TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 201 of 2000

EM–262GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

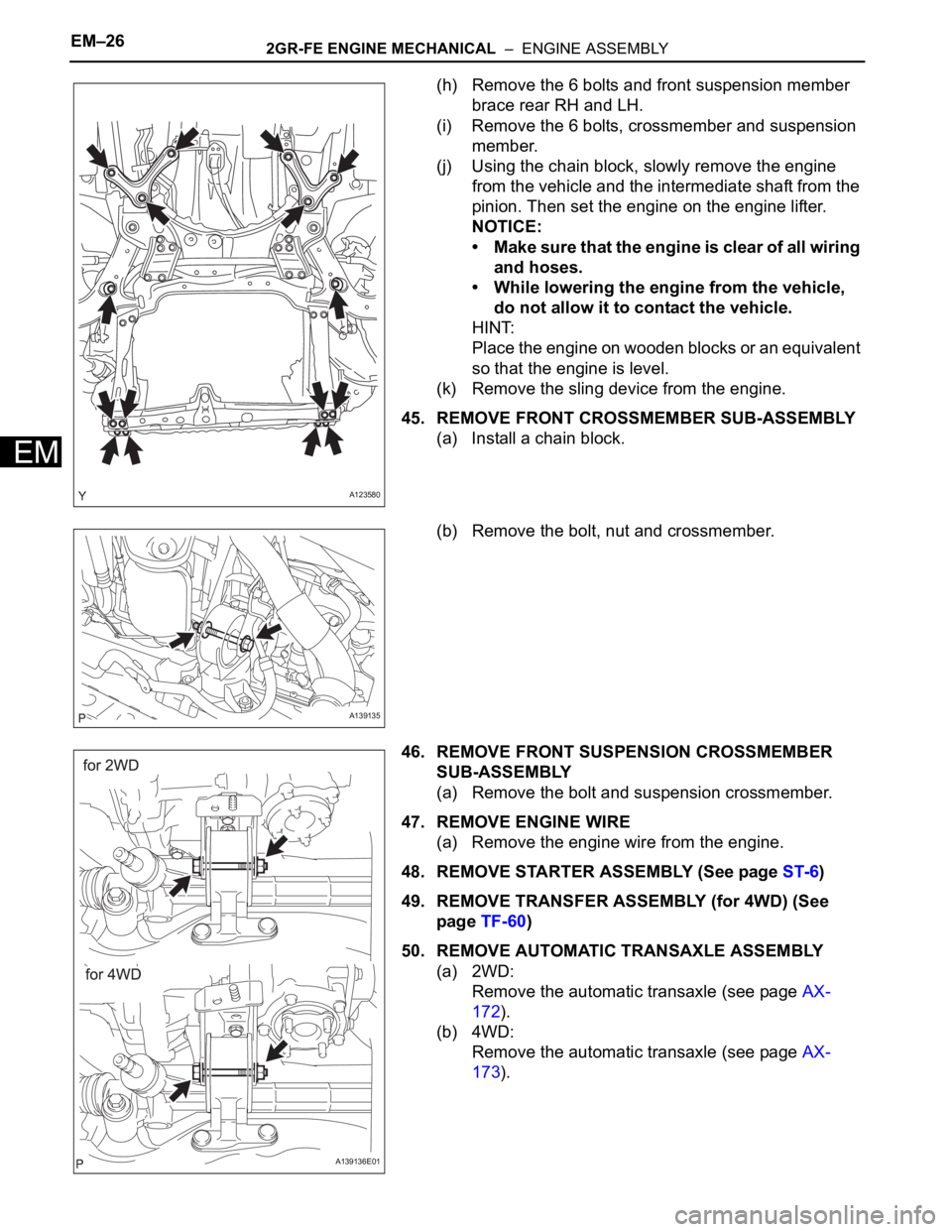

(h) Remove the 6 bolts and front suspension member

brace rear RH and LH.

(i) Remove the 6 bolts, crossmember and suspension

member.

(j) Using the chain block, slowly remove the engine

from the vehicle and the intermediate shaft from the

pinion. Then set the engine on the engine lifter.

NOTICE:

• Make sure that the engine is clear of all wiring

and hoses.

• While lowering the engine from the vehicle,

do not allow it to contact the vehicle.

HINT:

Place the engine on wooden blocks or an equivalent

so that the engine is level.

(k) Remove the sling device from the engine.

45. REMOVE FRONT CROSSMEMBER SUB-ASSEMBLY

(a) Install a chain block.

(b) Remove the bolt, nut and crossmember.

46. REMOVE FRONT SUSPENSION CROSSMEMBER

SUB-ASSEMBLY

(a) Remove the bolt and suspension crossmember.

47. REMOVE ENGINE WIRE

(a) Remove the engine wire from the engine.

48. REMOVE STARTER ASSEMBLY (See page ST-6)

49. REMOVE TRANSFER ASSEMBLY (for 4WD) (See

page TF-60)

50. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

(a) 2WD:

Remove the automatic transaxle (see page AX-

172).

(b) 4WD:

Remove the automatic transaxle (see page AX-

173).

