Control arm TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 76 of 2000

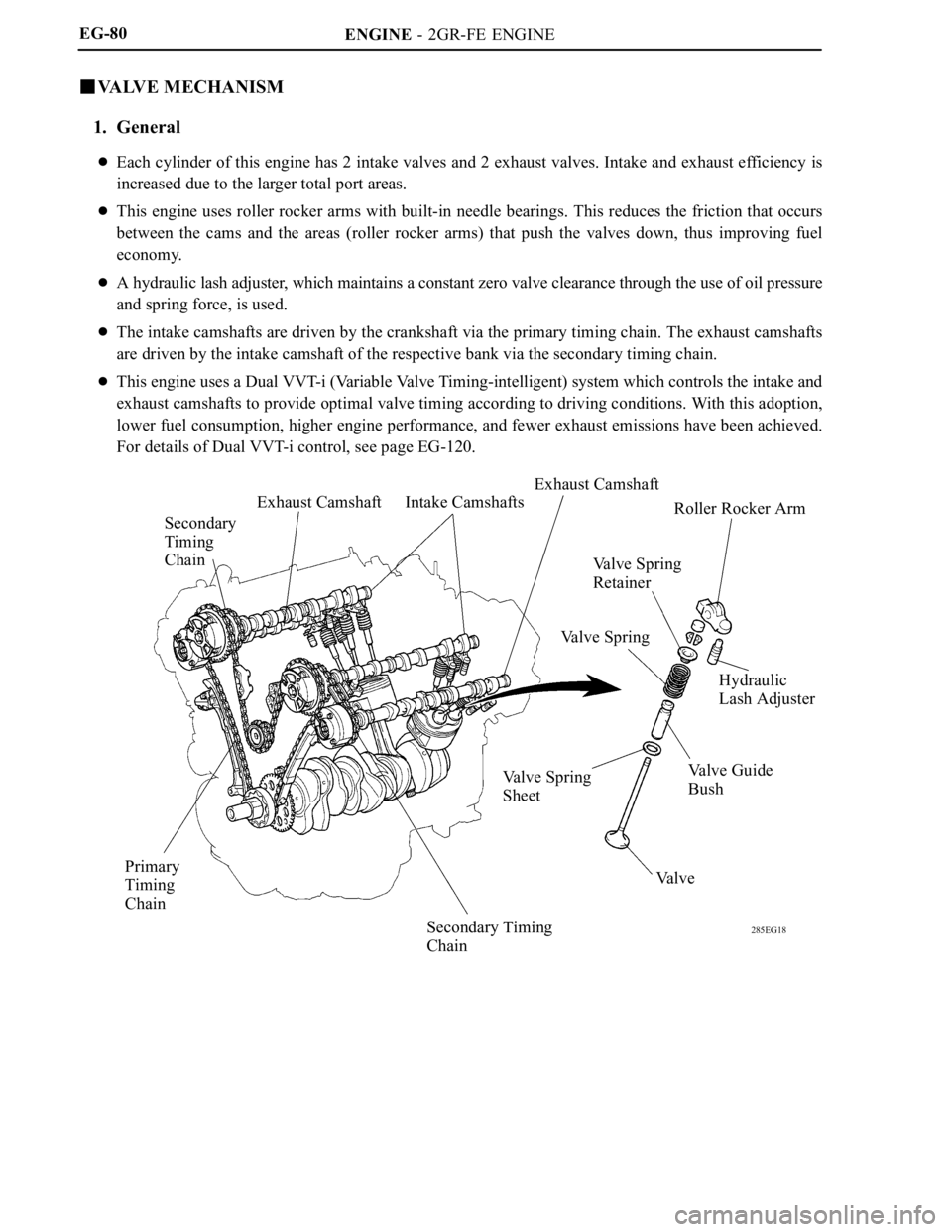

ENGINE - 2GR-FE ENGINE

285EG18

Secondary

Timing

ChainExhaust Camshaft Intake CamshaftsExhaust Camshaft

Roller Rocker Arm

Va l v e S p r i n g

Retainer

Va l v e S p r i n g

Hydraulic

Lash Adjuster

Va l v e G u i d e

Bush Va l v e S p r i n g

Sheet

Va l v e

Secondary Timing

Chain Primary

Timing

Chain EG-80

VA LV E M E C H A N I S M

1. General

Each cylinder of this engine has 2 intake valves and 2 exhaust valves. Intake and exhaust efficiency is

increased due to the larger total port areas.

This engine uses roller rocker arms with built-in needle bearings. This reduces the friction that occurs

between the cams and the areas (roller rocker arms) that push the valves down, thus improving fuel

economy.

A hydraulic lash adjuster, which maintains a constant zero valve clearance through the use of oil pressure

and spring force, is used.

The intake camshafts are driven by the crankshaft via the primary timing chain. The exhaust camshafts

are driven by the intake camshaft of the respective bank via the secondary timing chain.

This engine uses a Dual VVT-i (Variable Valve Timing-intelligent) system which controls the intake and

exhaust camshafts to provide optimal valve timing according to driving conditions. With this adoption,

lower fuel consumption, higher engine performance, and fewer exhaust emissions have been achieved.

For details of Dual VVT-i control, see page EG-120.

