sensor TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1527 of 2000

BC–24BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

CHECK FOR INTERMITTENT

PROBLEMS

1. CHECK FOR INTERMITTENT PROBLEMS

HINT:

A momentary interruption (open circuit) in the connectors

and/or wire harness between the sensors and ECUs can

be detected by using the ECU DATA LIST function of an

intelligent tester.

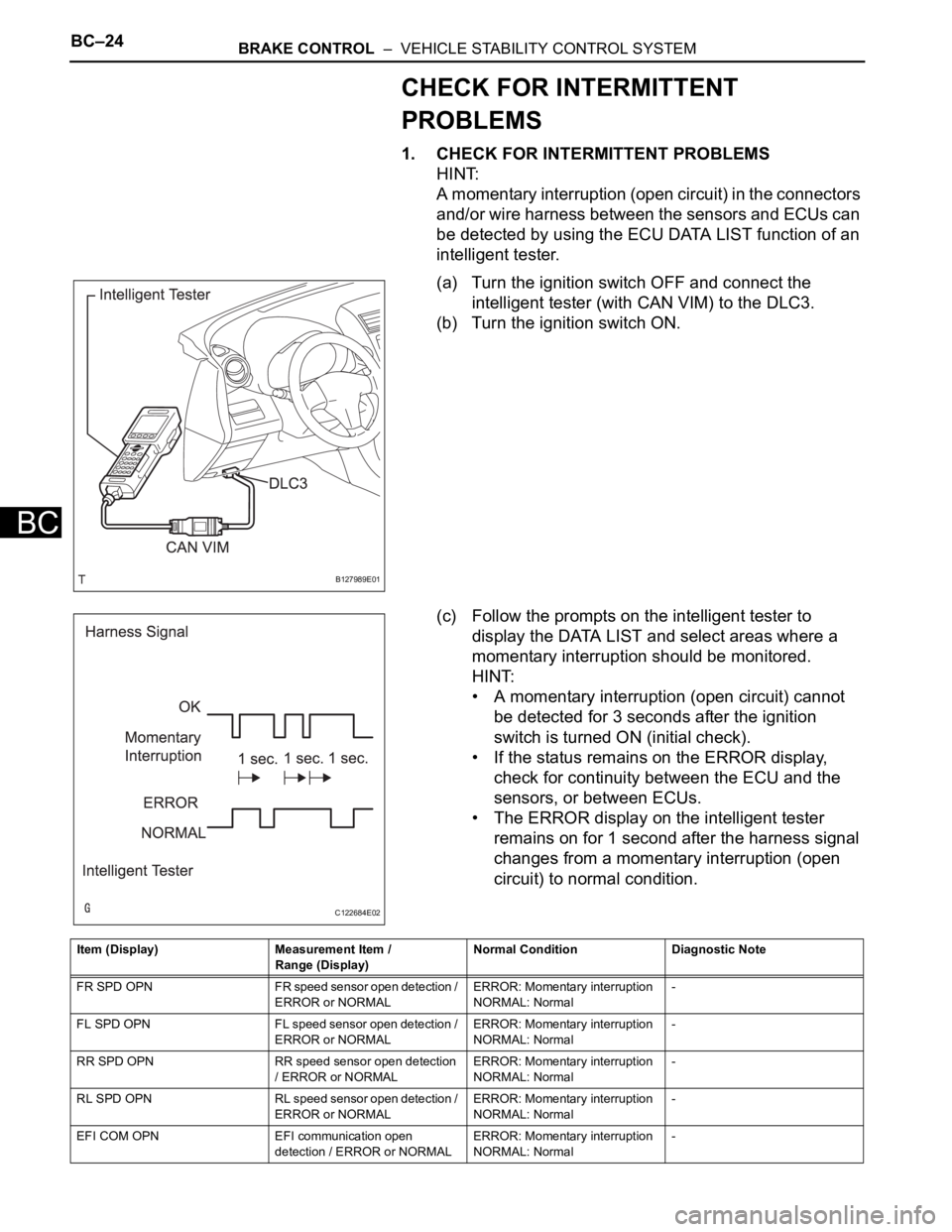

(a) Turn the ignition switch OFF and connect the

intelligent tester (with CAN VIM) to the DLC3.

(b) Turn the ignition switch ON.

