sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1735 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–63

AX

DESCRIPTION

The purpose of this circuit is to prevent the engine from stalling while driving in lock-up condition when

brakes are suddenly applied.

When the brake pedal is depressed, this switch sends a signals to the ECM. Then the ECM cancels the

operation of the lock-up clutch while braking is in progress.

MONITOR DESCRIPTION

This DTC indicates that the stop light switch remains on. When the stop light switch remains ON during

"stop and go" driving, the ECM interprets this as a fault in the stop light switch and the MIL comes on and

the ECM stores the DTC. The vehicle must stop (less than 3 km/h (2 mph)) and go (30 km/h (19 mph) or

more) 5 times for two driving cycles in order to detect a malfunction.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

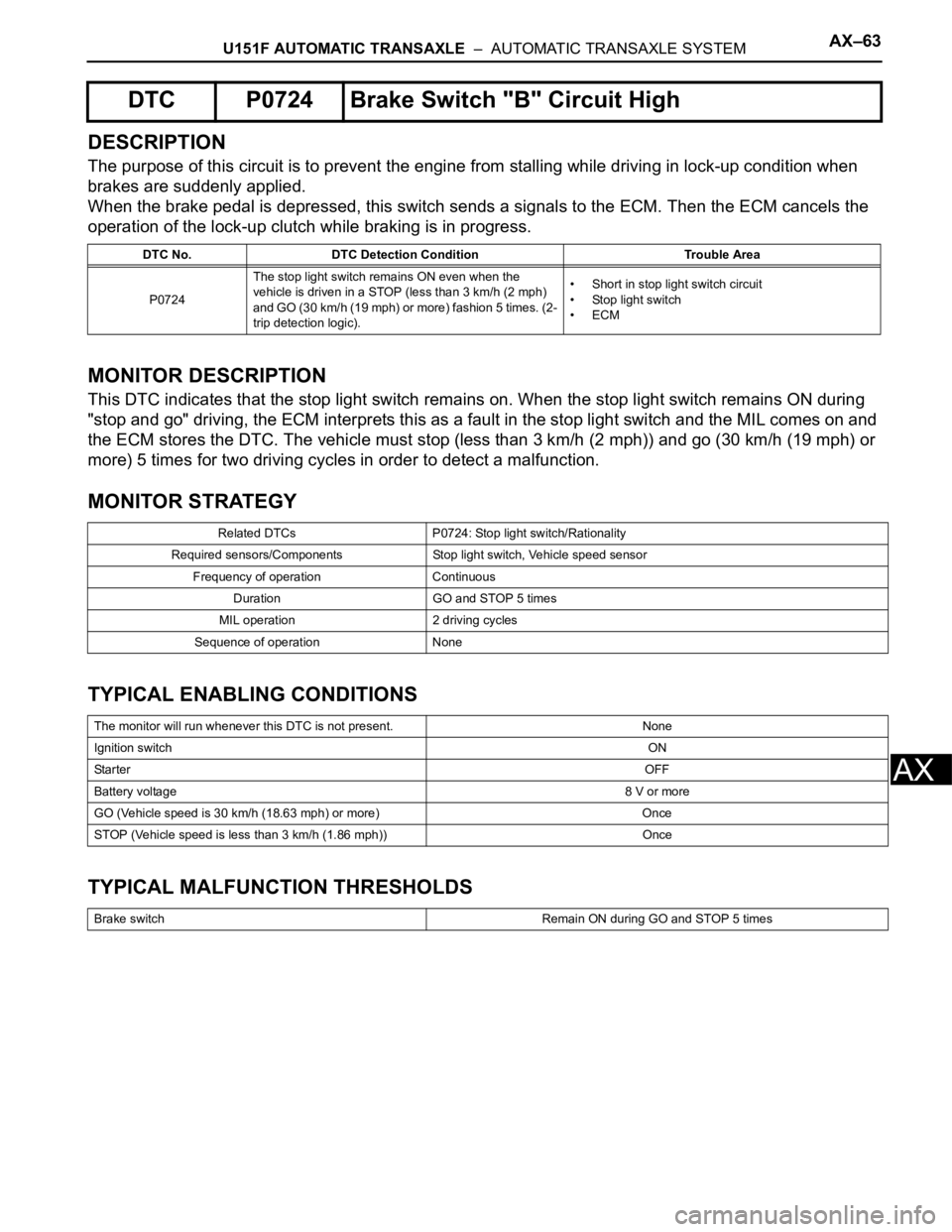

DTC P0724 Brake Switch "B" Circuit High

DTC No. DTC Detection Condition Trouble Area

P0724The stop light switch remains ON even when the

vehicle is driven in a STOP (less than 3 km/h (2 mph)

