLAverage of engine rpm values during fuel cut

of No. 1 to No. 4 cylindersOutput only when ACTIVE TEST is performed

VVTL AIM ANGL#1 VVT aim angle -

VVT CHNG ANGL#1 VVT angle -

VVT OCV DUTY B1 VVT OCV operation duty -

FC IDL Fuel cut idleON: when throttle valve fully closed and

engine speed over 3,500 rpm

FC TAU Fuel cut during very light loadFuel cut being performed under very light load

to prevent engine combustion from becoming

incomplete

IGNITION Ignition counter -

CYL #1 Cylinder #1 misfire Only displayed during idling

CYL #2 Cylinder #2 misfire Only displayed during idling

CYL #3 Cylinder #3 misfire Only displayed during idling

CYL #4 Cylinder #4 misfire Only displayed during idling

CYL ALL All cylinders misfire Only displayed during idling

MISFIRE RPM Engine speed when misfire occurred -

MISFIRE LOAD Engine load when misfire occurred -

MISFIRE MARGIN Margin to detect engine misfire -

MIL ON RUN DIST Distance after DTC is detected -

ENG RUN TIME Accumulated engine running time -

TIME DTC CLEAR Cumulative time after DTC cleared -

DIST DTC CLEAR Accumulated distance from DTC cleared -

WU CYC DTC CLEAR Warm-up cycle after DTC cleared -LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 535 of 2000