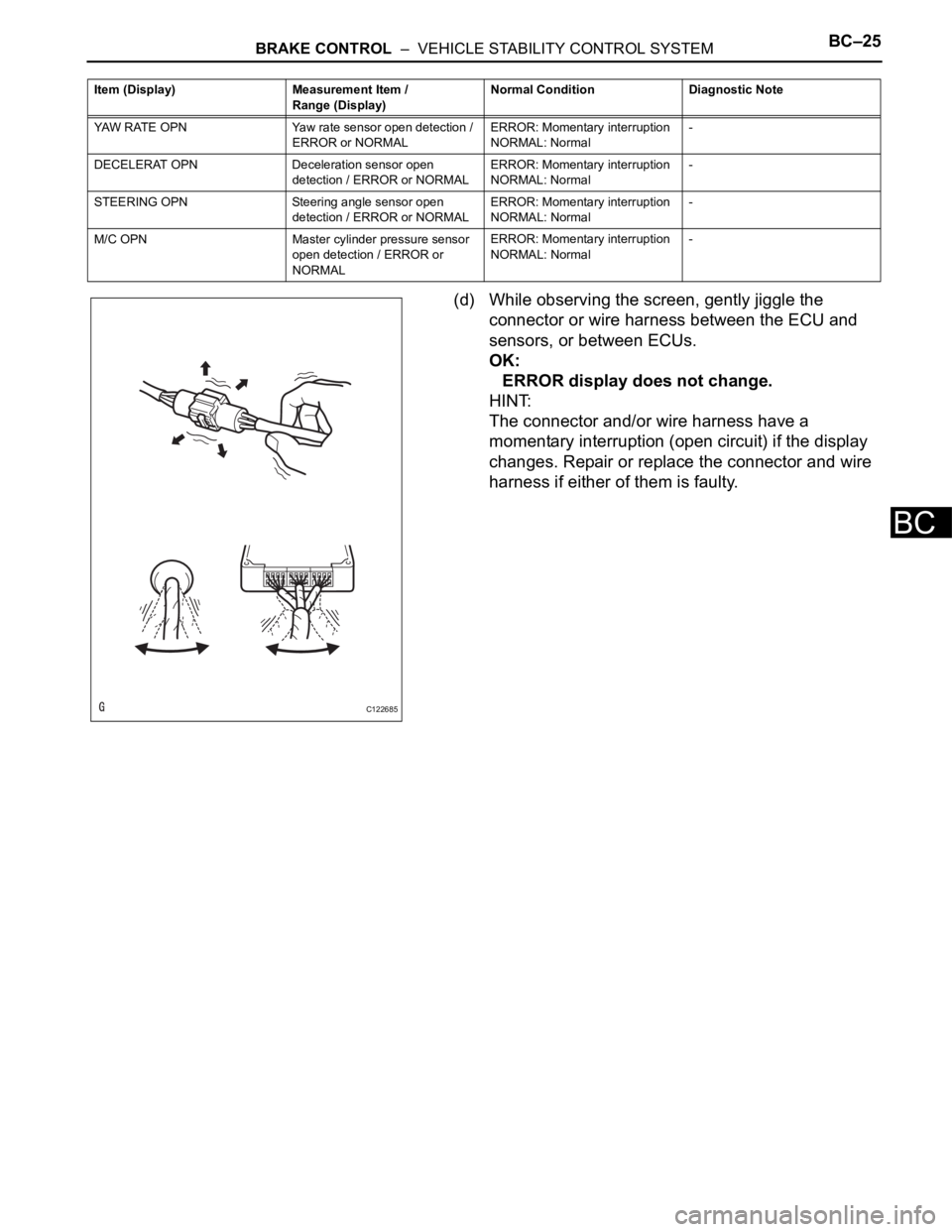

(c) Follow the prompts on the intelligent tester to

display the DATA LIST and select areas where a

momentary interruption should be monitored.

HINT:

• A momentary interruption (open circuit) cannot

be detected for 3 seconds after the ignition

switch is turned ON (initial check).

• If the status remains on the ERROR display,

check for continuity between the ECU and the

sensors, or between ECUs.

• The ERROR display on the intelligent tester

remains on for 1 second after the harness signal

changes from a momentary interruption (open

circuit) to normal condition.

B127989E01

C122684E02

Item (Display) Measurement Item /

Range (Display)Normal Condition Diagnostic Note

FR SPD OPN FR speed sensor open detection /

ERROR or NORMALERROR: Momentary interruption

NORMAL: Normal-

FL SPD OPN FL speed sensor open detection /

ERROR or NORMALERROR: Momentary interruption

NORMAL: Normal-

RR SPD OPN RR speed sensor open detection

/ ERROR or NORMALERROR: Momentary interruption

NORMAL: Normal-

RL SPD OPN RL speed sensor open detection /

ERROR or NORMALERROR: Momentary interruption

NORMAL: Normal-

EFI COM OPN EFI communication open

detection / ERROR or NORMALERROR: Momentary interruption

NORMAL: Normal-

Page 1528 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–25

BC

(d) While observing the screen, gently jiggle the

connector or wire harness between the ECU and

sensors, or between ECUs.

OK:

ERROR display does not change.

HINT:

The connector and/or wire harness have a

momentary interruption (open circuit) if the display

changes. Repair or replace the connector and wire

harness if either of them is faulty.

YAW RATE OPN Yaw rate sensor open detection /

ERROR or NORMALERROR: Momentary interruption

NORMAL: Normal-

DECELERAT OPN Deceleration sensor open

detection / ERROR or NORMALERROR: Momentary interruption

NORMAL: Normal-

STEERING OPN Steering angle sensor open

detection / ERROR or NORMALERROR: Momentary interruption

NORMAL: Normal-

M/C OPN Master cylinder pressure sensor

open detection / ERROR or

NORMALERROR: Momentary interruption

NORMAL: Normal- Item (Display) Measurement Item /

Range (Display)Normal Condition Diagnostic Note

C122685

Page 1529 of 2000

BC–26BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

CALIBRATION

1. DESCRIPTION

(a) After replacing components relating to the VSC or

performing "Front wheel alignment adjustment",

clear and read the sensor calibration data.

(b) Follow the chart to perform calibration.

