sensor TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1609 of 2000

POWER STEERING – ELECTRONIC POWER STEERING SYSTEMPS–9

PS

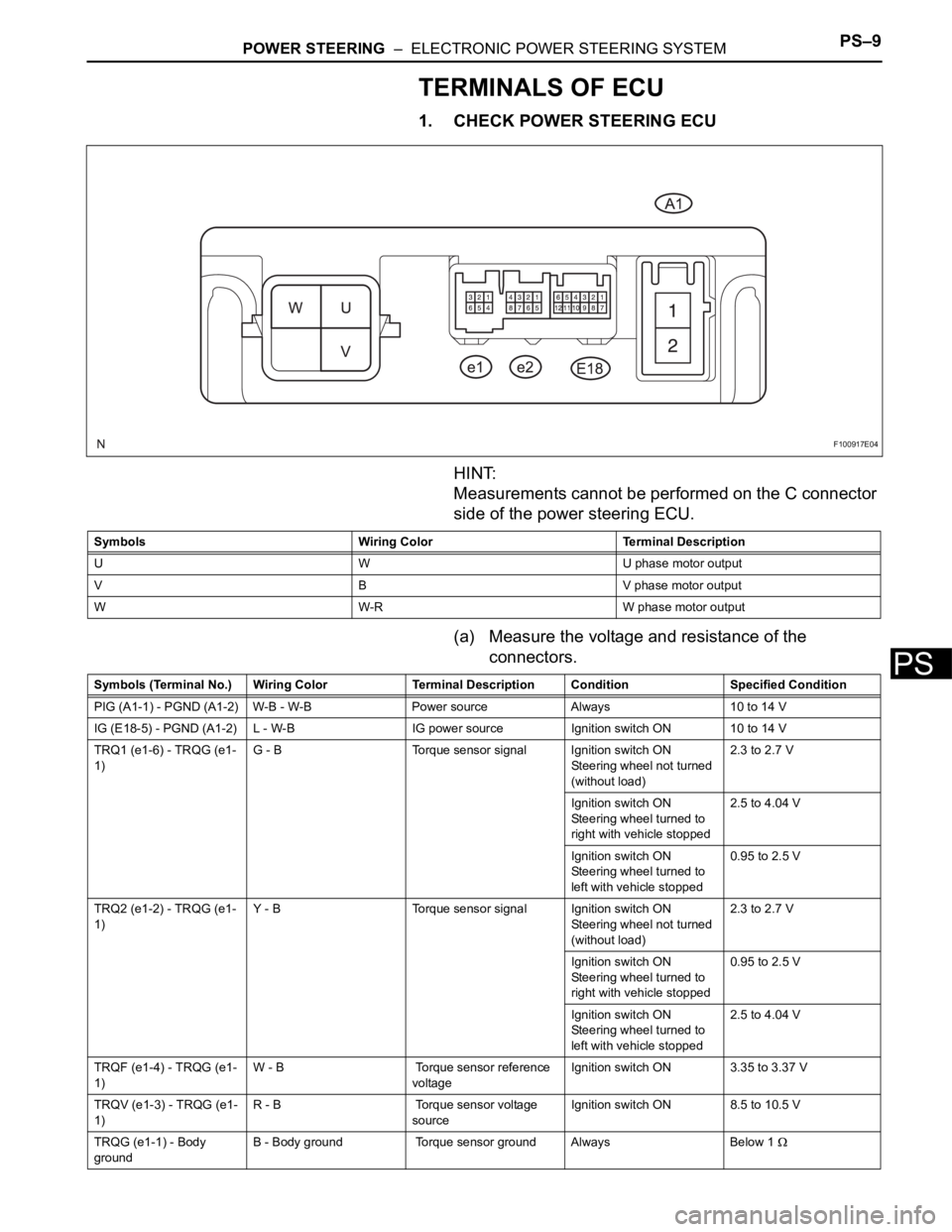

TERMINALS OF ECU

1. CHECK POWER STEERING ECU

HINT:

Measurements cannot be performed on the C connector

side of the power steering ECU.

(a) Measure the voltage and resistance of the

connectors.

F100917E04

Symbols Wiring Color Terminal Description

U W U phase motor output

V B V phase motor output

W W-R W phase motor output

Symbols (Terminal No.) Wiring Color Terminal Description ConditionSpecified Condition