A123580

A139135

A139136E01

Page 202 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–27

EM

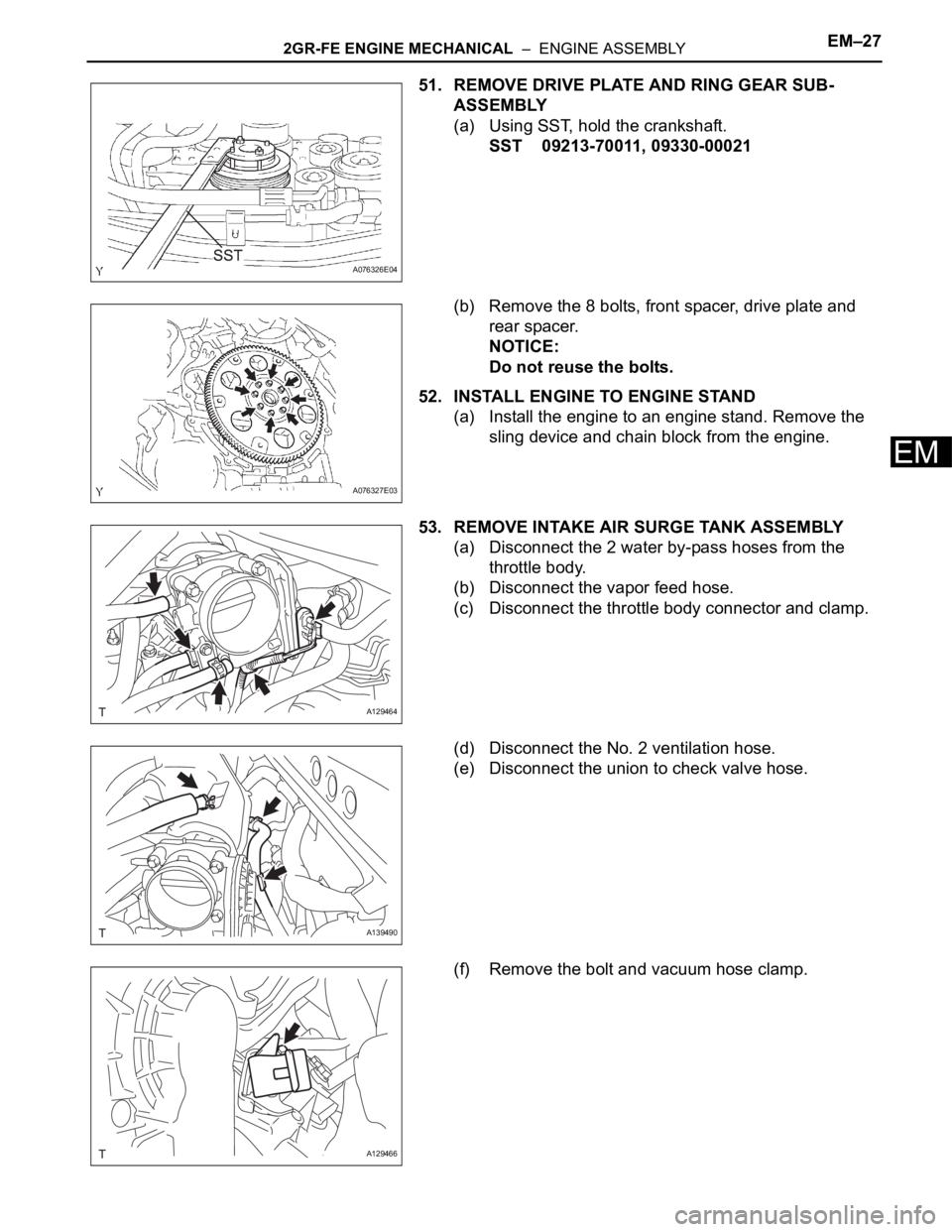

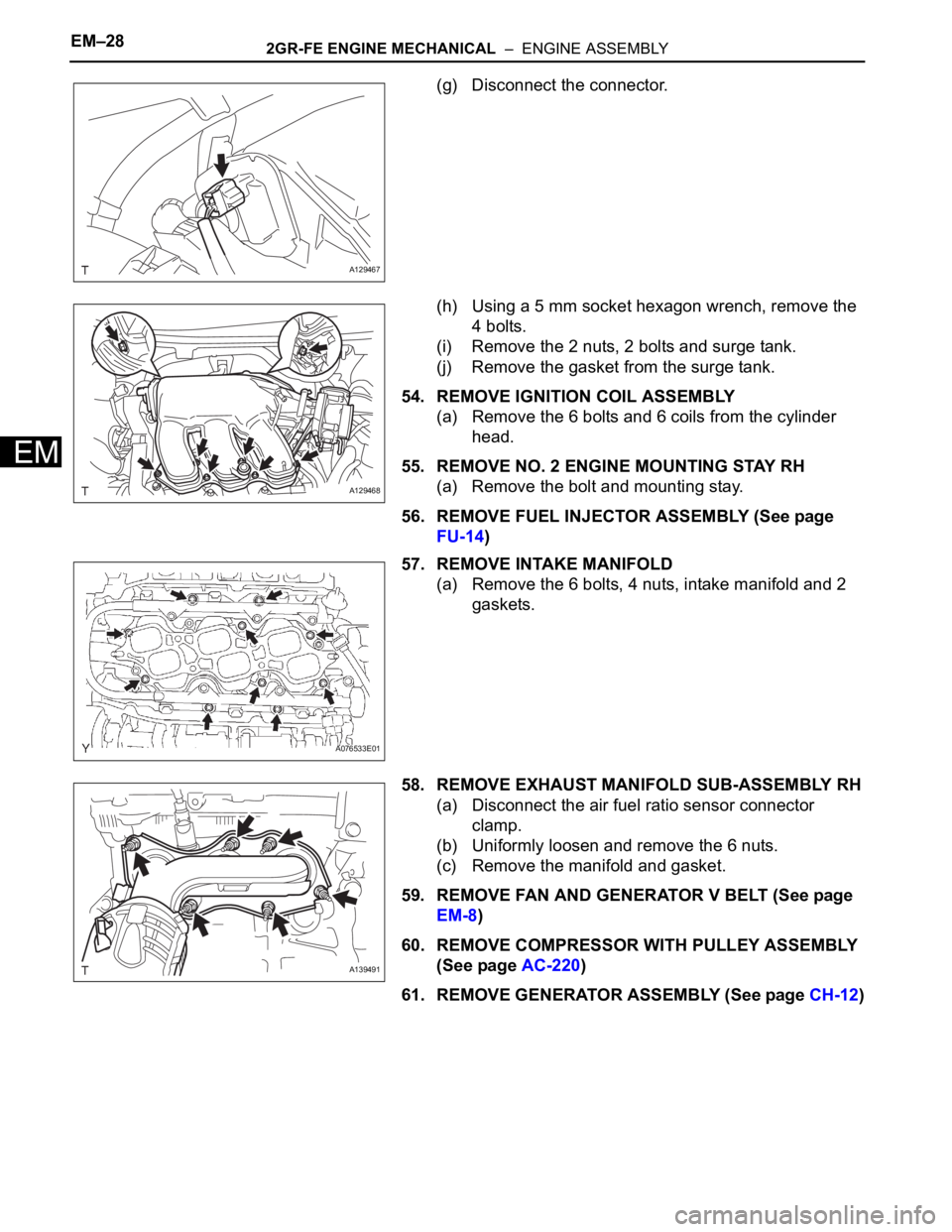

51. REMOVE DRIVE PLATE AND RING GEAR SUB-

ASSEMBLY

(a) Using SST, hold the crankshaft.

