engine oil TOYOTA RAV4 2006 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 114 of 2000

ENGINE - 2GR-FE ENGINE

01MEG18Y

Accelerator Pedal

Position SensorThrottle ValveThrottle Position Sensor

Throttle Control

Motor

Mass Air

Flow Meter

Cruise Control

Switch

Skid Control

ECUECMIgnition Coil

Fuel Injection EG-118

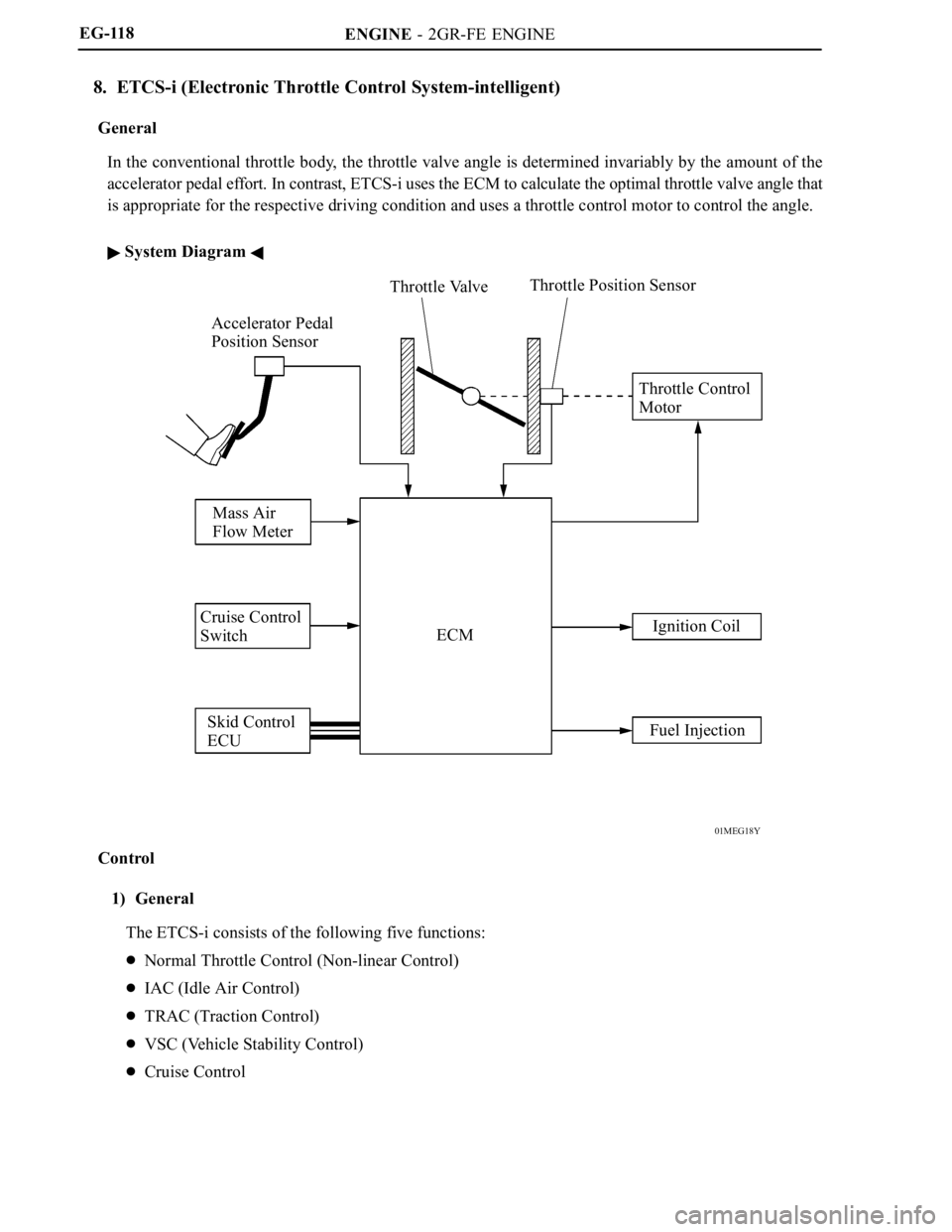

8. ETCS-i (Electronic Throttle Control System-intelligent)

General

In the conventional throttle body, the throttle valve angle is determined invariably by the amount of the

accelerator pedal effort. In contrast, ETCS-i uses the ECM to calculate the optimal throttle valve angle that

is appropriate for the respective driving condition and uses a throttle control motor to control the angle.

System Diagram

Control

1) General

The ETCS-i consists of the following five functions:

Normal Throttle Control (Non-linear Control)

IAC (Idle Air Control)

TRAC (Traction Control)

VSC (Vehicle Stability Control)

Cruise Control

Page 116 of 2000

ENGINE - 2GR-FE ENGINE

285EG57

Exhaust Camshaft Timing OCV* (Bank 1)

Intake Camshaft Timing OCV* (Bank 1)

Exhaust VVT Sensor (Bank 1)

Engine Coolant Temperature Sensor

Intake Camshaft

Timing OCV* (Bank 2)

Exhaust VVT

Sensor (Bank 2)

Exhaust Camshaft

Timing OCV*

(Bank 2)

Intake VVT Sensor (Bank 2)