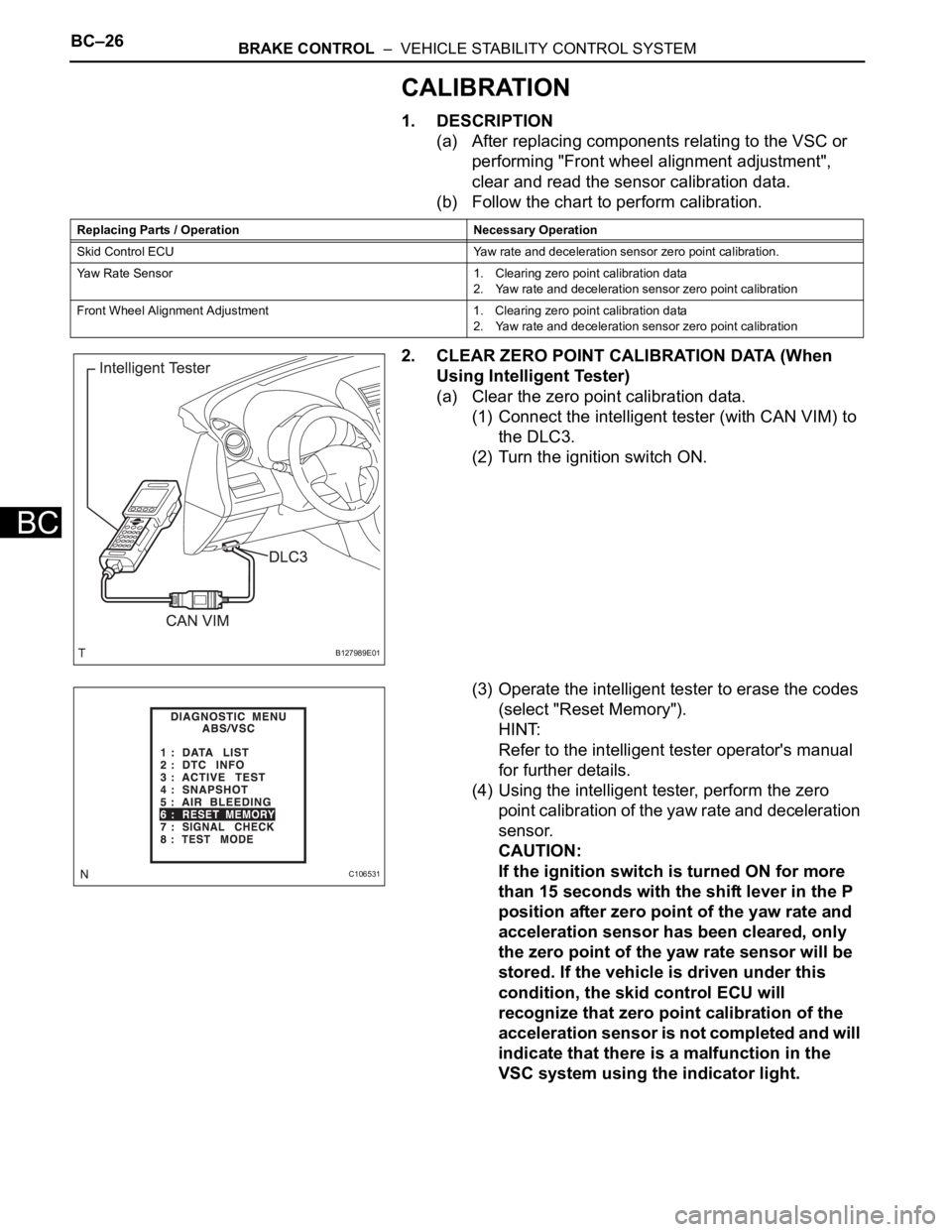

2. CLEAR ZERO POINT CALIBRATION DATA (When

Using Intelligent Tester)

(a) Clear the zero point calibration data.

(1) Connect the intelligent tester (with CAN VIM) to

the DLC3.

(2) Turn the ignition switch ON.

(3) Operate the intelligent tester to erase the codes

(select "Reset Memory").

HINT:

Refer to the intelligent tester operator's manual

for further details.

(4) Using the intelligent tester, perform the zero

point calibration of the yaw rate and deceleration

sensor.

CAUTION:

If the ignition switch is turned ON for more

than 15 seconds with the shift lever in the P

position after zero point of the yaw rate and

acceleration sensor has been cleared, only

the zero point of the yaw rate sensor will be

stored. If the vehicle is driven under this

condition, the skid control ECU will

recognize that zero point calibration of the

acceleration sensor is not completed and will

indicate that there is a malfunction in the

VSC system using the indicator light.

Replacing Parts / Operation Necessary Operation

Skid Control ECU Yaw rate and deceleration sensor zero point calibration.

Yaw Rate Sensor 1. Clearing zero point calibration data

2. Yaw rate and deceleration sensor zero point calibration

Front Wheel Alignment Adjustment 1. Clearing zero point calibration data

2. Yaw rate and deceleration sensor zero point calibration

B127989E01

C106531

Page 1530 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–27

BC

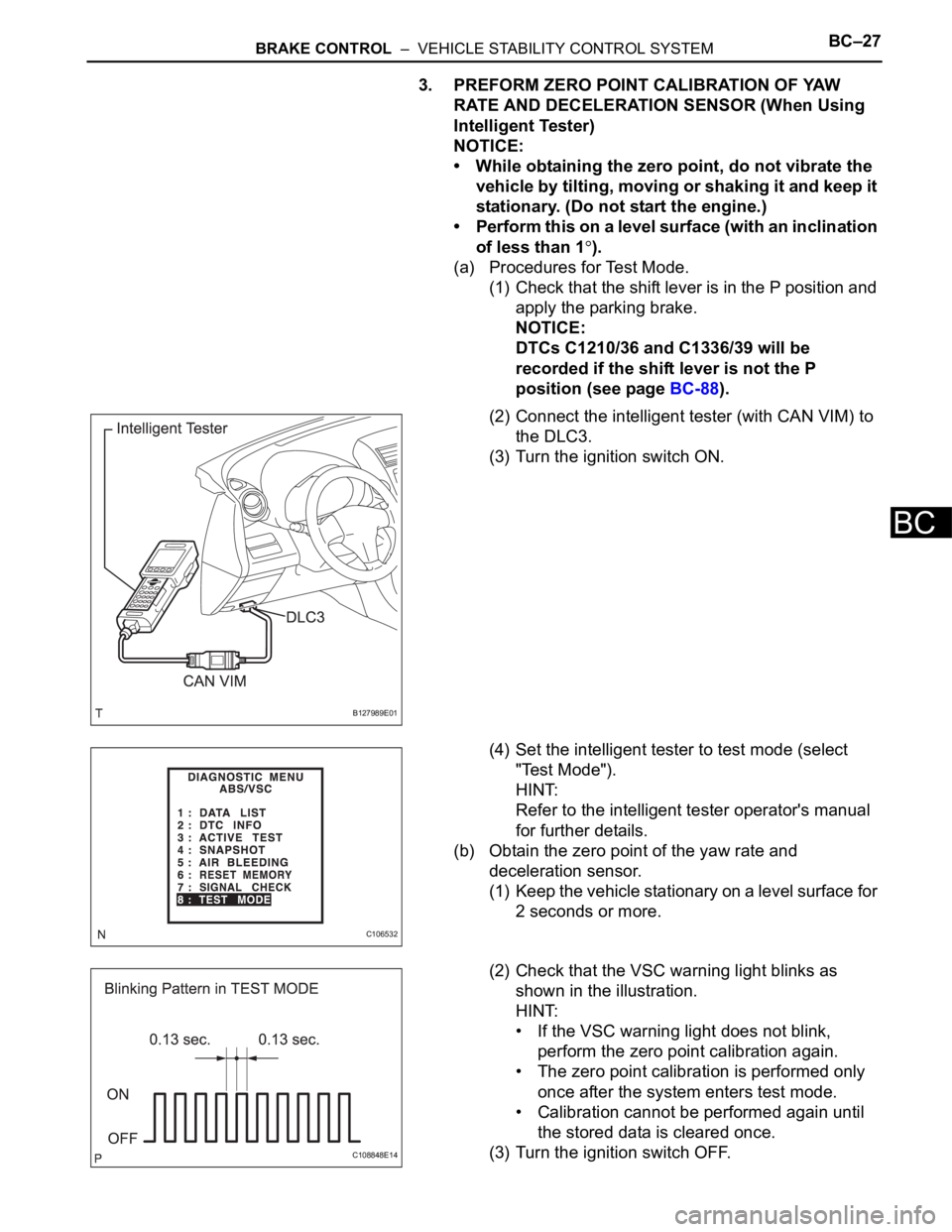

3. PREFORM ZERO POINT CALIBRATION OF YAW

RATE AND DECELERATION SENSOR (When Using

Intelligent Tester)

NOTICE:

• While obtaining the zero point, do not vibrate the

vehicle by tilting, moving or shaking it and keep it

stationary. (Do not start the engine.)