PIG (A1-1) - PGND (A1-2) W-B - W-B Power source Always 10 to 14 V

IG (E18-5) - PGND (A1-2) L - W-B IG power source Ignition switch ON 10 to 14 V

TRQ1 (e1-6) - TRQG (e1-

1)G - B Torque sensor signal Ignition switch ON

Steering wheel not turned

(without load)2.3 to 2.7 V

Ignition switch ON

Steering wheel turned to

right with vehicle stopped2.5 to 4.04 V

Ignition switch ON

Steering wheel turned to

left with vehicle stopped0.95 to 2.5 V

TRQ2 (e1-2) - TRQG (e1-

1)Y - B Torque sensor signal Ignition switch ON

Steering wheel not turned

(without load)2.3 to 2.7 V

Ignition switch ON

Steering wheel turned to

right with vehicle stopped0.95 to 2.5 V

Ignition switch ON

Steering wheel turned to

left with vehicle stopped2.5 to 4.04 V

TRQF (e1-4) - TRQG (e1-

1)W - B Torque sensor reference

voltageIgnition switch ON 3.35 to 3.37 V

TRQV (e1-3) - TRQG (e1-

1)R - B Torque sensor voltage

sourceIgnition switch ON 8.5 to 10.5 V

TRQG (e1-1) - Body

groundB - Body ground Torque sensor ground Always Below 1

Page 1616 of 2000

PS–16POWER STEERING – ELECTRONIC POWER STEERING SYSTEM

PS

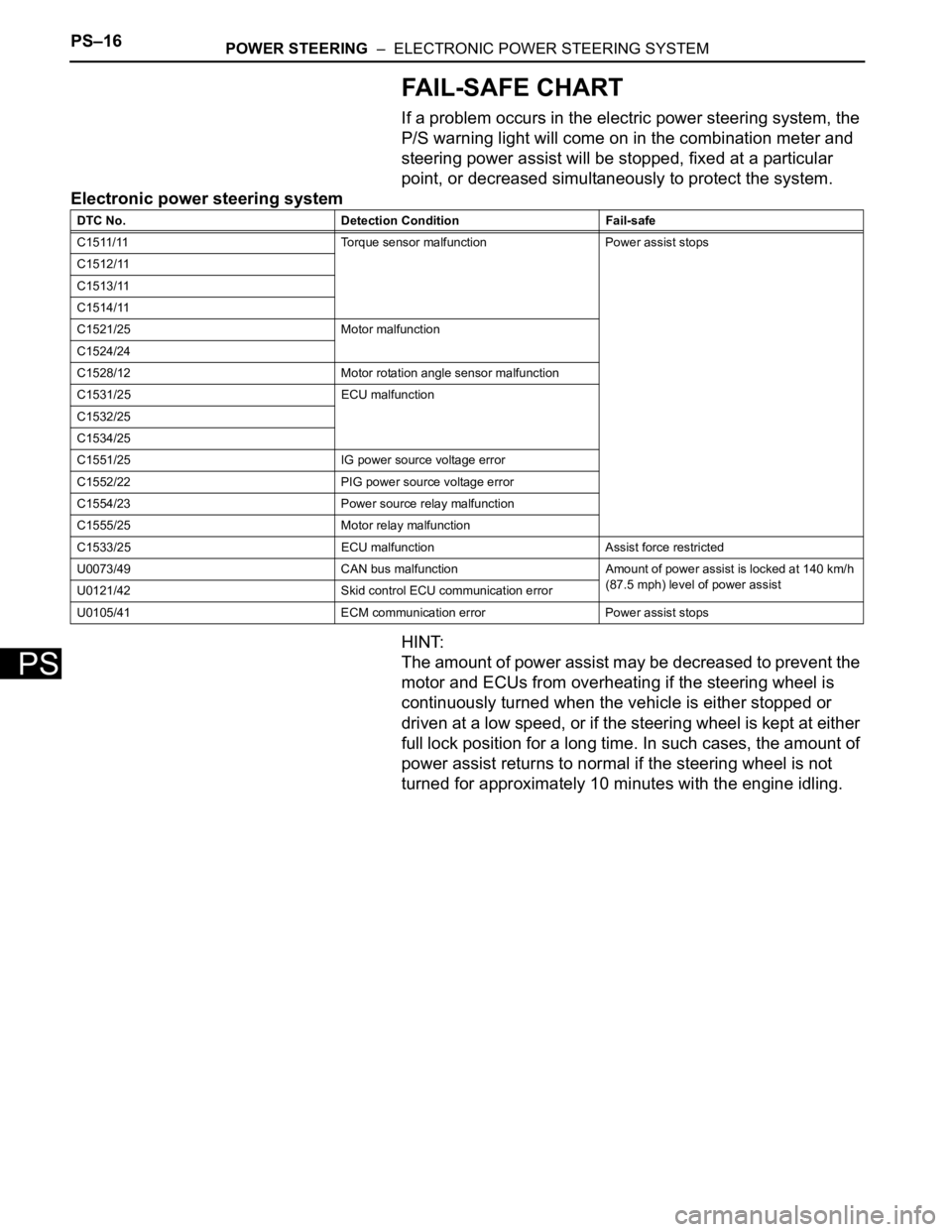

FAIL-SAFE CHART

If a problem occurs in the electric power steering system, the

P/S warning light will come on in the combination meter and

steering power assist will be stopped, fixed at a particular

point, or decreased simultaneously to protect the system.

Electronic power steering system

HINT:

The amount of power assist may be decreased to prevent the

motor and ECUs from overheating if the steering wheel is

continuously turned when the vehicle is either stopped or

driven at a low speed, or if the steering wheel is kept at either

full lock position for a long time. In such cases, the amount of

power assist returns to normal if the steering wheel is not

turned for approximately 10 minutes with the engine idling.

