brake TOYOTA SIENNA 2007 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1123 of 3000

FU–22GR-FE FUEL – FUEL SYSTEM

FU

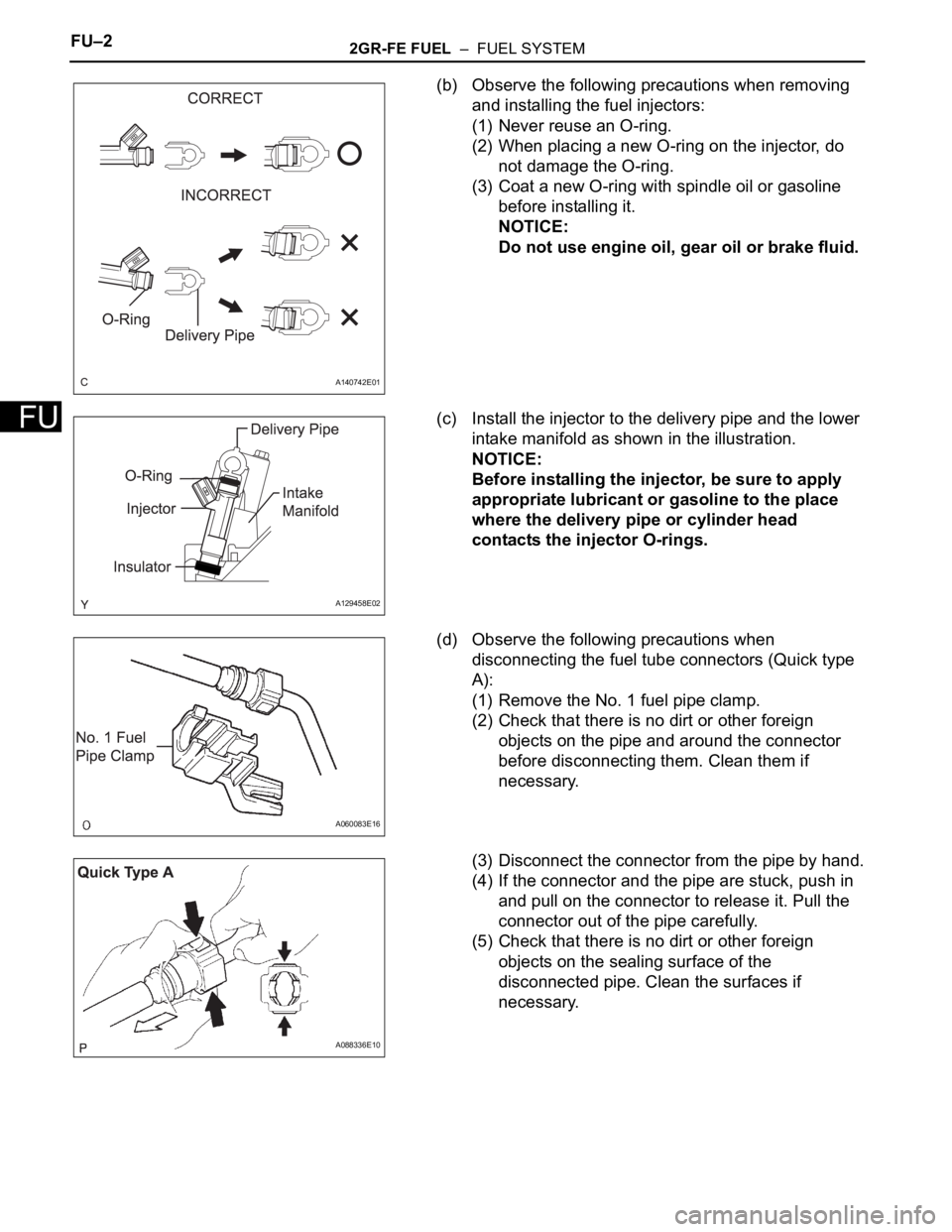

(b) Observe the following precautions when removing

and installing the fuel injectors:

(1) Never reuse an O-ring.

(2) When placing a new O-ring on the injector, do

not damage the O-ring.

(3) Coat a new O-ring with spindle oil or gasoline

before installing it.

NOTICE:

Do not use engine oil, gear oil or brake fluid.

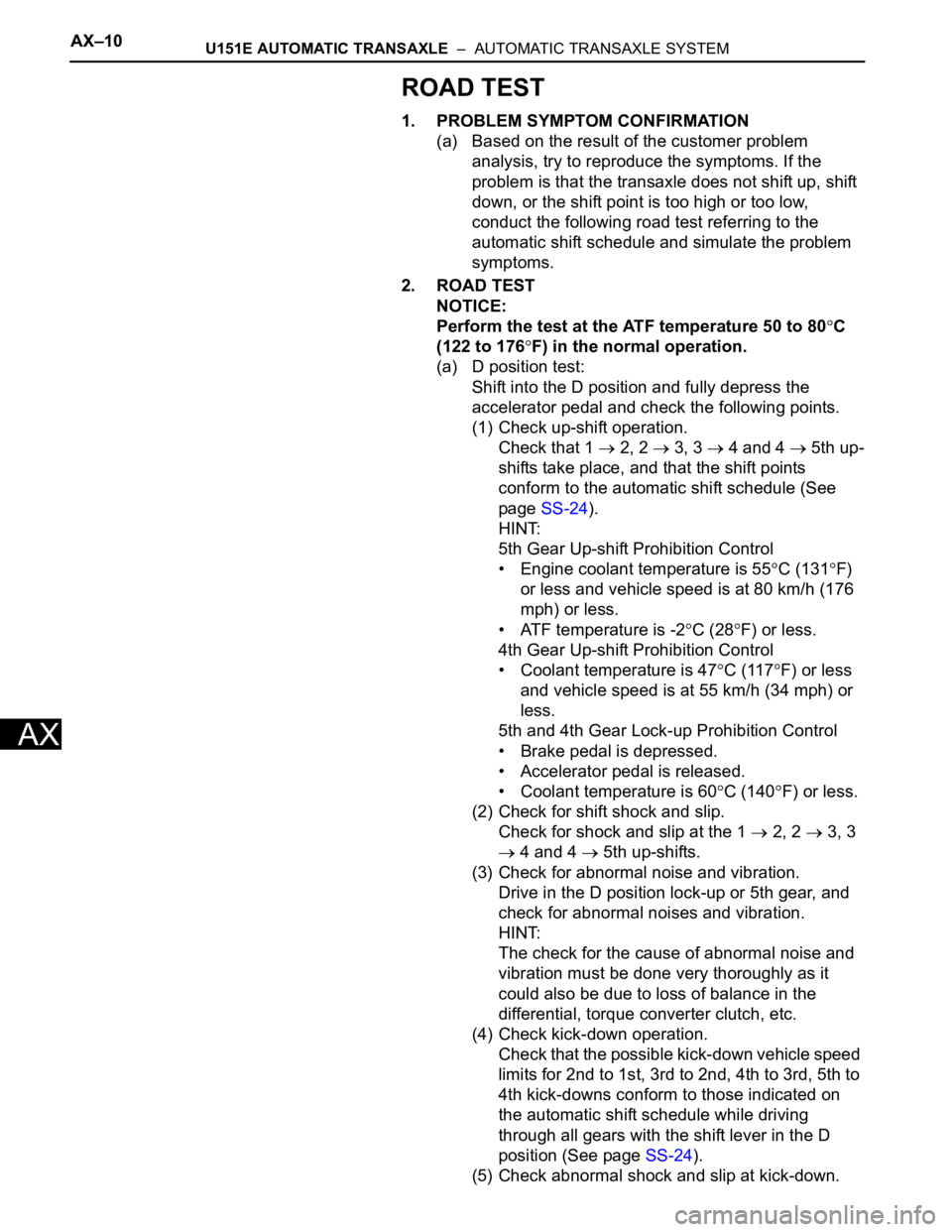

(c) Install the injector to the delivery pipe and the lower

intake manifold as shown in the illustration.