• Perform this on a level surface (with an inclination

of less than 1

).

(a) Procedures for Test Mode.

(1) Check that the shift lever is in the P position and

apply the parking brake.

NOTICE:

DTCs C1210/36 and C1336/39 will be

recorded if the shift lever is not the P

position (see page BC-88).

(2) Connect the intelligent tester (with CAN VIM) to

the DLC3.

(3) Turn the ignition switch ON.

(4) Set the intelligent tester to test mode (select

"Test Mode").

HINT:

Refer to the intelligent tester operator's manual

for further details.

(b) Obtain the zero point of the yaw rate and

deceleration sensor.

(1) Keep the vehicle stationary on a level surface for

2 seconds or more.

(2) Check that the VSC warning light blinks as

shown in the illustration.

HINT:

• If the VSC warning light does not blink,

perform the zero point calibration again.

• The zero point calibration is performed only

once after the system enters test mode.

• Calibration cannot be performed again until

the stored data is cleared once.

(3) Turn the ignition switch OFF.

B127989E01

C106532

C108848E14

Page 1531 of 2000

BC–28BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

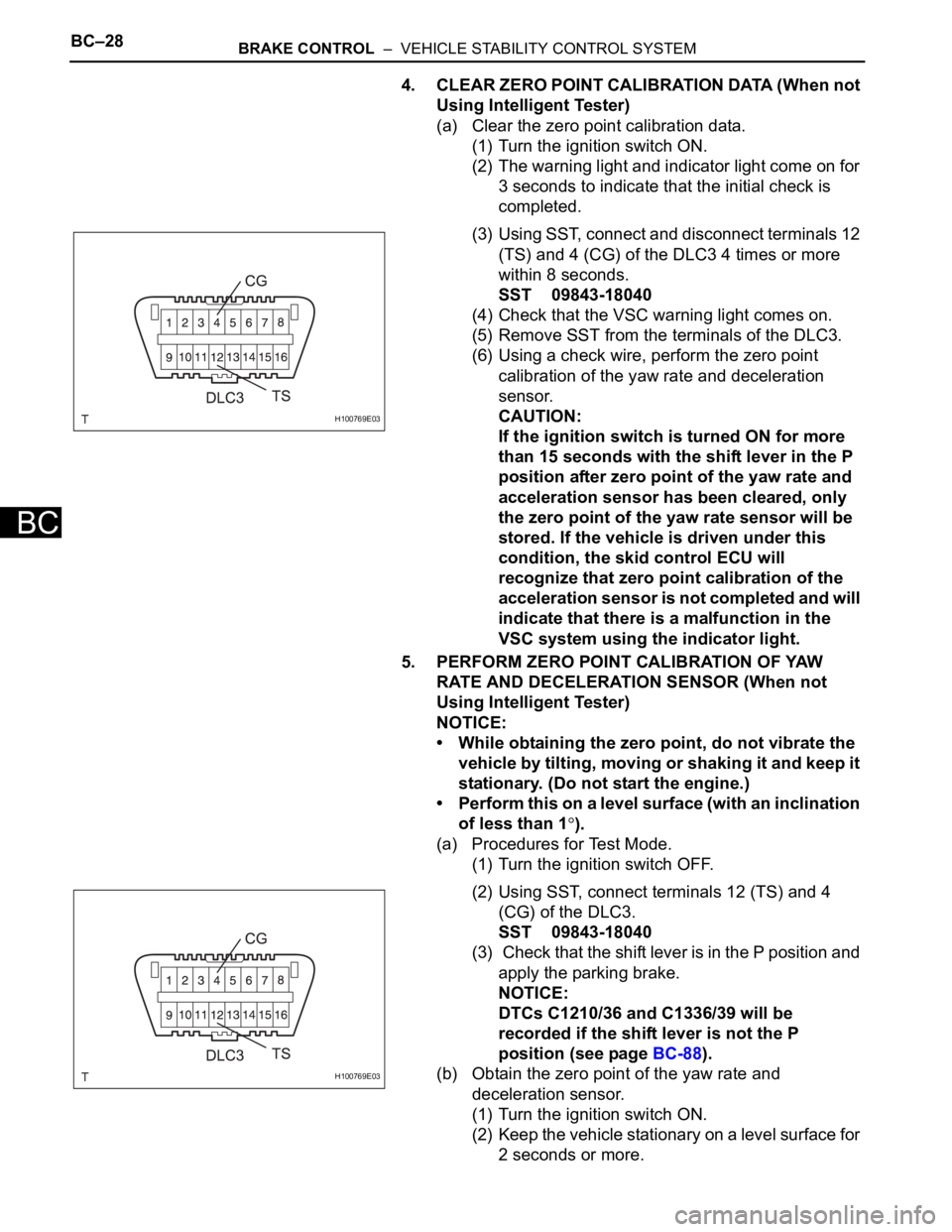

4. CLEAR ZERO POINT CALIBRATION DATA (When not

Using Intelligent Tester)

(a) Clear the zero point calibration data.

(1) Turn the ignition switch ON.

(2) The warning light and indicator light come on for

3 seconds to indicate that the initial check is

completed.

(3) Using SST, connect and disconnect terminals 12

(TS) and 4 (CG) of the DLC3 4 times or more

within 8 seconds.

SST 09843-18040

(4) Check that the VSC warning light comes on.

(5) Remove SST from the terminals of the DLC3.

(6) Using a check wire, perform the zero point

calibration of the yaw rate and deceleration

sensor.

CAUTION:

If the ignition switch is turned ON for more

than 15 seconds with the shift lever in the P

position after zero point of the yaw rate and

acceleration sensor has been cleared, only

the zero point of the yaw rate sensor will be

stored. If the vehicle is driven under this

condition, the skid control ECU will

recognize that zero point calibration of the

acceleration sensor is not completed and will

indicate that there is a malfunction in the

VSC system using the indicator light.

5. PERFORM ZERO POINT CALIBRATION OF YAW

RATE AND DECELERATION SENSOR (When not

Using Intelligent Tester)

NOTICE:

• While obtaining the zero point, do not vibrate the

vehicle by tilting, moving or shaking it and keep it

stationary. (Do not start the engine.)

• Perform this on a level surface (with an inclination

of less than 1

).

(a) Procedures for Test Mode.

(1) Turn the ignition switch OFF.

(2) Using SST, connect terminals 12 (TS) and 4

(CG) of the DLC3.

SST 09843-18040

(3) Check that the shift lever is in the P position and

apply the parking brake.

