fuse TOYOTA RAV4 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1353 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–25

TF

(a) Clear the DTC (see page TF-16).

(b) Turn the ignition switch ON and check that no CAN

communication system DTC is output.

(c) Start the engine.

(d) Drive the vehicle, accelerate to a speed of 3 km/h (2

mph) or more, and check that no speed sensor DTC

(brake control system DTC) is output (see page BC-57).

Result

B

C

A

(a) Remove the ECU-IG1 fuse from the instrument junction

block

(b) Measure the resistance of the fuse.

Standard resistance:

Below 1

HINT:

Check for short circuits in all harnesses and connector

connected to the ECU-IG1 fuse (see page IN-5).

NG

OK

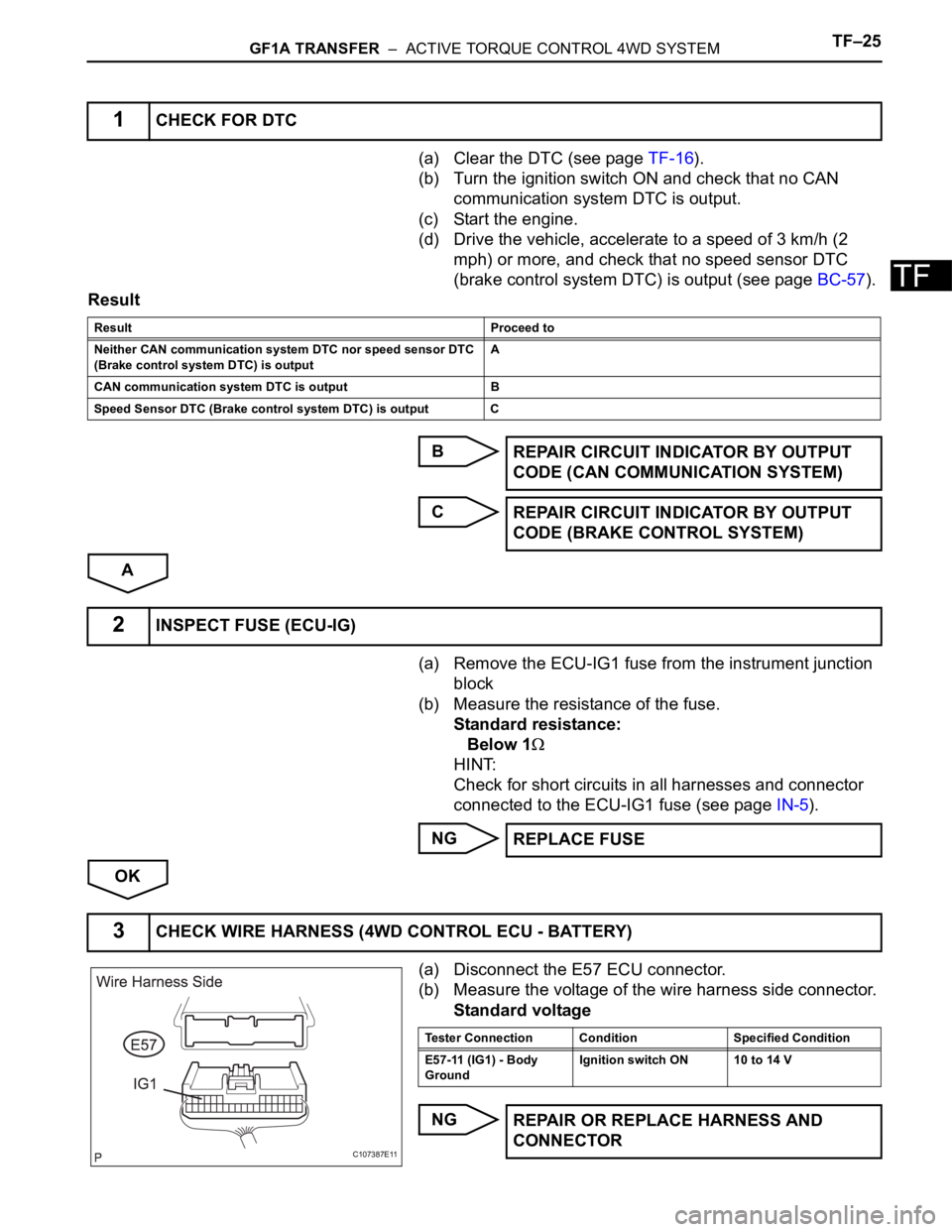

(a) Disconnect the E57 ECU connector.

(b) Measure the voltage of the wire harness side connector.

Standard voltage

NG

1CHECK FOR DTC

Result Proceed to

Neither CAN communication system DTC nor speed sensor DTC

(Brake control system DTC) is outputA

CAN communication system DTC is output B

Speed Sensor DTC (Brake control system DTC) is output C

REPAIR CIRCUIT INDICATOR BY OUTPUT

CODE (CAN COMMUNICATION SYSTEM)

REPAIR CIRCUIT INDICATOR BY OUTPUT

CODE (BRAKE CONTROL SYSTEM)

2INSPECT FUSE (ECU-IG)

REPLACE FUSE

3CHECK WIRE HARNESS (4WD CONTROL ECU - BATTERY)

