Control arm TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 490 of 2000

ES–362AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

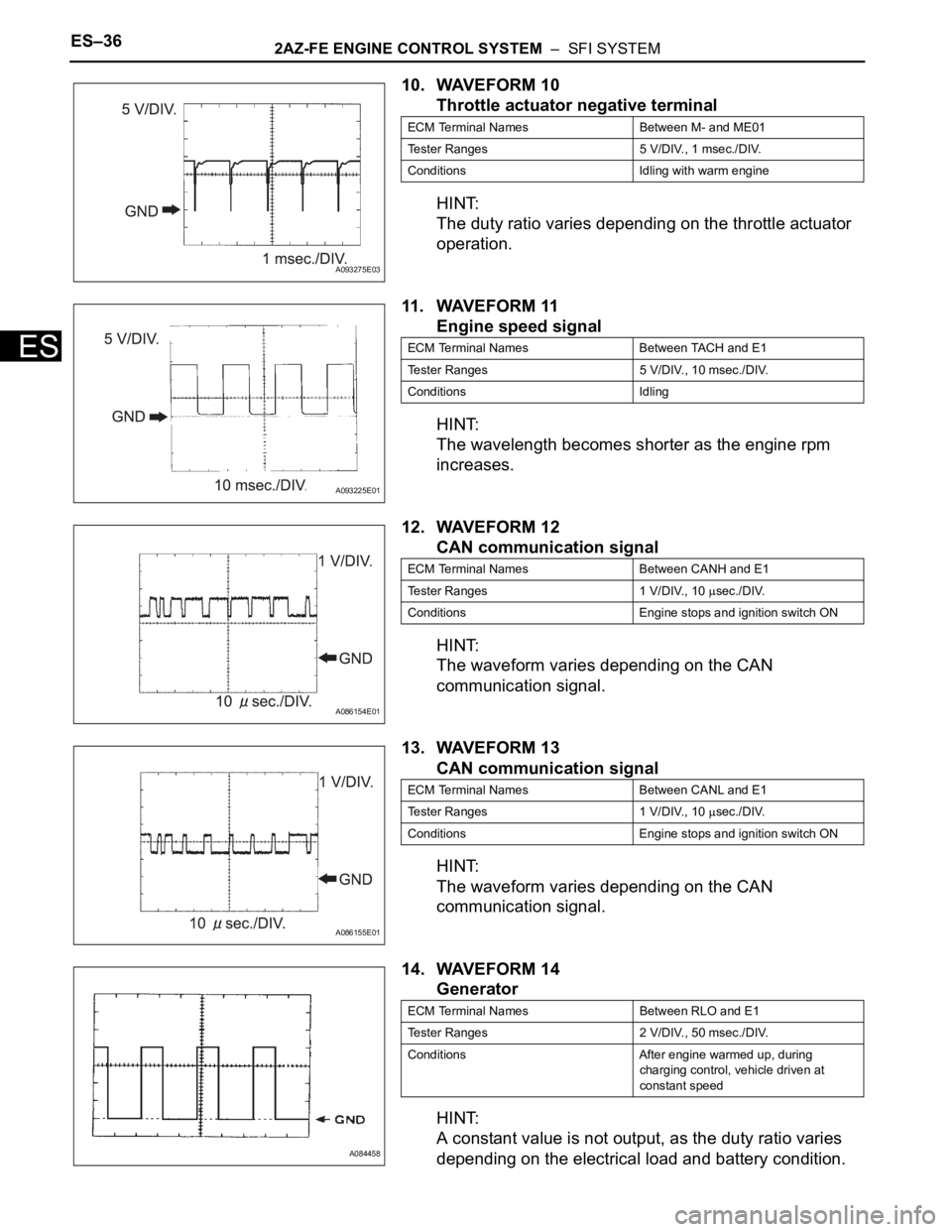

10. WAVEFORM 10

Throttle actuator negative terminal

HINT:

The duty ratio varies depending on the throttle actuator

operation.

