brake TOYOTA SIENNA 2007 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 163 of 3000

AH–6AXLE – FRONT AXLE HUB

AH

REMOVAL

HINT:

Replace the RH side using the same procedures as for the

LH side.

1. REMOVE FRONT WHEEL

2. REMOVE FRONT AXLE HUB LH NUT (See page DS-

5)

3. SEPARATE SPEED SENSOR FRONT LH (See page

DS-5)

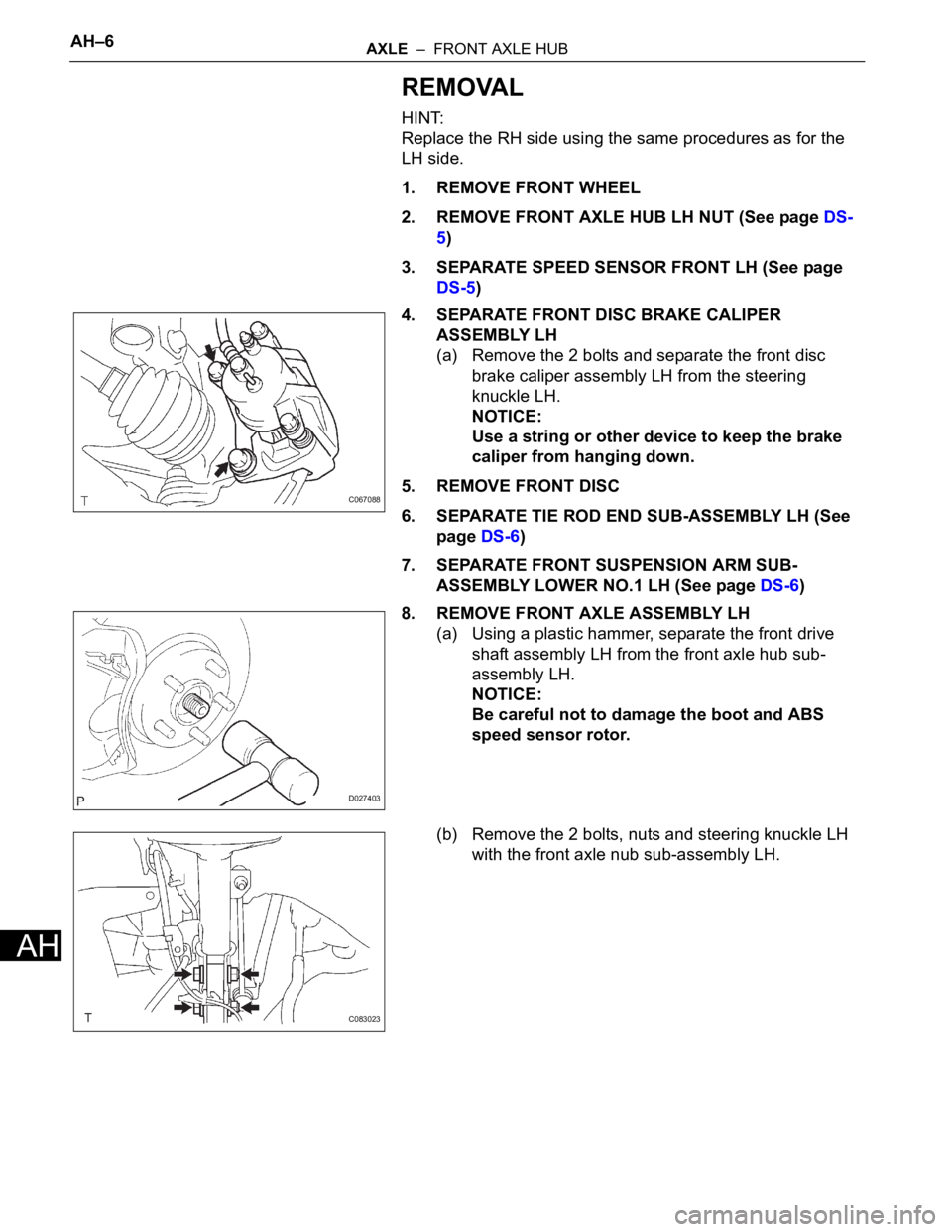

4. SEPARATE FRONT DISC BRAKE CALIPER

ASSEMBLY LH

(a) Remove the 2 bolts and separate the front disc

brake caliper assembly LH from the steering

knuckle LH.

NOTICE:

Use a string or other device to keep the brake

caliper from hanging down.

5. REMOVE FRONT DISC

6. SEPARATE TIE ROD END SUB-ASSEMBLY LH (See

page DS-6)

7. SEPARATE FRONT SUSPENSION ARM SUB-

ASSEMBLY LOWER NO.1 LH (See page DS-6)