NOTICE:

DTCs C1210/36 and C1336/39 will be

recorded if the shift lever is not the P

position (see page BC-88).

(b) Obtain the zero point of the yaw rate and

deceleration sensor.

(1) Turn the ignition switch ON.

(2) Keep the vehicle stationary on a level surface for

2 seconds or more.

H100769E03

H100769E03

Page 1533 of 2000

BC–30BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

TEST MODE PROCEDURE

HINT:

• By switching the skid control ECU from normal mode to

test mode, abnormality detection sensitivity is enhanced

and troubleshooting can be conducted efficiently.

• Perform a sensor check in test mode after the speed

sensor or sensor rotor has been repaired or replaced.

• If the ignition switch is turned from ON to ACC or OFF

during test mode, DTCs related to the signal check

function will be erased.

• During test mode, the skid control ECU stores all DTCs

related to the signal check function, and the DTCs are

erased if normality is confirmed. Any remaining DTCs are

those indicating abnormalities that were found.

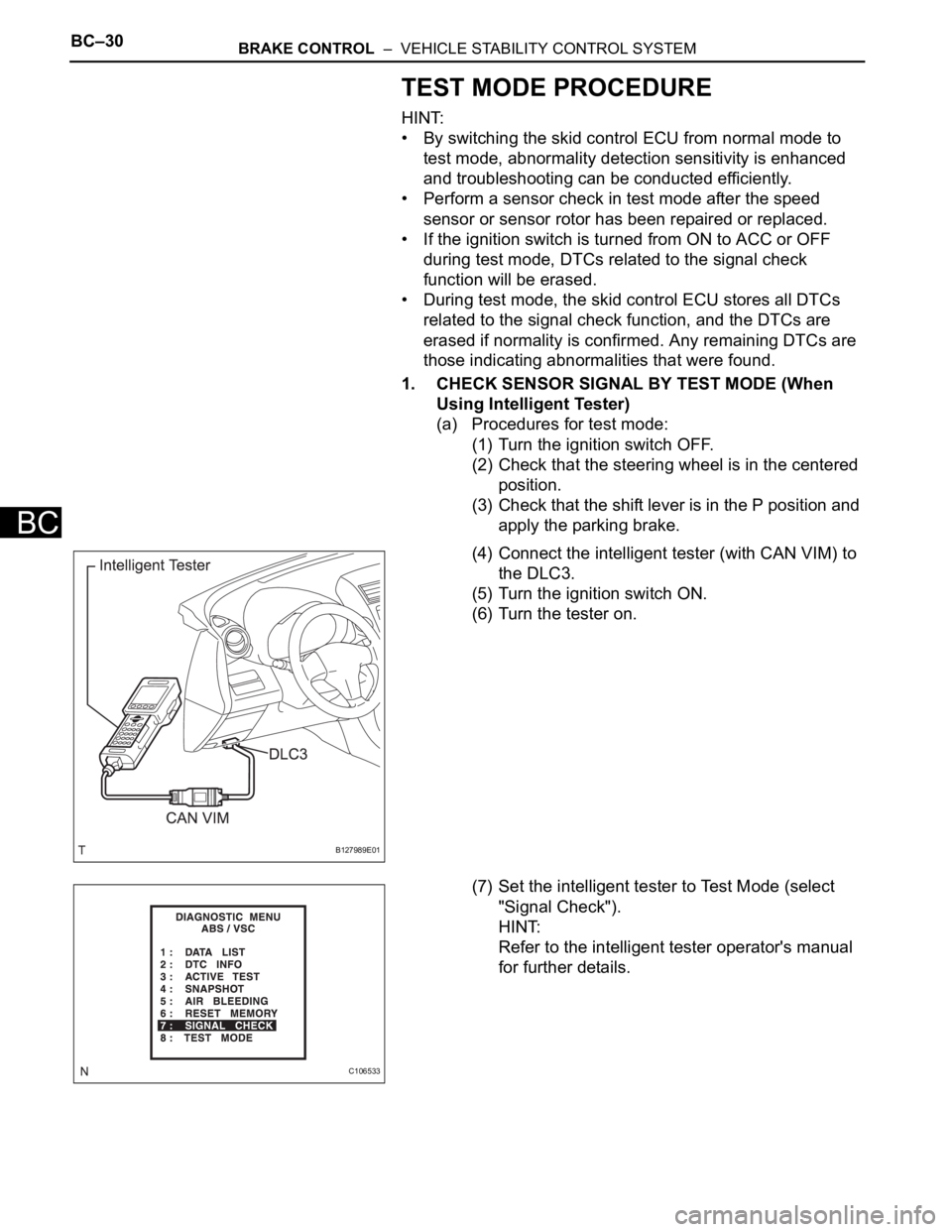

1. CHECK SENSOR SIGNAL BY TEST MODE (When

Using Intelligent Tester)

(a) Procedures for test mode:

(1) Turn the ignition switch OFF.

(2) Check that the steering wheel is in the centered

position.

(3) Check that the shift lever is in the P position and

apply the parking brake.

(4) Connect the intelligent tester (with CAN VIM) to

the DLC3.

(5) Turn the ignition switch ON.

(6) Turn the tester on.

(7) Set the intelligent tester to Test Mode (select

"Signal Check").

HINT:

Refer to the intelligent tester operator's manual

for further details.