and GO (30 km/h (19 mph) or more) fashion 5 times. (2-

trip detection logic).• Short in stop light switch circuit

• Stop light switch

•ECM

Related DTCs P0724: Stop light switch/Rationality

Required sensors/Components Stop light switch, Vehicle speed sensor

Frequency of operation Continuous

Duration GO and STOP 5 times

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present. None

Ignition switchON

Sta r t e rOFF

Battery voltage8 V or more

GO (Vehicle speed is 30 km/h (18.63 mph) or more) Once

STOP (Vehicle speed is less than 3 km/h (1.86 mph)) Once

Brake switch Remain ON during GO and STOP 5 times

Page 1736 of 3000

AX–64U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

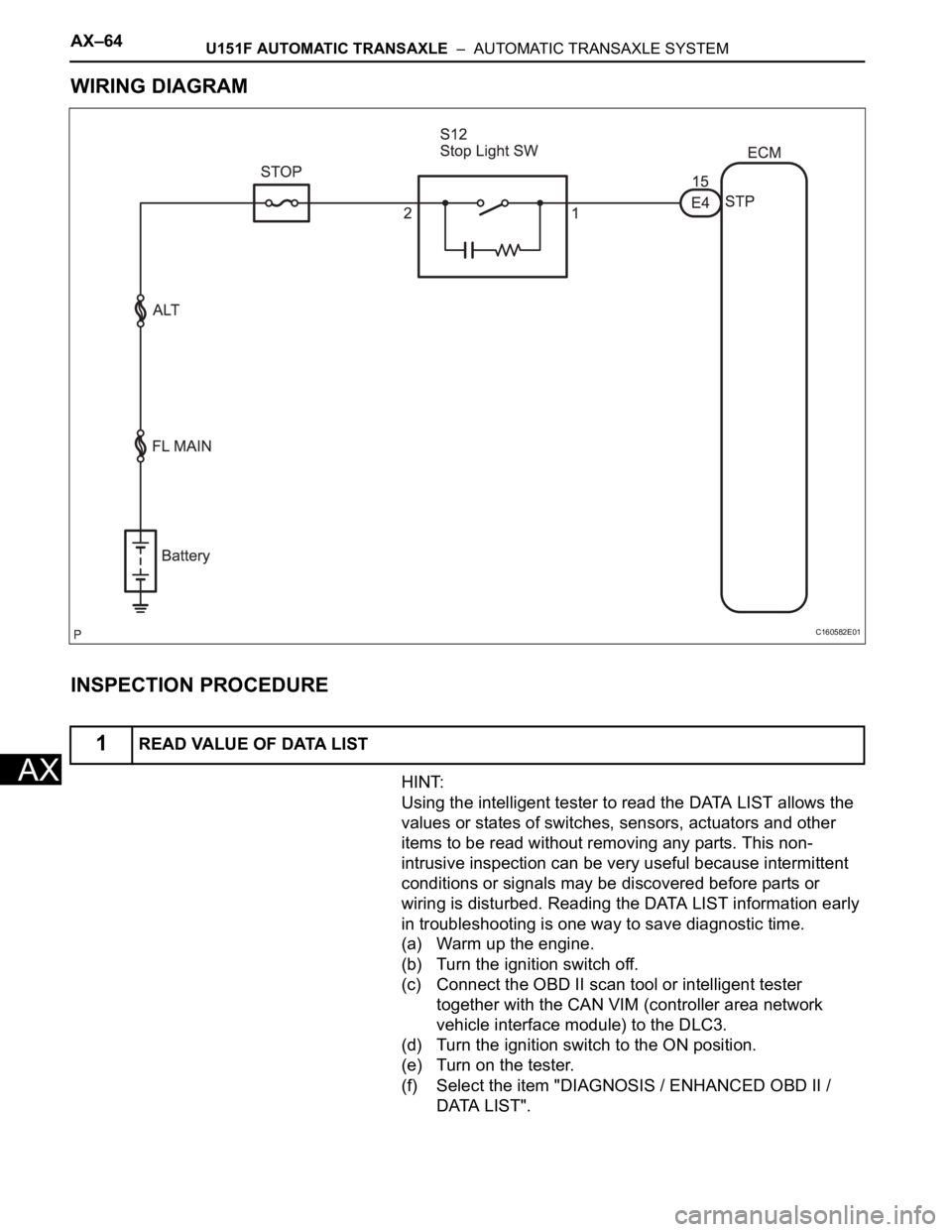

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Using the intelligent tester to read the DATA LIST allows the

values or states of switches, sensors, actuators and other

items to be read without removing any parts. This non-

intrusive inspection can be very useful because intermittent

conditions or signals may be discovered before parts or

wiring is disturbed. Reading the DATA LIST information early

in troubleshooting is one way to save diagnostic time.

(a) Warm up the engine.

(b) Turn the ignition switch off.

(c) Connect the OBD II scan tool or intelligent tester

together with the CAN VIM (controller area network

vehicle interface module) to the DLC3.

(d) Turn the ignition switch to the ON position.

(e) Turn on the tester.

(f) Select the item "DIAGNOSIS / ENHANCED OBD II /

DATA LIST".

1READ VALUE OF DATA LIST

C160582E01

Page 1739 of 3000

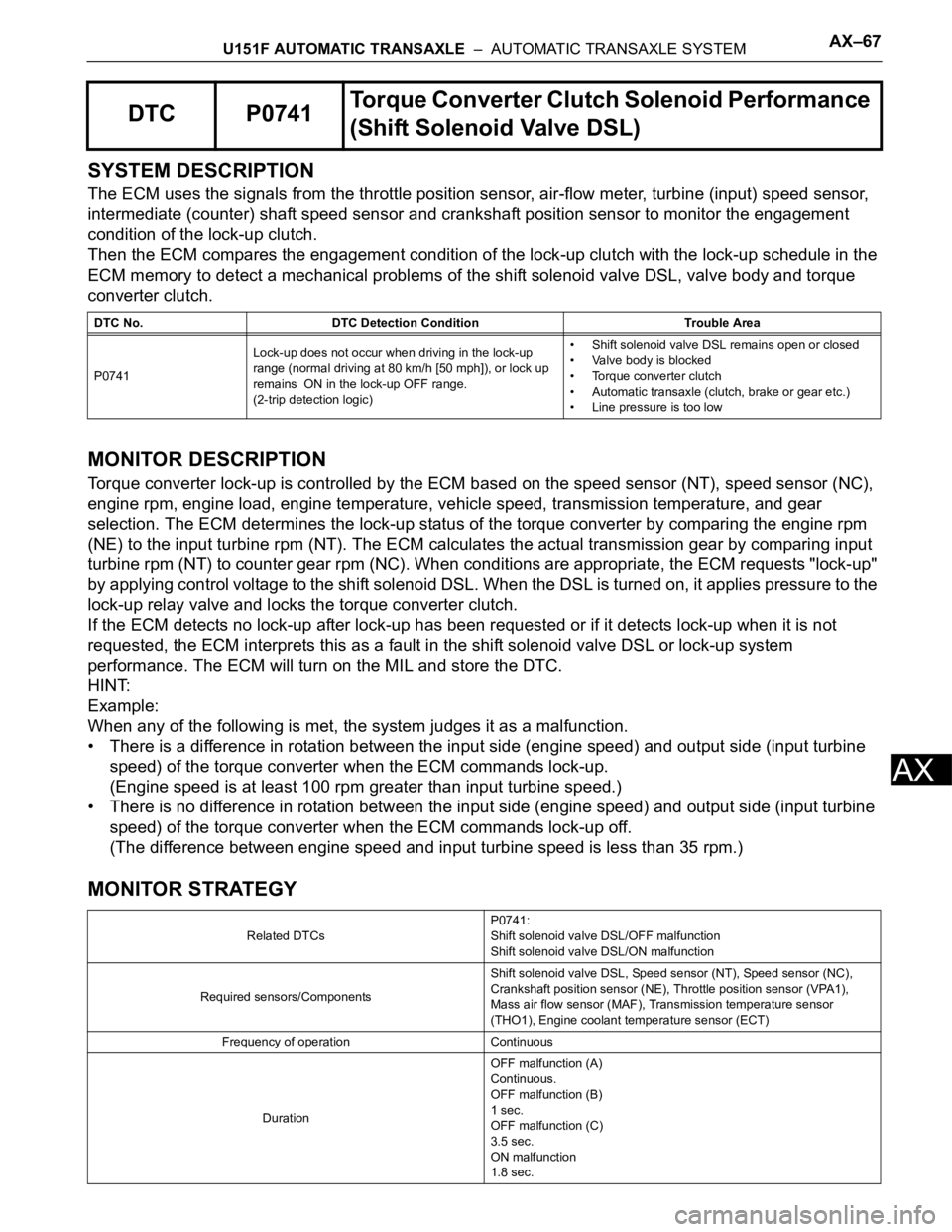

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–67

AX

SYSTEM DESCRIPTION

The ECM uses the signals from the throttle position sensor, air-flow meter, turbine (input) speed sensor,

intermediate (counter) shaft speed sensor and crankshaft position sensor to monitor the engagement

condition of the lock-up clutch.

