TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1701 of 3000

AX–18U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

INITIALIZATION

1. RESET MEMORY

NOTICE:

• Perform the RESET MEMORY (AT initialization)

when replacing the automatic transaxle assembly,

engine assembly or ECM.

• The RESET MEMORY can be performed only with

the Intelligent tester.

HINT:

The ECM memorizes the condition that the ECT controls

the automatic transaxle assembly and engine assembly

according to those characteristics. Therefore, when the

automatic transaxle assembly, engine assembly, or ECM

has been replaced, it is necessary to reset the memory

so that the ECM can memorize the new information.

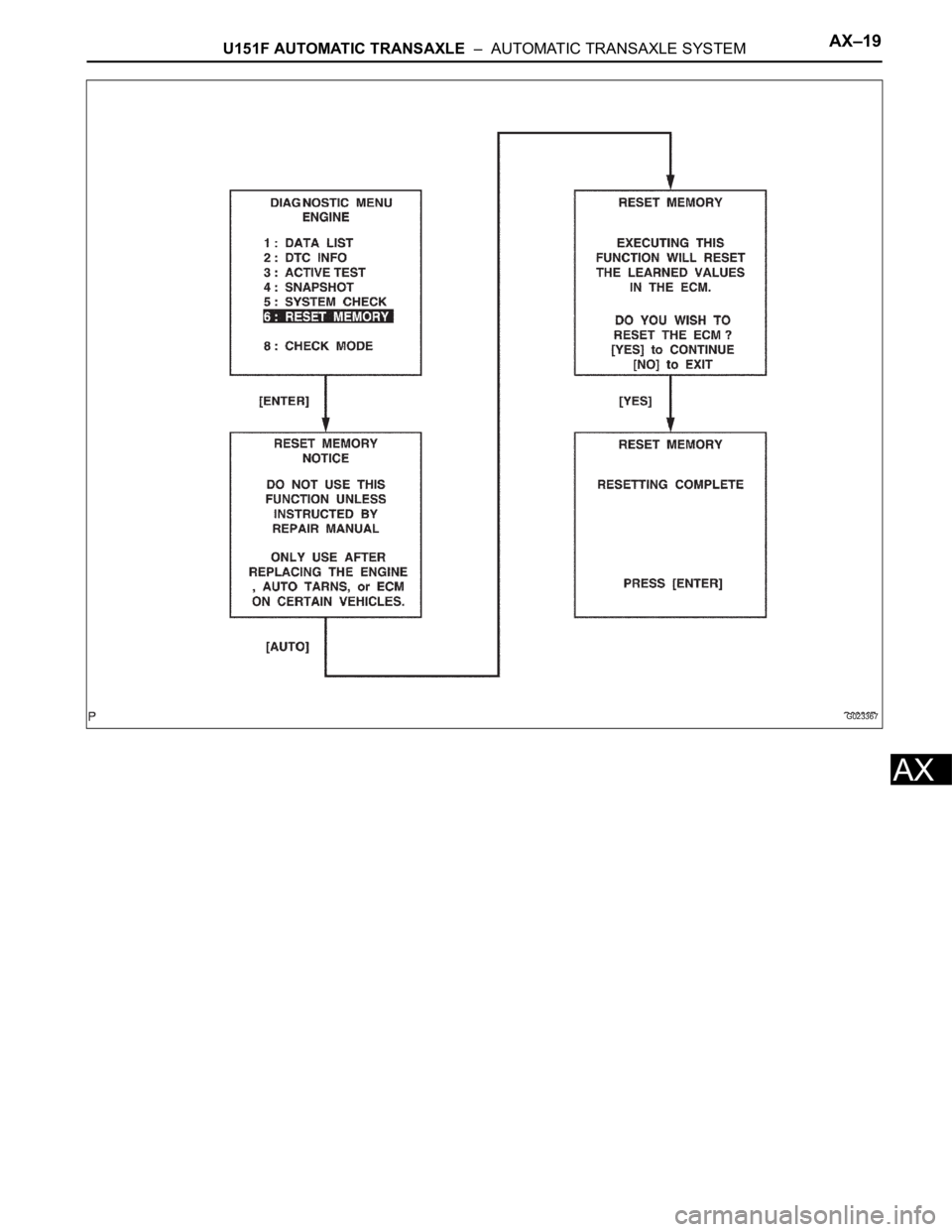

Reset procedure is as follows.

(a) Turn the engine switch off.

(b) Connect the intelligent tester together with the CAN

VIM (controller area network vehicle interface

module) to the DLC3.

(c) Turn the ignition switch to the ON position and push

the intelligent tester main switch on.

(d) Select the item "DIAGNOSIS / ENHANCED OBD

II".

(e) Perform the reset memory procedure from the

ENGINE menu.

CAUTION:

After performing the RESET MEMORY, be sure

to perform the ROAD TEST (See page AX-9)

described earlier.

HINT:

The ECM is learned by performing the ROAD TEST.