SST 09213-70011, 09330-00021

(b) Remove the 8 bolts, front spacer, drive plate and

rear spacer.

NOTICE:

Do not reuse the bolts.

52. INSTALL ENGINE TO ENGINE STAND

(a) Install the engine to an engine stand. Remove the

sling device and chain block from the engine.

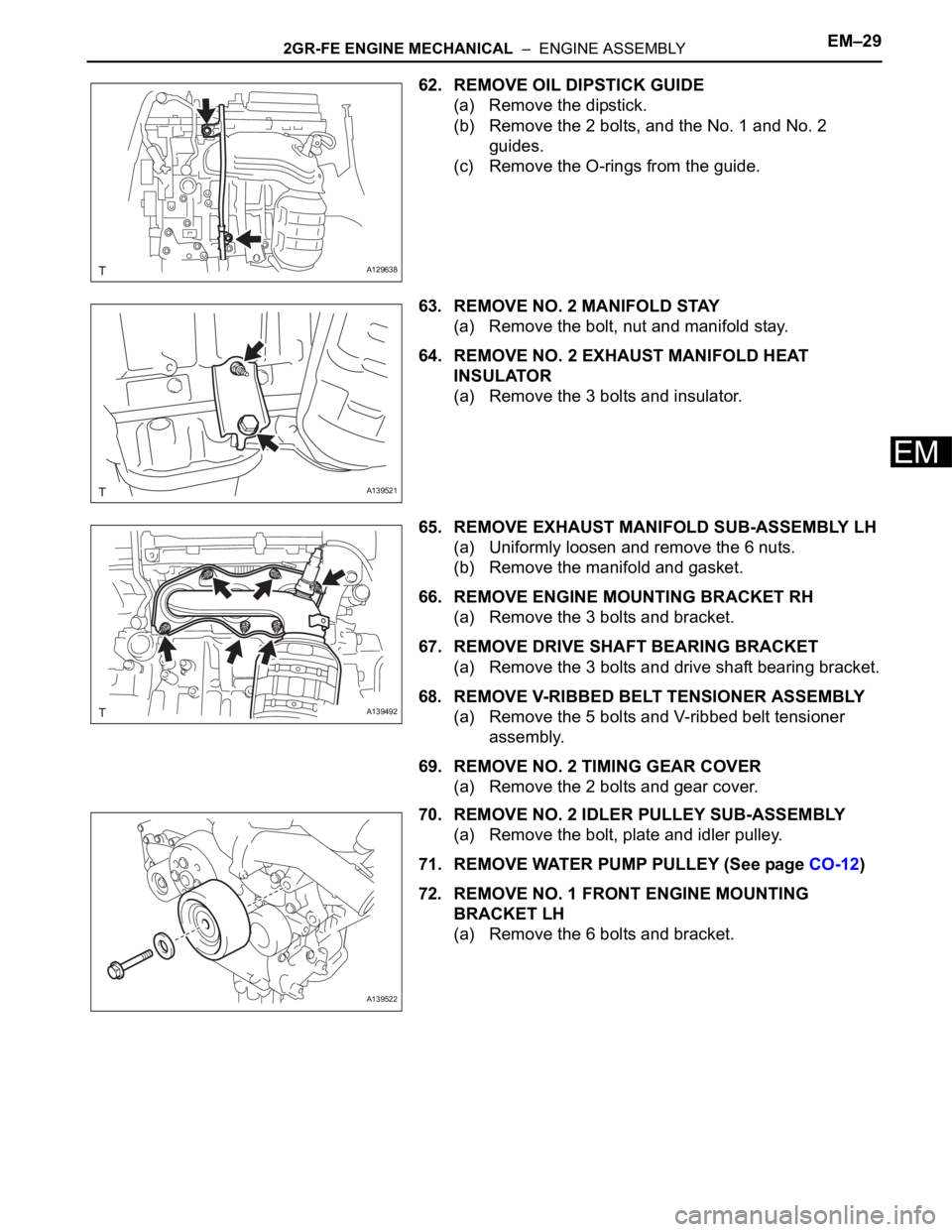

53. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(a) Disconnect the 2 water by-pass hoses from the

throttle body.

(b) Disconnect the vapor feed hose.

(c) Disconnect the throttle body connector and clamp.

(d) Disconnect the No. 2 ventilation hose.

(e) Disconnect the union to check valve hose.

(f) Remove the bolt and vacuum hose clamp.

A076326E04

A076327E03

A129464

A139490

A129466

Page 203 of 2000

EM–282GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(g) Disconnect the connector.

(h) Using a 5 mm socket hexagon wrench, remove the

4 bolts.

(i) Remove the 2 nuts, 2 bolts and surge tank.

(j) Remove the gasket from the surge tank.

54. REMOVE IGNITION COIL ASSEMBLY

(a) Remove the 6 bolts and 6 coils from the cylinder

head.

55. REMOVE NO. 2 ENGINE MOUNTING STAY RH

(a) Remove the bolt and mounting stay.

56. REMOVE FUEL INJECTOR ASSEMBLY (See page

FU-14)

57. REMOVE INTAKE MANIFOLD

(a) Remove the 6 bolts, 4 nuts, intake manifold and 2

gaskets.

58. REMOVE EXHAUST MANIFOLD SUB-ASSEMBLY RH

(a) Disconnect the air fuel ratio sensor connector

clamp.

(b) Uniformly loosen and remove the 6 nuts.

(c) Remove the manifold and gasket.

59. REMOVE FAN AND GENERATOR V BELT (See page

EM-8)

60. REMOVE COMPRESSOR WITH PULLEY ASSEMBLY

(See page AC-220)

61. REMOVE GENERATOR ASSEMBLY (See page CH-12)

A129467

A129468

A076533E01

A139491

Page 204 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–29

EM

62. REMOVE OIL DIPSTICK GUIDE

(a) Remove the dipstick.

(b) Remove the 2 bolts, and the No. 1 and No. 2

guides.

(c) Remove the O-rings from the guide.

63. REMOVE NO. 2 MANIFOLD STAY

(a) Remove the bolt, nut and manifold stay.

