TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2141 of 3000

DIFFERENTIAL – REAR DIFFERENTIAL CARRIERDF–19

DF

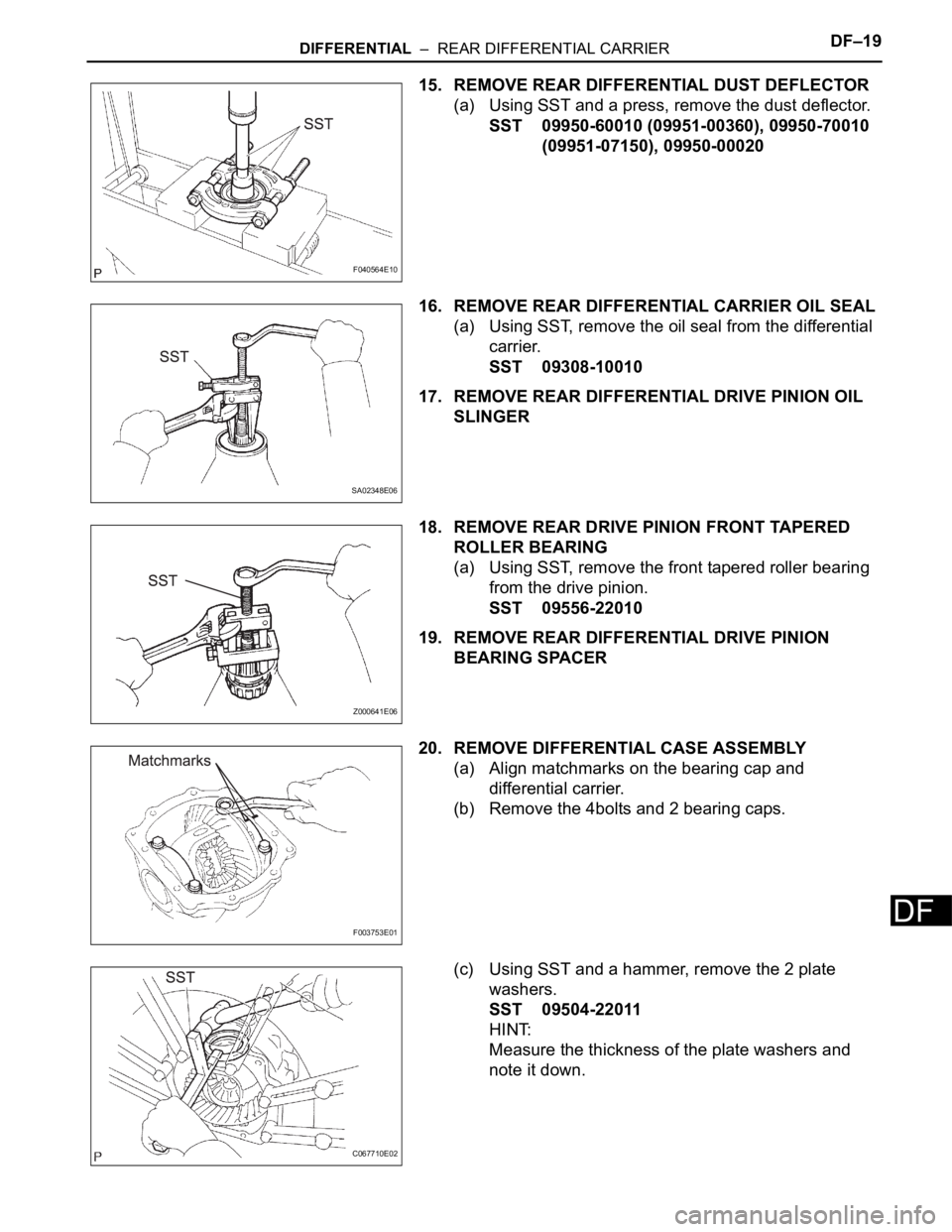

15. REMOVE REAR DIFFERENTIAL DUST DEFLECTOR

(a) Using SST and a press, remove the dust deflector.

SST 09950-60010 (09951-00360), 09950-70010

(09951-07150), 09950-00020

16. REMOVE REAR DIFFERENTIAL CARRIER OIL SEAL

(a) Using SST, remove the oil seal from the differential

carrier.

SST 09308-10010

17. REMOVE REAR DIFFERENTIAL DRIVE PINION OIL

SLINGER

18. REMOVE REAR DRIVE PINION FRONT TAPERED

ROLLER BEARING

(a) Using SST, remove the front tapered roller bearing

from the drive pinion.

