TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006,

Model line: RAV4,

Model: TOYOTA RAV4 2006

Pages: 2000, PDF Size: 45.84 MB

TOYOTA RAV4 2006 Service Repair Manual

RAV4 2006

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57463/w960_57463-0.png

TOYOTA RAV4 2006 Service Repair Manual

Trending: mirror, open hood, oil capacity, maintenance, ignition coil, spare wheel, ignition

Page 181 of 2000

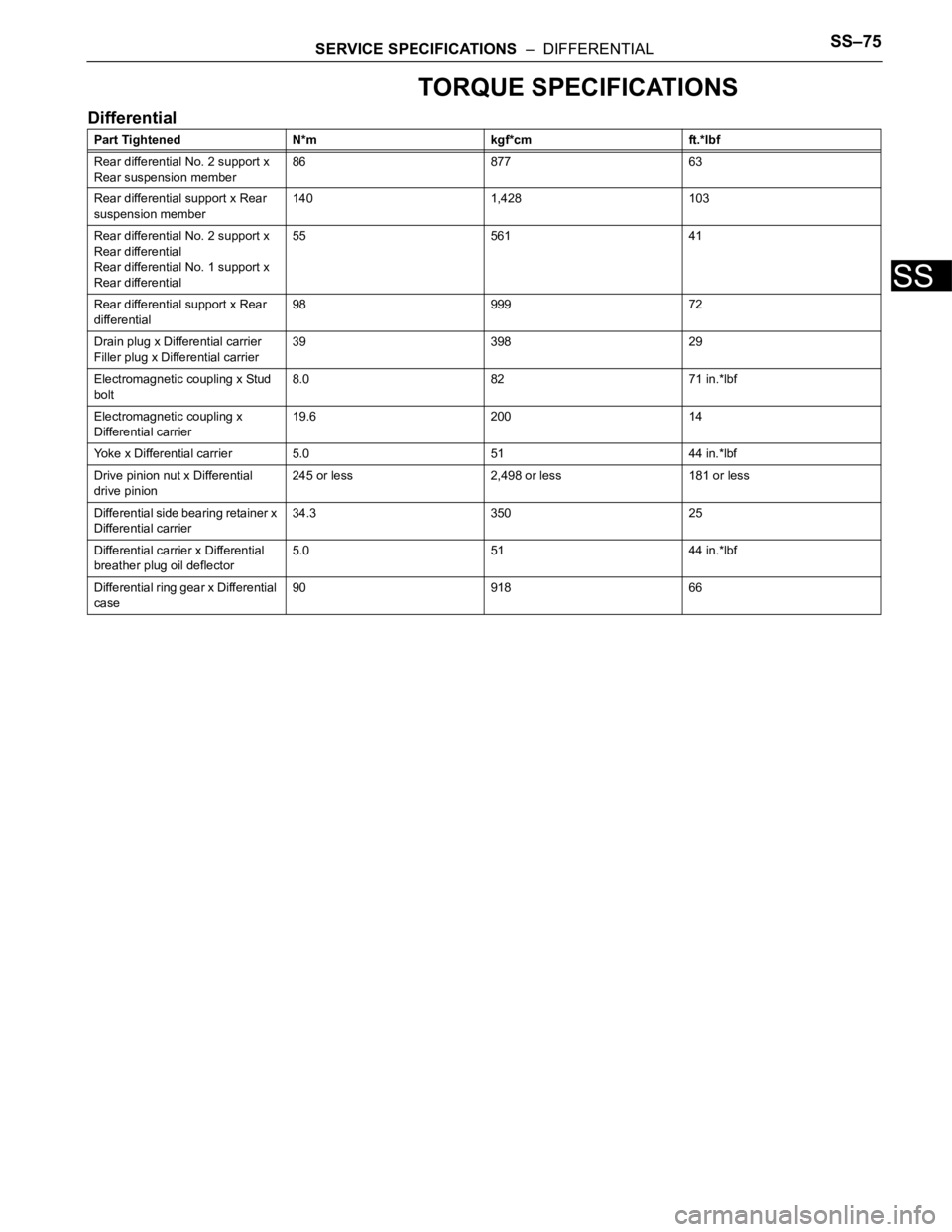

SERVICE SPECIFICATIONS – DIFFERENTIALSS–75

SS

TORQUE SPECIFICATIONS

Differential

Part Tightened N*m kgf*cm ft.*lbf

Rear differential No. 2 support x

Rear suspension member86 877 63

Rear differential support x Rear

suspension member140 1,428 103

Rear differential No. 2 support x

Rear differential

Rear differential No. 1 support x

Rear differential55 561 41

Rear differential support x Rear

differential98 999 72

Drain plug x Differential carrier

Filler plug x Differential carrier39 398 29

Electromagnetic coupling x Stud

bolt8.0 82 71 in.*lbf

Electromagnetic coupling x

Differential carrier19.6 200 14

Yoke x Differential carrier 5.0 51 44 in.*lbf

Drive pinion nut x Differential

drive pinion245 or less 2,498 or less 181 or less

Differential side bearing retainer x

Differential carrier34.3 350 25

Differential carrier x Differential

breather plug oil deflector5.0 51 44 in.*lbf

Differential ring gear x Differential

case90 918 66

Page 182 of 2000

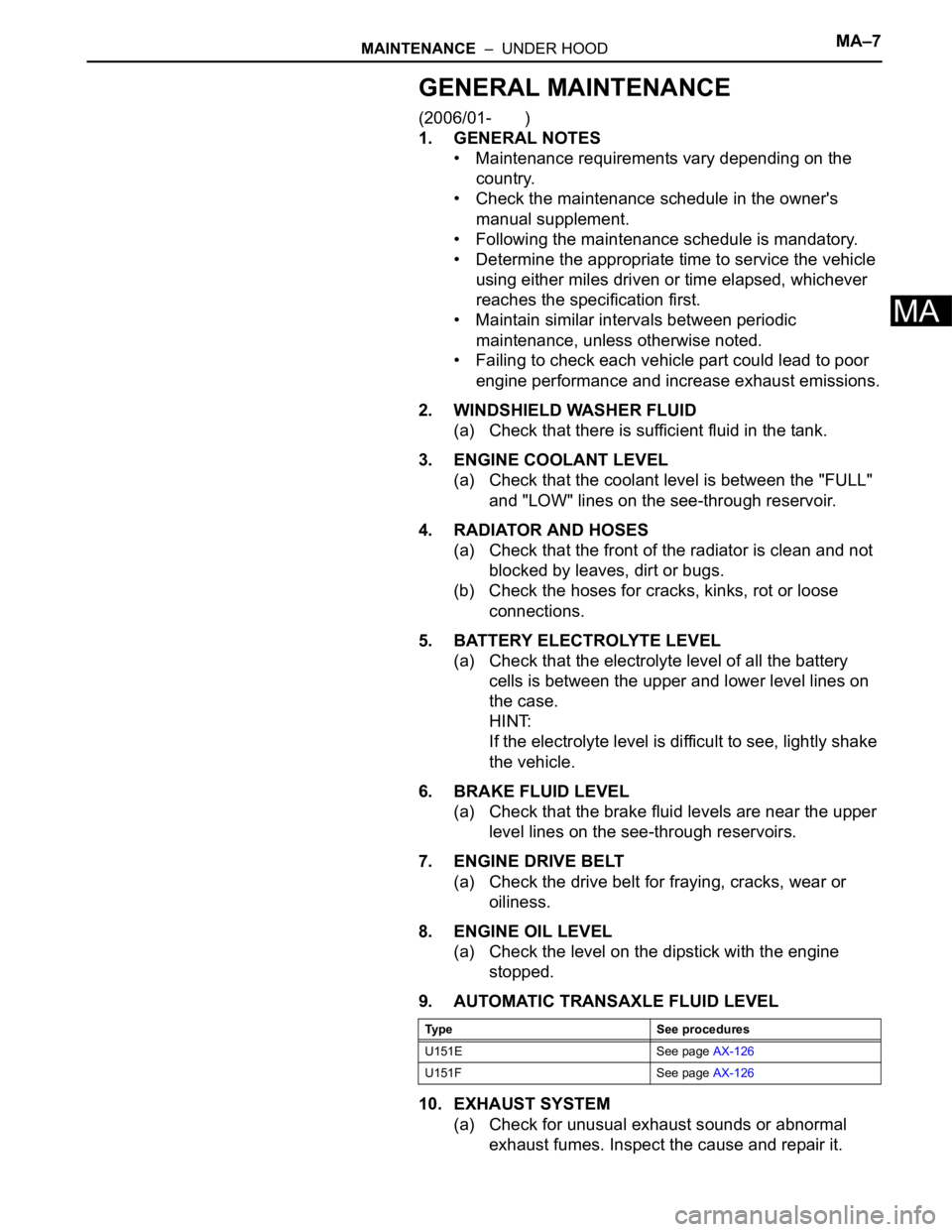

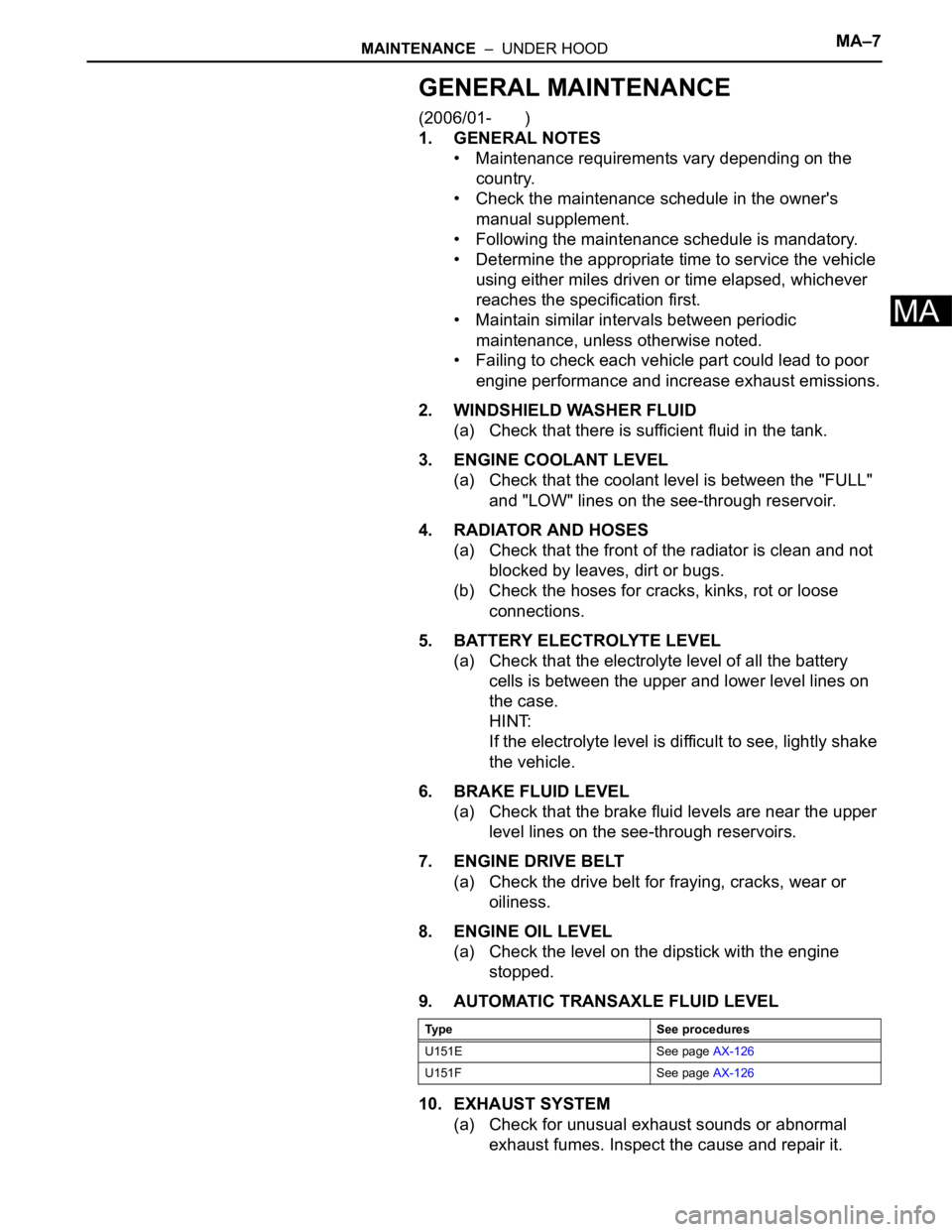

MAINTENANCE – UNDER HOODMA–7

MA

GENERAL MAINTENANCE

(2006/01- )

1. GENERAL NOTES

