Control arm TOYOTA RAV4 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 560 of 2000

ES–362GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

VV2+ (B30-67) - VV2- (B30-90) W - B Variable valve timing

(VVT) sensor (Intake side

(bank 2))Idling Pulse generation

(see waveform 5)

EV1+ (B30-68) - EV1- (B30-91) Y - G Variable valve timing

(VVT) sensor (Exhaust

side (bank 1))Idling Pulse generation

(see waveform 5)

EV2+ (B30-66) - EV2- (B30-89) R - L Variable valve timing

(VVT) sensor (Exhaust

side (bank 2))Idling Pulse generation

(see waveform 5)

NE+ (B30-110) - NE- (B30-111) G - R Crankshaft position sensor Idling Pulse generation (see

waveform 5)

IGT1 (B30-40) - E1 (B30-81)

IGT2 (B30-39) - E1 (B30-81)

IGT3 (B30-38) - E1 (B30-81)

IGT4 (B30-37) - E1 (B30-81)

IGT5 (B30-36) - E1 (B30-81)

IGT6 (B30-35) - E1 (B30-81)W - BR

G-R - BR

G - BR

LG - BR

P - BR

V - BRIgnition coil (ignition

signal)Idling Pulse generation (see

waveform 6)

IGF1 (B30-106) - E1 (B30-81) Y - BR Ignition coil (ignition

confirmation signal)Ignition switch ON 4.5 to 5.5 V

Idling Pulse generation (see

waveform 6)

PRG (B30-108) - E1 (B30-81) LG - BR Purge VSV Ignition switch ON 9 to 14 V

Idling Pulse generation (see

waveform 7)

SPD (A9-8) - E1 (B30-81) V - BR Speed signal from

combination meterDriving at 20 km/h (12 mph) Pulse generation (see

waveform 8)

STA (A9-48) - E1 (B30-81) LG - BR Starter signal Cranking 5.5 V or more

NSW (B30-62) - E1 (B30-81) G-R - BR Starter relay control Ignition switch ON Below 1.5 V

Cranking 6.0 V or more

STP (A9-36) - E1 (B30-81) L - BR Stop light switch Brake pedal depressed 7.5 to 14 V

Brake pedal released Below 1.5 V

ST1- (A9-35) - E1 (B30-81) GR - BR Stop light switch

(opposite to STP terminal)Ignition switch ON,

Brake pedal depressedBelow 1.5 V

Ignition switch ON,

Brake pedal released7.5 to 14 V

M+ (B30-19) - ME01 (B30-20) G - BR Throttle actuator Idling with warm engine Pulse generation (see

waveform 9)

M- (B30-18) - ME01 (B30-20) R - BR Throttle actuator Idling with warm engine Pulse generation (see

waveform 10)

FC (A9-7) - E1 (B30-81) W - BR Fuel pump control Ignition switch ON 9 to 14 V

Idling Below 1.5 V

FPR (B30-59) - E1 (B30-81) W - BR Fuel pump control Cranking 9 to 14 V

FPR (B30-59) - E1 (B30-81) W - BR Fuel pump control Idling 9 to 14 V

W (A9-24) - E1 (B30-81) R - BR MIL Ignition switch ON Below 1.5 V

Idling 9 to 14 V

TC (A9-27) - E1 (B30-81) G - BR Terminal TC of DLC3 Ignition switch ON 9 to 14 V

TACH (A9-15) - E1 (B30-81) GR - BR Engine speed Idling Pulse generation (see

waveform 11)

VPMP (A9-42) - E1 (B30-81) W - BR Vent valve (built into

canister pump module)Ignition switch ON 9 to 14 V

MPMP (A9-34) - E1 (B30-81) B - BR Leak detection pump (built

into canister pump

module)Leak detection pump OFF Below 3 V

Leak detection pump ON 9 to 14 V

VCPP (B30-75) - EPPM (B30-76) V - BR Power source for canister

pressure sensor (specific

voltage)Ignition switch ON 4.5 to 5.5 V Symbol (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

Page 561 of 2000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–37

ES

HINT:

*: The ECM terminal voltage is constant regardless

of the output voltage from the sensor.

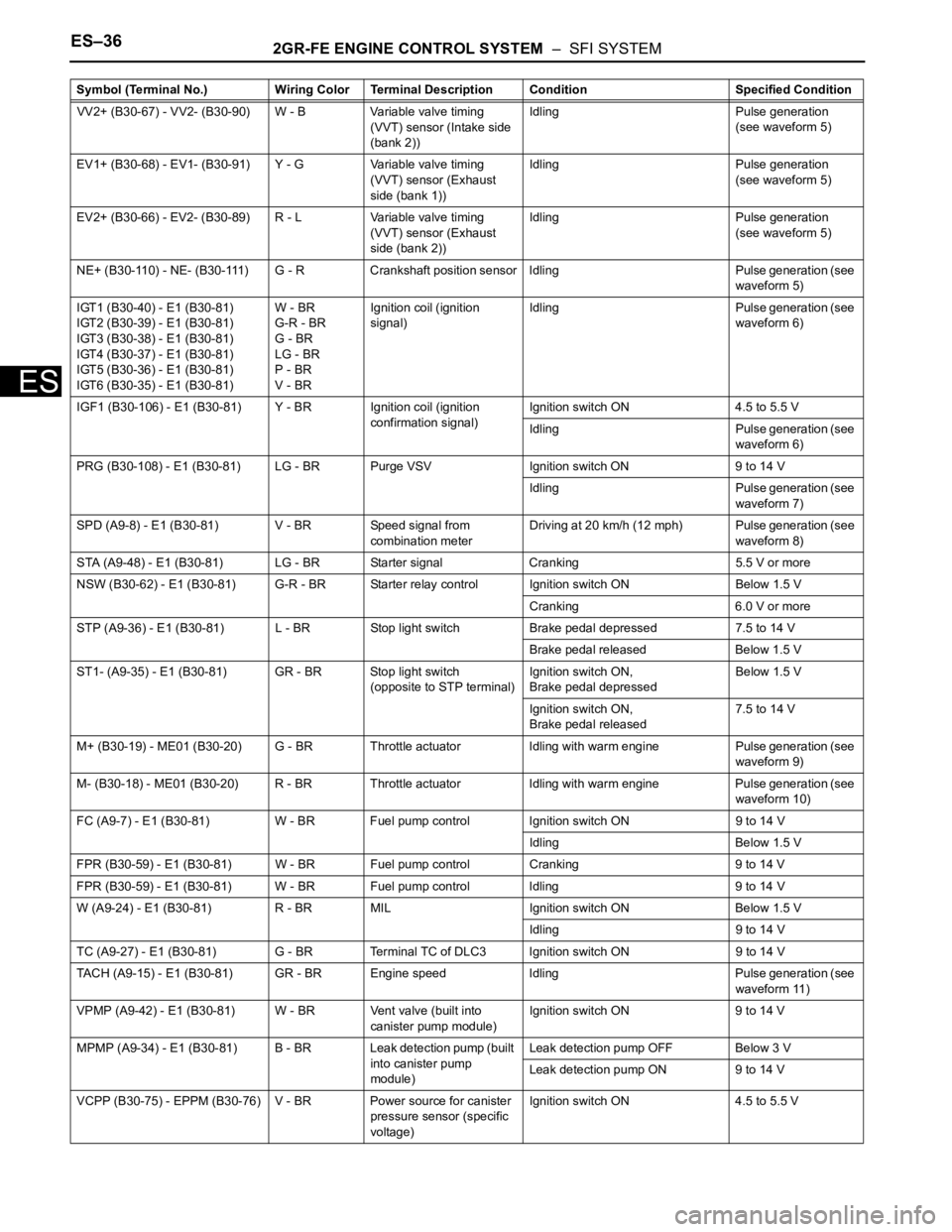

(b) WAVEFORM 1

Camshaft timing oil control valve (OCV)