NOTICE:

Before installing the injector, be sure to apply

appropriate lubricant or gasoline to the place

where the delivery pipe or cylinder head

contacts the injector O-rings.

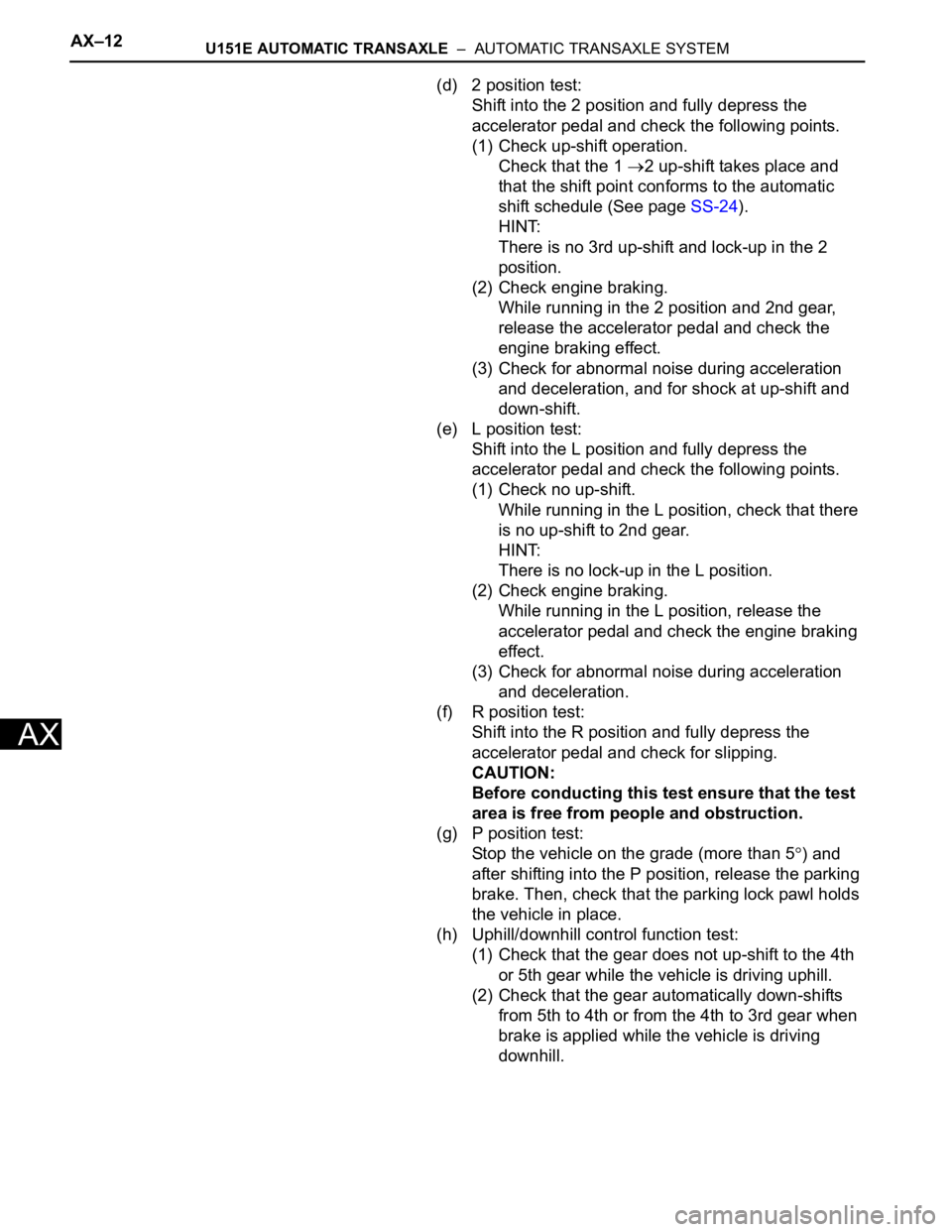

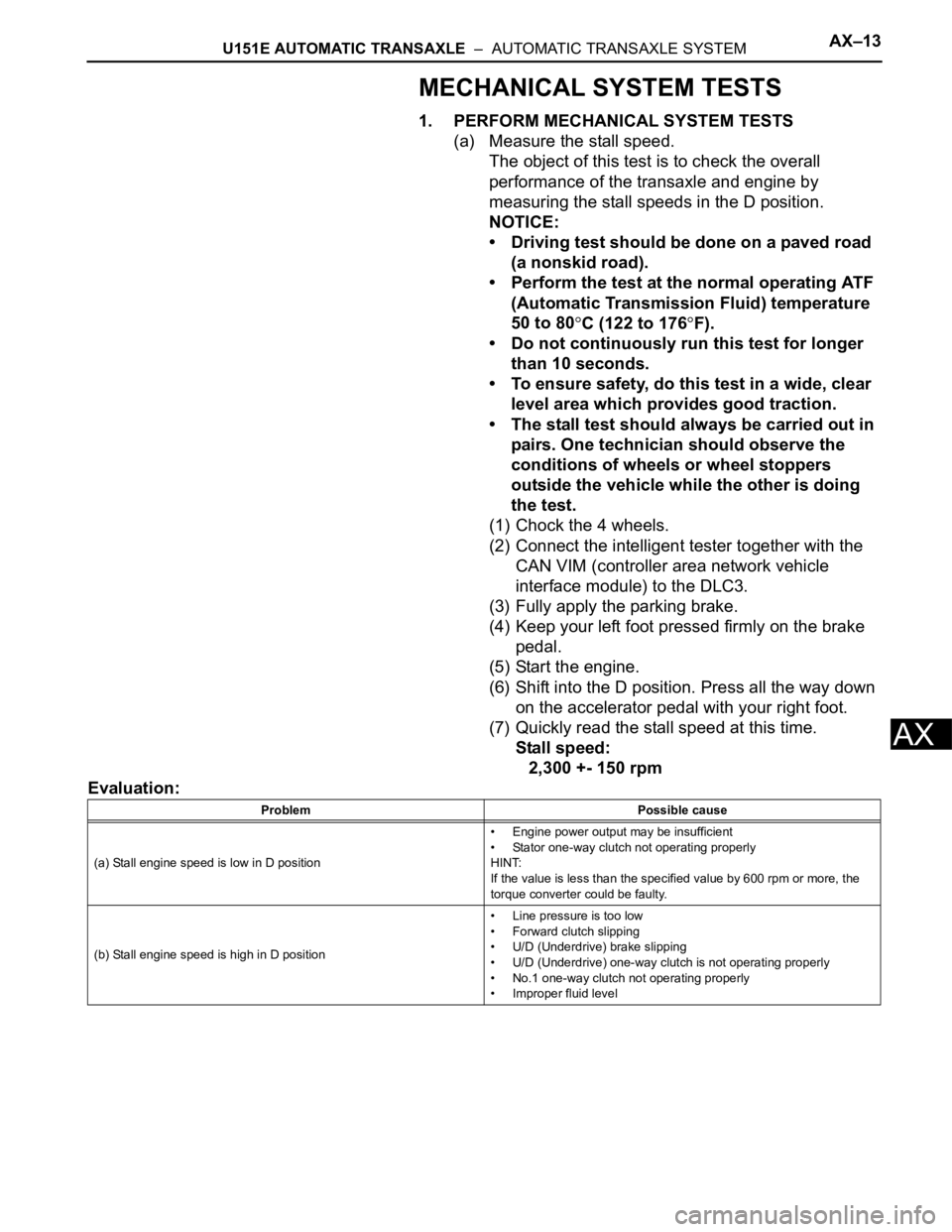

(d) Observe the following precautions when

disconnecting the fuel tube connectors (Quick type

A):

(1) Remove the No. 1 fuel pipe clamp.

(2) Check that there is no dirt or other foreign

objects on the pipe and around the connector

before disconnecting them. Clean them if

necessary.

(3) Disconnect the connector from the pipe by hand.

(4) If the connector and the pipe are stuck, push in

and pull on the connector to release it. Pull the

connector out of the pipe carefully.

(5) Check that there is no dirt or other foreign

objects on the sealing surface of the

disconnected pipe. Clean the surfaces if

necessary.

A140742E01

A129458E02

A060083E16

A088336E10

Page 1387 of 3000

AX–10U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

ROAD TEST

1. PROBLEM SYMPTOM CONFIRMATION

(a) Based on the result of the customer problem

analysis, try to reproduce the symptoms. If the

problem is that the transaxle does not shift up, shift

down, or the shift point is too high or too low,

conduct the following road test referring to the

automatic shift schedule and simulate the problem

symptoms.

2. ROAD TEST

NOTICE:

Perform the test at the ATF temperature 50 to 80

C

(122 to 176

F) in the normal operation.

(a) D position test:

Shift into the D position and fully depress the

accelerator pedal and check the following points.

(1) Check up-shift operation.

Check that 1

2, 2 3, 3 4 and 4 5th up-

shifts take place, and that the shift points

conform to the automatic shift schedule (See

page SS-24).

HINT:

5th Gear Up-shift Prohibition Control

• Engine coolant temperature is 55

C (131F)

or less and vehicle speed is at 80 km/h (176

mph) or less.

• ATF temperature is -2

C (28F) or less.

4th Gear Up-shift Prohibition Control

• Coolant temperature is 47

C (117F) or less

and vehicle speed is at 55 km/h (34 mph) or

less.

5th and 4th Gear Lock-up Prohibition Control

• Brake pedal is depressed.

• Accelerator pedal is released.

• Coolant temperature is 60

C (140F) or less.

(2) Check for shift shock and slip.

Check for shock and slip at the 1

2, 2 3, 3

4 and 4 5th up-shifts.

(3) Check for abnormal noise and vibration.

Drive in the D position lock-up or 5th gear, and

check for abnormal noises and vibration.

HINT:

The check for the cause of abnormal noise and

vibration must be done very thoroughly as it

could also be due to loss of balance in the

differential, torque converter clutch, etc.

(4) Check kick-down operation.

Check that the possible kick-down vehicle speed

limits for 2nd to 1st, 3rd to 2nd, 4th to 3rd, 5th to

4th kick-downs conform to those indicated on

the automatic shift schedule while driving

through all gears with the shift lever in the D

position (See page SS-24).

(5) Check abnormal shock and slip at kick-down.

Page 1389 of 3000

AX–12U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(d) 2 position test:

Shift into the 2 position and fully depress the