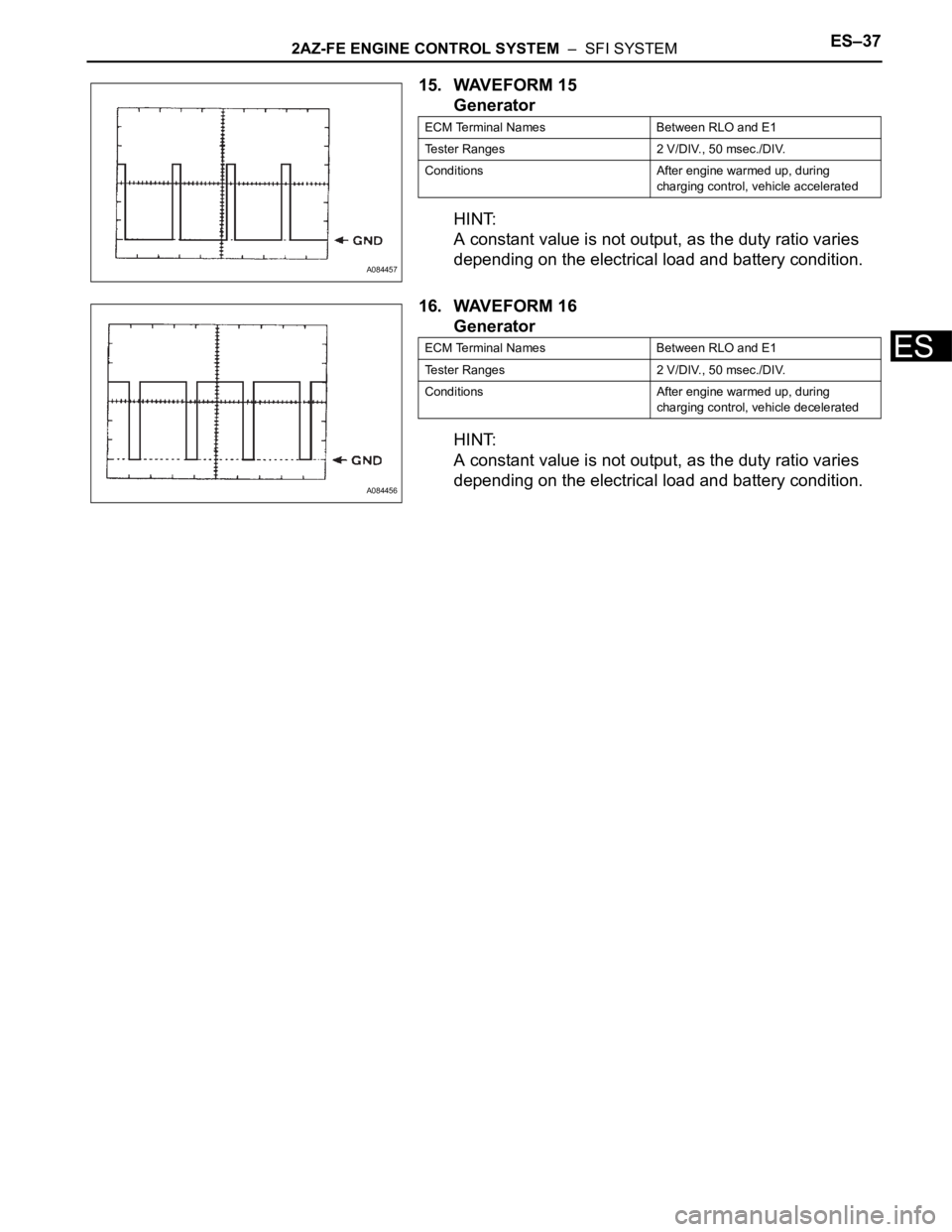

11 . WAVE F OR M 11

Engine speed signal

HINT:

The wavelength becomes shorter as the engine rpm

increases.

12. WAVEFORM 12

CAN communication signal

HINT:

The waveform varies depending on the CAN

communication signal.

13. WAVEFORM 13

CAN communication signal

HINT:

The waveform varies depending on the CAN

communication signal.

14. WAVEFORM 14

Generator

HINT:

A constant value is not output, as the duty ratio varies

depending on the electrical load and battery condition.

A093275E03

ECM Terminal Names Between M- and ME01

Tester Ranges 5 V/DIV., 1 msec./DIV.

Conditions Idling with warm engine

A093225E01

ECM Terminal Names Between TACH and E1

Tester Ranges 5 V/DIV., 10 msec./DIV.

Conditions Idling

A086154E01

ECM Terminal Names Between CANH and E1

Tester Ranges 1 V/DIV., 10

sec./DIV.

Conditions Engine stops and ignition switch ON

A086155E01

ECM Terminal Names Between CANL and E1

Tester Ranges 1 V/DIV., 10

sec./DIV.

Conditions Engine stops and ignition switch ON

A084458

ECM Terminal Names Between RLO and E1

Tester Ranges 2 V/DIV., 50 msec./DIV.

Conditions After engine warmed up, during

charging control, vehicle driven at

constant speed

Page 491 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–37

ES

15. WAVEFORM 15

Generator

HINT:

A constant value is not output, as the duty ratio varies

depending on the electrical load and battery condition.

16. WAVEFORM 16

Generator

HINT:

A constant value is not output, as the duty ratio varies

depending on the electrical load and battery condition.

A084457

ECM Terminal Names Between RLO and E1

Tester Ranges 2 V/DIV., 50 msec./DIV.

Conditions After engine warmed up, during

charging control, vehicle accelerated

A084456

ECM Terminal Names Between RLO and E1

Tester Ranges 2 V/DIV., 50 msec./DIV.

Conditions After engine warmed up, during

charging control, vehicle decelerated

Page 493 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–39

ES

3. 2 TRIP DETECTION LOGIC

When a malfunction is first detected, the malfunction is

temporarily stored in the ECM memory (1st trip). If the

same malfunction is detected during the next

subsequent drive cycle, the MIL is illuminated (2nd trip).

4. FREEZE FRAME DATA

Freeze frame data records the engine conditions (fuel

system, calculated engine load, engine coolant

temperature, fuel trim, engine speed, vehicle speed,

etc.) when malfunctions are detected. When

troubleshooting, freeze frame data can help determine if

the vehicle was moving or stationary, if the engine was

warmed up or not, if the air-fuel ratio was lean or rich,

and other data from the time the malfunction occurred.