Page 77 of 2000

ENGINE - 2GR-FE ENGINE

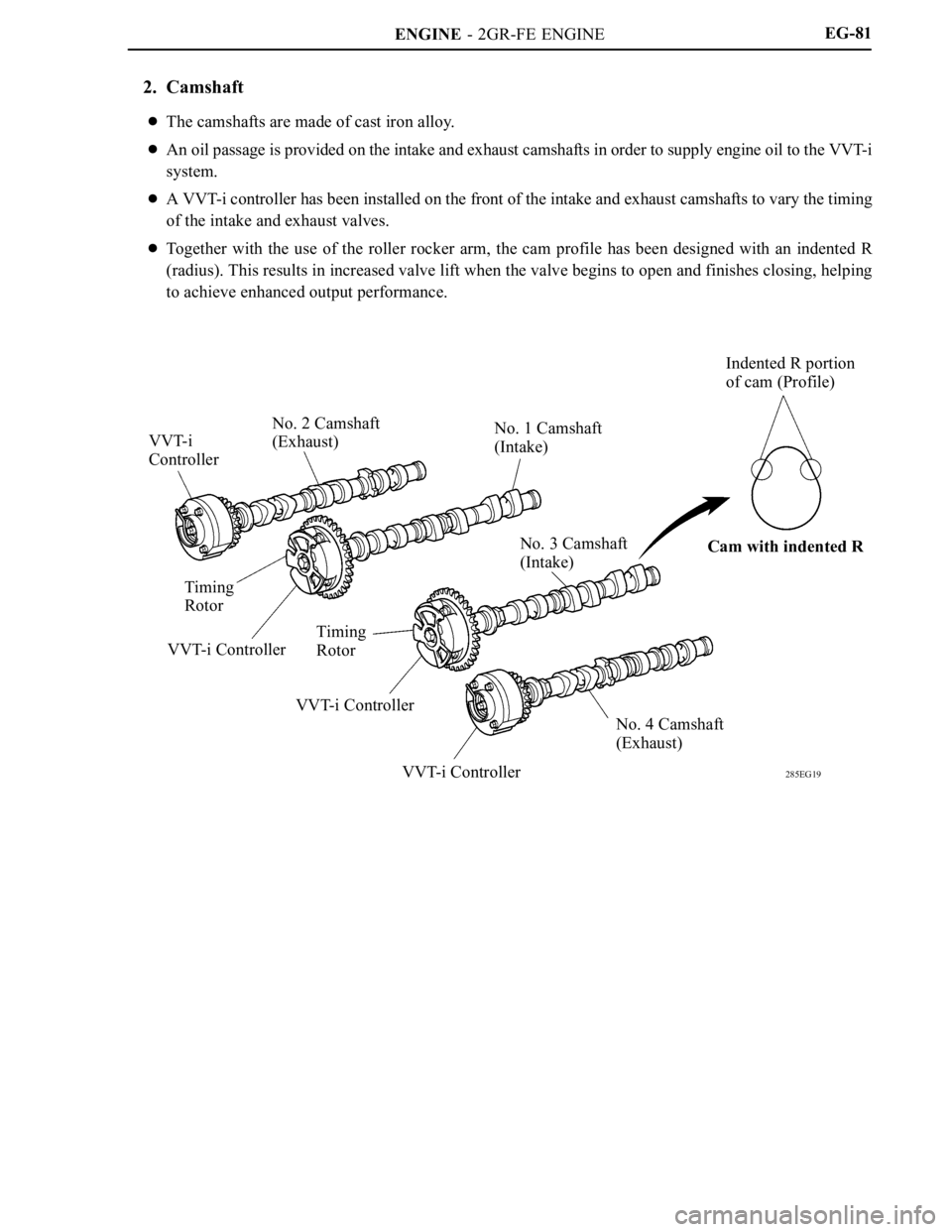

285EG19

VVT-i

ControllerNo. 2 Camshaft

(Exhaust)

Timing

Rotor

VVT-i ControllerNo. 1 Camshaft

(Intake)

No. 3 Camshaft

(Intake)

Timing

Rotor

VVT-i Controller

VVT-i ControllerNo. 4 Camshaft

(Exhaust)Indented R portion

of cam (Profile)

Cam with indented REG-81

2. Camshaft

The camshafts are made of cast iron alloy.

An oil passage is provided on the intake and exhaust camshafts in order to supply engine oil to the VVT-i

system.

A VVT-i controller has been installed on the front of the intake and exhaust camshafts to vary the timing

of the intake and exhaust valves.

Together with the use of the roller rocker arm, the cam profile has been designed with an indented R

(radius). This results in increased valve lift when the valve begins to open and finishes closing, helping

to achieve enhanced output performance.

Page 210 of 2000

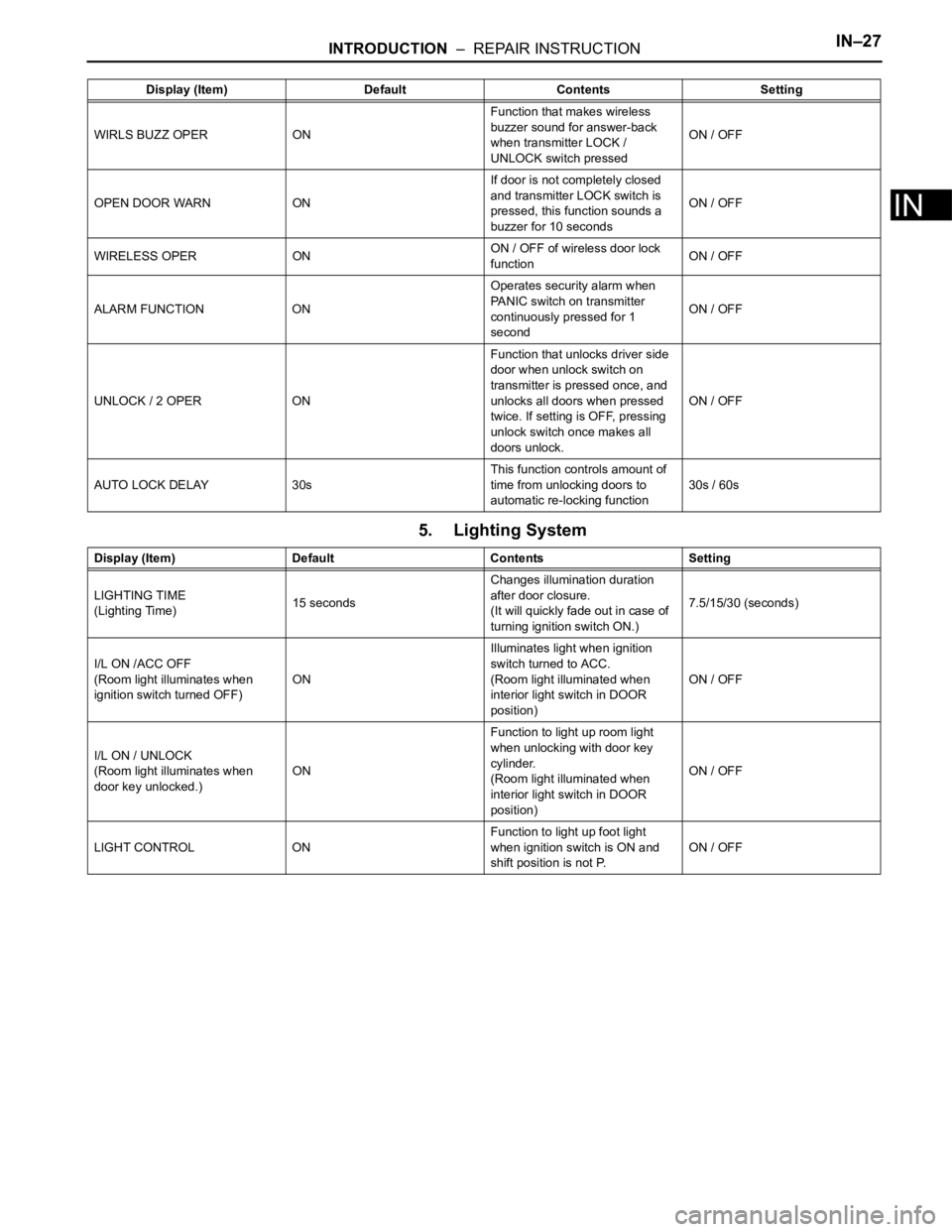

INTRODUCTION – REPAIR INSTRUCTIONIN–27

IN

5. Lighting System

WIRLS BUZZ OPER ONFunction that makes wireless

buzzer sound for answer-back

when transmitter LOCK /

UNLOCK switch pressedON / OFF

OPEN DOOR WARN ONIf door is not completely closed

and transmitter LOCK switch is

pressed, this function sounds a

buzzer for 10 secondsON / OFF

WIRELESS OPER ONON / OFF of wireless door lock

functionON / OFF

ALARM FUNCTION ONOperates security alarm when

PANIC switch on transmitter

continuously pressed for 1

secondON / OFF

UNLOCK / 2 OPER ONFunction that unlocks driver side

door when unlock switch on

transmitter is pressed once, and

unlocks all doors when pressed

twice. If setting is OFF, pressing

unlock switch once makes all

doors unlock.ON / OFF

AUTO LOCK DELAY 30sThis function controls amount of

time from unlocking doors to

automatic re-locking function30s / 60s Display (Item) Default Contents Setting

Display (Item) Default Contents Setting

LIGHTING TIME

(Lighting Time)15 secondsChanges illumination duration

after door closure.