PPMP (B30-77) - EPPM (B30-76) L - BR Canister pressure sensor

(built into canister pump

module)Ignition switch ON 3 to 3.6 V

ELS (A9-31) - E1 (B30-81) O - BR Electric load Taillight switch ON7.5 to 14 V

Taillight switch OFF Below 1.5 V

ELS2 (A9-33) - E1 (B30-81) G - BR Electric load Defogger switch ON7.5 to 14 V

Defogger switch OFF Below 1.5 V

ALT (B30-32) - E1 (B30-81) P - BR Generator Ignition switch ON 9 to 14 V

CANH (A9-41) - E1 (B30-81) Y - BR CAN communication line Ignition switch ON Pulse generation (see

waveform 12)

CANL (A9-49) - E1 (B30-81) W - BR CAN communication line Ignition switch ON Pulse generation (see

waveform 13)

VCIB (B30-80) - EIB (B30-101) LG - P Battery current sensor Ignition switch ON 4.5 to 5.5 V

IB (B30-100) - EIB (B30-101) R - P Battery current sensor Ignition switch ON 0.5 to 2.5 V

THB (B30-103) - EIB (B30-101) G-R - P Battery temperature

sensorIgnition switch ON, battery

temperature -30 to 80

C (-22 to

176

F)0.5 to 4.5 V

RLO (B30-31) - E1 (B30-81) Y - BR Generator After engine warmed up, during

charging control, vehicle driven at

constant speedPulse generation (see

waveform 14)

RLO (B30-31) - E1 (B30-81) Y - BR Generator After engine warmed up, during

charging control, vehicle

acceleratedPulse generation (see

waveform 15)

RLO (B30-31) - E1 (B30-81) Y - BR Generator After engine warmed up, during

charging control, vehicle

deceleratedPulse generation (see

waveform 16)

AICV (A9-4) - E1 (B30-81) L - BR VSV for air intake control

system operation signalIgnition switch ON 9 to 14 V

ACIS (B30-107) - E1 (B30-81) R - BR VSV for ACIS (Acoustic

Control Induction System)

operation signalIgnition switch ON 9 to 14 V Symbol (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

A093229E02

Symbol (Terminal No.) Between OC1+ and OC1-

Between OC2+ and OC2-

Between OE1+ and OE1-

Between OE2+ and OE2-

Tester Range 5 V/DIV., 1 msec./DIV.

Condition Idling

Page 562 of 2000

ES–382GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

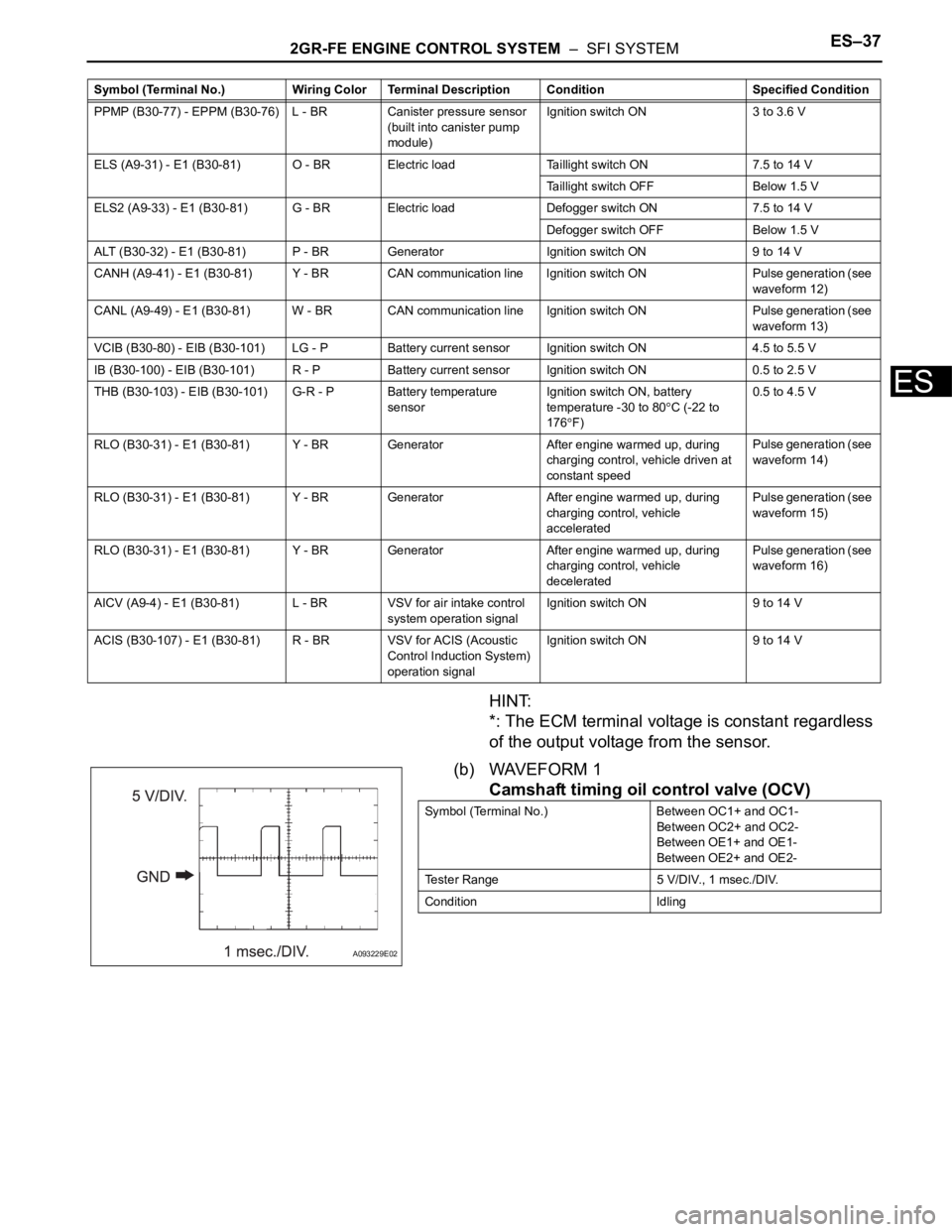

(c) WAVEFORM 2

Heated oxygen sensor

HINT:

In DATA LIST, item O2S B1 S2 shows the ECM

input values from the heated oxygen sensor.