C107387E11

Tester Connection Condition Specified Condition

E57-11 (IG1) - Body

GroundIgnition switch ON 10 to 14 V

REPAIR OR REPLACE HARNESS AND

CONNECTOR

Page 1490 of 2000

TW–18TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW

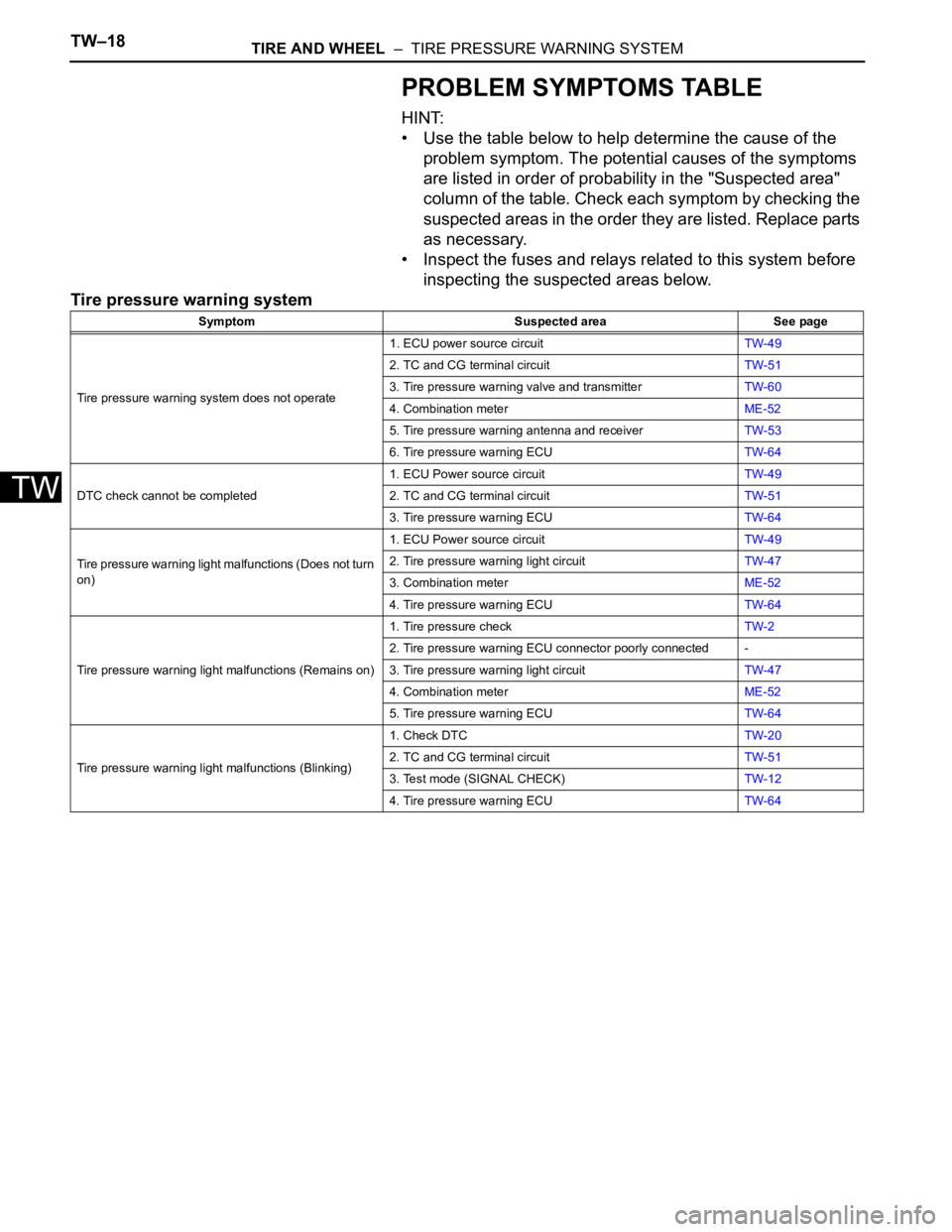

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

Tire pressure warning system

Symptom Suspected area See page

Tire pressure warning system does not operate1. ECU power source circuitTW-49

2. TC and CG terminal circuitTW-51

3. Tire pressure warning valve and transmitterTW-60

4. Combination meterME-52

5. Tire pressure warning antenna and receiverTW-53

6. Tire pressure warning ECUTW-64

DTC check cannot be completed1. ECU Power source circuitTW-49

2. TC and CG terminal circuitTW-51

3. Tire pressure warning ECUTW-64

Tire pressure warning light malfunctions (Does not turn

on)1. ECU Power source circuitTW-49

2. Tire pressure warning light circuitTW-47

3. Combination meterME-52

4. Tire pressure warning ECUTW-64

Tire pressure warning light malfunctions (Remains on)1. Tire pressure checkTW-2

2. Tire pressure warning ECU connector poorly connected -

3. Tire pressure warning light circuitTW-47

4. Combination meterME-52

5. Tire pressure warning ECUTW-64

Tire pressure warning light malfunctions (Blinking)1. Check DTCTW-20

2. TC and CG terminal circuitTW-51

3. Test mode (SIGNAL CHECK)TW-12

4. Tire pressure warning ECUTW-64

Page 1545 of 2000

BC–42BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

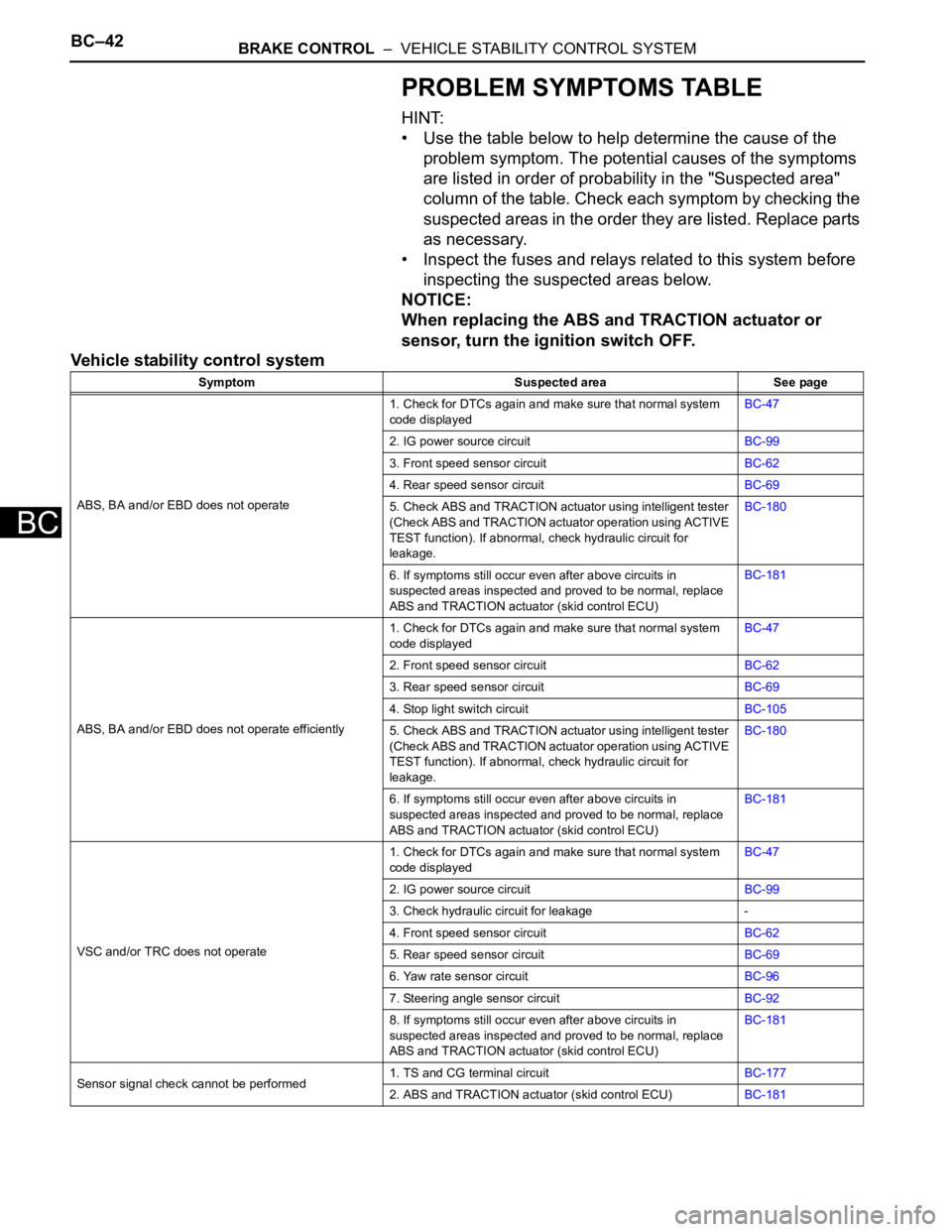

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

NOTICE:

When replacing the ABS and TRACTION actuator or

sensor, turn the ignition switch OFF.

Vehicle stability control system

Symptom Suspected area See page

ABS, BA and/or EBD does not operate1. Check for DTCs again and make sure that normal system

code displayedBC-47

