TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 971 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–37

AX

CHECK MODE PROCEDURE

1. DESCRIPTION

(a) Check mode has a higher sensitivity to malfunctions

and can detect malfunctions that normal mode

cannot detect. Check mode can also detect all the

malfunctions that normal mode can detect. In check

mode, DTCs are detected with 1 trip detection logic.

2. CHECK MODE PROCEDURE

(a) Make sure that the following conditions below are

met:

(1) Battery positive voltage 11 V or more

(2) Throttle valve fully closed

(3) Transaxle in the P or N position

(4) A/C OFF

(b) Turn the ignition switch OFF.

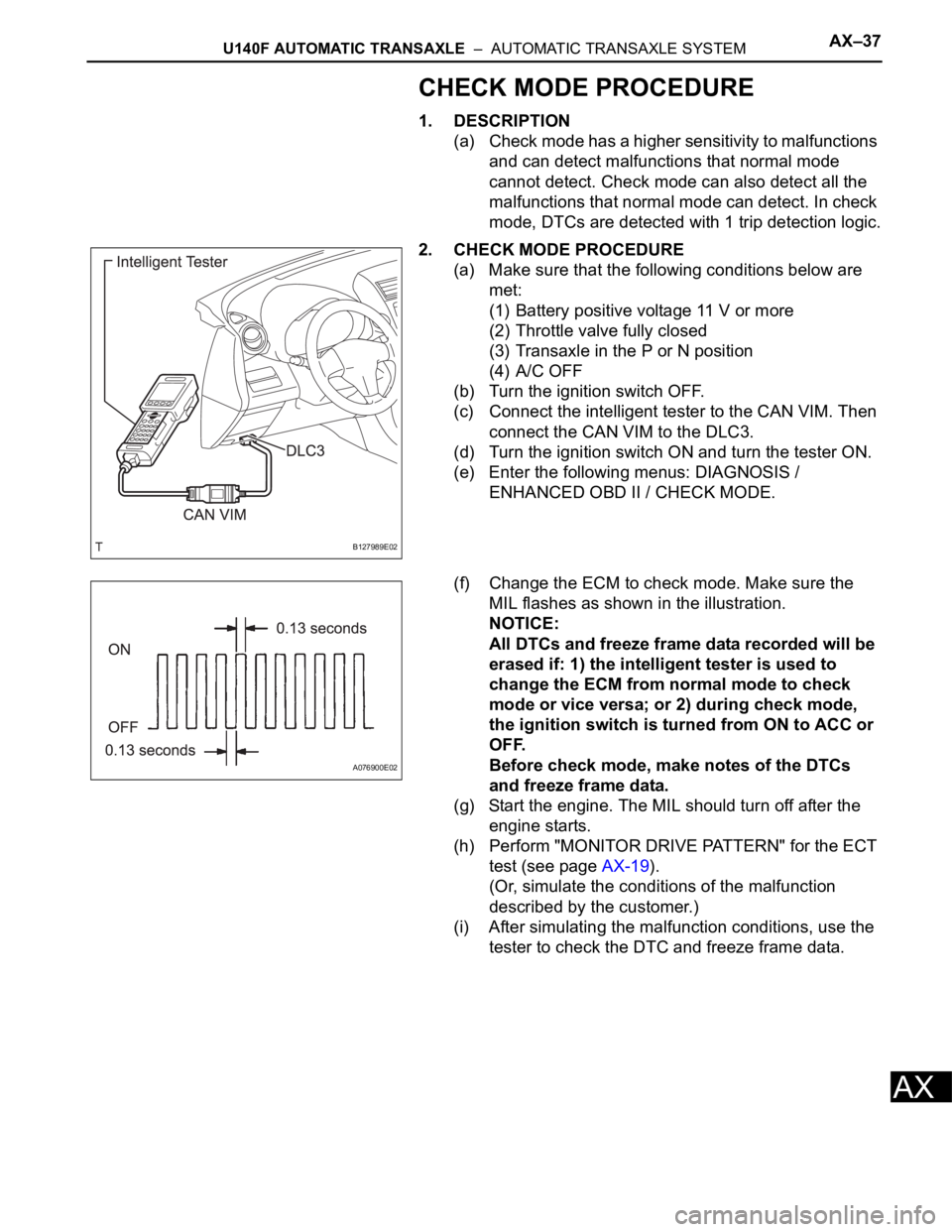

(c) Connect the intelligent tester to the CAN VIM. Then

connect the CAN VIM to the DLC3.

(d) Turn the ignition switch ON and turn the tester ON.

(e) Enter the following menus: DIAGNOSIS /

ENHANCED OBD II / CHECK MODE.

(f) Change the ECM to check mode. Make sure the

MIL flashes as shown in the illustration.

NOTICE:

All DTCs and freeze frame data recorded will be

erased if: 1) the intelligent tester is used to

change the ECM from normal mode to check

mode or vice versa; or 2) during check mode,

the ignition switch is turned from ON to ACC or

OFF.

Before check mode, make notes of the DTCs

and freeze frame data.

(g) Start the engine. The MIL should turn off after the

engine starts.

(h) Perform "MONITOR DRIVE PATTERN" for the ECT

test (see page AX-19).

(Or, simulate the conditions of the malfunction

described by the customer.)

(i) After simulating the malfunction conditions, use the

tester to check the DTC and freeze frame data.

B127989E02

A076900E02

Page 972 of 2000

U140F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLYAX–139

AX

ADJUSTMENT

1. INSPECT SHIFT LEVER POSITION

(a) When shifting the lever from P to the R position with

the ignition switch ON and the brake pedal

depressed, make sure that the shift lever moves

smoothly and moves correctly into position.

