oil pressure TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 82 of 2000

ENGINE - 2GR-FE ENGINE

285EG24

Timing Chain Cover

Oil Pump

Housing

Oil Pump Rotors

(Cycloid Rotor)Crankshaft

To Cylinder

Block

From Oil

Filter

To

Oil FilterFrom

Oil Strainer

Oil passage in the oil pump

285EG25

Oil Jet Cross Section

Oil JetsCheck

Va l v eEngine Oil EG-86

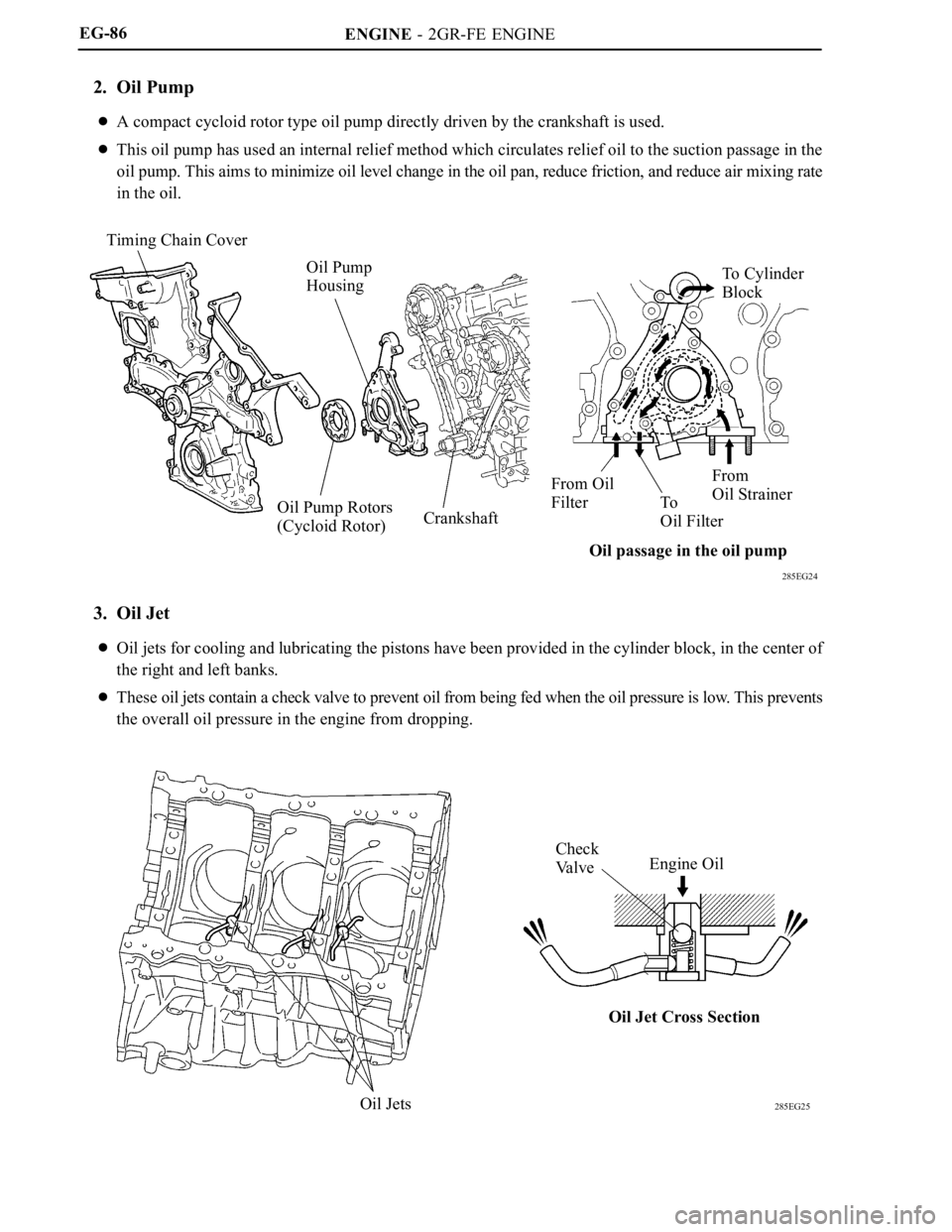

2. Oil Pump

A compact cycloid rotor type oil pump directly driven by the crankshaft is used.

This oil pump has used an internal relief method which circulates relief oil to the suction passage in the

oil pump. This aims to minimize oil level change in the oil pan, reduce friction, and reduce air mixing rate

in the oil.

3. Oil Jet

Oil jets for cooling and lubricating the pistons have been provided in the cylinder block, in the center of

the right and left banks.

These oil jets contain a check valve to prevent oil from being fed when the oil pressure is low. This prevents

the overall oil pressure in the engine from dropping.