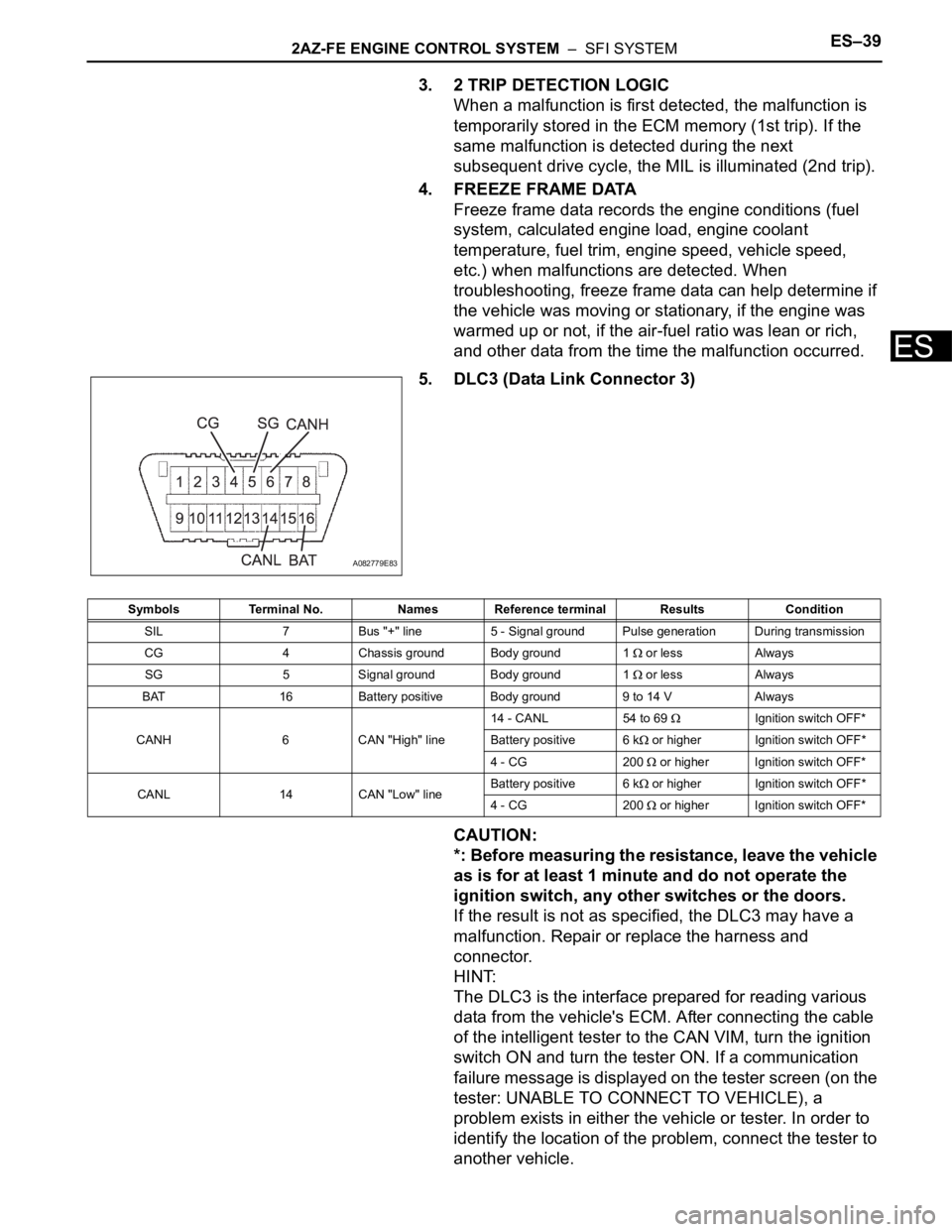

5. DLC3 (Data Link Connector 3)

CAUTION:

*: Before measuring the resistance, leave the vehicle

as is for at least 1 minute and do not operate the

ignition switch, any other switches or the doors.

If the result is not as specified, the DLC3 may have a

malfunction. Repair or replace the harness and

connector.

HINT:

The DLC3 is the interface prepared for reading various

data from the vehicle's ECM. After connecting the cable

of the intelligent tester to the CAN VIM, turn the ignition

switch ON and turn the tester ON. If a communication

failure message is displayed on the tester screen (on the

tester: UNABLE TO CONNECT TO VEHICLE), a

problem exists in either the vehicle or tester. In order to

identify the location of the problem, connect the tester to

another vehicle.

A082779E83

Symbols Terminal No. Names Reference terminal Results Condition

SIL 7 Bus "+" line 5 - Signal ground Pulse generation During transmission

CG 4 Chassis ground Body ground 1

or less Always

SG 5 Signal ground Body ground 1

or less Always

BAT 16 Battery positive Body ground 9 to 14 V Always

CANH 6 CAN "High" line14 - CANL 54 to 69

Ignition switch OFF*

Battery positive 6 k

or higher Ignition switch OFF*

4 - CG 200

or higher Ignition switch OFF*

CANL 14 CAN "Low" lineBattery positive 6 k

or higher Ignition switch OFF*

4 - CG 200

or higher Ignition switch OFF*

Page 496 of 2000

ES–422AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

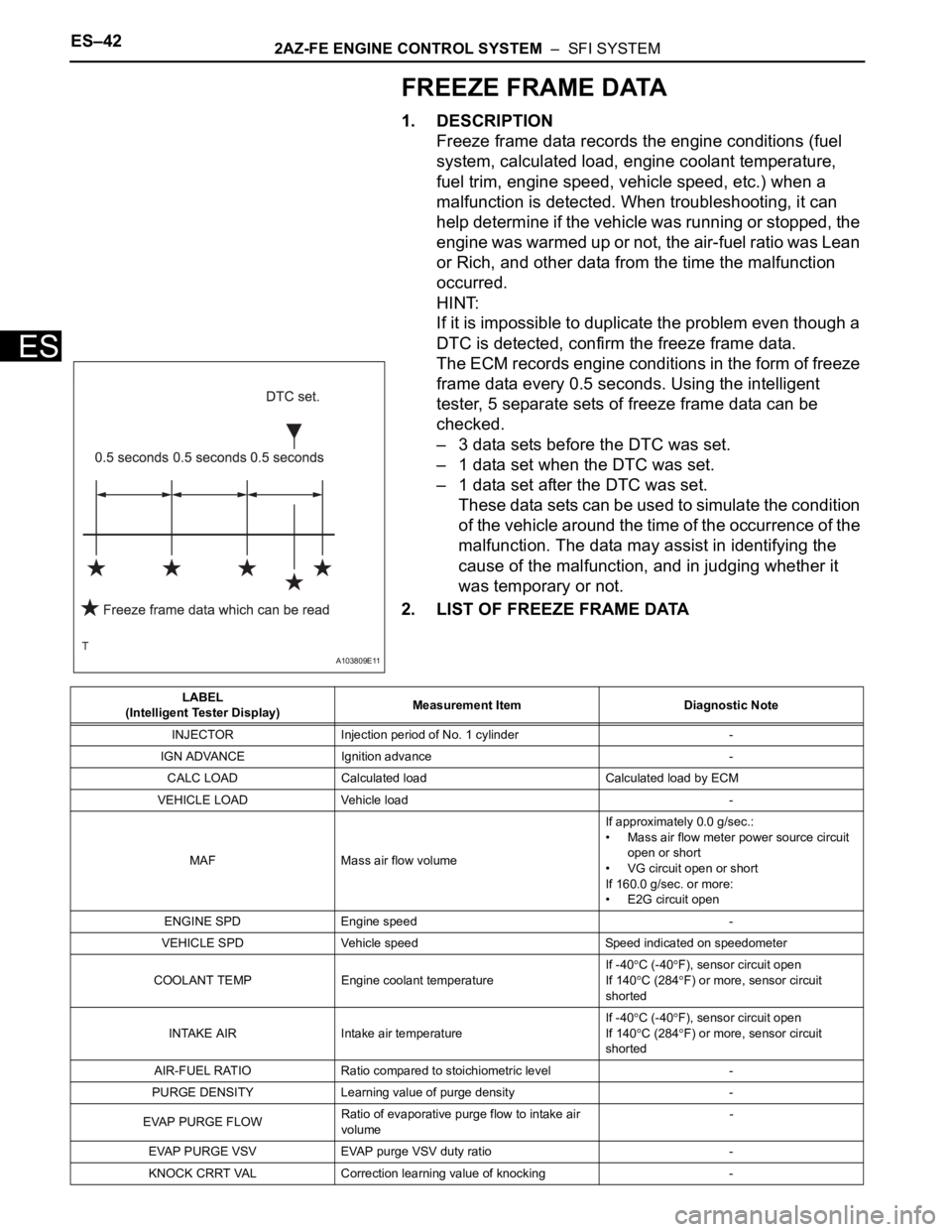

FREEZE FRAME DATA

1. DESCRIPTION

Freeze frame data records the engine conditions (fuel

system, calculated load, engine coolant temperature,

fuel trim, engine speed, vehicle speed, etc.) when a

malfunction is detected. When troubleshooting, it can

help determine if the vehicle was running or stopped, the

engine was warmed up or not, the air-fuel ratio was Lean

or Rich, and other data from the time the malfunction

occurred.