2. IG power source circuitBC-99

3. Front speed sensor circuitBC-62

4. Rear speed sensor circuitBC-69

5. Check ABS and TRACTION actuator using intelligent tester

(Check ABS and TRACTION actuator operation using ACTIVE

TEST function). If abnormal, check hydraulic circuit for

leakage.BC-180

6. If symptoms still occur even after above circuits in

suspected areas inspected and proved to be normal, replace

ABS and TRACTION actuator (skid control ECU)BC-181

ABS, BA and/or EBD does not operate efficiently1. Check for DTCs again and make sure that normal system

code displayedBC-47

2. Front speed sensor circuitBC-62

3. Rear speed sensor circuitBC-69

4. Stop light switch circuitBC-105

5. Check ABS and TRACTION actuator using intelligent tester

(Check ABS and TRACTION actuator operation using ACTIVE

TEST function). If abnormal, check hydraulic circuit for

leakage.BC-180

6. If symptoms still occur even after above circuits in

suspected areas inspected and proved to be normal, replace

ABS and TRACTION actuator (skid control ECU)BC-181

VSC and/or TRC does not operate1. Check for DTCs again and make sure that normal system

code displayedBC-47

2. IG power source circuitBC-99

3. Check hydraulic circuit for leakage -

4. Front speed sensor circuitBC-62

5. Rear speed sensor circuitBC-69

6. Yaw rate sensor circuitBC-96

7. Steering angle sensor circuitBC-92

8. If symptoms still occur even after above circuits in

suspected areas inspected and proved to be normal, replace

ABS and TRACTION actuator (skid control ECU)BC-181

Sensor signal check cannot be performed1. TS and CG terminal circuitBC-177

2. ABS and TRACTION actuator (skid control ECU)BC-181

Page 1555 of 2000

BC–52BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

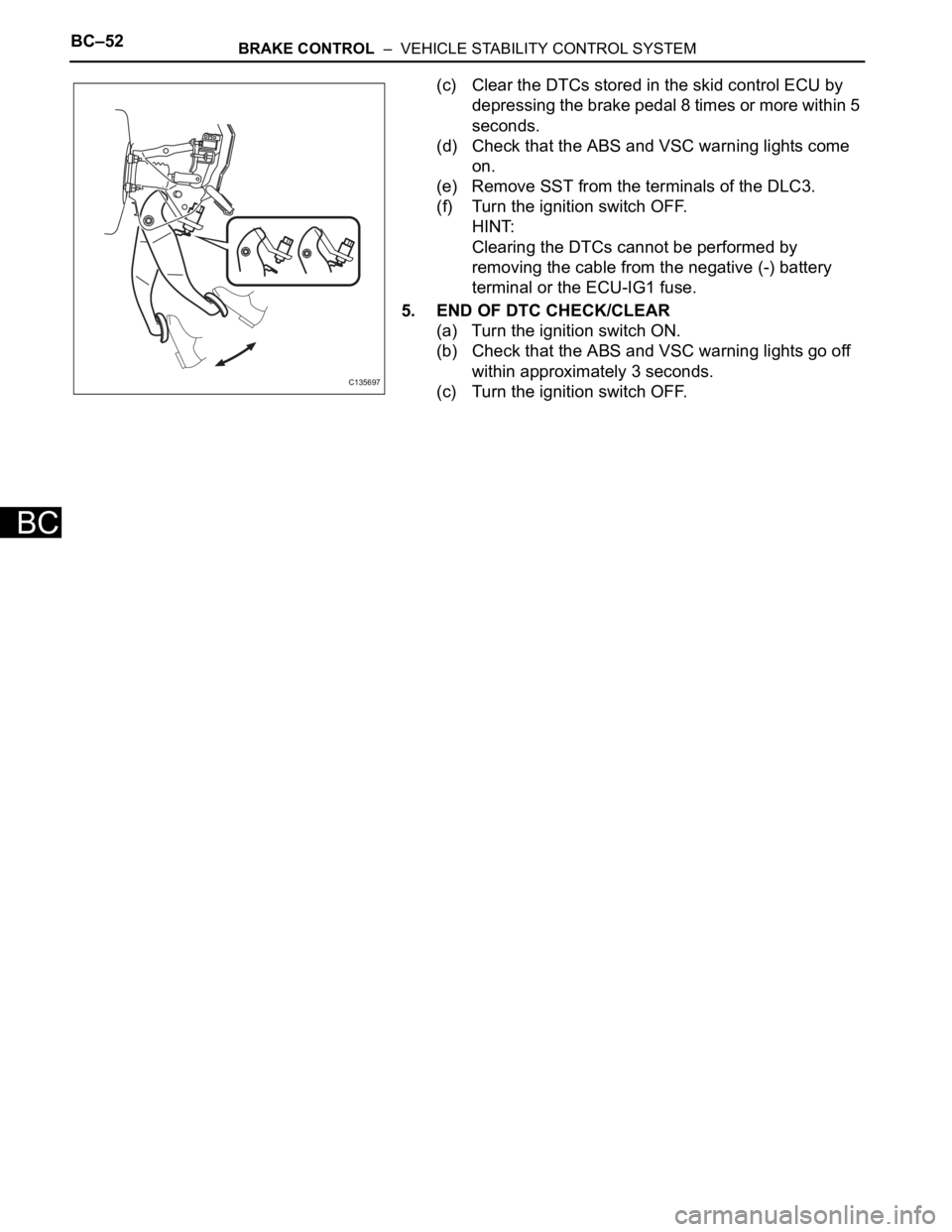

(c) Clear the DTCs stored in the skid control ECU by

depressing the brake pedal 8 times or more within 5

seconds.