Crankshaft Position Sensor

Intake VVT Sensor (Bank 1)ECM

Mass Air Flow MeterThrottle Position Sensor

221EG16

Crankshaft Position Sensor

Mass Air Flow Meter

Throttle Position Sensor

Engine Coolant Temp. Sensor

Intake and Exhaust VVT Sensors

Vehicle Speed SignalECM

Ta r g e t Va l v e Ti m i n g

Feedback

Correction

Actual Valve Timing

Duty-cycle

Control

Camshaft Timing

Oil Control Valve

EG-120

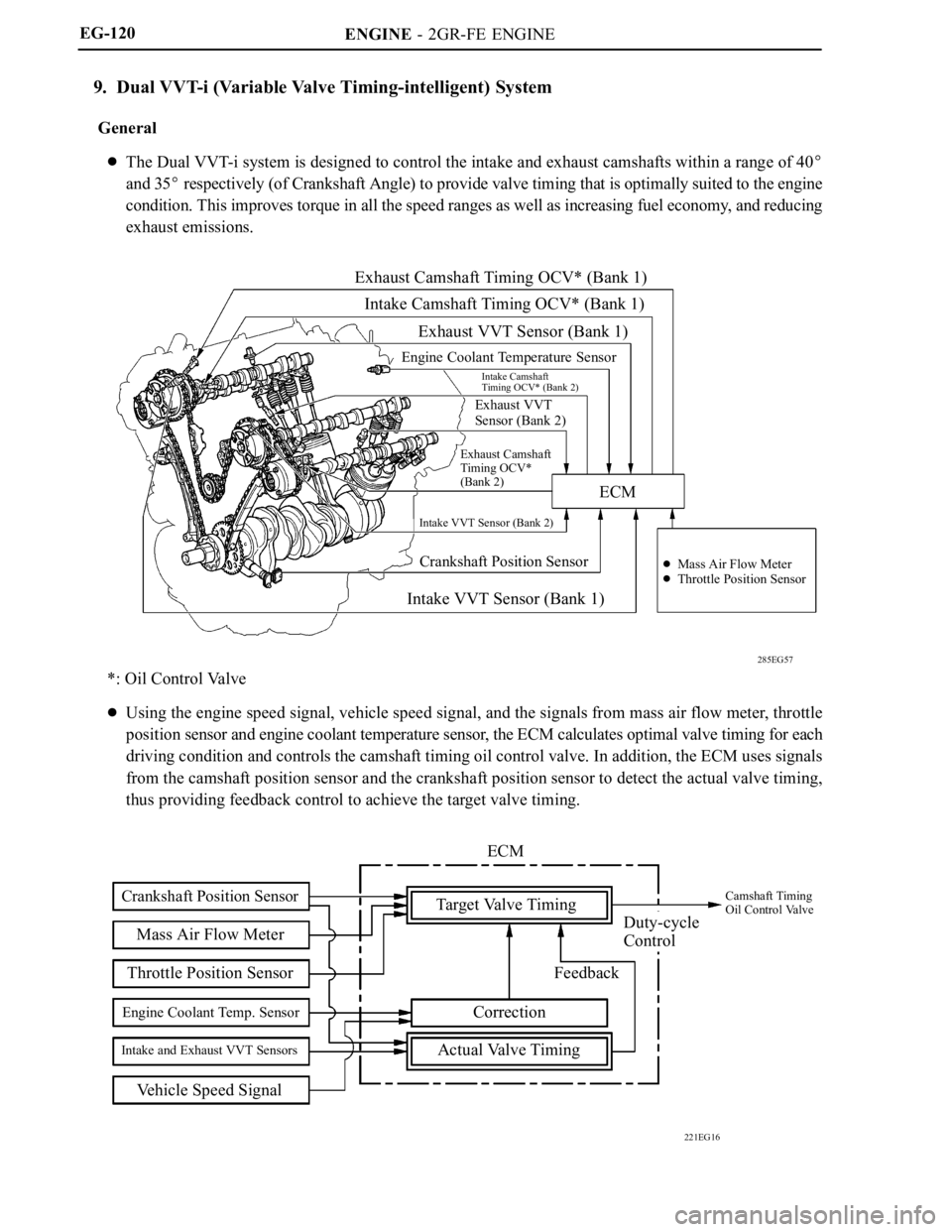

9. Dual VVT-i (Variable Valve Timing-intelligent) System

General

The Dual VVT-i system is designed to control the intake and exhaust camshafts within a range of 40

and 35 respectively (of Crankshaft Angle) to provide valve timing that is optimally suited to the engine

condition. This improves torque in all the speed ranges as well as increasing fuel economy, and reducing

exhaust emissions.

*: Oil Control Valve

Using the engine speed signal, vehicle speed signal, and the signals from mass air flow meter, throttle

position sensor and engine coolant temperature sensor, the ECM calculates optimal valve timing for each

driving condition and controls the camshaft timing oil control valve. In addition, the ECM uses signals

from the camshaft position sensor and the crankshaft position sensor to detect the actual valve timing,

thus providing feedback control to achieve the target valve timing.

