TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 951 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–17

AX

(2) Check engine braking.

While driving the vehicle with the shift lever on L,

release the accelerator pedal and check the

engine braking effect.

(3) Check for abnormal noises during acceleration

and deceleration.

(e) R position test

Move the shift lever to R and lightly depress the

accelerator pedal. Check that the vehicle moves

backward without any abnormal noise or vibration.

CAUTION:

Before conducting this test, ensure that no

people or obstacles are in the test area.

(f) P position test

Stop the vehicle on an incline (more than 5

). Then

move the shift lever to P and release the parking

brake. Check that the parking lock pawl holds the

vehicle in place.

Page 952 of 2000

AX–18U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

MECHANICAL SYSTEM TESTS

1. STALL SPEED TEST

HINT:

This test is to check the overall performance of the

engine and transaxle.

NOTICE:

• Do not perform the stall speed test longer than 5

seconds.

• To ensure safety, perform this test in an open and

level area that provides good traction.

• The stall speed test should always be performed

with at least 2 people. One person should observe

the condition of the wheels and wheel chocks

while the other is performing the test.

(a) Connect the intelligent tester to the CAN VIM. Then

connect the CAN VIM to the DLC3.

(b) Run the vehicle until the transmission fluid

temperature has reached 50 to 80

C (122 to 176F).

(c) Allow the engine to idle with the air conditioning

OFF.

(d) Chock all 4 wheels.

(e) Set the parking brake and keep the brake pedal

depressed firmly with your left foot.

(f) Move the shift lever to the D position.

(g) Depress the accelerator pedal as much as possible

with your right foot.

(h) Read the engine rpm (stall speed) and release the

accelerator pedal immediately.

Standard value:

2,150 to 2,450 rpm

Evaluation:

NOTICE:

Perform the test at the normal operating ATF

temperature of 50 to 80

C (122 to 176F).

2. SHIFT TIME LAG TEST

HINT:

This test is to check the condition of the direct clutch,

forward clutch, 1st brake and reverse brake.

(a) Connect the intelligent tester to the CAN VIM. Then

connect the CAN VIM to the DLC3.

(b) Run the vehicle until the transmission fluid

temperature has reached 50 to 80

C (122 to 176F).

(c) Allow the engine to idle with the air conditioning

OFF.

Test Result Possible Cause

Stall speed is lower than standard value • Stator one-way clutch is not operating properly

• Torque converter is faulty (stall speed is less than standard value

by 600 rpm or more)

• Engine power may be insufficient

Stall speed is higher than standard value • Line pressure is low

• C1 clutch slipping

• F3 one-way clutch is not operating properly

• F4 one-way clutch is not operating properly

Page 953 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–19

AX

(d) Set the parking brake and keep the brake pedal

depressed firmly.

(e) Check the D range time lag.

(1) Move the shift lever to N and wait for 1 minute.

(2) Move the shift lever to D and measure the time

until the shock is felt.

(3) Repeat the 2 procedures above 3 times, and

calculate the average time of the 3 tests.

(f) Check the R range time lag.

(1) Move the shift lever to N and wait for 1 minute.

(2) Move the shift lever to R and measure the time

until the shock is felt.

(3) Repeat the 2 procedures above 3 times, and

calculate the average time of the 3 tests.

Standard value:

D range time lag is less than 1.2 seconds

R range time lag is less than 1.5 seconds

Evaluation:

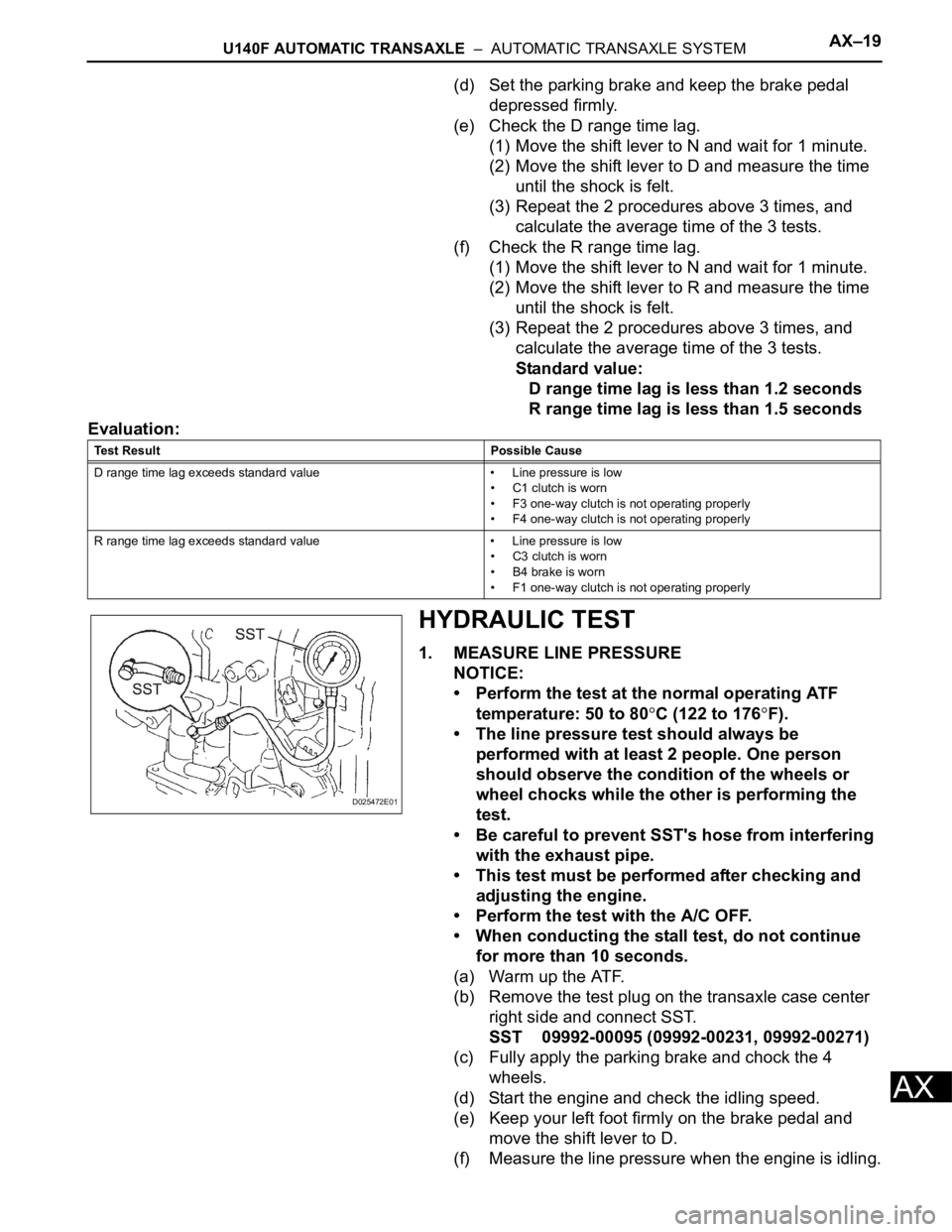

HYDRAULIC TEST

1. MEASURE LINE PRESSURE

NOTICE:

• Perform the test at the normal operating ATF

temperature: 50 to 80

C (122 to 176F).

• The line pressure test should always be

performed with at least 2 people. One person

should observe the condition of the wheels or

wheel chocks while the other is performing the

test.

• Be careful to prevent SST's hose from interfering

with the exhaust pipe.

• This test must be performed after checking and

adjusting the engine.

• Perform the test with the A/C OFF.

• When conducting the stall test, do not continue

for more than 10 seconds.

(a) Warm up the ATF.