Then the ECM compares the engagement condition of the lock-up clutch with the lock-up schedule in the

ECM memory to detect a mechanical problems of the shift solenoid valve DSL, valve body and torque

converter clutch.

MONITOR DESCRIPTION

Torque converter lock-up is controlled by the ECM based on the speed sensor (NT), speed sensor (NC),

engine rpm, engine load, engine temperature, vehicle speed, transmission temperature, and gear

selection. The ECM determines the lock-up status of the torque converter by comparing the engine rpm

(NE) to the input turbine rpm (NT). The ECM calculates the actual transmission gear by comparing input

turbine rpm (NT) to counter gear rpm (NC). When conditions are appropriate, the ECM requests "lock-up"

by applying control voltage to the shift solenoid DSL. When the DSL is turned on, it applies pressure to the

lock-up relay valve and locks the torque converter clutch.

If the ECM detects no lock-up after lock-up has been requested or if it detects lock-up when it is not

requested, the ECM interprets this as a fault in the shift solenoid valve DSL or lock-up system

performance. The ECM will turn on the MIL and store the DTC.

HINT:

Example:

When any of the following is met, the system judges it as a malfunction.

• There is a difference in rotation between the input side (engine speed) and output side (input turbine

speed) of the torque converter when the ECM commands lock-up.

(Engine speed is at least 100 rpm greater than input turbine speed.)

• There is no difference in rotation between the input side (engine speed) and output side (input turbine

speed) of the torque converter when the ECM commands lock-up off.

(The difference between engine speed and input turbine speed is less than 35 rpm.)

MONITOR STRATEGY

DTC P0741Torque Converter Clutch Solenoid Performance

(Shift Solenoid Valve DSL)

DTC No. DTC Detection Condition Trouble Area

P0741Lock-up does not occur when driving in the lock-up

range (normal driving at 80 km/h [50 mph]), or lock up

remains ON in the lock-up OFF range.

(2-trip detection logic)• Shift solenoid valve DSL remains open or closed

• Valve body is blocked

• Torque converter clutch

• Automatic transaxle (clutch, brake or gear etc.)

• Line pressure is too low

Related DTCsP0741:

Shift solenoid valve DSL/OFF malfunction

Shift solenoid valve DSL/ON malfunction

Required sensors/ComponentsShift solenoid valve DSL, Speed sensor (NT), Speed sensor (NC),

Crankshaft position sensor (NE), Throttle position sensor (VPA1),

Mass air flow sensor (MAF), Transmission temperature sensor

(THO1), Engine coolant temperature sensor (ECT)

Frequency of operation Continuous

DurationOFF malfunction (A)

Continuous.

OFF malfunction (B)

1 sec.

OFF malfunction (C)

3.5 sec.

ON malfunction

1.8 sec.