DTC No. Detection Condition Fail-safe

C1511/11 Torque sensor malfunction Power assist stops

C1512/11

C1513/11

C1514/11

C1521/25 Motor malfunction

C1524/24

C1528/12 Motor rotation angle sensor malfunction

C1531/25 ECU malfunction

C1532/25

C1534/25

C1551/25 IG power source voltage error

C1552/22 PIG power source voltage error

C1554/23 Power source relay malfunction

C1555/25 Motor relay malfunction

C1533/25 ECU malfunction Assist force restricted

U0073/49 CAN bus malfunction Amount of power assist is locked at 140 km/h

(87.5 mph) level of power assist

U0121/42 Skid control ECU communication error

U0105/41 ECM communication error Power assist stops

Page 1617 of 2000

POWER STEERING – ELECTRONIC POWER STEERING SYSTEMPS–17

PS

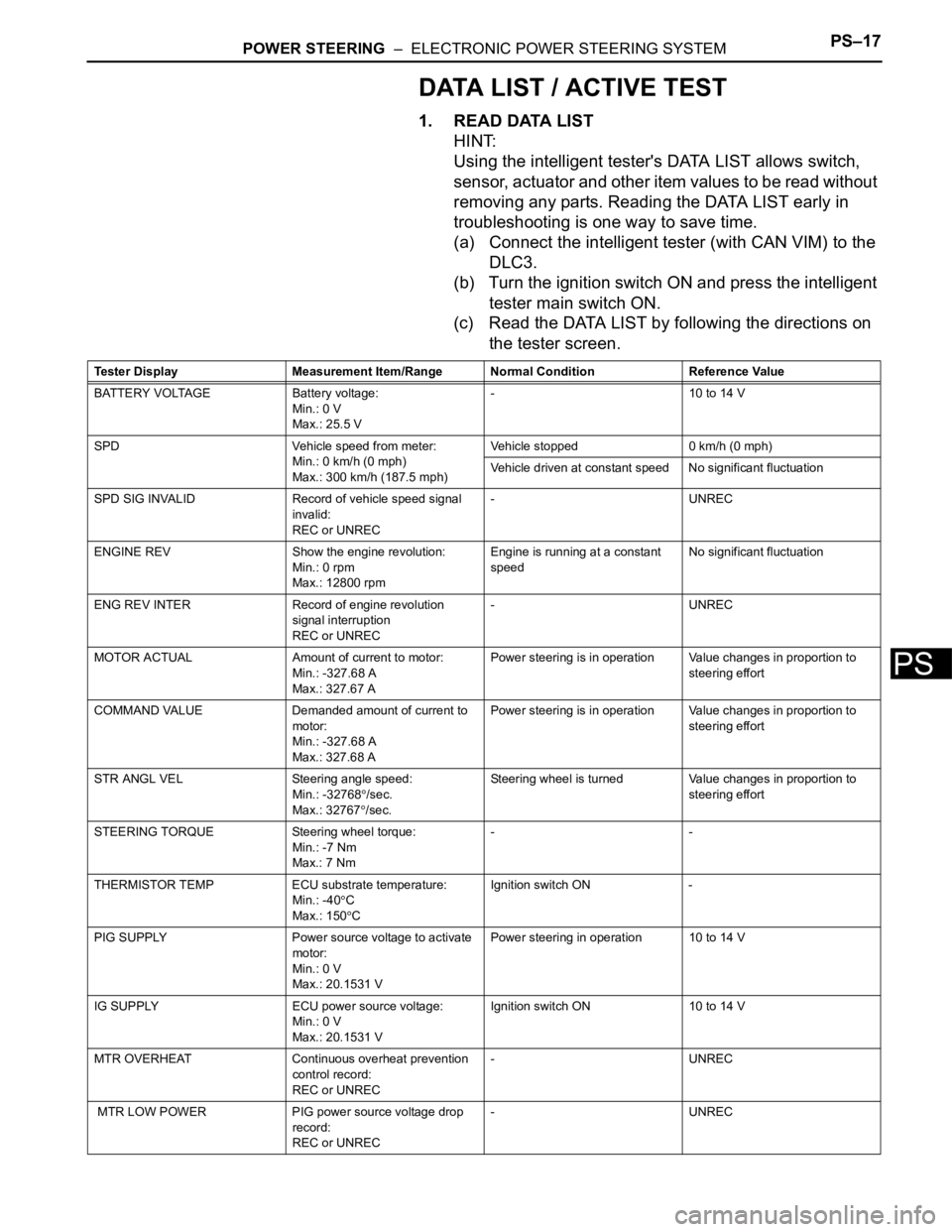

DATA LIST / ACTIVE TEST

1. READ DATA LIST

HINT:

Using the intelligent tester's DATA LIST allows switch,

sensor, actuator and other item values to be read without

removing any parts. Reading the DATA LIST early in

troubleshooting is one way to save time.

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON and press the intelligent

tester main switch ON.

(c) Read the DATA LIST by following the directions on

the tester screen.

Tester Display Measurement Item/Range Normal Condition Reference Value

BATTERY VOLTAGE Battery voltage:

Min.: 0 V

Max.: 25.5 V- 10 to 14 V

SPD Vehicle speed from meter:

Min.: 0 km/h (0 mph)

Max.: 300 km/h (187.5 mph)Vehicle stopped 0 km/h (0 mph)

Vehicle driven at constant speed No significant fluctuation

SPD SIG INVALID Record of vehicle speed signal

invalid:

REC or UNREC- UNREC

ENGINE REV Show the engine revolution:

Min.: 0 rpm

Max.: 12800 rpmEngine is running at a constant

speedNo significant fluctuation

ENG REV INTER Record of engine revolution

signal interruption

REC or UNREC- UNREC

MOTOR ACTUAL Amount of current to motor:

Min.: -327.68 A

Max.: 327.67 APower steering is in operation Value changes in proportion to

steering effort

COMMAND VALUE Demanded amount of current to

motor:

Min.: -327.68 A

Max.: 327.68 APower steering is in operation Value changes in proportion to

steering effort

STR ANGL VEL Steering angle speed:

Min.: -32768

/sec.

Max.: 32767

/sec.Steering wheel is turned Value changes in proportion to

steering effort

STEERING TORQUE Steering wheel torque:

Min.: -7 Nm

Max.: 7 Nm--

THERMISTOR TEMP ECU substrate temperature:

Min.: -40

C

Max.: 150

CIgnition switch ON -

PIG SUPPLY Power source voltage to activate

motor:

Min.: 0 V

Max.: 20.1531 VPower steering in operation 10 to 14 V

IG SUPPLY ECU power source voltage:

Min.: 0 V

Max.: 20.1531 VIgnition switch ON 10 to 14 V

MTR OVERHEAT Continuous overheat prevention

control record:

REC or UNREC- UNREC

MTR LOW POWER PIG power source voltage drop

record:

REC or UNREC- UNREC

Page 1619 of 2000

POWER STEERING – ELECTRONIC POWER STEERING SYSTEMPS–19

PS

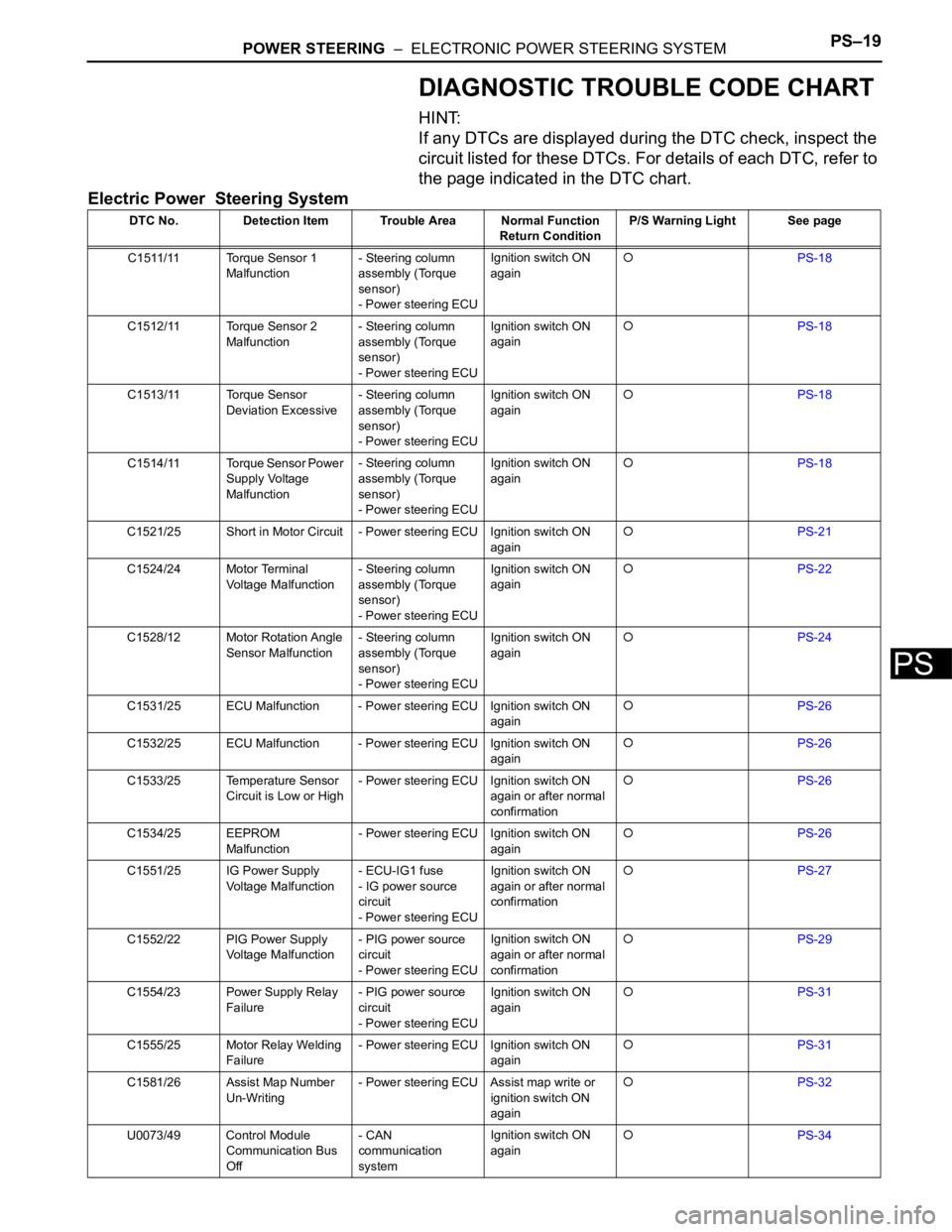

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If any DTCs are displayed during the DTC check, inspect the

circuit listed for these DTCs. For details of each DTC, refer to

the page indicated in the DTC chart.