HINT:

If it is impossible to duplicate the problem even though a

DTC is detected, confirm the freeze frame data.

The ECM records engine conditions in the form of freeze

frame data every 0.5 seconds. Using the intelligent

tester, 5 separate sets of freeze frame data can be

checked.

– 3 data sets before the DTC was set.

– 1 data set when the DTC was set.

– 1 data set after the DTC was set.

These data sets can be used to simulate the condition

of the vehicle around the time of the occurrence of the

malfunction. The data may assist in identifying the

cause of the malfunction, and in judging whether it

was temporary or not.

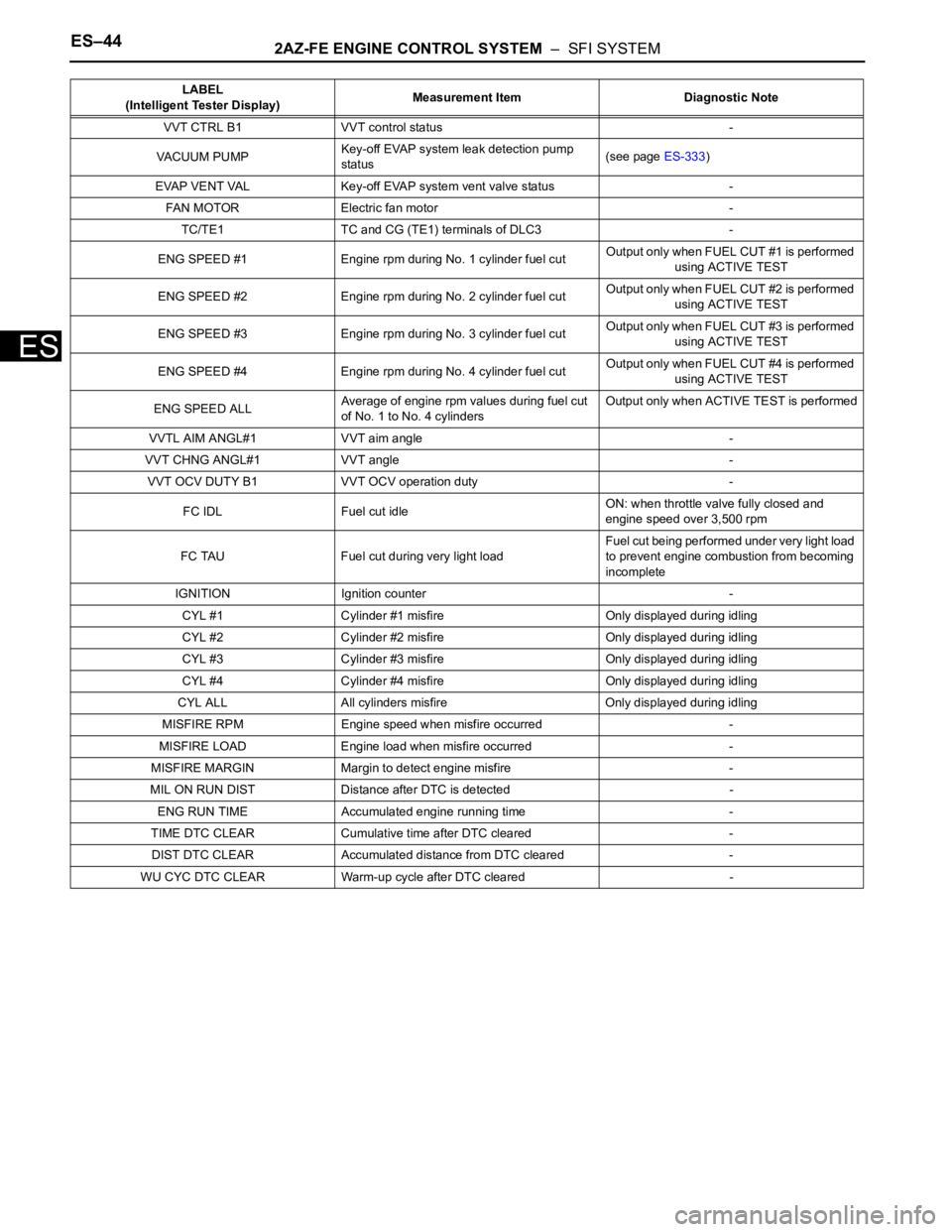

2. LIST OF FREEZE FRAME DATA

A103809E11

LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

INJECTOR Injection period of No. 1 cylinder -

IGN ADVANCE Ignition advance -

CALC LOAD Calculated load Calculated load by ECM

VEHICLE LOAD Vehicle load -

MAF Mass air flow volumeIf approximately 0.0 g/sec.:

• Mass air flow meter power source circuit

open or short

• VG circuit open or short

If 160.0 g/sec. or more:

• E2G circuit open

ENGINE SPD Engine speed -

VEHICLE SPD Vehicle speed Speed indicated on speedometer

COOLANT TEMP Engine coolant temperatureIf -40

C (-40F), sensor circuit open

If 140

C (284F) or more, sensor circuit

shorted

INTAKE AIR Intake air temperature If -40

C (-40F), sensor circuit open

If 140

C (284F) or more, sensor circuit

shorted

AIR-FUEL RATIO Ratio compared to stoichiometric level -

PURGE DENSITY Learning value of purge density -

EVAP PURGE FLOWRatio of evaporative purge flow to intake air

volume-

EVAP PURGE VSV EVAP purge VSV duty ratio -

KNOCK CRRT VAL Correction learning value of knocking -

Page 498 of 2000

ES–442AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

VVT CTRL B1 VVT control status -

VA C U U M P U M PKey-off EVAP system leak detection pump

status(see page ES-333)