(d) Check that the ABS and VSC warning lights come

on.

(e) Remove SST from the terminals of the DLC3.

(f) Turn the ignition switch OFF.

HINT:

Clearing the DTCs cannot be performed by

removing the cable from the negative (-) battery

terminal or the ECU-IG1 fuse.

5. END OF DTC CHECK/CLEAR

(a) Turn the ignition switch ON.

(b) Check that the ABS and VSC warning lights go off

within approximately 3 seconds.

(c) Turn the ignition switch OFF.

C135697

Page 1619 of 2000

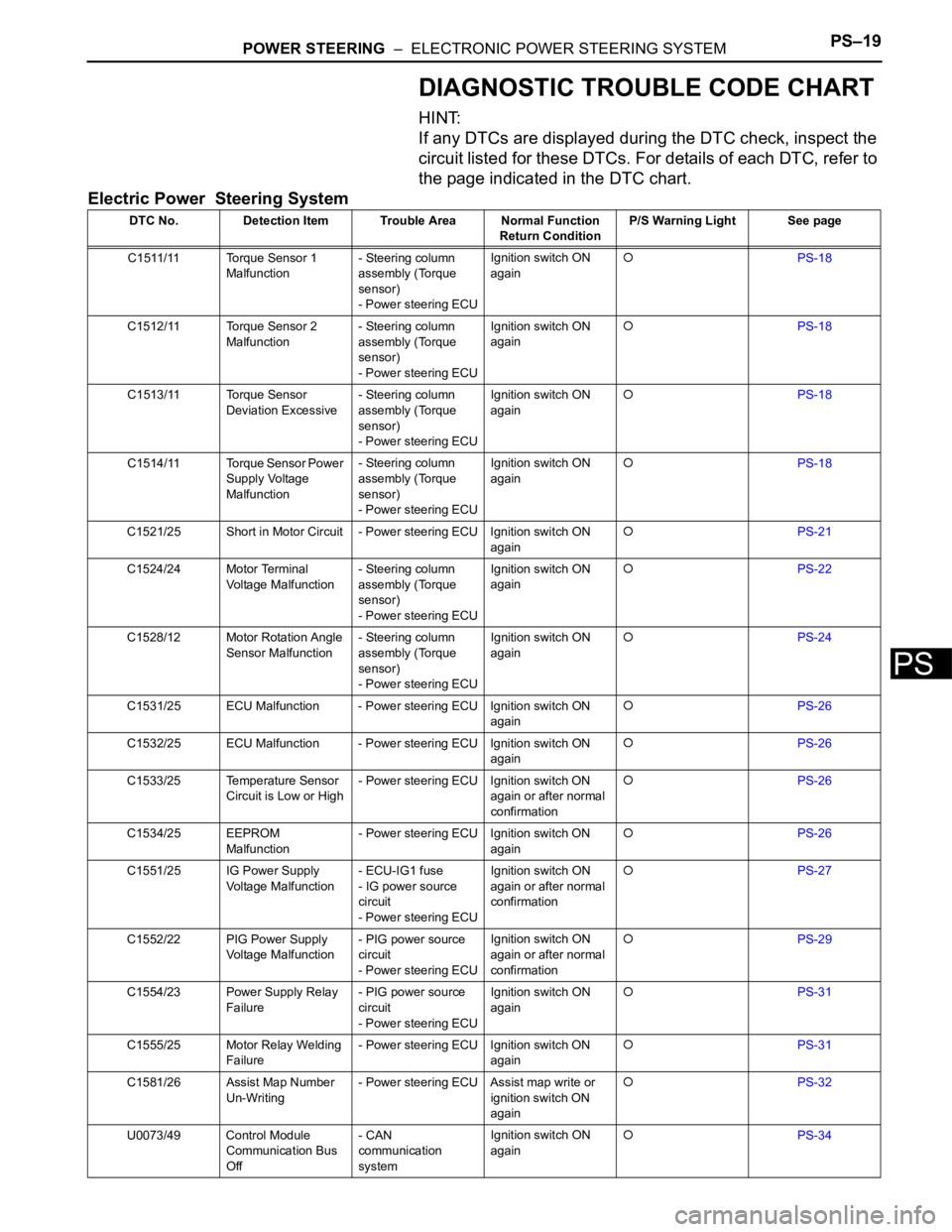

POWER STEERING – ELECTRONIC POWER STEERING SYSTEMPS–19

PS

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If any DTCs are displayed during the DTC check, inspect the

circuit listed for these DTCs. For details of each DTC, refer to

the page indicated in the DTC chart.