(d) WAVEFORM 3

Injector No. 1 (to No. 4) injection signal

HINT:

The wavelength becomes shorter as the engine rpm

increases.

(e) WAVEFORM 4

Knock sensor

HINT:

• The wavelength becomes shorter as the engine

rpm increases.

• The waveforms and amplitudes displayed differ

slightly depending on the vehicle.

(f) WAVEFORM 5

Crankshaft position sensor and Camshaft

position sensor

HINT:

The wavelength becomes shorter as the engine rpm

increases.

A088863E05

Symbol (Terminal No.) Between OX1B and EX1B

Between OX2B and EX2B

Tester Range 0.2 V/DIV., 200 msec./DIV.

Condition Engine speed maintained at 2,500 rpm

for 2 minutes after warming up sensor

A093279E04

Symbol (Terminal No.) Between #10 (to #60) and E01

Tester Range 20 V/DIV., 20 msec./DIV.

Condition Idling

A085286E03

Symbol (Terminal No.) Between KNK1 and EKNK

Between KNK2 and EKN2

Tester Range 1 V/DIV., 1 msec./DIV.

Condition Engine speed maintained at 4,000 rpm

after warming up engine

A122767E04

Symbol (Terminal No.) Between NE+ and NE-

Between VV1+ and VV1-

Between EV1+ and EV1-

Between VV2+ and VV2-

Between EV2+ and EV2-

Tester Range 5 V/DIV., 20 msec./DIV.

Condition Idling

Page 563 of 2000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–39

ES

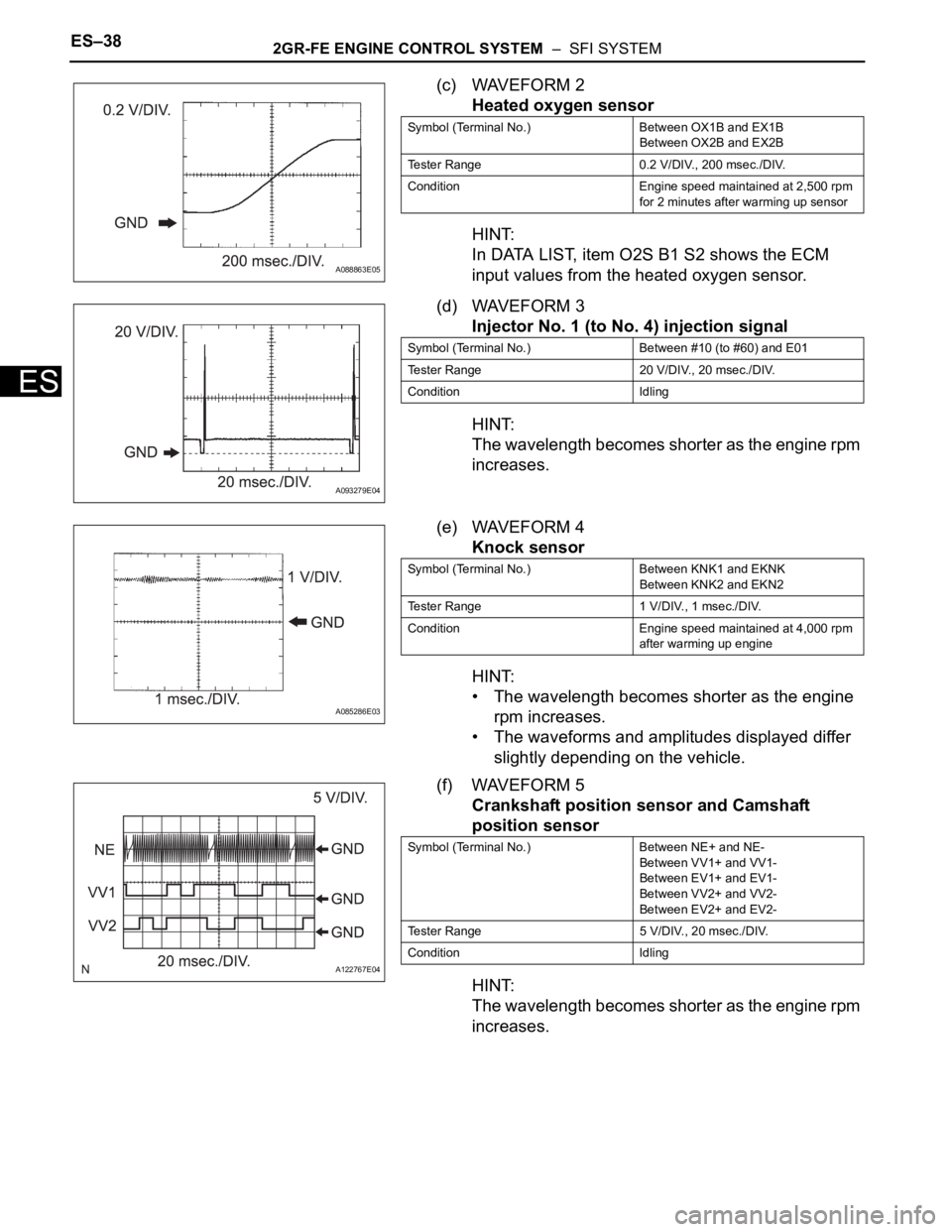

(g) WAVEFORM 6

Igniter IGT signal (from ECM to igniter) and

Igniter IGF signal (from igniter to ECM)

HINT:

The wavelength becomes shorter as the engine rpm

increases.

(h) WAVEFORM 7

Purge VSV

HINT:

If the waveform is not similar to the illustration,

check the waveform again after idling for 10 minutes

or more.

(i) WAVEFORM 8

Vehicle speed signal

HINT:

The wavelength becomes shorter as the vehicle

speed increases.

(j) WAVEFORM 9

Throttle actuator positive terminal

HINT:

The duty ratio varies depending on the throttle

actuator operation.

(k) WAVEFORM 10

Throttle actuator negative terminal

HINT:

The duty ratio varies depending on the throttle

actuator operation.

G035664E01

Symbol (Terminal No.) Between IGT (1 to 6) and E1

Between IGF1 and E1

Tester Range 2 V/DIV., 20 msec./DIV.

Condition Idling

A093230E01

Symbol (Terminal No.) Between PRG and E1

Tester Range 5 V/DIV., 50 msec./DIV.

Condition Idling

A093224E01

Symbol (Terminal No.) Between SPD and E1

Tester Range 2 V/DIV., 20 msec./DIV.

Condition Driving at 20 km/h (12 mph)

A093274E03

Symbol (Terminal No.) Between M+ and ME01

Tester Range 5 V/DIV., 1 msec./DIV.

Condition Idling with warm engine

A093275E03

Symbol (Terminal No.) Between M- and ME01

Tester Range 5 V/DIV., 1 msec./DIV.