64. REMOVE NO. 2 EXHAUST MANIFOLD HEAT

INSULATOR

(a) Remove the 3 bolts and insulator.

65. REMOVE EXHAUST MANIFOLD SUB-ASSEMBLY LH

(a) Uniformly loosen and remove the 6 nuts.

(b) Remove the manifold and gasket.

66. REMOVE ENGINE MOUNTING BRACKET RH

(a) Remove the 3 bolts and bracket.

67. REMOVE DRIVE SHAFT BEARING BRACKET

(a) Remove the 3 bolts and drive shaft bearing bracket.

68. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(a) Remove the 5 bolts and V-ribbed belt tensioner

assembly.

69. REMOVE NO. 2 TIMING GEAR COVER

(a) Remove the 2 bolts and gear cover.

70. REMOVE NO. 2 IDLER PULLEY SUB-ASSEMBLY

(a) Remove the bolt, plate and idler pulley.

71. REMOVE WATER PUMP PULLEY (See page CO-12)

72. REMOVE NO. 1 FRONT ENGINE MOUNTING

BRACKET LH

(a) Remove the 6 bolts and bracket.

A129638

A139521

A139492

A139522

Page 205 of 2000

EM–302GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

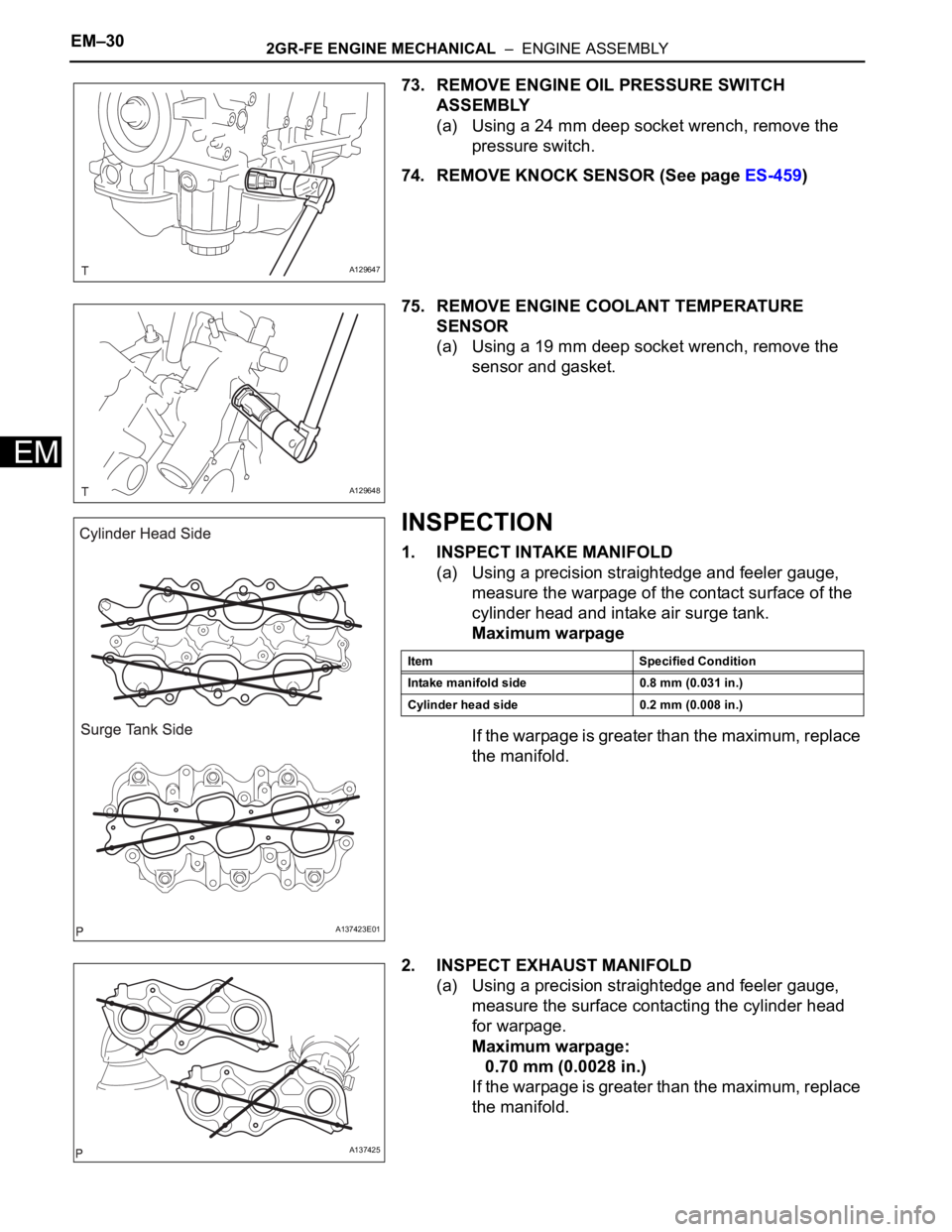

73. REMOVE ENGINE OIL PRESSURE SWITCH

ASSEMBLY

(a) Using a 24 mm deep socket wrench, remove the

pressure switch.

74. REMOVE KNOCK SENSOR (See page ES-459)

75. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using a 19 mm deep socket wrench, remove the

sensor and gasket.