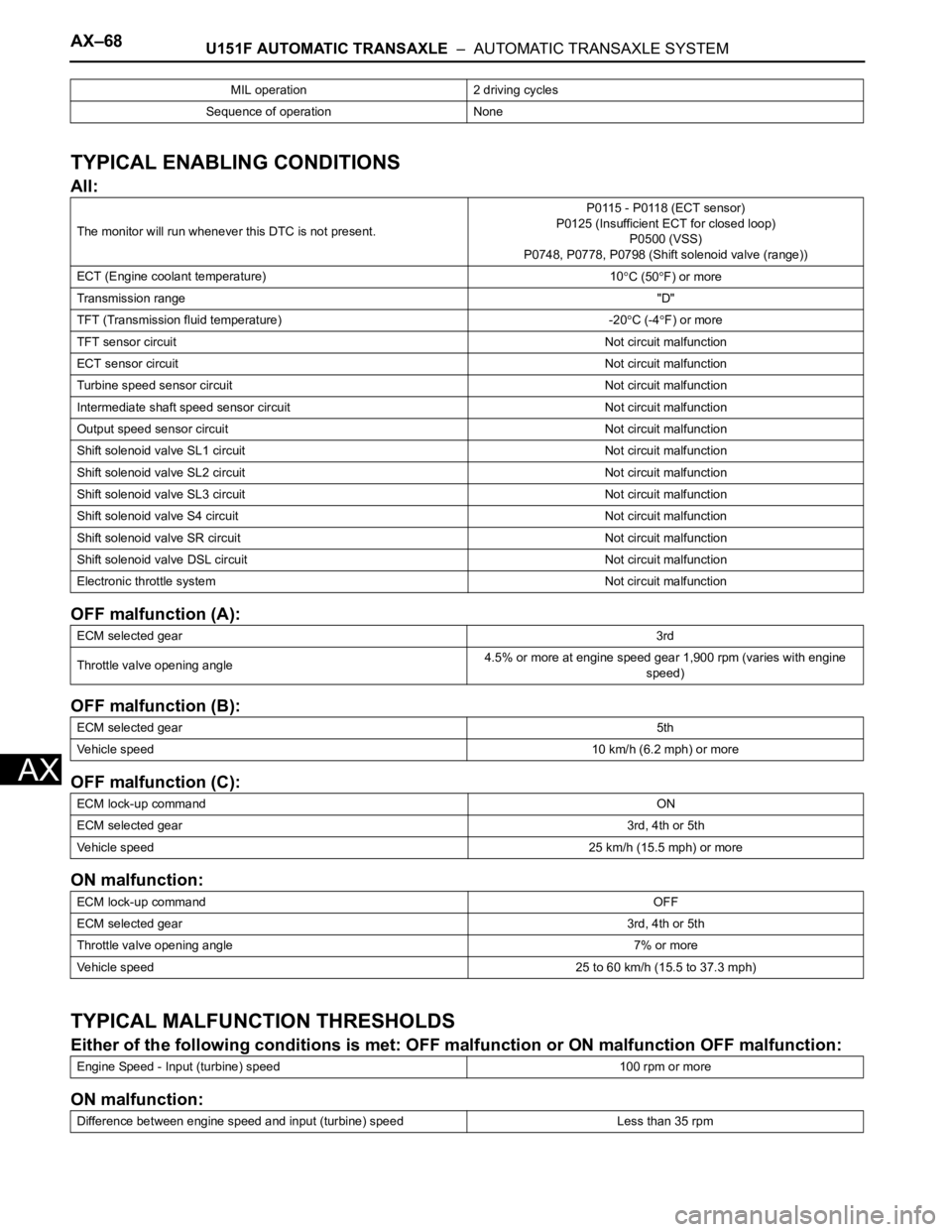

Page 1740 of 3000

AX–68U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

TYPICAL ENABLING CONDITIONS

All:

OFF malfunction (A):

OFF malfunction (B):

OFF malfunction (C):

ON malfunction:

TYPICAL MALFUNCTION THRESHOLDS

Either of the following conditions is met: OFF malfunction or ON malfunction OFF malfunction:

ON malfunction:

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present.P0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Shift solenoid valve SL3 circuit Not circuit malfunction

Shift solenoid valve S4 circuit Not circuit malfunction

Shift solenoid valve SR circuit Not circuit malfunction

Shift solenoid valve DSL circuit Not circuit malfunction

Electronic throttle systemNot circuit malfunction

ECM selected gear3rd

Throttle valve opening angle4.5% or more at engine speed gear 1,900 rpm (varies with engine

speed)

ECM selected gear5th

Vehicle speed10 km/h (6.2 mph) or more

ECM lock-up commandON

ECM selected gear3rd, 4th or 5th

Vehicle speed25 km/h (15.5 mph) or more

ECM lock-up commandOFF

ECM selected gear3rd, 4th or 5th

Throttle valve opening angle7% or more

Vehicle speed25 to 60 km/h (15.5 to 37.3 mph)

Engine Speed - Input (turbine) speed 100 rpm or more

Difference between engine speed and input (turbine) speed Less than 35 rpm

Page 1745 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–73

AX

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical

problems of the shift solenoid valves, valve body or automatic transaxle (clutch, brake or gear etc.).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input

shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the

actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the

ECM and the actual gear position are not the same, the ECM illuminates the MIL.

HINT:

Example:

When either condition (a) or (b) is met, the ECM detects a malfunction.

(a) The ECM commands the 1st gear, but the actual gear is 2nd.

(b) The ECM commands the 2nd gear, but the actual gear is 1st.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

ALL:

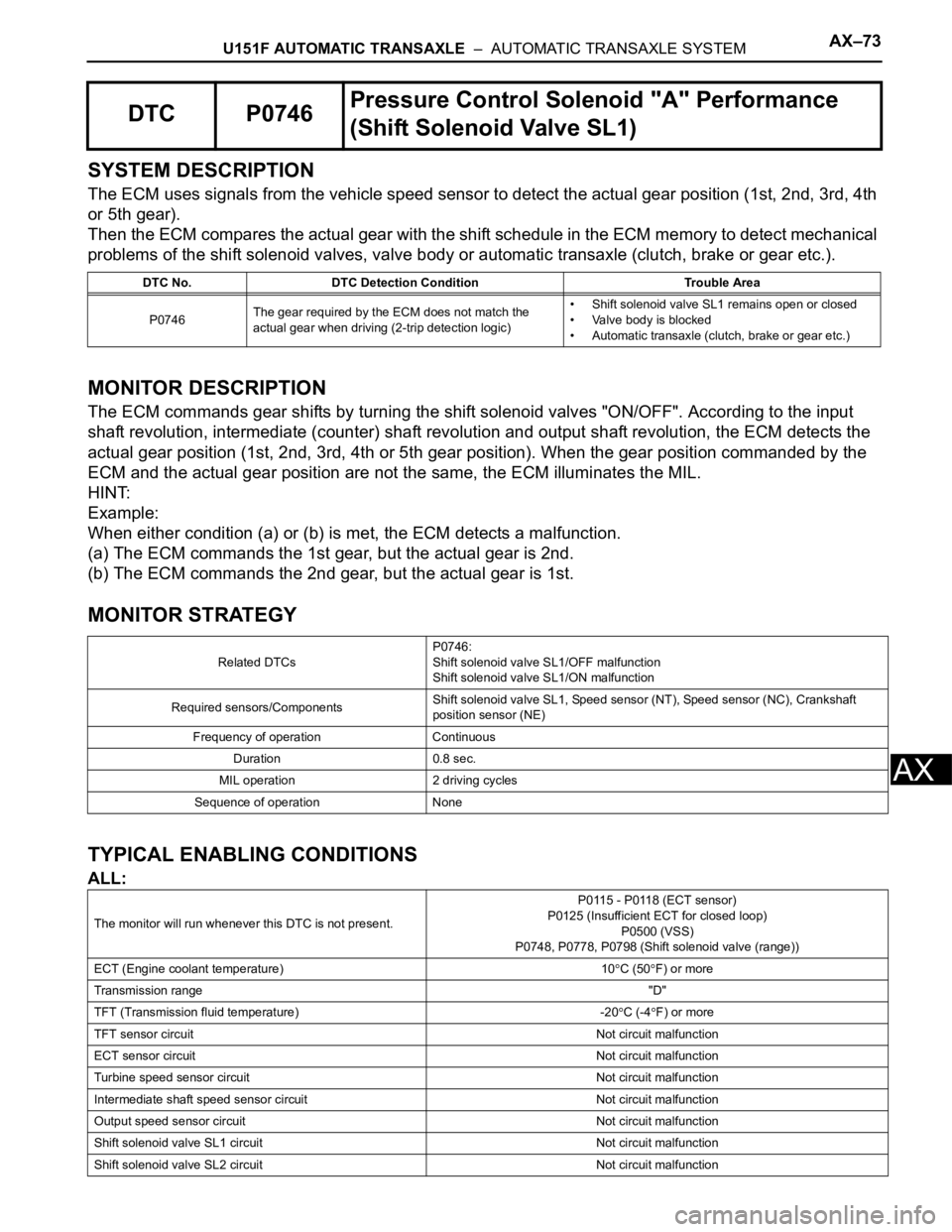

DTC P0746Pressure Control Solenoid "A" Performance

(Shift Solenoid Valve SL1)

DTC No. DTC Detection Condition Trouble Area

P0746The gear required by the ECM does not match the

actual gear when driving (2-trip detection logic)• Shift solenoid valve SL1 remains open or closed

• Valve body is blocked

• Automatic transaxle (clutch, brake or gear etc.)