Page 118 of 2000

ENGINE - 2GR-FE ENGINE

271EG93

Timing RotorHousingLock PinSprocket

Intake Camshaft

Vane (Fixed on Intake Camshaft)

Oil Pressure

In Operation At a Stop

Lock Pin

281EG47

Housing

Advanced Angle Assist SpringVane (Fixed on Exhaust Camshaft)Lock PinExhaust Camshaft Sprocket EG-122

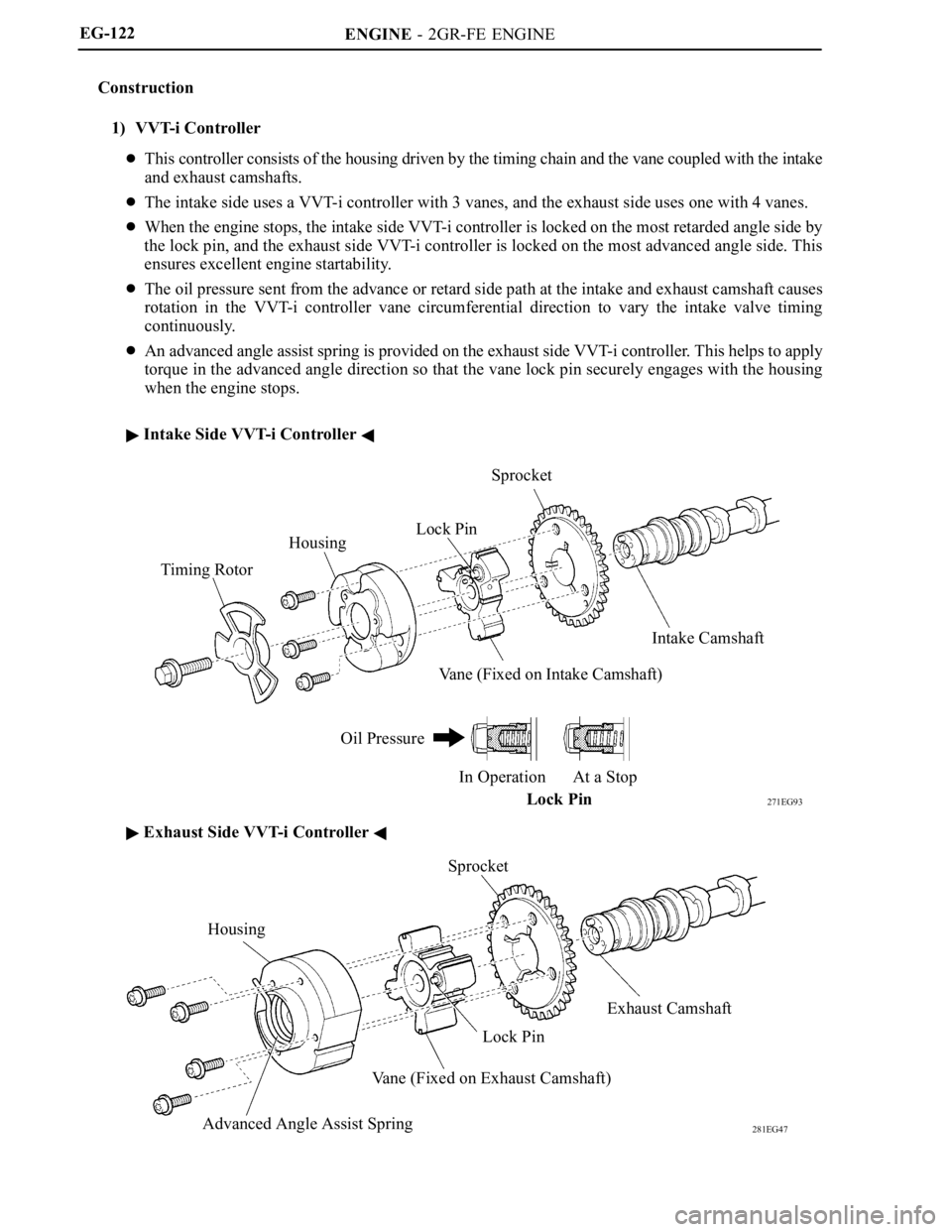

Construction

1) VVT-i Controller

This controller consists of the housing driven by the timing chain and the vane coupled with the intake

and exhaust camshafts.

The intake side uses a VVT-i controller with 3 vanes, and the exhaust side uses one with 4 vanes.

When the engine stops, the intake side VVT-i controller is locked on the most retarded angle side by

the lock pin, and the exhaust side VVT-i controller is locked on the most advanced angle side. This

ensures excellent engine startability.

The oil pressure sent from the advance or retard side path at the intake and exhaust camshaft causes

rotation in the VVT-i controller vane circumferential direction to vary the intake valve timing

continuously.

An advanced angle assist spring is provided on the exhaust side VVT-i controller. This helps to apply

torque in the advanced angle direction so that the vane lock pin securely engages with the housing

when the engine stops.