EVAP VENT VAL Key-off EVAP system vent valve status -

FAN MOTOR Electric fan motor -

TC/TE1 TC and CG (TE1) terminals of DLC3 -

ENG SPEED #1 Engine rpm during No. 1 cylinder fuel cutOutput only when FUEL CUT #1 is performed

using ACTIVE TEST

ENG SPEED #2 Engine rpm during No. 2 cylinder fuel cutOutput only when FUEL CUT #2 is performed

using ACTIVE TEST

ENG SPEED #3 Engine rpm during No. 3 cylinder fuel cutOutput only when FUEL CUT #3 is performed

using ACTIVE TEST

ENG SPEED #4 Engine rpm during No. 4 cylinder fuel cutOutput only when FUEL CUT #4 is performed

using ACTIVE TEST

ENG SPEED ALLAverage of engine rpm values during fuel cut

of No. 1 to No. 4 cylindersOutput only when ACTIVE TEST is performed

VVTL AIM ANGL#1 VVT aim angle -

VVT CHNG ANGL#1 VVT angle -

VVT OCV DUTY B1 VVT OCV operation duty -

FC IDL Fuel cut idleON: when throttle valve fully closed and

engine speed over 3,500 rpm

FC TAU Fuel cut during very light loadFuel cut being performed under very light load

to prevent engine combustion from becoming

incomplete

IGNITION Ignition counter -

CYL #1 Cylinder #1 misfire Only displayed during idling

CYL #2 Cylinder #2 misfire Only displayed during idling

CYL #3 Cylinder #3 misfire Only displayed during idling

CYL #4 Cylinder #4 misfire Only displayed during idling

CYL ALL All cylinders misfire Only displayed during idling

MISFIRE RPM Engine speed when misfire occurred -

MISFIRE LOAD Engine load when misfire occurred -

MISFIRE MARGIN Margin to detect engine misfire -

MIL ON RUN DIST Distance after DTC is detected -

ENG RUN TIME Accumulated engine running time -

TIME DTC CLEAR Cumulative time after DTC cleared -

DIST DTC CLEAR Accumulated distance from DTC cleared -

WU CYC DTC CLEAR Warm-up cycle after DTC cleared -LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 509 of 2000

SE–4SEAT – FRONT POWER SEAT CONTROL SYSTEM

SE

NOTICE:

• The inspection should be performed with the

seat installed in the vehicle.

• Perform the 4 steps below for the full range of

motion for each power seat function.

(1) Choose a power seat function. Operate the

power seat switch and move the seat as much

as possible in one direction. Keep the seat in

that position for approximately 60 seconds.

(2) Operate the power seat switch again and

continue to try to move the seat in the same

direction as in the previous step. Measure the

amount of time elapsed before current is

automatically cut (the sound of the motor has

stopped).

Standard:

4 to 90 seconds

(3) After current has been cut, release the power

seat switch and wait for approximately 60

seconds.

(4) Operate the same power seat switch and move

the seat in the opposite direction. Check that

the motor operates.

3. CHECK LUMBAR SUPPORT ADJUSTER ASSEMBLY

(a) Check the PTC operation inside the power seat

motor.

NOTICE:

The inspection should be performed with the

seat installed in the vehicle.

(1) Operate the lumbar support switch and move

the lumbar support to either the foremost or

rearmost position. Keep the seat in that

position for approximately 60 seconds.

(2) Operate the lumbar support switch again and

continue to try to move the lumbar support in

the same direction as in the previous step.

Measure the amount of time elapsed before

current is automatically cut (the sound of the

motor has stopped).

Standard:

4 to 90 seconds

(3) After current has been cut, release the lumbar

support switch and wait for approximately 60

seconds.

(4) Operate the lumbar support switch and move

the seat in the opposite direction. Check that

the motor operates.

Page 552 of 2000

ES–282GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

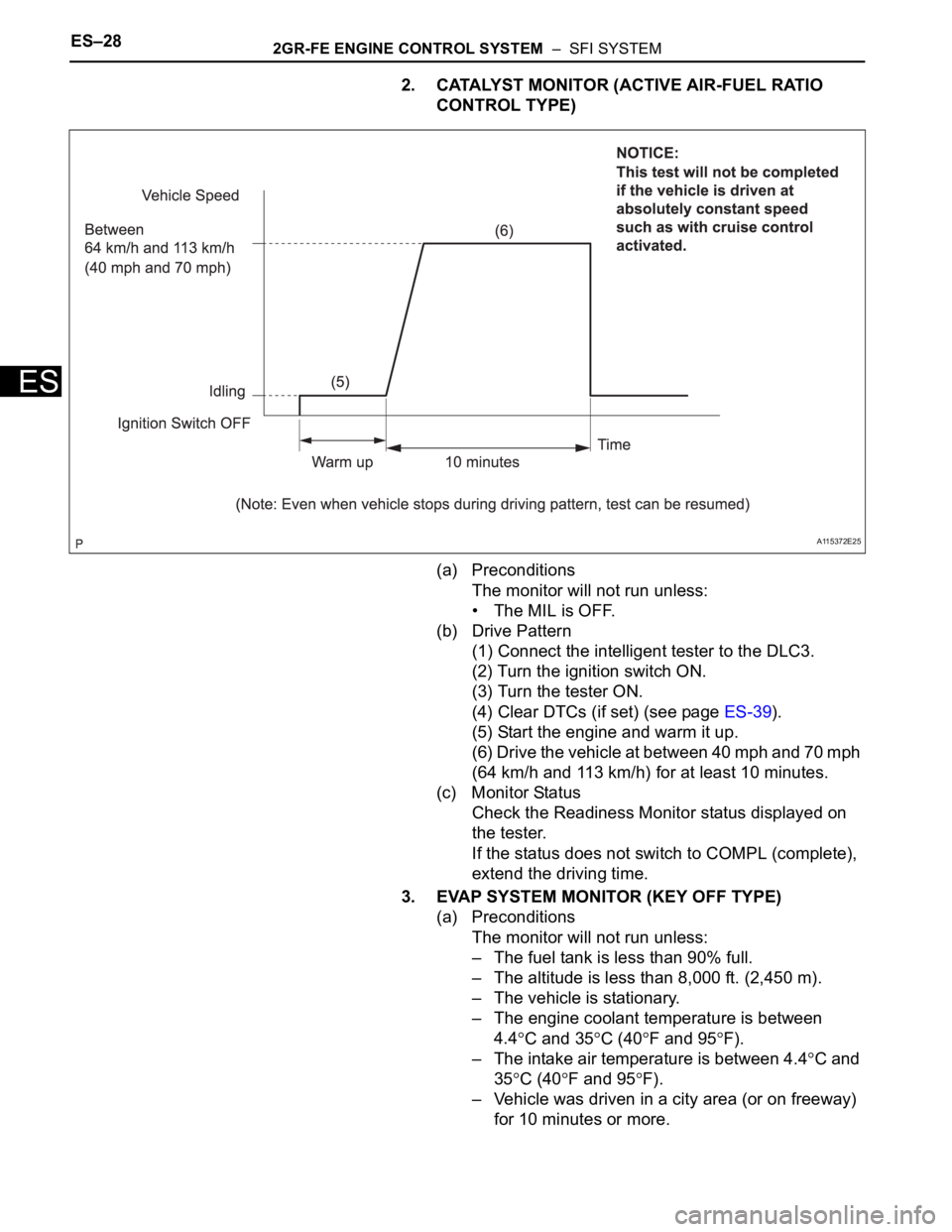

2. CATALYST MONITOR (ACTIVE AIR-FUEL RATIO

CONTROL TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch ON.

