sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 581 of 3000

ES–2882GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

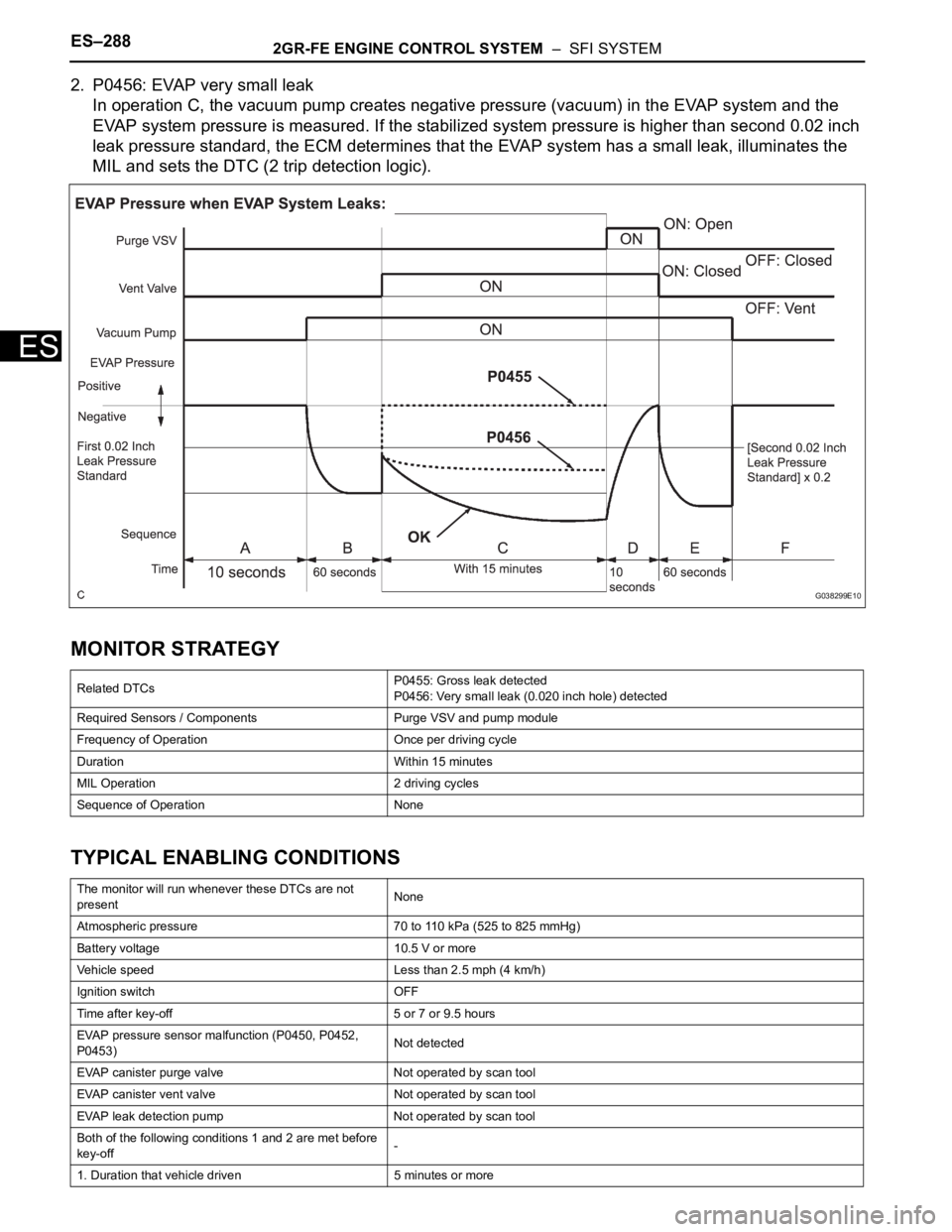

2. P0456: EVAP very small leak

In operation C, the vacuum pump creates negative pressure (vacuum) in the EVAP system and the

EVAP system pressure is measured. If the stabilized system pressure is higher than second 0.02 inch

leak pressure standard, the ECM determines that the EVAP system has a small leak, illuminates the

MIL and sets the DTC (2 trip detection logic).

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

Related DTCsP0455: Gross leak detected

P0456: Very small leak (0.020 inch hole) detected

Required Sensors / Components Purge VSV and pump module

Frequency of Operation Once per driving cycle

Duration Within 15 minutes

MIL Operation 2 driving cycles

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Atmospheric pressure 70 to 110 kPa (525 to 825 mmHg)

Battery voltage 10.5 V or more

Vehicle speed Less than 2.5 mph (4 km/h)