Related DTCsP0746:

Shift solenoid valve SL1/OFF malfunction

Shift solenoid valve SL1/ON malfunction

Required sensors/ComponentsShift solenoid valve SL1, Speed sensor (NT), Speed sensor (NC), Crankshaft

position sensor (NE)

Frequency of operation Continuous

Duration 0.8 sec.

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present.P0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Page 1749 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–77

AX

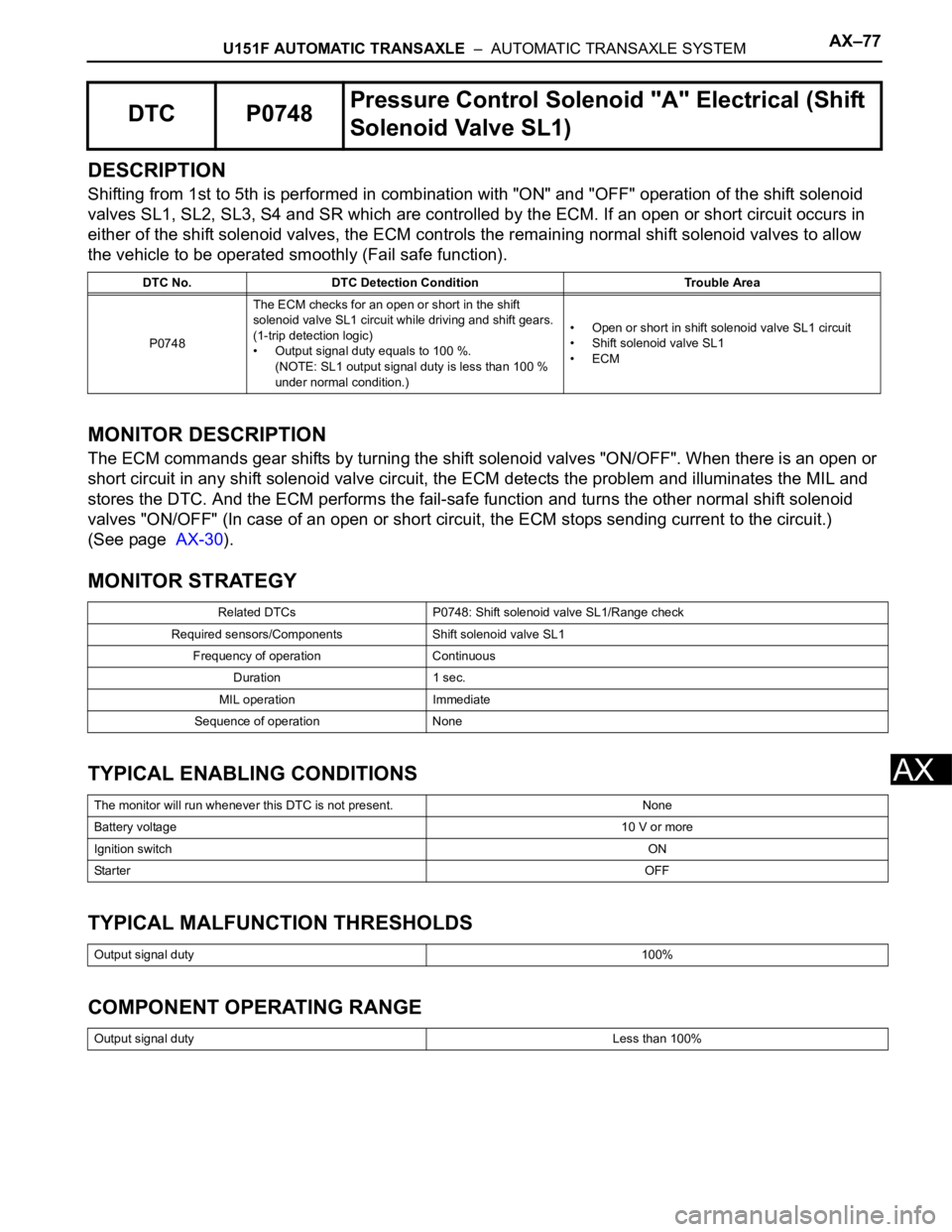

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF" operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or short circuit occurs in

either of the shift solenoid valves, the ECM controls the remaining normal shift solenoid valves to allow

the vehicle to be operated smoothly (Fail safe function).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". When there is an open or

short circuit in any shift solenoid valve circuit, the ECM detects the problem and illuminates the MIL and

stores the DTC. And the ECM performs the fail-safe function and turns the other normal shift solenoid

valves "ON/OFF" (In case of an open or short circuit, the ECM stops sending current to the circuit.)

(See page AX-30).

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

DTC P0748Pressure Control Solenoid "A" Electrical (Shift

Solenoid Valve SL1)

DTC No. DTC Detection Condition Trouble Area

P0748The ECM checks for an open or short in the shift

solenoid valve SL1 circuit while driving and shift gears.

(1-trip detection logic)

• Output signal duty equals to 100 %.

(NOTE: SL1 output signal duty is less than 100 %

under normal condition.)• Open or short in shift solenoid valve SL1 circuit

• Shift solenoid valve SL1

•ECM

Related DTCs P0748: Shift solenoid valve SL1/Range check

Required sensors/Components Shift solenoid valve SL1

Frequency of operation Continuous

Duration 1 sec.