B127989E01

C106533

Page 1534 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–31

BC

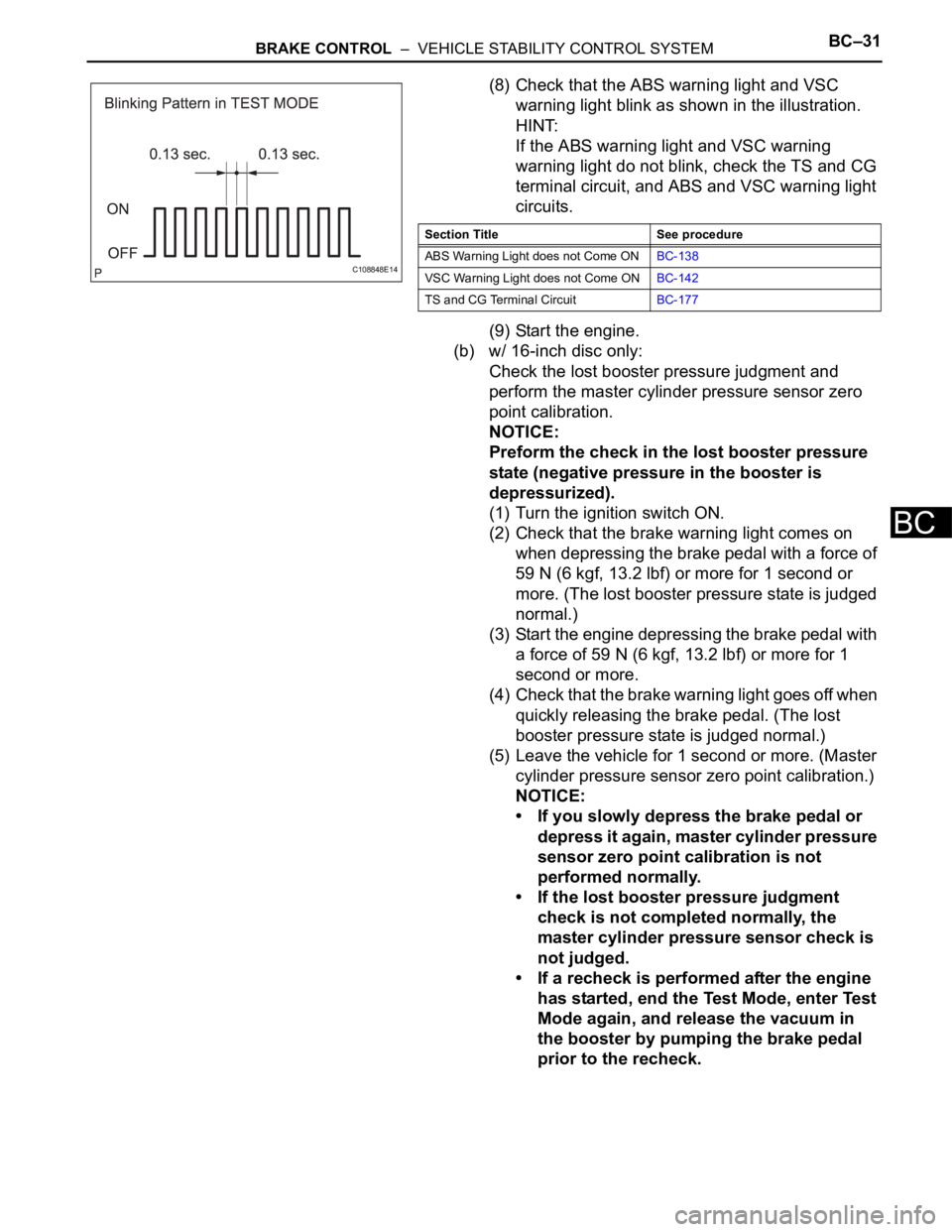

(8) Check that the ABS warning light and VSC

warning light blink as shown in the illustration.

HINT:

If the ABS warning light and VSC warning

warning light do not blink, check the TS and CG

terminal circuit, and ABS and VSC warning light

circuits.

(9) Start the engine.

(b) w/ 16-inch disc only:

Check the lost booster pressure judgment and

perform the master cylinder pressure sensor zero

point calibration.

NOTICE:

Preform the check in the lost booster pressure

state (negative pressure in the booster is

depressurized).

(1) Turn the ignition switch ON.

(2) Check that the brake warning light comes on

when depressing the brake pedal with a force of

59 N (6 kgf, 13.2 lbf) or more for 1 second or

more. (The lost booster pressure state is judged

normal.)

(3) Start the engine depressing the brake pedal with

a force of 59 N (6 kgf, 13.2 lbf) or more for 1

second or more.

(4) Check that the brake warning light goes off when

quickly releasing the brake pedal. (The lost

booster pressure state is judged normal.)

(5) Leave the vehicle for 1 second or more. (Master

cylinder pressure sensor zero point calibration.)

NOTICE:

• If you slowly depress the brake pedal or

depress it again, master cylinder pressure

sensor zero point calibration is not

performed normally.

• If the lost booster pressure judgment

check is not completed normally, the

master cylinder pressure sensor check is

not judged.

• If a recheck is performed after the engine

has started, end the Test Mode, enter Test

Mode again, and release the vacuum in

the booster by pumping the brake pedal

prior to the recheck.

C108848E14

Section Title See procedure

ABS Warning Light does not Come ONBC-138

VSC Warning Light does not Come ONBC-142

TS and CG Terminal CircuitBC-177

Page 1535 of 2000

BC–32BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

(c) Check the deceleration sensor.

(1) Keep the vehicle stationary on a level surface for

1 second or more.

HINT:

The deceleration sensor check can be

performed together with the following master

cylinder pressure sensor check.

(d) Check the master cylinder pressure sensor.

(1) Leave the vehicle in a stationary condition and

release the brake pedal for 1 second or more,

and quickly depress the brake pedal with a force

of 98 N (10 kgf, 22 lbf) or more for 1 second.

Check that the ABS warning light remains

illuminated for 3 seconds.

HINT:

• Ensure that the ABS warning light comes on.

• While the ABS warning light remains

illuminated, continue depressing the brake

pedal with a force of 98 N (10 kgf, 22 lbf) or

more.

• The ABS warning light comes on for 3

seconds every time the brake pedal operation

above is performed.