Ignition switch OFF

Time after key-off 5 or 7 or 9.5 hours

EVAP pressure sensor malfunction (P0450, P0452,

P0453)Not detected

EVAP canister purge valve Not operated by scan tool

EVAP canister vent valve Not operated by scan tool

EVAP leak detection pump Not operated by scan tool

Both of the following conditions 1 and 2 are met before

key-off-

1. Duration that vehicle driven 5 minutes or more

G038299E10

Page 584 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–291

ES

DESCRIPTION

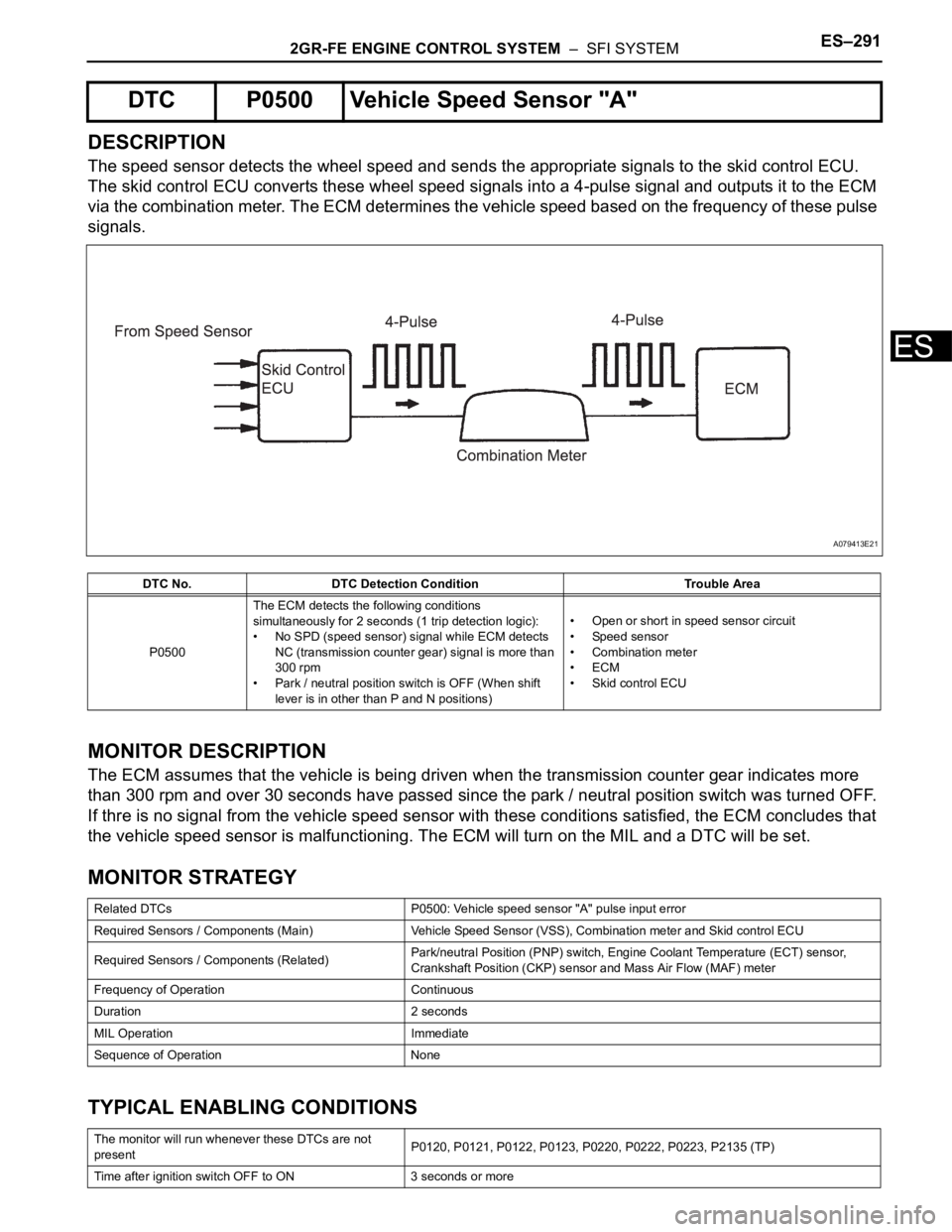

The speed sensor detects the wheel speed and sends the appropriate signals to the skid control ECU.

The skid control ECU converts these wheel speed signals into a 4-pulse signal and outputs it to the ECM

via the combination meter. The ECM determines the vehicle speed based on the frequency of these pulse

signals.

MONITOR DESCRIPTION

The ECM assumes that the vehicle is being driven when the transmission counter gear indicates more

than 300 rpm and over 30 seconds have passed since the park / neutral position switch was turned OFF.

If thre is no signal from the vehicle speed sensor with these conditions satisfied, the ECM concludes that

the vehicle speed sensor is malfunctioning. The ECM will turn on the MIL and a DTC will be set.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

DTC P0500 Vehicle Speed Sensor "A"

DTC No. DTC Detection Condition Trouble Area

P0500The ECM detects the following conditions

simultaneously for 2 seconds (1 trip detection logic):

• No SPD (speed sensor) signal while ECM detects

NC (transmission counter gear) signal is more than

300 rpm

• Park / neutral position switch is OFF (When shift

lever is in other than P and N positions)• Open or short in speed sensor circuit

• Speed sensor

• Combination meter

•ECM

• Skid control ECU

Related DTCs P0500: Vehicle speed sensor "A" pulse input error

Required Sensors / Components (Main) Vehicle Speed Sensor (VSS), Combination meter and Skid control ECU

Required Sensors / Components (Related)Park/neutral Position (PNP) switch, Engine Coolant Temperature (ECT) sensor,