INSPECTION

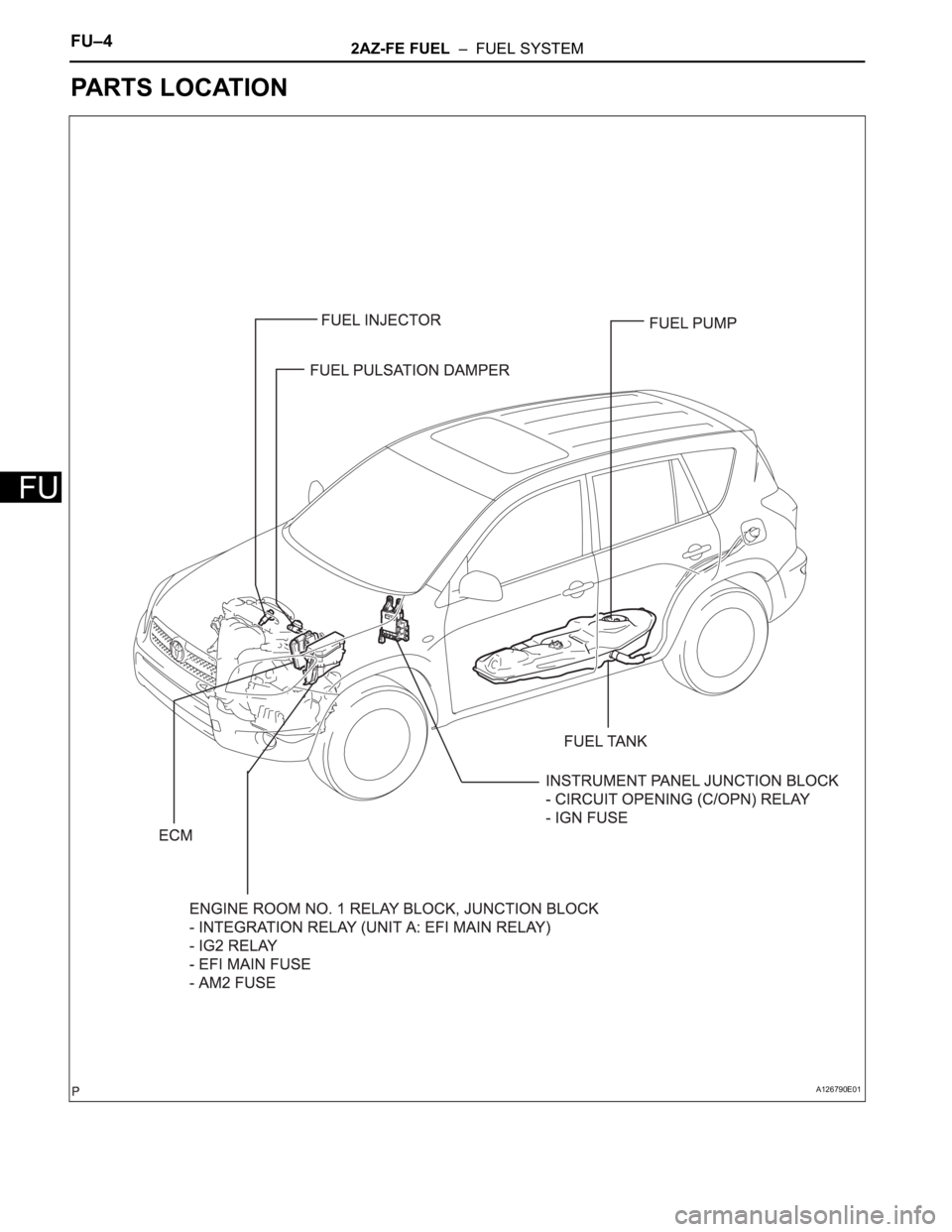

1. INSPECT INTAKE MANIFOLD

(a) Using a precision straightedge and feeler gauge,

measure the warpage of the contact surface of the

cylinder head and intake air surge tank.

Maximum warpage

If the warpage is greater than the maximum, replace

the manifold.

2. INSPECT EXHAUST MANIFOLD

(a) Using a precision straightedge and feeler gauge,

measure the surface contacting the cylinder head

for warpage.

Maximum warpage:

0.70 mm (0.0028 in.)

If the warpage is greater than the maximum, replace

the manifold.

A129647

A129648

A137423E01

Item Specified Condition

Intake manifold side 0.8 mm (0.031 in.)

Cylinder head side 0.2 mm (0.008 in.)