Page 102 of 2000

ENGINE - 2GR-FE ENGINE

01MEG29Y

Ignition SwitchCombination Meter

Vehicle Speed Signal

MIL

Battery Current Sensor

(Built-in Battery

Temperature Sensor)

Park / Neutral

Position Switch

Battery

Generator

Fuel Pump Relay

Fuel Pump

Vent Valve

Circuit Opening

RelayDLC3*1*2*3

CAN

ECM

Cruise Control Switch

Accelerator Pedal

Position Sensor

Stop Light Switch

Canister

Pressure

SensorLeak

Detection

Pump

Intake Air

Temp. Sensor

VSV (For

Air Intake

Control)Mass Air

Flow Meter

AirThrottle Position

Sensor

Purge VSV

Throttle

Control

Motor

*4*5

Fan

Motor No. 1Fan

Motor

No. 2

Cooling

Fan

ECUCooling

Fan

ECU

No. 1Cooling

Fan

ECU

No. 2

Fan Motor No. 1

Fan Motor No. 2

ACIS Actuator

Intake Camshaft Timing

Oil Control Valve (Bank 2)Injector Injector

Intake Camshaft Timing

Oil Control Valve (Bank 1)

Intake VVT Sensor (Bank 1)

Ignition Coil With Igniter

Exhaust VVT Sensor (Bank 1)

Exhaust Camshaft Timing

Oil Control Valve (Bank 1)

Air-fuel Ratio Sensor

(Bank1, Sensor1)

TWC

Knock

Sensor

Intake VVT

Sensor (Bank 2)

Exhaust VVT

Sensor (Bank 2)

Air-fuel Ratio Sensor

(Bank2, Sensor1)Exhaust Camshaft

Timing Oil Control

Valve (Bank 2)

Crankshaft Position

Sensor

Engine Coolant

Temperature Sensor Heated Oxygen Sensor

(Bank1, Sensor2)Heated Oxygen Sensor

(Bank2, Sensor2)TWCTWC

EG-106

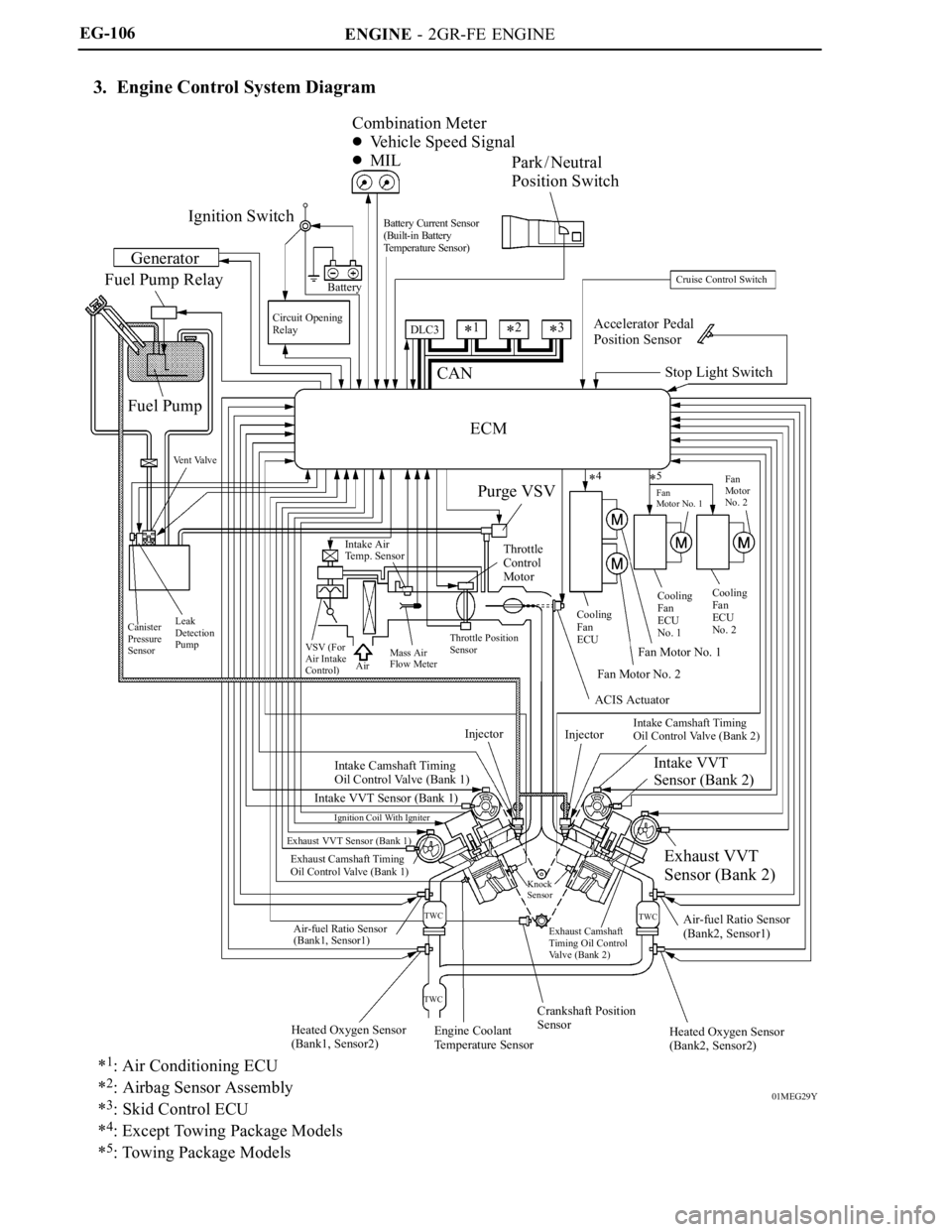

3. Engine Control System Diagram

*1: Air Conditioning ECU

*

2: Airbag Sensor Assembly

*

3: Skid Control ECU

*

4: Except Towing Package Models

*

5: Towing Package Models

Page 118 of 2000

ENGINE - 2GR-FE ENGINE

271EG93

Timing RotorHousingLock PinSprocket

Intake Camshaft

Vane (Fixed on Intake Camshaft)

Oil Pressure

In Operation At a Stop

Lock Pin

281EG47

Housing

Advanced Angle Assist SpringVane (Fixed on Exhaust Camshaft)Lock PinExhaust Camshaft Sprocket EG-122