(1) Tester menu flow:

Page 1702 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–19

AX

G023367

Page 1703 of 3000

AX–20U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

MONITOR DRIVE PATTERN

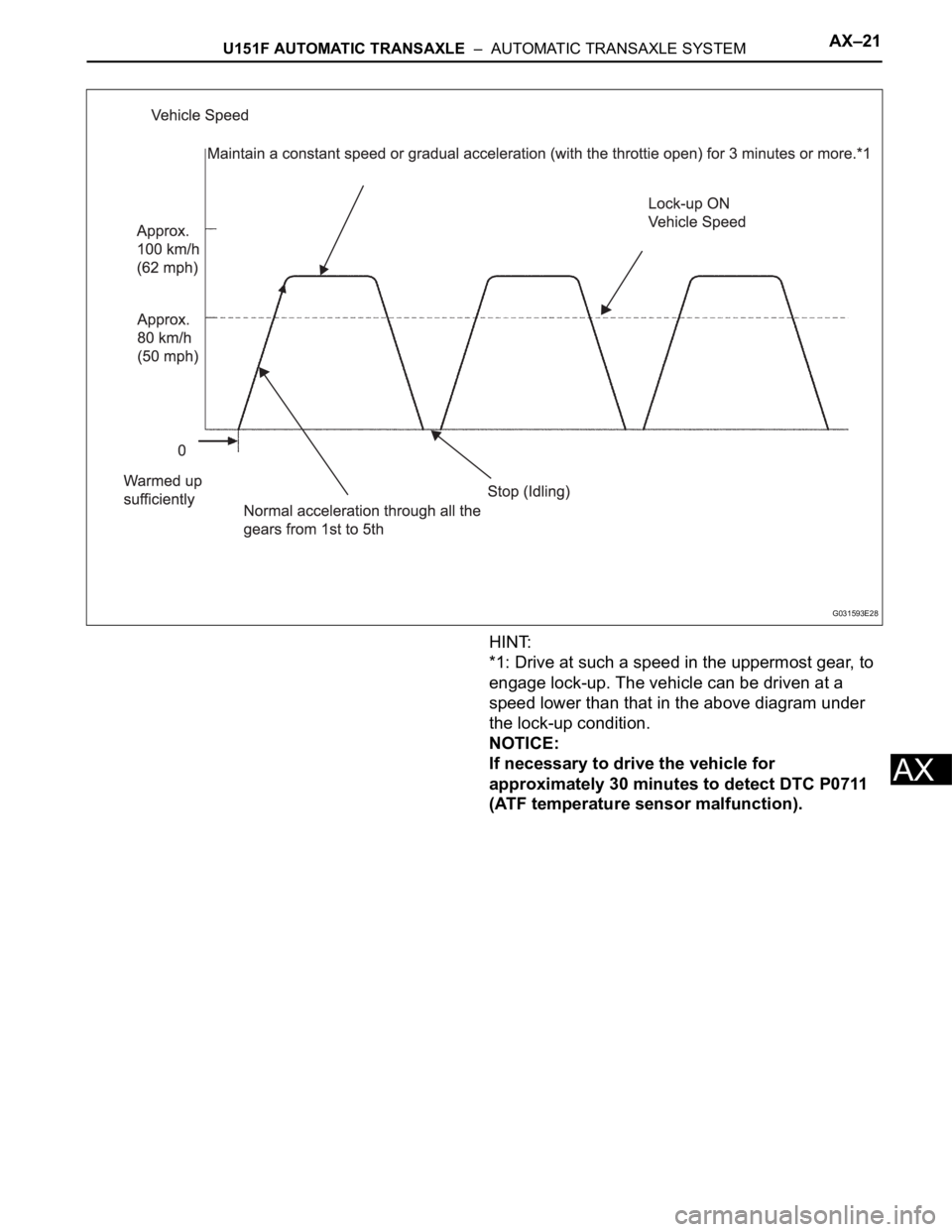

1. MONITOR DRIVE PATTERN FOR ECT TEST

(a) Perform this drive pattern as one method to

simulate the detection conditions of the ECT

malfunctions. (The DTCs may not be detected due

the actual driving conditions. And some codes may

not be detected through this drive pattern.)

HINT:

Preparation for driving

• Warm up the engine sufficiently. (Engine coolant

temperature is 60

C (140F) or higher)

• Drive the vehicle when the atmospheric

temperature is -10

C (14F) or higher.

(Malfunction is not detected when the

atmospheric temperature is less than -10

C

(14

F))

Driving note

• Drive the vehicle through all gears.

Stop

1st 2nd 3rd 4th 5th 5th

(lock-up ON).

• Repeat the above driving pattern three times or

more.

NOTICE:

• The monitor status can be checked using the

OBD II scan tool or intelligent tester. When

using the intelligent tester, monitor status

can be found in the "ENHANCED OBD II /

DATA LIST" or under "CARB OBD II".

• In the event that the drive pattern must be

interrupted (possibly due to traffic conditions

or other factors), the drive pattern can be

resumed and, in most cases, the monitor can

be completed.

• Perform this drive pattern on a level road as

much as possible and strictly observe the

posted speed limits and traffic laws while

driving.

Page 1704 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–21

AX

HINT:

*1: Drive at such a speed in the uppermost gear, to

engage lock-up. The vehicle can be driven at a

speed lower than that in the above diagram under

the lock-up condition.

NOTICE:

If necessary to drive the vehicle for

approximately 30 minutes to detect DTC P0711

(ATF temperature sensor malfunction).