(It will quickly fade out in case of

turning ignition switch ON.)7.5/15/30 (seconds)

I/L ON /ACC OFF

(Room light illuminates when

ignition switch turned OFF)ONIlluminates light when ignition

switch turned to ACC.

(Room light illuminated when

interior light switch in DOOR

position)ON / OFF

I/L ON / UNLOCK

(Room light illuminates when

door key unlocked.)ONFunction to light up room light

when unlocking with door key

cylinder.

(Room light illuminated when

interior light switch in DOOR

position)ON / OFF

LIGHT CONTROL ONFunction to light up foot light

when ignition switch is ON and

shift position is not P.ON / OFF

Page 479 of 2000

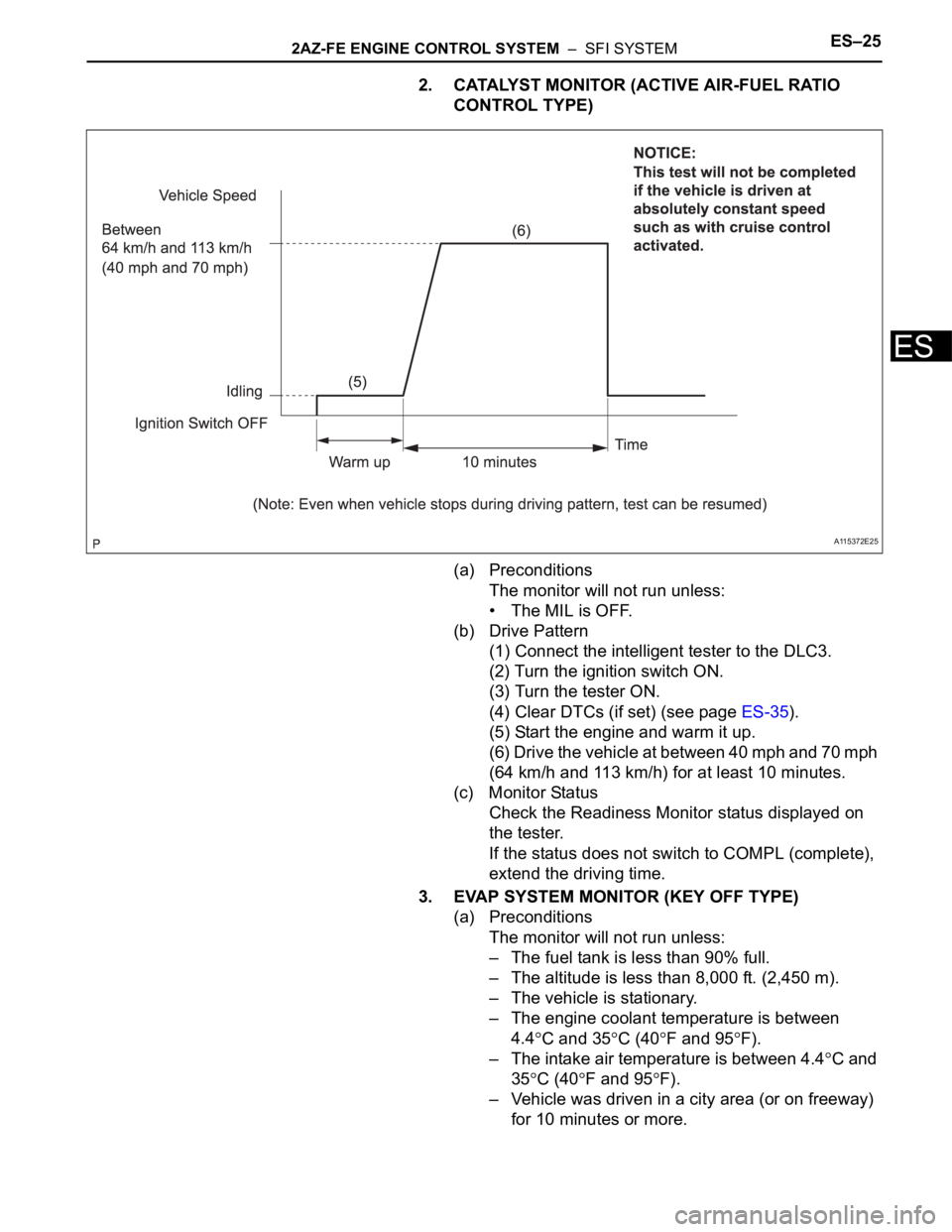

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–25

ES

2. CATALYST MONITOR (ACTIVE AIR-FUEL RATIO

CONTROL TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch ON.

(3) Turn the tester ON.

(4) Clear DTCs (if set) (see page ES-35).

(5) Start the engine and warm it up.

(6) Drive the vehicle at between 40 mph and 70 mph

(64 km/h and 113 km/h) for at least 10 minutes.

(c) Monitor Status

Check the Readiness Monitor status displayed on

the tester.

If the status does not switch to COMPL (complete),

extend the driving time.

3. EVAP SYSTEM MONITOR (KEY OFF TYPE)

(a) Preconditions

The monitor will not run unless:

– The fuel tank is less than 90% full.

– The altitude is less than 8,000 ft. (2,450 m).

– The vehicle is stationary.

– The engine coolant temperature is between

4.4

C and 35C (40F and 95F).

– The intake air temperature is between 4.4

C and

35

C (40F and 95F).

– Vehicle was driven in a city area (or on freeway)

for 10 minutes or more.

