Control arm TOYOTA RAV4 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1457 of 2000

AXLE – REAR AXLE HUB AND BEARINGAH–17

AH

REMOVAL

1. REMOVE REAR WHEEL

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

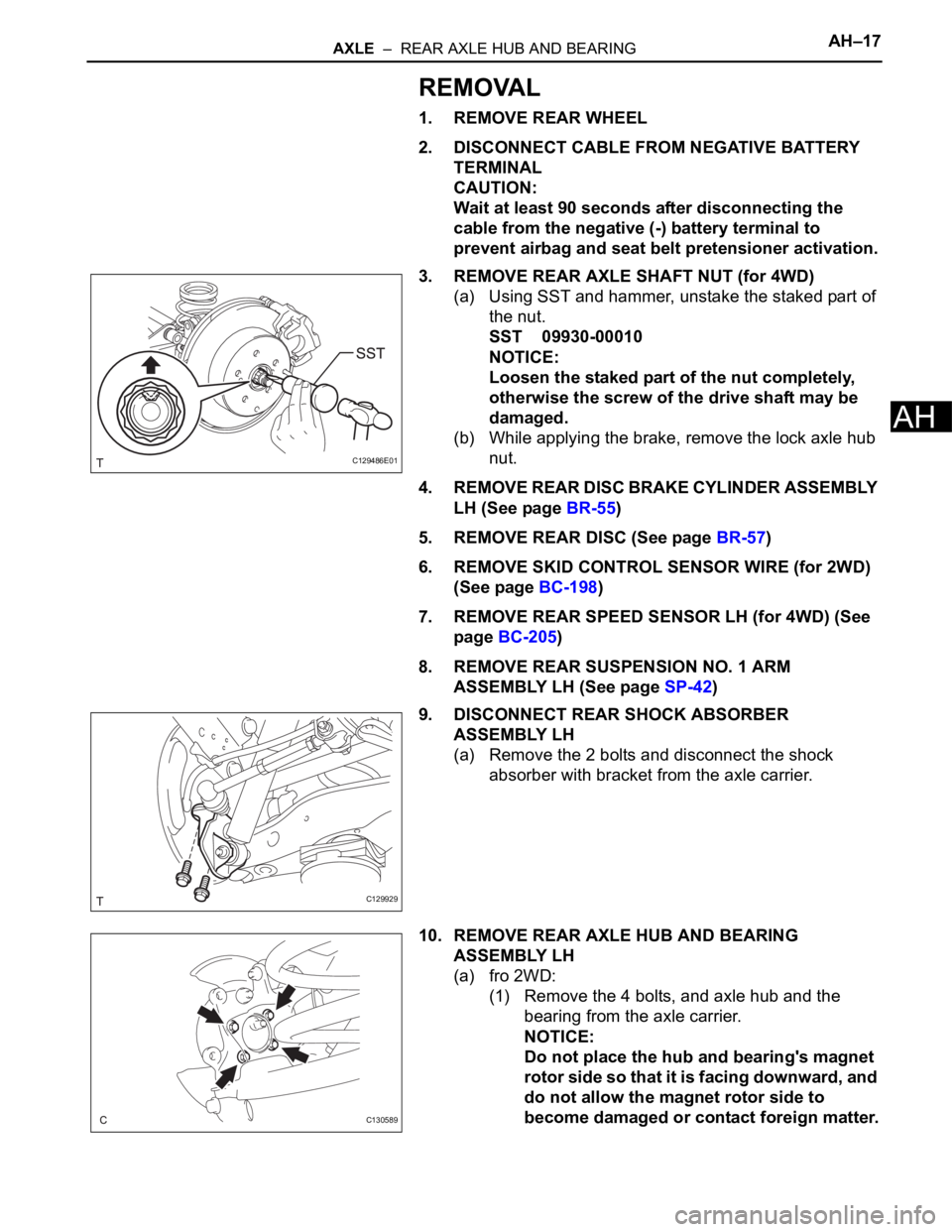

3. REMOVE REAR AXLE SHAFT NUT (for 4WD)

(a) Using SST and hammer, unstake the staked part of

the nut.

SST 09930-00010

NOTICE:

Loosen the staked part of the nut completely,

otherwise the screw of the drive shaft may be

damaged.

(b) While applying the brake, remove the lock axle hub

nut.

4. REMOVE REAR DISC BRAKE CYLINDER ASSEMBLY

LH (See page BR-55)

5. REMOVE REAR DISC (See page BR-57)

6. REMOVE SKID CONTROL SENSOR WIRE (for 2WD)

(See page BC-198)

7. REMOVE REAR SPEED SENSOR LH (for 4WD) (See

page BC-205)

8. REMOVE REAR SUSPENSION NO. 1 ARM

ASSEMBLY LH (See page SP-42)