accelerator pedal and check the following points.

(1) Check up-shift operation.

Check that the 1

2 up-shift takes place and

that the shift point conforms to the automatic

shift schedule (See page SS-24).

HINT:

There is no 3rd up-shift and lock-up in the 2

position.

(2) Check engine braking.

While running in the 2 position and 2nd gear,

release the accelerator pedal and check the

engine braking effect.

(3) Check for abnormal noise during acceleration

and deceleration, and for shock at up-shift and

down-shift.

(e) L position test:

Shift into the L position and fully depress the

accelerator pedal and check the following points.

(1) Check no up-shift.

While running in the L position, check that there

is no up-shift to 2nd gear.

HINT:

There is no lock-up in the L position.

(2) Check engine braking.

While running in the L position, release the

accelerator pedal and check the engine braking

effect.

(3) Check for abnormal noise during acceleration

and deceleration.

(f) R position test:

Shift into the R position and fully depress the

accelerator pedal and check for slipping.

CAUTION:

Before conducting this test ensure that the test

area is free from people and obstruction.

(g) P position test:

Stop the vehicle on the grade (more than 5

) and

after shifting into the P position, release the parking

brake. Then, check that the parking lock pawl holds

the vehicle in place.

(h) Uphill/downhill control function test:

(1) Check that the gear does not up-shift to the 4th

or 5th gear while the vehicle is driving uphill.

(2) Check that the gear automatically down-shifts

from 5th to 4th or from the 4th to 3rd gear when

brake is applied while the vehicle is driving

downhill.

Page 1390 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–13

AX

MECHANICAL SYSTEM TESTS

1. PERFORM MECHANICAL SYSTEM TESTS

(a) Measure the stall speed.

The object of this test is to check the overall

performance of the transaxle and engine by

measuring the stall speeds in the D position.

NOTICE:

• Driving test should be done on a paved road

(a nonskid road).

• Perform the test at the normal operating ATF

(Automatic Transmission Fluid) temperature

50 to 80

C (122 to 176F).

• Do not continuously run this test for longer

than 10 seconds.

• To ensure safety, do this test in a wide, clear

level area which provides good traction.

• The stall test should always be carried out in

pairs. One technician should observe the

conditions of wheels or wheel stoppers

outside the vehicle while the other is doing

the test.

(1) Chock the 4 wheels.

(2) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(3) Fully apply the parking brake.

(4) Keep your left foot pressed firmly on the brake

pedal.

(5) Start the engine.

(6) Shift into the D position. Press all the way down

on the accelerator pedal with your right foot.

(7) Quickly read the stall speed at this time.

Stall speed:

2,300 +- 150 rpm

Evaluation:

Problem Possible cause

(a) Stall engine speed is low in D position• Engine power output may be insufficient

• Stator one-way clutch not operating properly

HINT:

If the value is less than the specified value by 600 rpm or more, the

torque converter could be faulty.