A115372E25

Page 481 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–27

ES

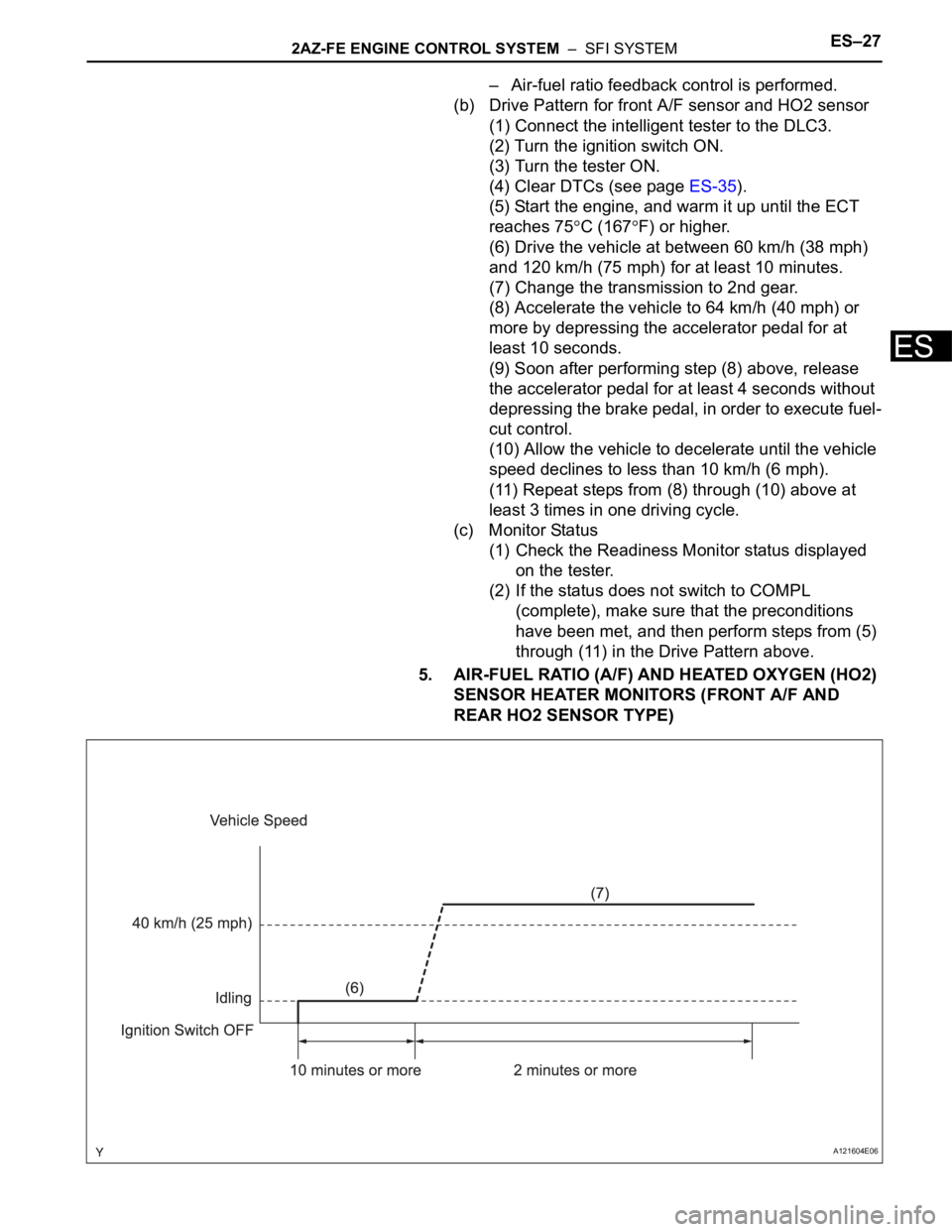

– Air-fuel ratio feedback control is performed.

(b) Drive Pattern for front A/F sensor and HO2 sensor

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch ON.

(3) Turn the tester ON.

(4) Clear DTCs (see page ES-35).

(5) Start the engine, and warm it up until the ECT

reaches 75

C (167F) or higher.

(6) Drive the vehicle at between 60 km/h (38 mph)

and 120 km/h (75 mph) for at least 10 minutes.

(7) Change the transmission to 2nd gear.

(8) Accelerate the vehicle to 64 km/h (40 mph) or

more by depressing the accelerator pedal for at

least 10 seconds.

(9) Soon after performing step (8) above, release

the accelerator pedal for at least 4 seconds without

depressing the brake pedal, in order to execute fuel-

cut control.

(10) Allow the vehicle to decelerate until the vehicle

speed declines to less than 10 km/h (6 mph).

(11) Repeat steps from (8) through (10) above at

least 3 times in one driving cycle.

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), make sure that the preconditions

have been met, and then perform steps from (5)

through (11) in the Drive Pattern above.

5. AIR-FUEL RATIO (A/F) AND HEATED OXYGEN (HO2)

SENSOR HEATER MONITORS (FRONT A/F AND

REAR HO2 SENSOR TYPE)

A121604E06

Page 483 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–29

ES

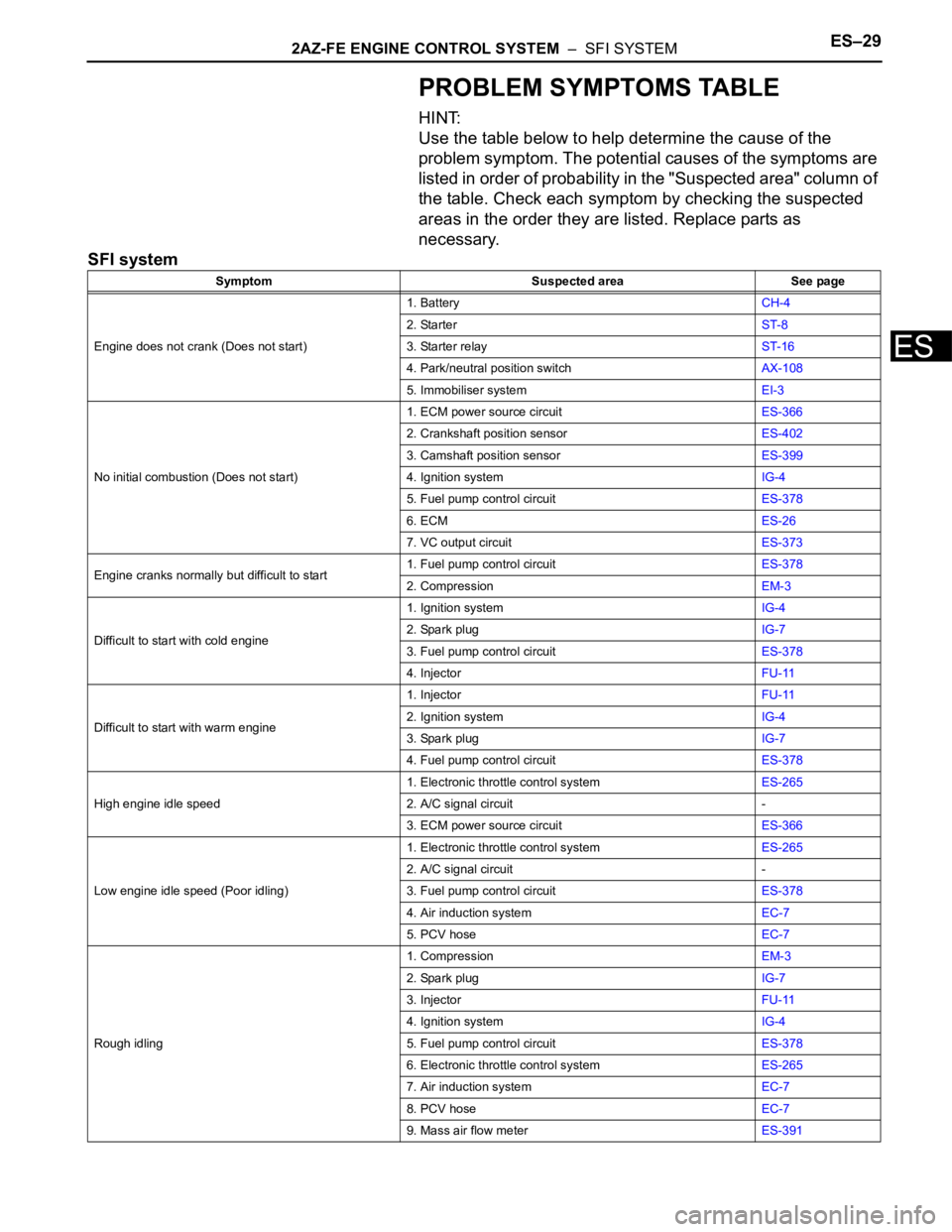

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "Suspected area" column of

the table. Check each symptom by checking the suspected

areas in the order they are listed. Replace parts as

necessary.