Condition Idling with warm engine

Page 564 of 2000

ES–402GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

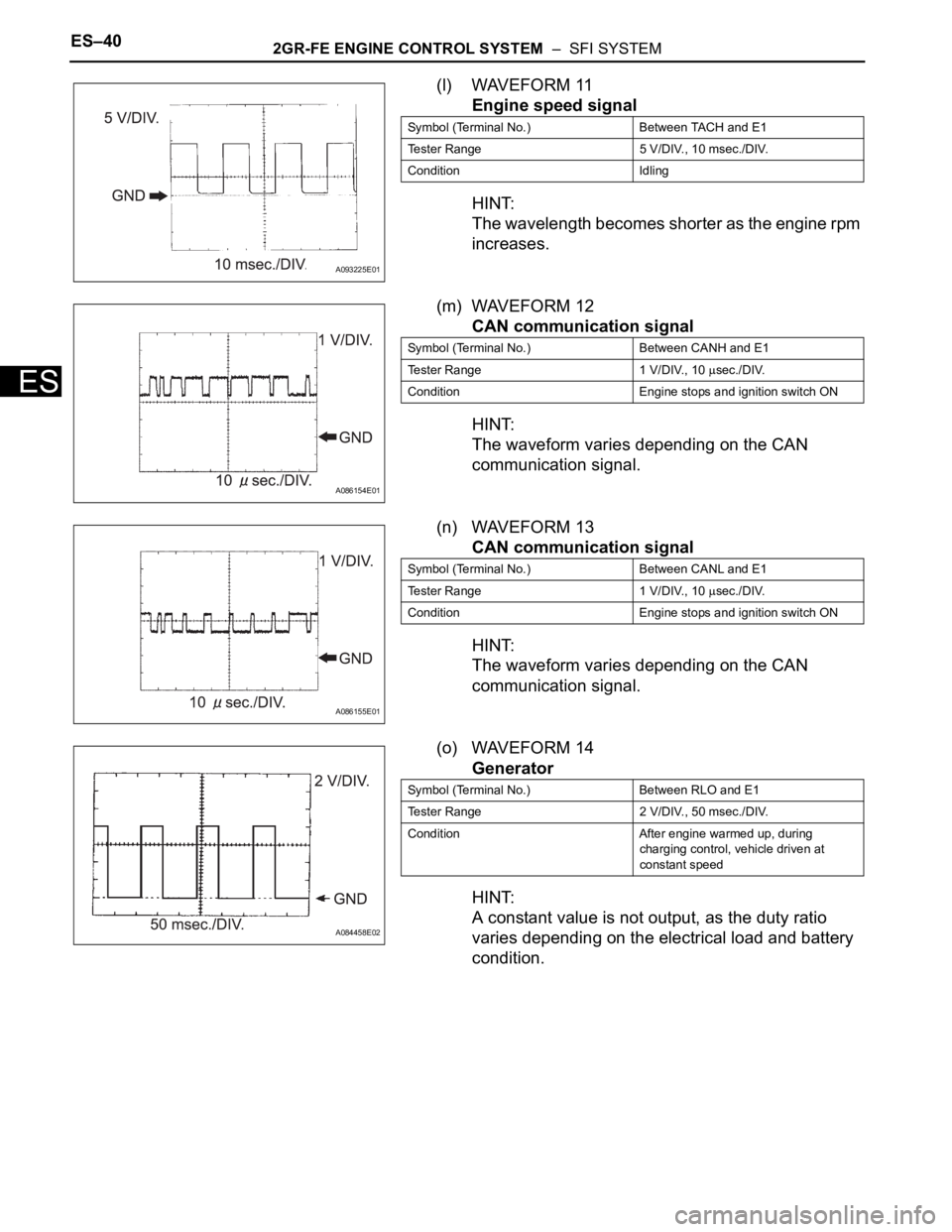

(l) WAVEFORM 11

Engine speed signal

HINT:

The wavelength becomes shorter as the engine rpm

increases.

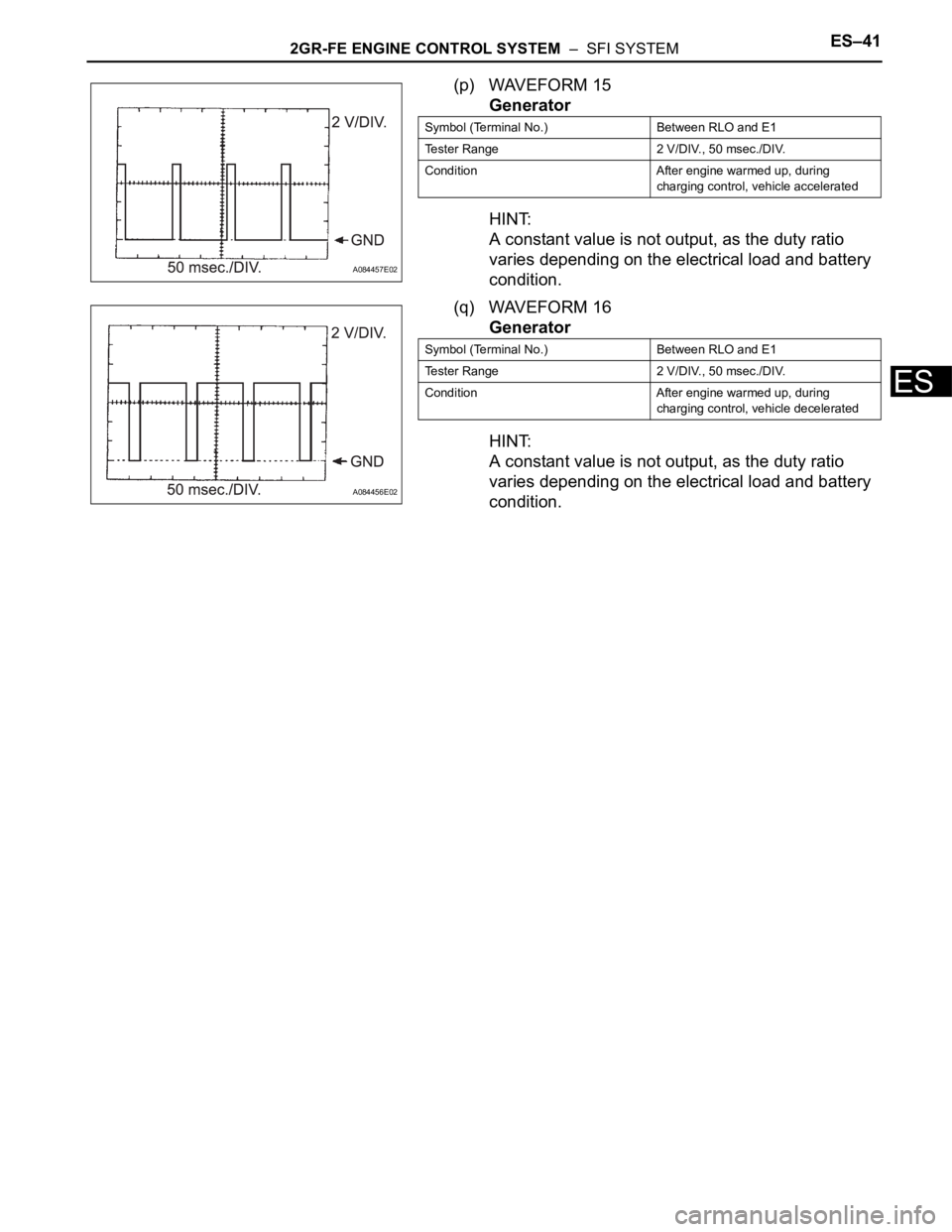

(m) WAVEFORM 12

CAN communication signal

HINT:

The waveform varies depending on the CAN

communication signal.