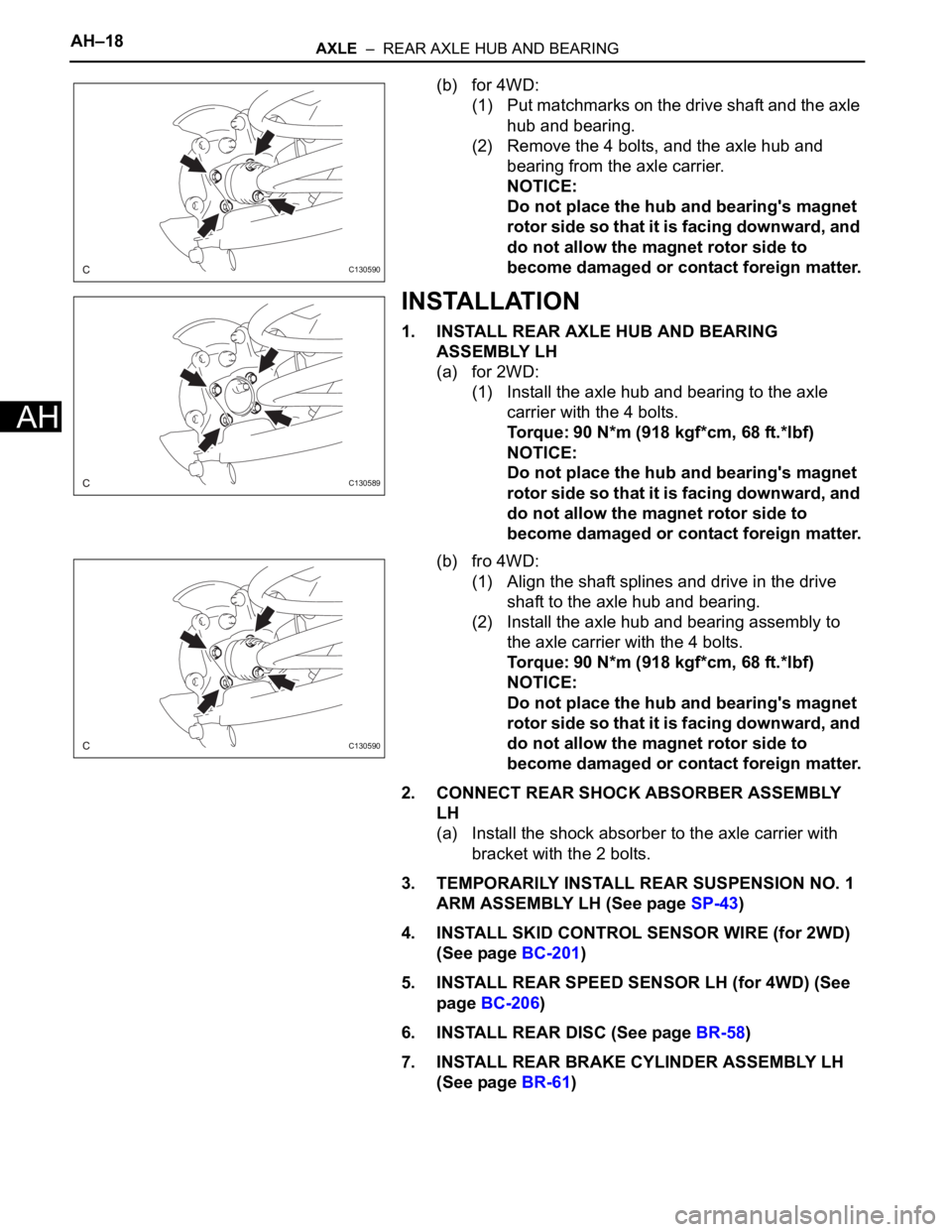

9. DISCONNECT REAR SHOCK ABSORBER

ASSEMBLY LH

(a) Remove the 2 bolts and disconnect the shock

absorber with bracket from the axle carrier.

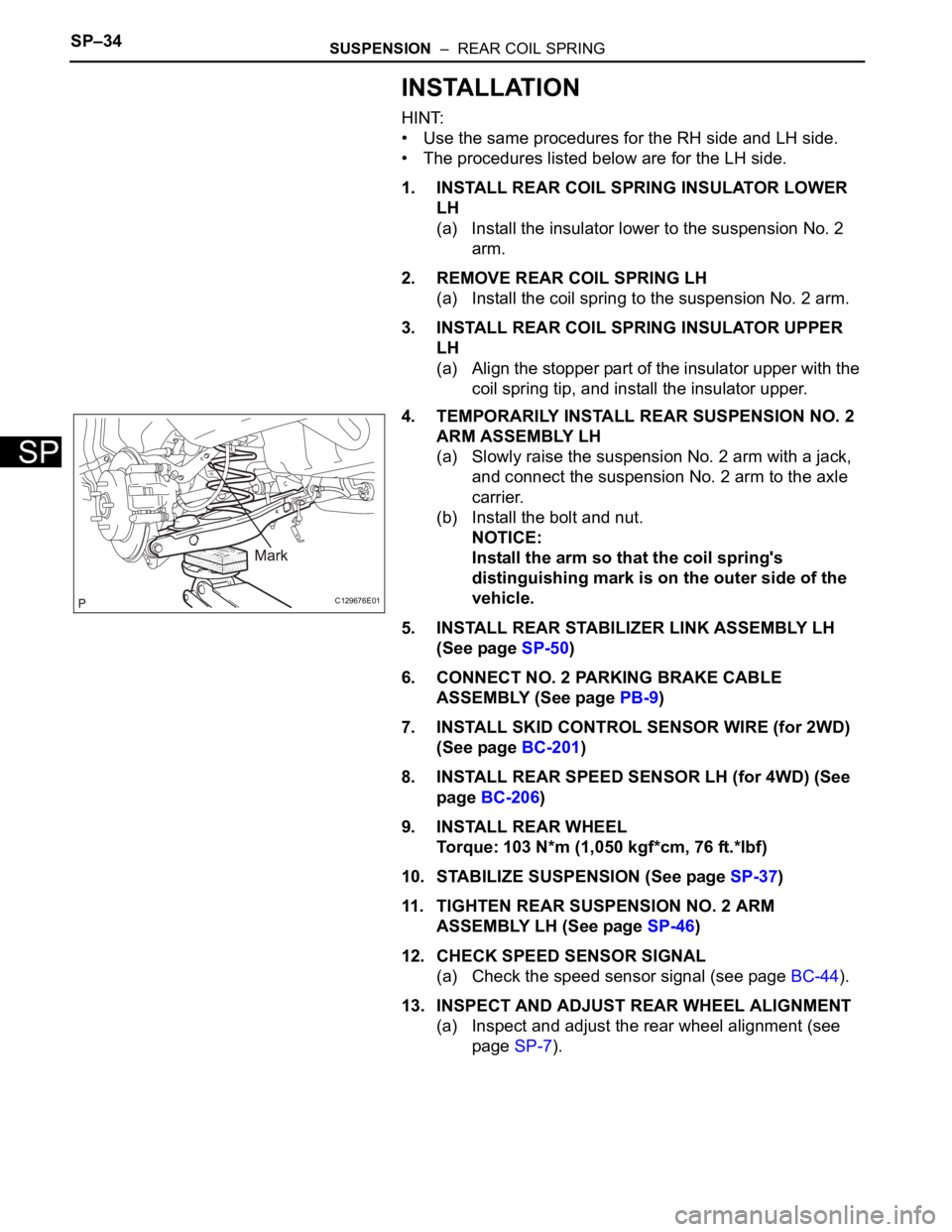

10. REMOVE REAR AXLE HUB AND BEARING

ASSEMBLY LH

(a) fro 2WD:

(1) Remove the 4 bolts, and axle hub and the

bearing from the axle carrier.

NOTICE:

Do not place the hub and bearing's magnet

rotor side so that it is facing downward, and

do not allow the magnet rotor side to

become damaged or contact foreign matter.

C129486E01

C129929

C130589

Page 1458 of 2000

AH–18AXLE – REAR AXLE HUB AND BEARING

AH

(b) for 4WD:

(1) Put matchmarks on the drive shaft and the axle

hub and bearing.

(2) Remove the 4 bolts, and the axle hub and

bearing from the axle carrier.

NOTICE:

Do not place the hub and bearing's magnet

rotor side so that it is facing downward, and

do not allow the magnet rotor side to

become damaged or contact foreign matter.

INSTALLATION

1. INSTALL REAR AXLE HUB AND BEARING

ASSEMBLY LH

(a) for 2WD:

(1) Install the axle hub and bearing to the axle

carrier with the 4 bolts.

Torque: 90 N*m (918 kgf*cm, 68 ft.*lbf)

NOTICE:

Do not place the hub and bearing's magnet

rotor side so that it is facing downward, and

do not allow the magnet rotor side to

become damaged or contact foreign matter.

(b) fro 4WD:

(1) Align the shaft splines and drive in the drive

shaft to the axle hub and bearing.

(2) Install the axle hub and bearing assembly to

the axle carrier with the 4 bolts.

Torque: 90 N*m (918 kgf*cm, 68 ft.*lbf)

NOTICE:

Do not place the hub and bearing's magnet

rotor side so that it is facing downward, and

do not allow the magnet rotor side to

become damaged or contact foreign matter.

2. CONNECT REAR SHOCK ABSORBER ASSEMBLY

LH

(a) Install the shock absorber to the axle carrier with

bracket with the 2 bolts.