Electric Power Steering System

DTC No. Detection Item Trouble Area Normal Function

Return ConditionP/S Warning Light See page

C1511/11 Torque Sensor 1

Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-18

C1512/11 Torque Sensor 2

Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-18

C1513/11 Torque Sensor

Deviation Excessive- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-18

C1514/11 Torque Sensor Power

Supply Voltage

Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-18

C1521/25 Short in Motor Circuit - Power steering ECU Ignition switch ON

again

PS-21

C1524/24 Motor Terminal

Voltage Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-22

C1528/12 Motor Rotation Angle

Sensor Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-24

C1531/25 ECU Malfunction - Power steering ECU Ignition switch ON

again

PS-26

C1532/25 ECU Malfunction - Power steering ECU Ignition switch ON

again

PS-26

C1533/25 Temperature Sensor

Circuit is Low or High- Power steering ECU Ignition switch ON

again or after normal

confirmation

PS-26

C1534/25 EEPROM

Malfunction- Power steering ECU Ignition switch ON

again

PS-26

C1551/25 IG Power Supply

Voltage Malfunction- ECU-IG1 fuse

- IG power source

circuit

- Power steering ECUIgnition switch ON

again or after normal

confirmation

PS-27

C1552/22 PIG Power Supply

Voltage Malfunction- PIG power source

circuit

- Power steering ECUIgnition switch ON

again or after normal

confirmation

PS-29

C1554/23 Power Supply Relay

Failure- PIG power source

circuit

- Power steering ECUIgnition switch ON

again

PS-31

C1555/25 Motor Relay Welding

Failure- Power steering ECU Ignition switch ON

again

PS-31

C1581/26 Assist Map Number

Un-Writing- Power steering ECU Assist map write or

ignition switch ON

again

PS-32

U0073/49 Control Module

Communication Bus

Off- CAN

communication

systemIgnition switch ON

again

PS-34

Page 1630 of 2000

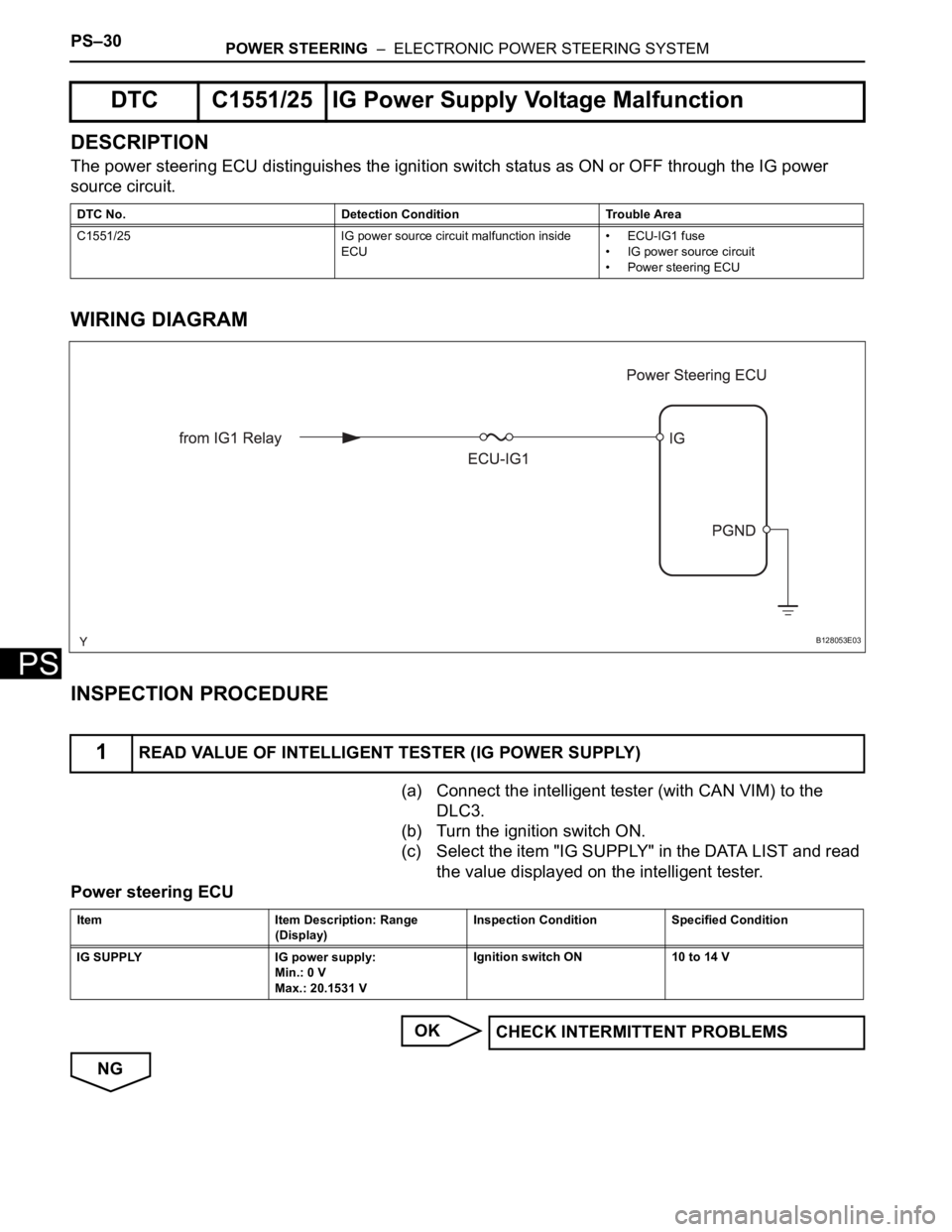

PS–30POWER STEERING – ELECTRONIC POWER STEERING SYSTEM

PS

DESCRIPTION

The power steering ECU distinguishes the ignition switch status as ON or OFF through the IG power

source circuit.

WIRING DIAGRAM

INSPECTION PROCEDURE

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON.

(c) Select the item "IG SUPPLY" in the DATA LIST and read

the value displayed on the intelligent tester.

Power steering ECU

OK

NG

DTC C1551/25 IG Power Supply Voltage Malfunction

DTC No. Detection Condition Trouble Area

C1551/25 IG power source circuit malfunction inside

ECU• ECU-IG1 fuse

• IG power source circuit

• Power steering ECU

1READ VALUE OF INTELLIGENT TESTER (IG POWER SUPPLY)

B128053E03

Item Item Description: Range

(Display)Inspection Condition Specified Condition

IG SUPPLY IG power supply:

Min.: 0 V

Max.: 20.1531 VIgnition switch ON 10 to 14 V

CHECK INTERMITTENT PROBLEMS

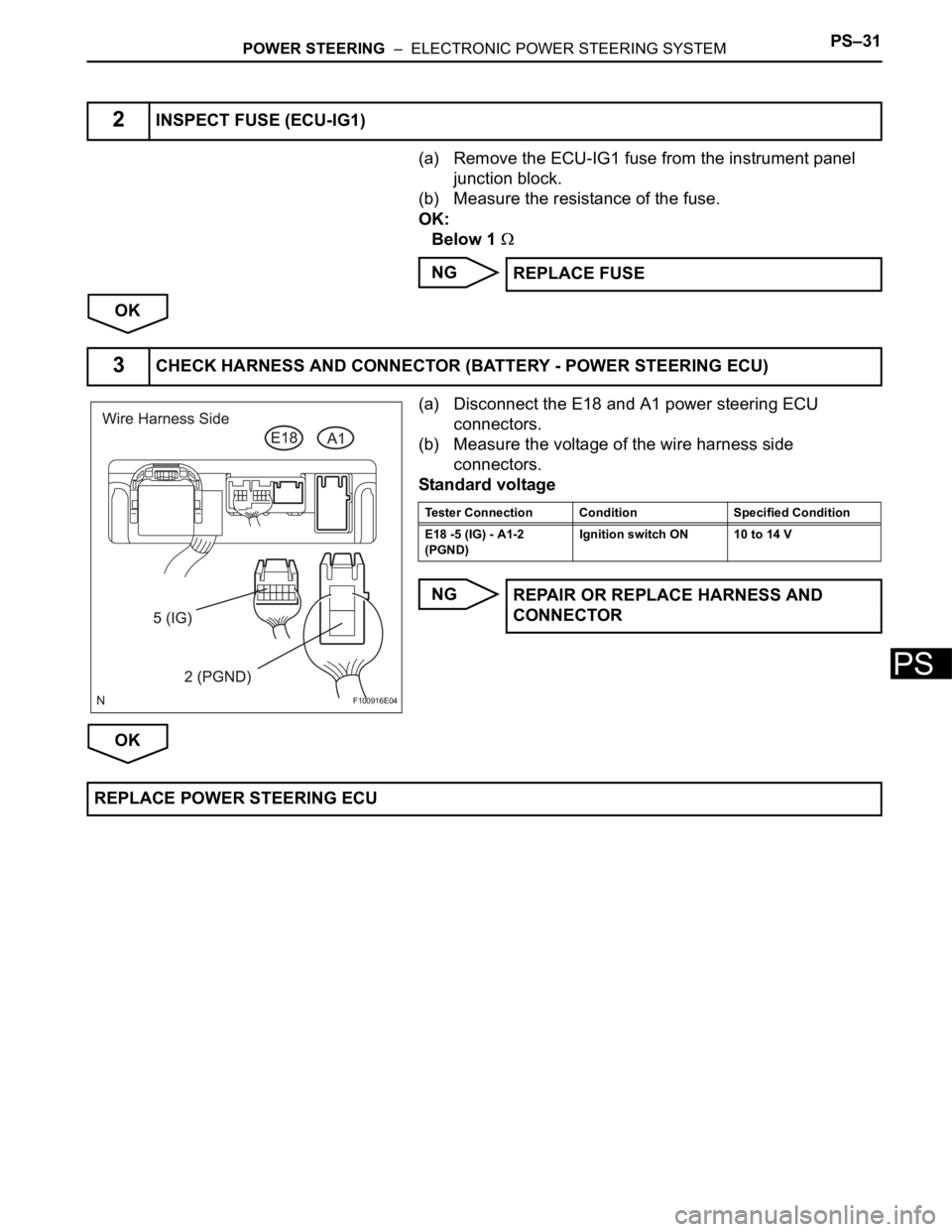

Page 1631 of 2000

POWER STEERING – ELECTRONIC POWER STEERING SYSTEMPS–31

PS

(a) Remove the ECU-IG1 fuse from the instrument panel

junction block.

(b) Measure the resistance of the fuse.

OK:

Below 1

NG

OK

(a) Disconnect the E18 and A1 power steering ECU

connectors.

(b) Measure the voltage of the wire harness side

connectors.

Standard voltage

NG

OK

2INSPECT FUSE (ECU-IG1)

REPLACE FUSE

3CHECK HARNESS AND CONNECTOR (BATTERY - POWER STEERING ECU)

F100916E04

Tester Connection Condition Specified Condition

E18 -5 (IG) - A1-2

(PGND)Ignition switch ON 10 to 14 V

REPAIR OR REPLACE HARNESS AND

CONNECTOR

REPLACE POWER STEERING ECU

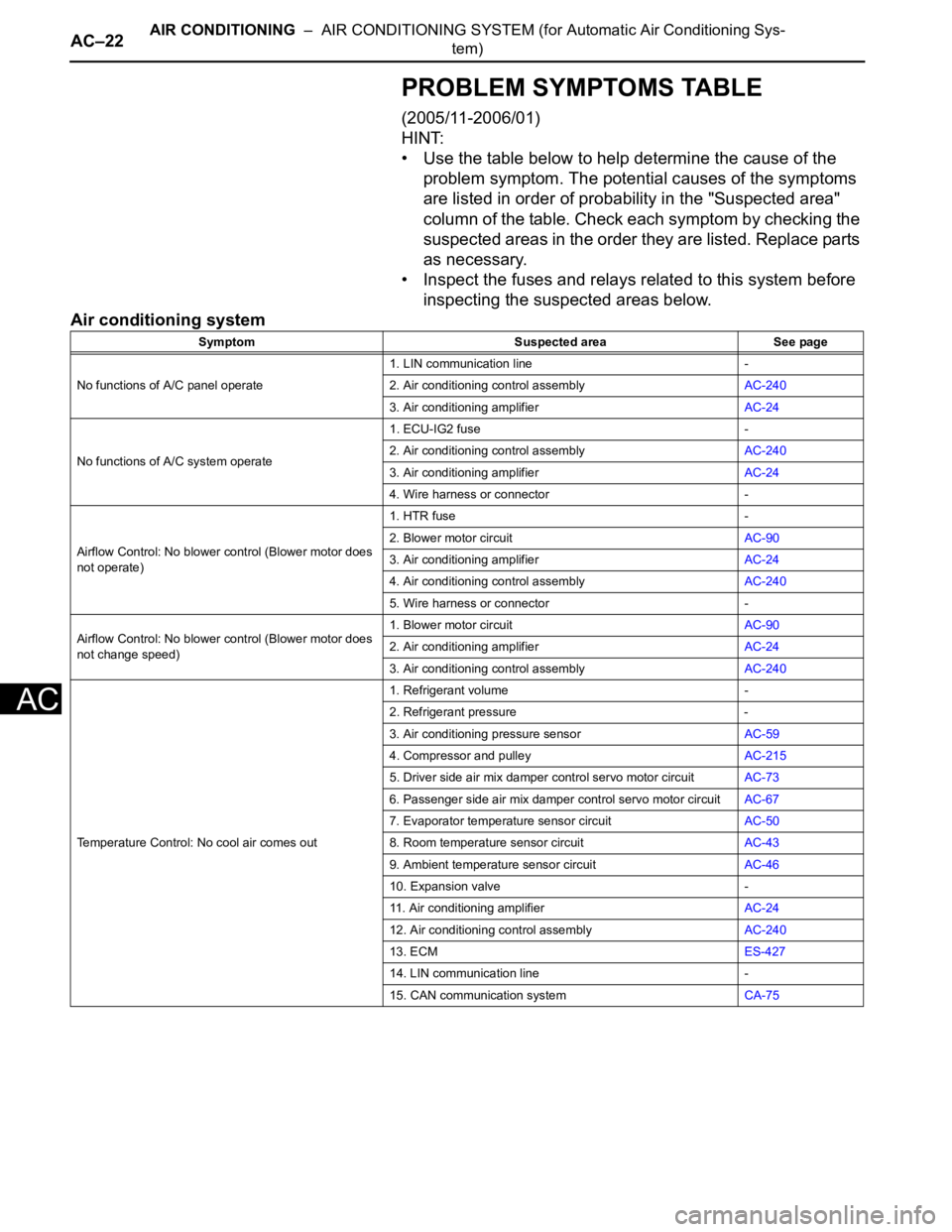

Page 1650 of 2000

AC–22AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

PROBLEM SYMPTOMS TABLE

(2005/11-2006/01)