(b) Start the engine and make sure that the vehicle

moves forward when shifting the lever from N to the

D position and moves rearward when shifting the

lever to the R position.

If the operation cannot be performed as specified,

inspect the park/neutral position switch assembly

and check the shift lever assembly installation

condition.

2. ADJUST SHIFT LEVER POSITION

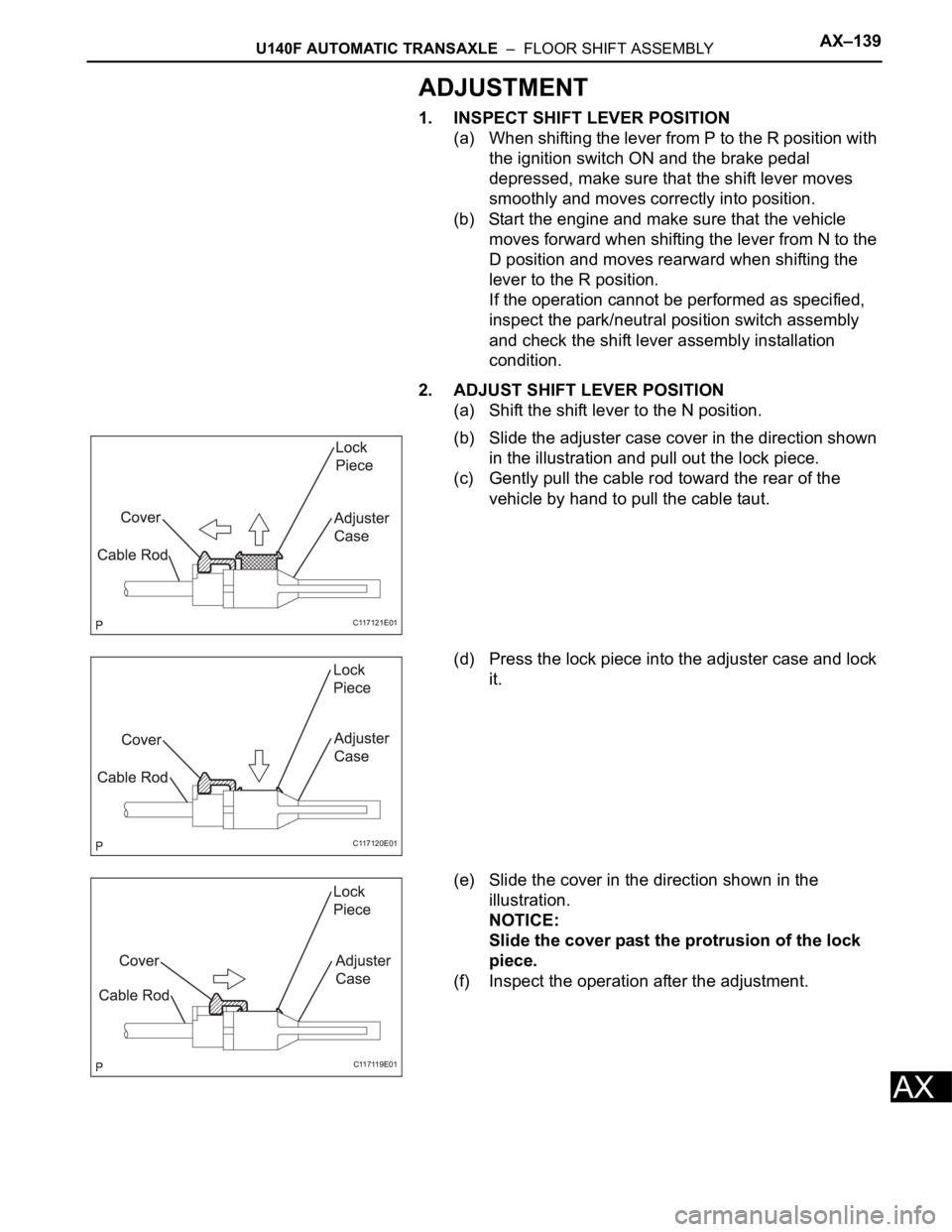

(a) Shift the shift lever to the N position.

(b) Slide the adjuster case cover in the direction shown

in the illustration and pull out the lock piece.

(c) Gently pull the cable rod toward the rear of the

vehicle by hand to pull the cable taut.

(d) Press the lock piece into the adjuster case and lock

it.

(e) Slide the cover in the direction shown in the

illustration.

NOTICE:

Slide the cover past the protrusion of the lock

piece.

(f) Inspect the operation after the adjustment.