(b) Stall engine speed is high in D position• Line pressure is too low

• Forward clutch slipping

• U/D (Underdrive) brake slipping

• U/D (Underdrive) one-way clutch is not operating properly

• No.1 one-way clutch not operating properly

• Improper fluid level

Page 1391 of 3000

AX–14U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

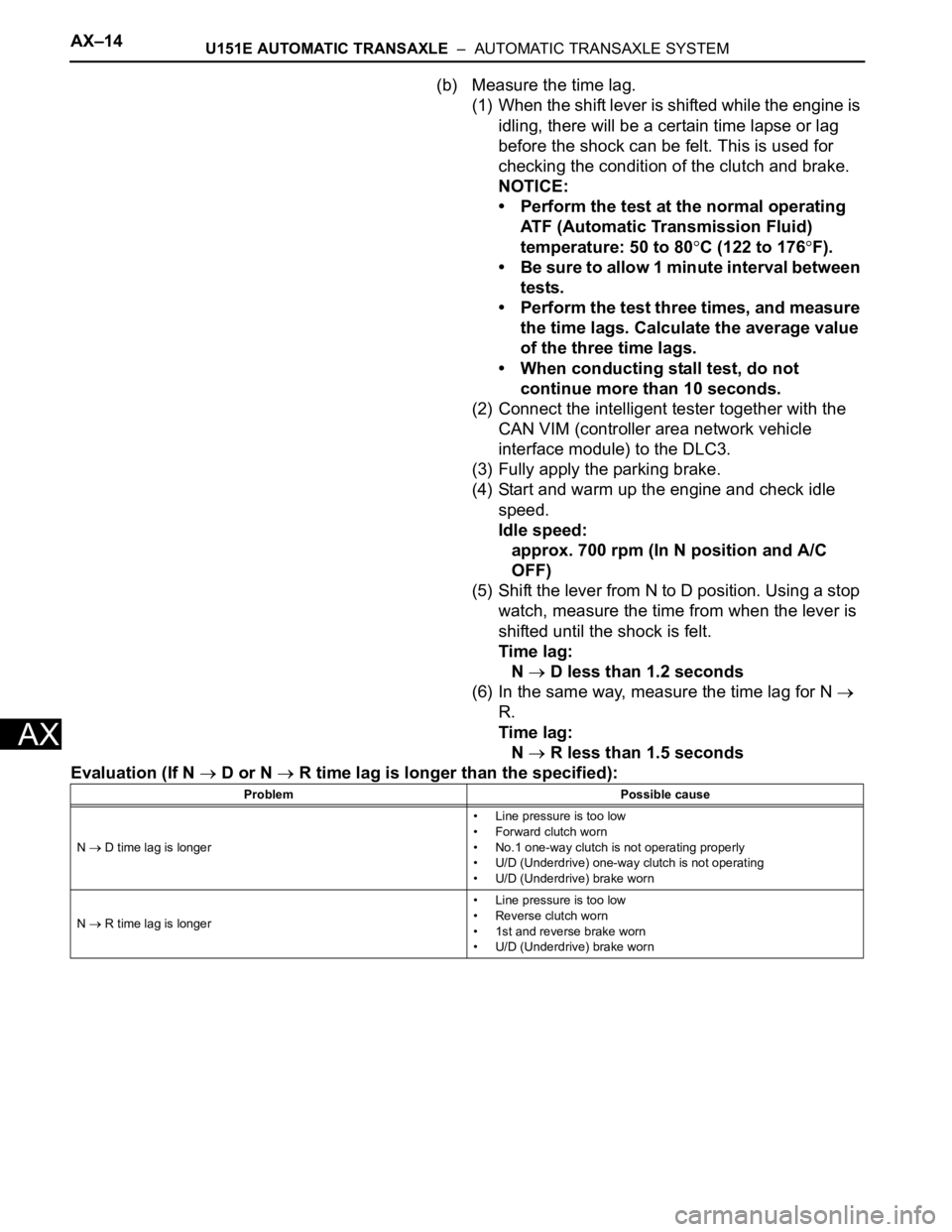

(b) Measure the time lag.

(1) When the shift lever is shifted while the engine is

idling, there will be a certain time lapse or lag

before the shock can be felt. This is used for

checking the condition of the clutch and brake.

NOTICE:

• Perform the test at the normal operating

ATF (Automatic Transmission Fluid)

temperature: 50 to 80

C (122 to 176F).

• Be sure to allow 1 minute interval between

tests.

• Perform the test three times, and measure

the time lags. Calculate the average value

of the three time lags.

• When conducting stall test, do not

continue more than 10 seconds.

(2) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(3) Fully apply the parking brake.

(4) Start and warm up the engine and check idle

speed.

Idle speed:

approx. 700 rpm (In N position and A/C

OFF)

(5) Shift the lever from N to D position. Using a stop

watch, measure the time from when the lever is

shifted until the shock is felt.

Time lag:

N

D less than 1.2 seconds

(6) In the same way, measure the time lag for N

R.

Time lag:

N

R less than 1.5 seconds

Evaluation (If N

D or N R time lag is longer than the specified):