Intake Side VVT-i Controller

Exhaust Side VVT-i Controller

Page 119 of 2000

ENGINE - 2GR-FE ENGINE

238EG62

To VVT-i Controller

(Advance Side) *To VVT-i Controller

(Retard Side) *

Sleeve

Spring

Drain

Oil PressureDrain

Spool ValveCoil

PlungerEG-123

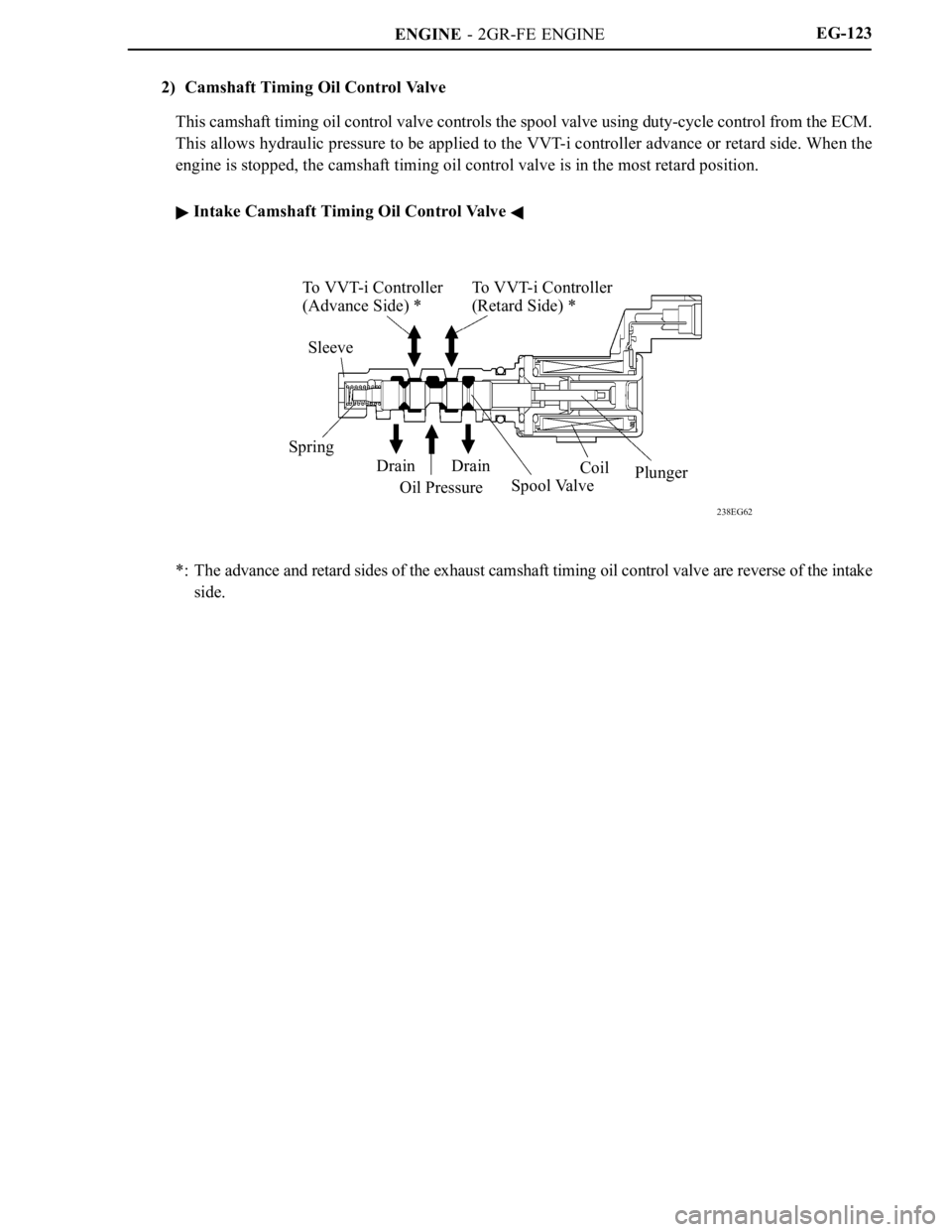

2) Camshaft Timing Oil Control Valve

This camshaft timing oil control valve controls the spool valve using duty-cycle control from the ECM.

This allows hydraulic pressure to be applied to the VVT-i controller advance or retard side. When the

engine is stopped, the camshaft timing oil control valve is in the most retard position.

Intake Camshaft Timing Oil Control Valve

*: The advance and retard sides of the exhaust camshaft timing oil control valve are reverse of the intake

side.