C117121E01

C117120E01

C117119E01

Page 973 of 2000

AX–140U140F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLY

AX

REASSEMBLY

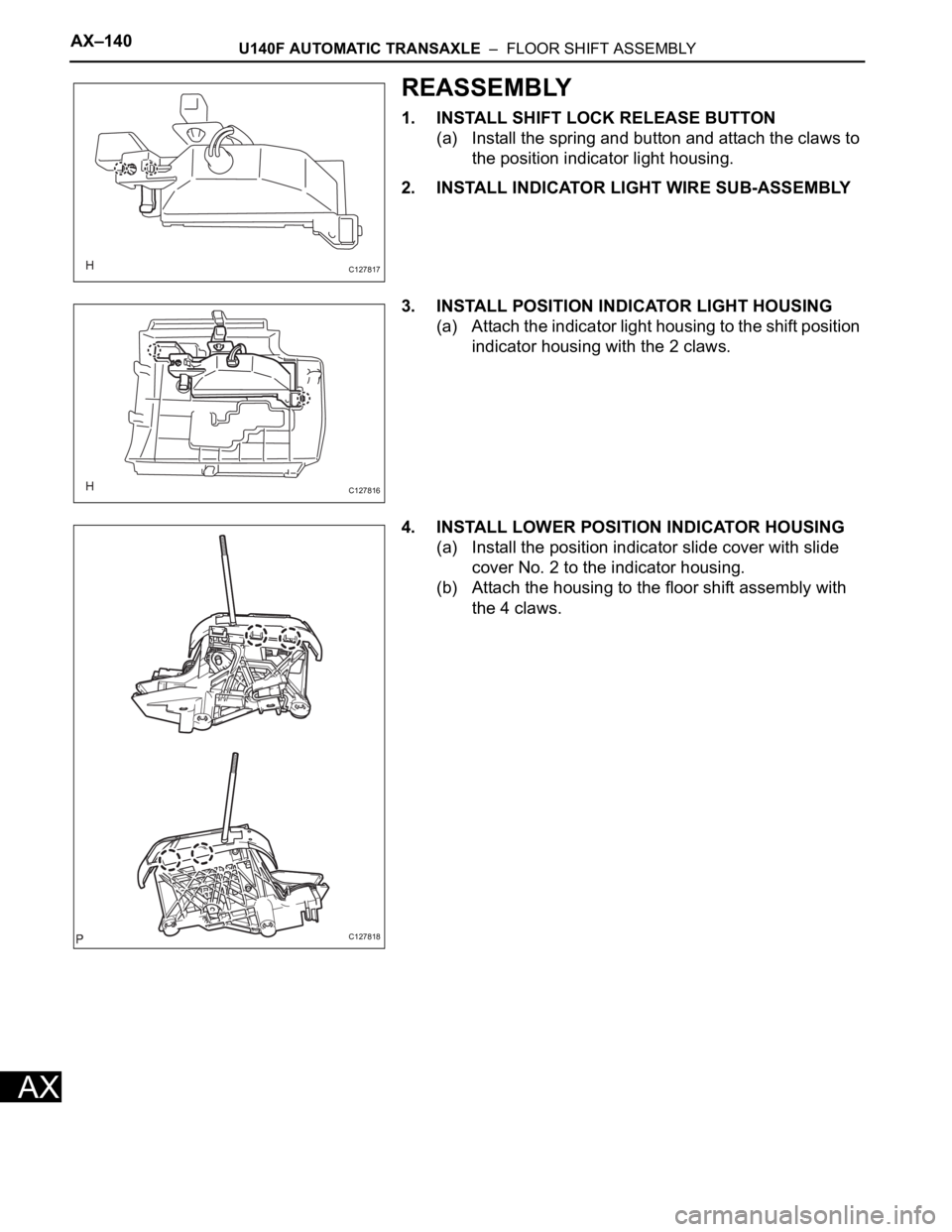

1. INSTALL SHIFT LOCK RELEASE BUTTON

(a) Install the spring and button and attach the claws to

the position indicator light housing.

2. INSTALL INDICATOR LIGHT WIRE SUB-ASSEMBLY

3. INSTALL POSITION INDICATOR LIGHT HOUSING

(a) Attach the indicator light housing to the shift position

indicator housing with the 2 claws.

4. INSTALL LOWER POSITION INDICATOR HOUSING

(a) Install the position indicator slide cover with slide

cover No. 2 to the indicator housing.

(b) Attach the housing to the floor shift assembly with

the 4 claws.