Problem Possible cause

N

D time lag is longer• Line pressure is too low

• Forward clutch worn

• No.1 one-way clutch is not operating properly

• U/D (Underdrive) one-way clutch is not operating

• U/D (Underdrive) brake worn

N

R time lag is longer• Line pressure is too low

• Reverse clutch worn

• 1st and reverse brake worn

• U/D (Underdrive) brake worn

Page 1393 of 3000

AX–16U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

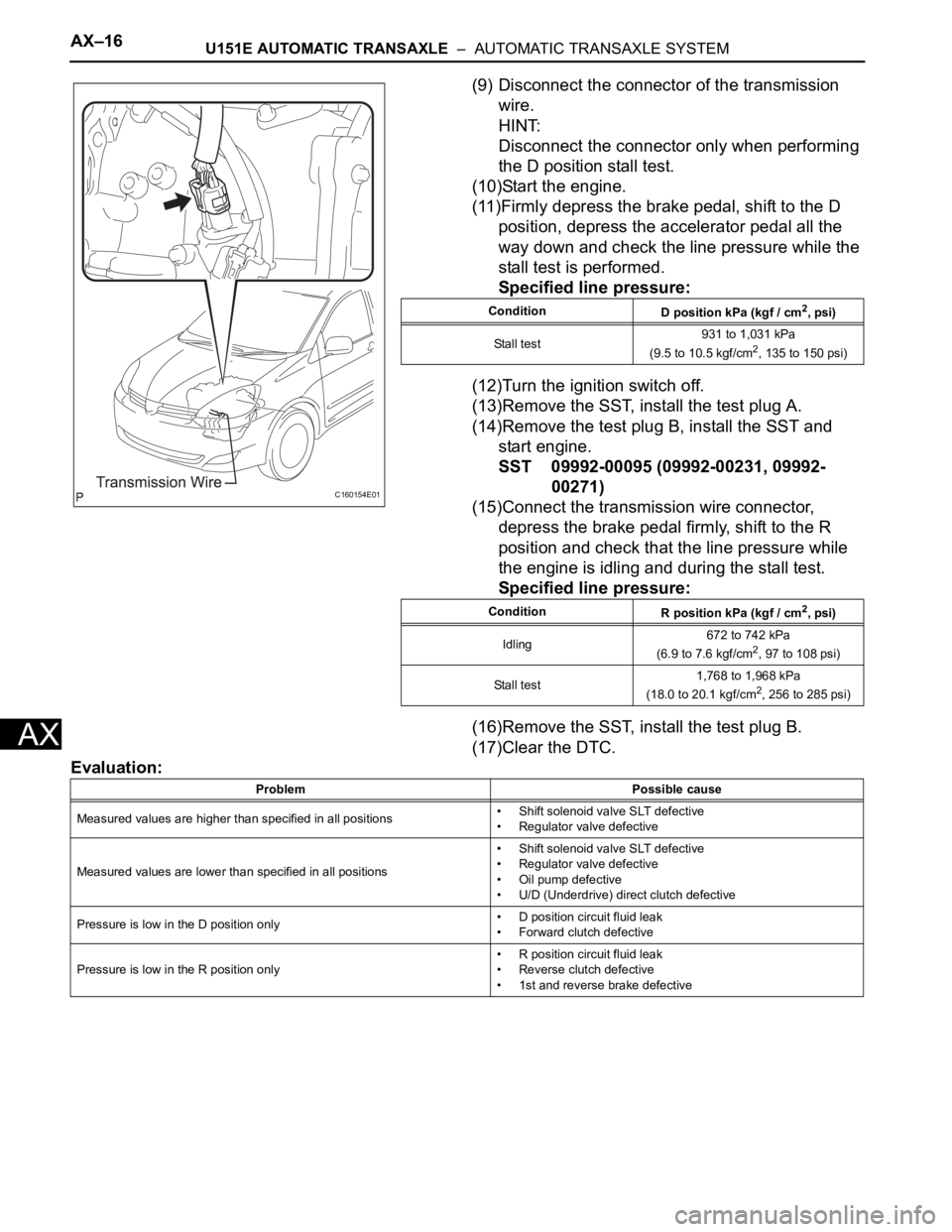

(9) Disconnect the connector of the transmission

wire.

HINT:

Disconnect the connector only when performing

the D position stall test.

(10)Start the engine.

(11)Firmly depress the brake pedal, shift to the D

position, depress the accelerator pedal all the

way down and check the line pressure while the

stall test is performed.

Specified line pressure:

(12)Turn the ignition switch off.

(13)Remove the SST, install the test plug A.

(14)Remove the test plug B, install the SST and

start engine.

SST 09992-00095 (09992-00231, 09992-

00271)

(15)Connect the transmission wire connector,

depress the brake pedal firmly, shift to the R

position and check that the line pressure while

the engine is idling and during the stall test.

Specified line pressure:

(16)Remove the SST, install the test plug B.

(17)Clear the DTC.

Evaluation:

C160154E01

Condition

D position kPa (kgf / cm2, psi)

Stall test931 to 1,031 kPa

(9.5 to 10.5 kgf/cm

2, 135 to 150 psi)

Condition

R position kPa (kgf / cm

2, psi)

Idling672 to 742 kPa

(6.9 to 7.6 kgf/cm

2, 97 to 108 psi)

Stall test1,768 to 1,968 kPa

(18.0 to 20.1 kgf/cm

2, 256 to 285 psi)

Problem Possible cause

Measured values are higher than specified in all positions• Shift solenoid valve SLT defective

• Regulator valve defective

Measured values are lower than specified in all positions• Shift solenoid valve SLT defective

• Regulator valve defective

• Oil pump defective

• U/D (Underdrive) direct clutch defective

Pressure is low in the D position only• D position circuit fluid leak

• Forward clutch defective

Pressure is low in the R position only• R position circuit fluid leak

• Reverse clutch defective

• 1st and reverse brake defective

Page 1400 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–23

AX

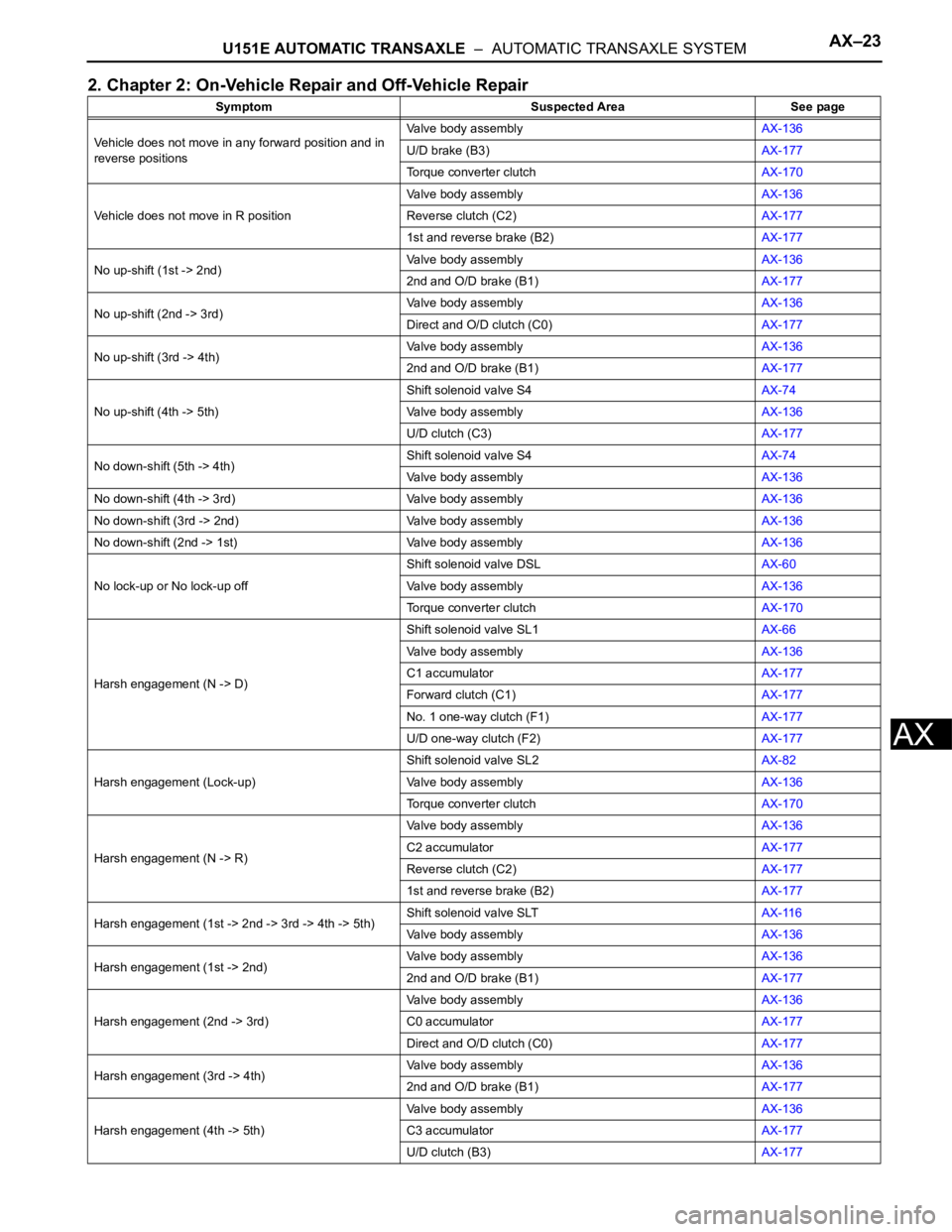

2. Chapter 2: On-Vehicle Repair and Off-Vehicle Repair

Symptom Suspected Area See page

Vehicle does not move in any forward position and in

reverse positionsValve body assemblyAX-136

U/D brake (B3)AX-177

Torque converter clutchAX-170

Vehicle does not move in R positionValve body assemblyAX-136

Reverse clutch (C2)AX-177

1st and reverse brake (B2)AX-177

No up-shift (1st -> 2nd)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-177