(b) Remove the test plug on the transaxle case center

right side and connect SST.

SST 09992-00095 (09992-00231, 09992-00271)

(c) Fully apply the parking brake and chock the 4

wheels.

(d) Start the engine and check the idling speed.

(e) Keep your left foot firmly on the brake pedal and

move the shift lever to D.

(f) Measure the line pressure when the engine is idling.

Test Result Possible Cause

D range time lag exceeds standard value • Line pressure is low

• C1 clutch is worn

• F3 one-way clutch is not operating properly

• F4 one-way clutch is not operating properly

R range time lag exceeds standard value • Line pressure is low

• C3 clutch is worn

• B4 brake is worn

• F1 one-way clutch is not operating properly

D025472E01

Page 954 of 2000

AX–20U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

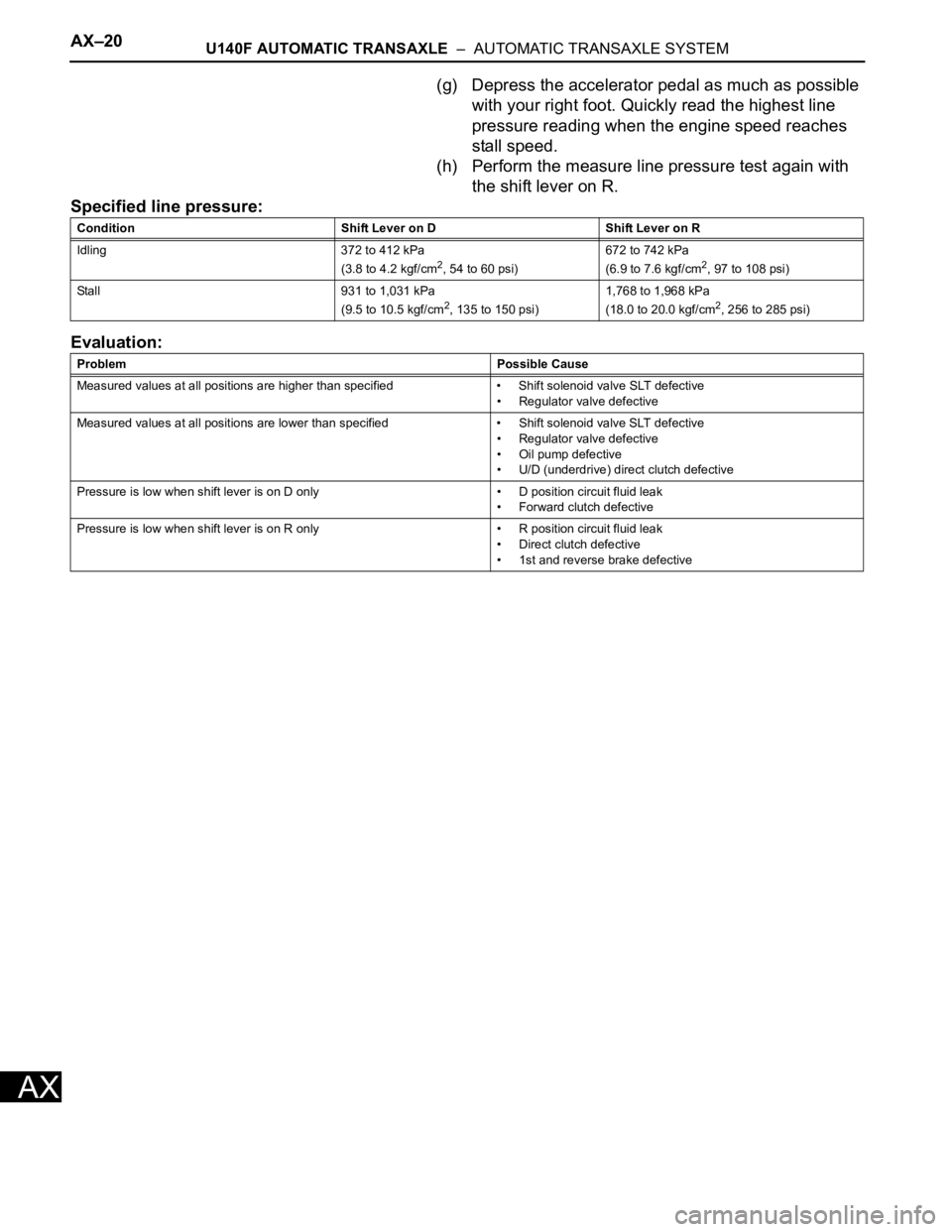

(g) Depress the accelerator pedal as much as possible

with your right foot. Quickly read the highest line

pressure reading when the engine speed reaches

stall speed.

(h) Perform the measure line pressure test again with

the shift lever on R.

Specified line pressure:

Evaluation:

Condition Shift Lever on D Shift Lever on R

Idling 372 to 412 kPa

(3.8 to 4.2 kgf/cm

2, 54 to 60 psi)672 to 742 kPa

(6.9 to 7.6 kgf/cm2, 97 to 108 psi)

Stall 931 to 1,031 kPa

(9.5 to 10.5 kgf/cm

2, 135 to 150 psi)1,768 to 1,968 kPa

(18.0 to 20.0 kgf/cm2, 256 to 285 psi)

Problem Possible Cause

Measured values at all positions are higher than specified • Shift solenoid valve SLT defective

• Regulator valve defective

Measured values at all positions are lower than specified • Shift solenoid valve SLT defective

• Regulator valve defective

• Oil pump defective

• U/D (underdrive) direct clutch defective

Pressure is low when shift lever is on D only • D position circuit fluid leak

• Forward clutch defective

Pressure is low when shift lever is on R only • R position circuit fluid leak

• Direct clutch defective

• 1st and reverse brake defective

Page 955 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–21

AX

MANUAL SHIFTING TEST

1. MANUAL SHIFTING TEST

HINT:

• Through this test, it can be determined whether the

trouble occurs in the electrical circuit or if it is a

mechanical problem in the transaxle.

• If any abnormalities are found in the following test, the

problem is in the transaxle itself.