• Maintenance requirements vary depending on the

country.

• Check the maintenance schedule in the owner's

manual supplement.

• Following the maintenance schedule is mandatory.

• Determine the appropriate time to service the vehicle

using either miles driven or time elapsed, whichever

reaches the specification first.

• Maintain similar intervals between periodic

maintenance, unless otherwise noted.

• Failing to check each vehicle part could lead to poor

engine performance and increase exhaust emissions.

2. WINDSHIELD WASHER FLUID

(a) Check that there is sufficient fluid in the tank.

3. ENGINE COOLANT LEVEL

(a) Check that the coolant level is between the "FULL"

and "LOW" lines on the see-through reservoir.

4. RADIATOR AND HOSES

(a) Check that the front of the radiator is clean and not

blocked by leaves, dirt or bugs.

(b) Check the hoses for cracks, kinks, rot or loose

connections.

5. BATTERY ELECTROLYTE LEVEL

(a) Check that the electrolyte level of all the battery

cells is between the upper and lower level lines on

the case.

HINT:

If the electrolyte level is difficult to see, lightly shake

the vehicle.

6. BRAKE FLUID LEVEL

(a) Check that the brake fluid levels are near the upper

level lines on the see-through reservoirs.

7. ENGINE DRIVE BELT

(a) Check the drive belt for fraying, cracks, wear or

oiliness.

8. ENGINE OIL LEVEL

(a) Check the level on the dipstick with the engine

stopped.

9. AUTOMATIC TRANSAXLE FLUID LEVEL

10. EXHAUST SYSTEM

(a) Check for unusual exhaust sounds or abnormal

exhaust fumes. Inspect the cause and repair it.