3. TEMPORARILY INSTALL REAR SUSPENSION NO. 1

ARM ASSEMBLY LH (See page SP-43)

4. INSTALL SKID CONTROL SENSOR WIRE (for 2WD)

(See page BC-201)

5. INSTALL REAR SPEED SENSOR LH (for 4WD) (See

page BC-206)

6. INSTALL REAR DISC (See page BR-58)

7. INSTALL REAR BRAKE CYLINDER ASSEMBLY LH

(See page BR-61)

C130590

C130589

C130590

Page 1470 of 2000

SP–34SUSPENSION – REAR COIL SPRING

SP

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

1. INSTALL REAR COIL SPRING INSULATOR LOWER

LH

(a) Install the insulator lower to the suspension No. 2

arm.

2. REMOVE REAR COIL SPRING LH

(a) Install the coil spring to the suspension No. 2 arm.

3. INSTALL REAR COIL SPRING INSULATOR UPPER

LH

(a) Align the stopper part of the insulator upper with the

coil spring tip, and install the insulator upper.

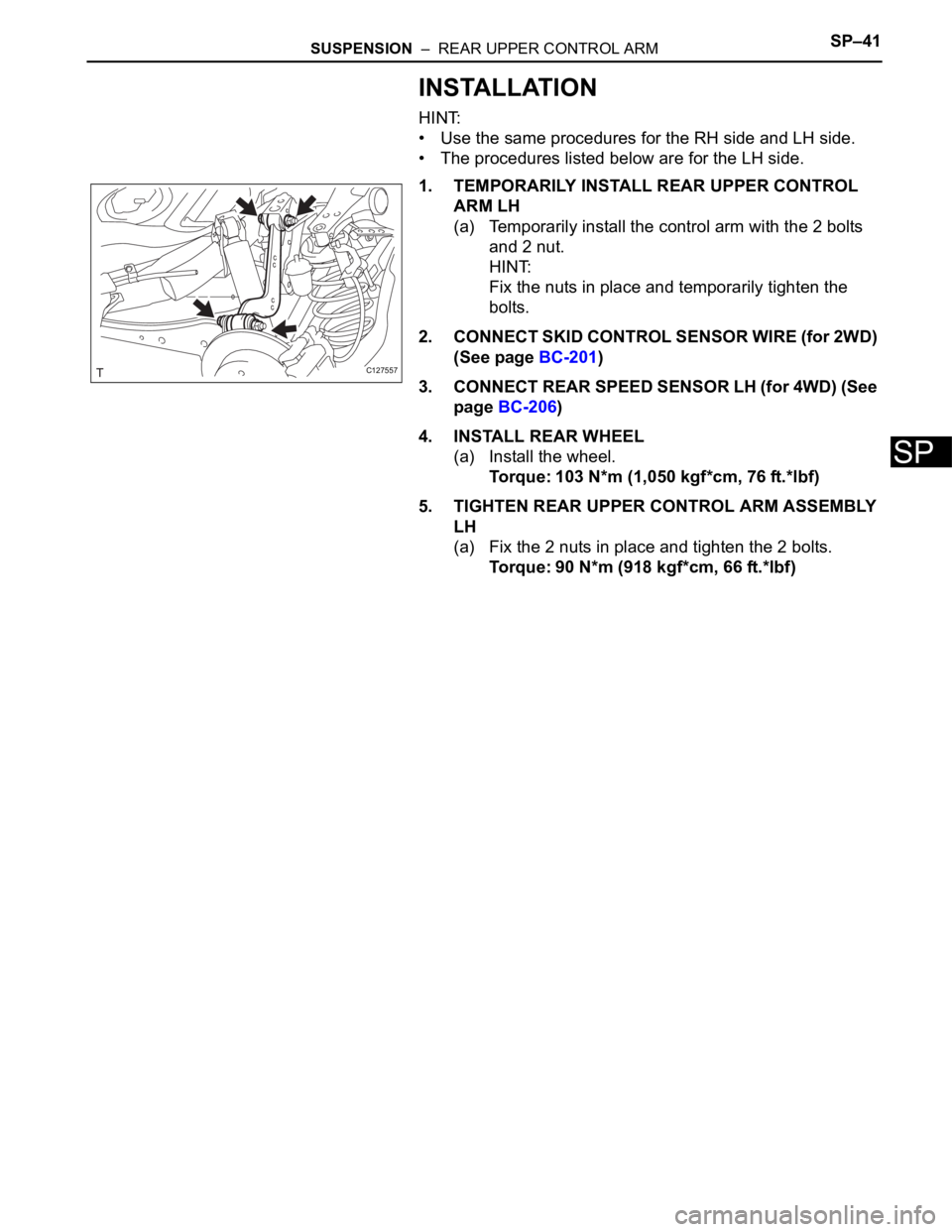

4. TEMPORARILY INSTALL REAR SUSPENSION NO. 2

ARM ASSEMBLY LH

(a) Slowly raise the suspension No. 2 arm with a jack,

and connect the suspension No. 2 arm to the axle

carrier.

(b) Install the bolt and nut.

NOTICE:

Install the arm so that the coil spring's

distinguishing mark is on the outer side of the

vehicle.

5. INSTALL REAR STABILIZER LINK ASSEMBLY LH

(See page SP-50)

6. CONNECT NO. 2 PARKING BRAKE CABLE

ASSEMBLY (See page PB-9)

7. INSTALL SKID CONTROL SENSOR WIRE (for 2WD)

(See page BC-201)

8. INSTALL REAR SPEED SENSOR LH (for 4WD) (See

page BC-206)

9. INSTALL REAR WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

10. STABILIZE SUSPENSION (See page SP-37)

11. TIGHTEN REAR SUSPENSION NO. 2 ARM

ASSEMBLY LH (See page SP-46)

12. CHECK SPEED SENSOR SIGNAL

(a) Check the speed sensor signal (see page BC-44).

13. INSPECT AND ADJUST REAR WHEEL ALIGNMENT

(a) Inspect and adjust the rear wheel alignment (see

page SP-7).

C129676E01

Page 1471 of 2000

SUSPENSION – REAR UPPER CONTROL ARMSP–41

SP

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

1. TEMPORARILY INSTALL REAR UPPER CONTROL

ARM LH

(a) Temporarily install the control arm with the 2 bolts

and 2 nut.

HINT:

Fix the nuts in place and temporarily tighten the

bolts.

2. CONNECT SKID CONTROL SENSOR WIRE (for 2WD)

(See page BC-201)

3. CONNECT REAR SPEED SENSOR LH (for 4WD) (See

page BC-206)

4. INSTALL REAR WHEEL

(a) Install the wheel.

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

5. TIGHTEN REAR UPPER CONTROL ARM ASSEMBLY

LH

(a) Fix the 2 nuts in place and tighten the 2 bolts.