C127817

C127816

C127818

Page 974 of 2000

U140F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLYAX–141

AX

INSTALLATION

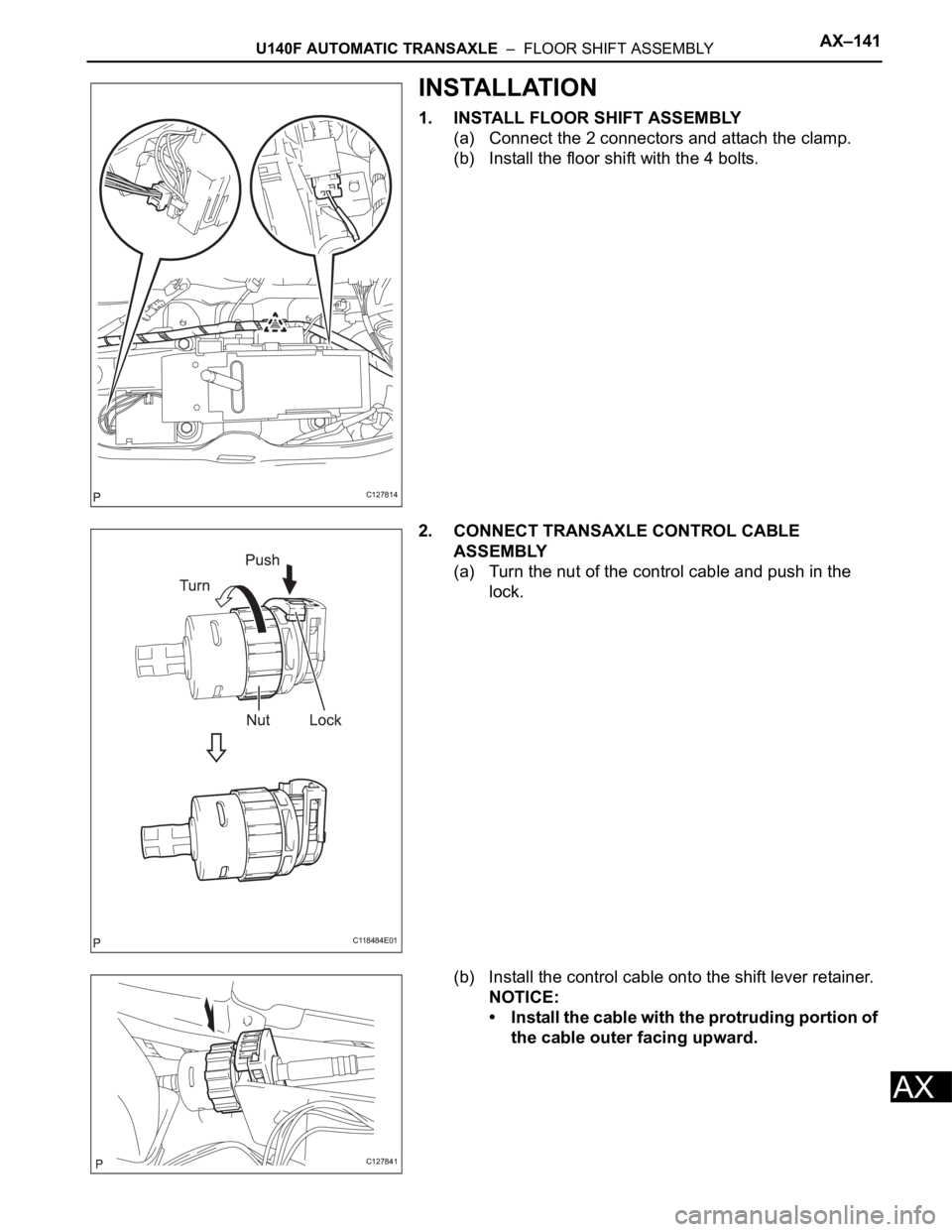

1. INSTALL FLOOR SHIFT ASSEMBLY

(a) Connect the 2 connectors and attach the clamp.

(b) Install the floor shift with the 4 bolts.

2. CONNECT TRANSAXLE CONTROL CABLE

ASSEMBLY

(a) Turn the nut of the control cable and push in the

lock.

(b) Install the control cable onto the shift lever retainer.

NOTICE:

• Install the cable with the protruding portion of

the cable outer facing upward.

C127814

C118484E01

C127841

Page 975 of 2000

AX–142U140F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLY

AX

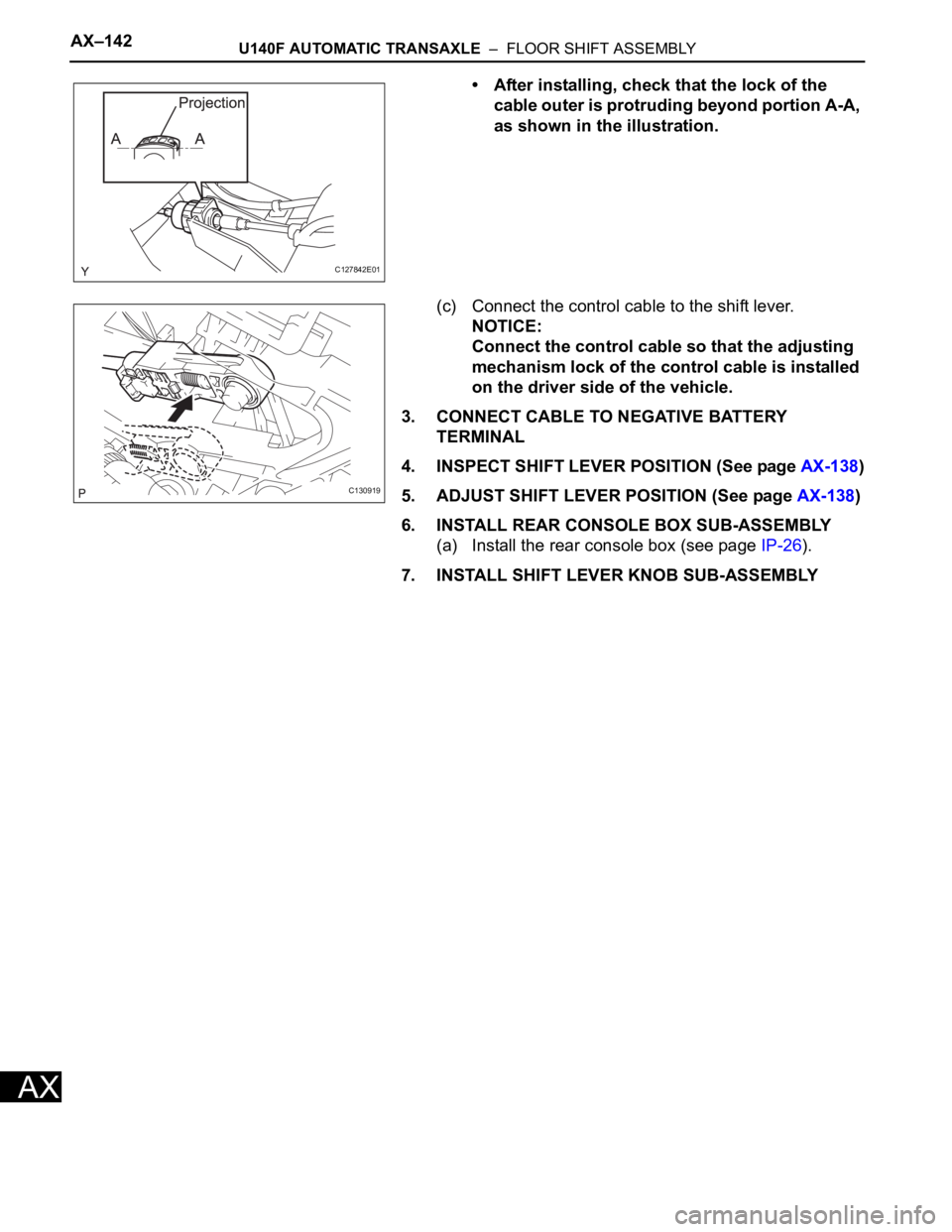

• After installing, check that the lock of the

cable outer is protruding beyond portion A-A,

as shown in the illustration.