SST 09556-22010

19. REMOVE REAR DIFFERENTIAL DRIVE PINION

BEARING SPACER

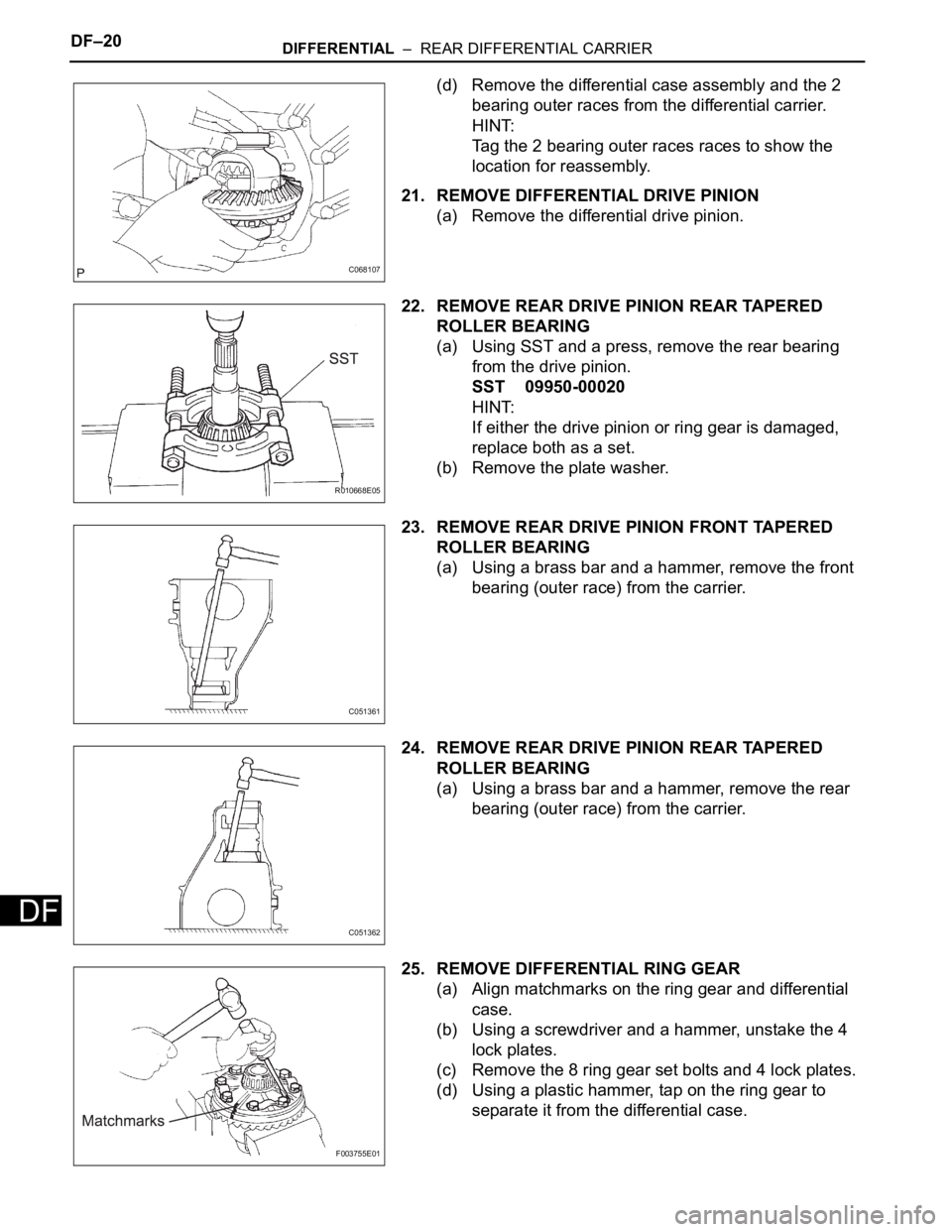

20. REMOVE DIFFERENTIAL CASE ASSEMBLY

(a) Align matchmarks on the bearing cap and

differential carrier.

(b) Remove the 4bolts and 2 bearing caps.

(c) Using SST and a hammer, remove the 2 plate

washers.

SST 09504-22011

HINT:

Measure the thickness of the plate washers and

note it down.

F040564E10

SA02348E06

Z000641E06

F003753E01

C067710E02

Page 2142 of 3000

DF–20DIFFERENTIAL – REAR DIFFERENTIAL CARRIER

DF

(d) Remove the differential case assembly and the 2

bearing outer races from the differential carrier.

HINT:

Tag the 2 bearing outer races races to show the

location for reassembly.

21. REMOVE DIFFERENTIAL DRIVE PINION

(a) Remove the differential drive pinion.

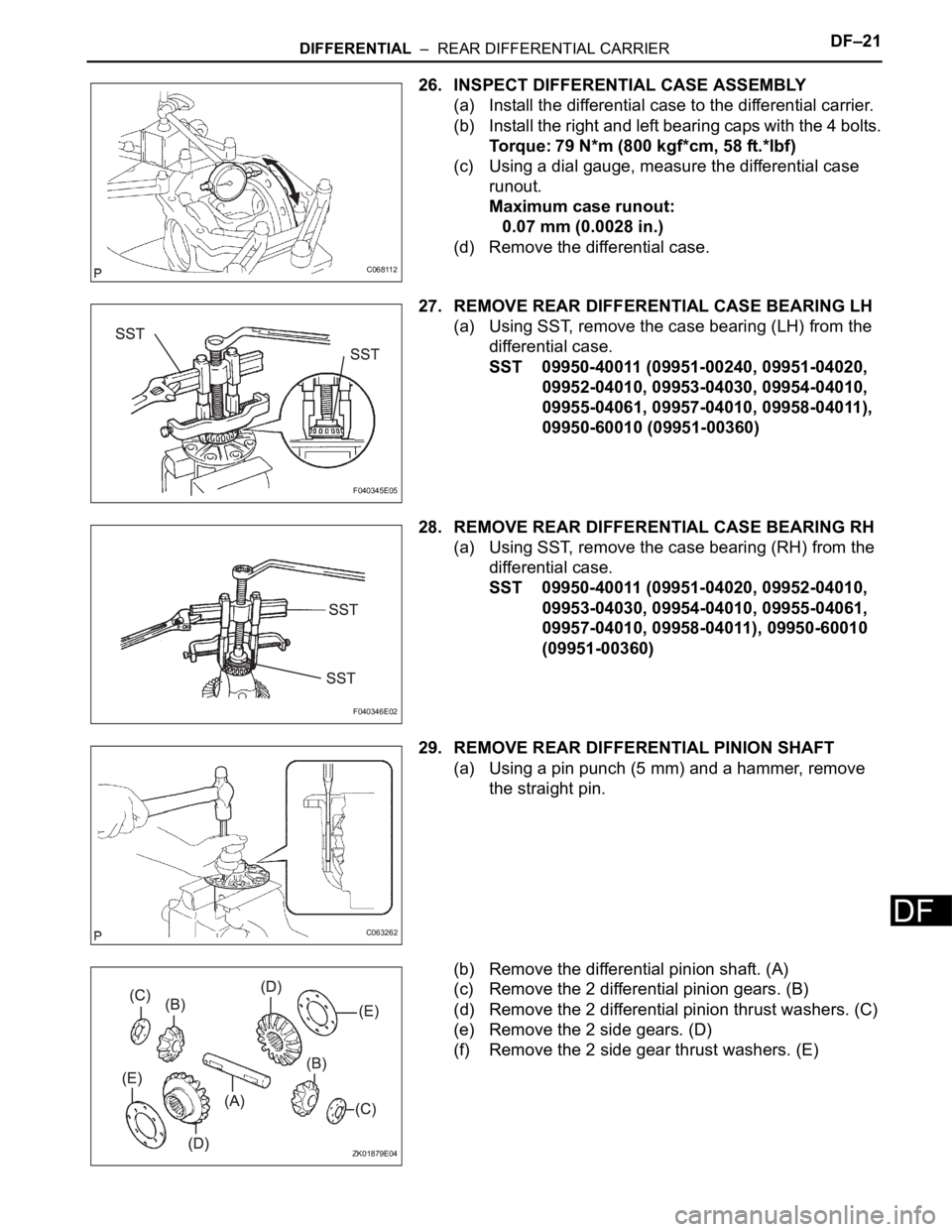

22. REMOVE REAR DRIVE PINION REAR TAPERED

ROLLER BEARING

(a) Using SST and a press, remove the rear bearing

from the drive pinion.

SST 09950-00020

HINT:

If either the drive pinion or ring gear is damaged,

replace both as a set.

(b) Remove the plate washer.

23. REMOVE REAR DRIVE PINION FRONT TAPERED

ROLLER BEARING

(a) Using a brass bar and a hammer, remove the front

bearing (outer race) from the carrier.

24. REMOVE REAR DRIVE PINION REAR TAPERED

ROLLER BEARING

(a) Using a brass bar and a hammer, remove the rear

bearing (outer race) from the carrier.