SFI system

Symptom Suspected area See page

Engine does not crank (Does not start)1. BatteryCH-4

2. StarterST-8

3. Starter relayST-16

4. Park/neutral position switchAX-108

5. Immobiliser systemEI-3

No initial combustion (Does not start)1. ECM power source circuitES-366

2. Crankshaft position sensorES-402

3. Camshaft position sensorES-399

4. Ignition systemIG-4

5. Fuel pump control circuitES-378

6. ECMES-26

7. VC output circuitES-373

Engine cranks normally but difficult to start1. Fuel pump control circuitES-378

2. CompressionEM-3

Difficult to start with cold engine1. Ignition systemIG-4

2. Spark plugIG-7

3. Fuel pump control circuitES-378

4. InjectorFU-11

Difficult to start with warm engine1. InjectorFU-11

2. Ignition systemIG-4

3. Spark plugIG-7

4. Fuel pump control circuitES-378

High engine idle speed1. Electronic throttle control systemES-265

2. A/C signal circuit -

3. ECM power source circuitES-366

Low engine idle speed (Poor idling)1. Electronic throttle control systemES-265

2. A/C signal circuit -

3. Fuel pump control circuitES-378

4. Air induction systemEC-7

5. PCV hoseEC-7

Rough idling1. CompressionEM-3

2. Spark plugIG-7

3. InjectorFU-11

4. Ignition systemIG-4

5. Fuel pump control circuitES-378

6. Electronic throttle control systemES-265

7. Air induction systemEC-7

8. PCV hoseEC-7

9. Mass air flow meterES-391

Page 486 of 2000

ES–322AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

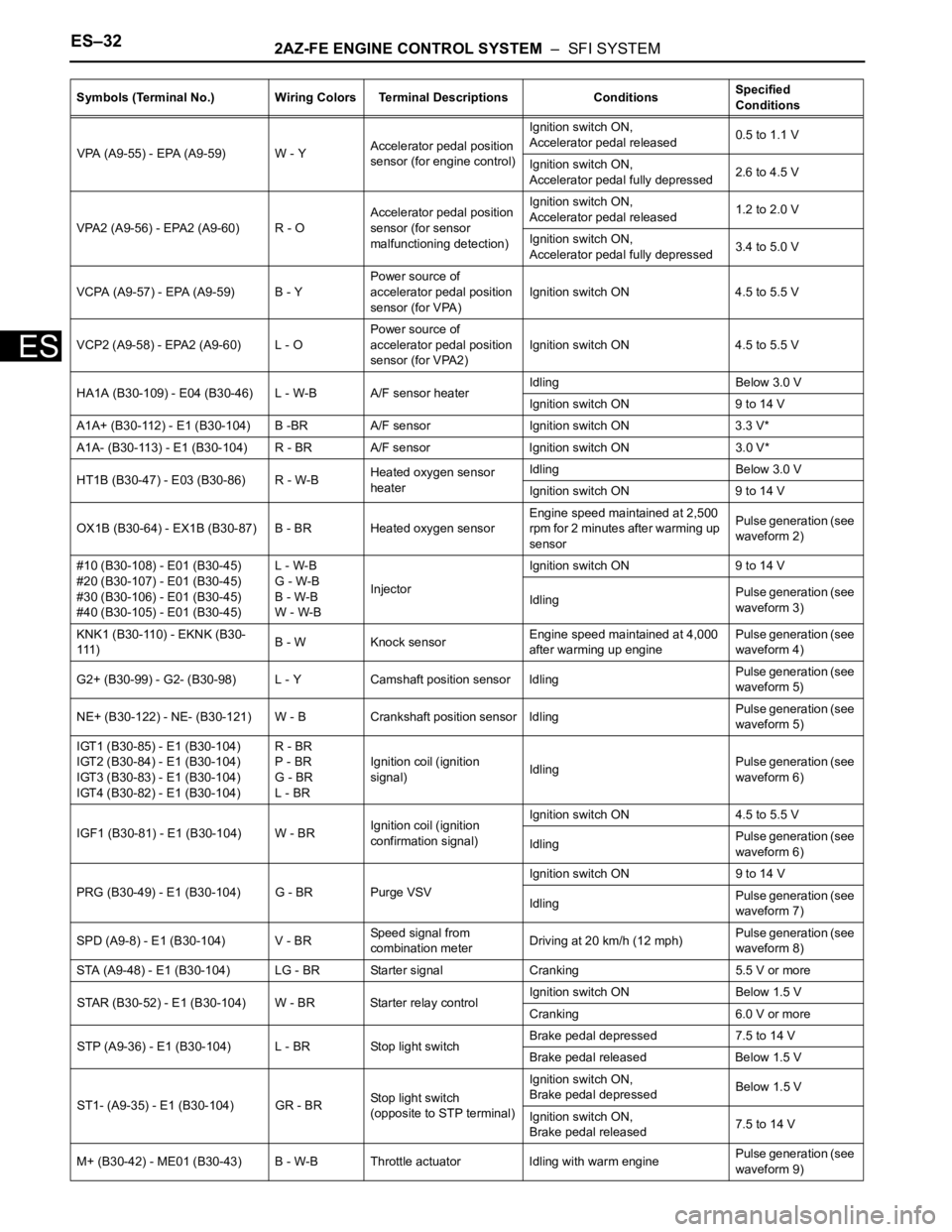

VPA (A9-55) - EPA (A9-59) W - YAccelerator pedal position

sensor (for engine control)Ignition switch ON,

Accelerator pedal released0.5 to 1.1 V

Ignition switch ON,

Accelerator pedal fully depressed2.6 to 4.5 V

VPA2 (A9-56) - EPA2 (A9-60) R - OAccelerator pedal position

sensor (for sensor

malfunctioning detection)Ignition switch ON,

Accelerator pedal released1.2 to 2.0 V

Ignition switch ON,

Accelerator pedal fully depressed3.4 to 5.0 V

VCPA (A9-57) - EPA (A9-59) B - YPower source of

accelerator pedal position

sensor (for VPA)Ignition switch ON 4.5 to 5.5 V

VCP2 (A9-58) - EPA2 (A9-60) L - OPower source of

accelerator pedal position

sensor (for VPA2)Ignition switch ON 4.5 to 5.5 V

HA1A (B30-109) - E04 (B30-46) L - W-B A/F sensor heaterIdling Below 3.0 V

Ignition switch ON 9 to 14 V

A1A+ (B30-112) - E1 (B30-104) B -BR A/F sensor Ignition switch ON 3.3 V*

A1A- (B30-113) - E1 (B30-104) R - BR A/F sensor Ignition switch ON3.0 V*

HT1B (B30-47) - E03 (B30-86) R - W-BHeated oxygen sensor

heaterIdling Below 3.0 V

Ignition switch ON 9 to 14 V

OX1B (B30-64) - EX1B (B30-87) B - BR Heated oxygen sensorEngine speed maintained at 2,500

rpm for 2 minutes after warming up

sensorPulse generation (see

waveform 2)