Page 120 of 2000

ENGINE - 2GR-FE ENGINE

238EG63

Va n e

Rotational Direction

Oil Pressure

IN DrainECM

281EG48

Va n e

Rotational DirectionECM

Oil Pressure

IN Drain EG-124

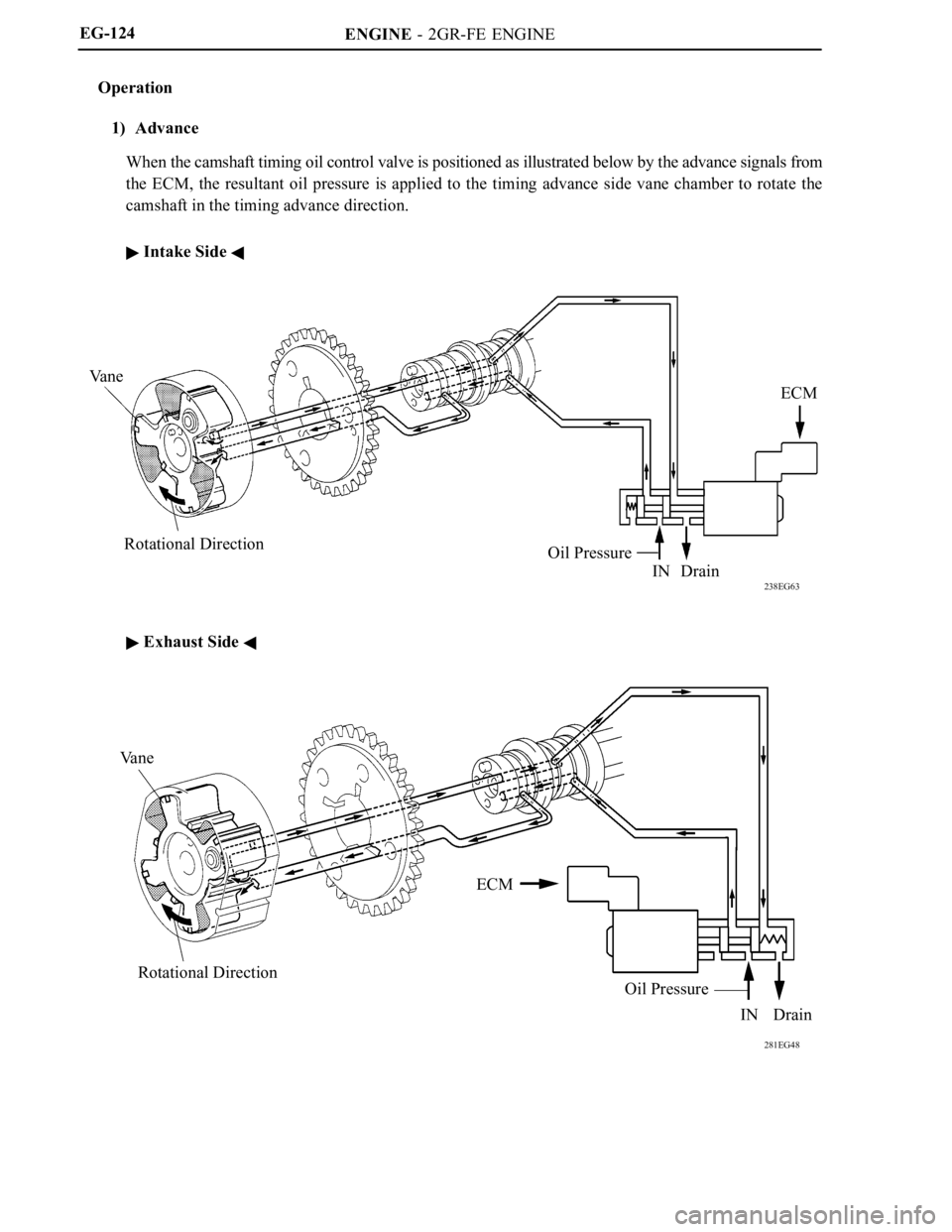

Operation

1) Advance

When the camshaft timing oil control valve is positioned as illustrated below by the advance signals from

the ECM, the resultant oil pressure is applied to the timing advance side vane chamber to rotate the

camshaft in the timing advance direction.