25. REMOVE DIFFERENTIAL RING GEAR

(a) Align matchmarks on the ring gear and differential

case.

(b) Using a screwdriver and a hammer, unstake the 4

lock plates.

(c) Remove the 8 ring gear set bolts and 4 lock plates.

(d) Using a plastic hammer, tap on the ring gear to

separate it from the differential case.

C068107

R010668E05

C051361

C051362

F003755E01

Page 2143 of 3000

DIFFERENTIAL – REAR DIFFERENTIAL CARRIERDF–21

DF

26. INSPECT DIFFERENTIAL CASE ASSEMBLY

(a) Install the differential case to the differential carrier.

(b) Install the right and left bearing caps with the 4 bolts.

Torque: 79 N*m (800 kgf*cm, 58 ft.*lbf)

(c) Using a dial gauge, measure the differential case

runout.

Maximum case runout:

0.07 mm (0.0028 in.)

(d) Remove the differential case.

27. REMOVE REAR DIFFERENTIAL CASE BEARING LH

(a) Using SST, remove the case bearing (LH) from the

differential case.

SST 09950-40011 (09951-00240, 09951-04020,

09952-04010, 09953-04030, 09954-04010,

09955-04061, 09957-04010, 09958-04011),

09950-60010 (09951-00360)

28. REMOVE REAR DIFFERENTIAL CASE BEARING RH

(a) Using SST, remove the case bearing (RH) from the

differential case.

SST 09950-40011 (09951-04020, 09952-04010,

09953-04030, 09954-04010, 09955-04061,

09957-04010, 09958-04011), 09950-60010

(09951-00360)

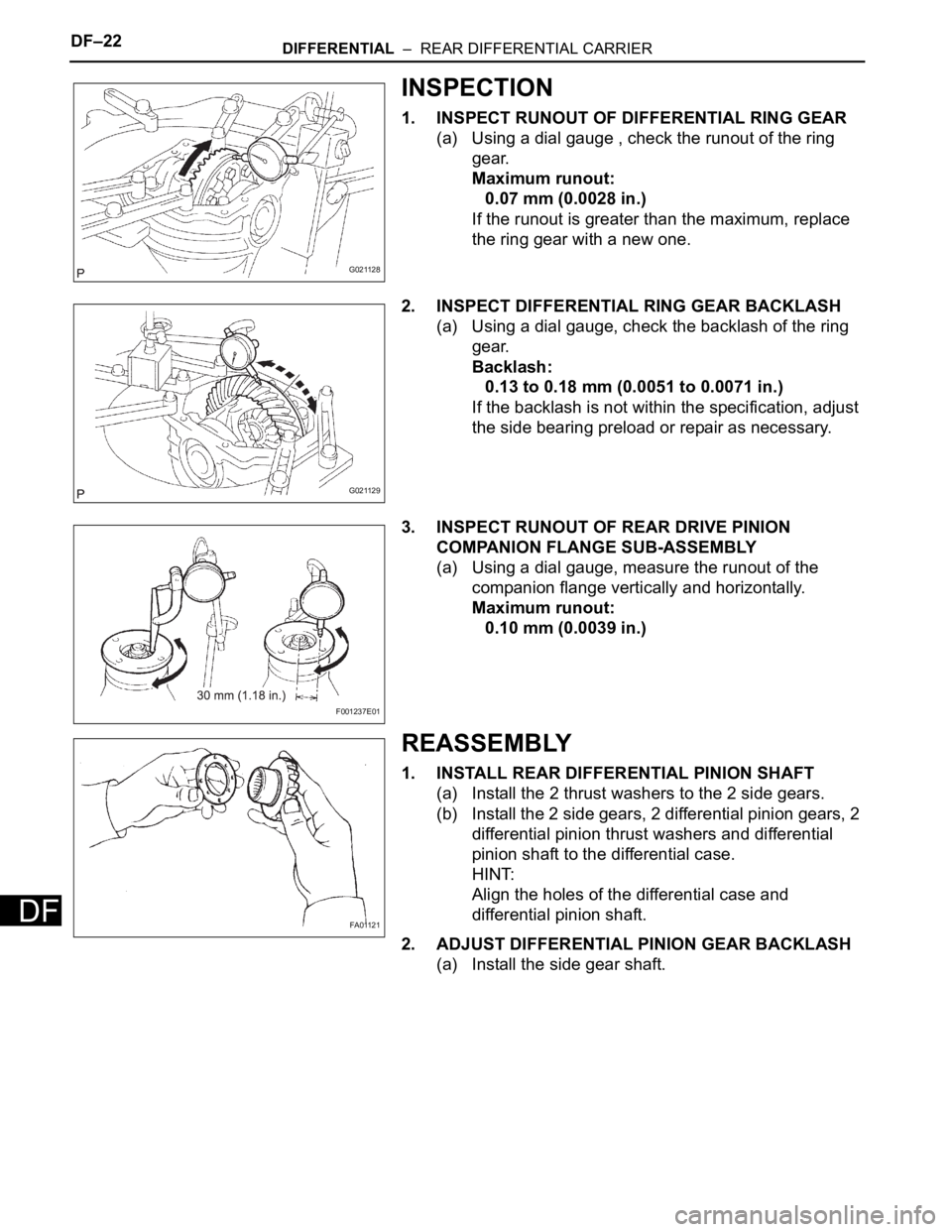

29. REMOVE REAR DIFFERENTIAL PINION SHAFT

(a) Using a pin punch (5 mm) and a hammer, remove

the straight pin.

(b) Remove the differential pinion shaft. (A)

(c) Remove the 2 differential pinion gears. (B)

(d) Remove the 2 differential pinion thrust washers. (C)

(e) Remove the 2 side gears. (D)

(f) Remove the 2 side gear thrust washers. (E)

C068112

F040345E05

F040346E02

C063262

ZK01879E04

Page 2144 of 3000

DF–22DIFFERENTIAL – REAR DIFFERENTIAL CARRIER

DF

INSPECTION

1. INSPECT RUNOUT OF DIFFERENTIAL RING GEAR

(a) Using a dial gauge , check the runout of the ring

gear.

Maximum runout:

0.07 mm (0.0028 in.)

If the runout is greater than the maximum, replace

the ring gear with a new one.

2. INSPECT DIFFERENTIAL RING GEAR BACKLASH

(a) Using a dial gauge, check the backlash of the ring

gear.

Backlash:

0.13 to 0.18 mm (0.0051 to 0.0071 in.)

If the backlash is not within the specification, adjust

the side bearing preload or repair as necessary.

3. INSPECT RUNOUT OF REAR DRIVE PINION

COMPANION FLANGE SUB-ASSEMBLY

(a) Using a dial gauge, measure the runout of the

companion flange vertically and horizontally.