Crankshaft Position (CKP) sensor and Mass Air Flow (MAF) meter

Frequency of Operation Continuous

Duration 2 seconds

MIL Operation Immediate

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentP0120, P0121, P0122, P0123, P0220, P0222, P0223, P2135 (TP)

Time after ignition switch OFF to ON 3 seconds or more

A079413E21

Page 585 of 3000

ES–2922GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

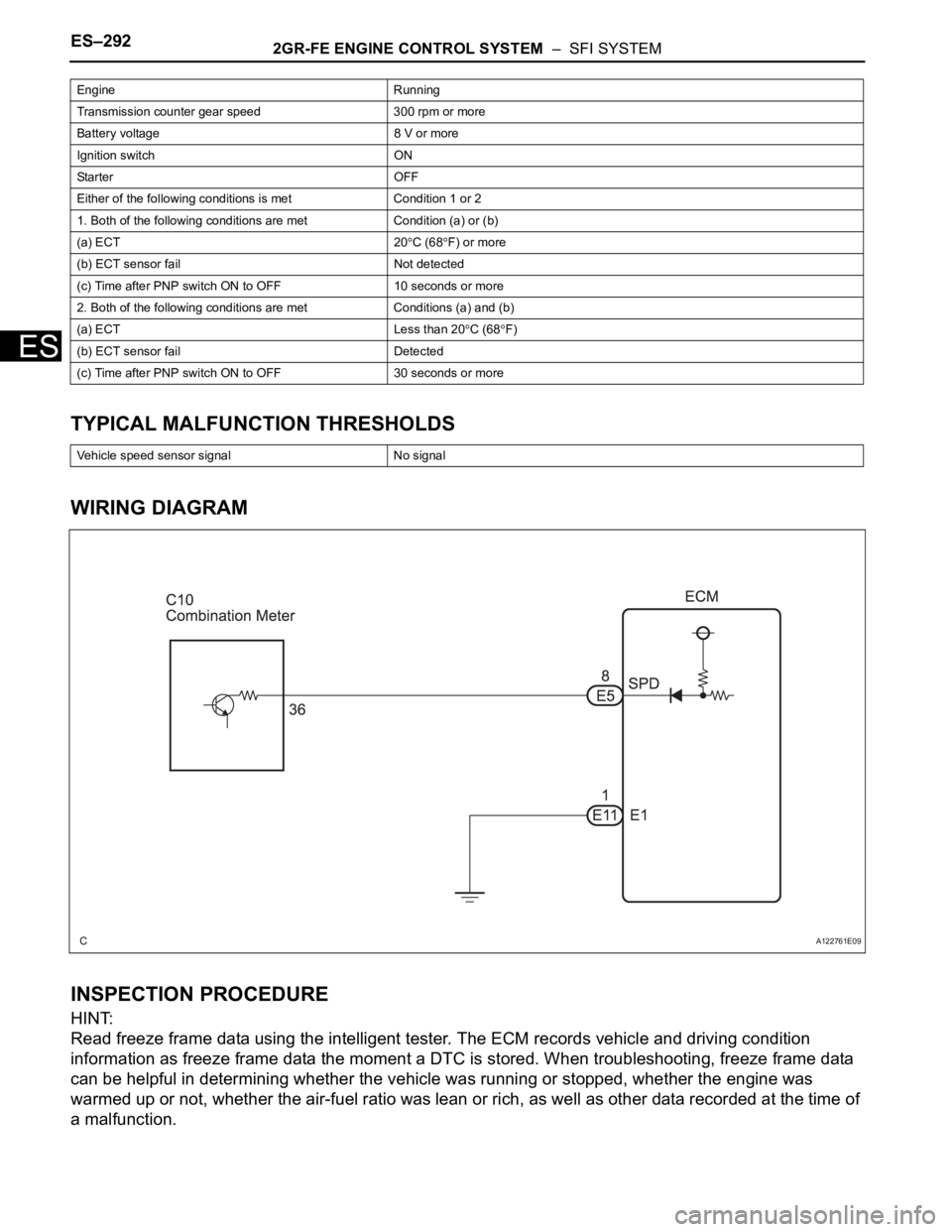

TYPICAL MALFUNCTION THRESHOLDS

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

Engine Running

Transmission counter gear speed 300 rpm or more

Battery voltage 8 V or more

Ignition switch ON

Starter OFF

Either of the following conditions is met Condition 1 or 2

1. Both of the following conditions are met Condition (a) or (b)

(a) ECT 20

C (68F) or more

(b) ECT sensor fail Not detected

(c) Time after PNP switch ON to OFF 10 seconds or more

2. Both of the following conditions are met Conditions (a) and (b)

(a) ECT Less than 20

C (68F)