Type See procedures

U151E See page AX-126

U151F See page AX-126

Page 183 of 2000

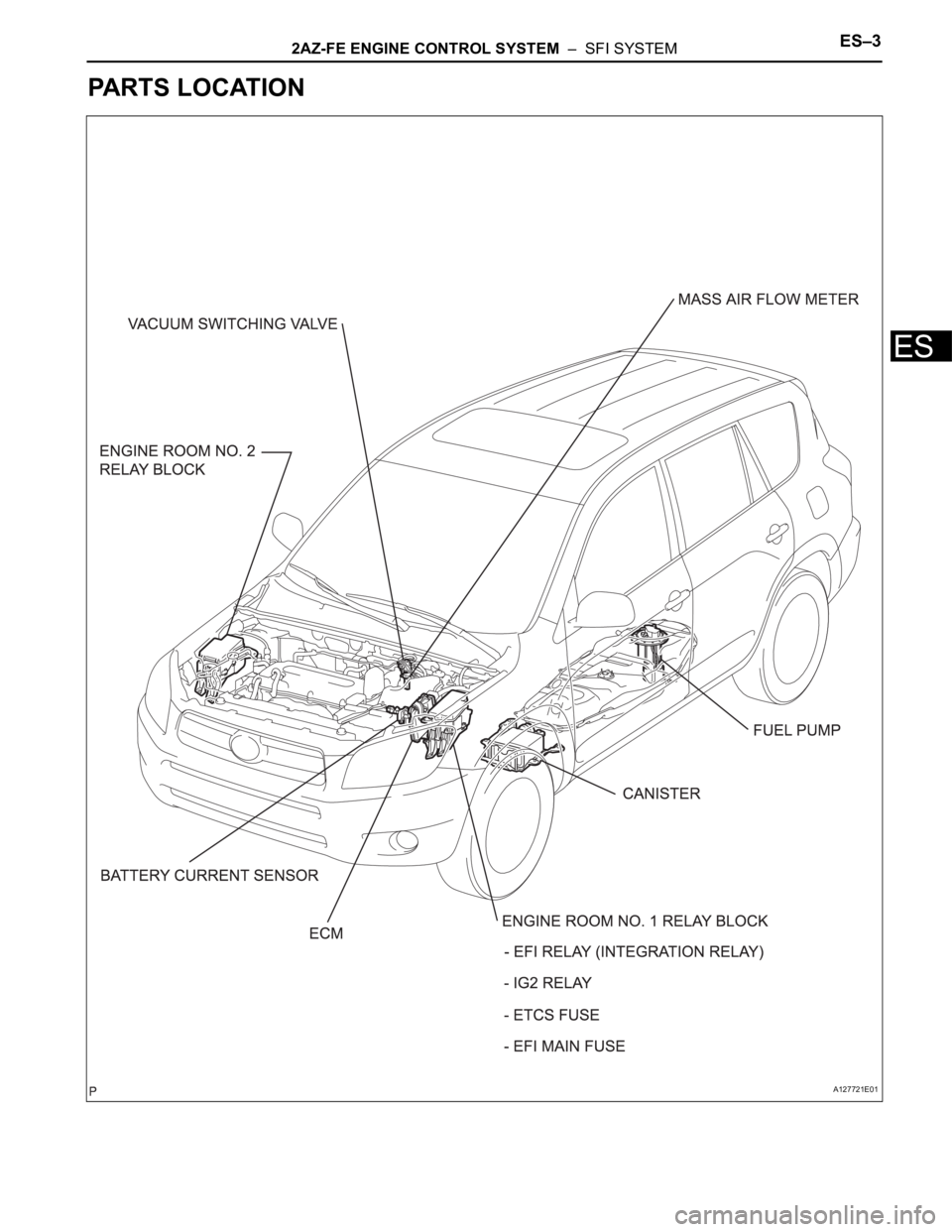

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–3

ES

PARTS LOCATION

A127721E01

Page 184 of 2000