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

Air conditioning system

Symptom Suspected area See page

No functions of A/C panel operate1. LIN communication line -

2. Air conditioning control assemblyAC-240

3. Air conditioning amplifierAC-24

No functions of A/C system operate1. ECU-IG2 fuse -

2. Air conditioning control assemblyAC-240

3. Air conditioning amplifierAC-24

4. Wire harness or connector -

Airflow Control: No blower control (Blower motor does

not operate)1. HTR fuse -

2. Blower motor circuitAC-90

3. Air conditioning amplifierAC-24

4. Air conditioning control assemblyAC-240

5. Wire harness or connector -

Airflow Control: No blower control (Blower motor does

not change speed)1. Blower motor circuitAC-90

2. Air conditioning amplifierAC-24

3. Air conditioning control assemblyAC-240

Temperature Control: No cool air comes out1. Refrigerant volume -

2. Refrigerant pressure -

3. Air conditioning pressure sensorAC-59

4. Compressor and pulleyAC-215

5. Driver side air mix damper control servo motor circuitAC-73

6. Passenger side air mix damper control servo motor circuitAC-67

7. Evaporator temperature sensor circuitAC-50

8. Room temperature sensor circuitAC-43

9. Ambient temperature sensor circuitAC-46

10. Expansion valve -

11. Air conditioning amplifierAC-24

12. Air conditioning control assemblyAC-240

13. ECMES-427

14. LIN communication line -

15. CAN communication systemCA-75

Page 1652 of 2000

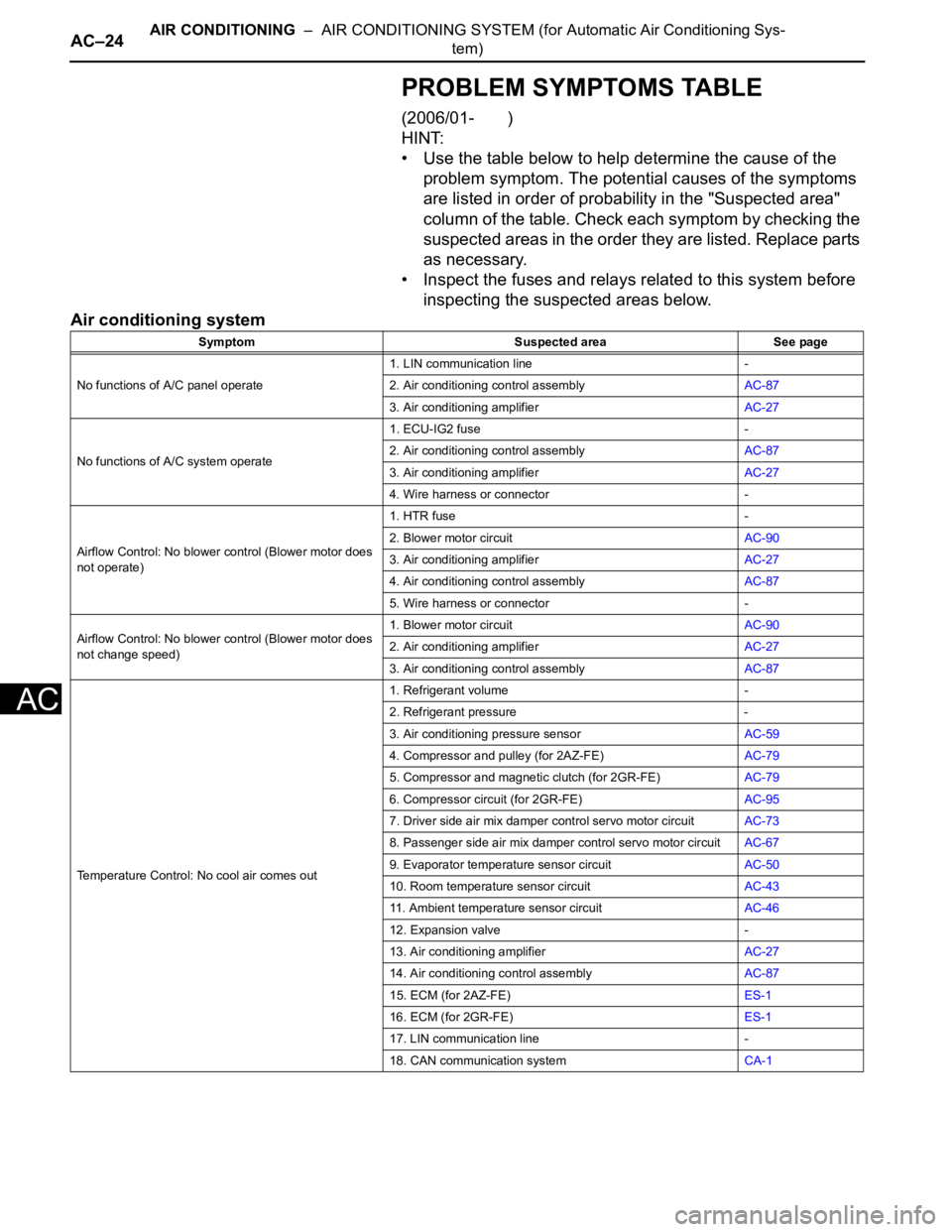

AC–24AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

PROBLEM SYMPTOMS TABLE

(2006/01- )