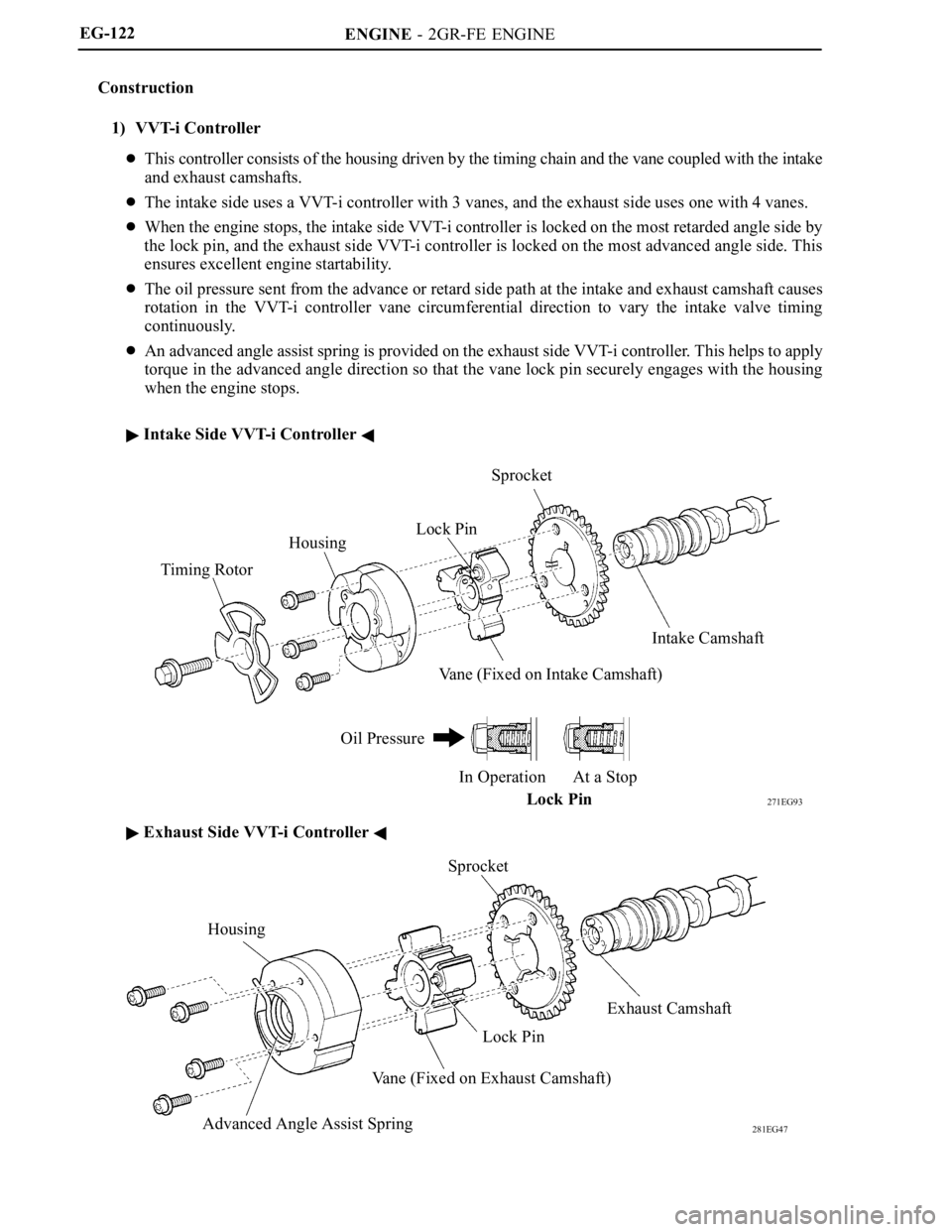

Construction

1) VVT-i Controller

This controller consists of the housing driven by the timing chain and the vane coupled with the intake

and exhaust camshafts.

The intake side uses a VVT-i controller with 3 vanes, and the exhaust side uses one with 4 vanes.

When the engine stops, the intake side VVT-i controller is locked on the most retarded angle side by

the lock pin, and the exhaust side VVT-i controller is locked on the most advanced angle side. This

ensures excellent engine startability.

The oil pressure sent from the advance or retard side path at the intake and exhaust camshaft causes

rotation in the VVT-i controller vane circumferential direction to vary the intake valve timing

continuously.

An advanced angle assist spring is provided on the exhaust side VVT-i controller. This helps to apply

torque in the advanced angle direction so that the vane lock pin securely engages with the housing

when the engine stops.