Torque: 90 N*m (918 kgf*cm, 66 ft.*lbf)

C127557

Page 1473 of 2000

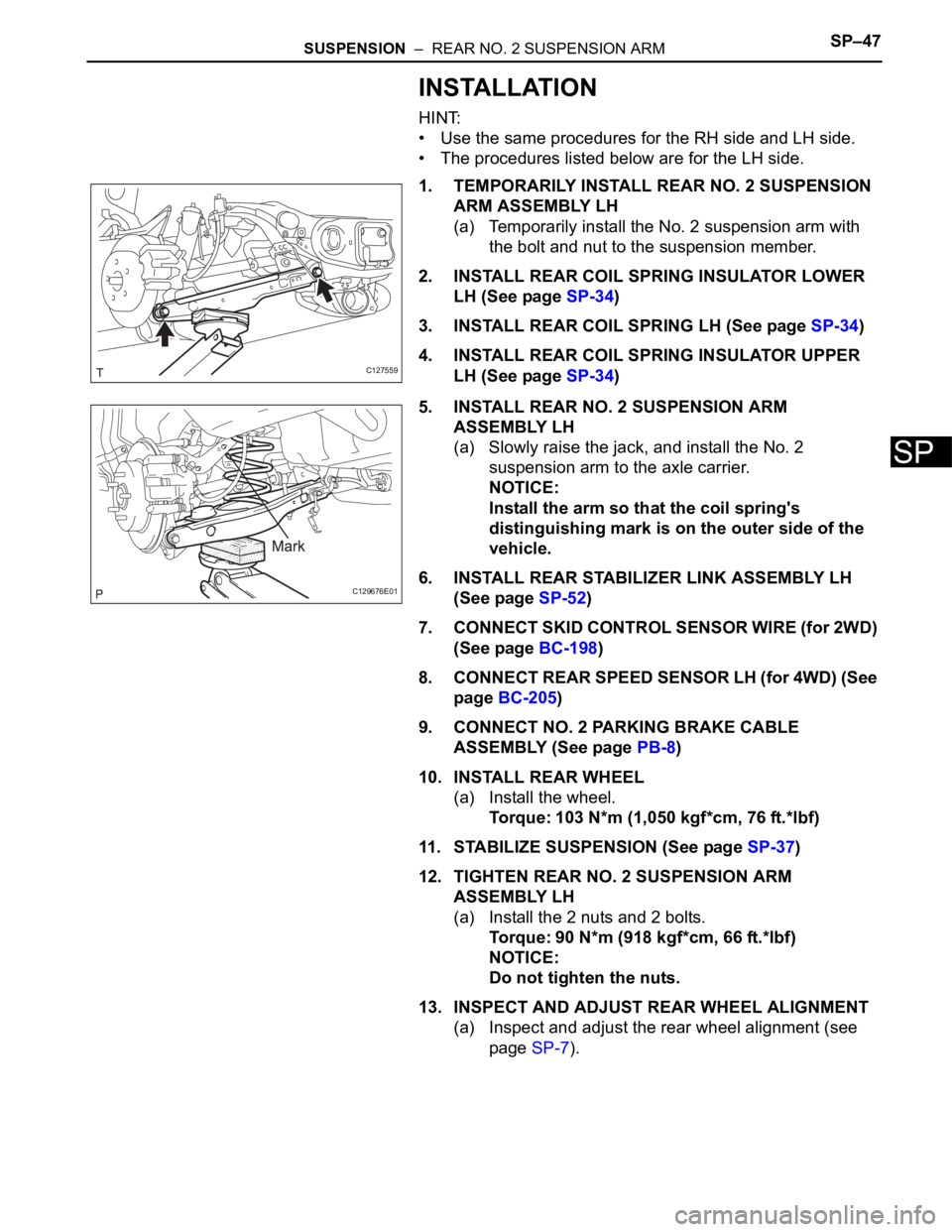

SUSPENSION – REAR NO. 2 SUSPENSION ARMSP–47

SP

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

1. TEMPORARILY INSTALL REAR NO. 2 SUSPENSION

ARM ASSEMBLY LH

(a) Temporarily install the No. 2 suspension arm with

the bolt and nut to the suspension member.

2. INSTALL REAR COIL SPRING INSULATOR LOWER

LH (See page SP-34)

3. INSTALL REAR COIL SPRING LH (See page SP-34)

4. INSTALL REAR COIL SPRING INSULATOR UPPER

LH (See page SP-34)

5. INSTALL REAR NO. 2 SUSPENSION ARM

ASSEMBLY LH

(a) Slowly raise the jack, and install the No. 2

suspension arm to the axle carrier.

NOTICE:

Install the arm so that the coil spring's

distinguishing mark is on the outer side of the

vehicle.

6. INSTALL REAR STABILIZER LINK ASSEMBLY LH

(See page SP-52)

7. CONNECT SKID CONTROL SENSOR WIRE (for 2WD)

(See page BC-198)

8. CONNECT REAR SPEED SENSOR LH (for 4WD) (See

page BC-205)

9. CONNECT NO. 2 PARKING BRAKE CABLE

ASSEMBLY (See page PB-8)

10. INSTALL REAR WHEEL

(a) Install the wheel.

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

11. STABILIZE SUSPENSION (See page SP-37)

12. TIGHTEN REAR NO. 2 SUSPENSION ARM

ASSEMBLY LH

(a) Install the 2 nuts and 2 bolts.

Torque: 90 N*m (918 kgf*cm, 66 ft.*lbf)

NOTICE:

Do not tighten the nuts.

13. INSPECT AND ADJUST REAR WHEEL ALIGNMENT

(a) Inspect and adjust the rear wheel alignment (see

page SP-7).