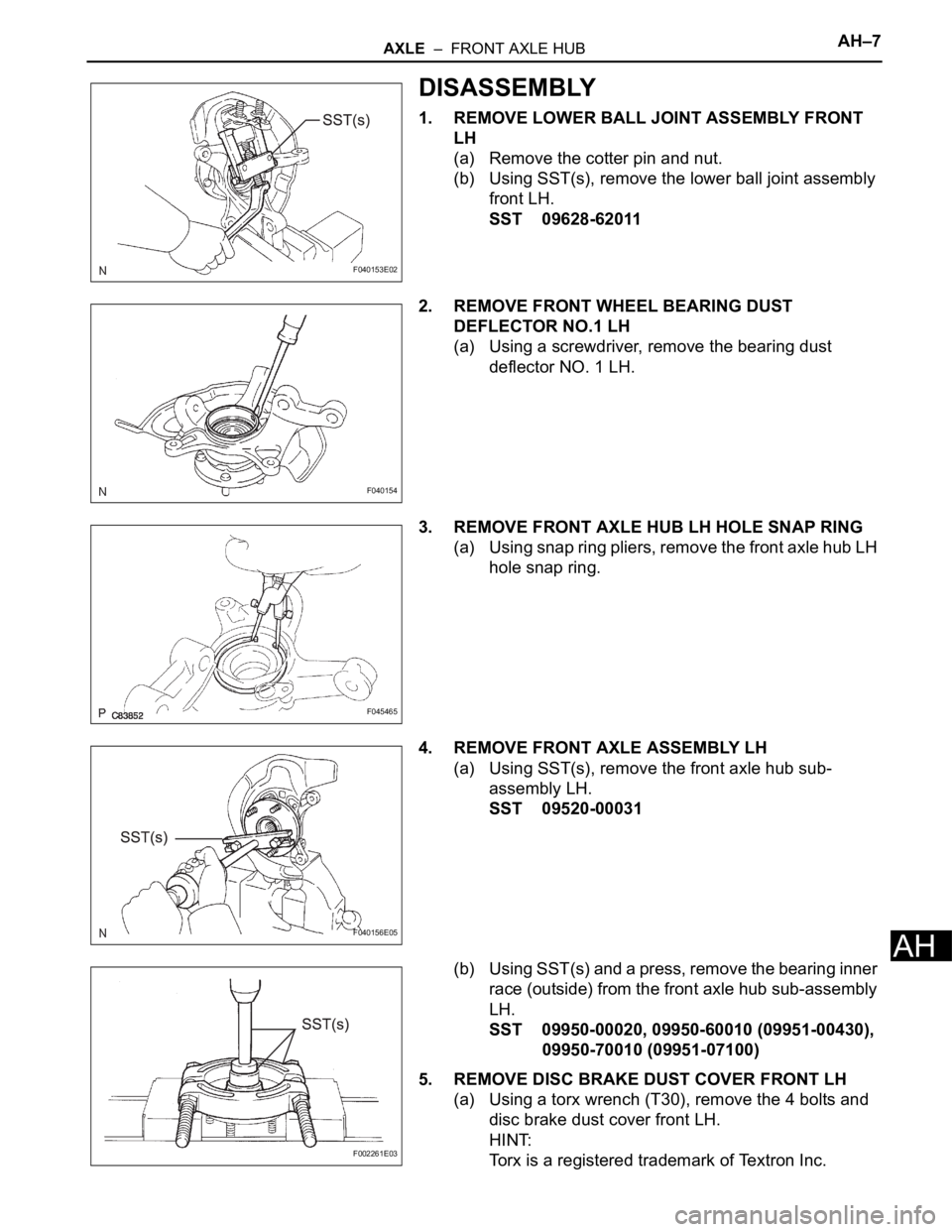

8. REMOVE FRONT AXLE ASSEMBLY LH

(a) Using a plastic hammer, separate the front drive

shaft assembly LH from the front axle hub sub-

assembly LH.

NOTICE:

Be careful not to damage the boot and ABS

speed sensor rotor.