A137425

Page 206 of 2000

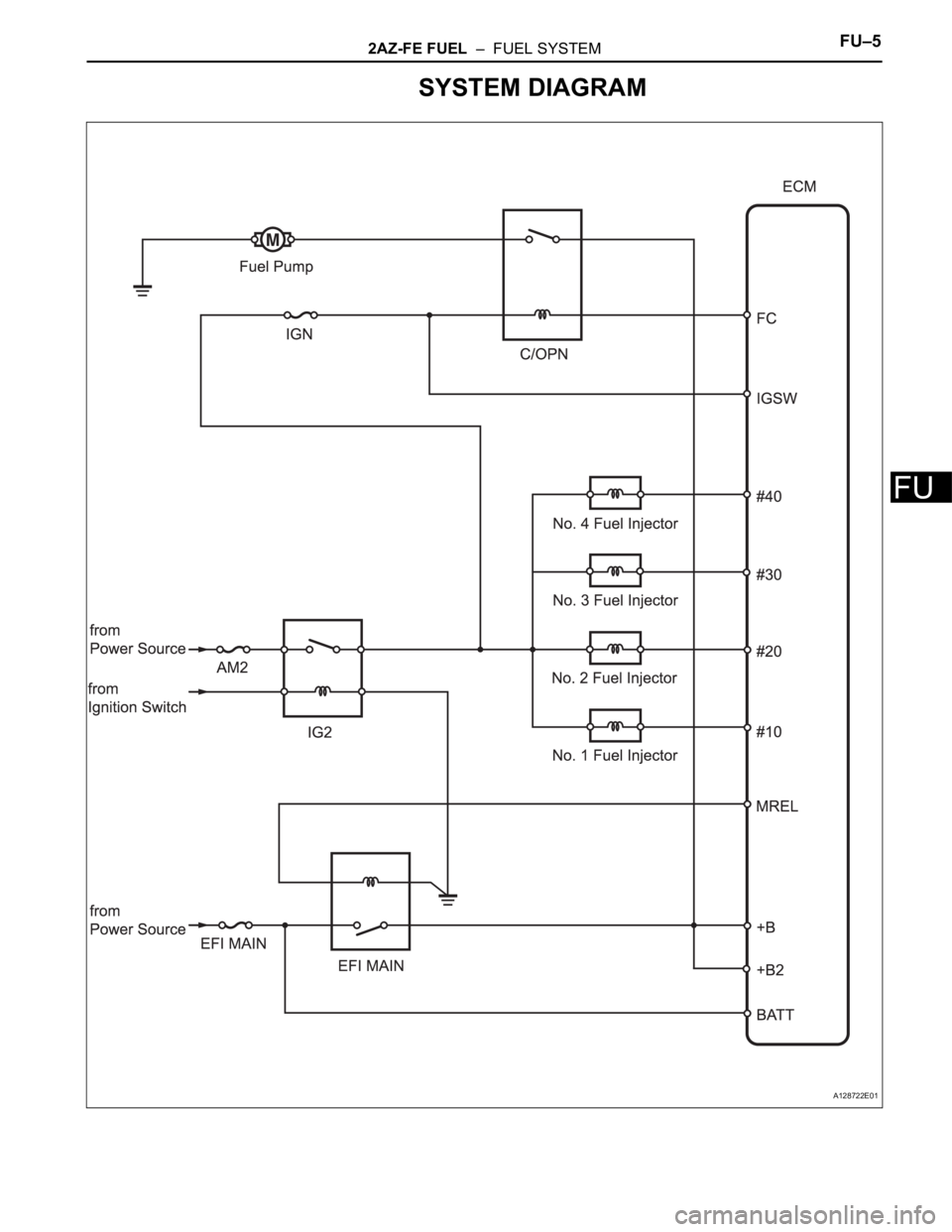

FU–42AZ-FE FUEL – FUEL SYSTEM

FU

PARTS LOCATION

A126790E01

Page 207 of 2000

2AZ-FE FUEL – FUEL SYSTEMFU–5

FU

SYSTEM DIAGRAM

A128722E01

Page 208 of 2000

FU–62AZ-FE FUEL – FUEL SYSTEM

FU

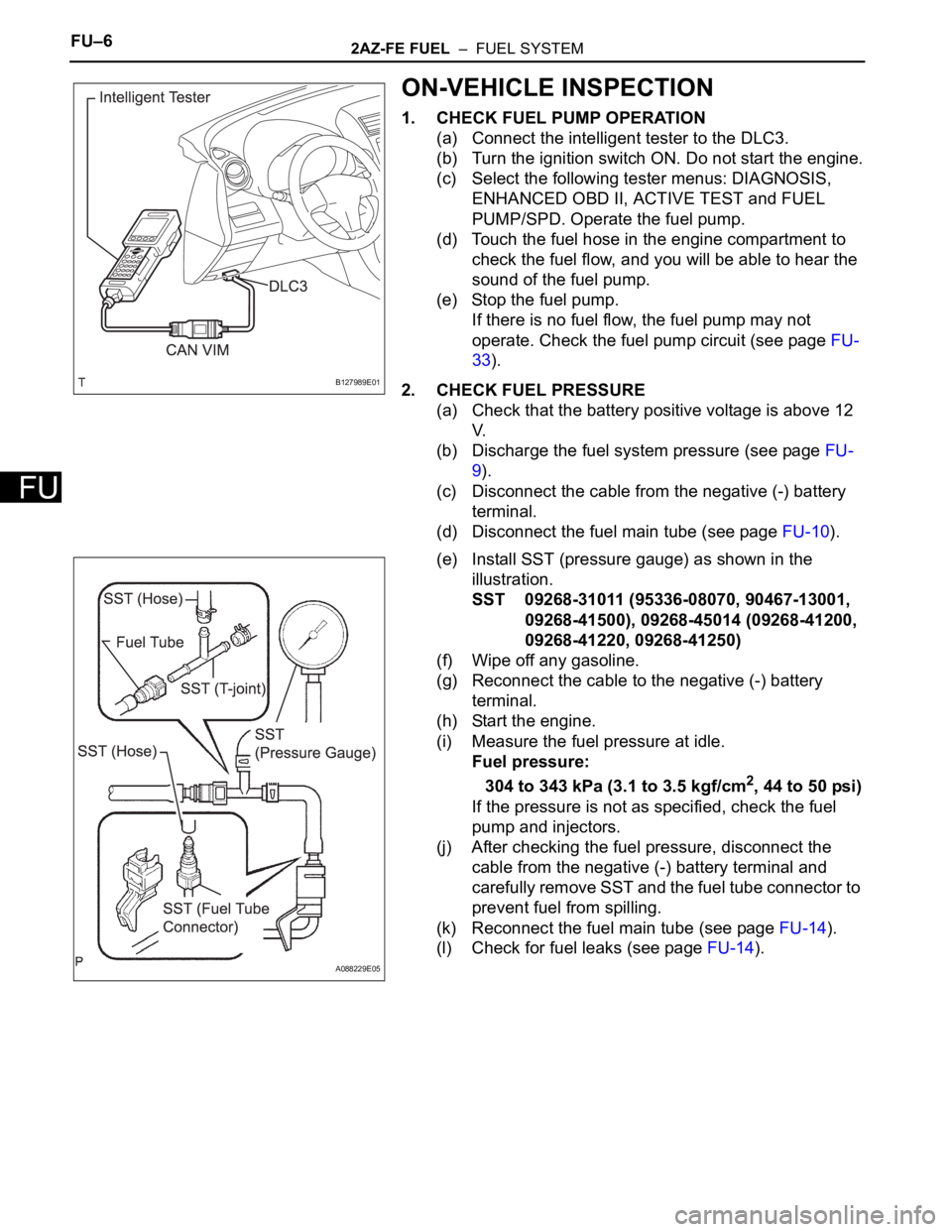

ON-VEHICLE INSPECTION

1. CHECK FUEL PUMP OPERATION

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch ON. Do not start the engine.

(c) Select the following tester menus: DIAGNOSIS,

ENHANCED OBD II, ACTIVE TEST and FUEL

PUMP/SPD. Operate the fuel pump.

(d) Touch the fuel hose in the engine compartment to

check the fuel flow, and you will be able to hear the

sound of the fuel pump.

(e) Stop the fuel pump.

If there is no fuel flow, the fuel pump may not

operate. Check the fuel pump circuit (see page FU-

33).

2. CHECK FUEL PRESSURE

(a) Check that the battery positive voltage is above 12

V.

(b) Discharge the fuel system pressure (see page FU-

9).

(c) Disconnect the cable from the negative (-) battery

terminal.

(d) Disconnect the fuel main tube (see page FU-10).

(e) Install SST (pressure gauge) as shown in the

illustration.

SST 09268-31011 (95336-08070, 90467-13001,

09268-41500), 09268-45014 (09268-41200,

09268-41220, 09268-41250)

(f) Wipe off any gasoline.

(g) Reconnect the cable to the negative (-) battery

terminal.