C127559

C129676E01

Page 1651 of 2000

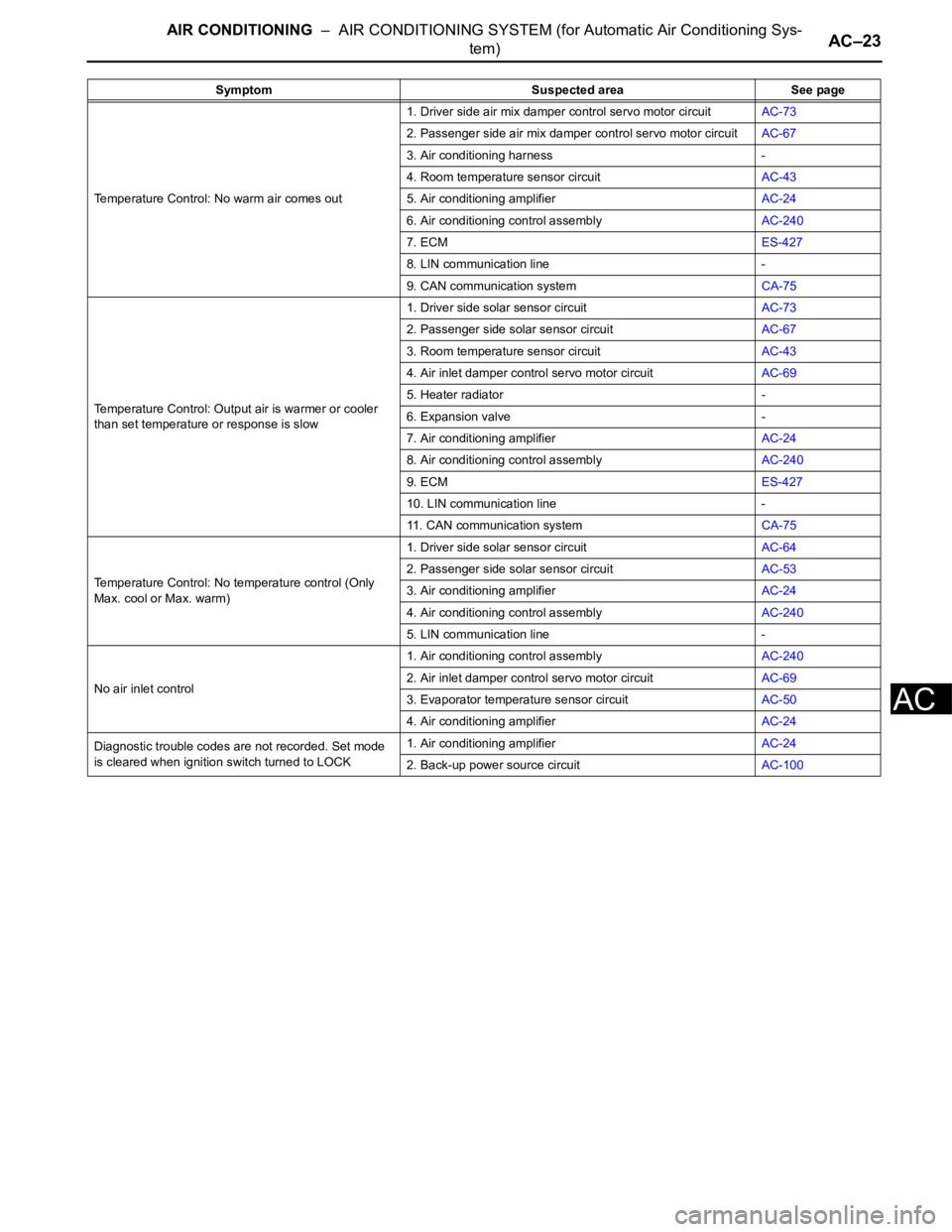

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–23

AC

Temperature Control: No warm air comes out1. Driver side air mix damper control servo motor circuitAC-73

2. Passenger side air mix damper control servo motor circuitAC-67

3. Air conditioning harness -

4. Room temperature sensor circuitAC-43

5. Air conditioning amplifierAC-24

6. Air conditioning control assemblyAC-240

7. ECMES-427

8. LIN communication line -

9. CAN communication systemCA-75

Temperature Control: Output air is warmer or cooler

than set temperature or response is slow1. Driver side solar sensor circuitAC-73

2. Passenger side solar sensor circuitAC-67

3. Room temperature sensor circuitAC-43

4. Air inlet damper control servo motor circuitAC-69

5. Heater radiator -

6. Expansion valve -

7. Air conditioning amplifierAC-24

8. Air conditioning control assemblyAC-240

9. ECMES-427

10. LIN communication line -

11. CAN communication systemCA-75

Temperature Control: No temperature control (Only

Max. cool or Max. warm)1. Driver side solar sensor circuitAC-64

2. Passenger side solar sensor circuitAC-53

3. Air conditioning amplifierAC-24

4. Air conditioning control assemblyAC-240

5. LIN communication line -

No air inlet control1. Air conditioning control assemblyAC-240

2. Air inlet damper control servo motor circuitAC-69

3. Evaporator temperature sensor circuitAC-50

4. Air conditioning amplifierAC-24

Diagnostic trouble codes are not recorded. Set mode

is cleared when ignition switch turned to LOCK1. Air conditioning amplifierAC-24

2. Back-up power source circuitAC-100 Symptom Suspected area See page

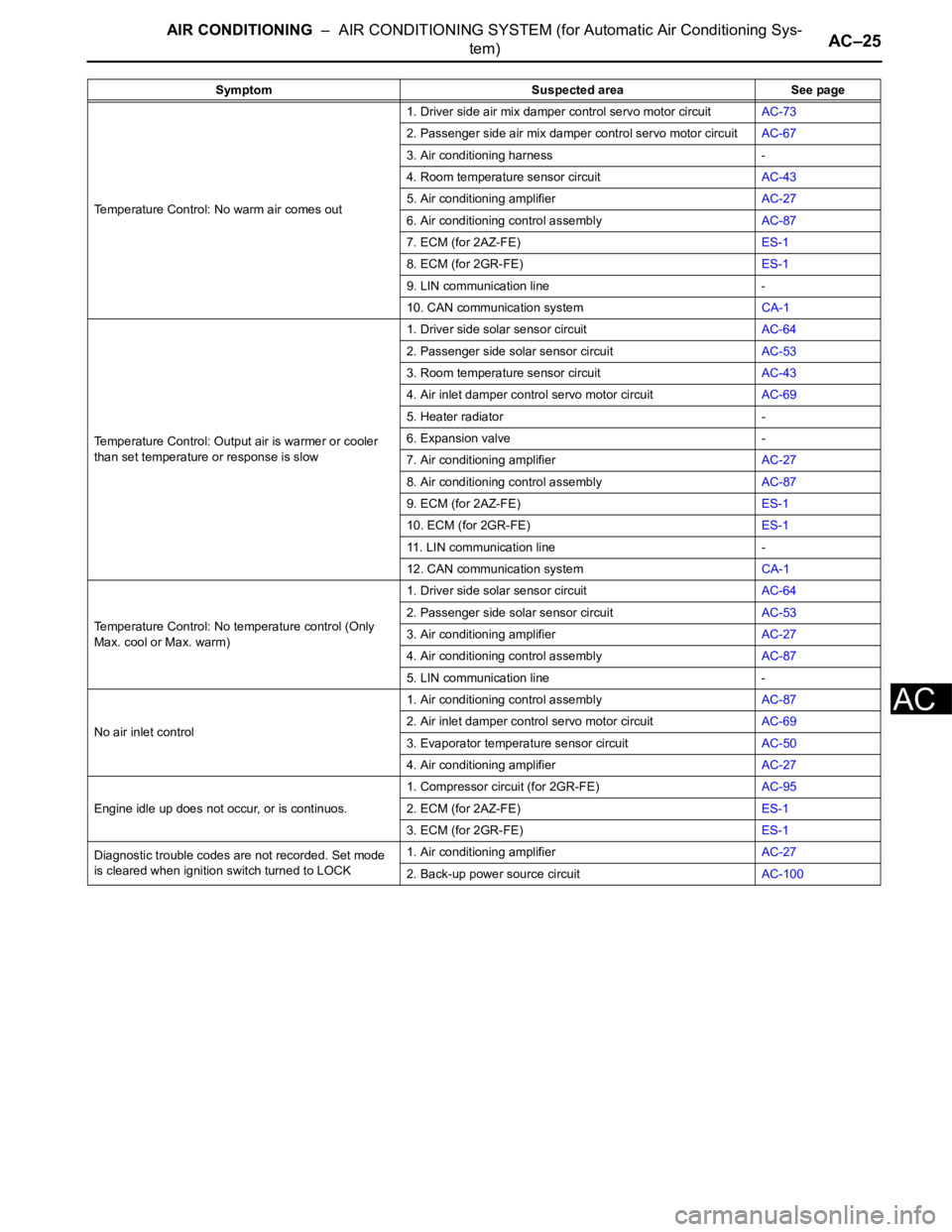

Page 1653 of 2000

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–25

AC

Temperature Control: No warm air comes out1. Driver side air mix damper control servo motor circuitAC-73