(b) ECT sensor fail Detected

(c) Time after PNP switch ON to OFF 30 seconds or more

Vehicle speed sensor signal No signal

A122761E09

Page 586 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–293

ES

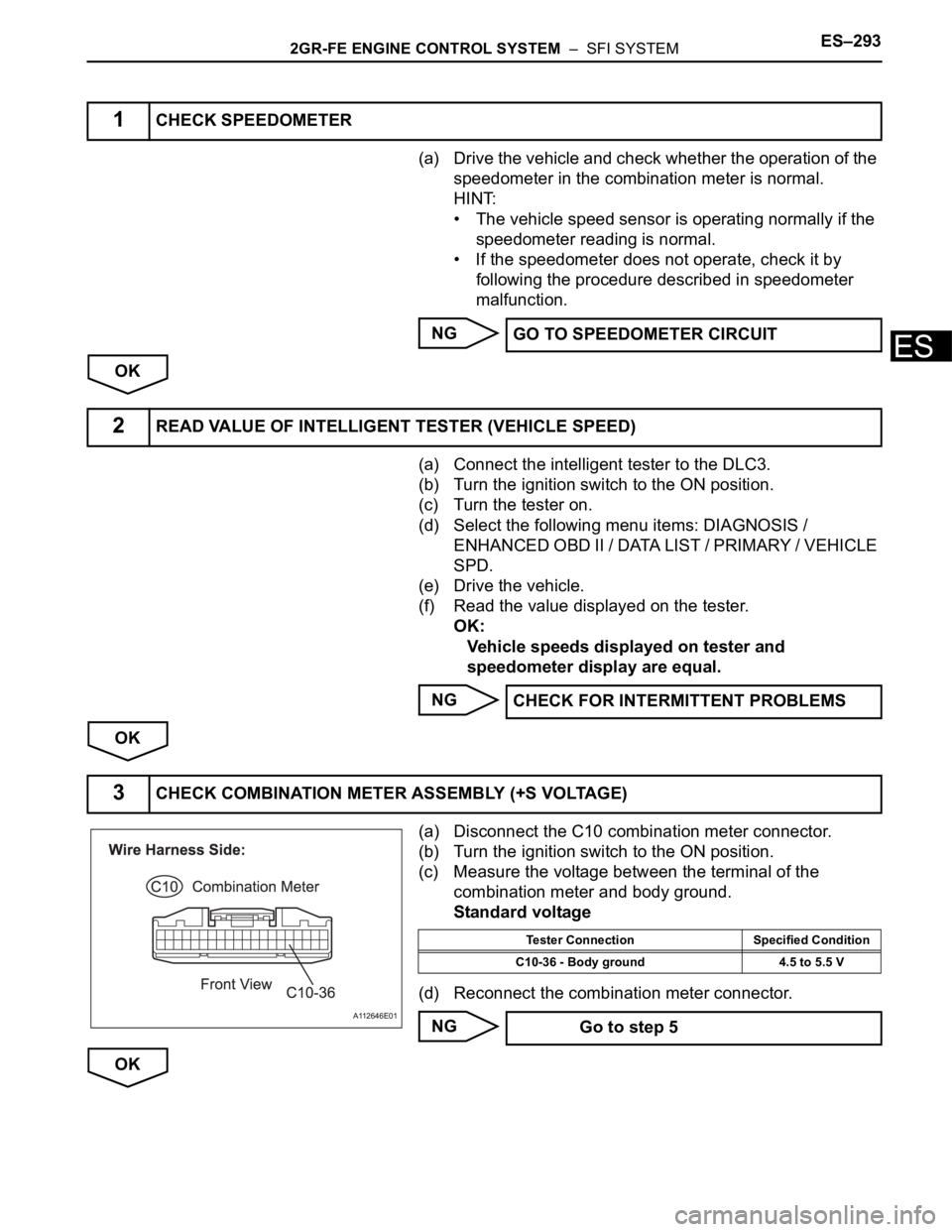

(a) Drive the vehicle and check whether the operation of the

speedometer in the combination meter is normal.

HINT:

• The vehicle speed sensor is operating normally if the

speedometer reading is normal.

• If the speedometer does not operate, check it by

following the procedure described in speedometer

malfunction.

NG

OK

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / PRIMARY / VEHICLE

SPD.

(e) Drive the vehicle.

(f) Read the value displayed on the tester.

OK:

Vehicle speeds displayed on tester and

speedometer display are equal.

NG

OK

(a) Disconnect the C10 combination meter connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage between the terminal of the

combination meter and body ground.

Standard voltage

(d) Reconnect the combination meter connector.

NG

OK

1CHECK SPEEDOMETER

GO TO SPEEDOMETER CIRCUIT

2READ VALUE OF INTELLIGENT TESTER (VEHICLE SPEED)

CHECK FOR INTERMITTENT PROBLEMS

3CHECK COMBINATION METER ASSEMBLY (+S VOLTAGE)

A112646E01

Tester Connection Specified Condition

C10-36 - Body ground 4.5 to 5.5 V

Go to step 5

Page 589 of 3000

ES–2962GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

DESCRIPTION

The stop light switch is a duplex system that transmits two signals: STP and ST1-. These two signals are

used by the ECM to monitor whether or not the brake system is working properly. If the signals, which

indicate the brake pedal is being depressed or released, are detected simultaneously, the ECM interprets

this as a malfunction in the stop light switch and sets the DTC.

HINT:

The normal conditions are as shown in the table below. The signals can be read using the intelligent

tester.