Maximum runout:

0.10 mm (0.0039 in.)

REASSEMBLY

1. INSTALL REAR DIFFERENTIAL PINION SHAFT

(a) Install the 2 thrust washers to the 2 side gears.

(b) Install the 2 side gears, 2 differential pinion gears, 2

differential pinion thrust washers and differential

pinion shaft to the differential case.

HINT:

Align the holes of the differential case and

differential pinion shaft.

2. ADJUST DIFFERENTIAL PINION GEAR BACKLASH

(a) Install the side gear shaft.

G021128

G021129

F001237E01

FA01121

Page 2145 of 3000

DIFFERENTIAL – REAR DIFFERENTIAL CARRIERDF–23

DF

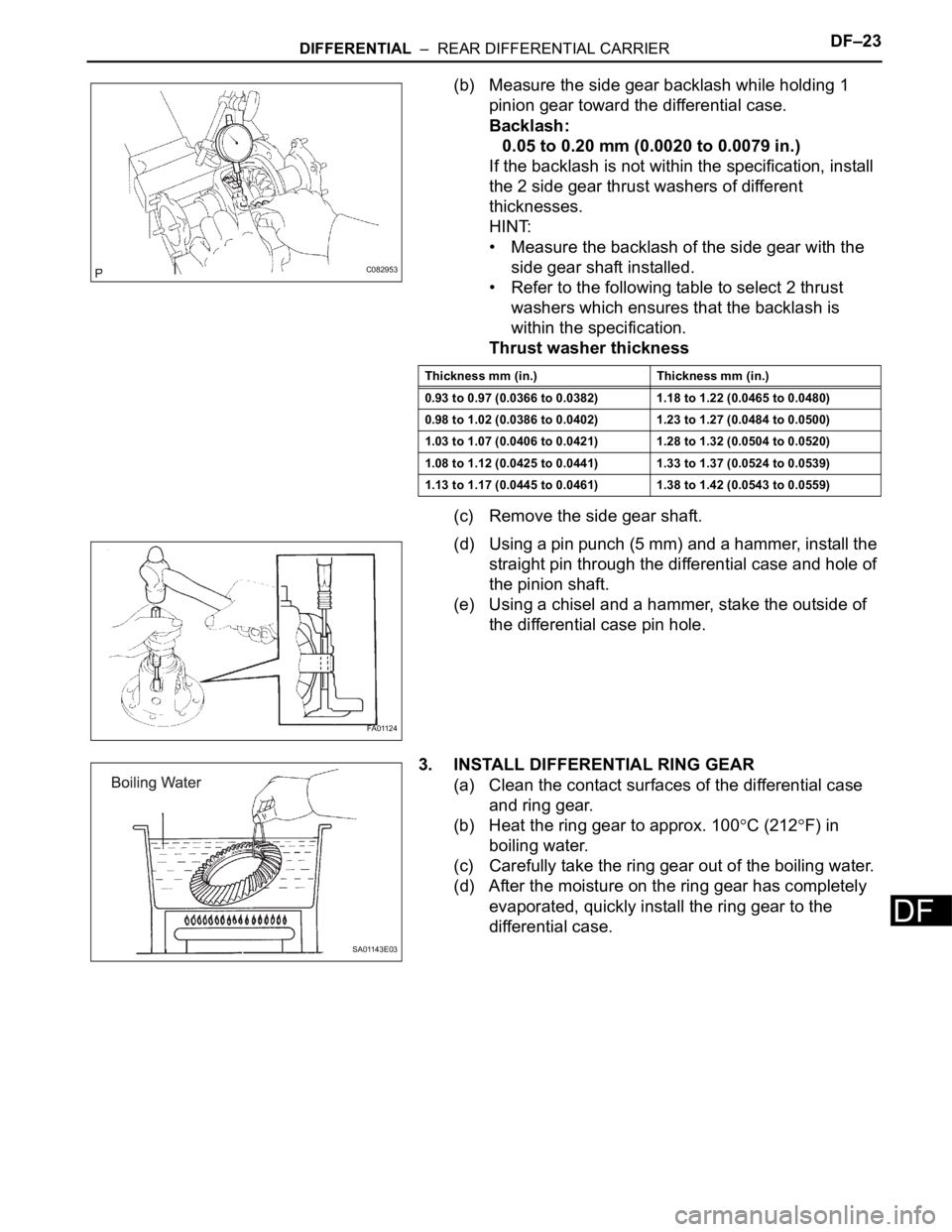

(b) Measure the side gear backlash while holding 1

pinion gear toward the differential case.

Backlash:

0.05 to 0.20 mm (0.0020 to 0.0079 in.)

If the backlash is not within the specification, install

the 2 side gear thrust washers of different

thicknesses.

HINT:

• Measure the backlash of the side gear with the

side gear shaft installed.

• Refer to the following table to select 2 thrust

washers which ensures that the backlash is

within the specification.

Thrust washer thickness

(c) Remove the side gear shaft.