(c) Connect the control cable to the shift lever.

NOTICE:

Connect the control cable so that the adjusting

mechanism lock of the control cable is installed

on the driver side of the vehicle.

3. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

4. INSPECT SHIFT LEVER POSITION (See page AX-138)

5. ADJUST SHIFT LEVER POSITION (See page AX-138)

6. INSTALL REAR CONSOLE BOX SUB-ASSEMBLY

(a) Install the rear console box (see page IP-26).

7. INSTALL SHIFT LEVER KNOB SUB-ASSEMBLY

C127842E01

C130919

Page 976 of 2000

AX–144U140F AUTOMATIC TRANSAXLE – DIFFERENTIAL OIL SEAL

AX

REPLACEMENT

1. REPLACE TRANSAXLE HOUSING OIL SEAL LH

(a) Drain the automatic transaxle fluid.

(1) Remove the drain plug and gasket, and drain

AT F.

(2) Install a new gasket and drain plug.

Torque: 47 N*m (479 kgf*cm, 35 ft.*lbf)

(b) Remove the front drive shaft LH (see page DS-41).

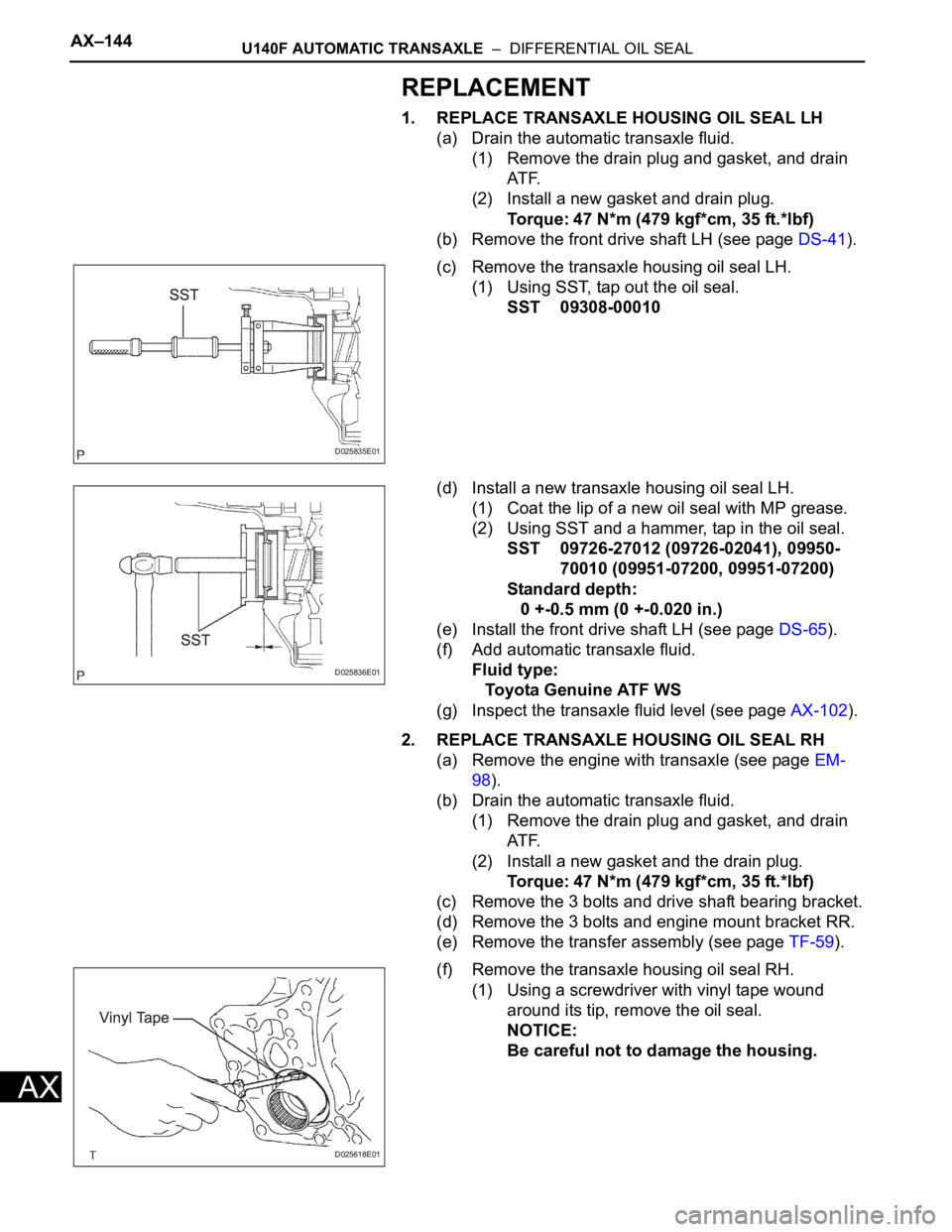

(c) Remove the transaxle housing oil seal LH.

(1) Using SST, tap out the oil seal.

SST 09308-00010

(d) Install a new transaxle housing oil seal LH.

(1) Coat the lip of a new oil seal with MP grease.

(2) Using SST and a hammer, tap in the oil seal.