MONITOR DESCRIPTION

This DTC indicates that the stop light switch remains on. When the stop light switch remains ON during

"stop and go" driving, the ECM interprets this as a fault in the stop light switch and the MIL comes on and

the ECM stores the DTC. The vehicle must stop (less than 2 mph (3 km/h)) and go (19 mph (30 km/h) or

more) 5 times for two driving cycles in order to detect a malfunction.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

DTC P0504 Brake Switch "A" / "B" Correlation

DTC P0724 Brake Switch "B" Circuit High

Signals Brake Pedal Released In Transition Brake Pedal Depressed

STP OFF ON ON

ST1- ON ON OFF

DTC No. DTC Detection Condition Trouble Area

P0504Conditions (a), (b) and (c) continue for 0.5 seconds or

more (1 trip detection logic):

(a) Ignition switch in the ON position

(b) Brake pedal released

(c) STP signal OFF when ST1- signal OFF• Short in stop light switch signal circuit

• STOP fuse

• Stop light switch

•ECM

P0724The stop light switch remains ON even when the

vehicle is driven in a STOP (less than 2 mph (3 km/h))

and GO (19 mph (30 km/h) or more) fashion 5 times. (2

trip detection logic)• Short in stop light switch signal circuit

• Stop light switch

•ECM

Related DTCs P0724: Stop light switch/Rationality

Required sensors/Components Stop light switch, Vehicle speed sensor

Frequency of operation Continuous

Duration GO and STOP 5 times

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present None

Ignition switch ON

Starter OFF

Battery voltage 8 V or more

GO (Vehicle speed is 18.65 mph (30 km/h) or more) Once

STOP (Vehicle speed is less than 1.86 mph (3 km/h)) Once

Page 593 of 3000

ES–3002GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

DESCRIPTION

The idling speed is controlled by the ETCS (Electronic Throttle Control System). The ETCS is comprised

of: 1) the one valve type throttle body; 2) the throttle actuator, which operates the throttle valve; 3) the

Throttle Position (TP) sensor, which detects the opening angle of the throttle valve; 4) the Accelerator

Pedal Position (APP) sensor, which detects the accelerator pedal position; and 5) the ECM, which

controls the ETCS.

Based on the target idling speed, the ECM controls the throttle actuator to provide the proper throttle valve

opening angle.

MONITOR DESCRIPTION

The ECM monitors the idling speed and idling air flow volume to conduct Idle Speed Control (ISC). The

ECM determines that the ISC system is malfunctioning if the following conditions are met:

• The learned idling air flow volume remains at the maximum or minimum volume 5 times or more in a

drive cycle.

• While driving at 6 mph (10 km/h) or more, the actual engine idling speed varies from the target idling

speed by between 100 rpm and 200 rpm, 5 times or more in a drive cycle.