(n) WAVEFORM 13

CAN communication signal

HINT:

The waveform varies depending on the CAN

communication signal.

(o) WAVEFORM 14

Generator

HINT:

A constant value is not output, as the duty ratio

varies depending on the electrical load and battery

condition.

A093225E01

Symbol (Terminal No.) Between TACH and E1

Tester Range 5 V/DIV., 10 msec./DIV.

Condition Idling

A086154E01

Symbol (Terminal No.) Between CANH and E1

Tester Range 1 V/DIV., 10

sec./DIV.

Condition Engine stops and ignition switch ON

A086155E01

Symbol (Terminal No.) Between CANL and E1

Tester Range 1 V/DIV., 10

sec./DIV.

Condition Engine stops and ignition switch ON

A084458E02

Symbol (Terminal No.) Between RLO and E1

Tester Range 2 V/DIV., 50 msec./DIV.

Condition After engine warmed up, during

charging control, vehicle driven at

constant speed

Page 565 of 2000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–41

ES

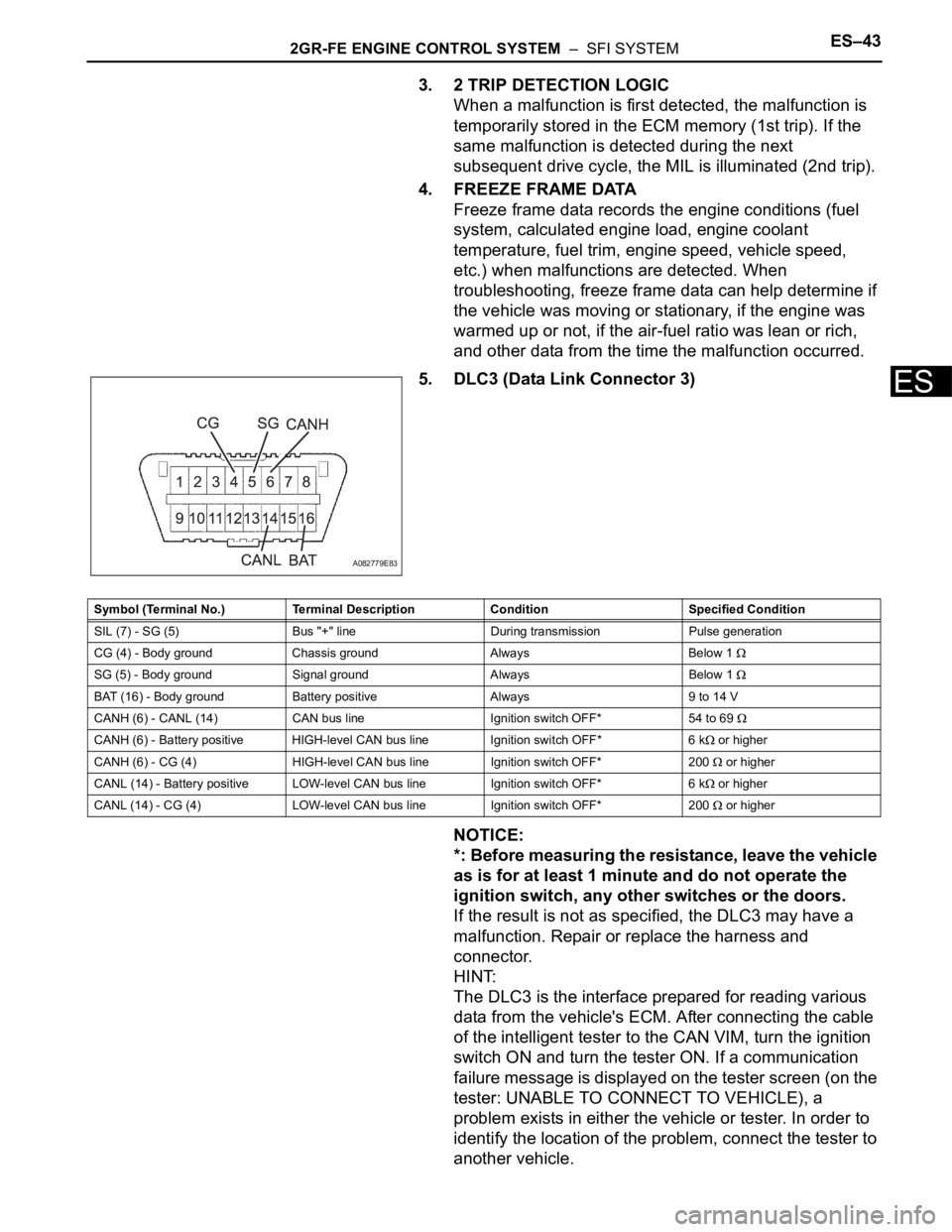

(p) WAVEFORM 15

Generator

HINT:

A constant value is not output, as the duty ratio

varies depending on the electrical load and battery

condition.

(q) WAVEFORM 16

Generator

HINT:

A constant value is not output, as the duty ratio

varies depending on the electrical load and battery

condition.

A084457E02

Symbol (Terminal No.) Between RLO and E1

Tester Range 2 V/DIV., 50 msec./DIV.

Condition After engine warmed up, during

charging control, vehicle accelerated

A084456E02

Symbol (Terminal No.) Between RLO and E1

Tester Range 2 V/DIV., 50 msec./DIV.

Condition After engine warmed up, during

charging control, vehicle decelerated

Page 567 of 2000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–43

ES

3. 2 TRIP DETECTION LOGIC

When a malfunction is first detected, the malfunction is

temporarily stored in the ECM memory (1st trip). If the

same malfunction is detected during the next

subsequent drive cycle, the MIL is illuminated (2nd trip).

4. FREEZE FRAME DATA

Freeze frame data records the engine conditions (fuel

system, calculated engine load, engine coolant

temperature, fuel trim, engine speed, vehicle speed,

etc.) when malfunctions are detected. When

troubleshooting, freeze frame data can help determine if

the vehicle was moving or stationary, if the engine was

warmed up or not, if the air-fuel ratio was lean or rich,

and other data from the time the malfunction occurred.