2. Passenger side air mix damper control servo motor circuitAC-67

3. Air conditioning harness -

4. Room temperature sensor circuitAC-43

5. Air conditioning amplifierAC-27

6. Air conditioning control assemblyAC-87

7. ECM (for 2AZ-FE)ES-1

8. ECM (for 2GR-FE)ES-1

9. LIN communication line -

10. CAN communication systemCA-1

Temperature Control: Output air is warmer or cooler

than set temperature or response is slow1. Driver side solar sensor circuitAC-64

2. Passenger side solar sensor circuitAC-53

3. Room temperature sensor circuitAC-43

4. Air inlet damper control servo motor circuitAC-69

5. Heater radiator -

6. Expansion valve -

7. Air conditioning amplifierAC-27

8. Air conditioning control assemblyAC-87

9. ECM (for 2AZ-FE)ES-1

10. ECM (for 2GR-FE)ES-1

11. LIN communication line -

12. CAN communication systemCA-1

Temperature Control: No temperature control (Only

Max. cool or Max. warm)1. Driver side solar sensor circuitAC-64

2. Passenger side solar sensor circuitAC-53

3. Air conditioning amplifierAC-27

4. Air conditioning control assemblyAC-87

5. LIN communication line -

No air inlet control1. Air conditioning control assemblyAC-87

2. Air inlet damper control servo motor circuitAC-69

3. Evaporator temperature sensor circuitAC-50

4. Air conditioning amplifierAC-27

Engine idle up does not occur, or is continuos.1. Compressor circuit (for 2GR-FE)AC-95