(3) Turn the tester ON.

(4) Clear DTCs (if set) (see page ES-39).

(5) Start the engine and warm it up.

(6) Drive the vehicle at between 40 mph and 70 mph

(64 km/h and 113 km/h) for at least 10 minutes.

(c) Monitor Status

Check the Readiness Monitor status displayed on

the tester.

If the status does not switch to COMPL (complete),

extend the driving time.

3. EVAP SYSTEM MONITOR (KEY OFF TYPE)

(a) Preconditions

The monitor will not run unless:

– The fuel tank is less than 90% full.

– The altitude is less than 8,000 ft. (2,450 m).

– The vehicle is stationary.

– The engine coolant temperature is between

4.4

C and 35C (40F and 95F).

– The intake air temperature is between 4.4

C and

35

C (40F and 95F).

– Vehicle was driven in a city area (or on freeway)

for 10 minutes or more.

A115372E25

Page 554 of 2000

ES–302GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

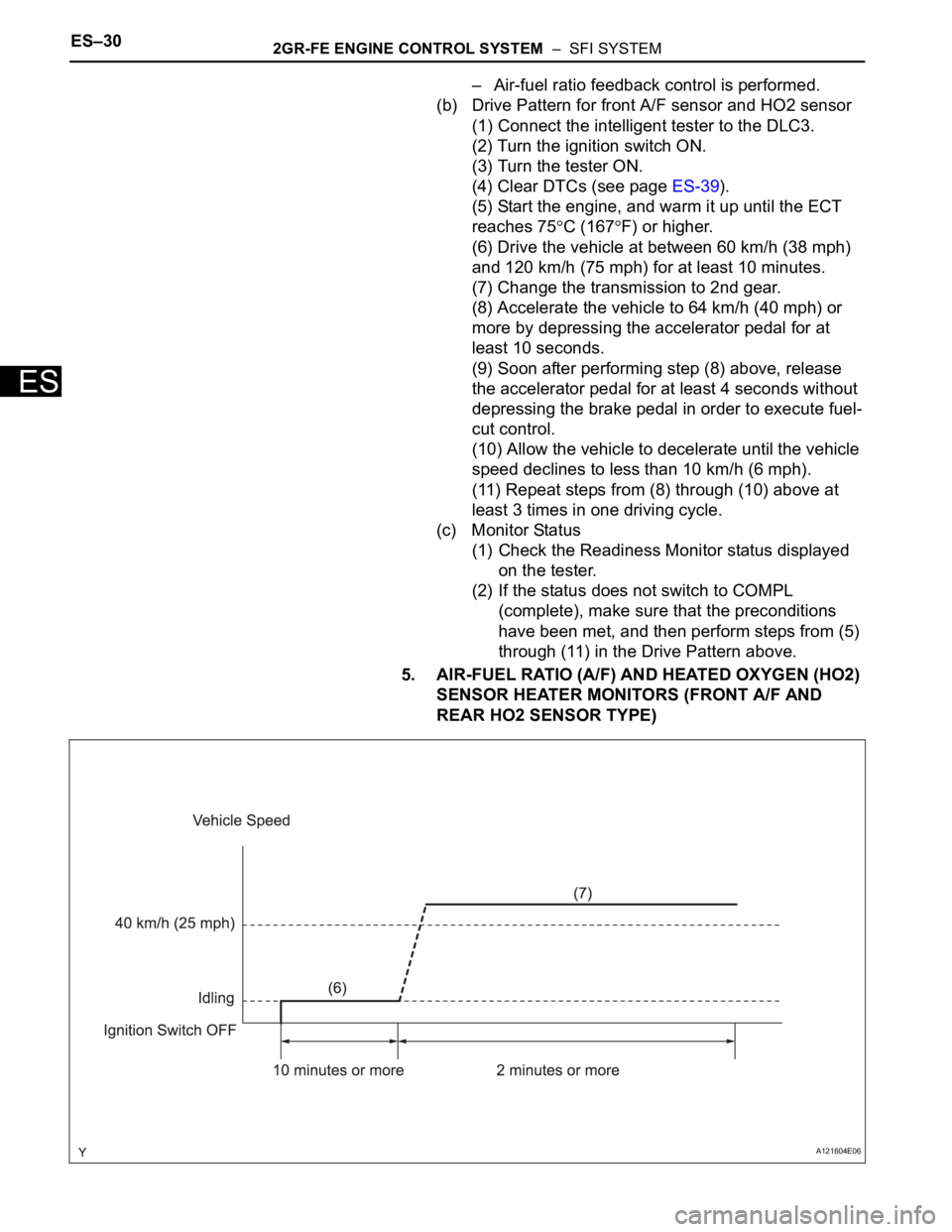

– Air-fuel ratio feedback control is performed.

(b) Drive Pattern for front A/F sensor and HO2 sensor

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch ON.

(3) Turn the tester ON.

(4) Clear DTCs (see page ES-39).

(5) Start the engine, and warm it up until the ECT

reaches 75

C (167F) or higher.

(6) Drive the vehicle at between 60 km/h (38 mph)

and 120 km/h (75 mph) for at least 10 minutes.

(7) Change the transmission to 2nd gear.

(8) Accelerate the vehicle to 64 km/h (40 mph) or

more by depressing the accelerator pedal for at

least 10 seconds.

(9) Soon after performing step (8) above, release

the accelerator pedal for at least 4 seconds without

depressing the brake pedal in order to execute fuel-

cut control.

(10) Allow the vehicle to decelerate until the vehicle

speed declines to less than 10 km/h (6 mph).

(11) Repeat steps from (8) through (10) above at

least 3 times in one driving cycle.

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), make sure that the preconditions

have been met, and then perform steps from (5)

through (11) in the Drive Pattern above.