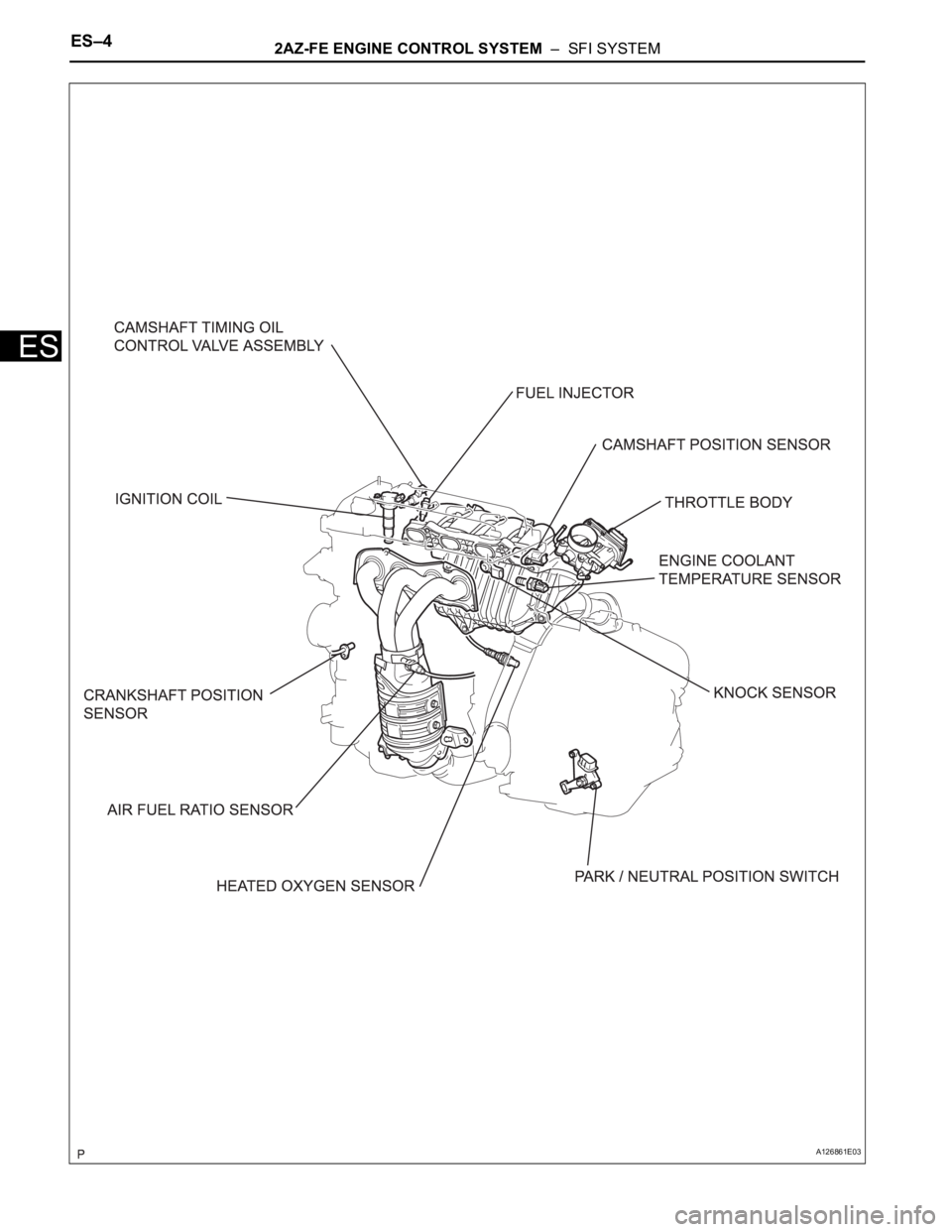

ES–42AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

A126861E03

Page 185 of 2000

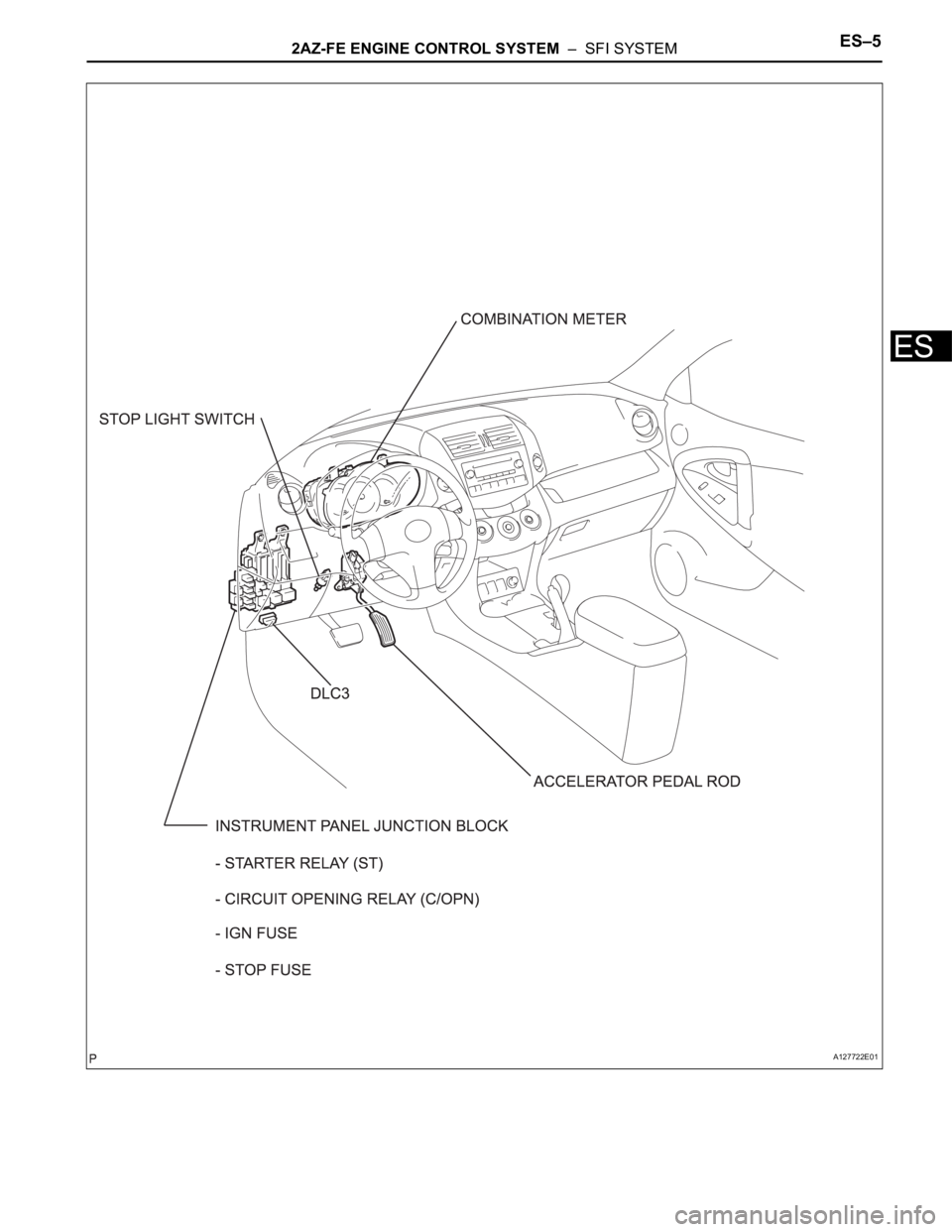

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–5

ES

A127722E01

Page 186 of 2000