G031593E28

Page 1705 of 3000

AX–22U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

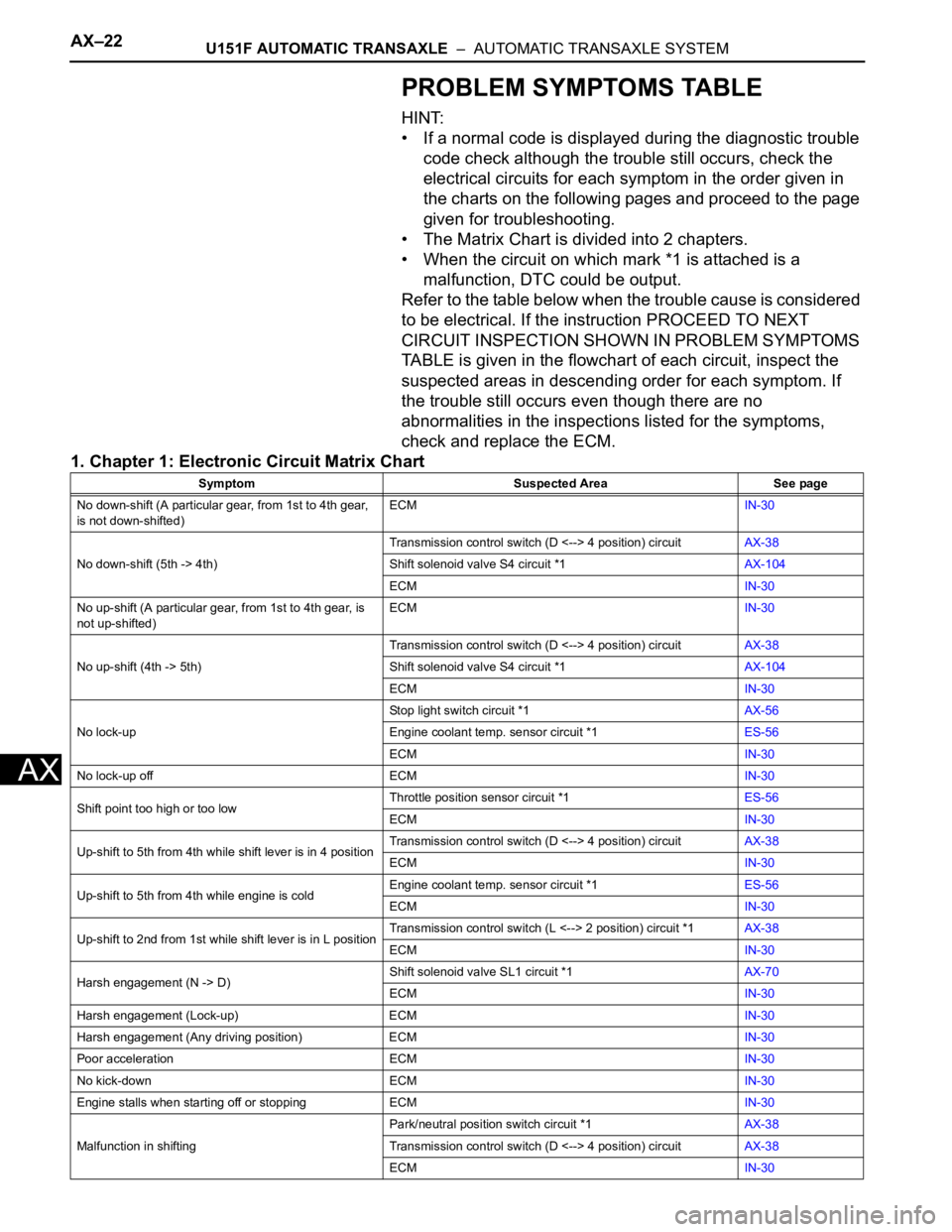

PROBLEM SYMPTOMS TABLE

HINT:

• If a normal code is displayed during the diagnostic trouble

code check although the trouble still occurs, check the

electrical circuits for each symptom in the order given in

the charts on the following pages and proceed to the page

given for troubleshooting.

• The Matrix Chart is divided into 2 chapters.

• When the circuit on which mark *1 is attached is a

malfunction, DTC could be output.

Refer to the table below when the trouble cause is considered

to be electrical. If the instruction PROCEED TO NEXT

CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE is given in the flowchart of each circuit, inspect the

suspected areas in descending order for each symptom. If

the trouble still occurs even though there are no

abnormalities in the inspections listed for the symptoms,

check and replace the ECM.

1. Chapter 1: Electronic Circuit Matrix Chart

Symptom Suspected Area See page

No down-shift (A particular gear, from 1st to 4th gear,

is not down-shifted)ECMIN-30

No down-shift (5th -> 4th)Transmission control switch (D <--> 4 position) circuitAX-38

Shift solenoid valve S4 circuit *1AX-104

ECMIN-30

No up-shift (A particular gear, from 1st to 4th gear, is

not up-shifted)ECMIN-30

No up-shift (4th -> 5th)Transmission control switch (D <--> 4 position) circuitAX-38

Shift solenoid valve S4 circuit *1AX-104

ECMIN-30

No lock-upStop light switch circuit *1AX-56

Engine coolant temp. sensor circuit *1ES-56

ECMIN-30

No lock-up off ECMIN-30

Shift point too high or too lowThrottle position sensor circuit *1ES-56

ECMIN-30

Up-shift to 5th from 4th while shift lever is in 4 positionTransmission control switch (D <--> 4 position) circuitAX-38

ECMIN-30

Up-shift to 5th from 4th while engine is coldEngine coolant temp. sensor circuit *1ES-56

ECMIN-30

Up-shift to 2nd from 1st while shift lever is in L positionTransmission control switch (L <--> 2 position) circuit *1AX-38