5. AIR-FUEL RATIO (A/F) AND HEATED OXYGEN (HO2)

SENSOR HEATER MONITORS (FRONT A/F AND

REAR HO2 SENSOR TYPE)

A121604E06

Page 556 of 2000

ES–322GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

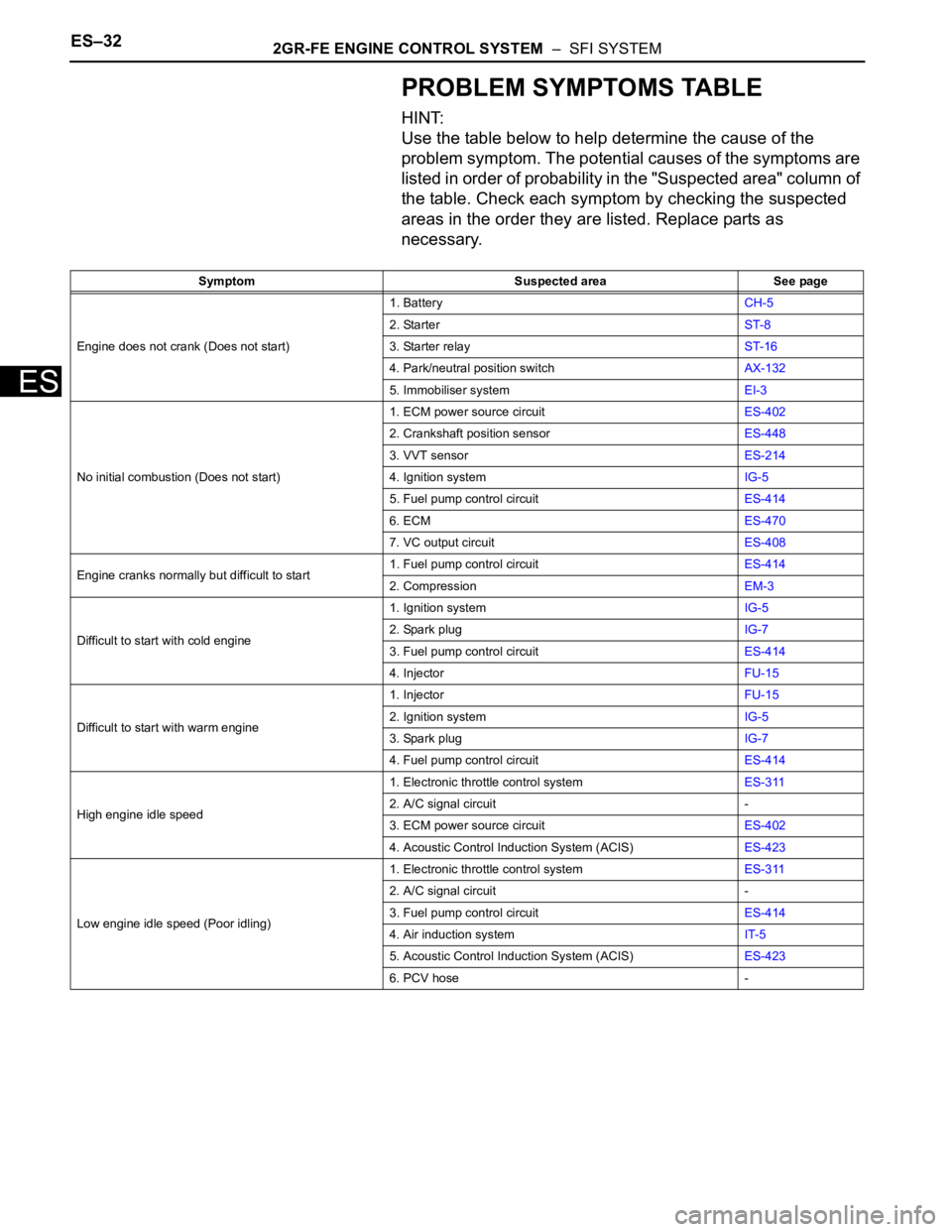

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "Suspected area" column of

the table. Check each symptom by checking the suspected

areas in the order they are listed. Replace parts as

necessary.