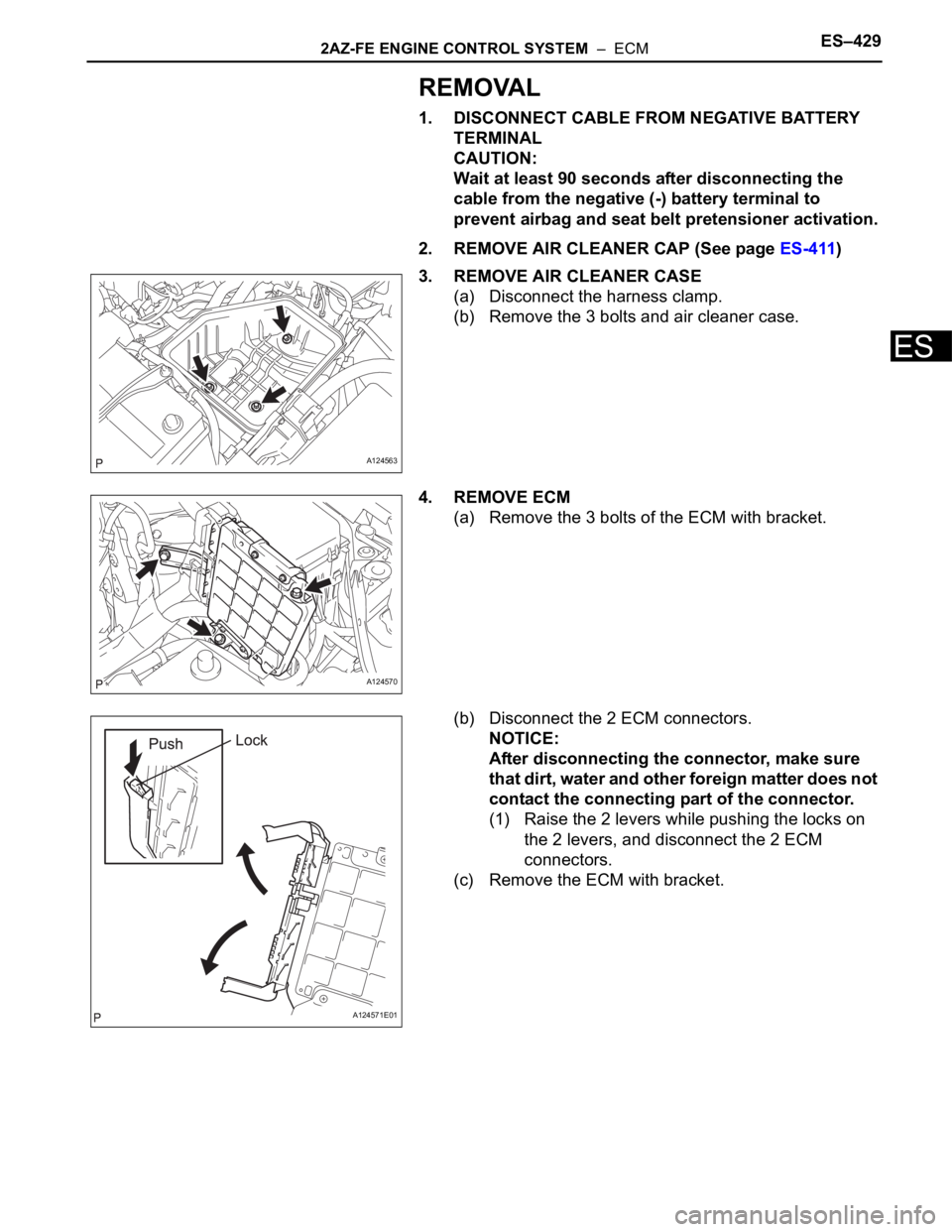

2AZ-FE ENGINE CONTROL SYSTEM – ECMES–429

ES

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

2. REMOVE AIR CLEANER CAP (See page ES-411)

3. REMOVE AIR CLEANER CASE

(a) Disconnect the harness clamp.