Intake Side

Exhaust Side

Page 121 of 2000

ENGINE - 2GR-FE ENGINE

238EG64

Rotational Direction

Va n e

Drain INOil PressureECM

281EG49

Rotational Direction

Va n eECM

Drain INOil Pressure

EG-125

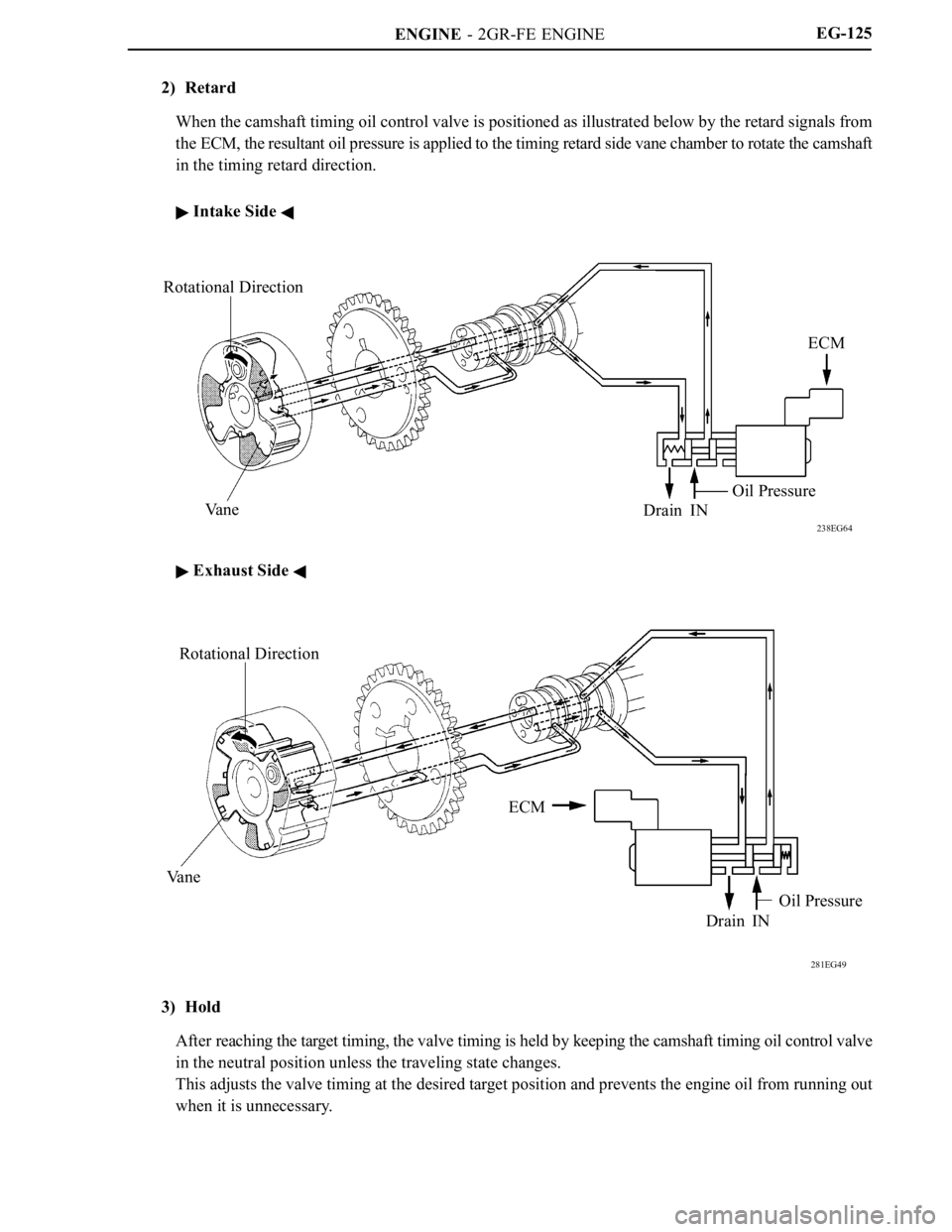

2) Retard

When the camshaft timing oil control valve is positioned as illustrated below by the retard signals from

the ECM, the resultant oil pressure is applied to the timing retard side vane chamber to rotate the camshaft

in the timing retard direction.

Intake Side

Exhaust Side

3) Hold

After reaching the target timing, the valve timing is held by keeping the camshaft timing oil control valve

in the neutral position unless the traveling state changes.

This adjusts the valve timing at the desired target position and prevents the engine oil from running out

when it is unnecessary.

Page 131 of 2000

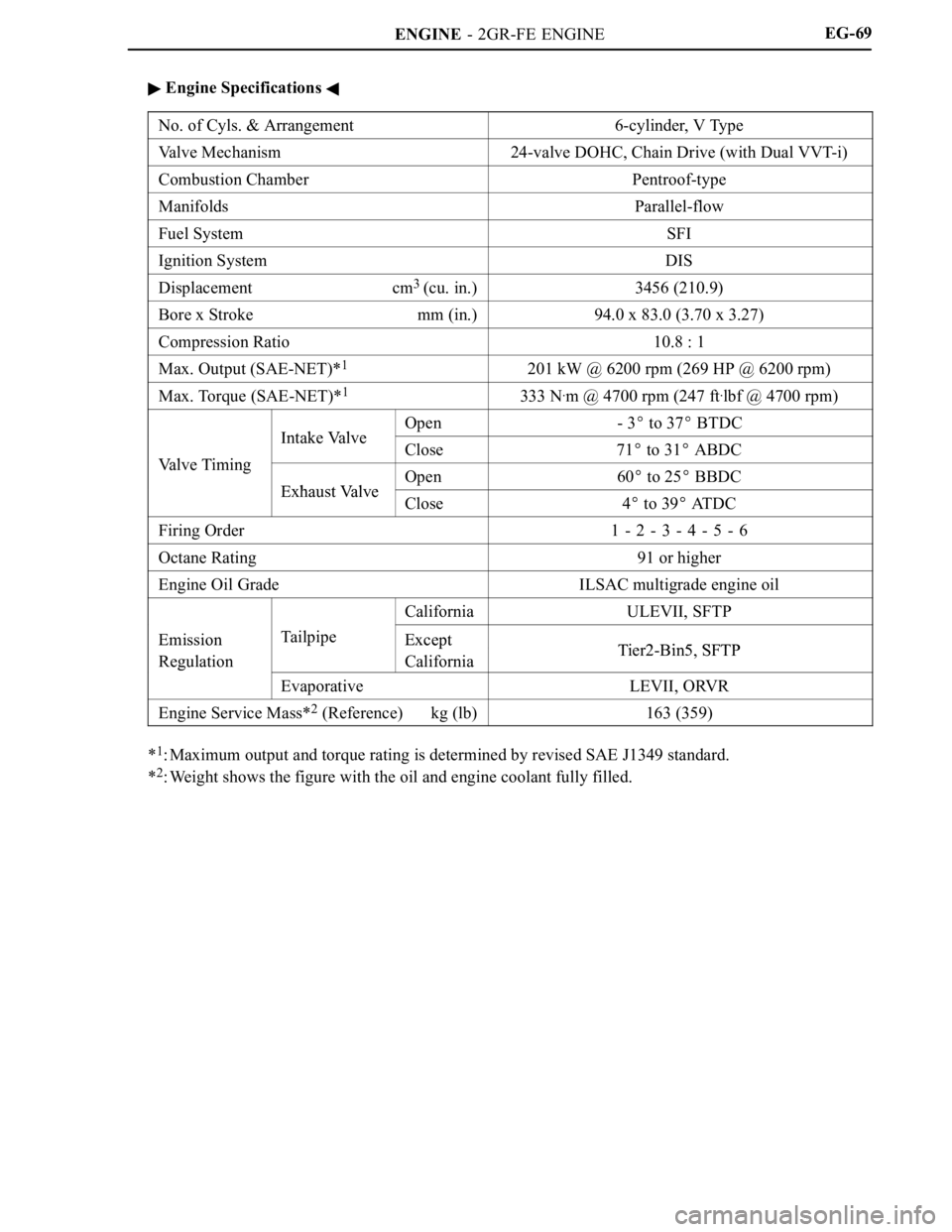

ENGINE - 2GR-FE ENGINEEG-69

Engine Specifications

No. of Cyls. & Arrangement6-cylinder, V Type

Valve Mechanism24-valve DOHC, Chain Drive (with Dual VVT-i)