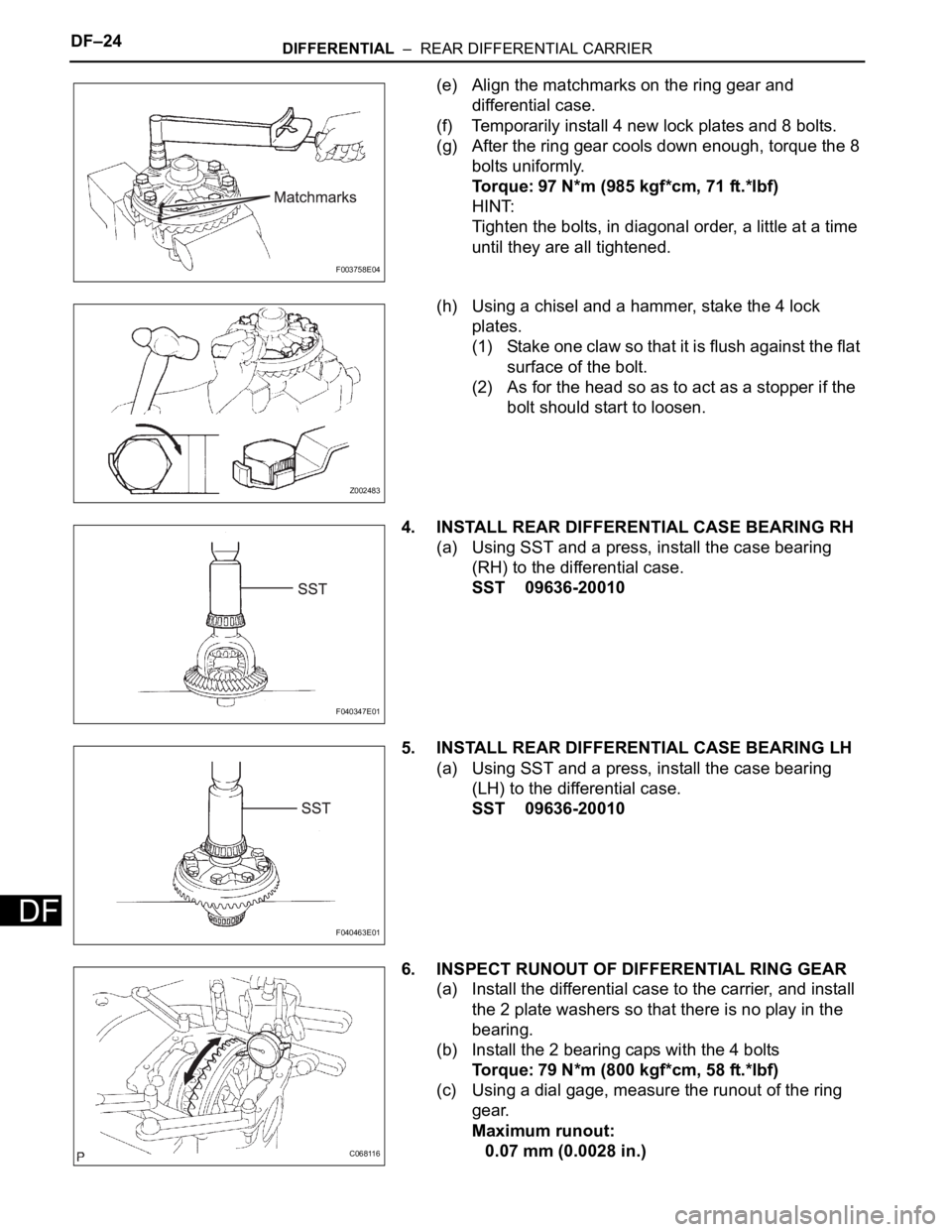

(d) Using a pin punch (5 mm) and a hammer, install the

straight pin through the differential case and hole of

the pinion shaft.

(e) Using a chisel and a hammer, stake the outside of

the differential case pin hole.

3. INSTALL DIFFERENTIAL RING GEAR

(a) Clean the contact surfaces of the differential case

and ring gear.

(b) Heat the ring gear to approx. 100

C (212F) in

boiling water.

(c) Carefully take the ring gear out of the boiling water.

(d) After the moisture on the ring gear has completely

evaporated, quickly install the ring gear to the

differential case.

C082953

Thickness mm (in.) Thickness mm (in.)

0.93 to 0.97 (0.0366 to 0.0382) 1.18 to 1.22 (0.0465 to 0.0480)

0.98 to 1.02 (0.0386 to 0.0402) 1.23 to 1.27 (0.0484 to 0.0500)

1.03 to 1.07 (0.0406 to 0.0421) 1.28 to 1.32 (0.0504 to 0.0520)

1.08 to 1.12 (0.0425 to 0.0441) 1.33 to 1.37 (0.0524 to 0.0539)

1.13 to 1.17 (0.0445 to 0.0461) 1.38 to 1.42 (0.0543 to 0.0559)

FA01124

SA01143E03

Page 2146 of 3000

DF–24DIFFERENTIAL – REAR DIFFERENTIAL CARRIER

DF

(e) Align the matchmarks on the ring gear and

differential case.

(f) Temporarily install 4 new lock plates and 8 bolts.

(g) After the ring gear cools down enough, torque the 8

bolts uniformly.

Torque: 97 N*m (985 kgf*cm, 71 ft.*lbf)

HINT:

Tighten the bolts, in diagonal order, a little at a time

until they are all tightened.

(h) Using a chisel and a hammer, stake the 4 lock

plates.

(1) Stake one claw so that it is flush against the flat

surface of the bolt.

(2) As for the head so as to act as a stopper if the

bolt should start to loosen.

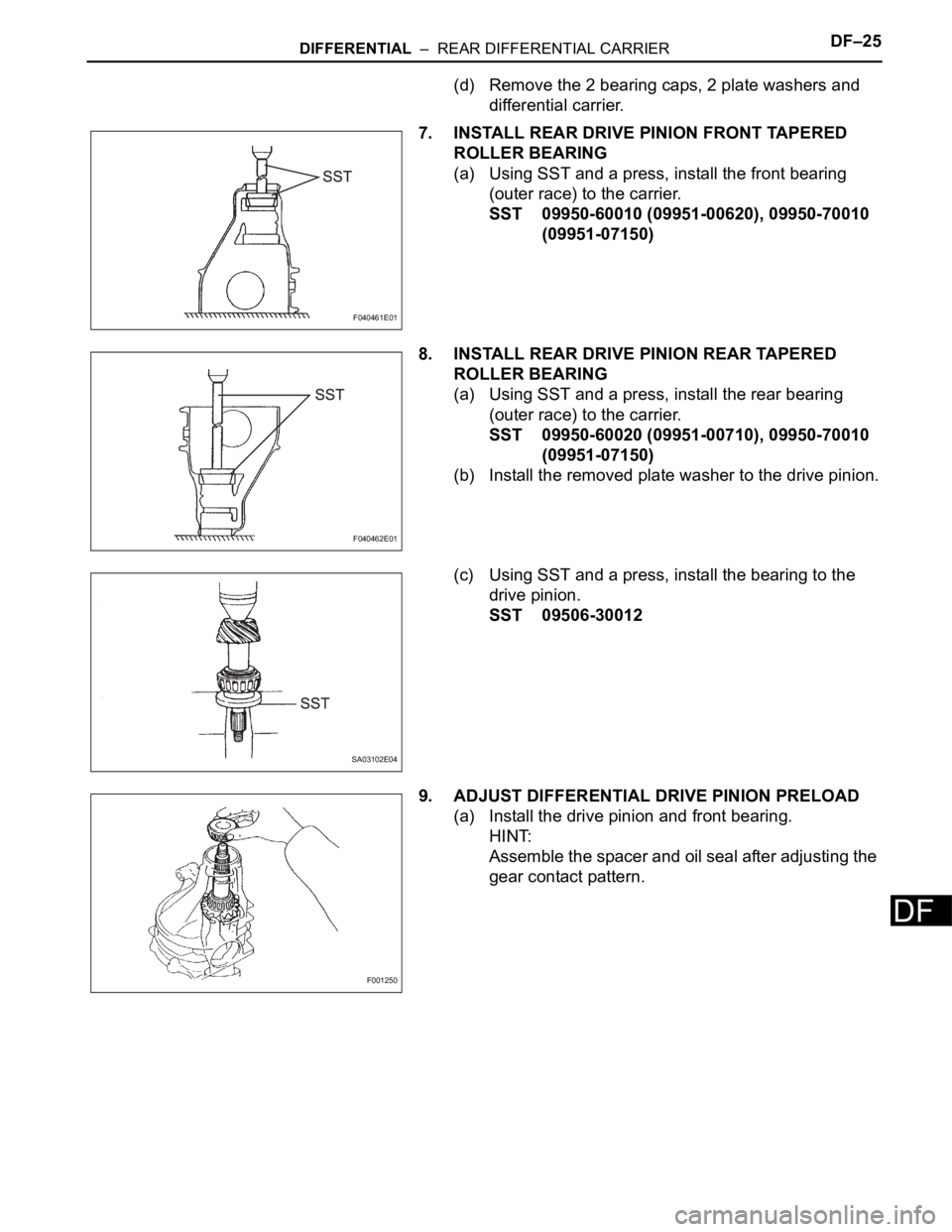

4. INSTALL REAR DIFFERENTIAL CASE BEARING RH

(a) Using SST and a press, install the case bearing

(RH) to the differential case.