SST 09726-27012 (09726-02041), 09950-

70010 (09951-07200, 09951-07200)

Standard depth:

0 +-0.5 mm (0 +-0.020 in.)

(e) Install the front drive shaft LH (see page DS-65).

(f) Add automatic transaxle fluid.

Fluid type:

Toyota Genuine ATF WS

(g) Inspect the transaxle fluid level (see page AX-102).

2. REPLACE TRANSAXLE HOUSING OIL SEAL RH

(a) Remove the engine with transaxle (see page EM-

98).

(b) Drain the automatic transaxle fluid.

(1) Remove the drain plug and gasket, and drain

AT F.

(2) Install a new gasket and the drain plug.

Torque: 47 N*m (479 kgf*cm, 35 ft.*lbf)

(c) Remove the 3 bolts and drive shaft bearing bracket.

(d) Remove the 3 bolts and engine mount bracket RR.

(e) Remove the transfer assembly (see page TF-59).

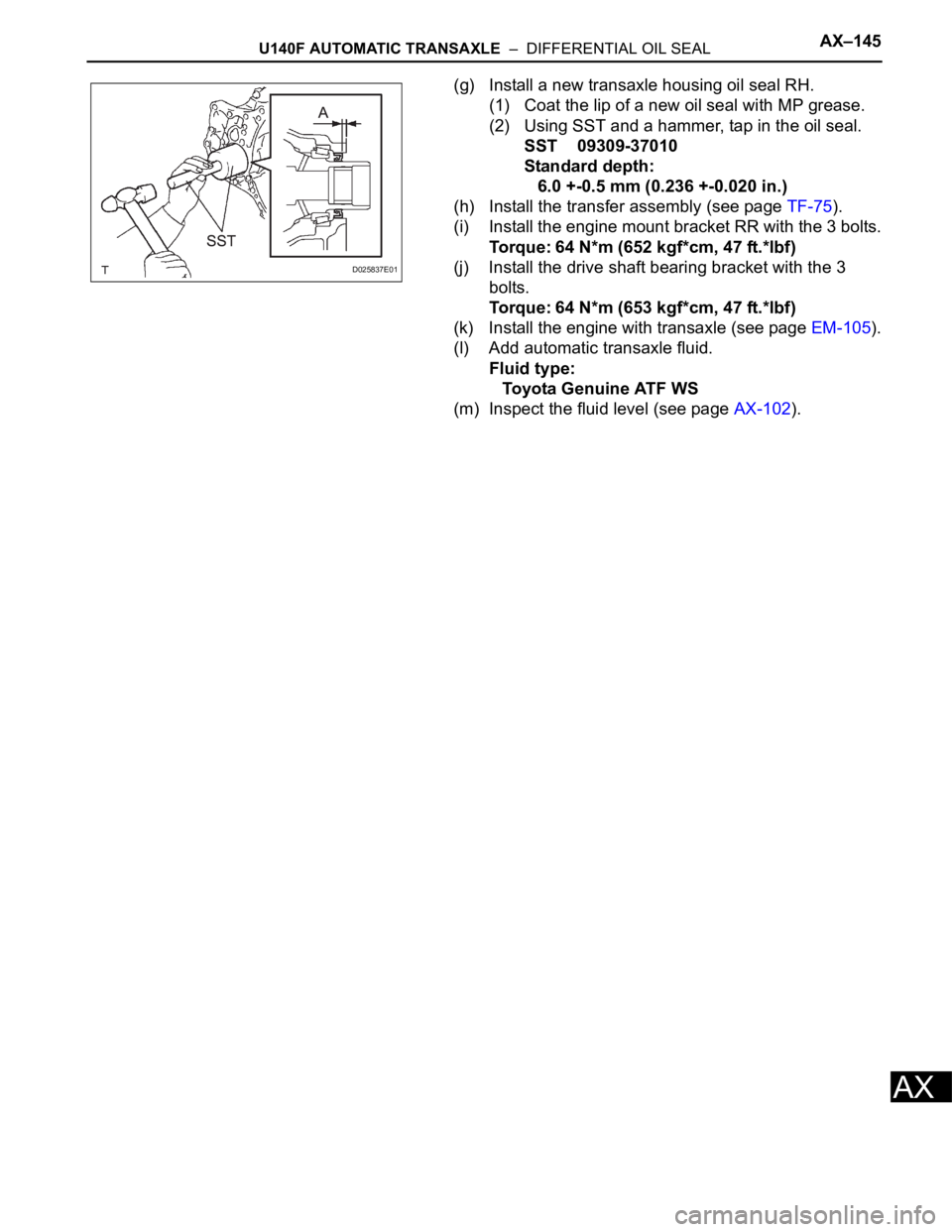

(f) Remove the transaxle housing oil seal RH.

(1) Using a screwdriver with vinyl tape wound

around its tip, remove the oil seal.

NOTICE:

Be careful not to damage the housing.

D025835E01

D025836E01

D025618E01

Page 977 of 2000

U140F AUTOMATIC TRANSAXLE – DIFFERENTIAL OIL SEALAX–145

AX

(g) Install a new transaxle housing oil seal RH.

(1) Coat the lip of a new oil seal with MP grease.

(2) Using SST and a hammer, tap in the oil seal.

SST 09309-37010

Standard depth:

6.0 +-0.5 mm (0.236 +-0.020 in.)

(h) Install the transfer assembly (see page TF-75).

(i) Install the engine mount bracket RR with the 3 bolts.

Torque: 64 N*m (652 kgf*cm, 47 ft.*lbf)

(j) Install the drive shaft bearing bracket with the 3

bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

(k) Install the engine with transaxle (see page EM-105).

(l) Add automatic transaxle fluid.