DTC P0505 Idle Control System Malfunction

DTC No. DTC Detection Condition Trouble Area

P0505Idling speed continues to vary greatly from target idling

speed (2 trip detection logic)•ETCS

• Intake system

• PCV hose connection

•ECM

Page 594 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–301

ES

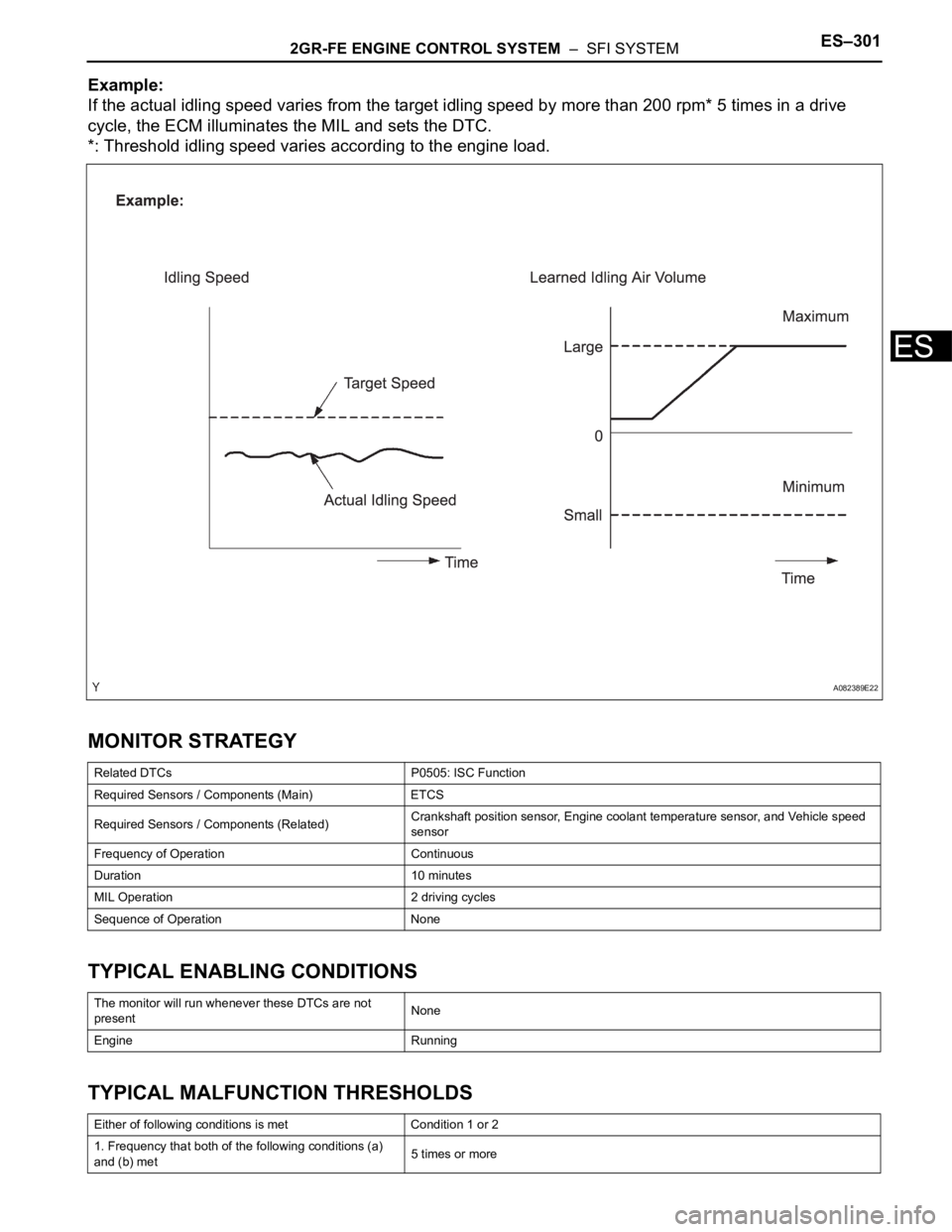

Example:

If the actual idling speed varies from the target idling speed by more than 200 rpm* 5 times in a drive

cycle, the ECM illuminates the MIL and sets the DTC.

*: Threshold idling speed varies according to the engine load.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

Related DTCs P0505: ISC Function

Required Sensors / Components (Main) ETCS

Required Sensors / Components (Related)Crankshaft position sensor, Engine coolant temperature sensor, and Vehicle speed

sensor

Frequency of Operation Continuous

Duration 10 minutes

MIL Operation 2 driving cycles

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Engine Running

Either of following conditions is met Condition 1 or 2

1. Frequency that both of the following conditions (a)

and (b) met5 times or more

A082389E22

Page 598 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–305

ES

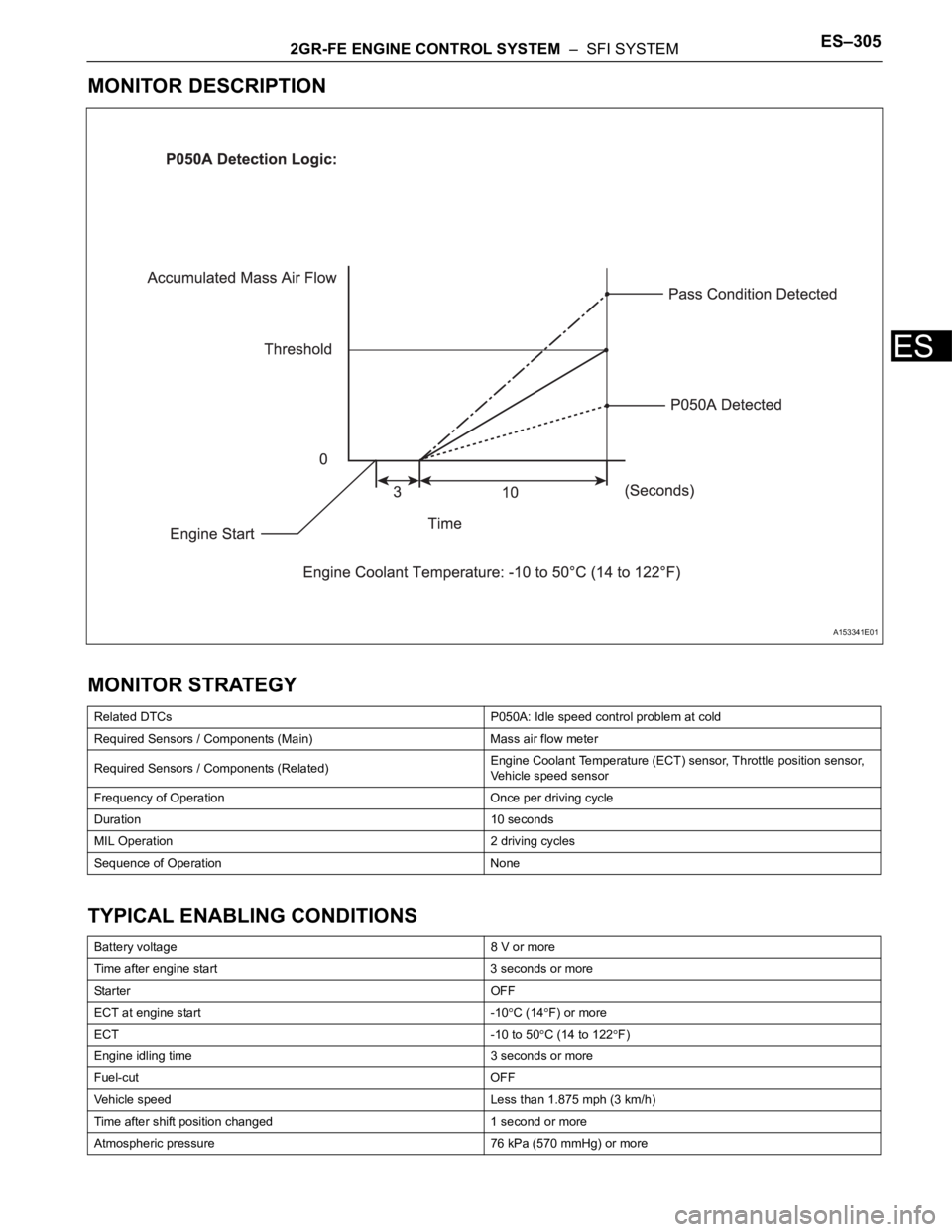

MONITOR DESCRIPTION

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

Related DTCs P050A: Idle speed control problem at cold

Required Sensors / Components (Main) Mass air flow meter

Required Sensors / Components (Related)Engine Coolant Temperature (ECT) sensor, Throttle position sensor,