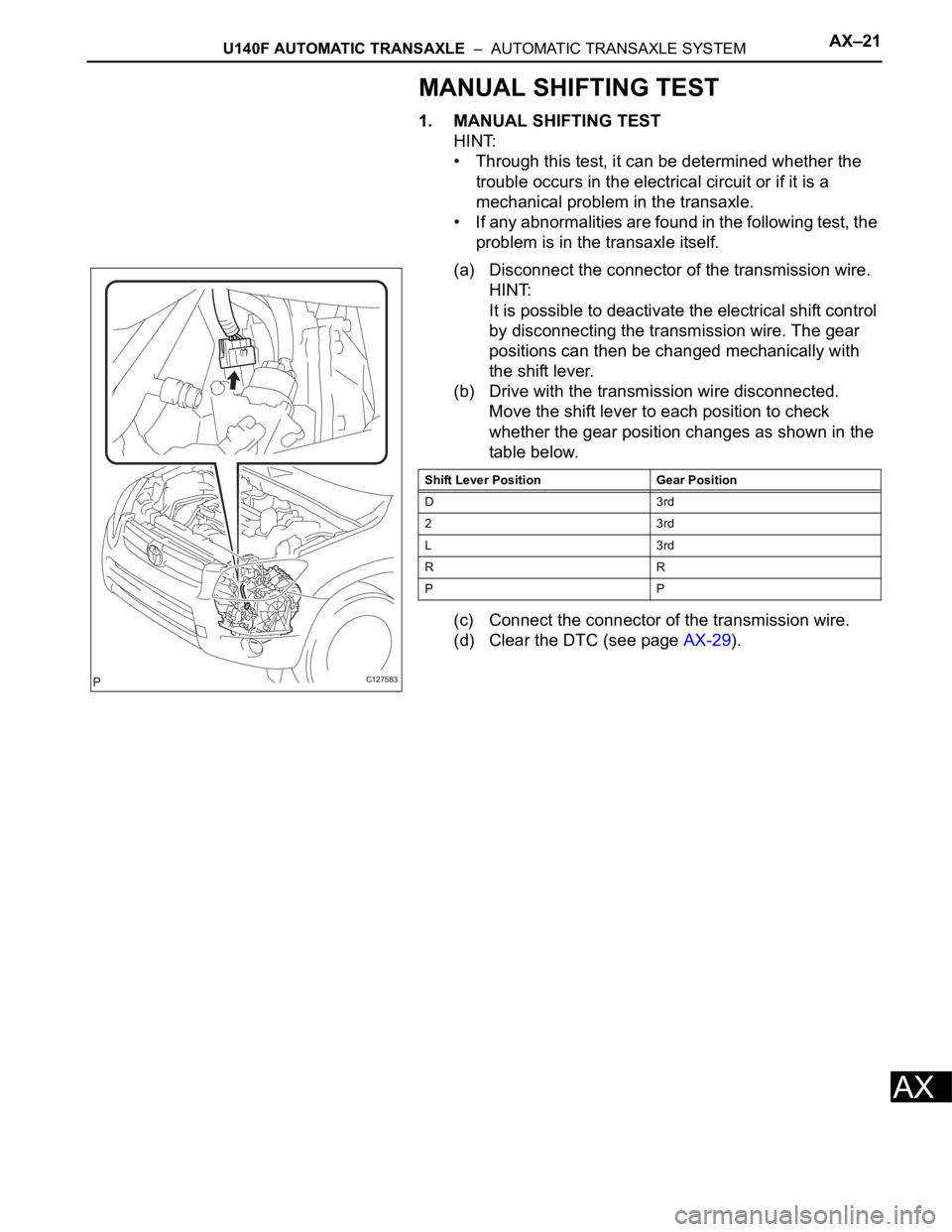

(a) Disconnect the connector of the transmission wire.

HINT:

It is possible to deactivate the electrical shift control

by disconnecting the transmission wire. The gear

positions can then be changed mechanically with

the shift lever.

(b) Drive with the transmission wire disconnected.

Move the shift lever to each position to check

whether the gear position changes as shown in the

table below.

(c) Connect the connector of the transmission wire.

(d) Clear the DTC (see page AX-29).

C127583

Shift Lever Position Gear Position

D3rd

23rd

L3rd

RR

PP

Page 956 of 2000

AX–22U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

INITIALIZATION

1. RESET MEMORY

NOTICE:

• Perform the RESET MEMORY procedures (A/T

initialization) when replacing the automatic

transaxle assembly, engine assembly or ECM.

• RESET MEMORY can be performed only with the

intelligent tester.

HINT:

The ECM memorizes the vehicle conditions when the

ECT controls the automatic transaxle assembly and

engine assembly. Therefore, when the automatic

transaxle assembly, engine assembly, or ECM has been

replaced, it is necessary to reset the memory so that the

ECM can memorize the new information.