ECMIN-30

Harsh engagement (N -> D)Shift solenoid valve SL1 circuit *1AX-70

ECMIN-30

Harsh engagement (Lock-up) ECMIN-30

Harsh engagement (Any driving position) ECMIN-30

Poor acceleration ECMIN-30

No kick-down ECMIN-30

Engine stalls when starting off or stopping ECMIN-30

Malfunction in shiftingPark/neutral position switch circuit *1AX-38

Transmission control switch (D <--> 4 position) circuitAX-38

ECMIN-30

Page 1706 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–23

AX

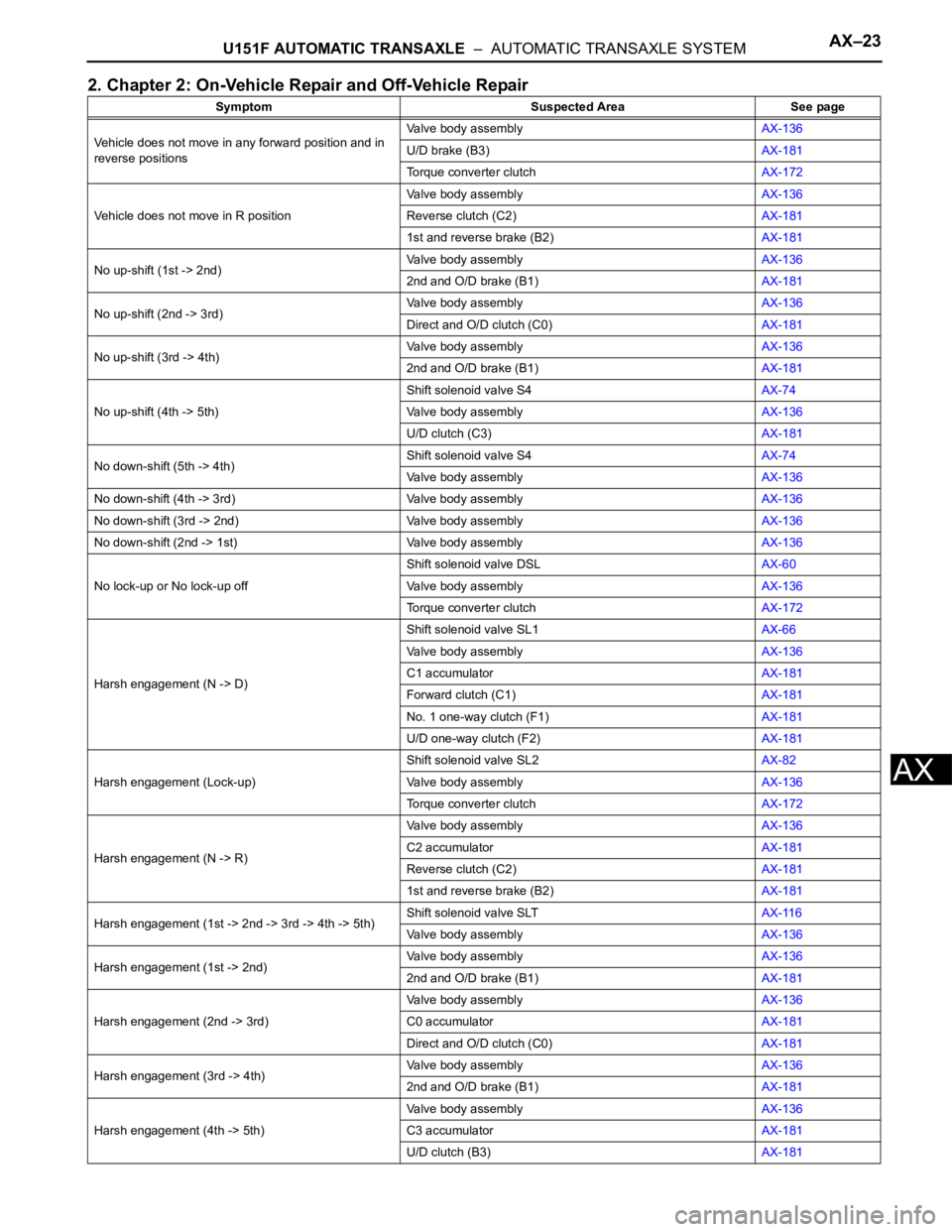

2. Chapter 2: On-Vehicle Repair and Off-Vehicle Repair

Symptom Suspected Area See page

Vehicle does not move in any forward position and in

reverse positionsValve body assemblyAX-136

U/D brake (B3)AX-181

Torque converter clutchAX-172

Vehicle does not move in R positionValve body assemblyAX-136

Reverse clutch (C2)AX-181

1st and reverse brake (B2)AX-181

No up-shift (1st -> 2nd)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-181

No up-shift (2nd -> 3rd)Valve body assemblyAX-136

Direct and O/D clutch (C0)AX-181

No up-shift (3rd -> 4th)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-181

No up-shift (4th -> 5th)Shift solenoid valve S4AX-74

Valve body assemblyAX-136

U/D clutch (C3)AX-181

No down-shift (5th -> 4th)Shift solenoid valve S4AX-74

Valve body assemblyAX-136

No down-shift (4th -> 3rd) Valve body assemblyAX-136

No down-shift (3rd -> 2nd) Valve body assemblyAX-136

No down-shift (2nd -> 1st) Valve body assemblyAX-136

No lock-up or No lock-up offShift solenoid valve DSLAX-60

Valve body assemblyAX-136

Torque converter clutchAX-172

Harsh engagement (N -> D)Shift solenoid valve SL1AX-66

Valve body assemblyAX-136

C1 accumulatorAX-181

Forward clutch (C1)AX-181

No. 1 one-way clutch (F1)AX-181

U/D one-way clutch (F2)AX-181

Harsh engagement (Lock-up)Shift solenoid valve SL2AX-82

Valve body assemblyAX-136

Torque converter clutchAX-172

Harsh engagement (N -> R)Valve body assemblyAX-136

C2 accumulatorAX-181

Reverse clutch (C2)AX-181

1st and reverse brake (B2)AX-181

Harsh engagement (1st -> 2nd -> 3rd -> 4th -> 5th)Shift solenoid valve SLTAX-116

Valve body assemblyAX-136

Harsh engagement (1st -> 2nd)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-181