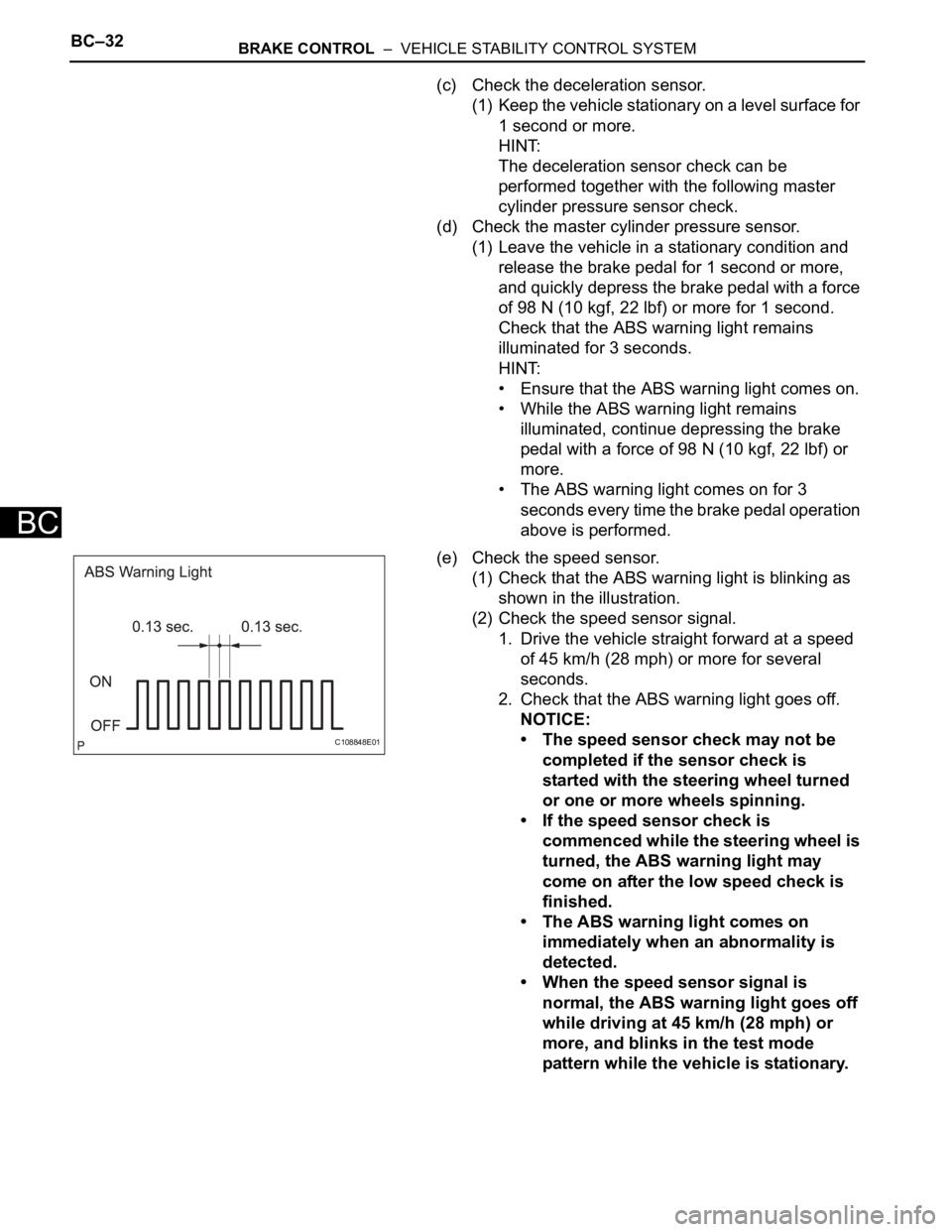

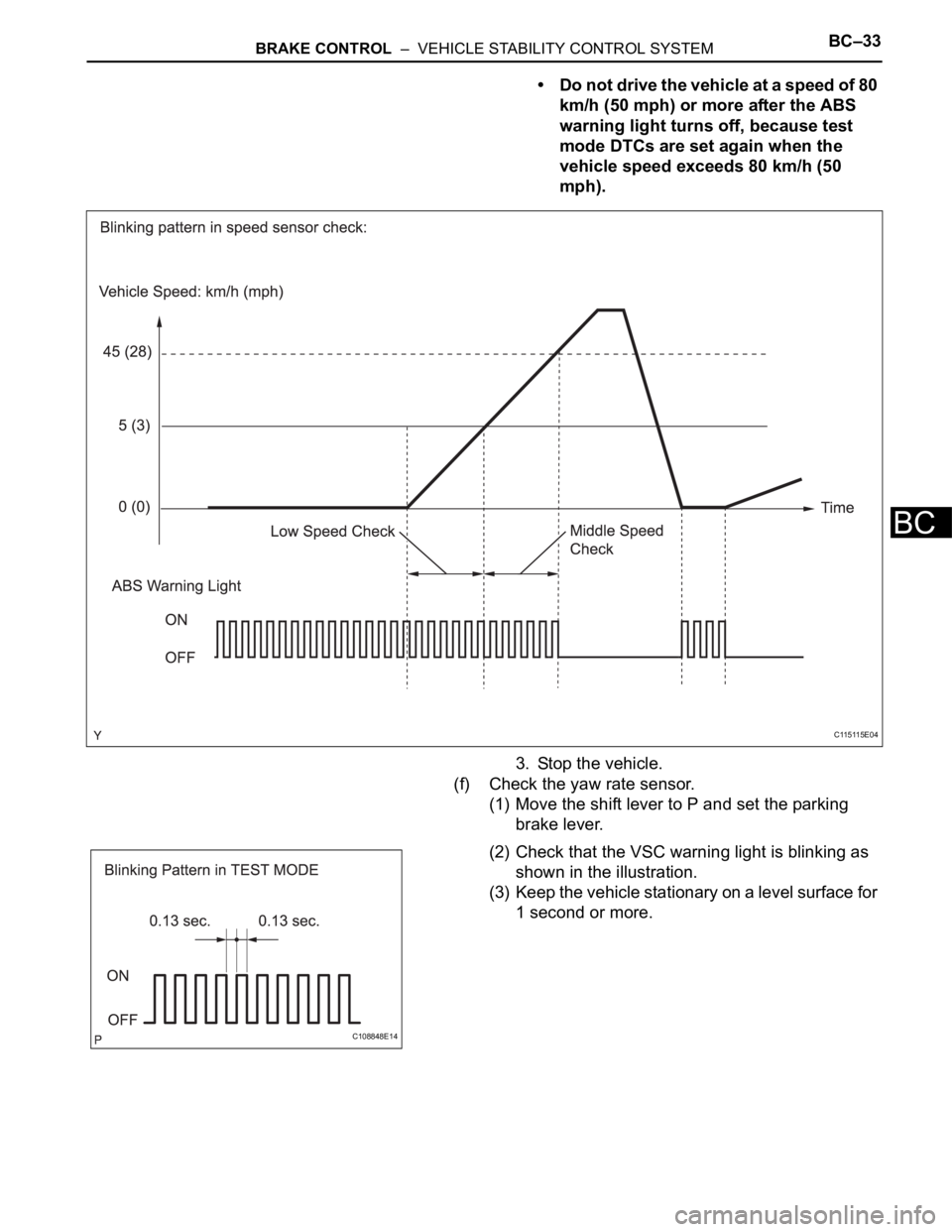

(e) Check the speed sensor.

(1) Check that the ABS warning light is blinking as

shown in the illustration.

(2) Check the speed sensor signal.

1. Drive the vehicle straight forward at a speed

of 45 km/h (28 mph) or more for several

seconds.

2. Check that the ABS warning light goes off.

NOTICE:

• The speed sensor check may not be

completed if the sensor check is

started with the steering wheel turned

or one or more wheels spinning.

• If the speed sensor check is

commenced while the steering wheel is

turned, the ABS warning light may

come on after the low speed check is

finished.