2. ECM (for 2AZ-FE)ES-1

3. ECM (for 2GR-FE)ES-1

Diagnostic trouble codes are not recorded. Set mode

is cleared when ignition switch turned to LOCK1. Air conditioning amplifierAC-27

2. Back-up power source circuitAC-100 Symptom Suspected area See page

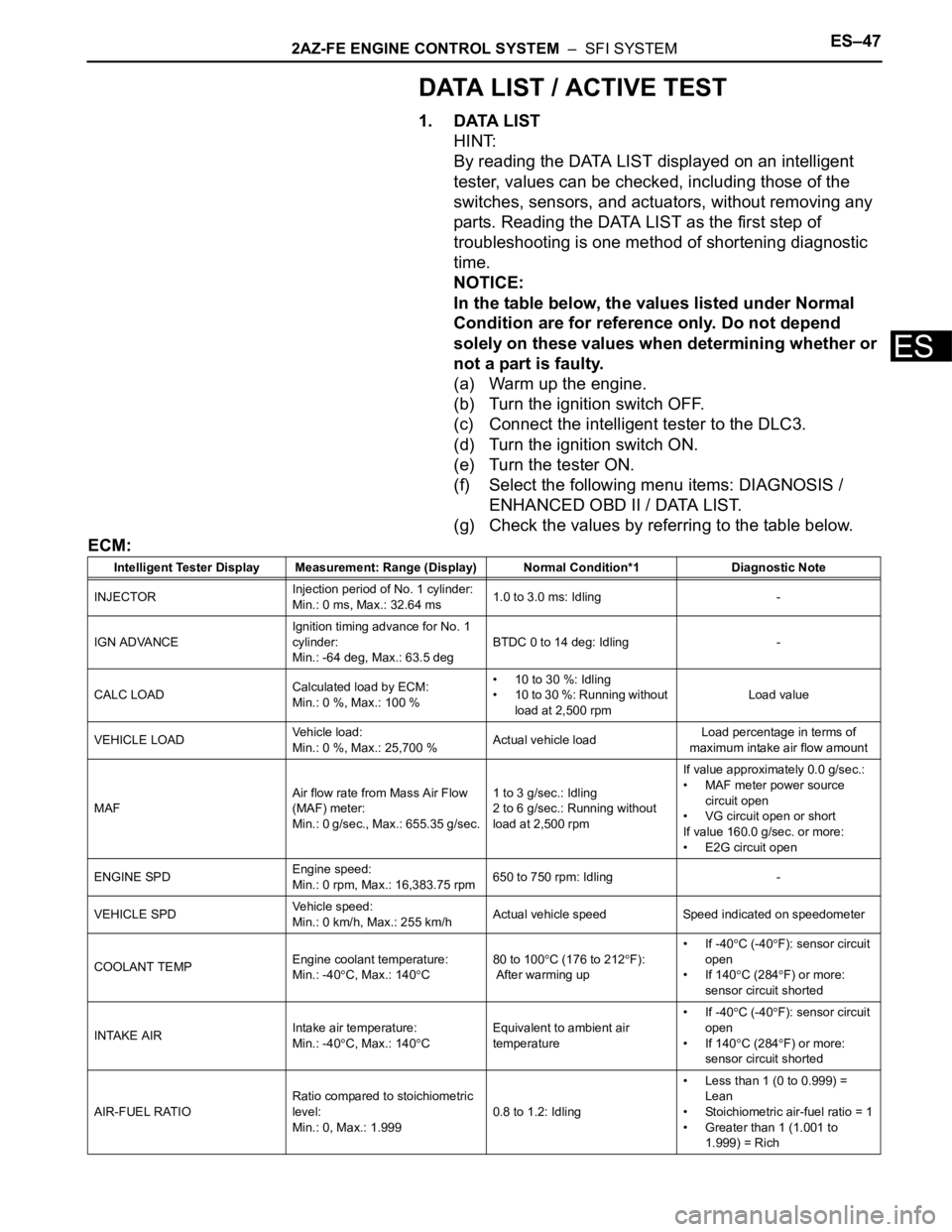

Page 1935 of 2000

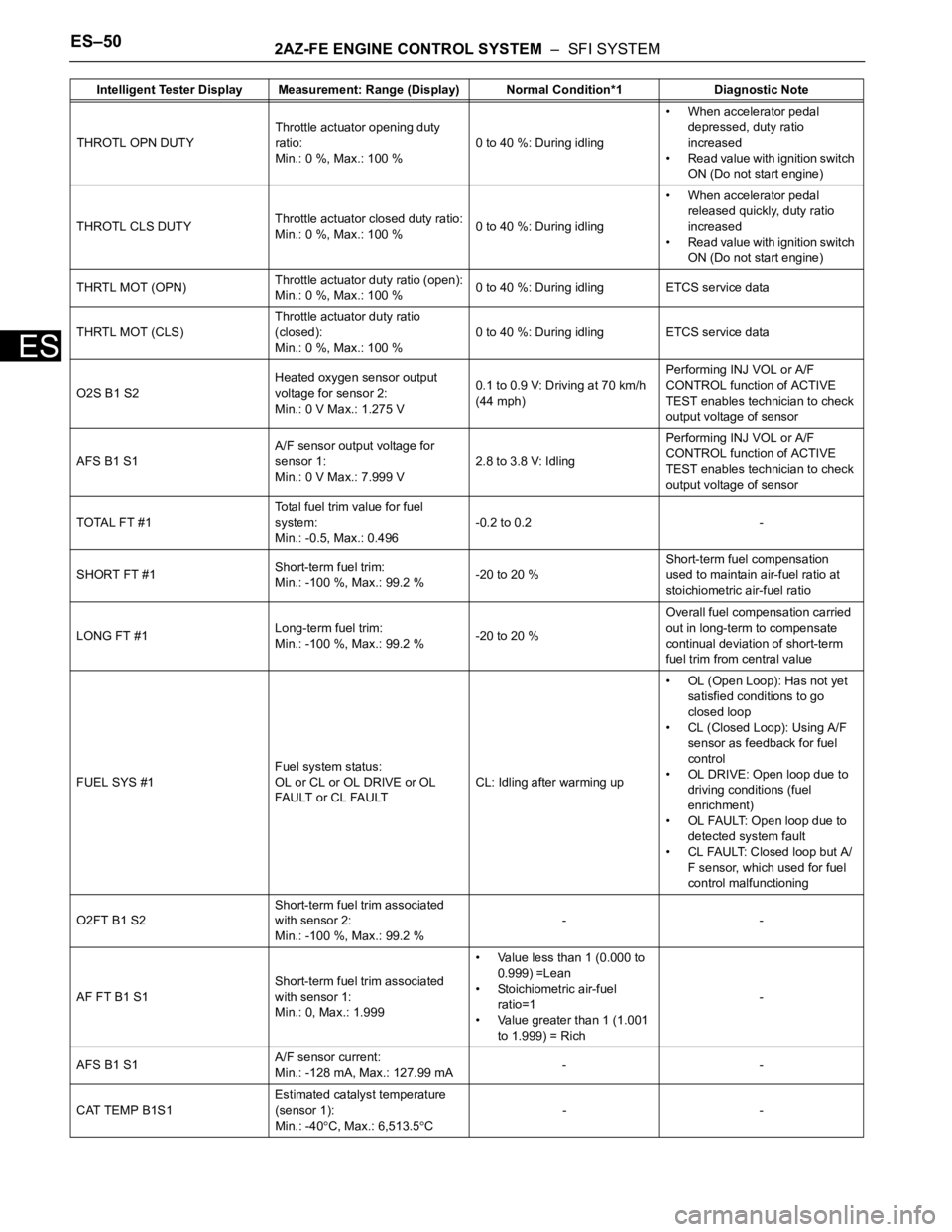

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–47

ES

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

By reading the DATA LIST displayed on an intelligent

tester, values can be checked, including those of the

switches, sensors, and actuators, without removing any

parts. Reading the DATA LIST as the first step of

troubleshooting is one method of shortening diagnostic

time.

NOTICE:

In the table below, the values listed under Normal

Condition are for reference only. Do not depend

solely on these values when determining whether or

not a part is faulty.

(a) Warm up the engine.

(b) Turn the ignition switch OFF.

(c) Connect the intelligent tester to the DLC3.

(d) Turn the ignition switch ON.

(e) Turn the tester ON.

(f) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST.

(g) Check the values by referring to the table below.

ECM:

Intelligent Tester Display Measurement: Range (Display) Normal Condition*1 Diagnostic Note

INJECTORInjection period of No. 1 cylinder:

Min.: 0 ms, Max.: 32.64 ms1.0 to 3.0 ms: Idling -

IGN ADVANCE Ignition timing advance for No. 1

cylinder:

Min.: -64 deg, Max.: 63.5 degBTDC 0 to 14 deg: Idling -

CALC LOADCalculated load by ECM:

Min.: 0 %, Max.: 100 %• 10 to 30 %: Idling

• 10 to 30 %: Running without

load at 2,500 rpmLoad value

VEHICLE LOADVehicle load:

Min.: 0 %, Max.: 25,700 %Actual vehicle loadLoad percentage in terms of

maximum intake air flow amount

MAFAir flow rate from Mass Air Flow

(MAF) meter:

Min.: 0 g/sec., Max.: 655.35 g/sec.1 to 3 g/sec.: Idling

2 to 6 g/sec.: Running without

load at 2,500 rpmIf value approximately 0.0 g/sec.:

• MAF meter power source

circuit open

• VG circuit open or short

If value 160.0 g/sec. or more:

• E2G circuit open

ENGINE SPDEngine speed:

Min.: 0 rpm, Max.: 16,383.75 rpm650 to 750 rpm: Idling -

VEHICLE SPDVehicle speed:

Min.: 0 km/h, Max.: 255 km/hActual vehicle speed Speed indicated on speedometer

COOLANT TEMPEngine coolant temperature:

Min.: -40

C, Max.: 140C80 to 100C (176 to 212F):

After warming up• If -40

C (-40F): sensor circuit

open

• If 140

C (284F) or more:

sensor circuit shorted

INTAKE AIRIntake air temperature:

Min.: -40

C, Max.: 140CEquivalent to ambient air

temperature• If -40

C (-40F): sensor circuit

open

• If 140

C (284F) or more:

sensor circuit shorted

AIR-FUEL RATIORatio compared to stoichiometric

level:

Min.: 0, Max.: 1.9990.8 to 1.2: Idling• Less than 1 (0 to 0.999) =

Lean

• Stoichiometric air-fuel ratio = 1

• Greater than 1 (1.001 to

1.999) = Rich

Page 1938 of 2000

ES–502AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

THROTL OPN DUTYThrottle actuator opening duty

ratio:

Min.: 0 %, Max.: 100 %0 to 40 %: During idling• When accelerator pedal

depressed, duty ratio

increased

• Read value with ignition switch

ON (Do not start engine)

THROTL CLS DUTYThrottle actuator closed duty ratio:

Min.: 0 %, Max.: 100 %0 to 40 %: During idling• When accelerator pedal

released quickly, duty ratio

increased

• Read value with ignition switch

ON (Do not start engine)

THRTL MOT (OPN)Throttle actuator duty ratio (open):

Min.: 0 %, Max.: 100 %0 to 40 %: During idling ETCS service data

THRTL MOT (CLS)Throttle actuator duty ratio

(closed):

Min.: 0 %, Max.: 100 %0 to 40 %: During idling ETCS service data

O2S B1 S2Heated oxygen sensor output

voltage for sensor 2:

Min.: 0 V Max.: 1.275 V0.1 to 0.9 V: Driving at 70 km/h

(44 mph)Performing INJ VOL or A/F

CONTROL function of ACTIVE

TEST enables technician to check

output voltage of sensor

AFS B1 S1A/F sensor output voltage for

sensor 1:

Min.: 0 V Max.: 7.999 V2.8 to 3.8 V: IdlingPerforming INJ VOL or A/F

CONTROL function of ACTIVE

TEST enables technician to check

output voltage of sensor

TOTAL FT #1Total fuel trim value for fuel

system:

Min.: -0.5, Max.: 0.496-0.2 to 0.2 -

SHORT FT #1Short-term fuel trim:

Min.: -100 %, Max.: 99.2 %-20 to 20 %Short-term fuel compensation

used to maintain air-fuel ratio at

stoichiometric air-fuel ratio

LONG FT #1Long-term fuel trim:

Min.: -100 %, Max.: 99.2 %-20 to 20 %Overall fuel compensation carried

out in long-term to compensate

continual deviation of short-term

fuel trim from central value

FUEL SYS #1Fuel system status:

OL or CL or OL DRIVE or OL

FAULT or CL FAULTCL: Idling after warming up• OL (Open Loop): Has not yet

satisfied conditions to go

closed loop

• CL (Closed Loop): Using A/F

sensor as feedback for fuel

control

• OL DRIVE: Open loop due to

driving conditions (fuel

enrichment)