Harsh engagement (2nd -> 3rd)Valve body assemblyAX-136

C0 accumulatorAX-181

Direct and O/D clutch (C0)AX-181

Harsh engagement (3rd -> 4th)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-181

Harsh engagement (4th -> 5th)Valve body assemblyAX-136

C3 accumulatorAX-181

U/D clutch (B3)AX-181

Page 1707 of 3000

AX–24U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

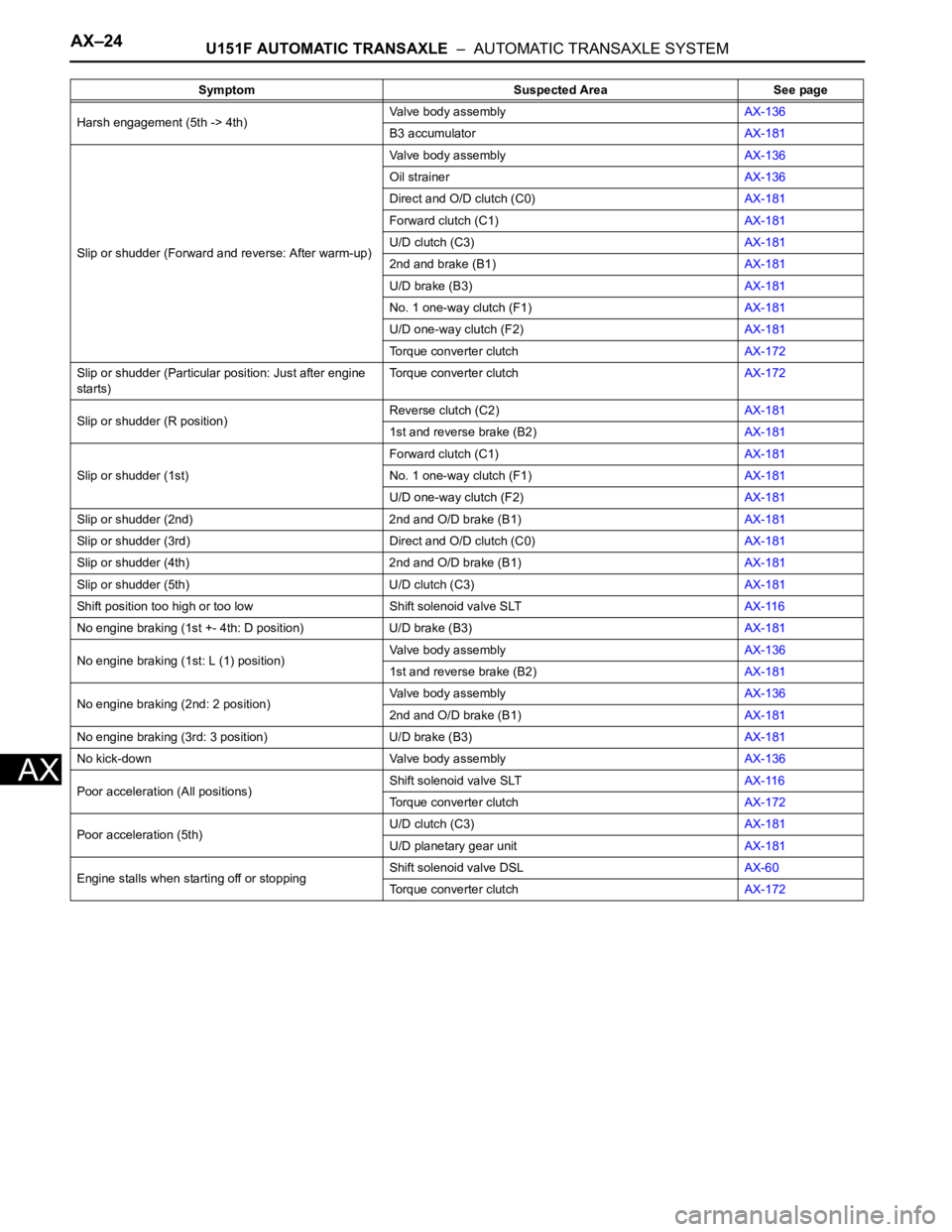

Harsh engagement (5th -> 4th)Valve body assemblyAX-136

B3 accumulatorAX-181

Slip or shudder (Forward and reverse: After warm-up)Valve body assemblyAX-136

Oil strainerAX-136

Direct and O/D clutch (C0)AX-181

Forward clutch (C1)AX-181

U/D clutch (C3)AX-181

2nd and brake (B1)AX-181

U/D brake (B3)AX-181

No. 1 one-way clutch (F1)AX-181

U/D one-way clutch (F2)AX-181

Torque converter clutchAX-172

Slip or shudder (Particular position: Just after engine

starts)Torque converter clutchAX-172

Slip or shudder (R position)Reverse clutch (C2)AX-181

1st and reverse brake (B2)AX-181

Slip or shudder (1st)Forward clutch (C1)AX-181

No. 1 one-way clutch (F1)AX-181

U/D one-way clutch (F2)AX-181

Slip or shudder (2nd) 2nd and O/D brake (B1)AX-181

Slip or shudder (3rd) Direct and O/D clutch (C0)AX-181

Slip or shudder (4th) 2nd and O/D brake (B1)AX-181

Slip or shudder (5th) U/D clutch (C3)AX-181

Shift position too high or too low Shift solenoid valve SLTAX-116

No engine braking (1st +- 4th: D position) U/D brake (B3)AX-181

No engine braking (1st: L (1) position)Valve body assemblyAX-136

1st and reverse brake (B2)AX-181

No engine braking (2nd: 2 position)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-181