(b) Remove the 3 bolts and air cleaner case.

4. REMOVE ECM

(a) Remove the 3 bolts of the ECM with bracket.

(b) Disconnect the 2 ECM connectors.

NOTICE:

After disconnecting the connector, make sure

that dirt, water and other foreign matter does not

contact the connecting part of the connector.

(1) Raise the 2 levers while pushing the locks on

the 2 levers, and disconnect the 2 ECM

connectors.

(c) Remove the ECM with bracket.

A124563

A124570

A124571E01

Page 187 of 2000

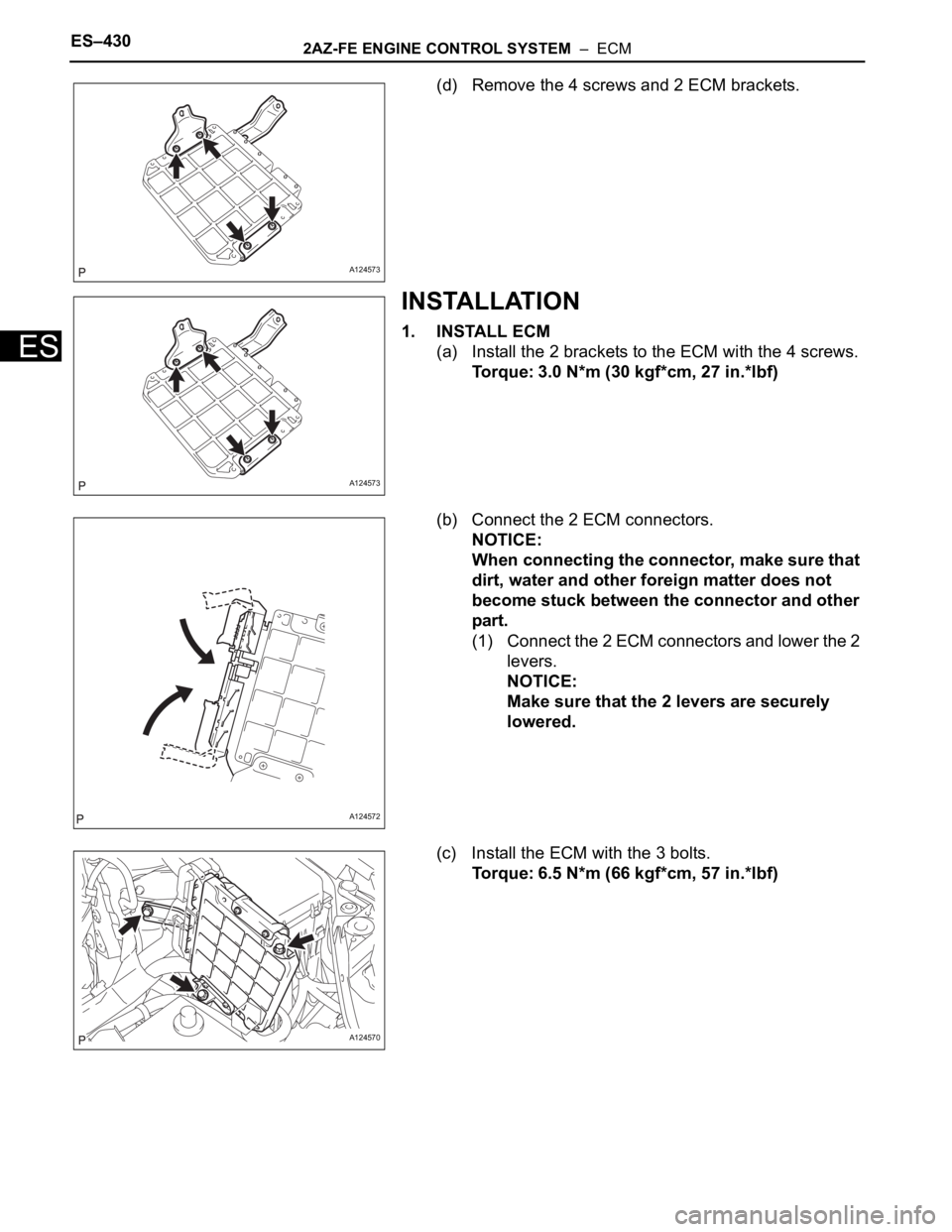

ES–4302AZ-FE ENGINE CONTROL SYSTEM – ECM

ES

(d) Remove the 4 screws and 2 ECM brackets.

INSTALLATION

1. INSTALL ECM

(a) Install the 2 brackets to the ECM with the 4 screws.

Torque: 3.0 N*m (30 kgf*cm, 27 in.*lbf)

(b) Connect the 2 ECM connectors.

NOTICE:

When connecting the connector, make sure that

dirt, water and other foreign matter does not

become stuck between the connector and other

part.

(1) Connect the 2 ECM connectors and lower the 2

levers.

NOTICE:

Make sure that the 2 levers are securely

lowered.

(c) Install the ECM with the 3 bolts.