(h) Start the engine.

(i) Measure the fuel pressure at idle.

Fuel pressure:

304 to 343 kPa (3.1 to 3.5 kgf/cm

2, 44 to 50 psi)

If the pressure is not as specified, check the fuel

pump and injectors.

(j) After checking the fuel pressure, disconnect the

cable from the negative (-) battery terminal and

carefully remove SST and the fuel tube connector to

prevent fuel from spilling.

(k) Reconnect the fuel main tube (see page FU-14).

(l) Check for fuel leaks (see page FU-14).

B127989E01

A088229E05

Page 209 of 2000

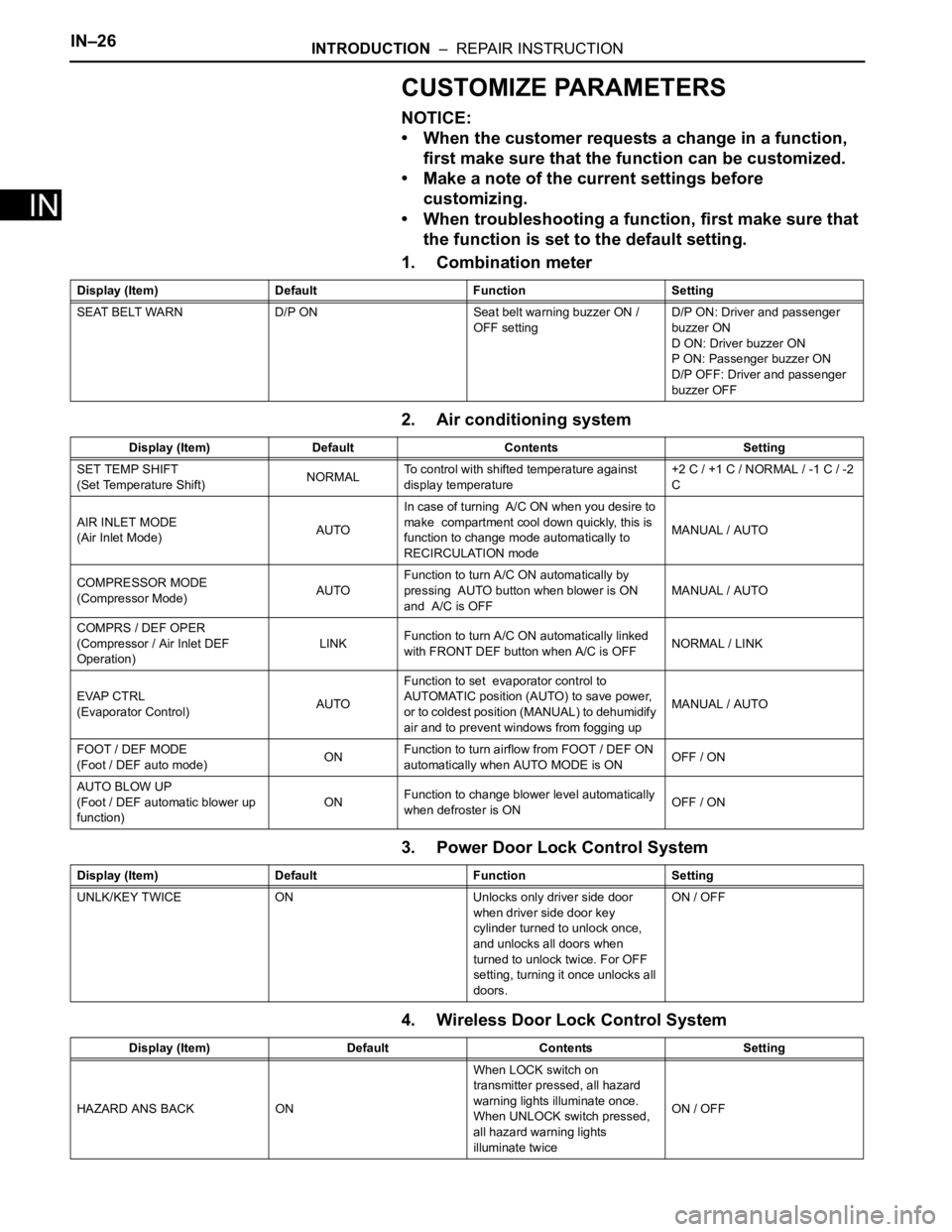

IN–26INTRODUCTION – REPAIR INSTRUCTION

IN

CUSTOMIZE PARAMETERS

NOTICE:

• When the customer requests a change in a function,

first make sure that the function can be customized.

• Make a note of the current settings before

customizing.

• When troubleshooting a function, first make sure that

the function is set to the default setting.

1. Combination meter

2. Air conditioning system

3. Power Door Lock Control System

4. Wireless Door Lock Control System

Display (Item) Default Function Setting

SEAT BELT WARN D/P ON Seat belt warning buzzer ON /

OFF settingD/P ON: Driver and passenger

buzzer ON

D ON: Driver buzzer ON

P ON: Passenger buzzer ON

D/P OFF: Driver and passenger

buzzer OFF

Display (Item) Default Contents Setting

SET TEMP SHIFT

(Set Temperature Shift)NORMALTo control with shifted temperature against

display temperature+2 C / +1 C / NORMAL / -1 C / -2

C

AIR INLET MODE

(Air Inlet Mode)AUTOIn case of turning A/C ON when you desire to

make compartment cool down quickly, this is

function to change mode automatically to

RECIRCULATION modeMANUAL / AUTO

COMPRESSOR MODE

(Compressor Mode)AUTOFunction to turn A/C ON automatically by

pressing AUTO button when blower is ON

and A/C is OFFMANUAL / AUTO

COMPRS / DEF OPER

(Compressor / Air Inlet DEF

Operation)LINKFunction to turn A/C ON automatically linked

with FRONT DEF button when A/C is OFFNORMAL / LINK

EVAP CTRL

(Evaporator Control)AUTOFunction to set evaporator control to

AUTOMATIC position (AUTO) to save power,

or to coldest position (MANUAL) to dehumidify

air and to prevent windows from fogging upMANUAL / AUTO

FOOT / DEF MODE

(Foot / DEF auto mode)ONFunction to turn airflow from FOOT / DEF ON

automatically when AUTO MODE is ONOFF / ON

AUTO BLOW UP

(Foot / DEF automatic blower up

function)ONFunction to change blower level automatically

when defroster is ONOFF / ON

Display (Item) Default Function Setting

UNLK/KEY TWICE ON Unlocks only driver side door

when driver side door key

cylinder turned to unlock once,

and unlocks all doors when

turned to unlock twice. For OFF

setting, turning it once unlocks all

doors.ON / OFF

Display (Item) Default Contents Setting

HAZARD ANS BACK ONWhen LOCK switch on

transmitter pressed, all hazard

warning lights illuminate once.