No engine braking (3rd: 3 position) U/D brake (B3)AX-181

No kick-down Valve body assemblyAX-136

Poor acceleration (All positions)Shift solenoid valve SLTAX-116

Torque converter clutchAX-172

Poor acceleration (5th)U/D clutch (C3)AX-181

U/D planetary gear unitAX-181

Engine stalls when starting off or stoppingShift solenoid valve DSLAX-60

Torque converter clutchAX-172 Symptom Suspected Area See page

Page 1708 of 3000

AX–32U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

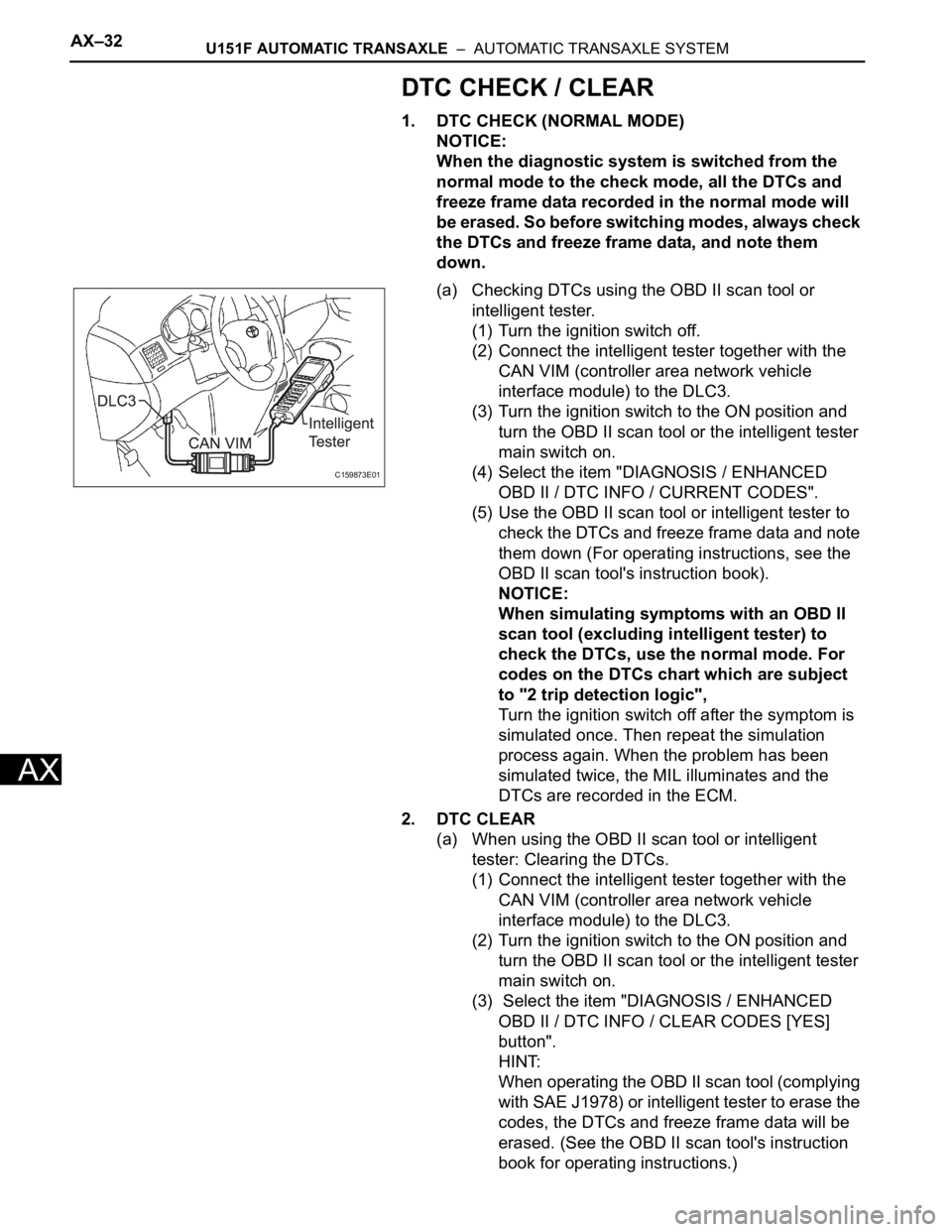

DTC CHECK / CLEAR

1. DTC CHECK (NORMAL MODE)

NOTICE:

When the diagnostic system is switched from the

normal mode to the check mode, all the DTCs and

freeze frame data recorded in the normal mode will

be erased. So before switching modes, always check

the DTCs and freeze frame data, and note them

down.