Intake Side VVT-i Controller

Exhaust Side VVT-i Controller

Page 119 of 2000

ENGINE - 2GR-FE ENGINE

238EG62

To VVT-i Controller

(Advance Side) *To VVT-i Controller

(Retard Side) *

Sleeve

Spring

Drain

Oil PressureDrain

Spool ValveCoil

PlungerEG-123

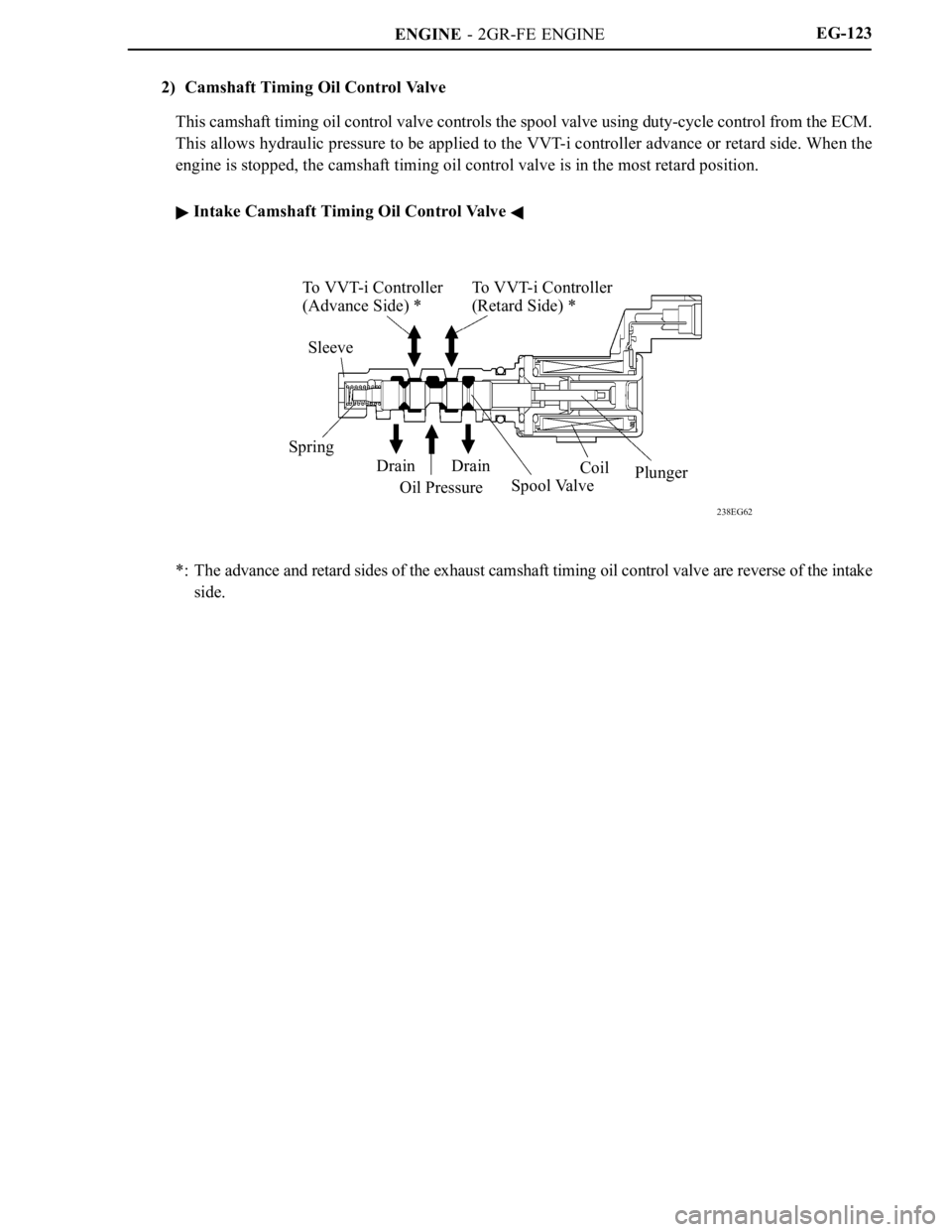

2) Camshaft Timing Oil Control Valve

This camshaft timing oil control valve controls the spool valve using duty-cycle control from the ECM.

This allows hydraulic pressure to be applied to the VVT-i controller advance or retard side. When the

engine is stopped, the camshaft timing oil control valve is in the most retard position.

Intake Camshaft Timing Oil Control Valve

*: The advance and retard sides of the exhaust camshaft timing oil control valve are reverse of the intake

side.