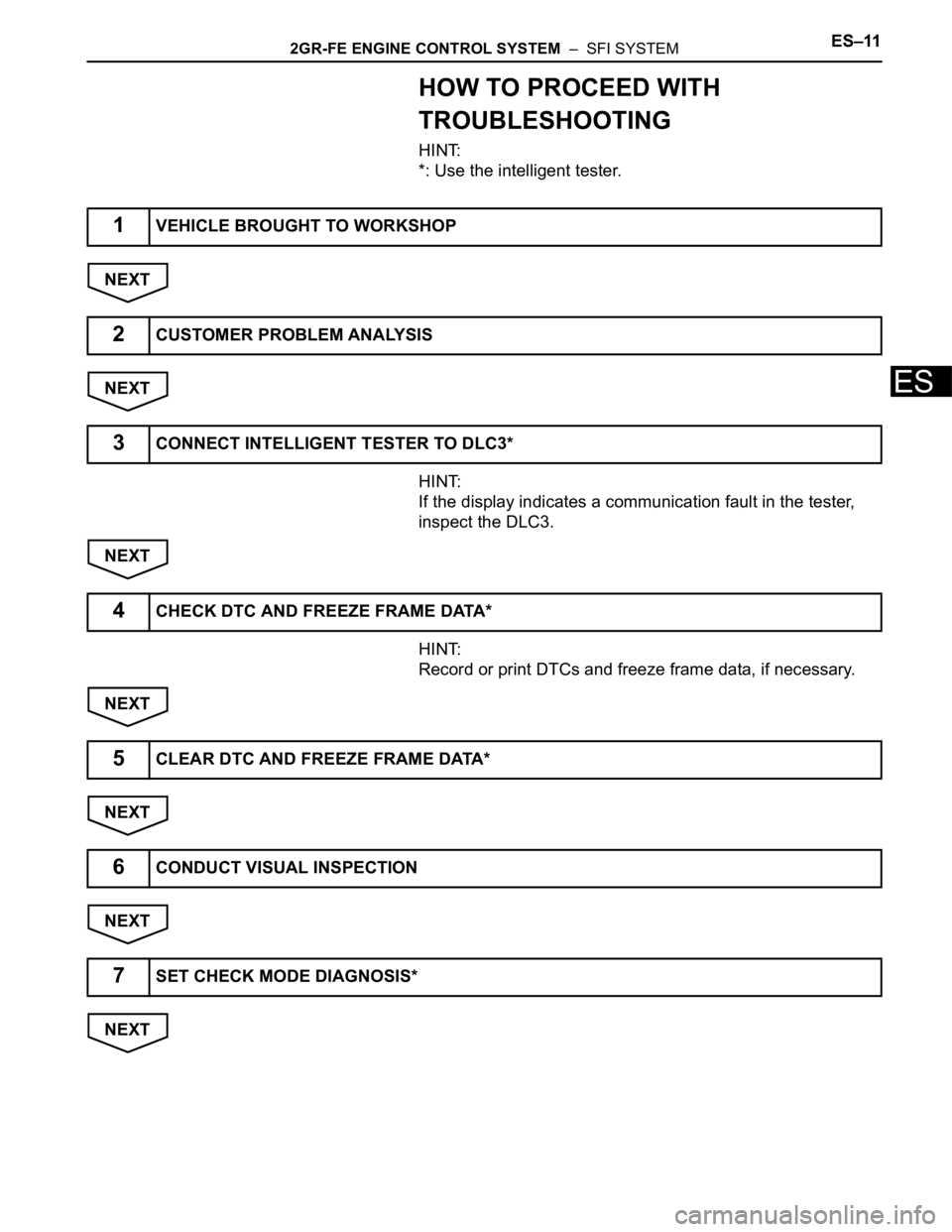

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–11

ES

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

*: Use the intelligent tester.

NEXT

NEXT

HINT:

If the display indicates a communication fault in the tester,

inspect the DLC3.

NEXT

HINT:

Record or print DTCs and freeze frame data, if necessary.