Electric Power Steering System

DTC No. Detection Item Trouble Area Normal Function

Return ConditionP/S Warning Light See page

C1511/11 Torque Sensor 1

Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-18

C1512/11 Torque Sensor 2

Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-18

C1513/11 Torque Sensor

Deviation Excessive- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-18

C1514/11 Torque Sensor Power

Supply Voltage

Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-18

C1521/25 Short in Motor Circuit - Power steering ECU Ignition switch ON

again

PS-21

C1524/24 Motor Terminal

Voltage Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-22

C1528/12 Motor Rotation Angle

Sensor Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-24

C1531/25 ECU Malfunction - Power steering ECU Ignition switch ON

again

PS-26

C1532/25 ECU Malfunction - Power steering ECU Ignition switch ON

again

PS-26

C1533/25 Temperature Sensor

Circuit is Low or High- Power steering ECU Ignition switch ON

again or after normal

confirmation

PS-26

C1534/25 EEPROM

Malfunction- Power steering ECU Ignition switch ON

again

PS-26

C1551/25 IG Power Supply

Voltage Malfunction- ECU-IG1 fuse

- IG power source

circuit

- Power steering ECUIgnition switch ON

again or after normal

confirmation

PS-27

C1552/22 PIG Power Supply

Voltage Malfunction- PIG power source

circuit

- Power steering ECUIgnition switch ON

again or after normal

confirmation

PS-29

C1554/23 Power Supply Relay

Failure- PIG power source

circuit

- Power steering ECUIgnition switch ON

again

PS-31

C1555/25 Motor Relay Welding

Failure- Power steering ECU Ignition switch ON

again

PS-31

C1581/26 Assist Map Number

Un-Writing- Power steering ECU Assist map write or

ignition switch ON

again

PS-32

U0073/49 Control Module

Communication Bus

Off- CAN

communication

systemIgnition switch ON

again

PS-34

Page 1621 of 2000

POWER STEERING – ELECTRONIC POWER STEERING SYSTEMPS–21

PS

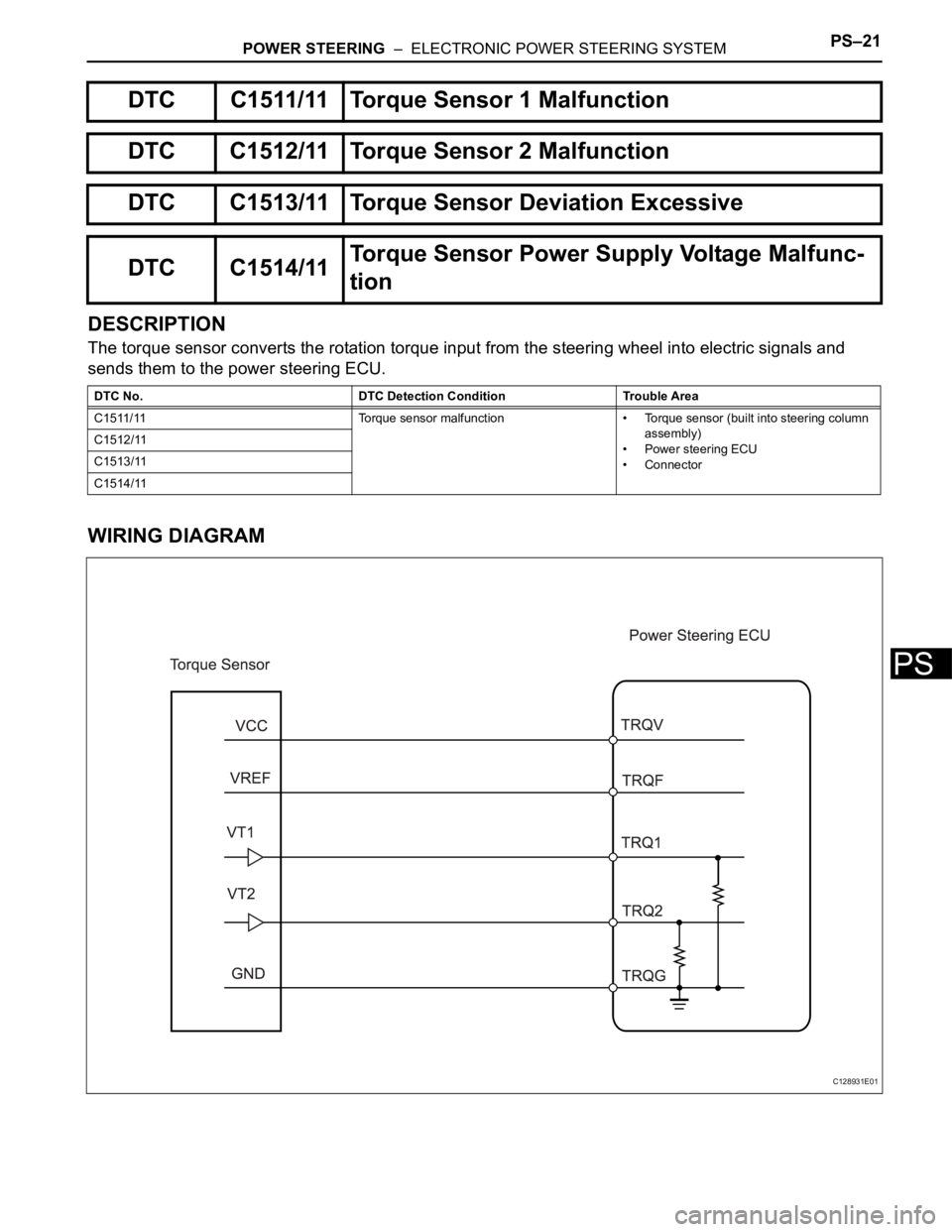

DESCRIPTION

The torque sensor converts the rotation torque input from the steering wheel into electric signals and

sends them to the power steering ECU.

WIRING DIAGRAM

DTC C1511/11 Torque Sensor 1 Malfunction

DTC C1512/11 Torque Sensor 2 Malfunction

DTC C1513/11 Torque Sensor Deviation Excessive

DTC C1514/11Torque Sensor Power Supply Voltage Malfunc-

tion

DTC No. DTC Detection Condition Trouble Area

C1511/11 Torque sensor malfunction • Torque sensor (built into steering column

assembly)