Page 120 of 2000

ENGINE - 2GR-FE ENGINE

238EG63

Va n e

Rotational Direction

Oil Pressure

IN DrainECM

281EG48

Va n e

Rotational DirectionECM

Oil Pressure

IN Drain EG-124

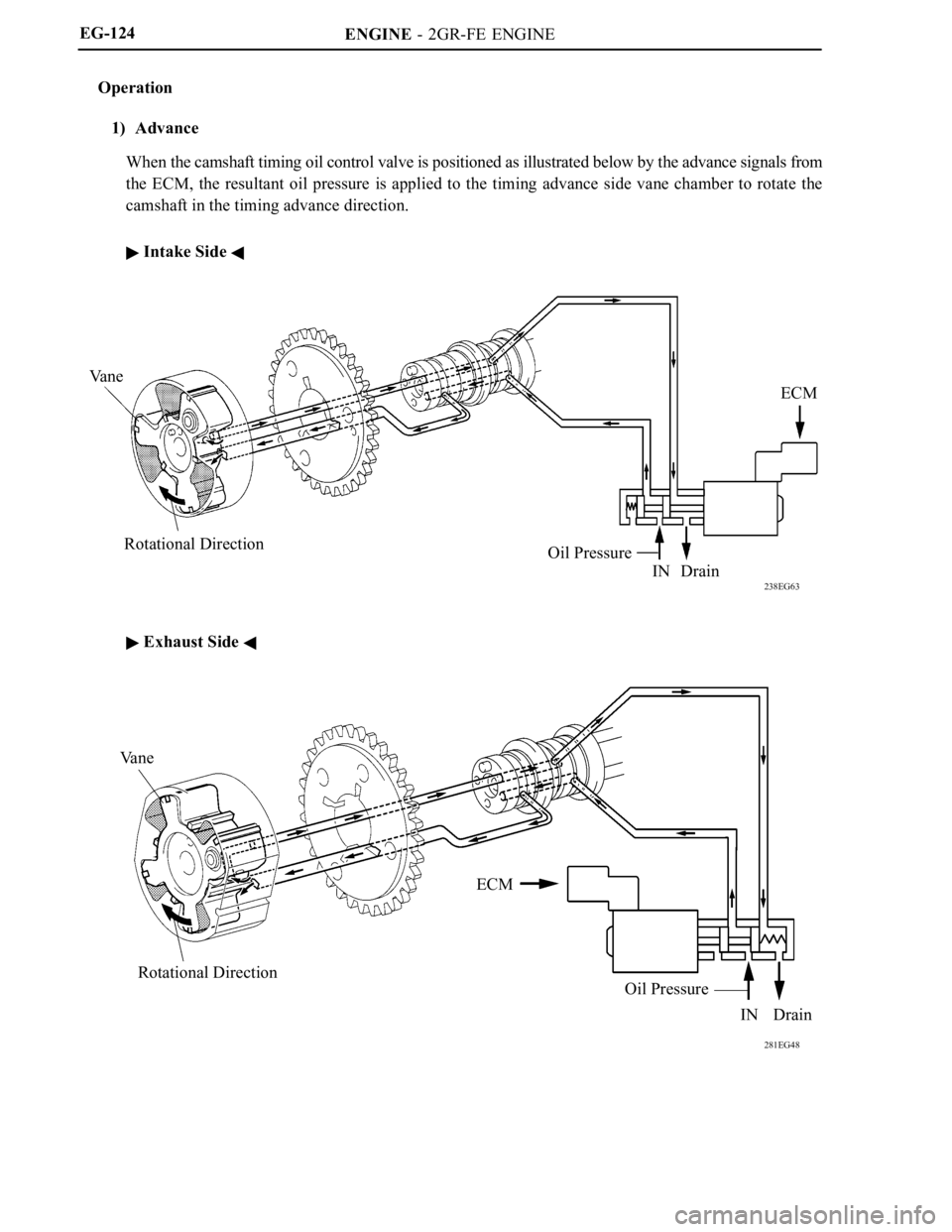

Operation

1) Advance

When the camshaft timing oil control valve is positioned as illustrated below by the advance signals from

the ECM, the resultant oil pressure is applied to the timing advance side vane chamber to rotate the

camshaft in the timing advance direction.

Intake Side

Exhaust Side

Page 121 of 2000

ENGINE - 2GR-FE ENGINE

238EG64

Rotational Direction

Va n e

Drain INOil PressureECM

281EG49

Rotational Direction

Va n eECM

Drain INOil Pressure

EG-125

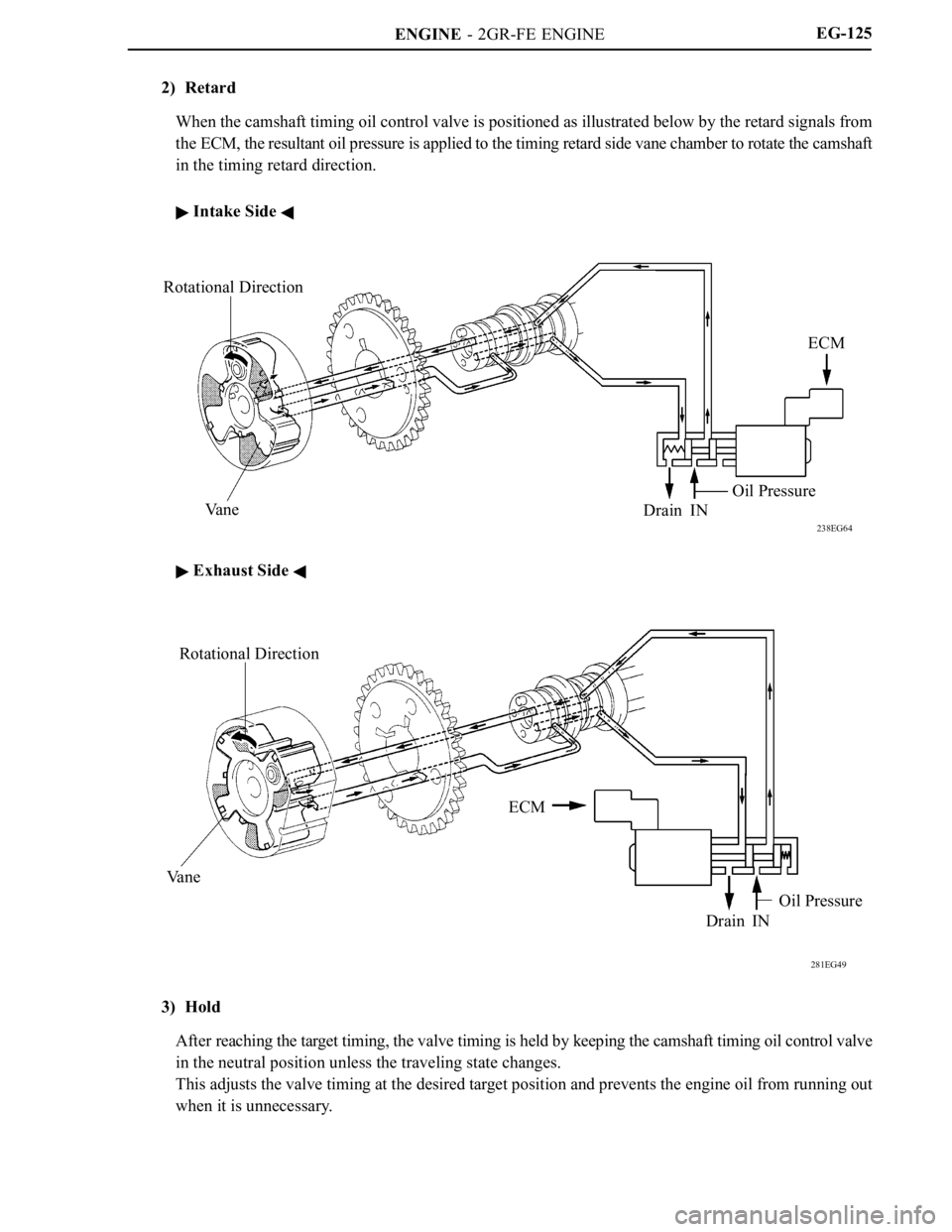

2) Retard

When the camshaft timing oil control valve is positioned as illustrated below by the retard signals from

the ECM, the resultant oil pressure is applied to the timing retard side vane chamber to rotate the camshaft

in the timing retard direction.