#10 (B30-108) - E01 (B30-45)

#20 (B30-107) - E01 (B30-45)

#30 (B30-106) - E01 (B30-45)

#40 (B30-105) - E01 (B30-45)L - W-B

G - W-B

B - W-B

W - W-BInjectorIgnition switch ON 9 to 14 V

IdlingPulse generation (see

waveform 3)

KNK1 (B30-110) - EKNK (B30-

111 )B - W Knock sensorEngine speed maintained at 4,000

after warming up enginePulse generation (see

waveform 4)

G2+ (B30-99) - G2- (B30-98) L - Y Camshaft position sensor IdlingPulse generation (see

waveform 5)

NE+ (B30-122) - NE- (B30-121) W - B Crankshaft position sensor IdlingPulse generation (see

waveform 5)

IGT1 (B30-85) - E1 (B30-104)

IGT2 (B30-84) - E1 (B30-104)

IGT3 (B30-83) - E1 (B30-104)

IGT4 (B30-82) - E1 (B30-104)R - BR

P - BR

G - BR

L - BRIgnition coil (ignition

signal)IdlingPulse generation (see

waveform 6)

IGF1 (B30-81) - E1 (B30-104) W - BRIgnition coil (ignition

confirmation signal)Ignition switch ON 4.5 to 5.5 V

IdlingPulse generation (see

waveform 6)

PRG (B30-49) - E1 (B30-104) G - BR Purge VSVIgnition switch ON 9 to 14 V

IdlingPulse generation (see

waveform 7)

SPD (A9-8) - E1 (B30-104) V - BRSpeed signal from

combination meterDriving at 20 km/h (12 mph)Pulse generation (see

waveform 8)

STA (A9-48) - E1 (B30-104) LG - BR Starter signal Cranking 5.5 V or

more

STAR (B30-52) - E1 (B30-104) W - BR Starter relay controlIgnition switch ON Below 1.5 V

Cranking 6.0 V or more

STP (A9-36) - E1 (B30-104) L - BR Stop light switchBrake pedal depressed 7.5 to 14 V

Brake pedal released Below 1.5 V

ST1- (A9-35) - E1 (B30-104) GR - BRStop light switch

(opposite to STP terminal)Ignition switch ON,

Brake pedal depressedBelow 1.5 V

Ignition switch ON,

Brake pedal released7.5 to 14 V

M+ (B30-42) - ME01 (B30-43) B - W-B Throttle actuator Idling with warm enginePulse generation (see

waveform 9) Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Conditions

Page 487 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–33

ES

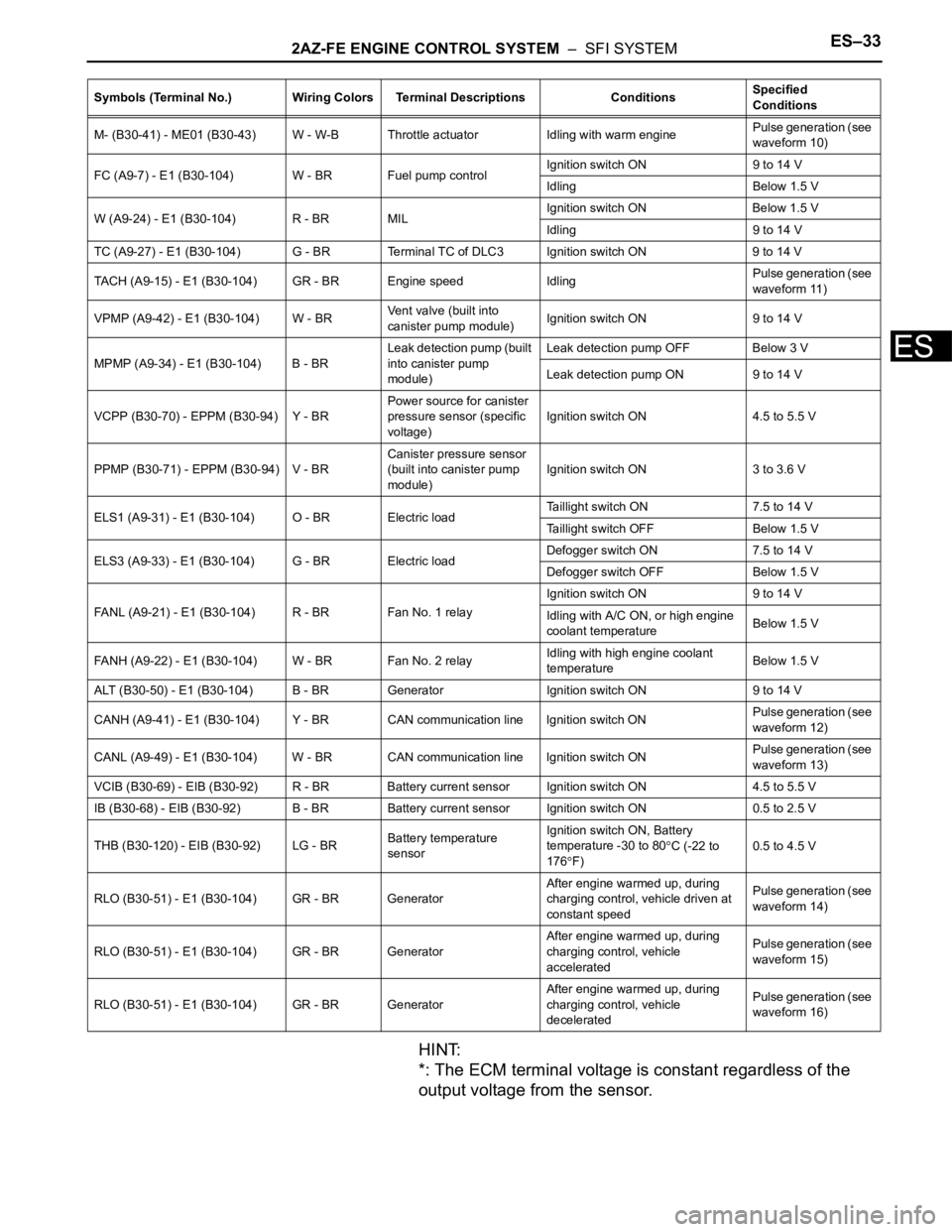

HINT:

*: The ECM terminal voltage is constant regardless of the

output voltage from the sensor.