• Power steering ECU

• Connector C1512/11

C1513/11

C1514/11

C128931E01

Page 1622 of 2000

PS–22POWER STEERING – ELECTRONIC POWER STEERING SYSTEM

PS

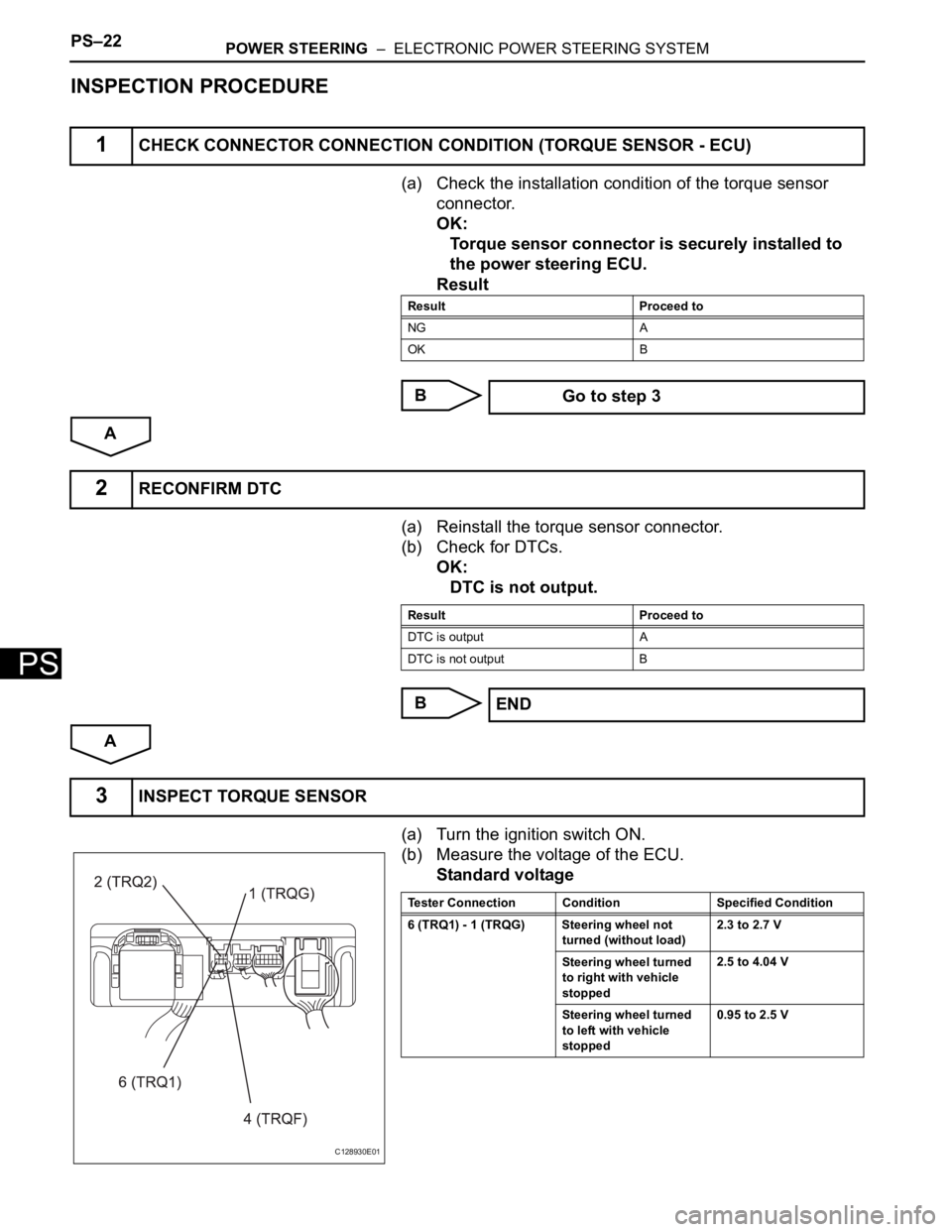

INSPECTION PROCEDURE

(a) Check the installation condition of the torque sensor

connector.

OK:

Torque sensor connector is securely installed to

the power steering ECU.

Result

B

A

(a) Reinstall the torque sensor connector.

(b) Check for DTCs.

OK:

DTC is not output.

B

A

(a) Turn the ignition switch ON.

(b) Measure the voltage of the ECU.

Standard voltage

1CHECK CONNECTOR CONNECTION CONDITION (TORQUE SENSOR - ECU)

Result Proceed to

NG A

OK B

Go to step 3

2RECONFIRM DTC

Result Proceed to

DTC is output A

DTC is not output B

END

3INSPECT TORQUE SENSOR

C128930E01

Tester Connection Condition Specified Condition

6 (TRQ1) - 1 (TRQG) Steering wheel not

turned (without load)2.3 to 2.7 V

Steering wheel turned

to right with vehicle

stopped2.5 to 4.04 V

Steering wheel turned

to left with vehicle

stopped0.95 to 2.5 V

Page 1627 of 2000

POWER STEERING – ELECTRONIC POWER STEERING SYSTEMPS–27

PS

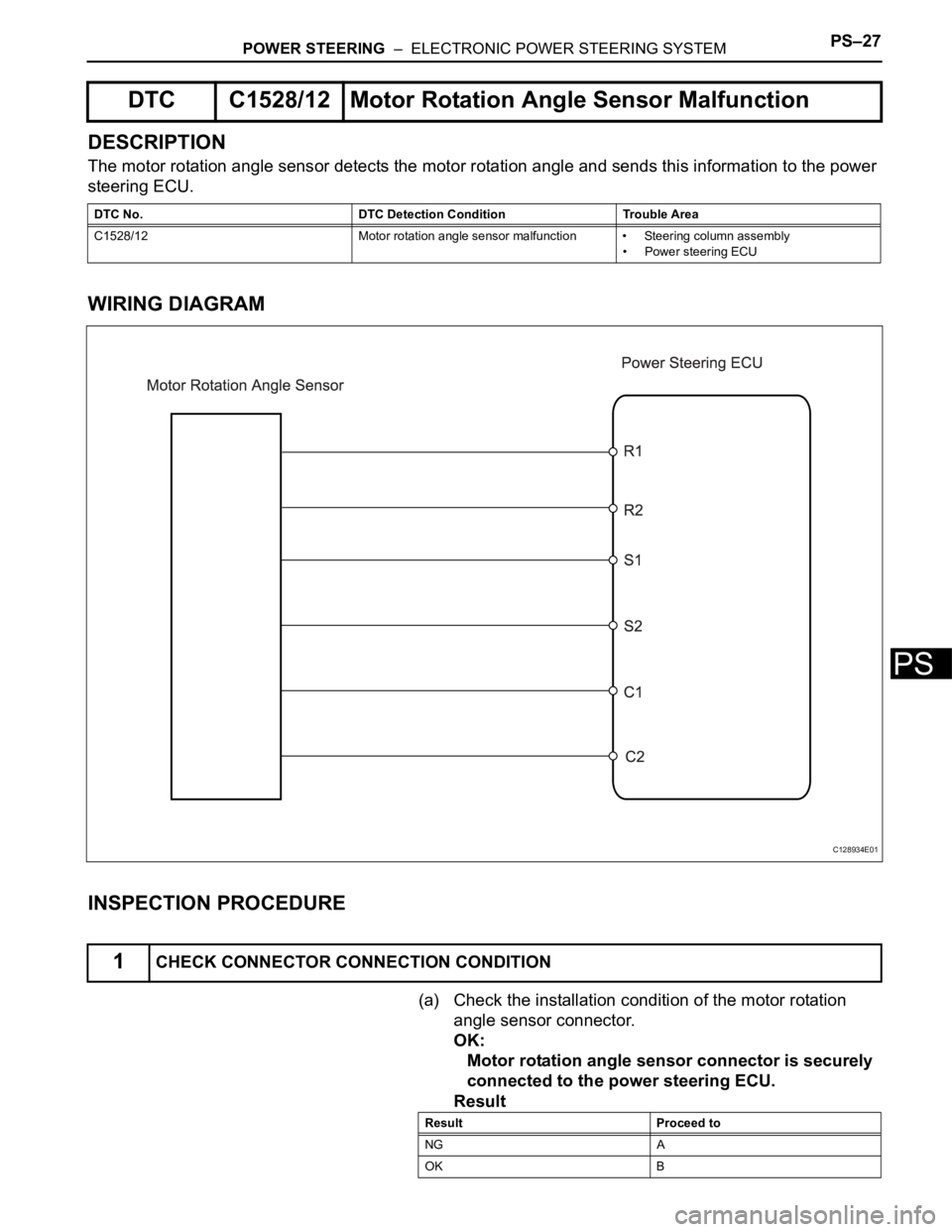

DESCRIPTION

The motor rotation angle sensor detects the motor rotation angle and sends this information to the power

steering ECU.