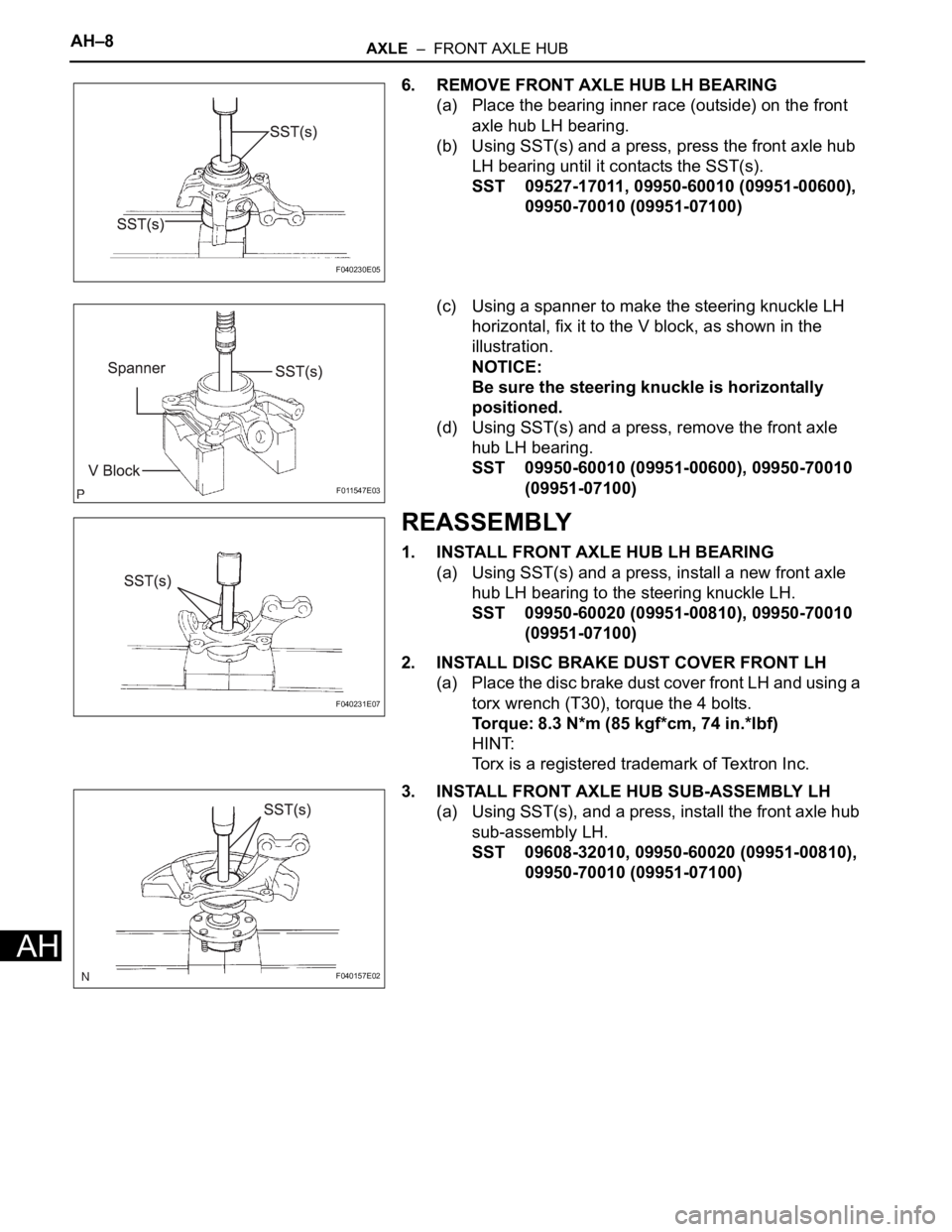

(b) Remove the 2 bolts, nuts and steering knuckle LH

with the front axle nub sub-assembly LH.

C067088

D027403

C083023

Page 164 of 3000

AXLE – FRONT AXLE HUBAH–7

AH

DISASSEMBLY

1. REMOVE LOWER BALL JOINT ASSEMBLY FRONT

LH

(a) Remove the cotter pin and nut.

(b) Using SST(s), remove the lower ball joint assembly

front LH.

SST 09628-62011

2. REMOVE FRONT WHEEL BEARING DUST

DEFLECTOR NO.1 LH

(a) Using a screwdriver, remove the bearing dust

deflector NO. 1 LH.

3. REMOVE FRONT AXLE HUB LH HOLE SNAP RING

(a) Using snap ring pliers, remove the front axle hub LH

hole snap ring.

4. REMOVE FRONT AXLE ASSEMBLY LH

(a) Using SST(s), remove the front axle hub sub-

assembly LH.

SST 09520-00031

(b) Using SST(s) and a press, remove the bearing inner

race (outside) from the front axle hub sub-assembly

LH.

SST 09950-00020, 09950-60010 (09951-00430),

09950-70010 (09951-07100)

5. REMOVE DISC BRAKE DUST COVER FRONT LH

(a) Using a torx wrench (T30), remove the 4 bolts and

disc brake dust cover front LH.

HINT:

Torx is a registered trademark of Textron Inc.

F040153E02

F040154

F045465

F040156E05

F002261E03

Page 165 of 3000

AH–8AXLE – FRONT AXLE HUB

AH

6. REMOVE FRONT AXLE HUB LH BEARING

(a) Place the bearing inner race (outside) on the front

axle hub LH bearing.

(b) Using SST(s) and a press, press the front axle hub

LH bearing until it contacts the SST(s).

SST 09527-17011, 09950-60010 (09951-00600),

09950-70010 (09951-07100)

(c) Using a spanner to make the steering knuckle LH

horizontal, fix it to the V block, as shown in the

illustration.

NOTICE:

Be sure the steering knuckle is horizontally

positioned.

(d) Using SST(s) and a press, remove the front axle

hub LH bearing.

SST 09950-60010 (09951-00600), 09950-70010

(09951-07100)

REASSEMBLY

1. INSTALL FRONT AXLE HUB LH BEARING

(a) Using SST(s) and a press, install a new front axle

hub LH bearing to the steering knuckle LH.

SST 09950-60020 (09951-00810), 09950-70010

(09951-07100)

2. INSTALL DISC BRAKE DUST COVER FRONT LH

(a) Place the disc brake dust cover front LH and using a

torx wrench (T30), torque the 4 bolts.

Torque: 8.3 N*m (85 kgf*cm, 74 in.*lbf)

HINT:

Torx is a registered trademark of Textron Inc.

3. INSTALL FRONT AXLE HUB SUB-ASSEMBLY LH

(a) Using SST(s), and a press, install the front axle hub

sub-assembly LH.

SST 09608-32010, 09950-60020 (09951-00810),

09950-70010 (09951-07100)

F040230E05

F011547E03

F040231E07

F040157E02

Page 167 of 3000

AH–10AXLE – FRONT AXLE HUB

AH

5. INSTALL FRONT DISC BRAKE CALIPER ASSEMBLY

LH

(a) Install the front disc brake caliper assembly LH with

the 2 bolts to the steering knuckle LH.

Torque: 104 N*m (1,060 kgf*cm, 77 ft.*lbf)

6. INSTALL FRONT AXLE HUB LH NUT

(a) Using a socket wrench (30mm), install a new axle

hub LH nut.

Torque: 294 N*m (3,000 kgf*cm, 217 ft.*lbf)

7. SEPARATE FRONT DISC BRAKE CALIPER

ASSEMBLY LH

(a) Remove the 2 bolts and separate the front disc

brake caliper assembly LH from the steering

knuckle LH.

NOTICE:

Use a string or other device to keep the brake

caliper from hanging down.

8. REMOVE FRONT DISC

9. INSPECT BEARING BACKLASH (See page AH-5)

10. INSPECT AXLE HUB DEVIATION (See page AH-5)

11. INSTALL FRONT DISC

12. INSTALL FRONT DISC BRAKE CALIPER ASSEMBLY

LH

(a) Install the front disc brake caliper assembly LH with

the 2 bolts to the steering knuckle LH.