When UNLOCK switch pressed,

all hazard warning lights

illuminate twiceON / OFF

Page 210 of 2000

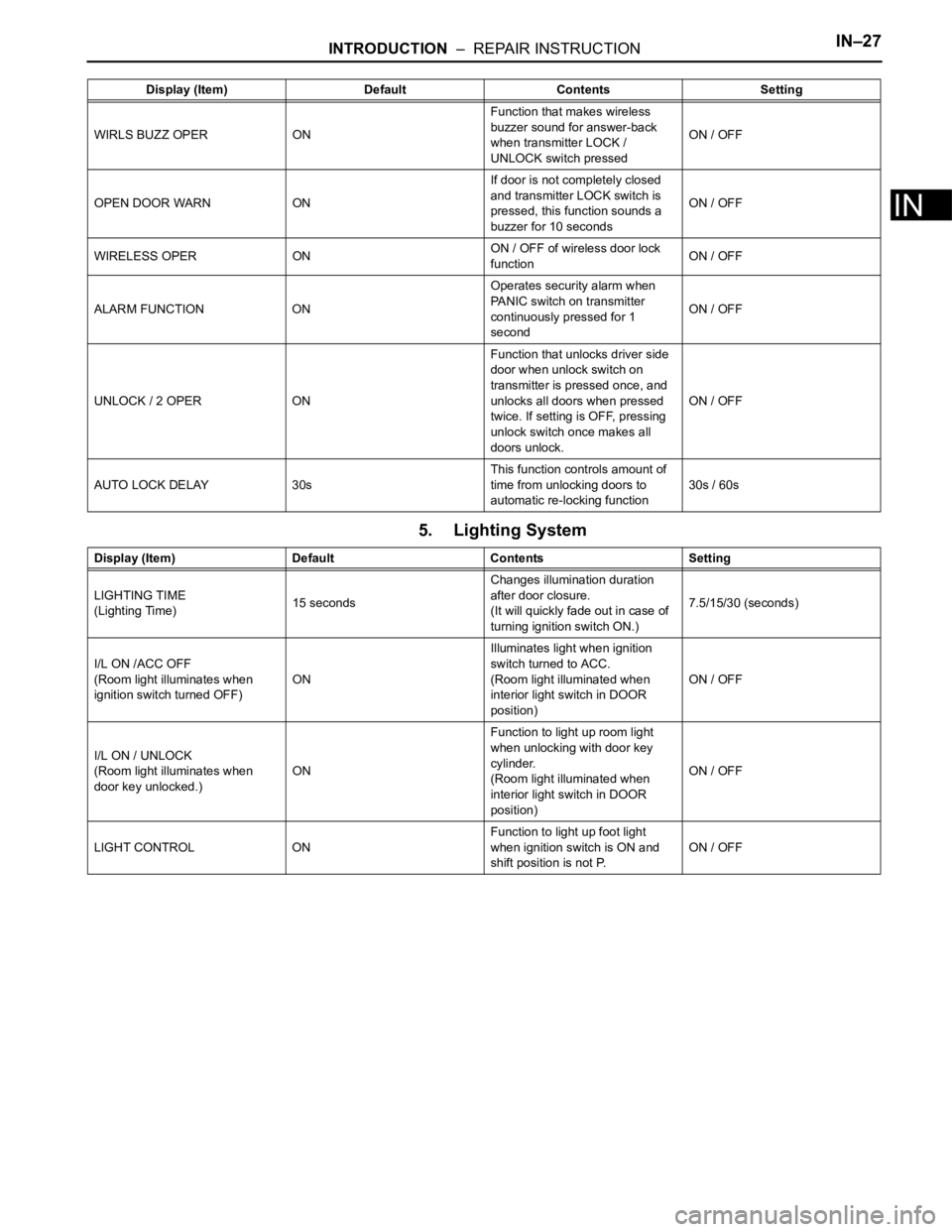

INTRODUCTION – REPAIR INSTRUCTIONIN–27

IN

5. Lighting System

WIRLS BUZZ OPER ONFunction that makes wireless

buzzer sound for answer-back

when transmitter LOCK /

UNLOCK switch pressedON / OFF

OPEN DOOR WARN ONIf door is not completely closed

and transmitter LOCK switch is

pressed, this function sounds a

buzzer for 10 secondsON / OFF

WIRELESS OPER ONON / OFF of wireless door lock

functionON / OFF

ALARM FUNCTION ONOperates security alarm when

PANIC switch on transmitter

continuously pressed for 1

secondON / OFF

UNLOCK / 2 OPER ONFunction that unlocks driver side

door when unlock switch on

transmitter is pressed once, and

unlocks all doors when pressed

twice. If setting is OFF, pressing

unlock switch once makes all

doors unlock.ON / OFF

AUTO LOCK DELAY 30sThis function controls amount of

time from unlocking doors to

automatic re-locking function30s / 60s Display (Item) Default Contents Setting

Display (Item) Default Contents Setting

LIGHTING TIME

(Lighting Time)15 secondsChanges illumination duration

after door closure.

(It will quickly fade out in case of

turning ignition switch ON.)7.5/15/30 (seconds)

I/L ON /ACC OFF

(Room light illuminates when

ignition switch turned OFF)ONIlluminates light when ignition

switch turned to ACC.

(Room light illuminated when

interior light switch in DOOR

position)ON / OFF

I/L ON / UNLOCK

(Room light illuminates when

door key unlocked.)ONFunction to light up room light

when unlocking with door key

cylinder.

(Room light illuminated when

interior light switch in DOOR

position)ON / OFF

LIGHT CONTROL ONFunction to light up foot light

when ignition switch is ON and

shift position is not P.ON / OFF