MIL operation Immediate

Sequence of operation None

The monitor will run whenever this DTC is not present. None

Battery voltage10 V or more

Ignition switchON

Sta r t e rOFF

Output signal duty100%

Output signal dutyLess than 100%

Page 1753 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–81

AX

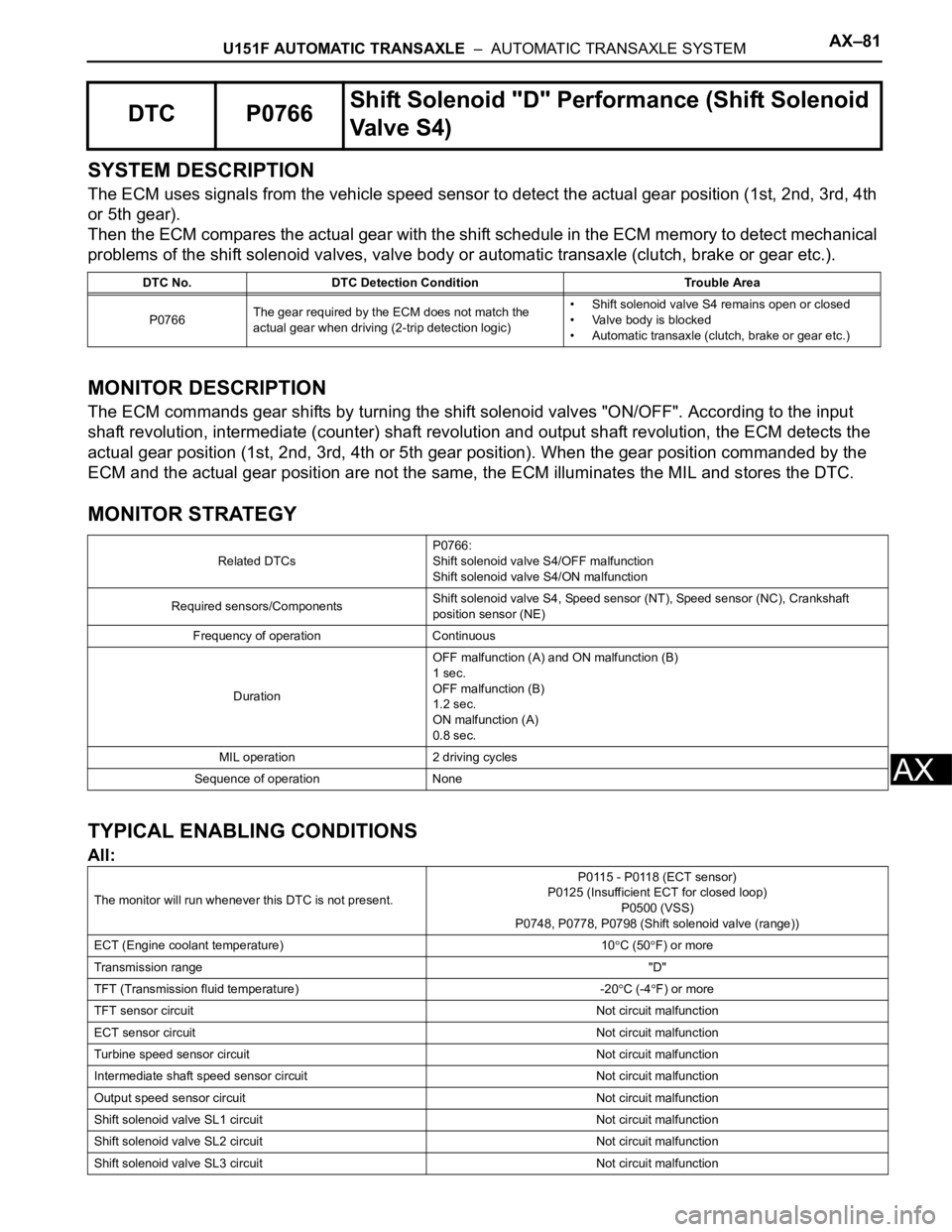

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical

problems of the shift solenoid valves, valve body or automatic transaxle (clutch, brake or gear etc.).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input

shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the

actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the

ECM and the actual gear position are not the same, the ECM illuminates the MIL and stores the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

DTC P0766Shift Solenoid "D" Performance (Shift Solenoid

Valve S4)

DTC No. DTC Detection Condition Trouble Area

P0766The gear required by the ECM does not match the

actual gear when driving (2-trip detection logic)• Shift solenoid valve S4 remains open or closed

• Valve body is blocked

• Automatic transaxle (clutch, brake or gear etc.)

Related DTCsP0766:

Shift solenoid valve S4/OFF malfunction

Shift solenoid valve S4/ON malfunction

Required sensors/ComponentsShift solenoid valve S4, Speed sensor (NT), Speed sensor (NC), Crankshaft

position sensor (NE)

Frequency of operation Continuous

DurationOFF malfunction (A) and ON malfunction (B)

1 sec.

OFF malfunction (B)

1.2 sec.

ON malfunction (A)

0.8 sec.

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present.P0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Shift solenoid valve SL3 circuit Not circuit malfunction