Vehicle speed sensor

Frequency of Operation Once per driving cycle

Duration 10 seconds

MIL Operation 2 driving cycles

Sequence of Operation None

Battery voltage 8 V or more

Time after engine start 3 seconds or more

Sta r t e r OF F

ECT at engine start -10

C (14F) or more

ECT -10 to 50

C (14 to 122F)

Engine idling time 3 seconds or more

Fuel-cut OFF

Vehicle speed Less than 1.875 mph (3 km/h)

Time after shift position changed 1 second or more

Atmospheric pressure 76 kPa (570 mmHg) or more

A153341E01

Page 604 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–311

ES

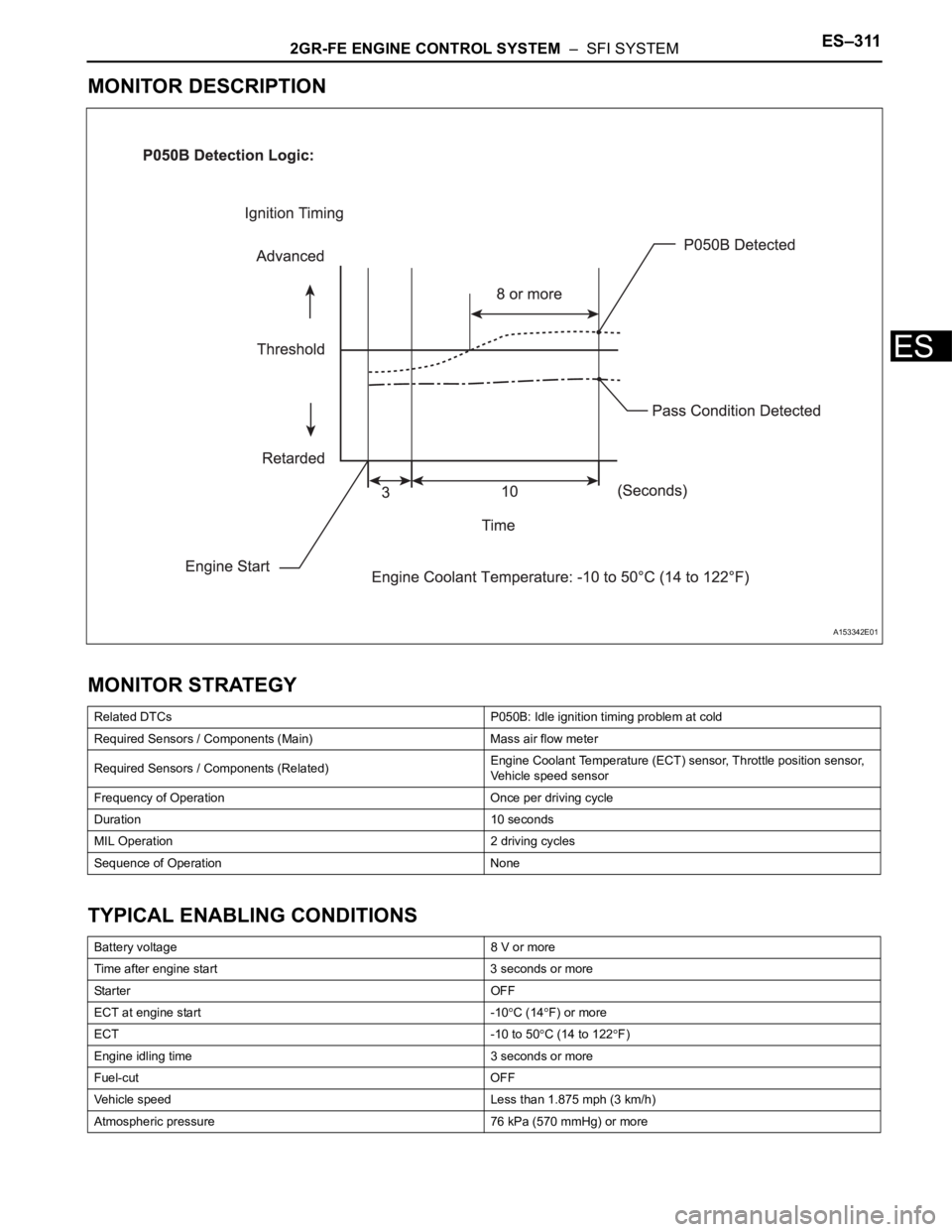

MONITOR DESCRIPTION

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

Related DTCs P050B: Idle ignition timing problem at cold

Required Sensors / Components (Main) Mass air flow meter

Required Sensors / Components (Related)Engine Coolant Temperature (ECT) sensor, Throttle position sensor,