WIRING DIAGRAM

INSPECTION PROCEDURE

(a) Check the installation condition of the motor rotation

angle sensor connector.

OK:

Motor rotation angle sensor connector is securely

connected to the power steering ECU.

Result

DTC C1528/12 Motor Rotation Angle Sensor Malfunction

DTC No. DTC Detection Condition Trouble Area

C1528/12 Motor rotation angle sensor malfunction • Steering column assembly

• Power steering ECU

1CHECK CONNECTOR CONNECTION CONDITION

C128934E01

Result Proceed to

NG A

OK B

Page 1628 of 2000

PS–28POWER STEERING – ELECTRONIC POWER STEERING SYSTEM

PS

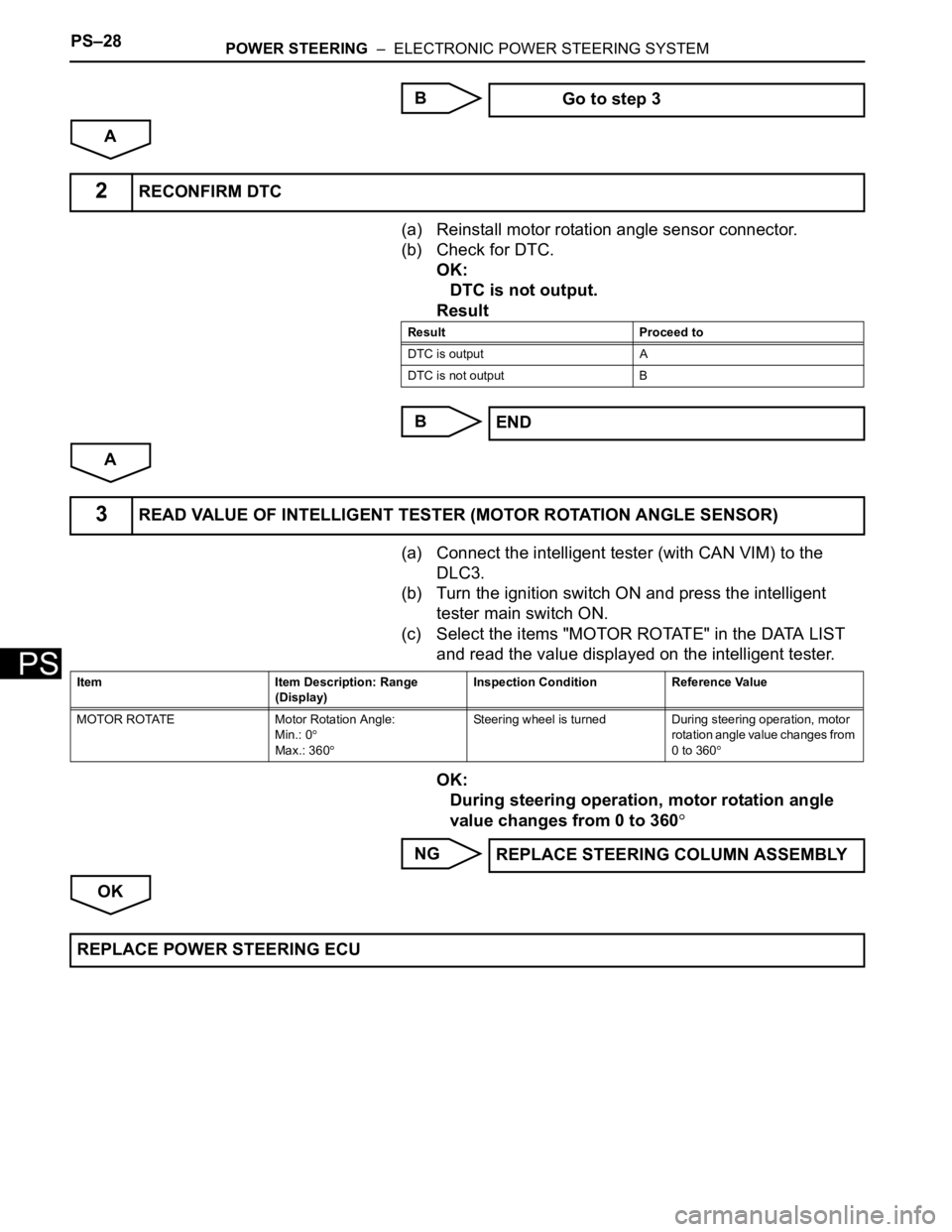

B

A

(a) Reinstall motor rotation angle sensor connector.

(b) Check for DTC.

OK:

DTC is not output.

Result

B

A

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON and press the intelligent

tester main switch ON.

(c) Select the items "MOTOR ROTATE" in the DATA LIST

and read the value displayed on the intelligent tester.

OK:

During steering operation, motor rotation angle

value changes from 0 to 360

NG

OK Go to step 3

2RECONFIRM DTC

Result Proceed to

DTC is output A

DTC is not output B

END

3READ VALUE OF INTELLIGENT TESTER (MOTOR ROTATION ANGLE SENSOR)

Item Item Description: Range

(Display)Inspection Condition Reference Value

MOTOR ROTATE Motor Rotation Angle:

Min.: 0

Max.: 360

Steering wheel is turned During steering operation, motor

rotation angle value changes from

0 to 360

REPLACE STEERING COLUMN ASSEMBLY

REPLACE POWER STEERING ECU

Page 1629 of 2000

POWER STEERING – ELECTRONIC POWER STEERING SYSTEMPS–29

PS

DESCRIPTION

INSPECTION PROCEDURE

If the power steering ECU detects these DTCs, it will shut off the motor relay circuit (built into the power

steering ECU) and stop power assist. However, power assist continues if DTC C1533 is output.