Intake Side

Exhaust Side

3) Hold

After reaching the target timing, the valve timing is held by keeping the camshaft timing oil control valve

in the neutral position unless the traveling state changes.

This adjusts the valve timing at the desired target position and prevents the engine oil from running out

when it is unnecessary.

Page 196 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–21

EM

REMOVAL

1. DISCHARGE REFRIGERANT FROM

REFRIGERATION SYSTEM (See page AC-172)

2. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-13)

3. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

4. REMOVE NO. 1 ENGINE UNDER COVER

(a) Remove the 4 bolts, 12 clips and under cover.

5. REMOVE REAR ENGINE UNDER COVER RH

(a) Remove the 2 clips and under cover.

6. REMOVE REAR ENGINE UNDER COVER LH

(a) Remove the 2 clips and under cover.

7. REMOVE NO. 2 ENGINE UNDER COVER

(a) Remove the 2 clips and under cover.

8. REMOVE FRONT FLOOR COVER (See page FU-34)

9. DRAIN ENGINE COOLANT (See page CO-8)

10. DRAIN ENGINE OIL (See page LU-4)

11. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) 2WD:

Drain automatic transaxle fluid (see page AX-172).

(b) 4WD:

Drain automatic transaxle fluid (see page AX-173)

12. DRAIN TRANSFER OIL (for 4WD)

13. REMOVE HOOD SUB-ASSEMBLY (See page ED-4)

14. REMOVE V-BANK COVER SUB-ASSEMBLY

(a) Detach the 3 clips and remove the V-bank cover.

A137900

Page 205 of 2000

EM–302GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

73. REMOVE ENGINE OIL PRESSURE SWITCH

ASSEMBLY

(a) Using a 24 mm deep socket wrench, remove the

pressure switch.

74. REMOVE KNOCK SENSOR (See page ES-459)

75. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using a 19 mm deep socket wrench, remove the

sensor and gasket.