Torque: 104 N*m (1,060 kgf*cm, 77 ft.*lbf)

13. INSTALL SPEED SENSOR FRONT LH (See page DS-

18)

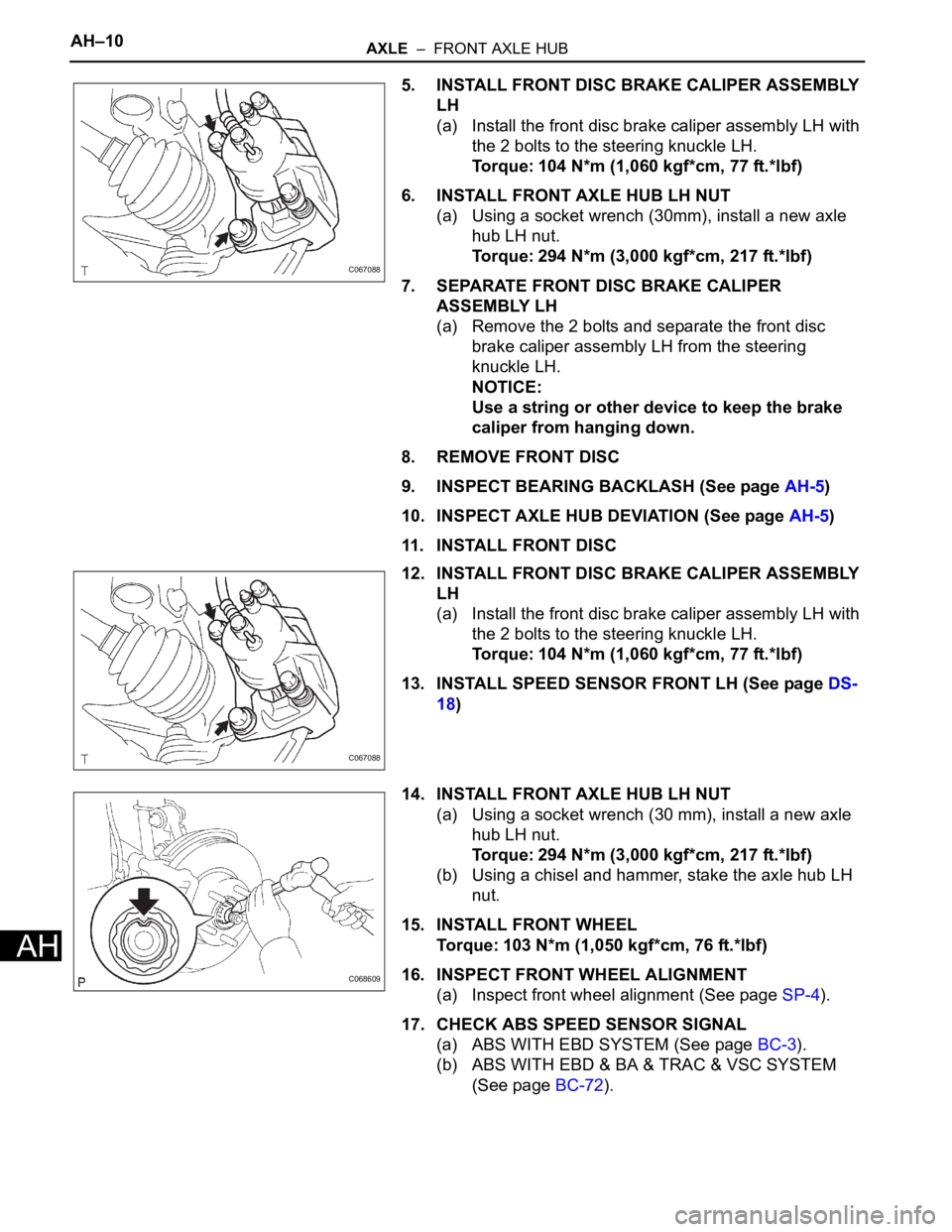

14. INSTALL FRONT AXLE HUB LH NUT

(a) Using a socket wrench (30 mm), install a new axle

hub LH nut.

Torque: 294 N*m (3,000 kgf*cm, 217 ft.*lbf)

(b) Using a chisel and hammer, stake the axle hub LH

nut.

15. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

16. INSPECT FRONT WHEEL ALIGNMENT

(a) Inspect front wheel alignment (See page SP-4).

17. CHECK ABS SPEED SENSOR SIGNAL

(a) ABS WITH EBD SYSTEM (See page BC-3).

(b) ABS WITH EBD & BA & TRAC & VSC SYSTEM

(See page BC-72).

C067088

C067088

C068609

Page 180 of 3000

BC–4BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

TEST MODE PROCEDURE

1. SPEED SENSOR SIGNAL CHECK (WHEN USING SST

CHECK WIRE):

HINT:

• If the ignition switch is turned from the ON to the ACC

or LOCK position during Test Mode, the DTCs of the

signal check function will be erased.

(a) Turn the ignition switch off.

(b) Check that the steering wheel is in the straight-

ahead position and move the shift lever to the P

position (Automatic Transmission) or apply the

parking brake (Manual Transmission).