(a) Check for DTC.

OK:

DTC is not output.

OK

NG

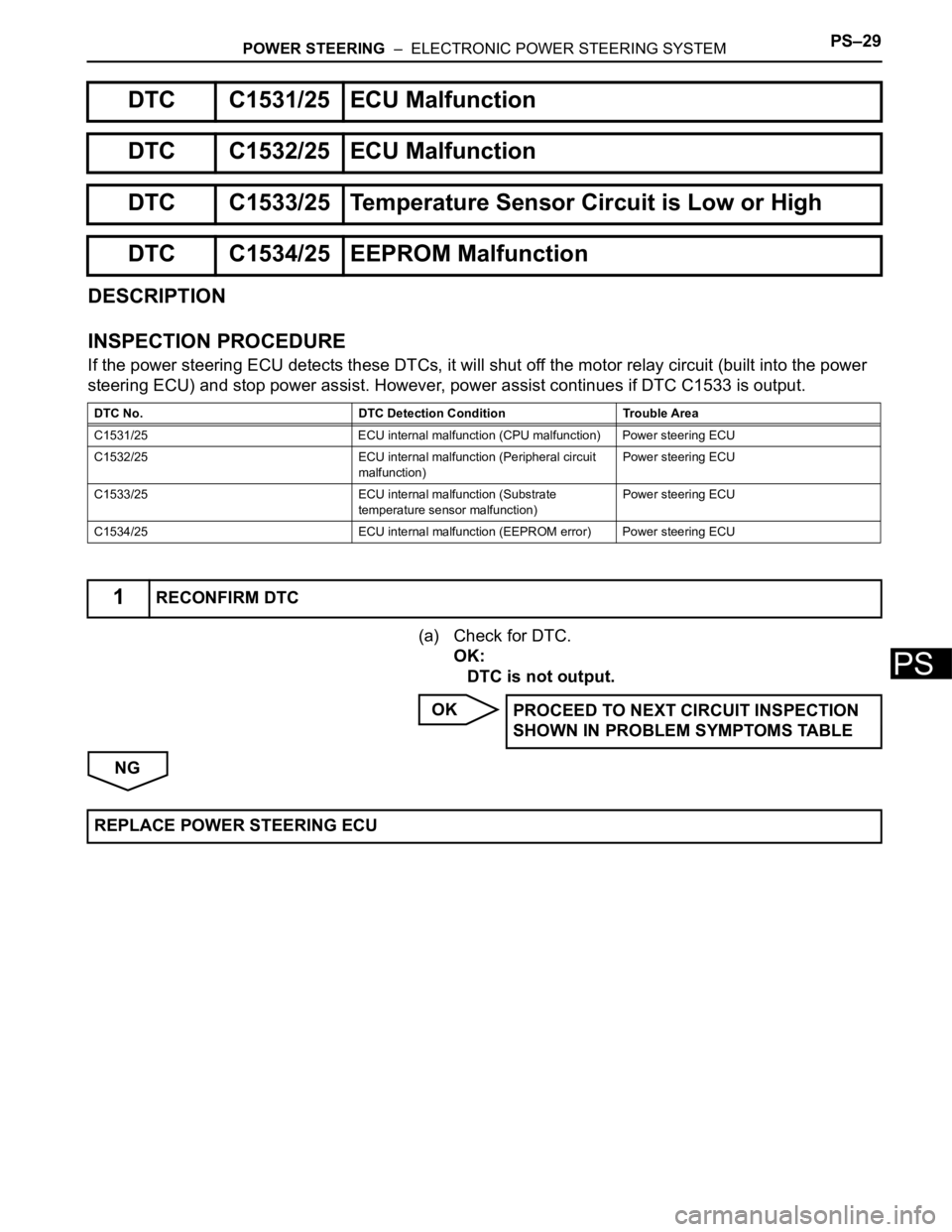

DTC C1531/25 ECU Malfunction

DTC C1532/25 ECU Malfunction

DTC C1533/25 Temperature Sensor Circuit is Low or High

DTC C1534/25 EEPROM Malfunction

DTC No. DTC Detection Condition Trouble Area

C1531/25 ECU internal malfunction (CPU malfunction) Power steering ECU

C1532/25 ECU internal malfunction (Peripheral circuit

malfunction)Power steering ECU

C1533/25 ECU internal malfunction (Substrate

temperature sensor malfunction)Power steering ECU

C1534/25 ECU internal malfunction (EEPROM error) Power steering ECU

1RECONFIRM DTC

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

REPLACE POWER STEERING ECU

Page 1641 of 2000

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–13

AC

SYSTEM DESCRIPTION

1. GENERAL

(a) The air conditioning system has the following

features:

• In accordance with the temperature set using the

temperature control switch, the air conditioning

amplifier determines the outlet temperature

based on the input signals from various sensors.

In addition, corrections are made in accordance

with the signals from the water temperature

sensor to control the outlet air temperature.

• Controls the blower motor in accordance with the

airflow volume determined by the air conditioning

amplifier based on the input signals from various

sensors.

• Automatically changes the outlets in accordance

with the outlet mode ratio that is determined by

the air conditioning amplifier based on the input

signals from various sensors.

• Based on the signals from the ambient

temperature sensor, this system calculates the

outside temperature and indicates it in the multi-

information display in the combination meter

assembly.

• The left/right independent temperature control

and neural network control make air conditioner

control available to suit the persons in the driver

seat and in the passenger seat.

• Turns the rear defogger and outside rear mirror

heaters on for 15 minutes when the rear

defogger switch is pressed. Turns them off if the

switch is pressed while they are operating.

• Checks the sensors in accordance with the

operation of the air conditioner switches.

• The air conditioning amplifier has the function of

controlling the indicator lighting.