Fluid type:

Toyota Genuine ATF WS

(m) Inspect the fluid level (see page AX-102).

D025837E01

Page 978 of 2000

AX–150U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

INSTALLATION

1. INSPECT TORQUE CONVERTER CLUTCH

ASSEMBLY

(a) Inspect the torque converter (see page AX-153).

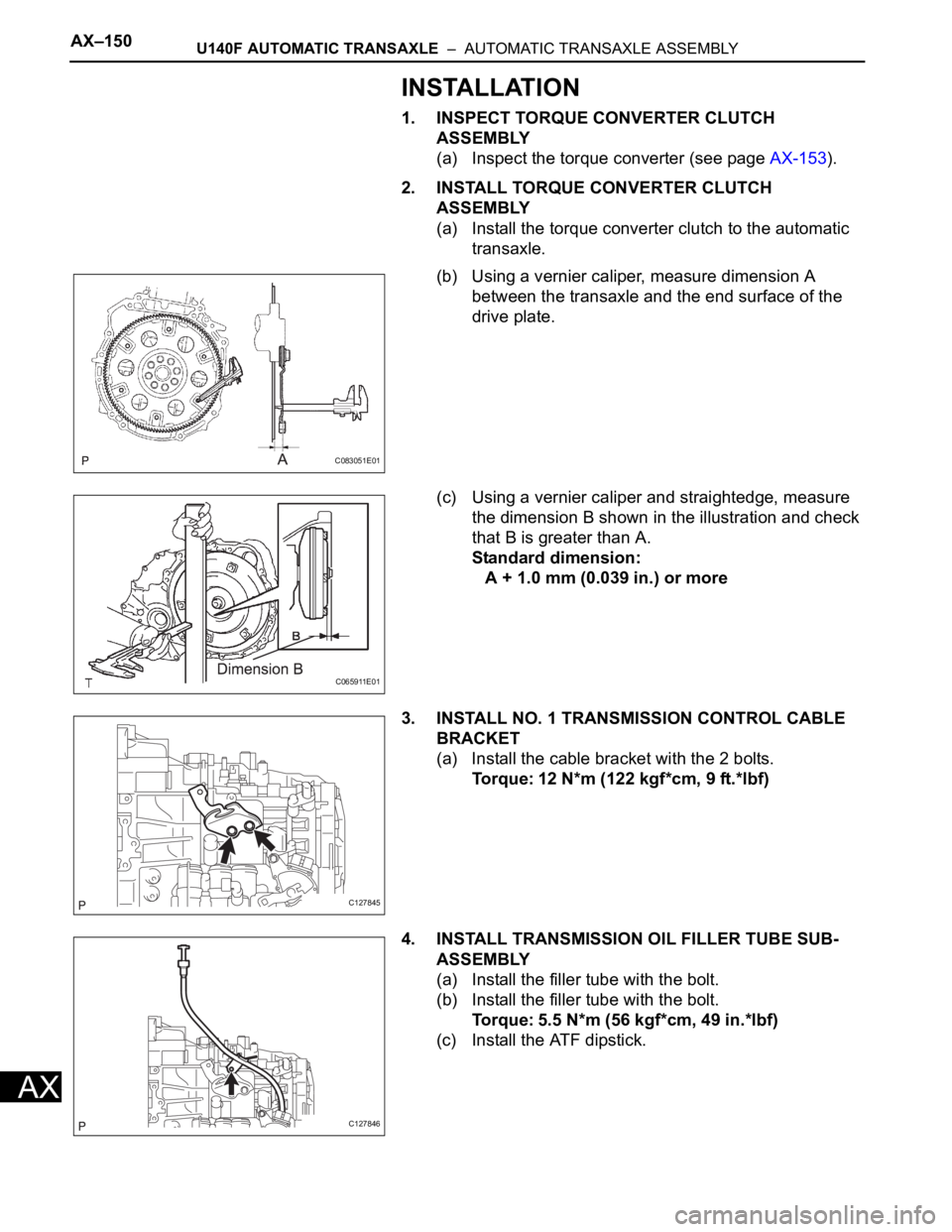

2. INSTALL TORQUE CONVERTER CLUTCH

ASSEMBLY

(a) Install the torque converter clutch to the automatic

transaxle.

(b) Using a vernier caliper, measure dimension A

between the transaxle and the end surface of the

drive plate.

(c) Using a vernier caliper and straightedge, measure

the dimension B shown in the illustration and check

that B is greater than A.

Standard dimension:

A + 1.0 mm (0.039 in.) or more

3. INSTALL NO. 1 TRANSMISSION CONTROL CABLE

BRACKET

(a) Install the cable bracket with the 2 bolts.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

4. INSTALL TRANSMISSION OIL FILLER TUBE SUB-

ASSEMBLY

(a) Install the filler tube with the bolt.

(b) Install the filler tube with the bolt.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

(c) Install the ATF dipstick.