Combustion ChamberPentroof-type

ManifoldsParallel-flow

Fuel SystemSFI

Ignition SystemDIS

Displacement cm3

(cu. in.)3456 (210.9)

Bore x Stroke mm (in.)94.0 x 83.0 (3.70 x 3.27)

Compression Ratio10.8 : 1

Max. Output (SAE-NET)*1201 kW @ 6200 rpm (269 HP @ 6200 rpm)

Max. Torque (SAE-NET)*1333 N.m @ 4700 rpm (247 ft.lbf @ 4700 rpm)

Intake ValveOpen-3 to 37 BTDC

Valve Timing

Intake ValveClose71 to 31 ABDCVa l v e T i m i n g

Exhaust ValveOpen60 to 25 BBDCExhaust ValveClose4 to 39 ATDC

Firing Order1 - 2 - 3 - 4 - 5 - 6

Octane Rating91 or higher

Engine Oil GradeILSAC multigrade engine oil

CaliforniaULEVII, SFTP

EmissionTailpipeExceptTier2 Bin5 SFTPEmission

Regulation

ppExcept

CaliforniaTier2-Bin5, SFTPg

EvaporativeLEVII, ORVR

Engine Service Mass*2 (Reference) kg (lb)163 (359)

*1: Maximum output and torque rating is determined by revised SAE J1349 standard.

*

2: Weight shows the figure with the oil and engine coolant fully filled.

Page 179 of 2000

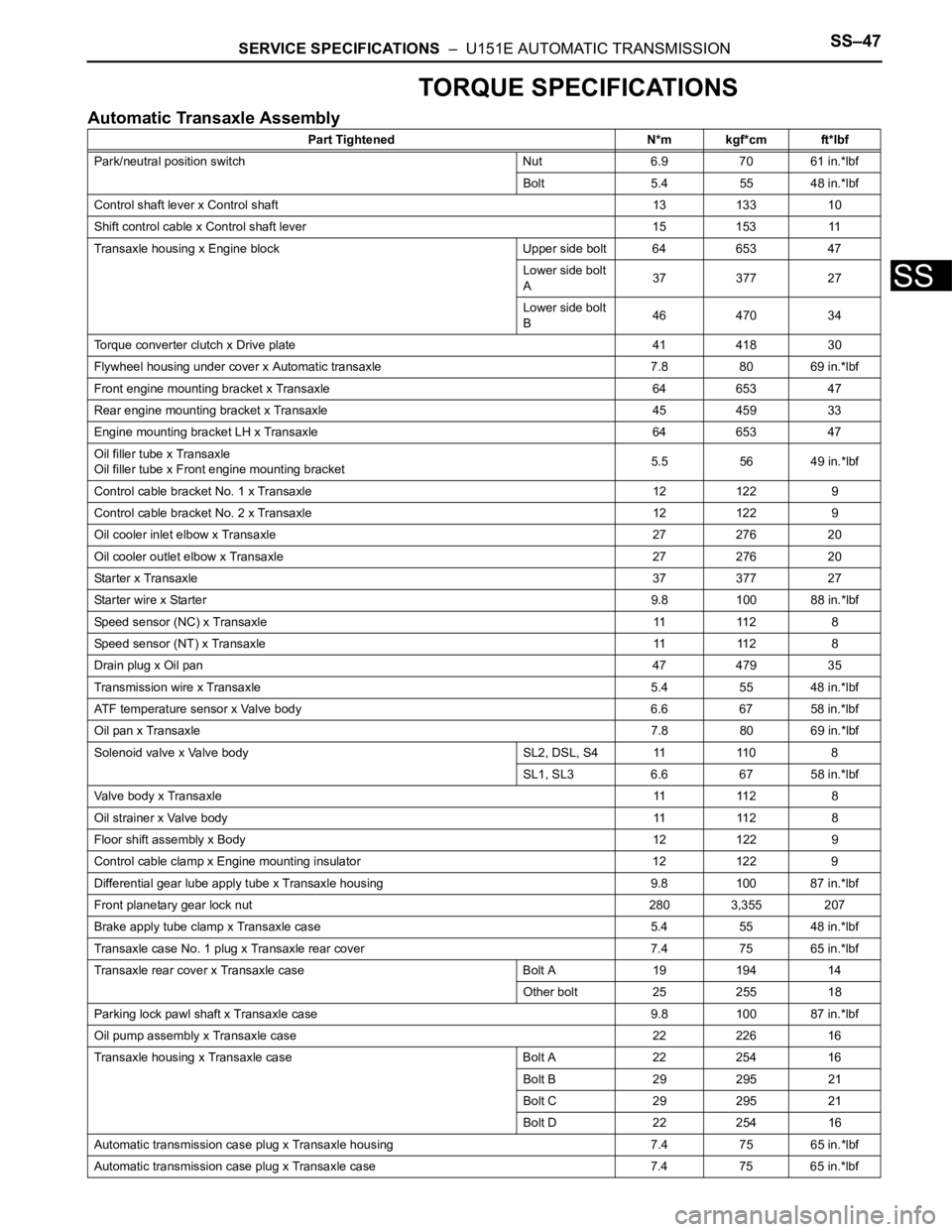

SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSMISSIONSS–47

SS

TORQUE SPECIFICATIONS

Automatic Transaxle Assembly

Part Tightened N*m kgf*cm ft*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 13 133 10