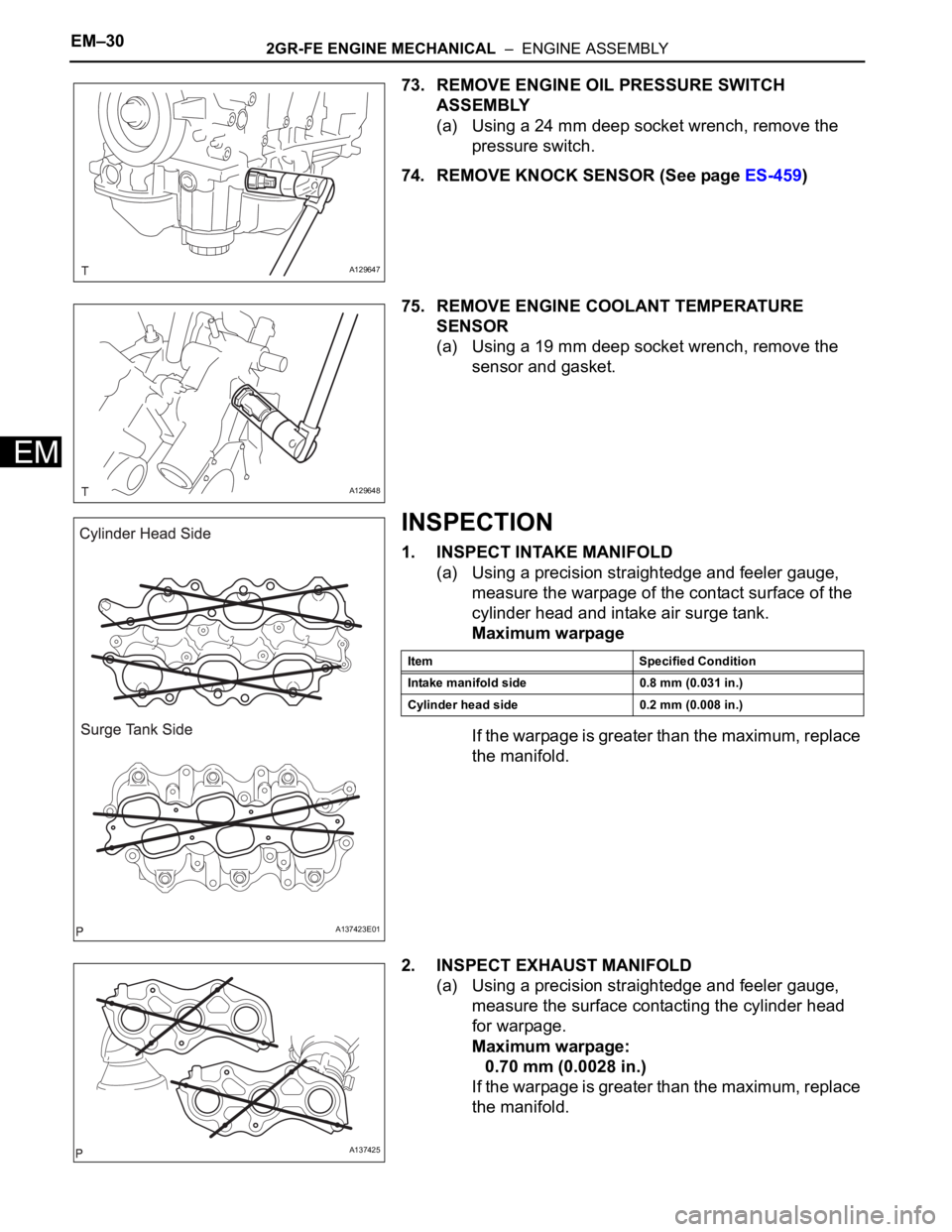

INSPECTION

1. INSPECT INTAKE MANIFOLD

(a) Using a precision straightedge and feeler gauge,

measure the warpage of the contact surface of the

cylinder head and intake air surge tank.

Maximum warpage

If the warpage is greater than the maximum, replace

the manifold.

2. INSPECT EXHAUST MANIFOLD

(a) Using a precision straightedge and feeler gauge,

measure the surface contacting the cylinder head

for warpage.

Maximum warpage:

0.70 mm (0.0028 in.)

If the warpage is greater than the maximum, replace

the manifold.

A129647

A129648

A137423E01

Item Specified Condition

Intake manifold side 0.8 mm (0.031 in.)

Cylinder head side 0.2 mm (0.008 in.)

A137425

Page 227 of 2000

2AZ-FE EMISSION CONTROL – EMISSION CONTROL SYSTEMEC–7

EC

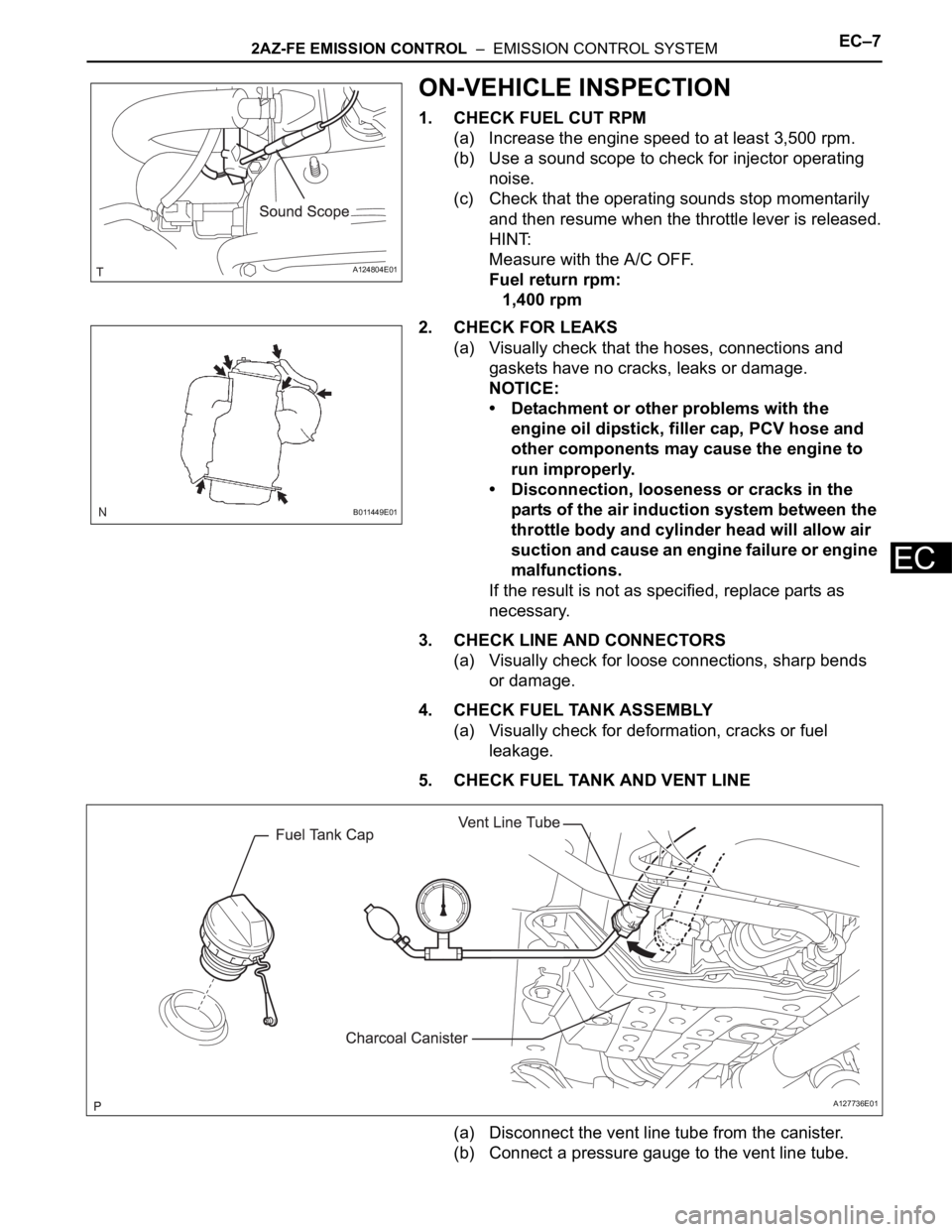

ON-VEHICLE INSPECTION

1. CHECK FUEL CUT RPM

(a) Increase the engine speed to at least 3,500 rpm.

(b) Use a sound scope to check for injector operating

noise.