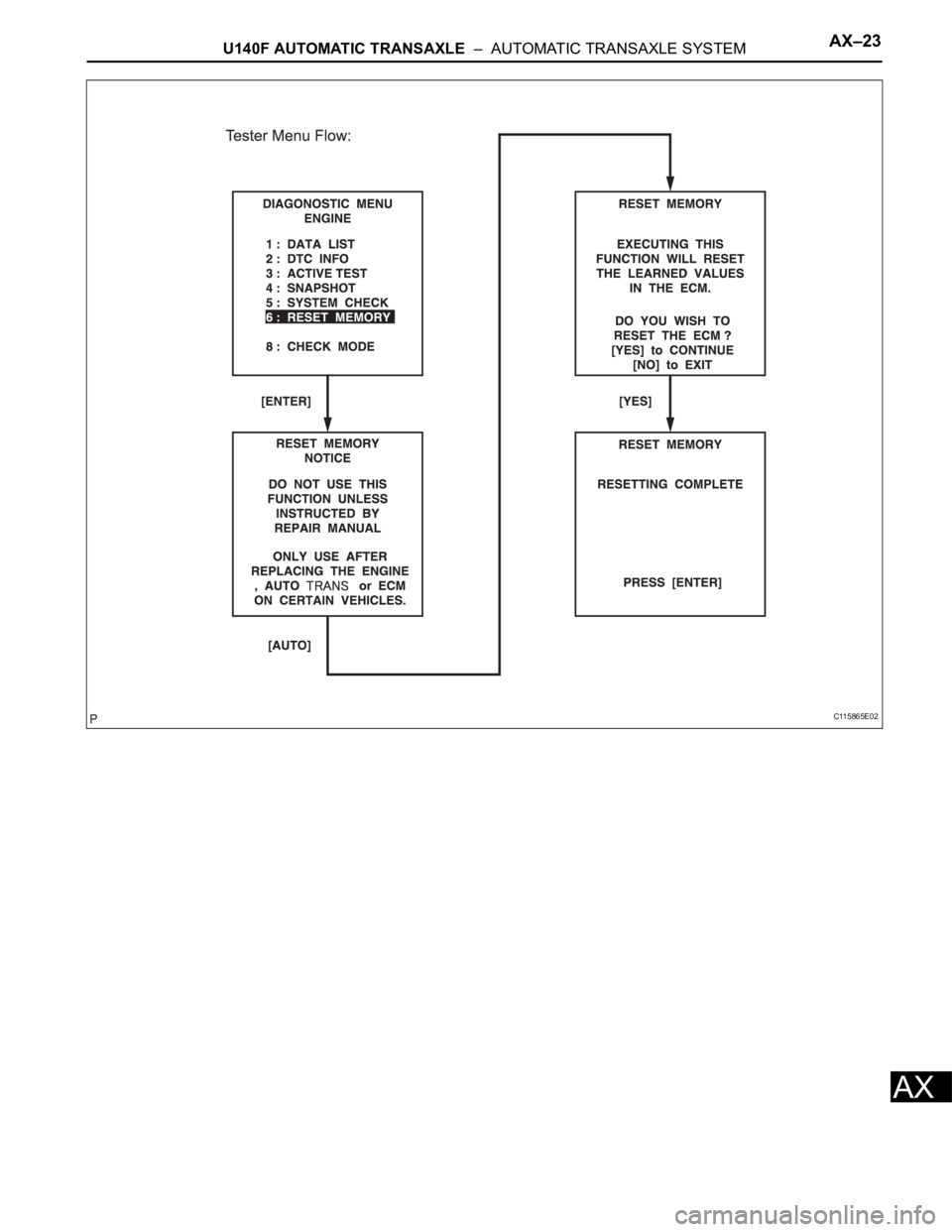

The reset procedures are as follows.

(a) Turn the ignition switch OFF.

(b) Connect the intelligent tester to the CAN VIM. Then

connect the CAN VIM to the DLC3.

(c) Turn the ignition switch ON and turn the tester ON.

(d) Enter the following menus: DIAGNOSIS /

ENHANCED OBD II.

(e) Perform the reset memory procedures from the

Engine menu.

CAUTION:

After performing the RESET MEMORY

procedures, be sure to perform the ROAD TEST

(see page AX-12) as described earlier.

HINT:

The ECM learns through the ROAD TEST.