Vehicle speed sensor

Frequency of Operation Once per driving cycle

Duration 10 seconds

MIL Operation 2 driving cycles

Sequence of Operation None

Battery voltage 8 V or more

Time after engine start 3 seconds or more

Sta r t e r OF F

ECT at engine start -10

C (14F) or more

ECT -10 to 50

C (14 to 122F)

Engine idling time 3 seconds or more

Fuel-cut OFF

Vehicle speed Less than 1.875 mph (3 km/h)

Atmospheric pressure 76 kPa (570 mmHg) or more

A153342E01

Page 607 of 3000

ES–3142GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

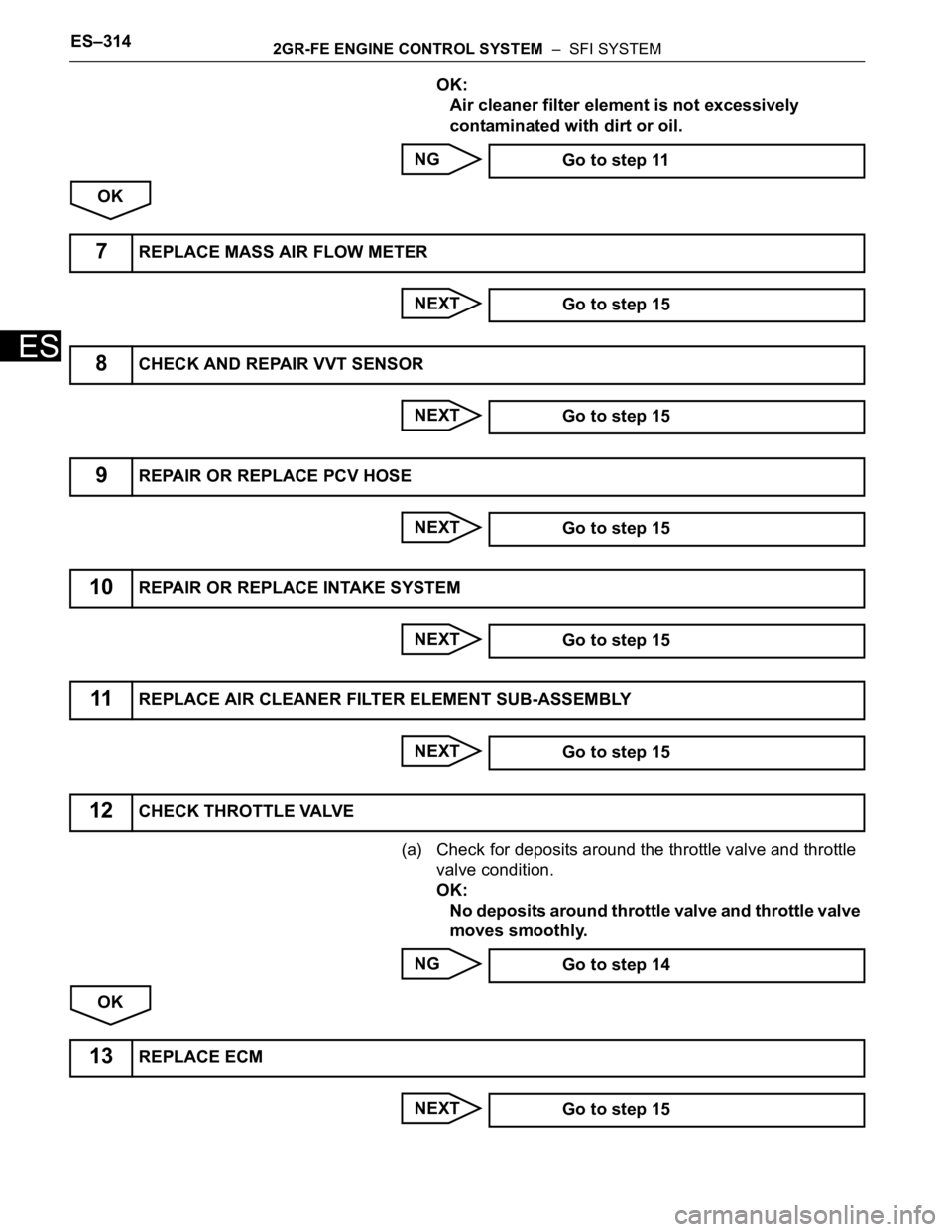

OK:

Air cleaner filter element is not excessively

contaminated with dirt or oil.

NG

OK

NEXT

NEXT

NEXT

NEXT

NEXT

(a) Check for deposits around the throttle valve and throttle

valve condition.

OK:

No deposits around throttle valve and throttle valve

moves smoothly.

NG

OK

NEXT Go to step 11

7REPLACE MASS AIR FLOW METER

Go to step 15

8CHECK AND REPAIR VVT SENSOR

Go to step 15

9REPAIR OR REPLACE PCV HOSE

Go to step 15

10REPAIR OR REPLACE INTAKE SYSTEM

Go to step 15

11REPLACE AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

Go to step 15

12CHECK THROTTLE VALVE

Go to step 14

13REPLACE ECM

Go to step 15