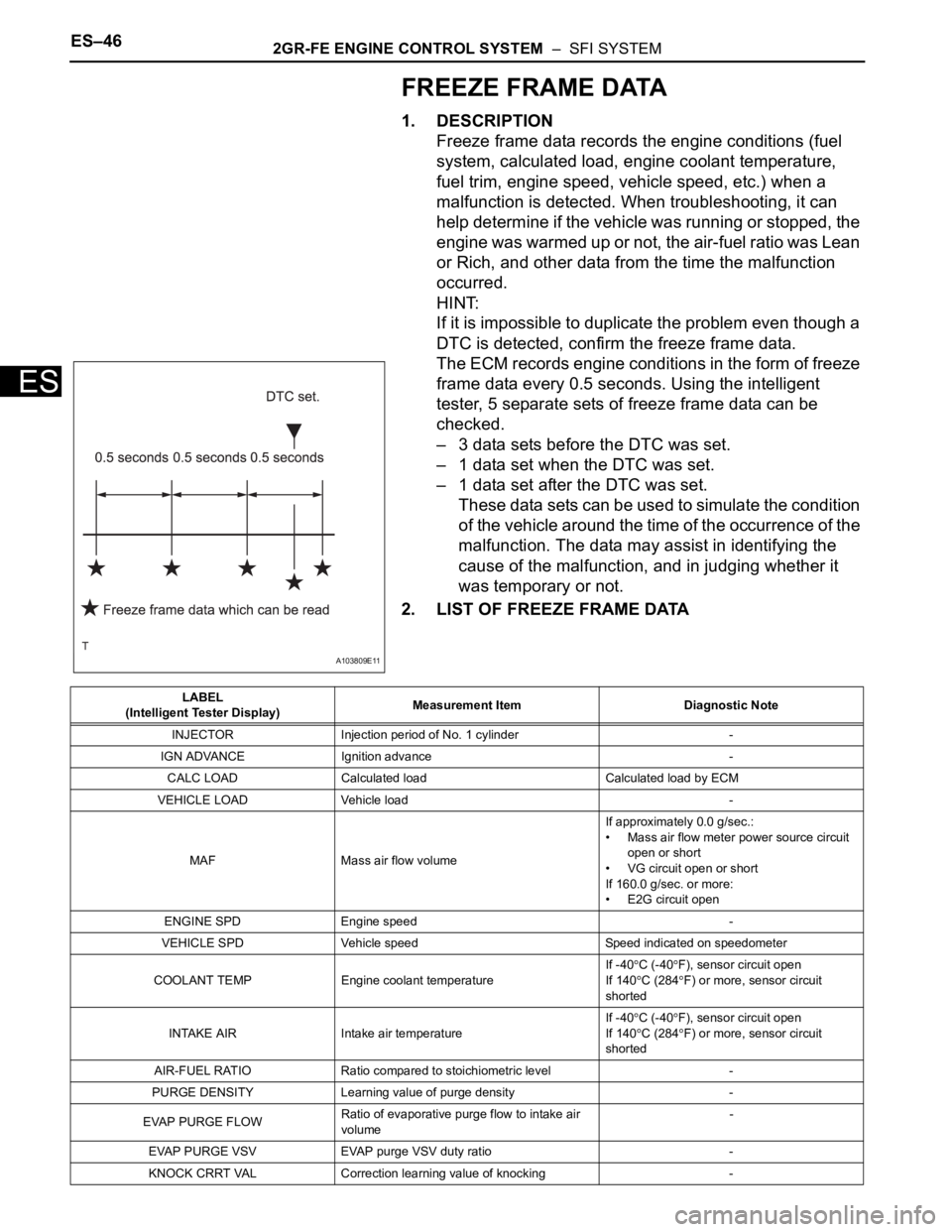

5. DLC3 (Data Link Connector 3)

NOTICE:

*: Before measuring the resistance, leave the vehicle

as is for at least 1 minute and do not operate the

ignition switch, any other switches or the doors.

If the result is not as specified, the DLC3 may have a

malfunction. Repair or replace the harness and

connector.

HINT:

The DLC3 is the interface prepared for reading various

data from the vehicle's ECM. After connecting the cable

of the intelligent tester to the CAN VIM, turn the ignition

switch ON and turn the tester ON. If a communication

failure message is displayed on the tester screen (on the

tester: UNABLE TO CONNECT TO VEHICLE), a

problem exists in either the vehicle or tester. In order to

identify the location of the problem, connect the tester to

another vehicle.