• OL FAULT: Open loop due to

detected system fault

• CL FAULT: Closed loop but A/

F sensor, which used for fuel

control malfunctioning

O2FT B1 S2Short-term fuel trim associated

with sensor 2:

Min.: -100 %, Max.: 99.2 %--

AF FT B1 S1Short-term fuel trim associated

with sensor 1:

Min.: 0, Max.: 1.999• Value less than 1 (0.000 to

0.999) =Lean

• Stoichiometric air-fuel

ratio=1

• Value greater than 1 (1.001

to 1.999) = Rich-

AFS B1 S1A/F sensor current:

Min.: -128 mA, Max.: 127.99 mA--

CAT TEMP B1S1Estimated catalyst temperature

(sensor 1):

Min.: -40

C, Max.: 6,513.5C-- Intelligent Tester Display Measurement: Range (Display) Normal Condition*1 Diagnostic Note

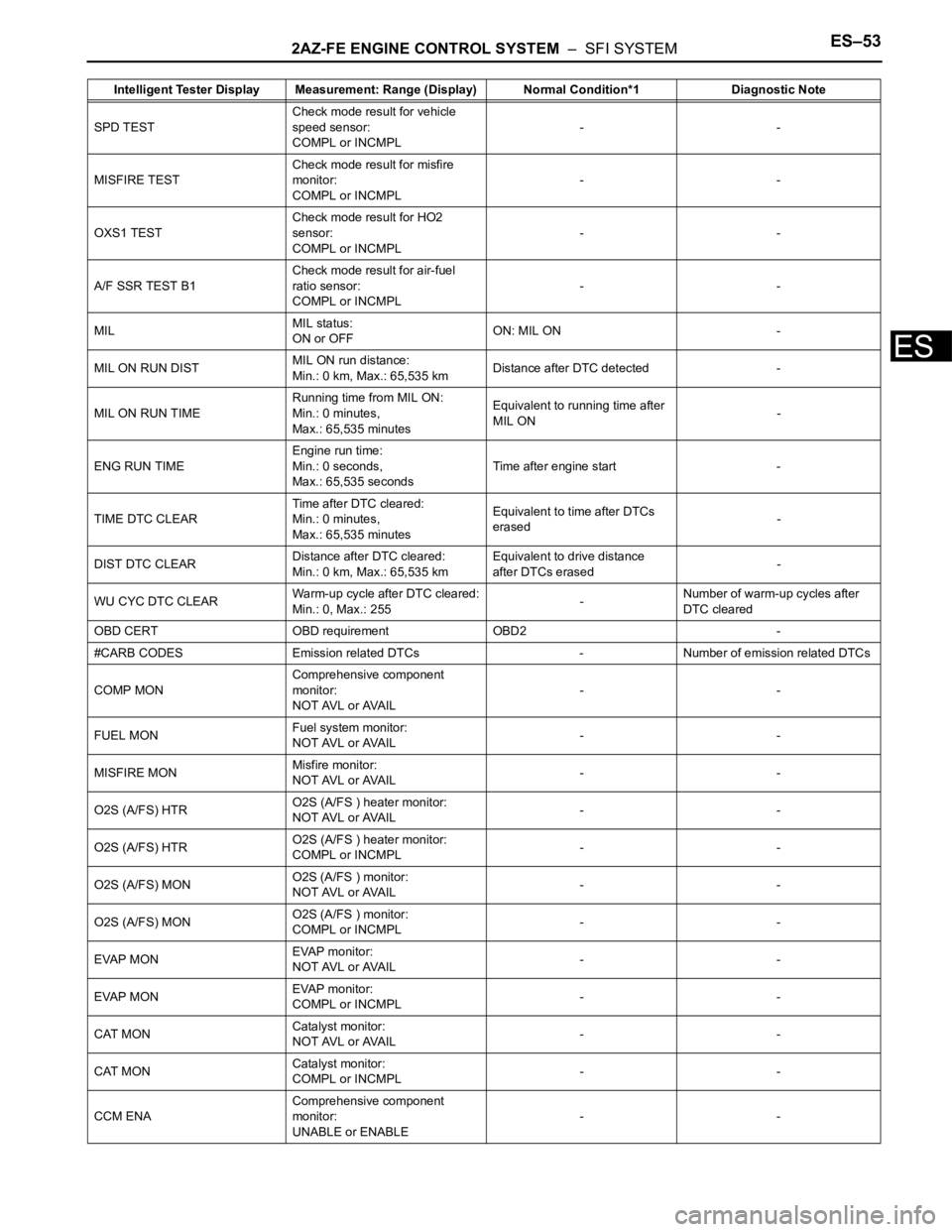

Page 1941 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–53

ES

SPD TESTCheck mode result for vehicle

speed sensor:

COMPL or INCMPL--

MISFIRE TESTCheck mode result for misfire

monitor:

COMPL or INCMPL--

OXS1 TESTCheck mode result for HO2

sensor:

COMPL or INCMPL--

A/F SSR TEST B1Check mode result for air-fuel

ratio sensor:

COMPL or INCMPL--

MIL MIL status:

ON or OFFON: MIL ON -

MIL ON RUN DISTMIL ON run distance:

Min.: 0 km, Max.: 65,535 kmDistance after DTC detected -

MIL ON RUN TIMERunning time from MIL ON:

Min.: 0 minutes,

Max.: 65,535 minutesEquivalent to running time after

MIL ON-

ENG RUN TIMEEngine run time:

Min.: 0 seconds,

Max.: 65,535 secondsTime after engine start -

TIME DTC CLEARTime after DTC cleared:

Min.: 0 minutes,

Max.: 65,535 minutesEquivalent to time after DTCs

erased-

DIST DTC CLEARDistance after DTC cleared:

Min.: 0 km, Max.: 65,535 kmEquivalent to drive distance

after DTCs erased-

WU CYC DTC CLEARWarm-up cycle after DTC cleared:

Min.: 0, Max.: 255-Number of warm-up cycles after

DTC cleared

OBD CERT OBD requirement OBD2 -

#CARB CODES Emission related DTCs - Number of emission related DTCs

COMP MONComprehensive component

monitor:

N O T AV L o r AVA I L--

FUEL MONFuel system monitor:

N O T AV L o r AVA I L--

MISFIRE MONMisfire monitor:

N O T AV L o r AVA I L--

O2S (A/FS) HTRO2S (A/FS ) heater monitor:

N O T AV L o r AVA I L--

O2S (A/FS) HTRO2S (A/FS ) heater monitor:

COMPL or INCMPL--

O2S (A/FS) MONO2S (A/FS ) monitor:

N O T AV L o r AVA I L--

O2S (A/FS) MONO2S (A/FS ) monitor:

COMPL or INCMPL--

EVAP MONEVAP monitor:

N O T AV L o r AVA I L--

EVAP MONEVAP monitor:

COMPL or INCMPL--

CAT MONCatalyst monitor:

N O T AV L o r AVA I L--

CAT MONCatalyst monitor:

COMPL or INCMPL--

CCM ENAComprehensive component

monitor:

UNABLE or ENABLE-- Intelligent Tester Display Measurement: Range (Display) Normal Condition*1 Diagnostic Note