Shift control cable x Control shaft lever 15 153 11

Transaxle housing x Engine block Upper side bolt 64 653 47

Lower side bolt

A37 377 27

Lower side bolt

B46 470 34

Torque converter clutch x Drive plate 41 418 30

Flywheel housing under cover x Automatic transaxle 7.8 80 69 in.*lbf

Front engine mounting bracket x Transaxle 64 653 47

Rear engine mounting bracket x Transaxle 45 459 33

Engine mounting bracket LH x Transaxle 64 653 47

Oil filler tube x Transaxle

Oil filler tube x Front engine mounting bracket5.5 56 49 in.*lbf

Control cable bracket No. 1 x Transaxle 12 122 9

Control cable bracket No. 2 x Transaxle 12 122 9

Oil cooler inlet elbow x Transaxle 27 276 20

Oil cooler outlet elbow x Transaxle 27 276 20

Starter x Transaxle37 377 27

Starter wire x Starter9.8 100 88 in.*lbf

Speed sensor (NC) x Transaxle 11 112 8

Speed sensor (NT) x Transaxle 11 112 8

Drain plug x Oil pan47 479 35

Transmission wire x Transaxle 5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.8 80 69 in.*lbf

Solenoid valve x Valve body SL2, DSL, S4 11 110 8

SL1, SL3 6.6 67 58 in.*lbf

Valve body x Transaxle11 11 2 8

Oil strainer x Valve body11 11 2 8

Floor shift assembly x Body12 122 9

Control cable clamp x Engine mounting insulator 12 122 9

Differential gear lube apply tube x Transaxle housing 9.8 100 87 in.*lbf

Front planetary gear lock nut 280 3,355 207

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 19 194 14

Other bolt 25 255 18

Parking lock pawl shaft x Transaxle case 9.8 100 87 in.*lbf

Oil pump assembly x Transaxle case 22 226 16

Transaxle housing x Transaxle case Bolt A 22 254 16

Bolt B 29 295 21

Bolt C 29 295 21

Bolt D 22 254 16

Automatic transmission case plug x Transaxle housing 7.4 75 65 in.*lbf

Automatic transmission case plug x Transaxle case 7.4 75 65 in.*lbf

Page 182 of 2000

MAINTENANCE – UNDER HOODMA–7

MA

GENERAL MAINTENANCE

(2006/01- )

1. GENERAL NOTES

• Maintenance requirements vary depending on the

country.

• Check the maintenance schedule in the owner's

manual supplement.

• Following the maintenance schedule is mandatory.

• Determine the appropriate time to service the vehicle

using either miles driven or time elapsed, whichever

reaches the specification first.

• Maintain similar intervals between periodic

maintenance, unless otherwise noted.

• Failing to check each vehicle part could lead to poor

engine performance and increase exhaust emissions.

2. WINDSHIELD WASHER FLUID

(a) Check that there is sufficient fluid in the tank.

3. ENGINE COOLANT LEVEL

(a) Check that the coolant level is between the "FULL"

and "LOW" lines on the see-through reservoir.

4. RADIATOR AND HOSES

(a) Check that the front of the radiator is clean and not

blocked by leaves, dirt or bugs.

(b) Check the hoses for cracks, kinks, rot or loose

connections.

5. BATTERY ELECTROLYTE LEVEL

(a) Check that the electrolyte level of all the battery

cells is between the upper and lower level lines on

the case.

HINT:

If the electrolyte level is difficult to see, lightly shake

the vehicle.

6. BRAKE FLUID LEVEL

(a) Check that the brake fluid levels are near the upper

level lines on the see-through reservoirs.

7. ENGINE DRIVE BELT

(a) Check the drive belt for fraying, cracks, wear or

oiliness.

8. ENGINE OIL LEVEL

(a) Check the level on the dipstick with the engine

stopped.

9. AUTOMATIC TRANSAXLE FLUID LEVEL

10. EXHAUST SYSTEM

(a) Check for unusual exhaust sounds or abnormal

exhaust fumes. Inspect the cause and repair it.

Type See procedures

U151E See page AX-126

U151F See page AX-126

Page 196 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–21

EM

REMOVAL

1. DISCHARGE REFRIGERANT FROM

REFRIGERATION SYSTEM (See page AC-172)

2. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-13)

3. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

4. REMOVE NO. 1 ENGINE UNDER COVER

(a) Remove the 4 bolts, 12 clips and under cover.

5. REMOVE REAR ENGINE UNDER COVER RH

(a) Remove the 2 clips and under cover.

6. REMOVE REAR ENGINE UNDER COVER LH

(a) Remove the 2 clips and under cover.

7. REMOVE NO. 2 ENGINE UNDER COVER

(a) Remove the 2 clips and under cover.

8. REMOVE FRONT FLOOR COVER (See page FU-34)

9. DRAIN ENGINE COOLANT (See page CO-8)

10. DRAIN ENGINE OIL (See page LU-4)

11. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) 2WD:

Drain automatic transaxle fluid (see page AX-172).

(b) 4WD:

Drain automatic transaxle fluid (see page AX-173)

12. DRAIN TRANSFER OIL (for 4WD)

13. REMOVE HOOD SUB-ASSEMBLY (See page ED-4)

14. REMOVE V-BANK COVER SUB-ASSEMBLY

(a) Detach the 3 clips and remove the V-bank cover.

A137900