SST 09636-20010

5. INSTALL REAR DIFFERENTIAL CASE BEARING LH

(a) Using SST and a press, install the case bearing

(LH) to the differential case.

SST 09636-20010

6. INSPECT RUNOUT OF DIFFERENTIAL RING GEAR

(a) Install the differential case to the carrier, and install

the 2 plate washers so that there is no play in the

bearing.

(b) Install the 2 bearing caps with the 4 bolts

Torque: 79 N*m (800 kgf*cm, 58 ft.*lbf)

(c) Using a dial gage, measure the runout of the ring

gear.

Maximum runout:

0.07 mm (0.0028 in.)

F003758E04

Z002483

F040347E01

F040463E01

C068116

Page 2147 of 3000

DIFFERENTIAL – REAR DIFFERENTIAL CARRIERDF–25

DF

(d) Remove the 2 bearing caps, 2 plate washers and

differential carrier.

7. INSTALL REAR DRIVE PINION FRONT TAPERED

ROLLER BEARING

(a) Using SST and a press, install the front bearing

(outer race) to the carrier.

SST 09950-60010 (09951-00620), 09950-70010

(09951-07150)

8. INSTALL REAR DRIVE PINION REAR TAPERED

ROLLER BEARING

(a) Using SST and a press, install the rear bearing

(outer race) to the carrier.

SST 09950-60020 (09951-00710), 09950-70010

(09951-07150)

(b) Install the removed plate washer to the drive pinion.

(c) Using SST and a press, install the bearing to the

drive pinion.

SST 09506-30012

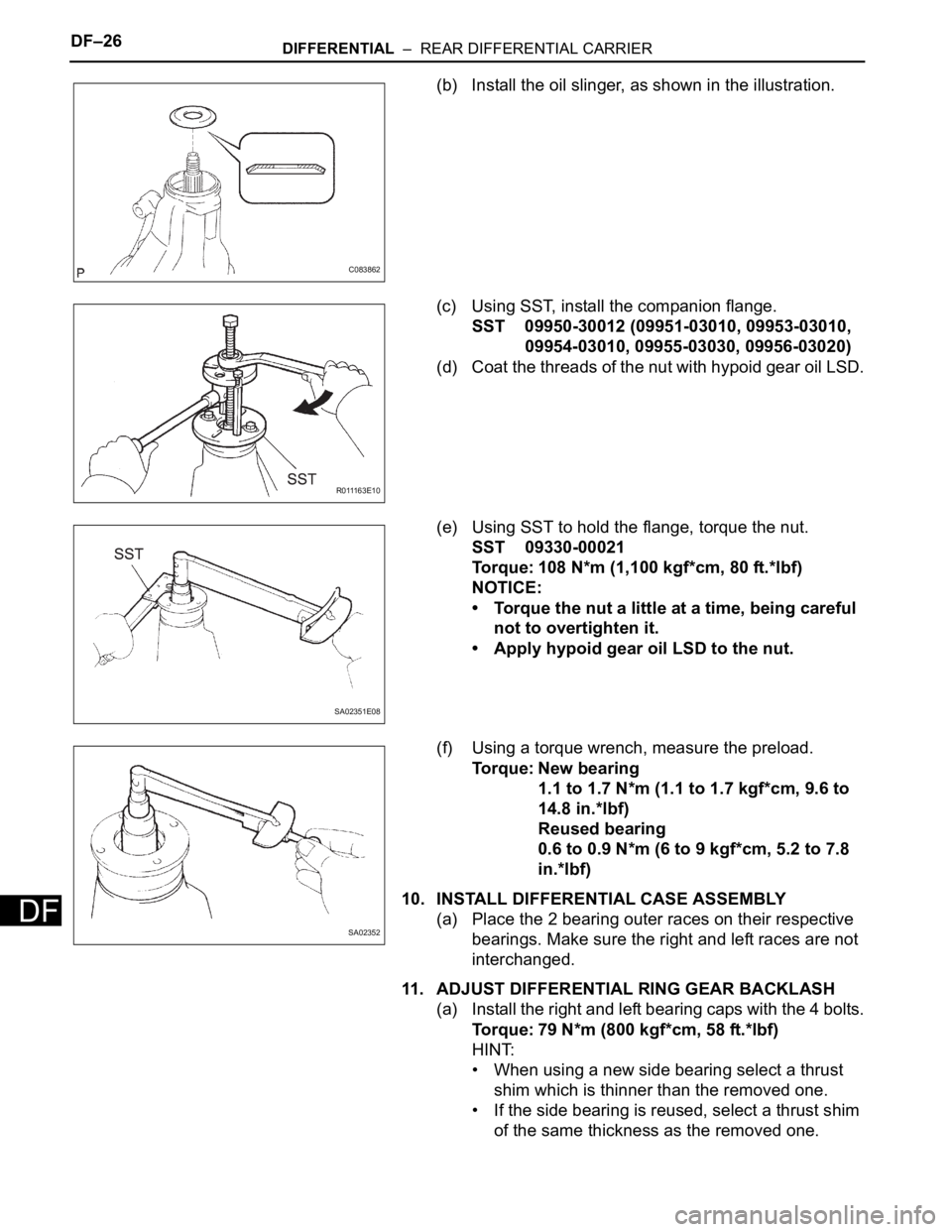

9. ADJUST DIFFERENTIAL DRIVE PINION PRELOAD

(a) Install the drive pinion and front bearing.

HINT:

Assemble the spacer and oil seal after adjusting the

gear contact pattern.

F040461E01

F040462E01

SA03102E04

F001250

Page 2148 of 3000

DF–26DIFFERENTIAL – REAR DIFFERENTIAL CARRIER

DF

(b) Install the oil slinger, as shown in the illustration.

(c) Using SST, install the companion flange.