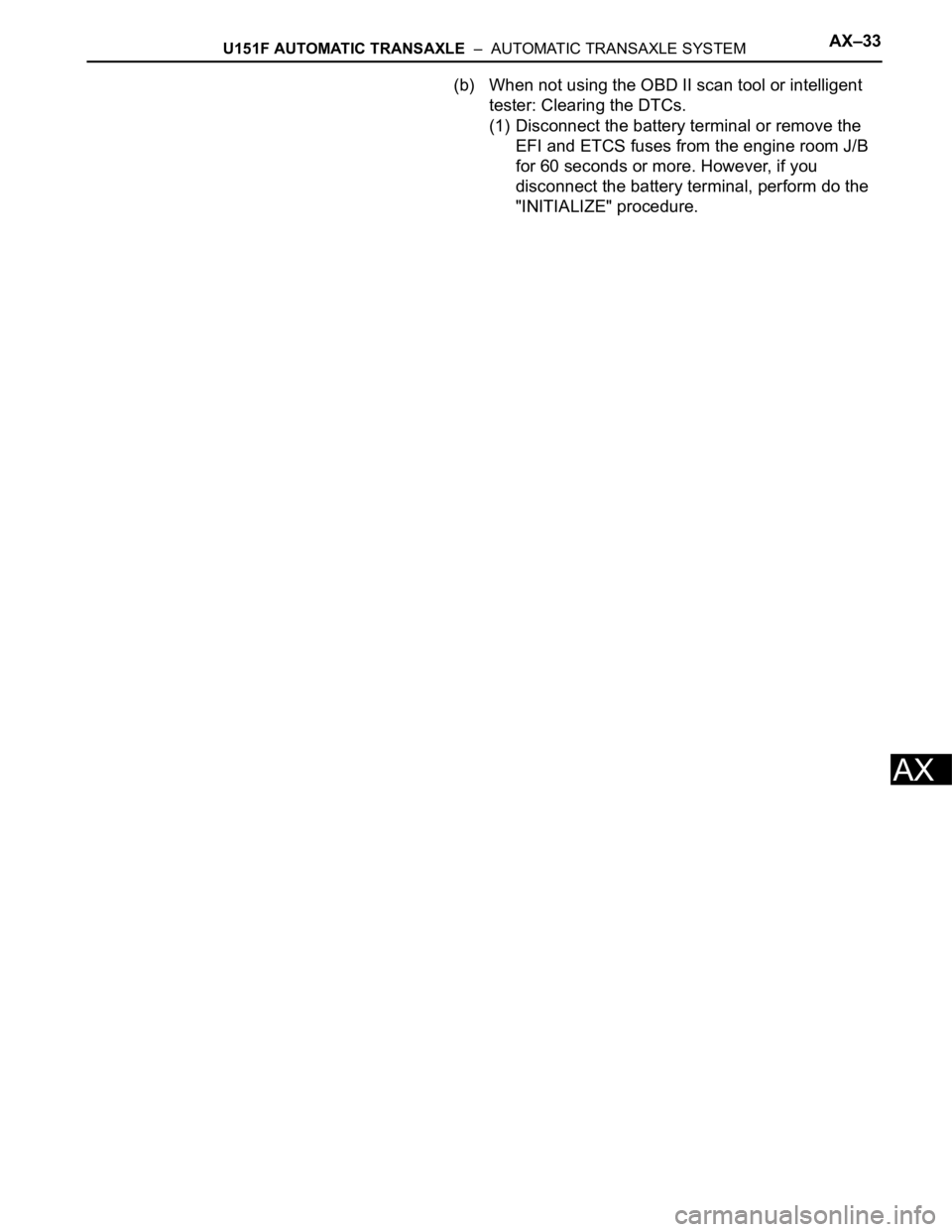

(a) Checking DTCs using the OBD II scan tool or

intelligent tester.

(1) Turn the ignition switch off.

(2) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(3) Turn the ignition switch to the ON position and

turn the OBD II scan tool or the intelligent tester

main switch on.

(4) Select the item "DIAGNOSIS / ENHANCED

OBD II / DTC INFO / CURRENT CODES".

(5) Use the OBD II scan tool or intelligent tester to

check the DTCs and freeze frame data and note

them down (For operating instructions, see the

OBD II scan tool's instruction book).

NOTICE:

When simulating symptoms with an OBD II

scan tool (excluding intelligent tester) to

check the DTCs, use the normal mode. For

codes on the DTCs chart which are subject

to "2 trip detection logic",

Turn the ignition switch off after the symptom is

simulated once. Then repeat the simulation

process again. When the problem has been

simulated twice, the MIL illuminates and the

DTCs are recorded in the ECM.

2. DTC CLEAR

(a) When using the OBD II scan tool or intelligent

tester: Clearing the DTCs.

(1) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(2) Turn the ignition switch to the ON position and

turn the OBD II scan tool or the intelligent tester

main switch on.

(3) Select the item "DIAGNOSIS / ENHANCED

OBD II / DTC INFO / CLEAR CODES [YES]

button".

HINT:

When operating the OBD II scan tool (complying

with SAE J1978) or intelligent tester to erase the

codes, the DTCs and freeze frame data will be

erased. (See the OBD II scan tool's instruction

book for operating instructions.)

C159873E01

Page 1709 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–33

AX

(b) When not using the OBD II scan tool or intelligent

tester: Clearing the DTCs.

(1) Disconnect the battery terminal or remove the

EFI and ETCS fuses from the engine room J/B

for 60 seconds or more. However, if you

disconnect the battery terminal, perform do the

"INITIALIZE" procedure.

Page 1710 of 3000

AX–34U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

CHECK MODE PROCEDURE

HINT:

Check mode has a higher sensitivity to malfunctions and can

detect malfunction that normal mode cannot detect. Check

mode can also detect all the malfunctions that normal mode

can detect. In check mode, DTCs are detected with 1-trip

detection logic.