Torque: 6.5 N*m (66 kgf*cm, 57 in.*lbf)

A124573

A124573

A124572

A124570

Page 188 of 2000

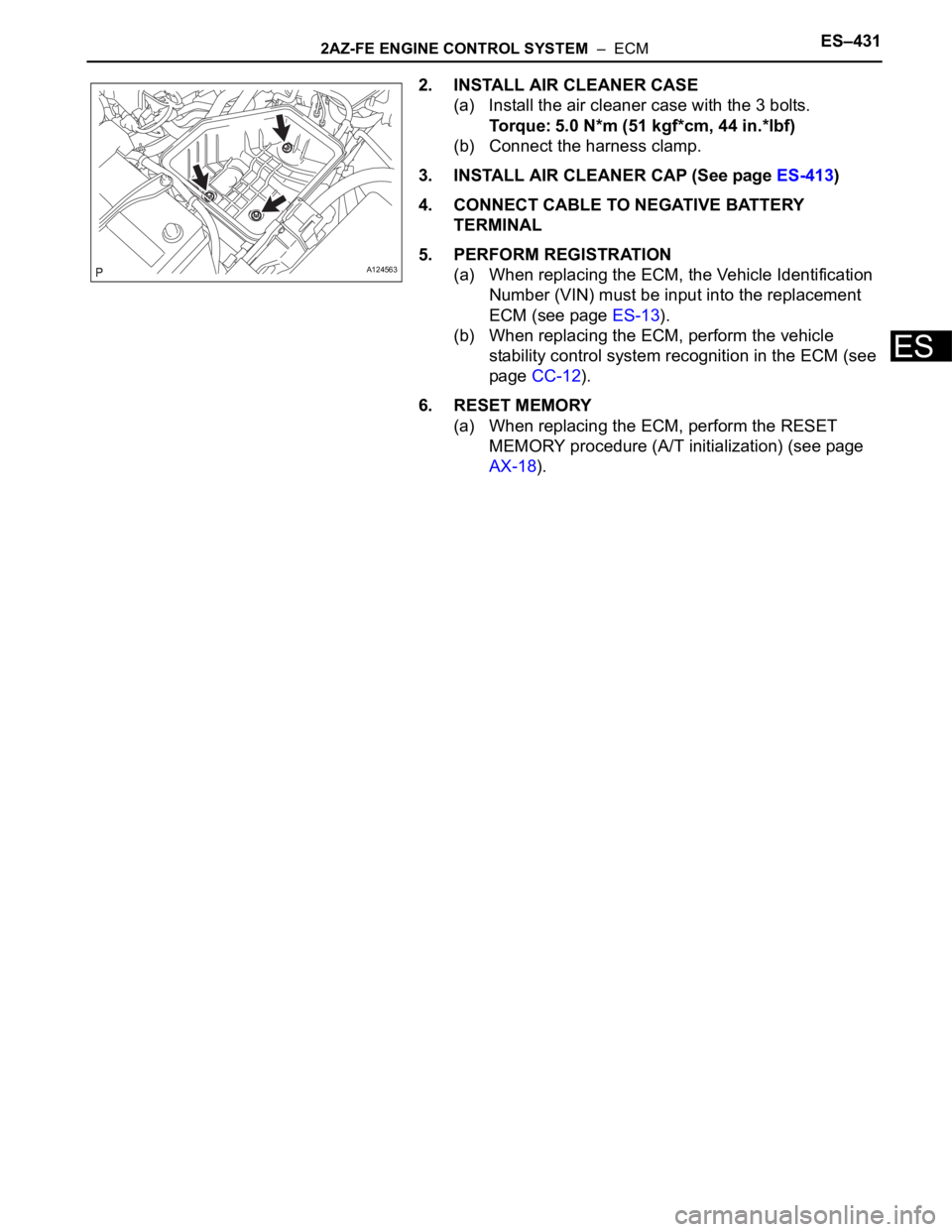

2AZ-FE ENGINE CONTROL SYSTEM – ECMES–431

ES

2. INSTALL AIR CLEANER CASE

(a) Install the air cleaner case with the 3 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

(b) Connect the harness clamp.

3. INSTALL AIR CLEANER CAP (See page ES-413)

4. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

5. PERFORM REGISTRATION

(a) When replacing the ECM, the Vehicle Identification

Number (VIN) must be input into the replacement

ECM (see page ES-13).

(b) When replacing the ECM, perform the vehicle

stability control system recognition in the ECM (see

page CC-12).

6. RESET MEMORY

(a) When replacing the ECM, perform the RESET

MEMORY procedure (A/T initialization) (see page

AX-18).