Page 1757 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–85

AX

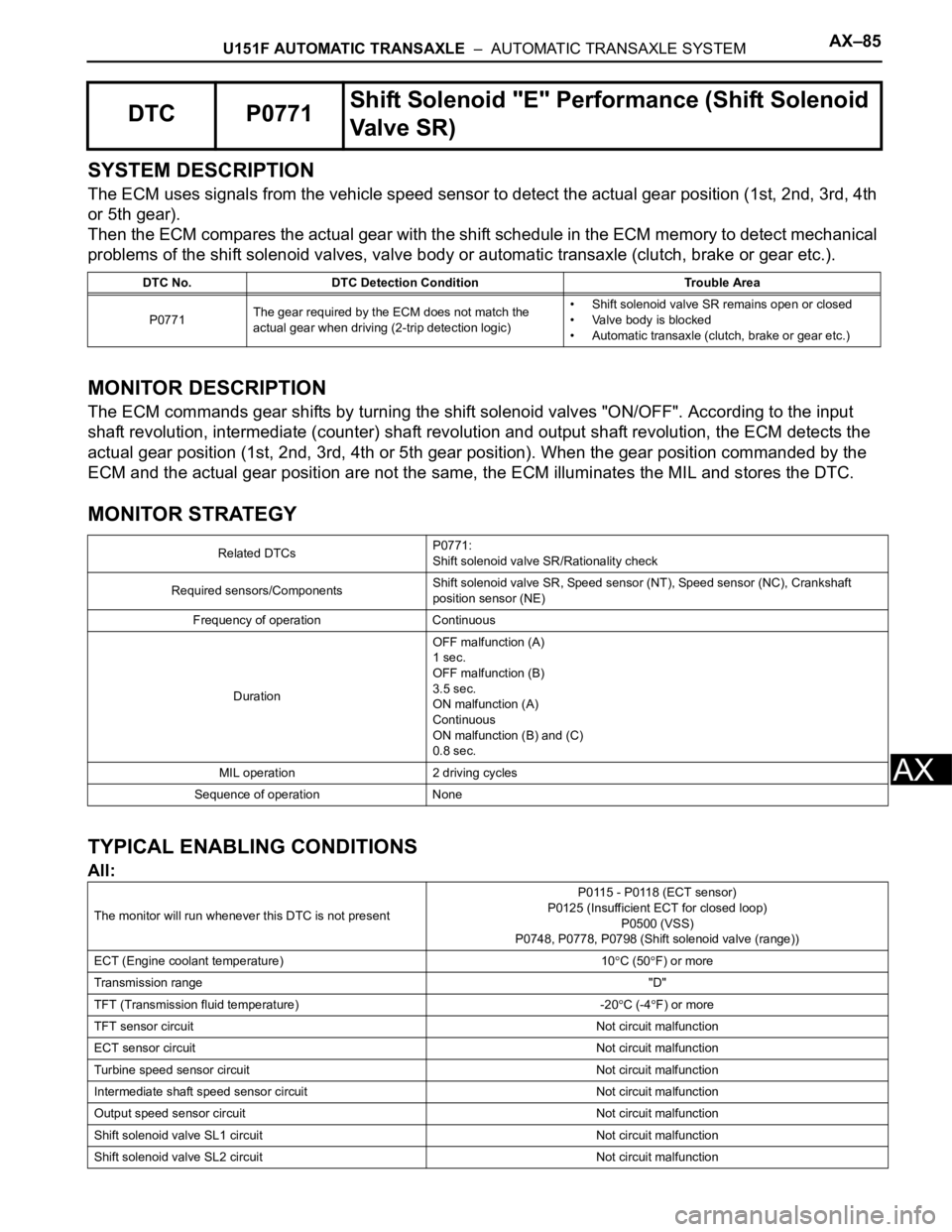

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical

problems of the shift solenoid valves, valve body or automatic transaxle (clutch, brake or gear etc.).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input

shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the

actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the

ECM and the actual gear position are not the same, the ECM illuminates the MIL and stores the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

DTC P0771Shift Solenoid "E" Performance (Shift Solenoid

Va l v e S R )

DTC No. DTC Detection Condition Trouble Area

P0771The gear required by the ECM does not match the

actual gear when driving (2-trip detection logic)• Shift solenoid valve SR remains open or closed

• Valve body is blocked

• Automatic transaxle (clutch, brake or gear etc.)

Related DTCsP0771:

Shift solenoid valve SR/Rationality check

Required sensors/ComponentsShift solenoid valve SR, Speed sensor (NT), Speed sensor (NC), Crankshaft

position sensor (NE)

Frequency of operation Continuous

DurationOFF malfunction (A)

1 sec.

OFF malfunction (B)

3.5 sec.

ON malfunction (A)

Continuous

ON malfunction (B) and (C)

0.8 sec.

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not presentP0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Page 1761 of 3000

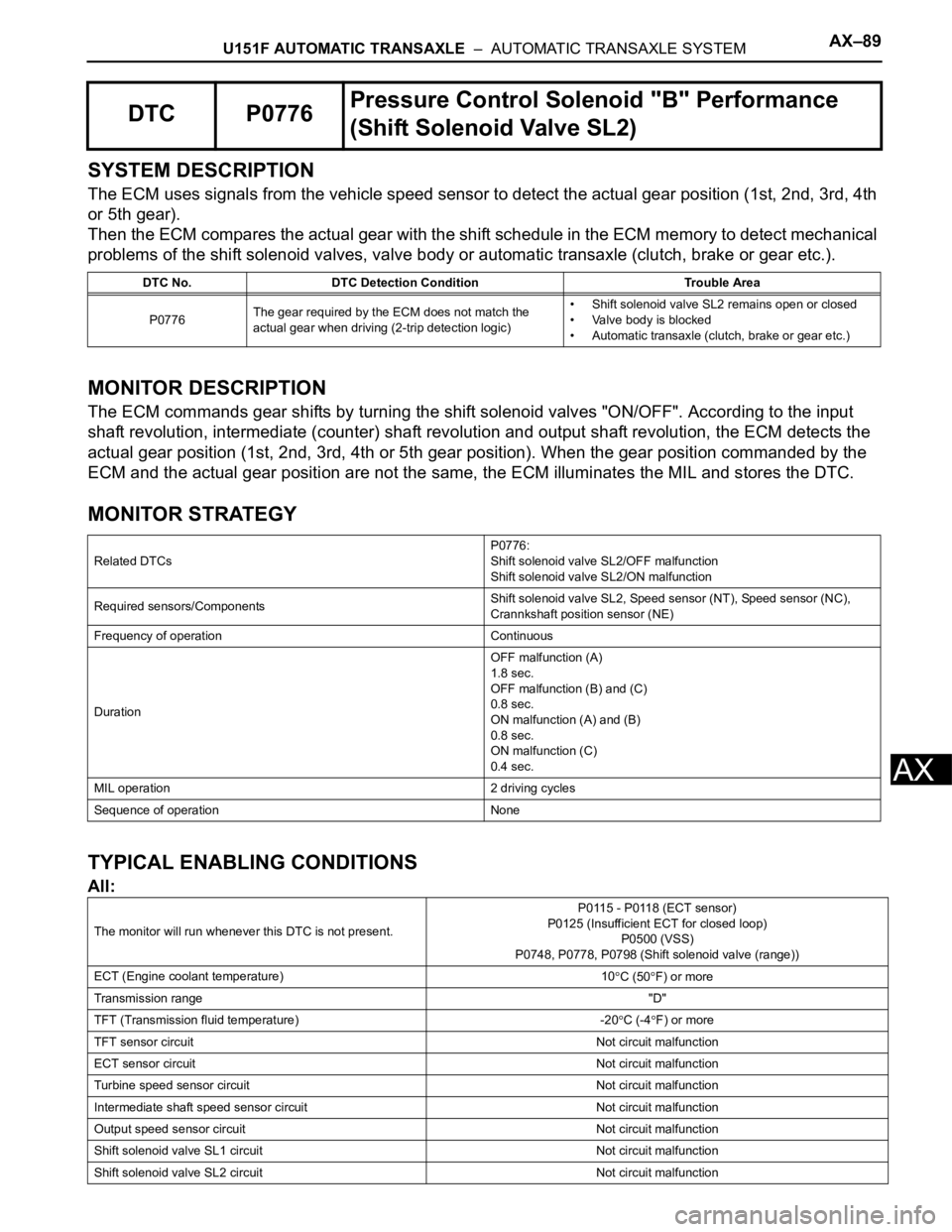

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–89

AX

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical

problems of the shift solenoid valves, valve body or automatic transaxle (clutch, brake or gear etc.).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input

shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the

actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the

ECM and the actual gear position are not the same, the ECM illuminates the MIL and stores the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

DTC P0776Pressure Control Solenoid "B" Performance

(Shift Solenoid Valve SL2)

DTC No. DTC Detection Condition Trouble Area

P0776The gear required by the ECM does not match the

actual gear when driving (2-trip detection logic)• Shift solenoid valve SL2 remains open or closed

• Valve body is blocked

• Automatic transaxle (clutch, brake or gear etc.)