1. DTC CHECK (CHECK MODE)

HINT:

Intelligent tester only: Compared to the normal mode, the

check mode is more sensitive for detecting malfunctions.

Furthermore, the same diagnostic items which are

detected in the normal mode can also be detected in the

check mode.

(a) Procedure for Check Mode using the intelligent

tester.

(1) Check the initial conditions.

• Battery positive voltage 11 V or more

• Throttle valve fully closed

• Transaxle in the P or N position

• A/C switch is off

(2) Turn the ignition switch off.

(3) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(4) Turn the ignition switch to ON position and turn

the intelligent tester main switch on.

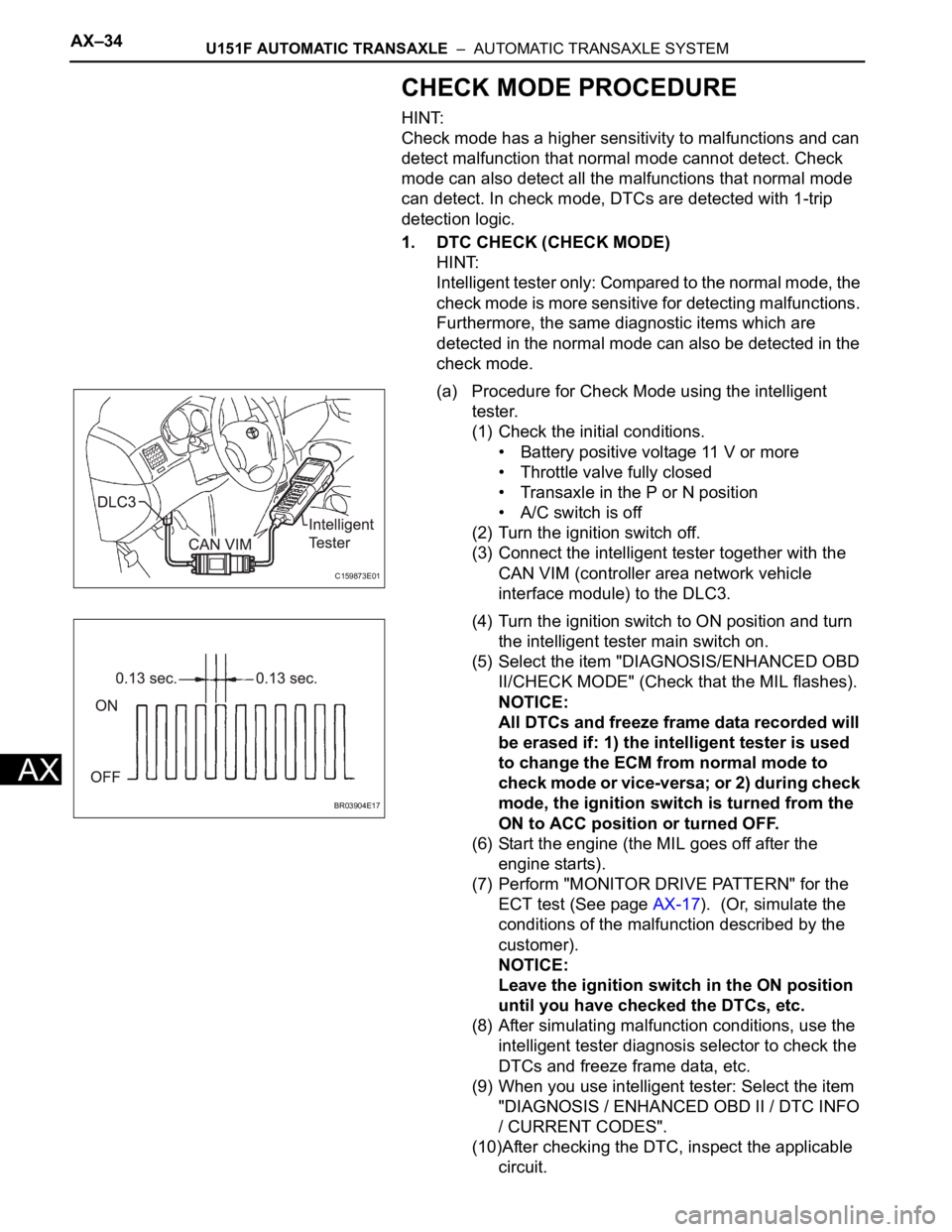

(5) Select the item "DIAGNOSIS/ENHANCED OBD

II/CHECK MODE" (Check that the MIL flashes).

NOTICE:

All DTCs and freeze frame data recorded will

be erased if: 1) the intelligent tester is used

to change the ECM from normal mode to

check mode or vice-versa; or 2) during check

mode, the ignition switch is turned from the

ON to ACC position or turned OFF.

(6) Start the engine (the MIL goes off after the

engine starts).

(7) Perform "MONITOR DRIVE PATTERN" for the

ECT test (See page AX-17). (Or, simulate the

conditions of the malfunction described by the

customer).

NOTICE:

Leave the ignition switch in the ON position

until you have checked the DTCs, etc.

(8) After simulating malfunction conditions, use the

intelligent tester diagnosis selector to check the

DTCs and freeze frame data, etc.

(9) When you use intelligent tester: Select the item

"DIAGNOSIS / ENHANCED OBD II / DTC INFO

/ CURRENT CODES".

(10)After checking the DTC, inspect the applicable

circuit.

C159873E01

BR03904E17