A124563

Page 189 of 2000

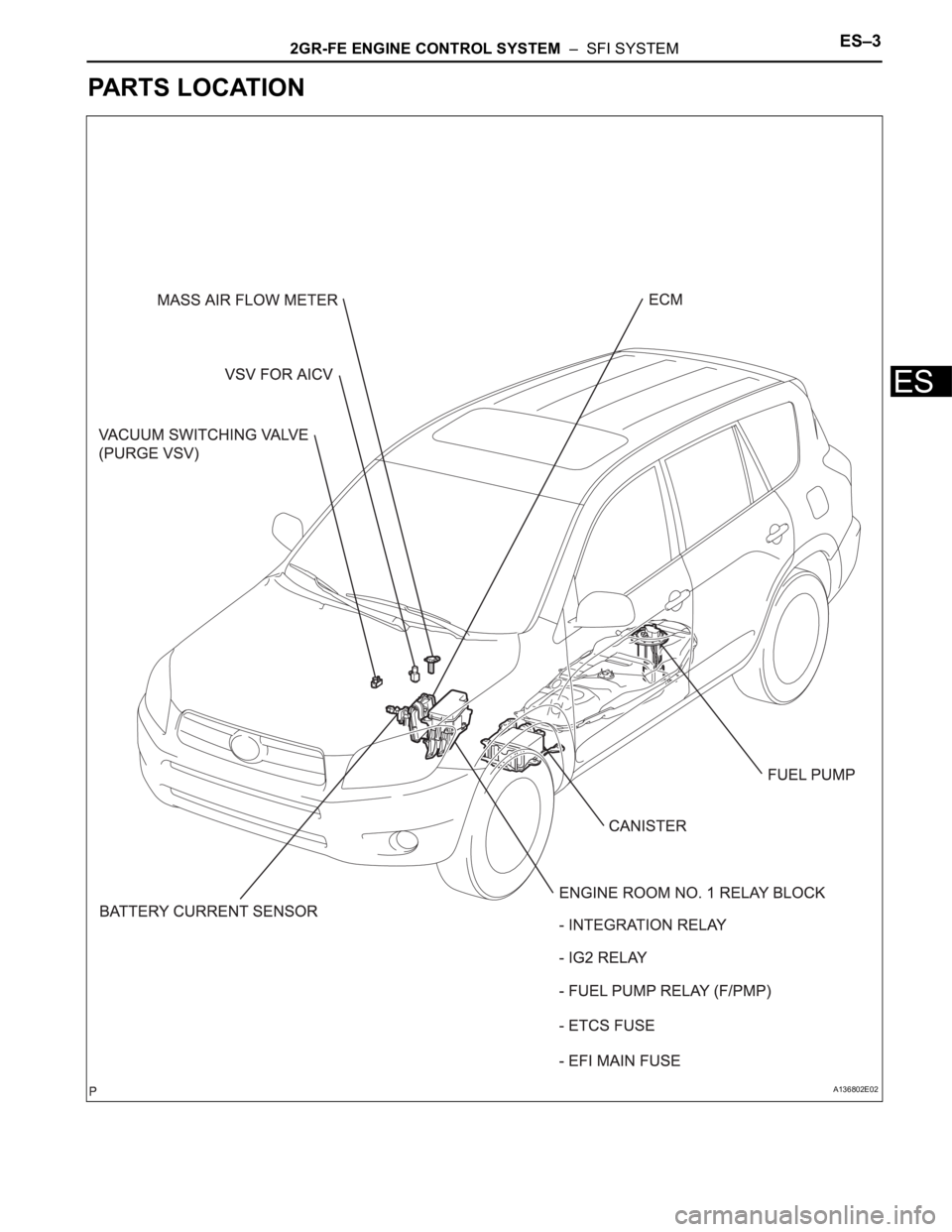

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–3

ES

PARTS LOCATION

A136802E02

Page 190 of 2000

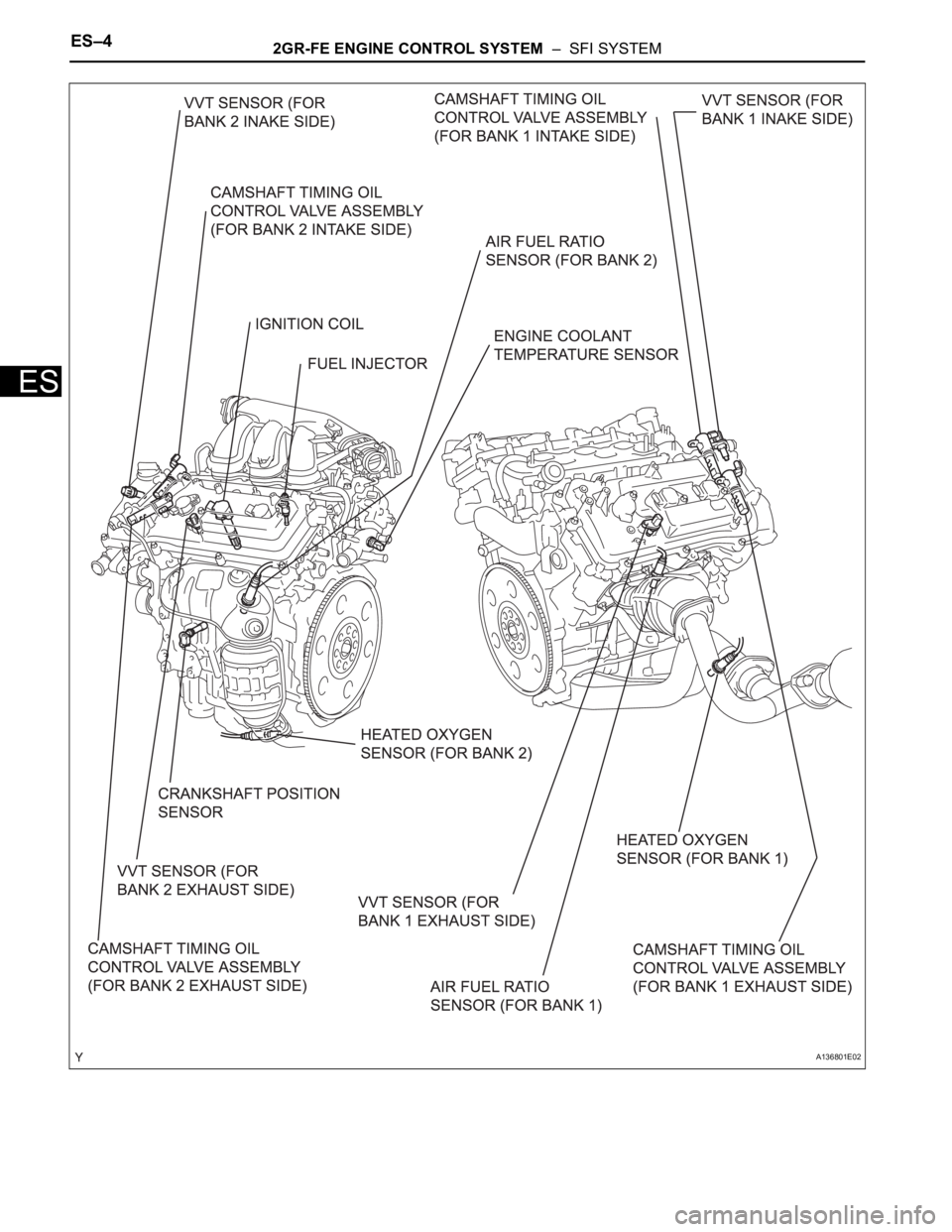

ES–42GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

A136801E02

Trending: cowl, weight, Hub bearing, Timing chain cover, oil viscosity, dimensions, oil type