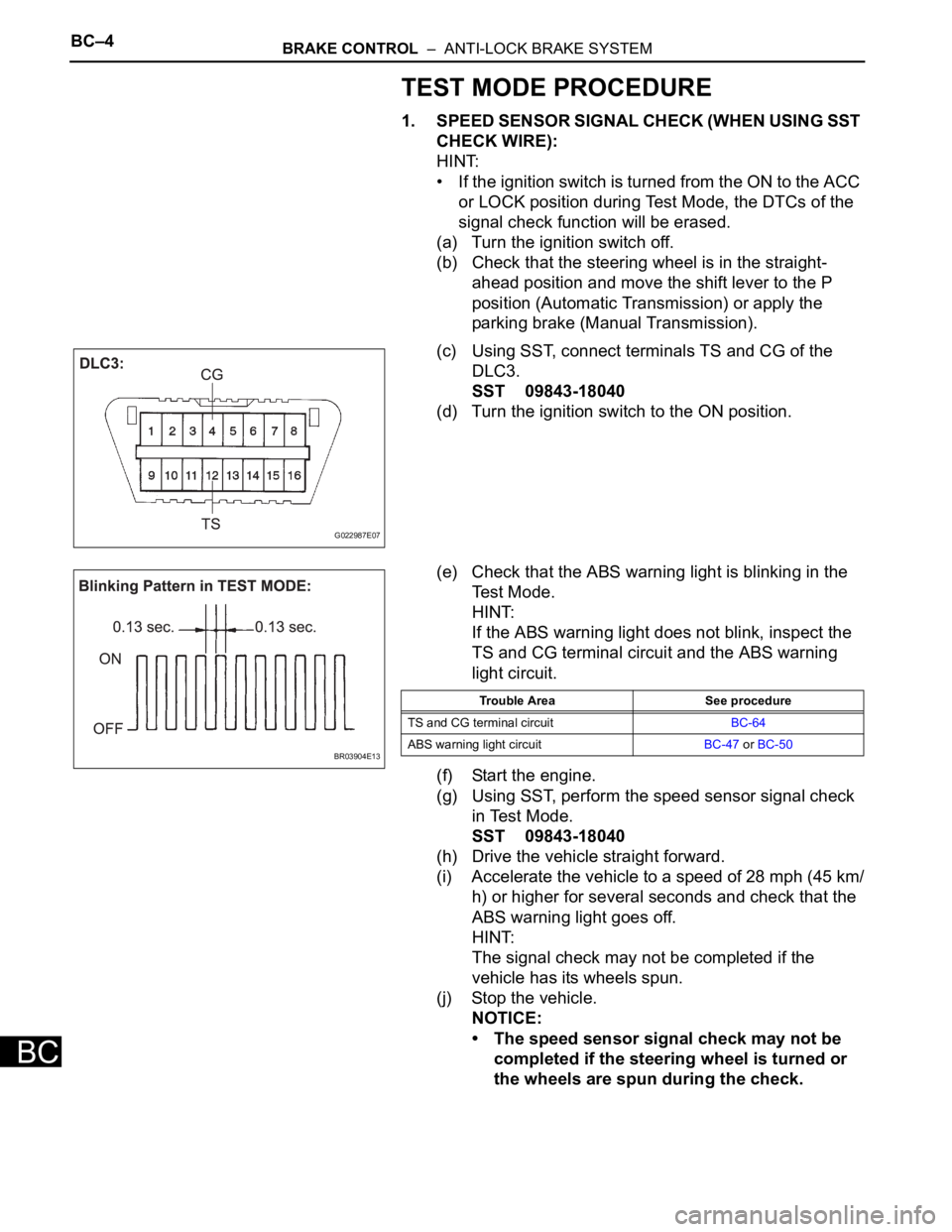

(c) Using SST, connect terminals TS and CG of the

DLC3.

SST 09843-18040

(d) Turn the ignition switch to the ON position.