Page 957 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–23

AX

C115865E02

Page 958 of 2000

AX–24U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

MONITOR DRIVE PATTERN

1. TEST MONITOR DRIVE PATTERN FOR ECT

CAUTION:

Perform this drive pattern on a level surface and

strictly observe the posted speed limits and traffic

laws while driving.

HINT:

Performing this drive pattern is one method to simulate

the ECT's malfunction detection conditions.

The DTCs may not be detected through ordinary,

everyday driving. Also, DTCs may not be detected

through this drive pattern.

(a) Preparation for driving

(1) Warm up the engine sufficiently (engine coolant

temperature is 60

C (140F) or higher).

(2) Drive the vehicle when the atmospheric

temperature is -10

C (14F) or higher.

Malfunction is not detected when the

atmospheric temperature is less than -10

C

(14

F).

(b) Drive pattern

(1) Drive the vehicle through all the gears.

St o p

1st 2nd 3rd O/D O/D (lock-up

ON).

(2) Repeat the above drive pattern 3 times or more.

NOTICE:

• When using the intelligent tester, the

monitor status can be found in

"ENHANCED OBD II / DATA LIST" or under

"CARB OBD II".

• In the event that the drive pattern must be

interrupted (due to traffic conditions or

other factors), the drive pattern can be

resumed and, in most cases, the monitor

can be completed.

CAUTION:

Perform this drive pattern on a level road as

much as possible and strictly observe the

posted speed limits and traffic laws while

driving.

Page 959 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–25

AX

HINT:

*: Drive at such a speed in the uppermost gear to engage

lock-up. The vehicle can be driven at a speed lower than the

speed shown in the above diagram under the lock-up

condition.

NOTICE:

It is necessary to drive the vehicle for approximately 30

minutes to detect DTC P0711 (Transmission fluid

temperature sensor "A" performance).