No up-shift (2nd -> 3rd)Valve body assemblyAX-136

Direct and O/D clutch (C0)AX-177

No up-shift (3rd -> 4th)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-177

No up-shift (4th -> 5th)Shift solenoid valve S4AX-74

Valve body assemblyAX-136

U/D clutch (C3)AX-177

No down-shift (5th -> 4th)Shift solenoid valve S4AX-74

Valve body assemblyAX-136

No down-shift (4th -> 3rd) Valve body assemblyAX-136

No down-shift (3rd -> 2nd) Valve body assemblyAX-136

No down-shift (2nd -> 1st) Valve body assemblyAX-136

No lock-up or No lock-up offShift solenoid valve DSLAX-60

Valve body assemblyAX-136

Torque converter clutchAX-170

Harsh engagement (N -> D)Shift solenoid valve SL1AX-66

Valve body assemblyAX-136

C1 accumulatorAX-177

Forward clutch (C1)AX-177

No. 1 one-way clutch (F1)AX-177

U/D one-way clutch (F2)AX-177

Harsh engagement (Lock-up)Shift solenoid valve SL2AX-82

Valve body assemblyAX-136

Torque converter clutchAX-170

Harsh engagement (N -> R)Valve body assemblyAX-136

C2 accumulatorAX-177

Reverse clutch (C2)AX-177

1st and reverse brake (B2)AX-177

Harsh engagement (1st -> 2nd -> 3rd -> 4th -> 5th)Shift solenoid valve SLTAX-116

Valve body assemblyAX-136

Harsh engagement (1st -> 2nd)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-177

Harsh engagement (2nd -> 3rd)Valve body assemblyAX-136

C0 accumulatorAX-177

Direct and O/D clutch (C0)AX-177

Harsh engagement (3rd -> 4th)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-177

Harsh engagement (4th -> 5th)Valve body assemblyAX-136

C3 accumulatorAX-177

U/D clutch (B3)AX-177

Page 1401 of 3000

AX–24U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

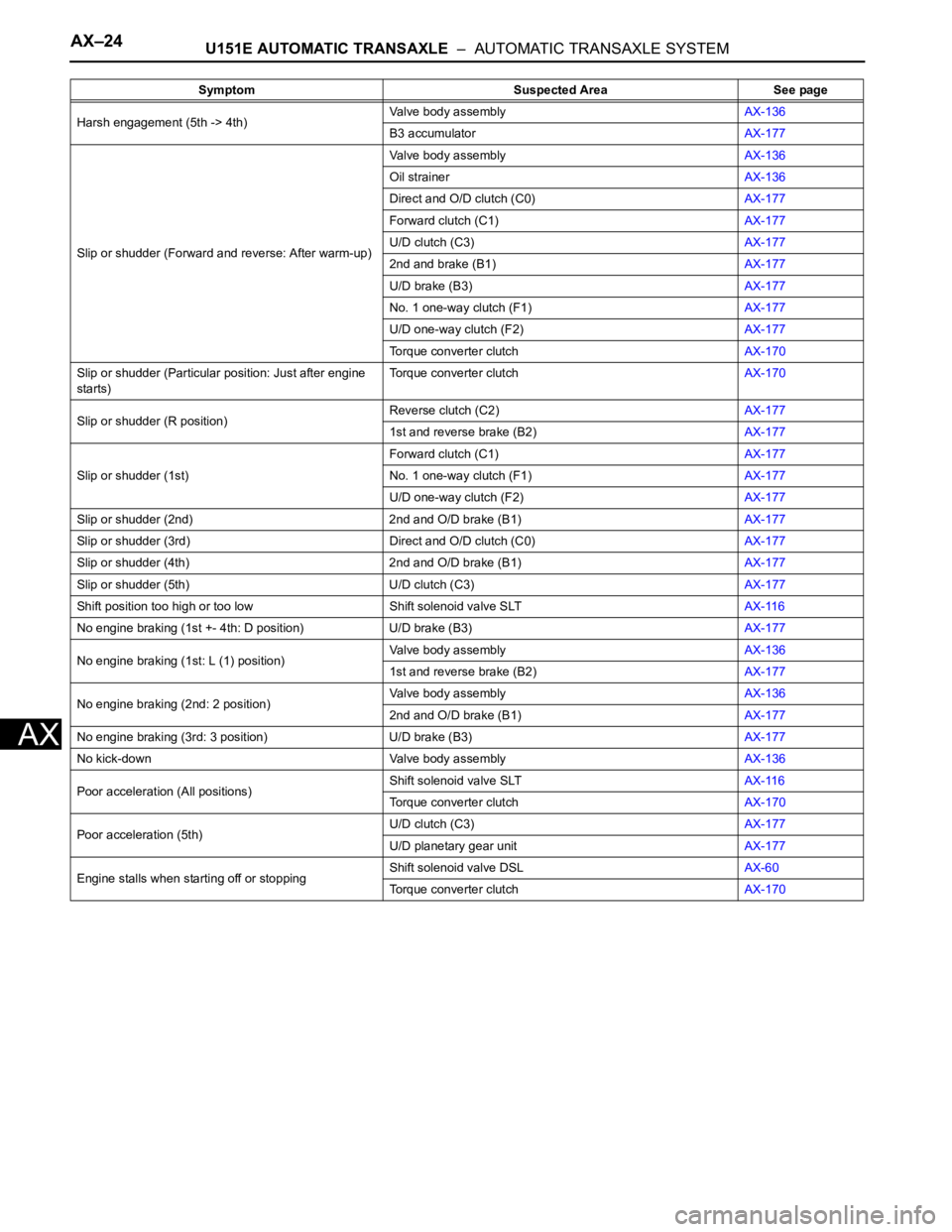

Harsh engagement (5th -> 4th)Valve body assemblyAX-136

B3 accumulatorAX-177

Slip or shudder (Forward and reverse: After warm-up)Valve body assemblyAX-136

Oil strainerAX-136

Direct and O/D clutch (C0)AX-177

Forward clutch (C1)AX-177

U/D clutch (C3)AX-177

2nd and brake (B1)AX-177

U/D brake (B3)AX-177

No. 1 one-way clutch (F1)AX-177

U/D one-way clutch (F2)AX-177

Torque converter clutchAX-170

Slip or shudder (Particular position: Just after engine

starts)Torque converter clutchAX-170

Slip or shudder (R position)Reverse clutch (C2)AX-177

1st and reverse brake (B2)AX-177

Slip or shudder (1st)Forward clutch (C1)AX-177

No. 1 one-way clutch (F1)AX-177

U/D one-way clutch (F2)AX-177

Slip or shudder (2nd) 2nd and O/D brake (B1)AX-177

Slip or shudder (3rd) Direct and O/D clutch (C0)AX-177

Slip or shudder (4th) 2nd and O/D brake (B1)AX-177

Slip or shudder (5th) U/D clutch (C3)AX-177

Shift position too high or too low Shift solenoid valve SLTAX-116

No engine braking (1st +- 4th: D position) U/D brake (B3)AX-177

No engine braking (1st: L (1) position)Valve body assemblyAX-136

1st and reverse brake (B2)AX-177

No engine braking (2nd: 2 position)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-177