Related DTCsP0776:

Shift solenoid valve SL2/OFF malfunction

Shift solenoid valve SL2/ON malfunction

Required sensors/ComponentsShift solenoid valve SL2, Speed sensor (NT), Speed sensor (NC),

Crannkshaft position sensor (NE)

Frequency of operation Continuous

DurationOFF malfunction (A)

1.8 sec.

OFF malfunction (B) and (C)

0.8 sec.

ON malfunction (A) and (B)

0.8 sec.

ON malfunction (C)

0.4 sec.

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present.P0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Page 1766 of 3000

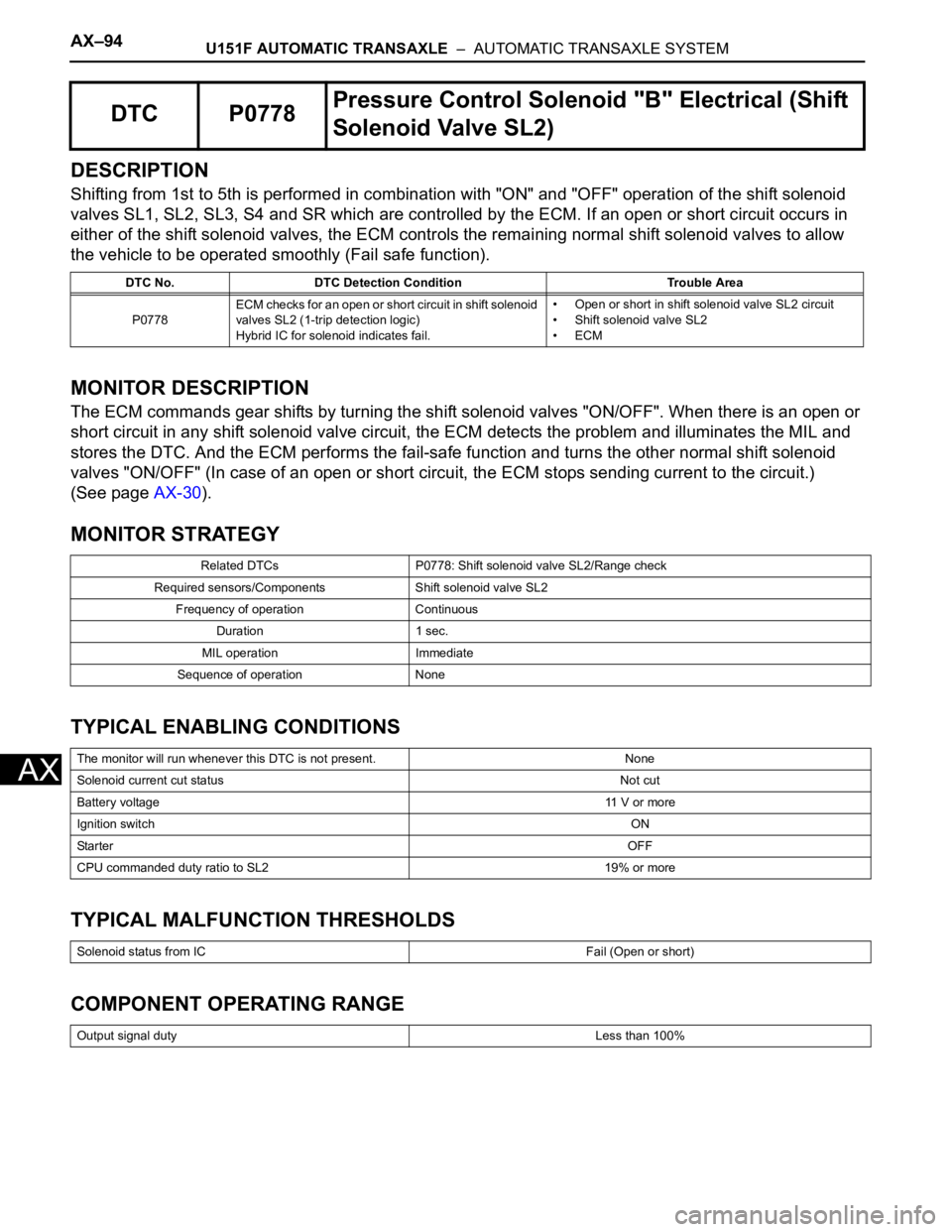

AX–94U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF" operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or short circuit occurs in

either of the shift solenoid valves, the ECM controls the remaining normal shift solenoid valves to allow

the vehicle to be operated smoothly (Fail safe function).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". When there is an open or

short circuit in any shift solenoid valve circuit, the ECM detects the problem and illuminates the MIL and

stores the DTC. And the ECM performs the fail-safe function and turns the other normal shift solenoid

valves "ON/OFF" (In case of an open or short circuit, the ECM stops sending current to the circuit.)

(See page AX-30).

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

DTC P0778Pressure Control Solenoid "B" Electrical (Shift

Solenoid Valve SL2)

DTC No. DTC Detection Condition Trouble Area

P0778ECM checks for an open or short circuit in shift solenoid

valves SL2 (1-trip detection logic)

Hybrid IC for solenoid indicates fail.• Open or short in shift solenoid valve SL2 circuit

• Shift solenoid valve SL2

•ECM

Related DTCs P0778: Shift solenoid valve SL2/Range check

Required sensors/Components Shift solenoid valve SL2

Frequency of operation Continuous

Duration 1 sec.

MIL operation Immediate

Sequence of operation None

The monitor will run whenever this DTC is not present. None

Solenoid current cut status Not cut

Battery voltage11 V or more

Ignition switchON

StarterOFF

CPU commanded duty ratio to SL2 19% or more

Solenoid status from IC Fail (Open or short)

Output signal dutyLess than 100%