Symptom Suspected area See page

Engine does not crank (Does not start)1. BatteryCH-5

2. StarterST-8

3. Starter relayST-16

4. Park/neutral position switchAX-132

5. Immobiliser systemEI-3

No initial combustion (Does not start)1. ECM power source circuitES-402

2. Crankshaft position sensorES-448

3. VVT sensorES-214

4. Ignition systemIG-5

5. Fuel pump control circuitES-414

6. ECMES-470

7. VC output circuitES-408

Engine cranks normally but difficult to start1. Fuel pump control circuitES-414

2. CompressionEM-3

Difficult to start with cold engine1. Ignition systemIG-5

2. Spark plugIG-7

3. Fuel pump control circuitES-414

4. InjectorFU-15

Difficult to start with warm engine1. InjectorFU-15

2. Ignition systemIG-5

3. Spark plugIG-7

4. Fuel pump control circuitES-414

High engine idle speed1. Electronic throttle control systemES-311

2. A/C signal circuit -

3. ECM power source circuitES-402

4. Acoustic Control Induction System (ACIS)ES-423

Low engine idle speed (Poor idling)1. Electronic throttle control systemES-311

2. A/C signal circuit -

3. Fuel pump control circuitES-414

4. Air induction systemIT-5

5. Acoustic Control Induction System (ACIS)ES-423

6. PCV hose -

Page 559 of 2000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–35

ES

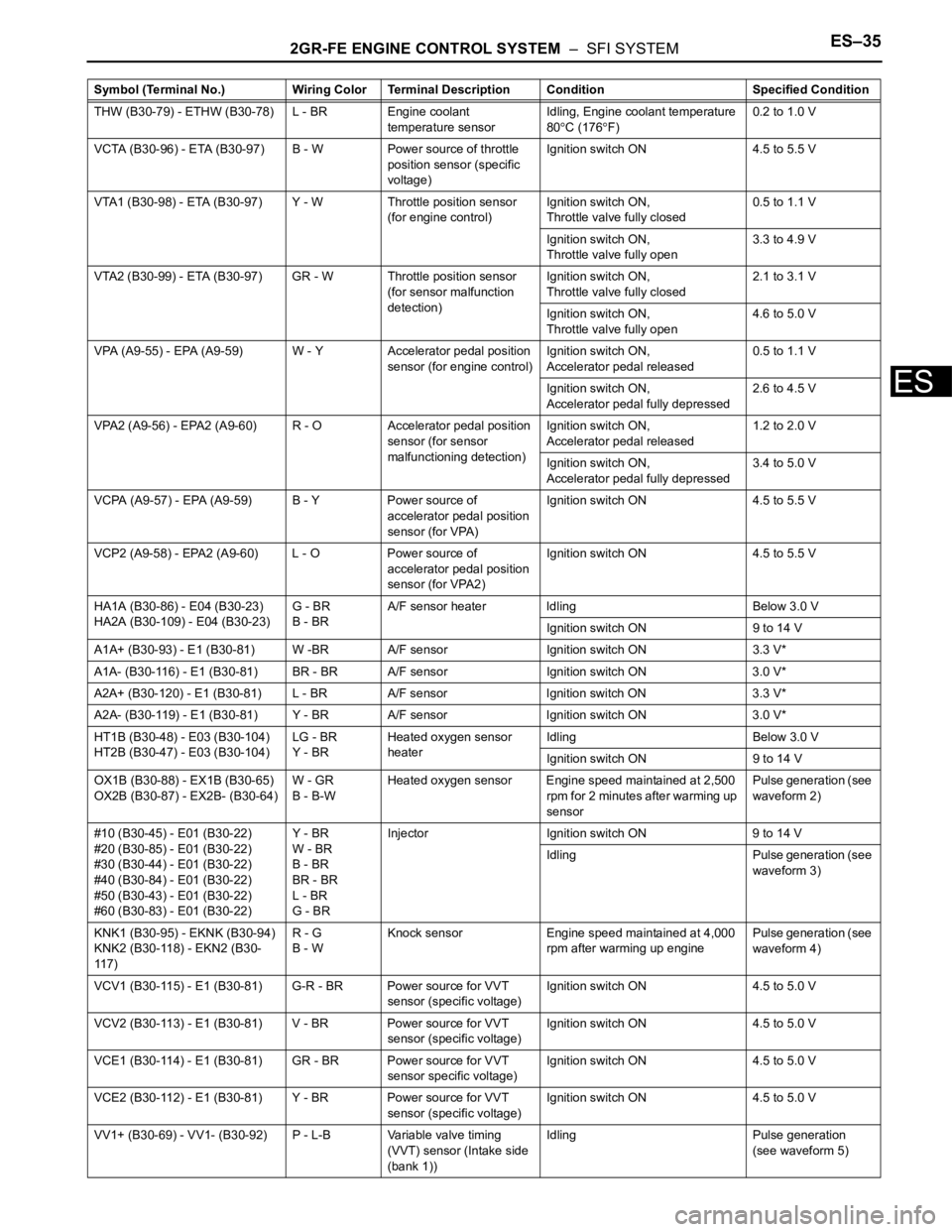

THW (B30-79) - ETHW (B30-78) L - BR Engine coolant

temperature sensorIdling, Engine coolant temperature

80

C (176F)0.2 to 1.0 V

VCTA (B30-96) - ETA (B30-97) B - W Power source of throttle

position sensor (specific

voltage)Ignition switch ON 4.5 to 5.5 V

VTA1 (B30-98) - ETA (B30-97) Y - W Throttle position sensor

(for engine control)Ignition switch ON,

Throttle valve fully closed0.5 to 1.1 V

Ignition switch ON,

Throttle valve fully open3.3 to 4.9 V

VTA2 (B30-99) - ETA (B30-97) GR - W Throttle position sensor

(for sensor malfunction

detection)Ignition switch ON,

Throttle valve fully closed2.1 to 3.1 V

Ignition switch ON,

Throttle valve fully open4.6 to 5.0 V

VPA (A9-55) - EPA (A9-59) W - Y Accelerator pedal position

sensor (for engine control)Ignition switch ON,

Accelerator pedal released0.5 to 1.1 V

Ignition switch ON,

Accelerator pedal fully depressed2.6 to 4.5 V

VPA2 (A9-56) - EPA2 (A9-60) R - O Accelerator pedal position

sensor (for sensor

malfunctioning detection)Ignition switch ON,

Accelerator pedal released1.2 to 2.0 V

Ignition switch ON,

Accelerator pedal fully depressed3.4 to 5.0 V

VCPA (A9-57) - EPA (A9-59) B - Y Power source of

accelerator pedal position

sensor (for VPA)Ignition switch ON 4.5 to 5.5 V

VCP2 (A9-58) - EPA2 (A9-60) L - O Power source of

accelerator pedal position

sensor (for VPA2)Ignition switch ON 4.5 to 5.5 V

HA1A (B30-86) - E04 (B30-23)

HA2A (B30-109) - E04 (B30-23) G - BR

B - BRA/F sensor heater Idling Below 3.0 V

Ignition switch ON 9 to 14 V

A1A+ (B30-93) - E1 (B30-81) W -BR A/F sensor Ignition switch ON 3.3 V*

A1A- (B30-116) - E1 (B30-81) BR - BR A/F sensor Ignition switch ON3.0 V*

A2A+ (B30-120) - E1 (B30-81) L - BR A/F sensor Ignition switch ON 3.3 V*

A2A- (B30-119) - E1 (B30-81) Y - BR A/F sensor Ignition switch ON 3.0 V*

HT1B (B30-48) - E03 (B30-104)

HT2B (B30-47) - E03 (B30-104)LG - BR

Y - BRHeated oxygen sensor

heaterIdling Below 3.0 V

Ignition switch ON 9 to 14 V

OX1B (B30-88) - EX1B (B30-65)

OX2B (B30-87) - EX2B- (B30-64)W - GR

B - B-WHeated oxygen sensor Engine speed maintained at 2,500

rpm for 2 minutes after warming up

sensorPulse generation (see

waveform 2)

#10 (B30-45) - E01 (B30-22)

#20 (B30-85) - E01 (B30-22)

#30 (B30-44) - E01 (B30-22)

#40 (B30-84) - E01 (B30-22)

#50 (B30-43) - E01 (B30-22)

#60 (B30-83) - E01 (B30-22)Y - BR

W - BR

B - BR

BR - BR

L - BR

G - BRInjector Ignition switch ON 9 to 14 V

Idling Pulse generation (see

waveform 3)

KNK1 (B30-95) - EKNK (B30-94)

KNK2 (B30-118) - EKN2 (B30-

11 7 )R - G

B - WKnock sensor Engine speed maintained at 4,000

rpm after warming up enginePulse generation (see

waveform 4)

VCV1 (B30-115) - E1 (B30-81) G-R - BR Power source for VVT

sensor (specific voltage)Ignition switch ON 4.5 to 5.0 V

VCV2 (B30-113) - E1 (B30-81) V - BR Power source for VVT

sensor (specific voltage)Ignition switch ON 4.5 to 5.0 V

VCE1 (B30-114) - E1 (B30-81) GR - BR Power source for VVT

sensor specific voltage)Ignition switch ON 4.5 to 5.0 V

VCE2 (B30-112) - E1 (B30-81) Y - BR Power source for VVT

sensor (specific voltage)Ignition switch ON 4.5 to 5.0 V

VV1+ (B30-69) - VV1- (B30-92) P - L-B Variable valve timing

(VVT) sensor (Intake side

(bank 1))Idling Pulse generation

(see waveform 5) Symbol (Terminal No.) Wiring Color Terminal Description Condition Specified Condition