SST 09950-30012 (09951-03010, 09953-03010,

09954-03010, 09955-03030, 09956-03020)

(d) Coat the threads of the nut with hypoid gear oil LSD.

(e) Using SST to hold the flange, torque the nut.

SST 09330-00021

Torque: 108 N*m (1,100 kgf*cm, 80 ft.*lbf)

NOTICE:

• Torque the nut a little at a time, being careful

not to overtighten it.

• Apply hypoid gear oil LSD to the nut.

(f) Using a torque wrench, measure the preload.

Torque: New bearing

1.1 to 1.7 N*m (1.1 to 1.7 kgf*cm, 9.6 to

14.8 in.*lbf)

Reused bearing

0.6 to 0.9 N*m (6 to 9 kgf*cm, 5.2 to 7.8

in.*lbf)

10. INSTALL DIFFERENTIAL CASE ASSEMBLY

(a) Place the 2 bearing outer races on their respective

bearings. Make sure the right and left races are not

interchanged.

11. ADJUST DIFFERENTIAL RING GEAR BACKLASH

(a) Install the right and left bearing caps with the 4 bolts.

Torque: 79 N*m (800 kgf*cm, 58 ft.*lbf)

HINT:

• When using a new side bearing select a thrust

shim which is thinner than the removed one.

• If the side bearing is reused, select a thrust shim

of the same thickness as the removed one.

C083862

R 0 111 6 3 E 1 0

SA02351E08

SA02352

Page 2149 of 3000

DIFFERENTIAL – REAR DIFFERENTIAL CARRIERDF–27

DF

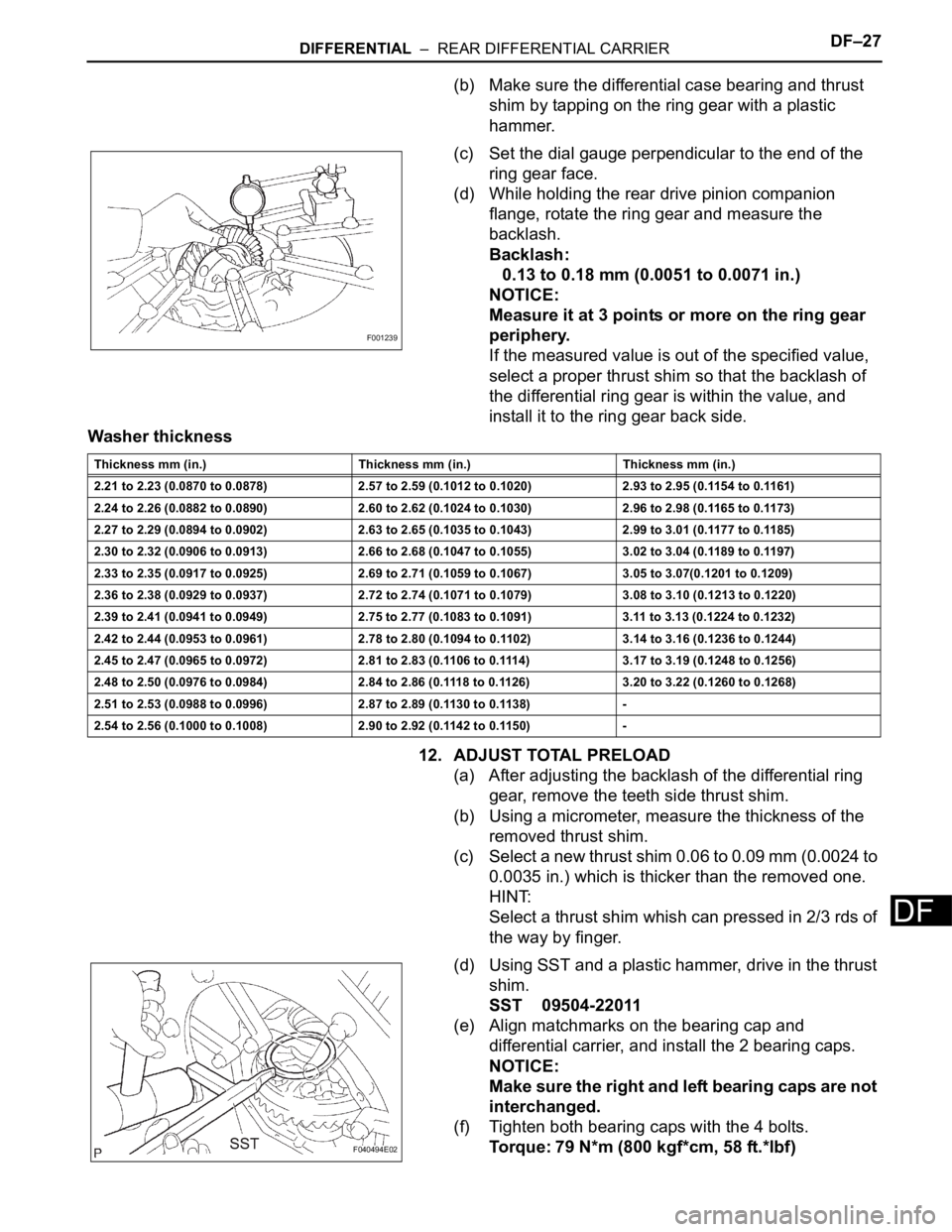

(b) Make sure the differential case bearing and thrust

shim by tapping on the ring gear with a plastic

hammer.

(c) Set the dial gauge perpendicular to the end of the

ring gear face.

(d) While holding the rear drive pinion companion

flange, rotate the ring gear and measure the

backlash.

Backlash:

0.13 to 0.18 mm (0.0051 to 0.0071 in.)

NOTICE:

Measure it at 3 points or more on the ring gear

periphery.

If the measured value is out of the specified value,

select a proper thrust shim so that the backlash of

the differential ring gear is within the value, and

install it to the ring gear back side.

Washer thickness

12. ADJUST TOTAL PRELOAD

(a) After adjusting the backlash of the differential ring

gear, remove the teeth side thrust shim.

(b) Using a micrometer, measure the thickness of the

removed thrust shim.

(c) Select a new thrust shim 0.06 to 0.09 mm (0.0024 to

0.0035 in.) which is thicker than the removed one.

HINT:

Select a thrust shim whish can pressed in 2/3 rds of

the way by finger.

(d) Using SST and a plastic hammer, drive in the thrust

shim.

SST 09504-22011

(e) Align matchmarks on the bearing cap and

differential carrier, and install the 2 bearing caps.

NOTICE:

Make sure the right and left bearing caps are not

interchanged.

(f) Tighten both bearing caps with the 4 bolts.

Torque: 79 N*m (800 kgf*cm, 58 ft.*lbf)

F001239

Thickness mm (in.) Thickness mm (in.) Thickness mm (in.)