NEXT

NEXT

NEXT

NEXT

1VEHICLE BROUGHT TO WORKSHOP

2CUSTOMER PROBLEM ANALYSIS

3CONNECT INTELLIGENT TESTER TO DLC3*

4CHECK DTC AND FREEZE FRAME DATA*

5CLEAR DTC AND FREEZE FRAME DATA*

6CONDUCT VISUAL INSPECTION

7SET CHECK MODE DIAGNOSIS*

Page 547 of 2000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–23

ES

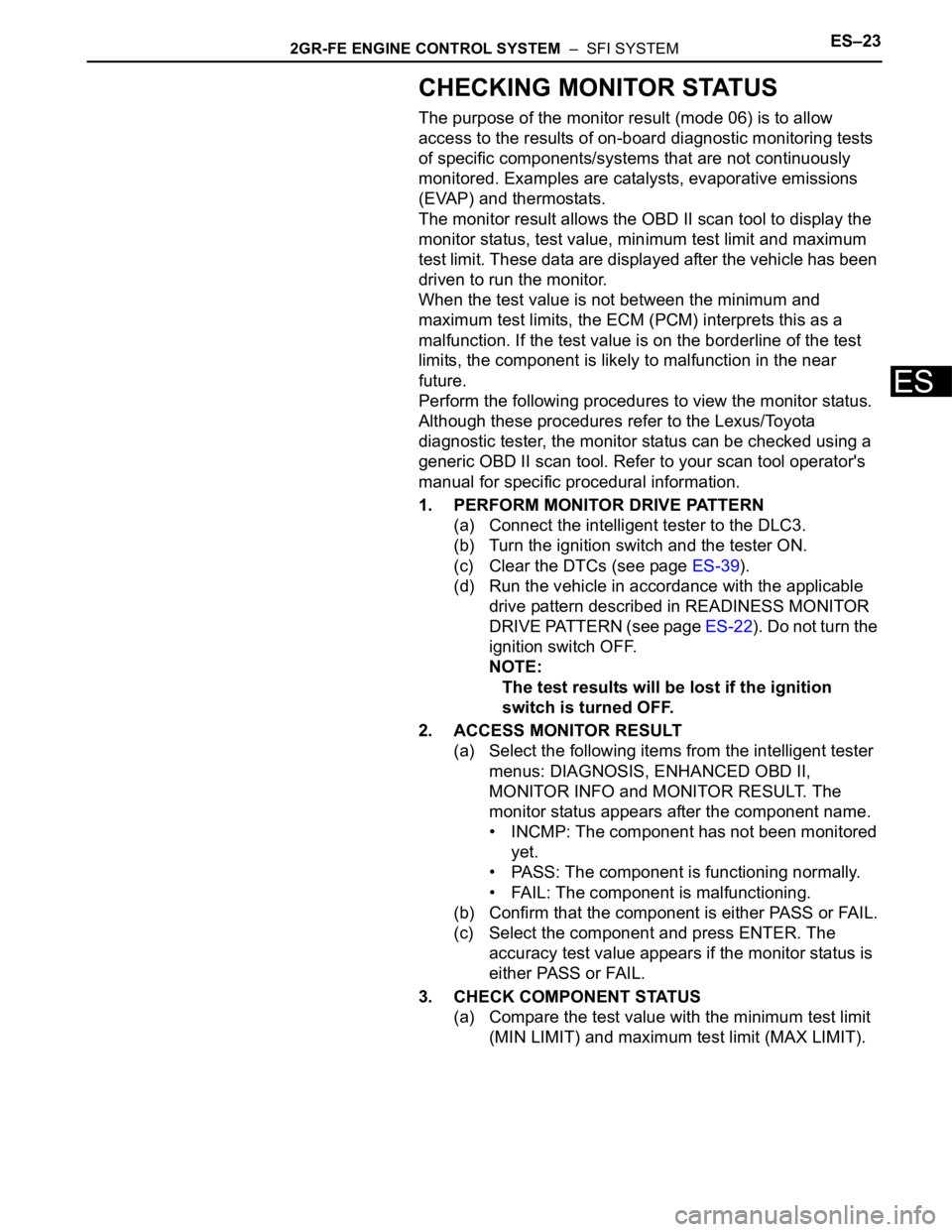

CHECKING MONITOR STATUS

The purpose of the monitor result (mode 06) is to allow

access to the results of on-board diagnostic monitoring tests

of specific components/systems that are not continuously

monitored. Examples are catalysts, evaporative emissions

(EVAP) and thermostats.

The monitor result allows the OBD II scan tool to display the

monitor status, test value, minimum test limit and maximum

test limit. These data are displayed after the vehicle has been

driven to run the monitor.

When the test value is not between the minimum and

maximum test limits, the ECM (PCM) interprets this as a

malfunction. If the test value is on the borderline of the test

limits, the component is likely to malfunction in the near

future.

Perform the following procedures to view the monitor status.

Although these procedures refer to the Lexus/Toyota

diagnostic tester, the monitor status can be checked using a

generic OBD II scan tool. Refer to your scan tool operator's

manual for specific procedural information.

1. PERFORM MONITOR DRIVE PATTERN

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch and the tester ON.

(c) Clear the DTCs (see page ES-39).

(d) Run the vehicle in accordance with the applicable

drive pattern described in READINESS MONITOR

DRIVE PATTERN (see page ES-22). Do not turn the

ignition switch OFF.

NOTE:

The test results will be lost if the ignition

switch is turned OFF.

2. ACCESS MONITOR RESULT

(a) Select the following items from the intelligent tester

menus: DIAGNOSIS, ENHANCED OBD II,

MONITOR INFO and MONITOR RESULT. The

monitor status appears after the component name.

• INCMP: The component has not been monitored

yet.

• PASS: The component is functioning normally.

• FAIL: The component is malfunctioning.

(b) Confirm that the component is either PASS or FAIL.

(c) Select the component and press ENTER. The

accuracy test value appears if the monitor status is

either PASS or FAIL.

3. CHECK COMPONENT STATUS

(a) Compare the test value with the minimum test limit

(MIN LIMIT) and maximum test limit (MAX LIMIT).