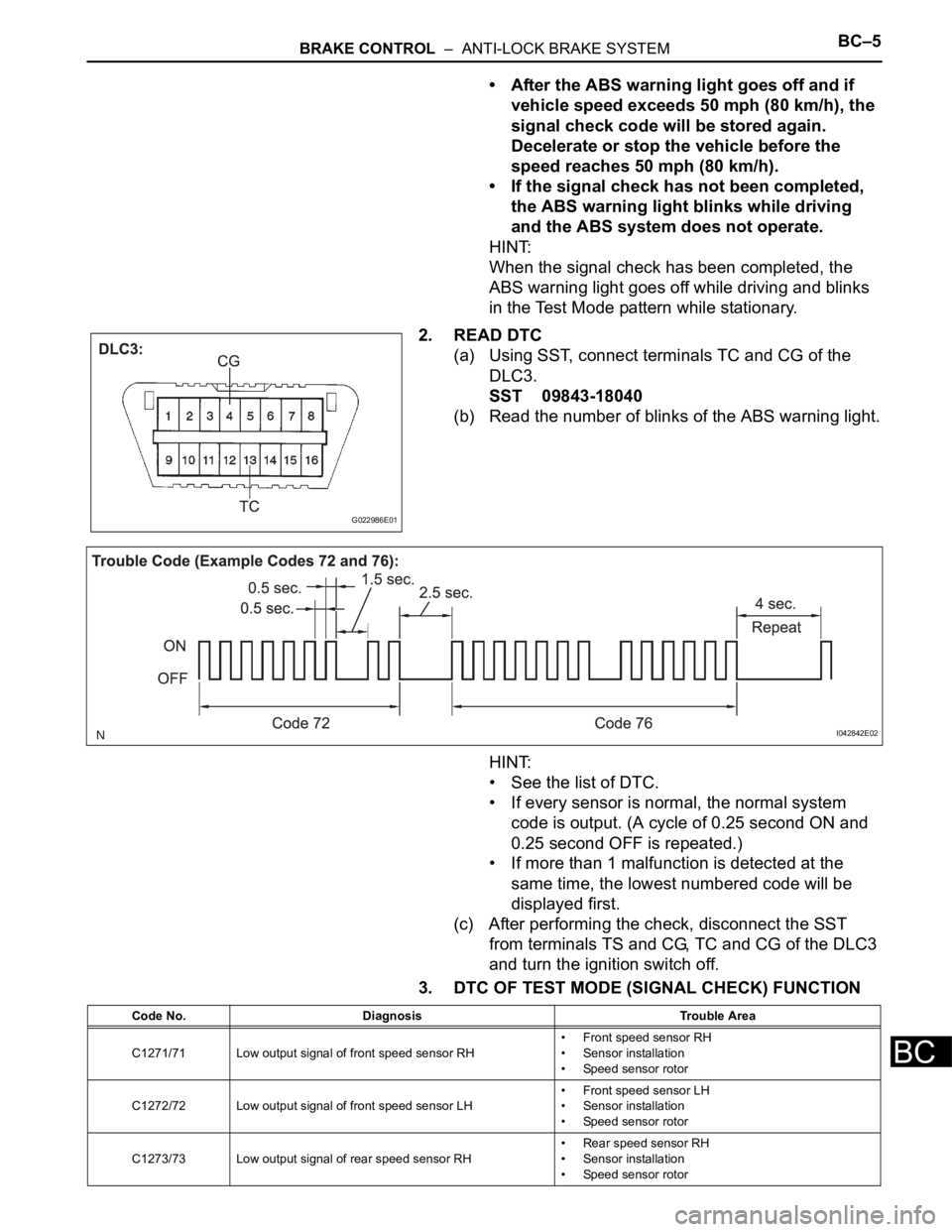

(e) Check that the ABS warning light is blinking in the

Test Mode.

HINT:

If the ABS warning light does not blink, inspect the

TS and CG terminal circuit and the ABS warning

light circuit.

(f) Start the engine.

(g) Using SST, perform the speed sensor signal check

in Test Mode.

SST 09843-18040

(h) Drive the vehicle straight forward.

(i) Accelerate the vehicle to a speed of 28 mph (45 km/

h) or higher for several seconds and check that the

ABS warning light goes off.

HINT:

The signal check may not be completed if the

vehicle has its wheels spun.

(j) Stop the vehicle.

NOTICE:

• The speed sensor signal check may not be

completed if the steering wheel is turned or

the wheels are spun during the check.

G022987E07

BR03904E13

Trouble Area See procedure

TS and CG terminal circuitBC-64

ABS warning light circuitBC-47 or BC-50

Page 181 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–5

BC

• After the ABS warning light goes off and if

vehicle speed exceeds 50 mph (80 km/h), the

signal check code will be stored again.

Decelerate or stop the vehicle before the

speed reaches 50 mph (80 km/h).

• If the signal check has not been completed,

the ABS warning light blinks while driving

and the ABS system does not operate.

HINT:

When the signal check has been completed, the

ABS warning light goes off while driving and blinks

in the Test Mode pattern while stationary.

2. READ DTC

(a) Using SST, connect terminals TC and CG of the

DLC3.

SST 09843-18040

(b) Read the number of blinks of the ABS warning light.

HINT:

• See the list of DTC.

• If every sensor is normal, the normal system

code is output. (A cycle of 0.25 second ON and

0.25 second OFF is repeated.)

• If more than 1 malfunction is detected at the

same time, the lowest numbered code will be

displayed first.

(c) After performing the check, disconnect the SST

from terminals TS and CG, TC and CG of the DLC3

and turn the ignition switch off.

3. DTC OF TEST MODE (SIGNAL CHECK) FUNCTION

G022986E01

I042842E02

Code No. Diagnosis Trouble Area

C1271/71 Low output signal of front speed sensor RH• Front speed sensor RH

• Sensor installation

• Speed sensor rotor

C1272/72 Low output signal of front speed sensor LH• Front speed sensor LH

• Sensor installation

• Speed sensor rotor

C1273/73 Low output signal of rear speed sensor RH• Rear speed sensor RH

• Sensor installation

• Speed sensor rotor

Page 182 of 3000

BC–6BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

HINT:

The codes in this table are output only in Test Mode

(signal check).