2.21 to 2.23 (0.0870 to 0.0878) 2.57 to 2.59 (0.1012 to 0.1020) 2.93 to 2.95 (0.1154 to 0.1161)

2.24 to 2.26 (0.0882 to 0.0890) 2.60 to 2.62 (0.1024 to 0.1030) 2.96 to 2.98 (0.1165 to 0.1173)

2.27 to 2.29 (0.0894 to 0.0902) 2.63 to 2.65 (0.1035 to 0.1043) 2.99 to 3.01 (0.1177 to 0.1185)

2.30 to 2.32 (0.0906 to 0.0913) 2.66 to 2.68 (0.1047 to 0.1055) 3.02 to 3.04 (0.1189 to 0.1197)

2.33 to 2.35 (0.0917 to 0.0925) 2.69 to 2.71 (0.1059 to 0.1067) 3.05 to 3.07(0.1201 to 0.1209)

2.36 to 2.38 (0.0929 to 0.0937) 2.72 to 2.74 (0.1071 to 0.1079) 3.08 to 3.10 (0.1213 to 0.1220)

2.39 to 2.41 (0.0941 to 0.0949) 2.75 to 2.77 (0.1083 to 0.1091) 3.11 to 3.13 (0.1224 to 0.1232)

2.42 to 2.44 (0.0953 to 0.0961) 2.78 to 2.80 (0.1094 to 0.1102) 3.14 to 3.16 (0.1236 to 0.1244)

2.45 to 2.47 (0.0965 to 0.0972) 2.81 to 2.83 (0.1106 to 0.1114) 3.17 to 3.19 (0.1248 to 0.1256)

2.48 to 2.50 (0.0976 to 0.0984) 2.84 to 2.86 (0.1118 to 0.1126) 3.20 to 3.22 (0.1260 to 0.1268)

2.51 to 2.53 (0.0988 to 0.0996) 2.87 to 2.89 (0.1130 to 0.1138) -

2.54 to 2.56 (0.1000 to 0.1008) 2.90 to 2.92 (0.1142 to 0.1150) -

F040494E02

Page 2150 of 3000

DF–28DIFFERENTIAL – REAR DIFFERENTIAL CARRIER

DF

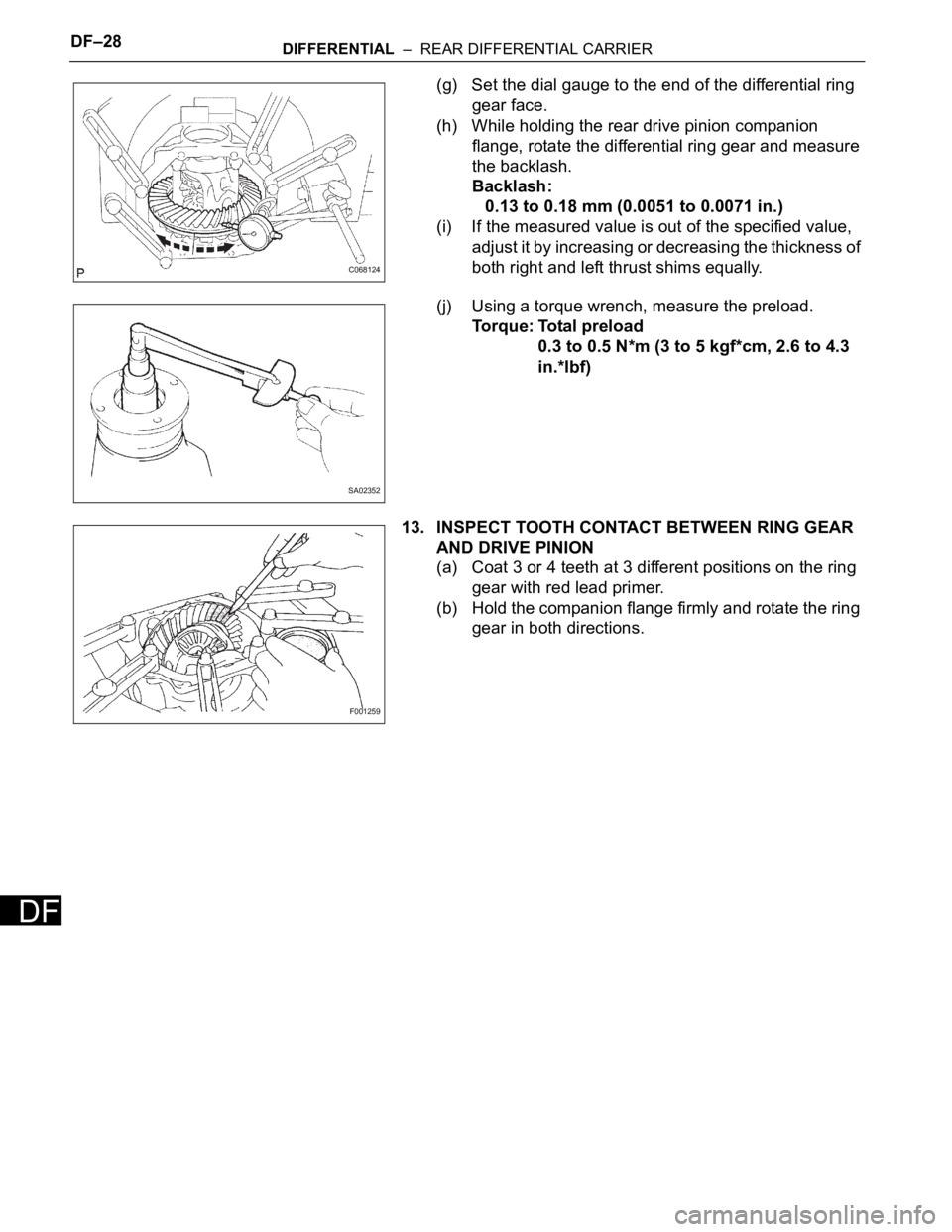

(g) Set the dial gauge to the end of the differential ring

gear face.

(h) While holding the rear drive pinion companion

flange, rotate the differential ring gear and measure

the backlash.

Backlash:

0.13 to 0.18 mm (0.0051 to 0.0071 in.)

(i) If the measured value is out of the specified value,

adjust it by increasing or decreasing the thickness of

both right and left thrust shims equally.

(j) Using a torque wrench, measure the preload.

Torque: Total preload

0.3 to 0.5 N*m (3 to 5 kgf*cm, 2.6 to 4.3

in.*lbf)

13. INSPECT TOOTH CONTACT BETWEEN RING GEAR

AND DRIVE PINION

(a) Coat 3 or 4 teeth at 3 different positions on the ring

gear with red lead primer.

(b) Hold the companion flange firmly and rotate the ring

gear in both directions.

C068124

SA02352

F001259