C115866E05

Page 960 of 2000

AX–26U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

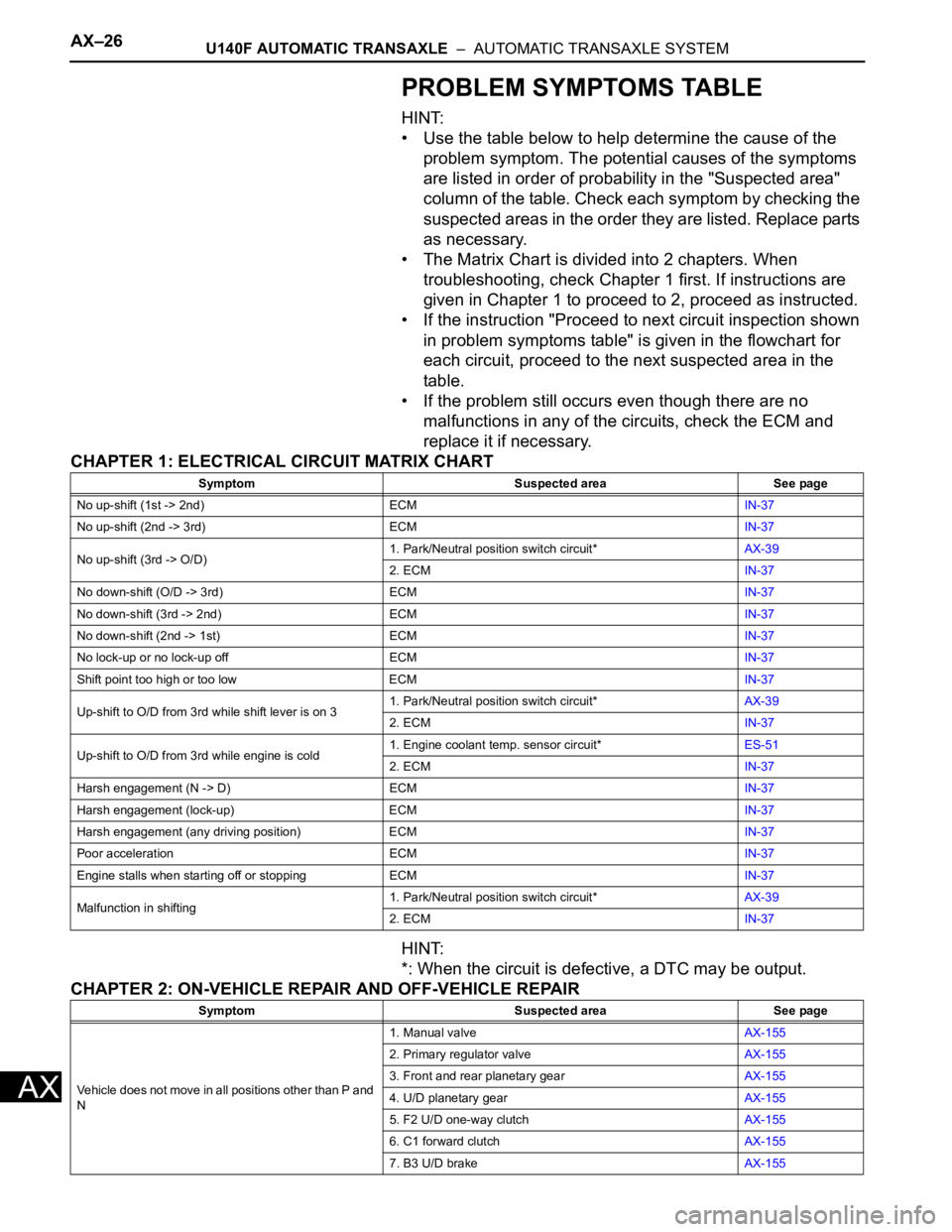

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• The Matrix Chart is divided into 2 chapters. When

troubleshooting, check Chapter 1 first. If instructions are

given in Chapter 1 to proceed to 2, proceed as instructed.

• If the instruction "Proceed to next circuit inspection shown

in problem symptoms table" is given in the flowchart for

each circuit, proceed to the next suspected area in the

table.

• If the problem still occurs even though there are no

malfunctions in any of the circuits, check the ECM and

replace it if necessary.

CHAPTER 1: ELECTRICAL CIRCUIT MATRIX CHART

HINT:

*: When the circuit is defective, a DTC may be output.

CHAPTER 2: ON-VEHICLE REPAIR AND OFF-VEHICLE REPAIR

Symptom Suspected area See page

No up-shift (1st -> 2nd) ECMIN-37

No up-shift (2nd -> 3rd) ECMIN-37

No up-shift (3rd -> O/D)1. Park/Neutral position switch circuit*AX-39

2. ECMIN-37

No down-shift (O/D -> 3rd) ECMIN-37

No down-shift (3rd -> 2nd) ECMIN-37

No down-shift (2nd -> 1st) ECMIN-37

No lock-up or no lock-up off ECMIN-37

Shift point too high or too low ECMIN-37

Up-shift to O/D from 3rd while shift lever is on 31. Park/Neutral position switch circuit*AX-39

2. ECMIN-37

Up-shift to O/D from 3rd while engine is cold1. Engine coolant temp. sensor circuit*ES-51

2. ECMIN-37

Harsh engagement (N -> D) ECMIN-37

Harsh engagement (lock-up) ECMIN-37

Harsh engagement (any driving position) ECMIN-37

Poor acceleration ECMIN-37

Engine stalls when starting off or stopping ECMIN-37

Malfunction in shifting1. Park/Neutral position switch circuit*AX-39

2. ECMIN-37

Symptom Suspected area See page

Vehicle does not move in all positions other than P and

N1. Manual valveAX-155

2. Primary regulator valveAX-155

3. Front and rear planetary gearAX-155

4. U/D planetary gearAX-155

5. F2 U/D one-way clutchAX-155

6. C1 forward clutchAX-155

7. B3 U/D brakeAX-155