M- (B30-41) - ME01 (B30-43) W - W-B Throttle actuator Idling with warm enginePulse generation (see

waveform 10)

FC (A9-7) - E1 (B30-104) W - BR Fuel pump controlIgnition switch ON 9 to 14 V

Idling Below 1.5 V

W (A9-24) - E1 (B30-104) R - BR MILIgnition switch ON Below 1.5 V

Idling 9 to 14 V

TC (A9-27) - E1 (B30-104) G - BR Terminal TC of DLC3 Ignition switch ON 9 to 14 V

TACH (A9-15) - E1 (B30-104) GR - BR Engine speed IdlingPulse generation (see

waveform 11)

VPMP (A9-42) - E1 (B30-104) W - BRVent valve (built into

canister pump module)Ignition switch ON 9 to 14 V

MPMP (A9-34) - E1 (B30-104) B - BRLeak detection pump (built

into canister pump

module)Leak detection pump OFF Below 3 V

Leak detection pump ON 9 to 14 V

VCPP (B30-70) - EPPM (B30-94) Y - BRPower source for canister

pressure sensor (specific

voltage)Ignition switch ON 4.5 to 5.5 V

PPMP (B30-71) - EPPM (B30-94) V - BRCanister pressure sensor

(built into canister pump

module)Ignition switch ON 3 to 3.6 V

ELS1 (A9-31) - E1 (B30-104) O - BR Electric loadTaillight switch ON 7.5 to 14 V

Taillight switch OFF Below 1.5 V

ELS3 (A9-33) - E1 (B30-104) G - BR Electric loadDefogger switch ON 7.5 to 14 V

Defogger switch OFF Below 1.5 V

FANL (A9-21) - E1 (B30-104) R - BR Fan No. 1 relayIgnition switch ON 9 to 14 V

Idling with A/C ON, or high engine

coolant temperatureBelow 1.5 V

FANH (A9-22) - E1 (B30-104) W - BR Fan No. 2 relayIdling with high engine coolant

temperatureBelow 1.5 V

ALT (B30-50) - E1 (B30-104) B - BR Generator Ignition switch ON 9 to 14 V

CANH (A9-41) - E1 (B30-104) Y - BR CAN communication line Ignition switch ONPulse generation (see

waveform 12)

CANL (A9-49) - E1 (B30-104) W - BR CAN communication line Ignition switch ONPulse generation (see

waveform 13)

VCIB (B30-69) - EIB (B30-92) R - BR Battery current sensor Ignition switch ON 4.5 to 5.5 V

IB (B30-68) - EIB (B30-92) B - BR Battery current sensor Ignition switch ON 0.5 to 2.5 V

THB (B30-120) - EIB (B30-92) LG - BRBattery temperature

sensorIgnition switch ON, Battery

temperature -30 to 80

C (-22 to

176

F)0.5 to 4.5 V

RLO (B30-51) - E1 (B30-104) GR - BR GeneratorAfter engine warmed up, during

charging control, vehicle driven at

constant speedPulse generation (see

waveform 14)

RLO (B30-51) - E1 (B30-104) GR - BR GeneratorAfter engine warmed up, during

charging control, vehicle

acceleratedPulse generation (see

waveform 15)

RLO (B30-51) - E1 (B30-104) GR - BR GeneratorAfter engine warmed up, during

charging control, vehicle

deceleratedPulse generation (see

waveform 16) Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Conditions

Page 488 of 2000

ES–342AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

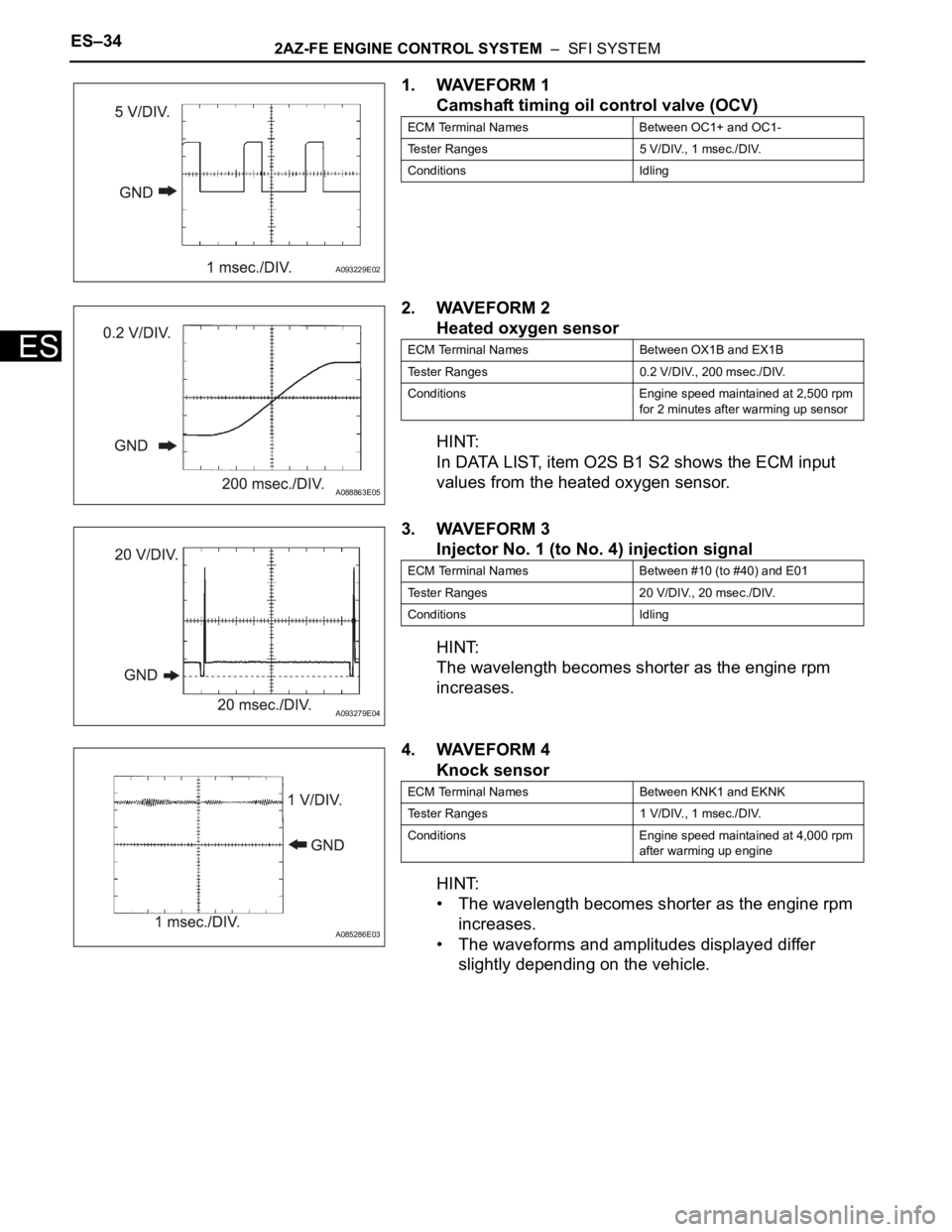

1. WAVEFORM 1

Camshaft timing oil control valve (OCV)

2. WAVEFORM 2

Heated oxygen sensor

HINT:

In DATA LIST, item O2S B1 S2 shows the ECM input

values from the heated oxygen sensor.