A082779E83

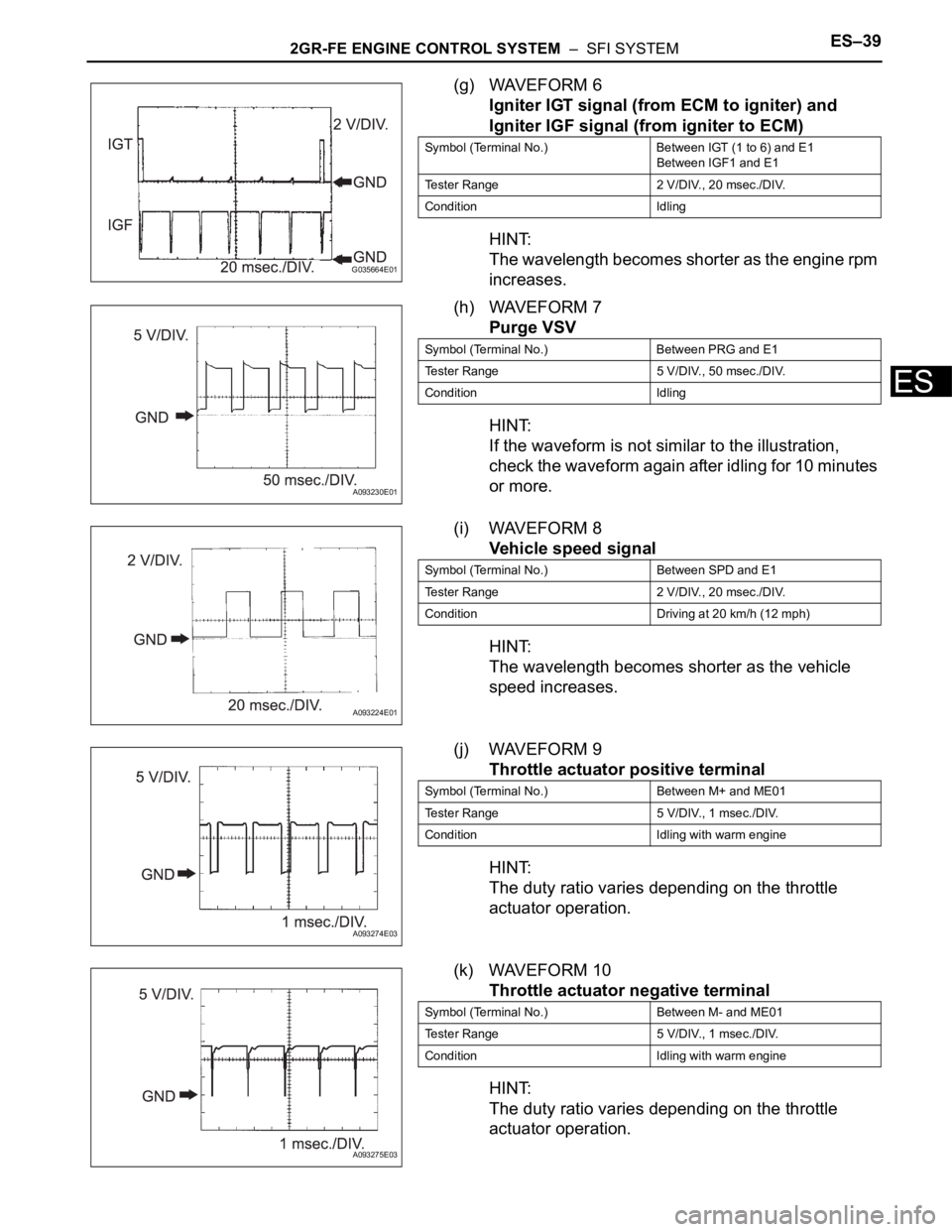

Symbol (Terminal No.) Terminal Description Condition Specified Condition

SIL (7) - SG (5) Bus "+" line During transmission Pulse generation

CG (4) - Body ground Chassis ground Always Below 1

SG (5) - Body ground Signal ground Always Below 1

BAT (16) - Body ground Battery positive Always 9 to 14 V

CANH (6) - CANL (14) CAN bus line Ignition switch OFF* 54 to 69

CANH (6) - Battery positive HIGH-level CAN bus line Ignition switch OFF* 6 k or higher

CANH (6) - CG (4) HIGH-level CAN bus line Ignition switch OFF* 200

or higher

CANL (14) - Battery positive LOW-level CAN bus line Ignition switch OFF* 6 k

or higher

CANL (14) - CG (4) LOW-level CAN bus line Ignition switch OFF* 200

or higher

Page 570 of 2000

ES–462GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

FREEZE FRAME DATA

1. DESCRIPTION

Freeze frame data records the engine conditions (fuel

system, calculated load, engine coolant temperature,

fuel trim, engine speed, vehicle speed, etc.) when a

malfunction is detected. When troubleshooting, it can

help determine if the vehicle was running or stopped, the

engine was warmed up or not, the air-fuel ratio was Lean

or Rich, and other data from the time the malfunction

occurred.

HINT:

If it is impossible to duplicate the problem even though a

DTC is detected, confirm the freeze frame data.

The ECM records engine conditions in the form of freeze

frame data every 0.5 seconds. Using the intelligent

tester, 5 separate sets of freeze frame data can be

checked.

– 3 data sets before the DTC was set.

– 1 data set when the DTC was set.

– 1 data set after the DTC was set.

These data sets can be used to simulate the condition

of the vehicle around the time of the occurrence of the

malfunction. The data may assist in identifying the

cause of the malfunction, and in judging whether it

was temporary or not.

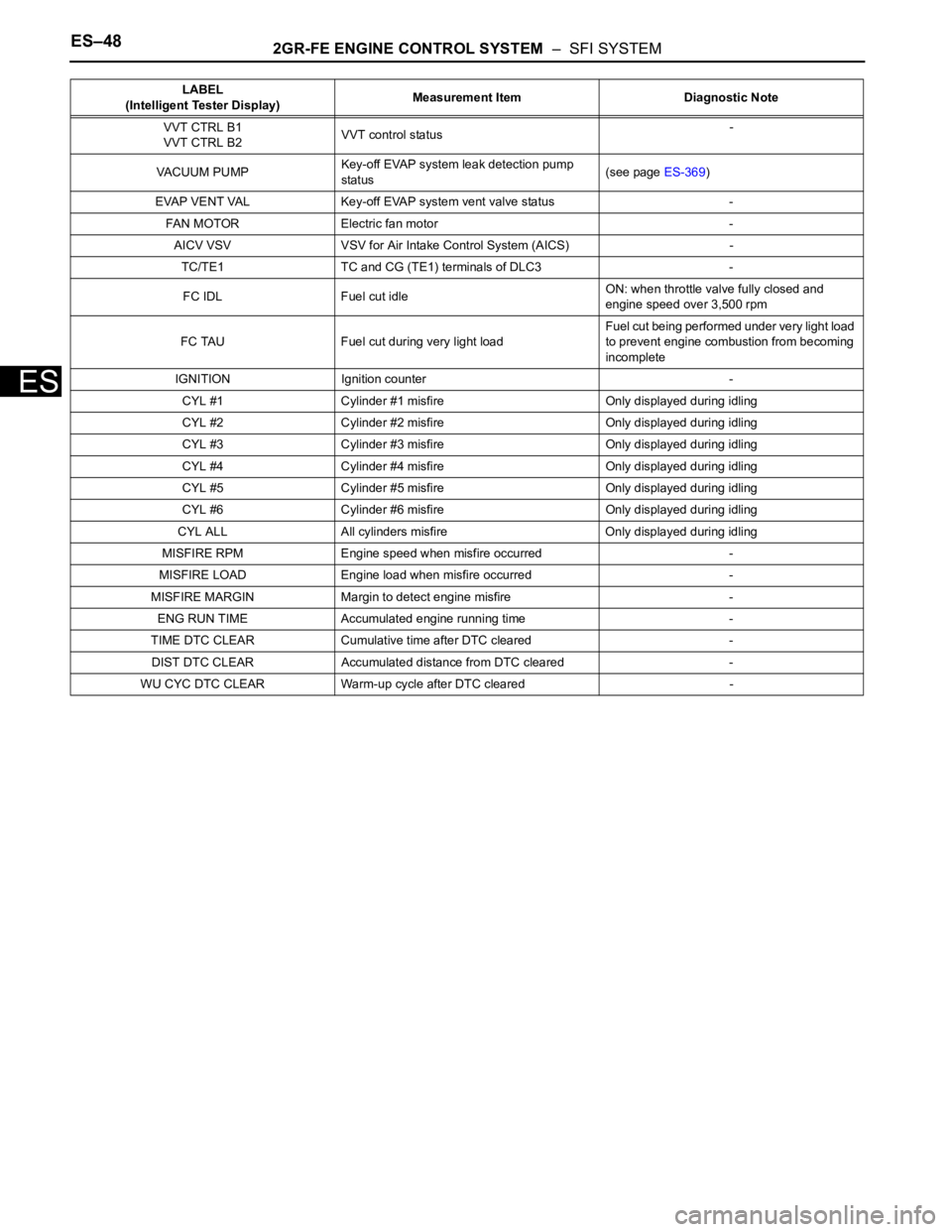

2. LIST OF FREEZE FRAME DATA

A103809E11

LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

INJECTOR Injection period of No. 1 cylinder -

IGN ADVANCE Ignition advance -

CALC LOAD Calculated load Calculated load by ECM

VEHICLE LOAD Vehicle load -

MAF Mass air flow volumeIf approximately 0.0 g/sec.:

• Mass air flow meter power source circuit

open or short

• VG circuit open or short

If 160.0 g/sec. or more:

• E2G circuit open

ENGINE SPD Engine speed -

VEHICLE SPD Vehicle speed Speed indicated on speedometer

COOLANT TEMP Engine coolant temperatureIf -40

C (-40F), sensor circuit open

If 140

C (284F) or more, sensor circuit

shorted

INTAKE AIR Intake air temperature If -40

C (-40F), sensor circuit open

If 140

C (284F) or more, sensor circuit

shorted

AIR-FUEL RATIO Ratio compared to stoichiometric level -

PURGE DENSITY Learning value of purge density -

EVAP PURGE FLOWRatio of evaporative purge flow to intake air

volume-

EVAP PURGE VSV EVAP purge VSV duty ratio -

KNOCK CRRT VAL Correction learning value of knocking -

Page 572 of 2000

ES–482GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

VVT CTRL B1

VVT CTRL B2VVT control status-

VA C U U M P U M PKey-off EVAP system leak detection pump

status(see page ES-369)

EVAP VENT VAL Key-off EVAP system vent valve status -

FAN MOTOR Electric fan motor -

AICV VSV VSV for Air Intake Control System (AICS) -

TC/TE1 TC and CG (TE1) terminals of DLC3 -

FC IDL Fuel cut idleON: when throttle valve fully closed and

engine speed over 3,500 rpm

FC TAU Fuel cut during very light loadFuel cut being performed under very light load

to prevent engine combustion from becoming

incomplete

IGNITION Ignition counter -

CYL #1 Cylinder #1 misfire Only displayed during idling

CYL #2 Cylinder #2 misfire Only displayed during idling

CYL #3 Cylinder #3 misfire Only displayed during idling

CYL #4 Cylinder #4 misfire Only displayed during idling

CYL #5 Cylinder #5 misfire Only displayed during idling

CYL #6 Cylinder #6 misfire Only displayed during idling

CYL ALL All cylinders misfire Only displayed during idling

MISFIRE RPM Engine speed when misfire occurred -

MISFIRE LOAD Engine load when misfire occurred -

MISFIRE MARGIN Margin to detect engine misfire -

ENG RUN TIME Accumulated engine running time -

TIME DTC CLEAR Cumulative time after DTC cleared -

DIST DTC CLEAR Accumulated distance from DTC cleared -

WU CYC DTC CLEAR Warm-up cycle after DTC cleared -LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 1337 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–9

TF

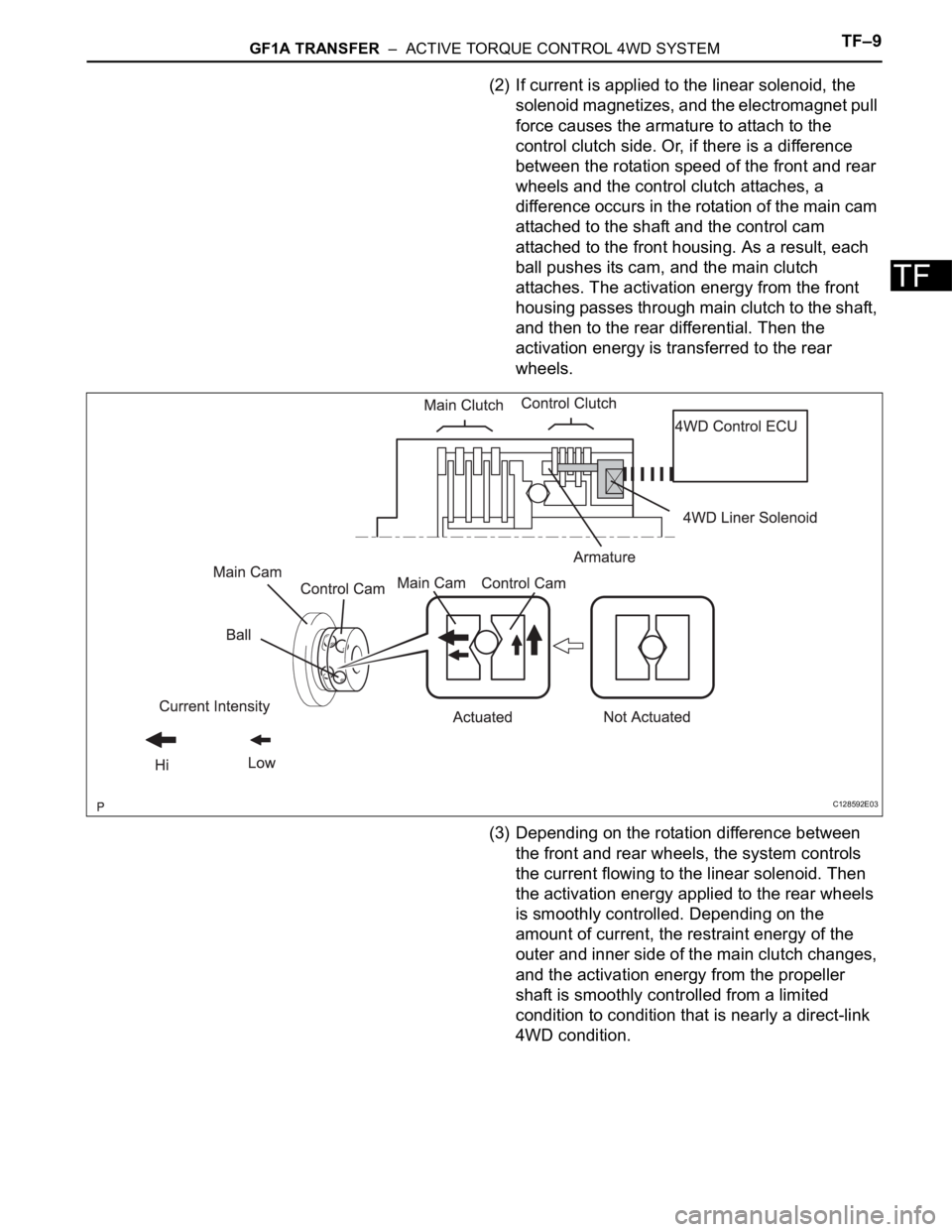

(2) If current is applied to the linear solenoid, the

solenoid magnetizes, and the electromagnet pull

force causes the armature to attach to the

control clutch side. Or, if there is a difference

between the rotation speed of the front and rear

wheels and the control clutch attaches, a

difference occurs in the rotation of the main cam

attached to the shaft and the control cam

attached to the front housing. As a result, each

ball pushes its cam, and the main clutch

attaches. The activation energy from the front

housing passes through main clutch to the shaft,

and then to the rear differential. Then the

activation energy is transferred to the rear

wheels.

(3) Depending on the rotation difference between

the front and rear wheels, the system controls

the current flowing to the linear solenoid. Then

the activation energy applied to the rear wheels

is smoothly controlled. Depending on the

amount of current, the restraint energy of the

outer and inner side of the main clutch changes,

and the activation energy from the propeller

shaft is smoothly controlled from a limited

condition to condition that is nearly a direct-link

4WD condition.

C128592E03