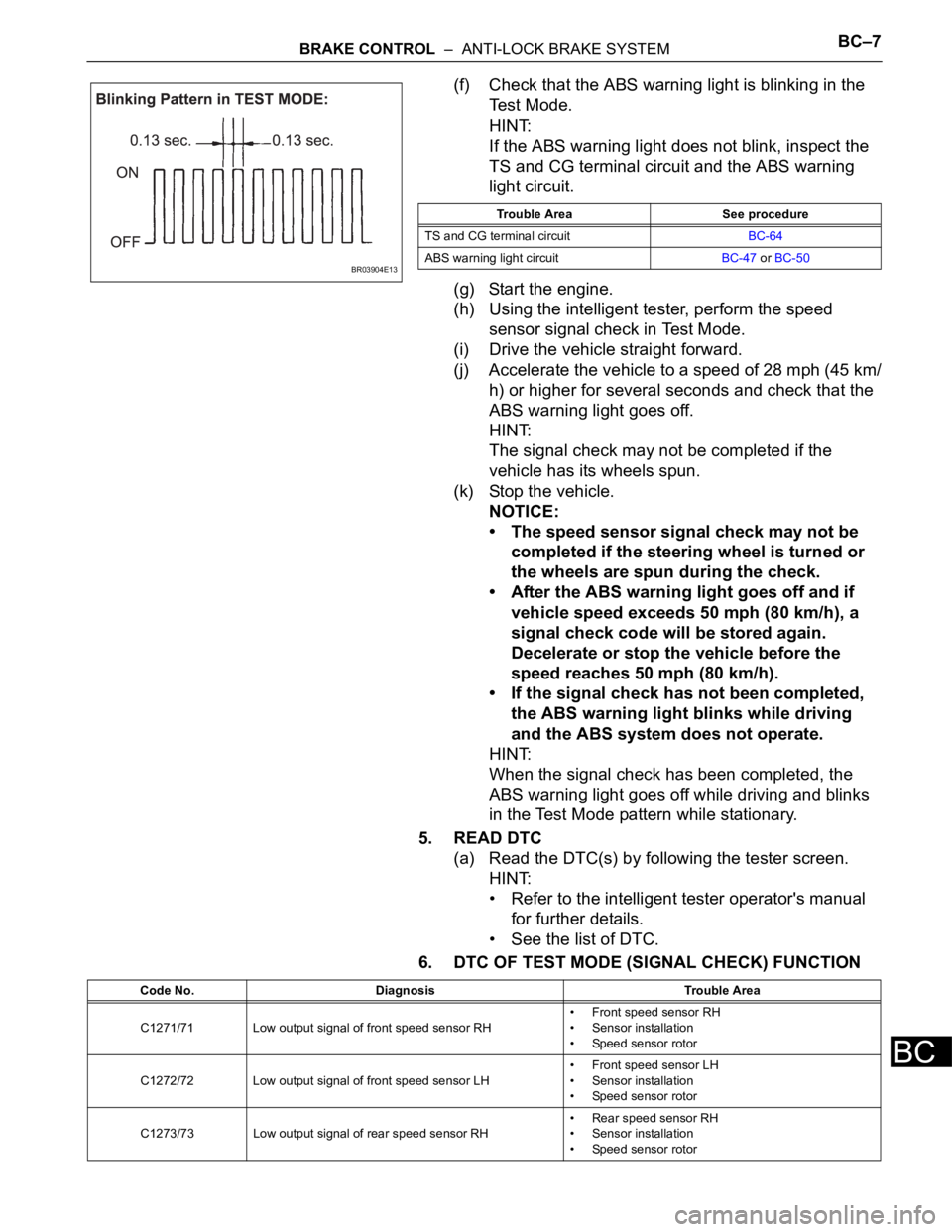

4. SPEED SENSOR SIGNAL CHECK (WHEN USING

INTELLIGENT TESTER):

HINT:

• If the ignition switch is turned from the ON to the ACC

or LOCK position during Test Mode, DTCs of the

signal check function will be erased.

• During Test Mode, the ECU records all DTCs of the

signal check function. By performing the signal check,

the codes are erased if normality is confirmed. The

remaining codes are the codes where an abnormality

was found.

(a) Turn the ignition switch off.

(b) Check that the steering wheel is in the straight-

ahead position.

(c) Connect the intelligent tester to the DLC3.

(d) Turn the ignition switch to the ON position.

(e) Set the intelligent tester to Test Mode (select

"SIGNAL CHECK").

HINT:

Refer to the intelligent tester operator's manual for

further details.

C1274/74 Low output signal of rear speed sensor LH• Rear speed sensor LH

• Sensor installation

• Speed sensor rotor

C1275/75Abnormal change in output signal of front speed sensor

RHSpeed sensor rotor

C1276/76Abnormal change in output signal of front speed sensor

LHSpeed sensor rotor

C1277/77Abnormal change in output signal of rear speed sensor

RHSpeed sensor rotor

C1278/78Abnormal change in output signal of rear speed sensor

LHSpeed sensor rotor Code No. Diagnosis Trouble Area

E144486E01

Page 183 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–7

BC

(f) Check that the ABS warning light is blinking in the

Test Mode.

HINT:

If the ABS warning light does not blink, inspect the

TS and CG terminal circuit and the ABS warning

light circuit.

(g) Start the engine.

(h) Using the intelligent tester, perform the speed

sensor signal check in Test Mode.

(i) Drive the vehicle straight forward.

(j) Accelerate the vehicle to a speed of 28 mph (45 km/

h) or higher for several seconds and check that the

ABS warning light goes off.

HINT:

The signal check may not be completed if the

vehicle has its wheels spun.

(k) Stop the vehicle.

NOTICE:

• The speed sensor signal check may not be

completed if the steering wheel is turned or

the wheels are spun during the check.

• After the ABS warning light goes off and if

vehicle speed exceeds 50 mph (80 km/h), a

signal check code will be stored again.

Decelerate or stop the vehicle before the

speed reaches 50 mph (80 km/h).

• If the signal check has not been completed,

the ABS warning light blinks while driving

and the ABS system does not operate.

HINT:

When the signal check has been completed, the

ABS warning light goes off while driving and blinks

in the Test Mode pattern while stationary.

5. READ DTC

(a) Read the DTC(s) by following the tester screen.

HINT:

• Refer to the intelligent tester operator's manual

for further details.

• See the list of DTC.