C083051E01

C065911E01

C127845

C127846

Page 979 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–151

AX

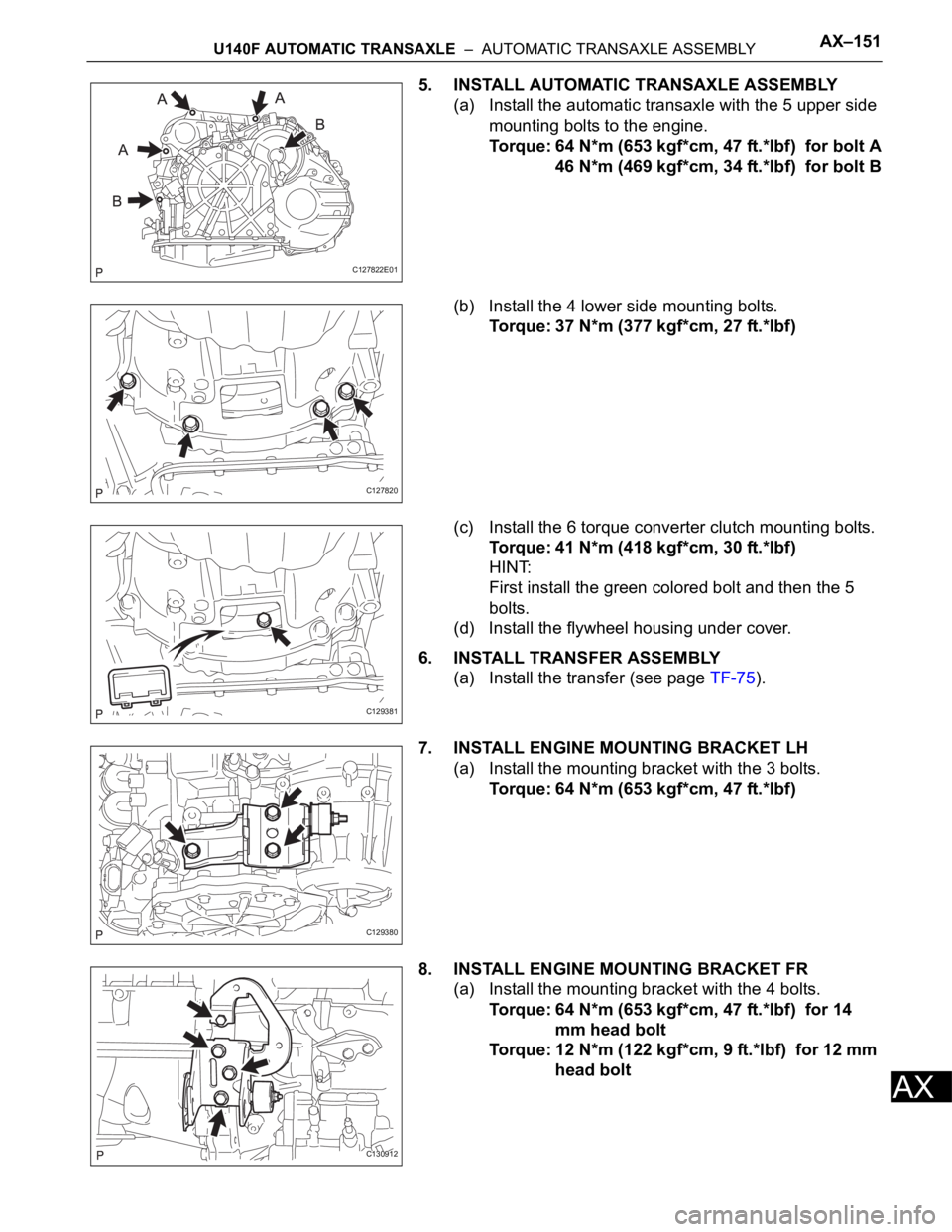

5. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

(a) Install the automatic transaxle with the 5 upper side

mounting bolts to the engine.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf) for bolt A

46 N*m (469 kgf*cm, 34 ft.*lbf) for bolt B

(b) Install the 4 lower side mounting bolts.

Torque: 37 N*m (377 kgf*cm, 27 ft.*lbf)

(c) Install the 6 torque converter clutch mounting bolts.

Torque: 41 N*m (418 kgf*cm, 30 ft.*lbf)

HINT:

First install the green colored bolt and then the 5

bolts.

(d) Install the flywheel housing under cover.

6. INSTALL TRANSFER ASSEMBLY

(a) Install the transfer (see page TF-75).

7. INSTALL ENGINE MOUNTING BRACKET LH

(a) Install the mounting bracket with the 3 bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

8. INSTALL ENGINE MOUNTING BRACKET FR

(a) Install the mounting bracket with the 4 bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf) for 14

mm head bolt

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf) for 12 mm

head bolt

C127822E01

C127820

C129381

C129380

C130912

Page 980 of 2000

AX–152U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

9. INSTALL ENGINE MOUNTING BRACKET RR

(a) Install the mounting bracket with the 3 bolts.

Torque: 45 N*m (459 kgf*cm, 33 ft.*lbf)

10. INSTALL TRANSMISSION OIL COOLER

(a) Install the oil cooler (see page AX-127).

11. CONNECT WIRE HARNESS

(a) Connect the wire harness clamps.

(b) Connect the 2 speed sensor connectors.

(c) Connect the transaxle wire connector.

(d) Connect the park/neutral position switch connector.

12. INSTALL STARTER ASSEMBLY

(a) Install the starter with the 2 bolts.

Torque: 37 N*m (377 kgf*cm, 27 ft.*lbf)

(b) Connect the starter wire with the nut.

Torque: 13 N*m (133 kgf*cm, 10 ft.*lbf)

(c) Connect the starter connector.

(d) Install the terminal nut and cover the nut with the

cap.

Torque: 9.8 N*m (100 kgf*cm, 7 in.*lbf)

13. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

(a) Install the engine with transaxle. (see page EM-

105).

14. ADD AUTOMATIC TRANSAXLE FLUID

Fluid type:

Toyota Genuine ATF WS

15. INSPECT AUTOMATIC TRANSAXLE FLUID

(a) Inspect the automatic transaxle fluid (see page AX-

102).

16. PERFORM RESET MEMORY

(a) Perform the RESET MEMORY procedures (A/T

initialization) (see page AX-18).

C130913

C127821

A124921

A124920