No engine braking (3rd: 3 position) U/D brake (B3)AX-177

No kick-down Valve body assemblyAX-136

Poor acceleration (All positions)Shift solenoid valve SLTAX-116

Torque converter clutchAX-170

Poor acceleration (5th)U/D clutch (C3)AX-177

U/D planetary gear unitAX-177

Engine stalls when starting off or stoppingShift solenoid valve DSLAX-60

Torque converter clutchAX-170 Symptom Suspected Area See page

Page 1408 of 3000

AX–42U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

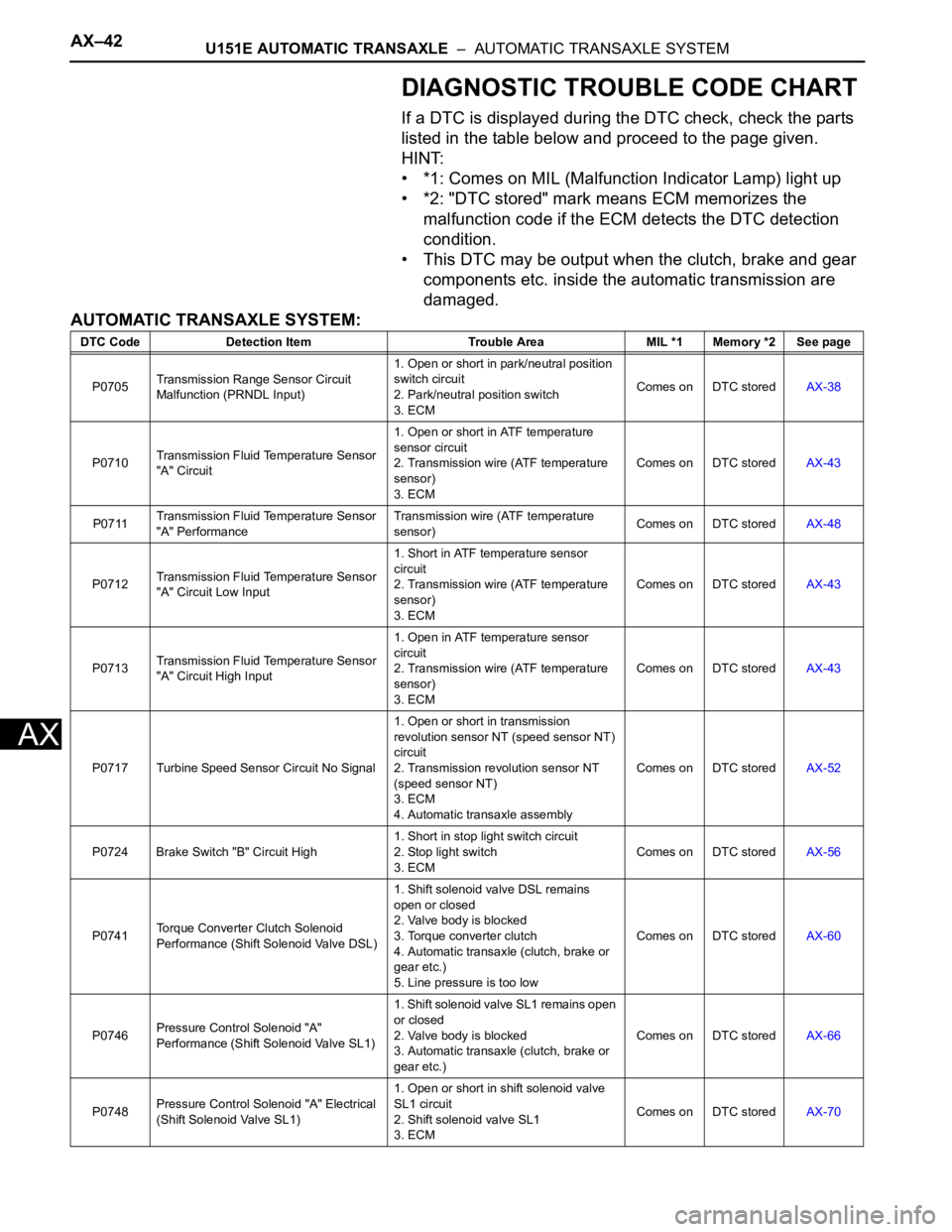

DIAGNOSTIC TROUBLE CODE CHART

If a DTC is displayed during the DTC check, check the parts

listed in the table below and proceed to the page given.

HINT:

• *1: Comes on MIL (Malfunction Indicator Lamp) light up

• *2: "DTC stored" mark means ECM memorizes the

malfunction code if the ECM detects the DTC detection

condition.

• This DTC may be output when the clutch, brake and gear

components etc. inside the automatic transmission are

damaged.

AUTOMATIC TRANSAXLE SYSTEM:

DTC Code Detection Item Trouble Area MIL *1 Memory *2 See page

P0705Transmission Range Sensor Circuit

Malfunction (PRNDL Input)1. Open or short in park/neutral position

switch circuit

2. Park/neutral position switch

3. ECMComes on DTC storedAX-38

P0710Transmission Fluid Temperature Sensor

"A" Circuit1. Open or short in ATF temperature

sensor circuit

2. Transmission wire (ATF temperature

sensor)

3. ECMComes on DTC storedAX-43

P0711Transmission Fluid Temperature Sensor

"A" PerformanceTransmission wire (ATF temperature

sensor)Comes on DTC storedAX-48

P0712Transmission Fluid Temperature Sensor

"A" Circuit Low Input1. Short in ATF temperature sensor

circuit

2. Transmission wire (ATF temperature

sensor)

3. ECMComes on DTC storedAX-43

P0713Transmission Fluid Temperature Sensor

"A" Circuit High Input1. Open in ATF temperature sensor

circuit

2. Transmission wire (ATF temperature

sensor)

3. ECMComes on DTC storedAX-43

P0717 Turbine Speed Sensor Circuit No Signal1. Open or short in transmission

revolution sensor NT (speed sensor NT)

circuit

2. Transmission revolution sensor NT

(speed sensor NT)

3. ECM

4. Automatic transaxle assemblyComes on DTC storedAX-52

P0724 Brake Switch "B" Circuit High1. Short in stop light switch circuit

2. Stop light switch

3. ECMComes on DTC storedAX-56

P0741Torque Converter Clutch Solenoid

Performance (Shift Solenoid Valve DSL)1. Shift solenoid valve DSL remains

open or closed

2. Valve body is blocked

3. Torque converter clutch

4. Automatic transaxle (clutch, brake or

gear etc.)