• The ABS warning light comes on

immediately when an abnormality is

detected.

• When the speed sensor signal is

normal, the ABS warning light goes off

while driving at 45 km/h (28 mph) or

more, and blinks in the test mode

pattern while the vehicle is stationary.

C108848E01

Page 1536 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–33

BC

• Do not drive the vehicle at a speed of 80

km/h (50 mph) or more after the ABS

warning light turns off, because test

mode DTCs are set again when the

vehicle speed exceeds 80 km/h (50

mph).

3. Stop the vehicle.

(f) Check the yaw rate sensor.

(1) Move the shift lever to P and set the parking

brake lever.

(2) Check that the VSC warning light is blinking as

shown in the illustration.

(3) Keep the vehicle stationary on a level surface for

1 second or more.

C115115E04

C108848E14

Page 1537 of 2000

BC–34BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

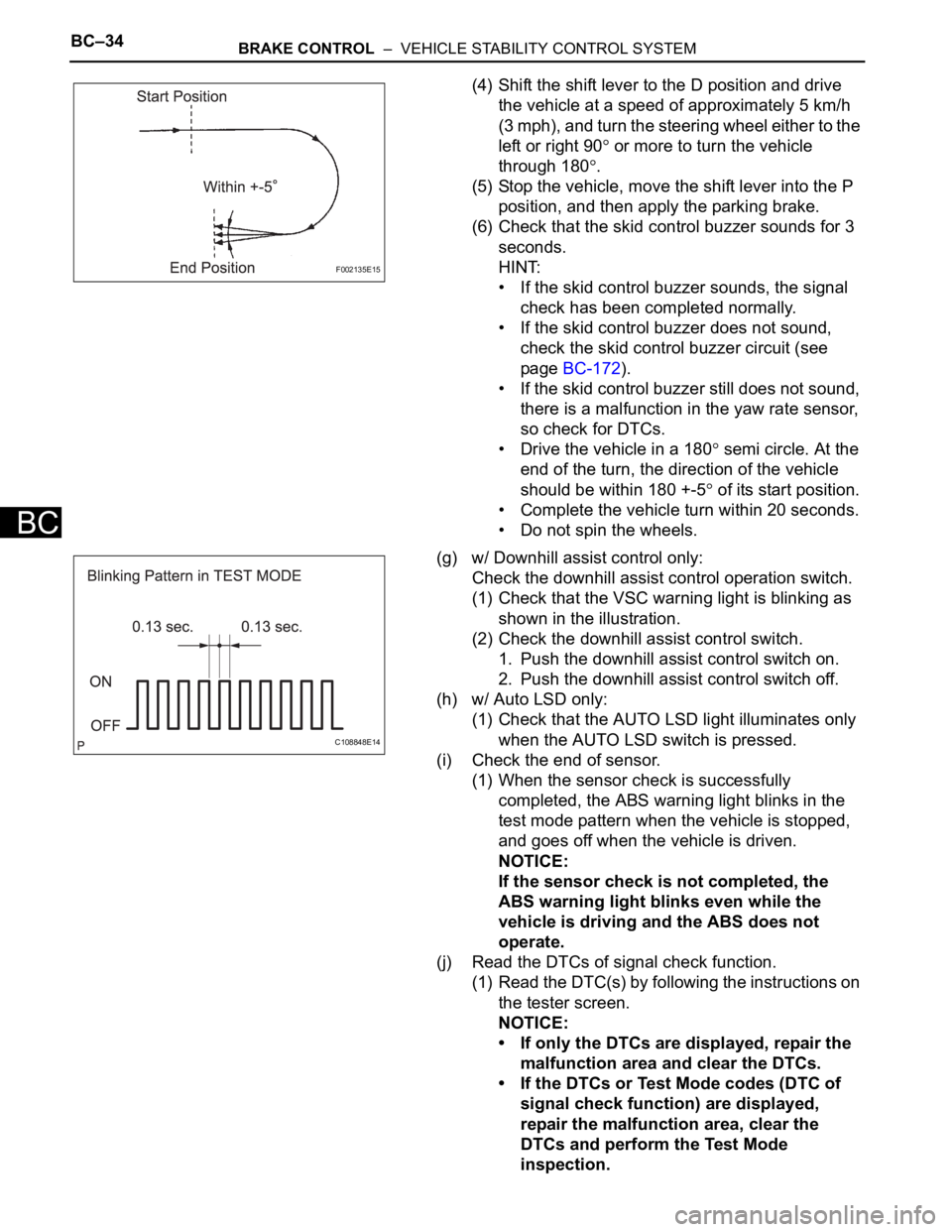

(4) Shift the shift lever to the D position and drive

the vehicle at a speed of approximately 5 km/h

(3 mph), and turn the steering wheel either to the

left or right 90

or more to turn the vehicle

through 180

.

(5) Stop the vehicle, move the shift lever into the P

position, and then apply the parking brake.

(6) Check that the skid control buzzer sounds for 3

seconds.

HINT:

• If the skid control buzzer sounds, the signal

check has been completed normally.

• If the skid control buzzer does not sound,

check the skid control buzzer circuit (see

page BC-172).

• If the skid control buzzer still does not sound,

there is a malfunction in the yaw rate sensor,

so check for DTCs.

• Drive the vehicle in a 180

semi circle. At the

end of the turn, the direction of the vehicle

should be within 180 +-5

of its start position.

• Complete the vehicle turn within 20 seconds.

• Do not spin the wheels.

(g) w/ Downhill assist control only:

Check the downhill assist control operation switch.

(1) Check that the VSC warning light is blinking as

shown in the illustration.

(2) Check the downhill assist control switch.

1. Push the downhill assist control switch on.

2. Push the downhill assist control switch off.

(h) w/ Auto LSD only:

(1) Check that the AUTO LSD light illuminates only

when the AUTO LSD switch is pressed.

(i) Check the end of sensor.

(1) When the sensor check is successfully

completed, the ABS warning light blinks in the

test mode pattern when the vehicle is stopped,

and goes off when the vehicle is driven.

NOTICE:

If the sensor check is not completed, the

ABS warning light blinks even while the

vehicle is driving and the ABS does not

operate.

(j) Read the DTCs of signal check function.

(1) Read the DTC(s) by following the instructions on

the tester screen.

NOTICE:

• If only the DTCs are displayed, repair the

malfunction area and clear the DTCs.

• If the DTCs or Test Mode codes (DTC of

signal check function) are displayed,

repair the malfunction area, clear the

DTCs and perform the Test Mode

inspection.

F002135E15

C108848E14