(c) Check that the operating sounds stop momentarily

and then resume when the throttle lever is released.

HINT:

Measure with the A/C OFF.

Fuel return rpm:

1,400 rpm

2. CHECK FOR LEAKS

(a) Visually check that the hoses, connections and

gaskets have no cracks, leaks or damage.

NOTICE:

• Detachment or other problems with the

engine oil dipstick, filler cap, PCV hose and

other components may cause the engine to

run improperly.

• Disconnection, looseness or cracks in the

parts of the air induction system between the

throttle body and cylinder head will allow air

suction and cause an engine failure or engine

malfunctions.

If the result is not as specified, replace parts as

necessary.

3. CHECK LINE AND CONNECTORS

(a) Visually check for loose connections, sharp bends

or damage.

4. CHECK FUEL TANK ASSEMBLY

(a) Visually check for deformation, cracks or fuel

leakage.

5. CHECK FUEL TANK AND VENT LINE

(a) Disconnect the vent line tube from the canister.

(b) Connect a pressure gauge to the vent line tube.

A124804E01

B011449E01

A127736E01

Page 247 of 2000

LU–122GR-FE LUBRICATION – OIL PUMP

LU

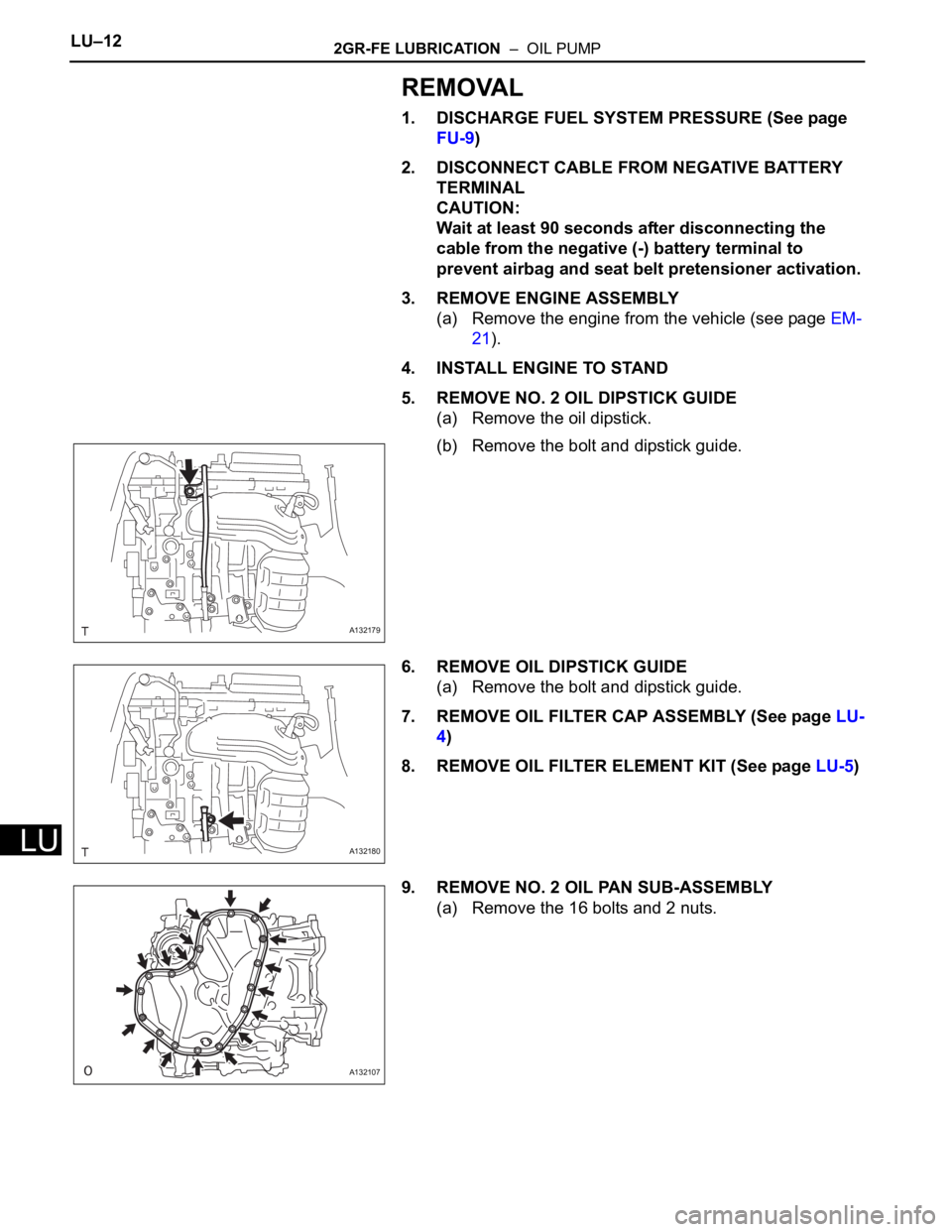

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-9)

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

3. REMOVE ENGINE ASSEMBLY

(a) Remove the engine from the vehicle (see page EM-

21).

4. INSTALL ENGINE TO STAND

5. REMOVE NO. 2 OIL DIPSTICK GUIDE

(a) Remove the oil dipstick.

(b) Remove the bolt and dipstick guide.

6. REMOVE OIL DIPSTICK GUIDE

(a) Remove the bolt and dipstick guide.

7. REMOVE OIL FILTER CAP ASSEMBLY (See page LU-

4)

8. REMOVE OIL FILTER ELEMENT KIT (See page LU-5)

9. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY

(a) Remove the 16 bolts and 2 nuts.

A132179

A132180

A132107