6. DTC OF TEST MODE (SIGNAL CHECK) FUNCTION

BR03904E13

Trouble Area See procedure

TS and CG terminal circuitBC-64

ABS warning light circuitBC-47 or BC-50

Code No. Diagnosis Trouble Area

C1271/71 Low output signal of front speed sensor RH• Front speed sensor RH

• Sensor installation

• Speed sensor rotor

C1272/72 Low output signal of front speed sensor LH• Front speed sensor LH

• Sensor installation

• Speed sensor rotor

C1273/73 Low output signal of rear speed sensor RH• Rear speed sensor RH

• Sensor installation

• Speed sensor rotor

Page 184 of 3000

BC–8BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

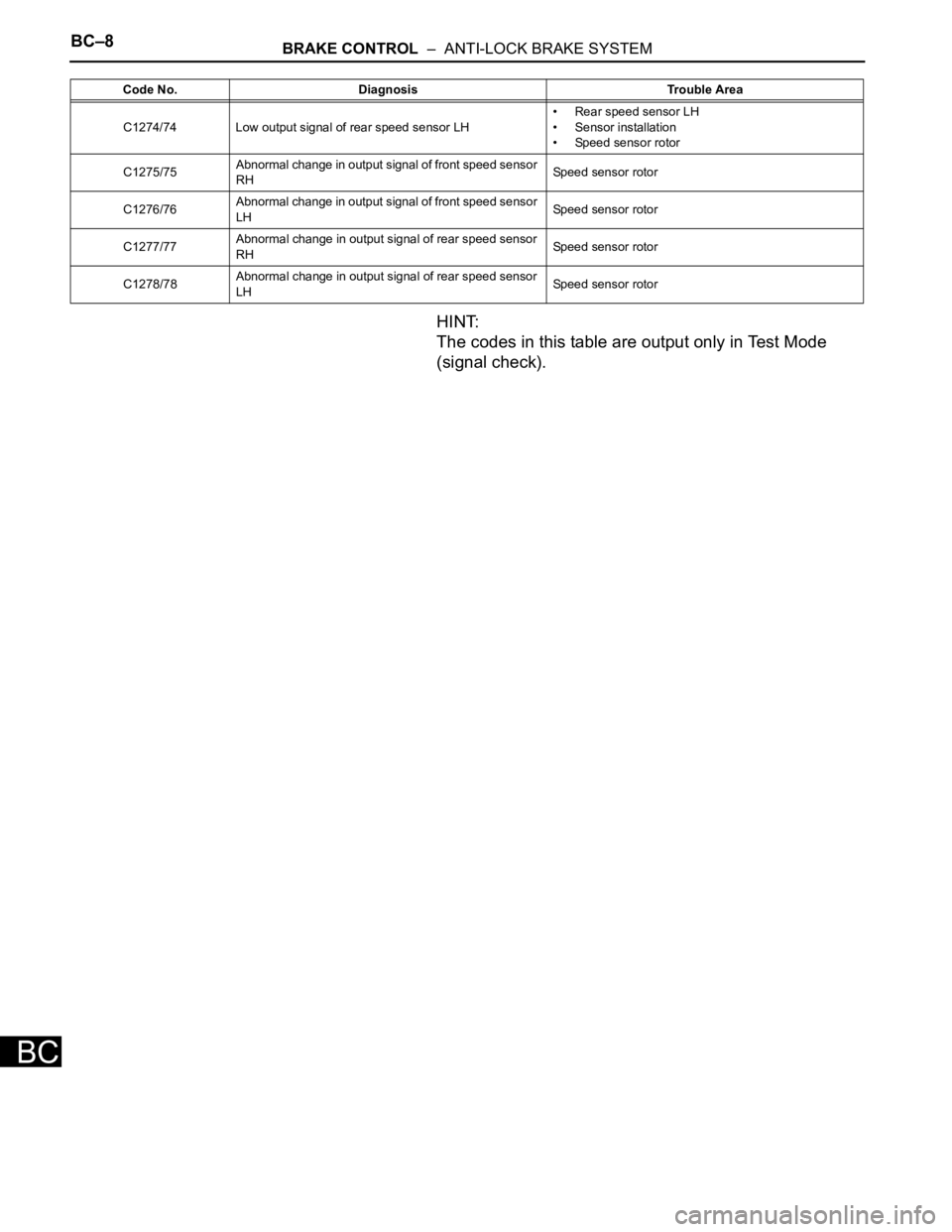

HINT:

The codes in this table are output only in Test Mode

(signal check).

C1274/74 Low output signal of rear speed sensor LH• Rear speed sensor LH

• Sensor installation

• Speed sensor rotor

C1275/75Abnormal change in output signal of front speed sensor

RHSpeed sensor rotor

C1276/76Abnormal change in output signal of front speed sensor

LHSpeed sensor rotor

C1277/77Abnormal change in output signal of rear speed sensor

RHSpeed sensor rotor

C1278/78Abnormal change in output signal of rear speed sensor

LHSpeed sensor rotor Code No. Diagnosis Trouble Area

Page 185 of 3000

BRAKE – BRAKE PEDALBR–11

BR

REMOVAL

1. SEPARATE BATTERY NEGATIVE TERMINAL

2. REMOVE FRONT DOOR SCUFF PLATE LH

3. REMOVE COWL SIDE TRIM BOARD LH

4. REMOVE INSTRUMENT PANEL FINISH PANEL SUB-

ASSEMBLY LOWER LH

(a) Remove the 2 bolts and instrument panel finish

panel sub-assembly lower LH.

5. REMOVE INSTRUMENT PANEL SAFETY PAD

INSERT SUB-ASSEMBLY NO. 1

(a) Remove the 4 bolts and instrument panel safety pad

insert sub-assembly No. 1.

6. LOOSEN BRAKE PEDAL SHAFT

(a) Loosen the 2 brake pedal shafts.

7. REMOVE BRAKE PEDAL SUPPORT ASSEMBLY

(a) Remove the 4 nuts and brake pedal support sub-

assembly.

(b) Using needle-nose pliers, remove the tension

spring.

(c) Remove the clip and clevis pin from the brake pedal

lever.

(d) Remove the 2 bolts from the brake pedal bracket

No. 3.

(e) Remove the stop light switch harness clamp from

the brake pedal support sub-assembly.

(f) Disconnect the stop light switch connector.

F045360E01

G024262

G024263