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

Air conditioning system

Symptom Suspected area See page

No functions of A/C panel operate1. LIN communication line -

2. Air conditioning control assemblyAC-87

3. Air conditioning amplifierAC-27

No functions of A/C system operate1. ECU-IG2 fuse -

2. Air conditioning control assemblyAC-87

3. Air conditioning amplifierAC-27

4. Wire harness or connector -

Airflow Control: No blower control (Blower motor does

not operate)1. HTR fuse -

2. Blower motor circuitAC-90

3. Air conditioning amplifierAC-27

4. Air conditioning control assemblyAC-87

5. Wire harness or connector -

Airflow Control: No blower control (Blower motor does

not change speed)1. Blower motor circuitAC-90

2. Air conditioning amplifierAC-27

3. Air conditioning control assemblyAC-87

Temperature Control: No cool air comes out1. Refrigerant volume -

2. Refrigerant pressure -

3. Air conditioning pressure sensorAC-59

4. Compressor and pulley (for 2AZ-FE)AC-79

5. Compressor and magnetic clutch (for 2GR-FE)AC-79

6. Compressor circuit (for 2GR-FE)AC-95

7. Driver side air mix damper control servo motor circuitAC-73

8. Passenger side air mix damper control servo motor circuitAC-67

9. Evaporator temperature sensor circuitAC-50

10. Room temperature sensor circuitAC-43

11. Ambient temperature sensor circuitAC-46

12. Expansion valve -

13. Air conditioning amplifierAC-27

14. Air conditioning control assemblyAC-87

15. ECM (for 2AZ-FE)ES-1

16. ECM (for 2GR-FE)ES-1

17. LIN communication line -

18. CAN communication systemCA-1

Page 1686 of 2000

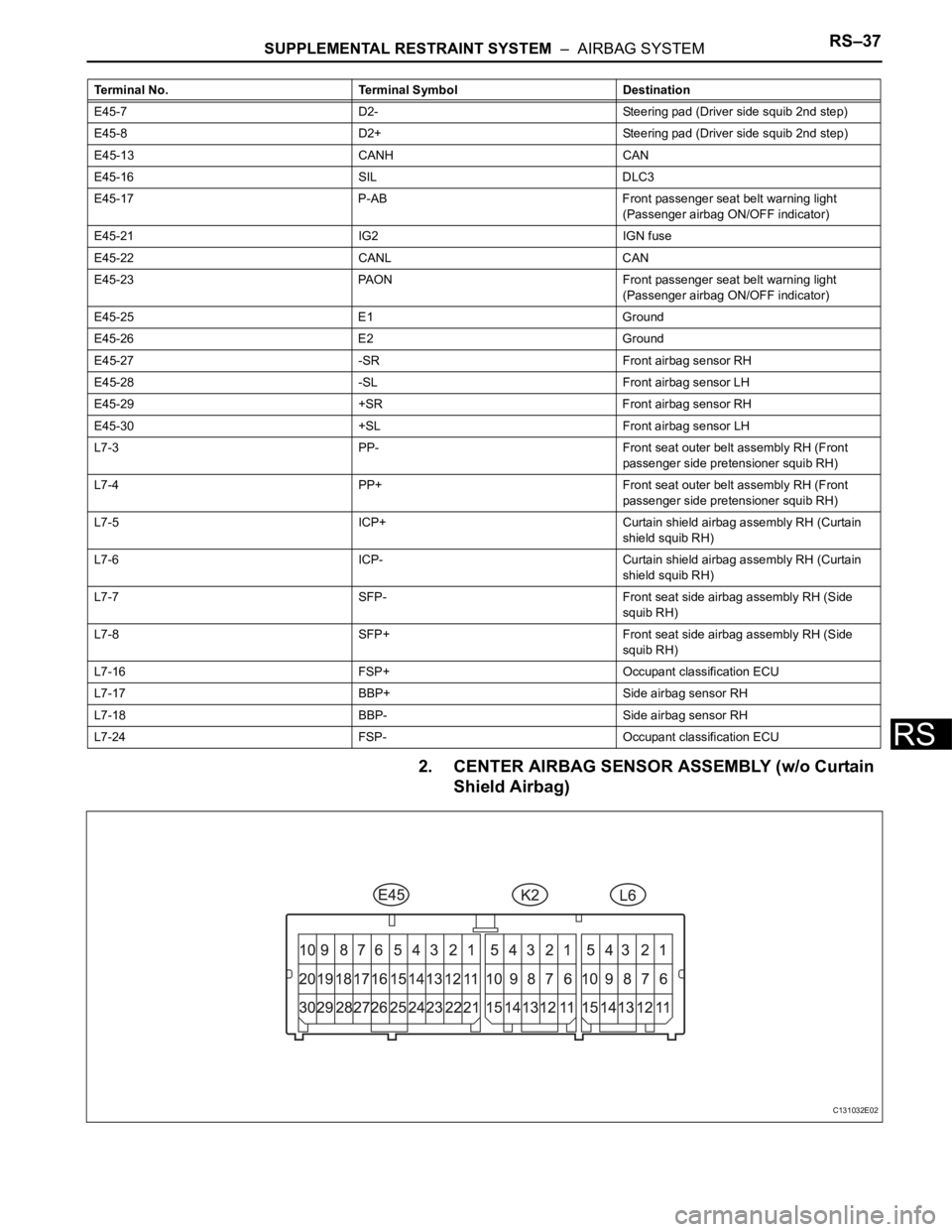

SUPPLEMENTAL RESTRAINT SYSTEM – AIRBAG SYSTEMRS–37

RS

2. CENTER AIRBAG SENSOR ASSEMBLY (w/o Curtain

Shield Airbag)

E45-7 D2- Steering pad (Driver side squib 2nd step)

E45-8 D2+ Steering pad (Driver side squib 2nd step)

E45-13 CANH CAN

E45-16 SIL DLC3

E45-17 P-AB Front passenger seat belt warning light

(Passenger airbag ON/OFF indicator)

E45-21 IG2 IGN fuse

E45-22 CANL CAN

E45-23 PAON Front passenger seat belt warning light

(Passenger airbag ON/OFF indicator)

E45-25 E1 Ground

E45-26 E2 Ground

E45-27 -SR Front airbag sensor RH

E45-28 -SL Front airbag sensor LH

E45-29 +SR Front airbag sensor RH

E45-30 +SL Front airbag sensor LH

L7-3 PP- Front seat outer belt assembly RH (Front

passenger side pretensioner squib RH)

L7-4 PP+ Front seat outer belt assembly RH (Front

passenger side pretensioner squib RH)

L7-5 ICP+ Curtain shield airbag assembly RH (Curtain

shield squib RH)

L7-6 ICP- Curtain shield airbag assembly RH (Curtain

shield squib RH)

L7-7 SFP- Front seat side airbag assembly RH (Side

squib RH)

L7-8 SFP+ Front seat side airbag assembly RH (Side

squib RH)

L7-16 FSP+ Occupant classification ECU

L7-17 BBP+ Side airbag sensor RH

L7-18 BBP- Side airbag sensor RH

L7-24 FSP- Occupant classification ECU Terminal No. Terminal Symbol Destination

C131032E02