5. Line pressure is too lowComes on DTC storedAX-60

P0746Pressure Control Solenoid "A"

Performance (Shift Solenoid Valve SL1)1. Shift solenoid valve SL1 remains open

or closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC storedAX-66

P0748Pressure Control Solenoid "A" Electrical

(Shift Solenoid Valve SL1)1. Open or short in shift solenoid valve

SL1 circuit

2. Shift solenoid valve SL1

3. ECMComes on DTC storedAX-70

Page 1409 of 3000

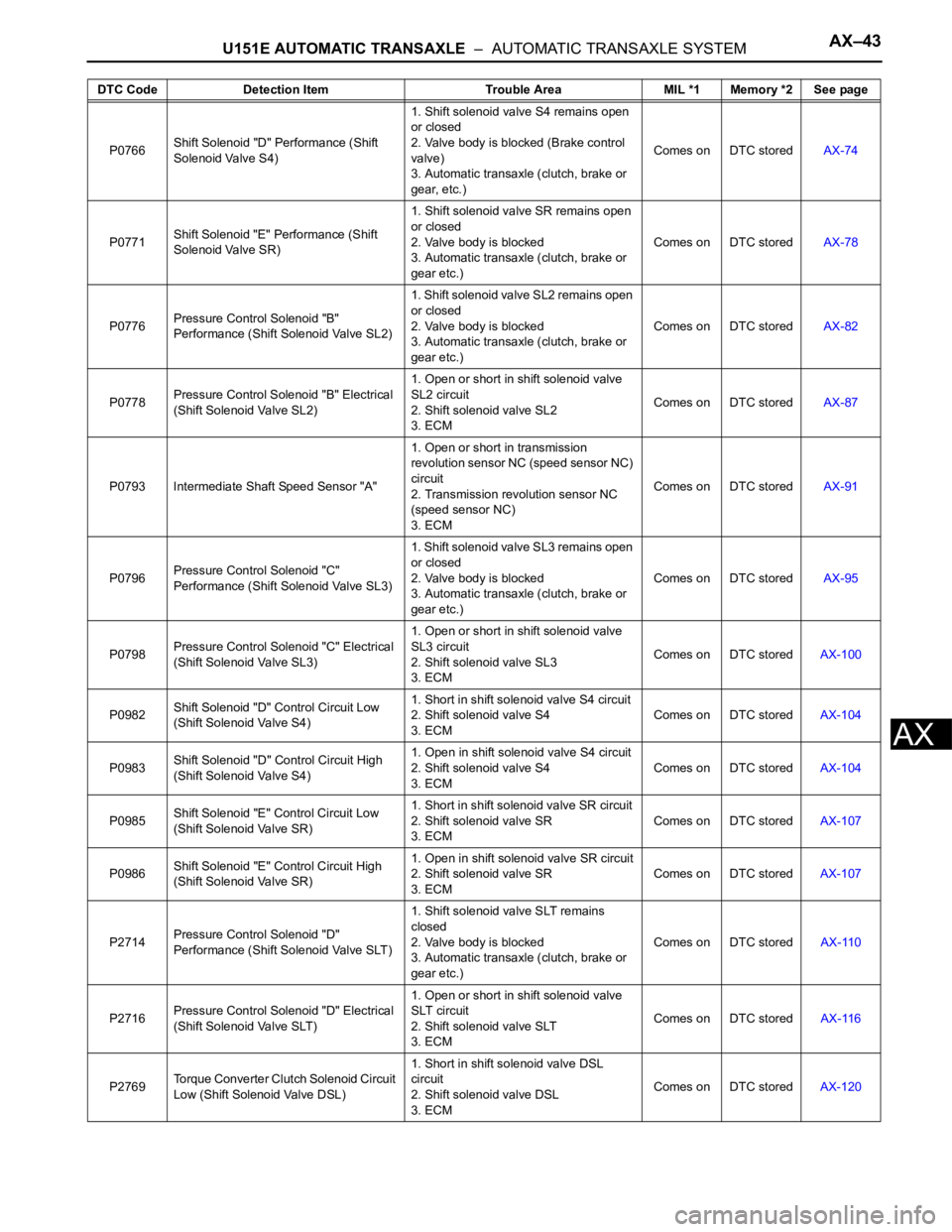

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–43

AX

P0766Shift Solenoid "D" Performance (Shift

Solenoid Valve S4)1. Shift solenoid valve S4 remains open

or closed

2. Valve body is blocked (Brake control

valve)

3. Automatic transaxle (clutch, brake or

gear, etc.)Comes on DTC storedAX-74

P0771Shift Solenoid "E" Performance (Shift

Solenoid Valve SR)1. Shift solenoid valve SR remains open

or closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC storedAX-78

P0776Pressure Control Solenoid "B"

Performance (Shift Solenoid Valve SL2)1. Shift solenoid valve SL2 remains open

or closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC storedAX-82

P0778Pressure Control Solenoid "B" Electrical

(Shift Solenoid Valve SL2)1. Open or short in shift solenoid valve

SL2 circuit

2. Shift solenoid valve SL2

3. ECMComes on DTC storedAX-87

P0793 Intermediate Shaft Speed Sensor "A"1. Open or short in transmission

revolution sensor NC (speed sensor NC)

circuit

2. Transmission revolution sensor NC

(speed sensor NC)

3. ECMComes on DTC storedAX-91

P0796Pressure Control Solenoid "C"

Performance (Shift Solenoid Valve SL3)1. Shift solenoid valve SL3 remains open

or closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC storedAX-95

P0798Pressure Control Solenoid "C" Electrical

(Shift Solenoid Valve SL3)1. Open or short in shift solenoid valve

SL3 circuit

2. Shift solenoid valve SL3

3. ECMComes on DTC storedAX-100

P0982Shift Solenoid "D" Control Circuit Low

(Shift Solenoid Valve S4)1. Short in shift solenoid valve S4 circuit

2. Shift solenoid valve S4

3. ECMComes on DTC storedAX-104

P0983Shift Solenoid "D" Control Circuit High

(Shift Solenoid Valve S4)1. Open in shift solenoid valve S4 circuit

2. Shift solenoid valve S4

3. ECMComes on DTC storedAX-104

P0985Shift Solenoid "E" Control Circuit Low

(Shift Solenoid Valve SR)1. Short in shift solenoid valve SR circuit

2. Shift solenoid valve SR

3. ECMComes on DTC storedAX-107

P0986Shift Solenoid "E" Control Circuit High

(Shift Solenoid Valve SR)1. Open in shift solenoid valve SR circuit

2. Shift solenoid valve SR

3. ECMComes on DTC storedAX-107

P2714Pressure Control Solenoid "D"

Performance (Shift Solenoid Valve SLT)1. Shift solenoid valve SLT remains

closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC stored

AX-110

P2716Pressure Control Solenoid "D" Electrical

(Shift Solenoid Valve SLT)1. Open or short in shift solenoid valve

SLT circuit

2. Shift solenoid valve SLT

3. ECMComes on DTC storedAX-116

P2769Torque Converter Clutch Solenoid Circuit

Low (Shift Solenoid Valve DSL)1. Short in shift solenoid valve DSL

circuit

2. Shift solenoid valve DSL

3. ECMComes on DTC storedAX-120 DTC Code Detection Item Trouble Area MIL *1 Memory *2 See page