3. WAVEFORM 3

Injector No. 1 (to No. 4) injection signal

HINT:

The wavelength becomes shorter as the engine rpm

increases.

4. WAVEFORM 4

Knock sensor

HINT:

• The wavelength becomes shorter as the engine rpm

increases.

• The waveforms and amplitudes displayed differ

slightly depending on the vehicle.

A093229E02

ECM Terminal Names Between OC1+ and OC1-

Tester Ranges 5 V/DIV., 1 msec./DIV.

Conditions Idling

A088863E05

ECM Terminal Names Between OX1B and EX1B

Tester Ranges 0.2 V/DIV., 200 msec./DIV.

Conditions Engine speed maintained at 2,500 rpm

for 2 minutes after warming up sensor

A093279E04

ECM Terminal Names Between #10 (to #40) and E01

Tester Ranges 20 V/DIV., 20 msec./DIV.

Conditions Idling

A085286E03

ECM Terminal Names Between KNK1 and EKNK

Tester Ranges 1 V/DIV., 1 msec./DIV.

Conditions Engine speed maintained at 4,000 rpm

after warming up engine

Page 489 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–35

ES

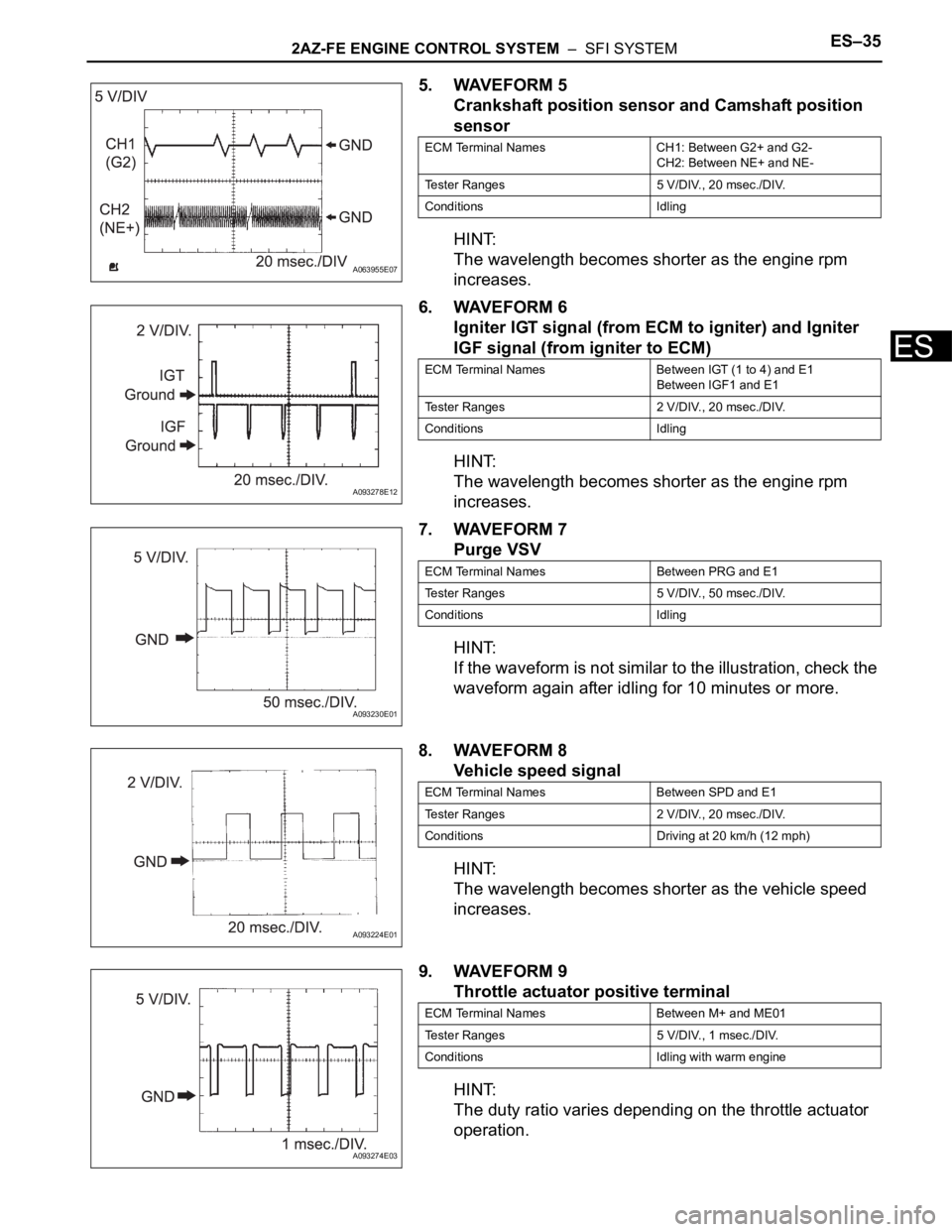

5. WAVEFORM 5

Crankshaft position sensor and Camshaft position

sensor

HINT:

The wavelength becomes shorter as the engine rpm

increases.

6. WAVEFORM 6

Igniter IGT signal (from ECM to igniter) and Igniter

IGF signal (from igniter to ECM)

HINT:

The wavelength becomes shorter as the engine rpm

increases.

7. WAVEFORM 7

Purge VSV

HINT:

If the waveform is not similar to the illustration, check the

waveform again after idling for 10 minutes or more.

8. WAVEFORM 8

Vehicle speed signal

HINT:

The wavelength becomes shorter as the vehicle speed

increases.

9. WAVEFORM 9

Throttle actuator positive terminal

HINT:

The duty ratio varies depending on the throttle actuator

operation.

A063955E07

ECM Terminal Names CH1: Between G2+ and G2-

CH2: Between NE+ and NE-

Tester Ranges 5 V/DIV., 20 msec./DIV.

Conditions Idling

A093278E12

ECM Terminal Names Between IGT (1 to 4) and E1

Between IGF1 and E1

Tester Ranges 2 V/DIV., 20 msec./DIV.

Conditions Idling

A093230E01

ECM Terminal Names Between PRG and E1

Tester Ranges 5 V/DIV., 50 msec./DIV.

Conditions Idling

A093224E01

ECM Terminal Names Between SPD and E1

Tester Ranges 2 V/DIV., 20 msec./DIV.

Conditions Driving at 20 km/h (12 mph)

A093274E03

ECM Terminal Names Between M+ and ME01

Tester Ranges 5 V/DIV., 1 msec./DIV.

Conditions Idling with warm engine