sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1615 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–229

AX

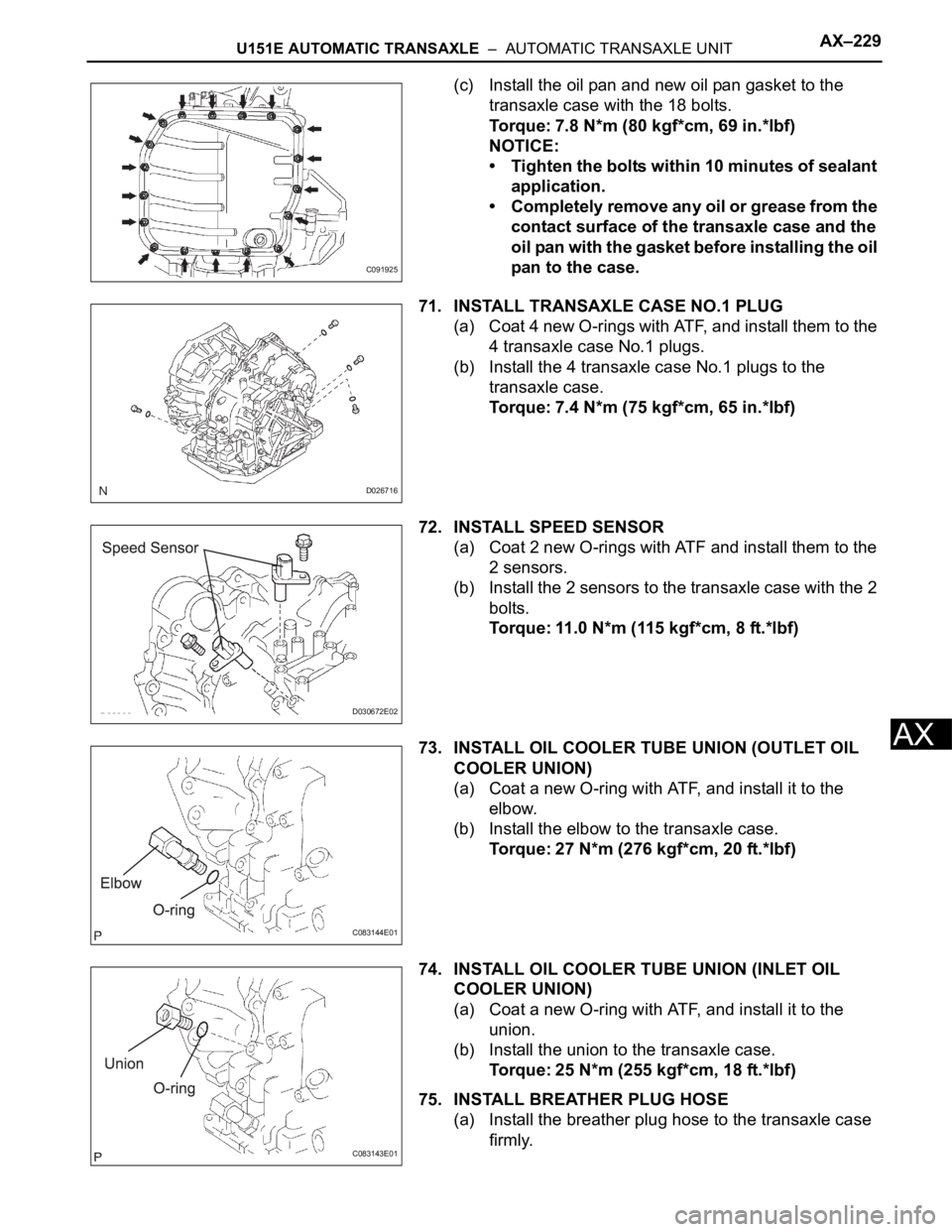

(c) Install the oil pan and new oil pan gasket to the

transaxle case with the 18 bolts.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

NOTICE:

• Tighten the bolts within 10 minutes of sealant

application.

• Completely remove any oil or grease from the

contact surface of the transaxle case and the

oil pan with the gasket before installing the oil

pan to the case.

71. INSTALL TRANSAXLE CASE NO.1 PLUG

(a) Coat 4 new O-rings with ATF, and install them to the

4 transaxle case No.1 plugs.

(b) Install the 4 transaxle case No.1 plugs to the

transaxle case.

Torque: 7.4 N*m (75 kgf*cm, 65 in.*lbf)

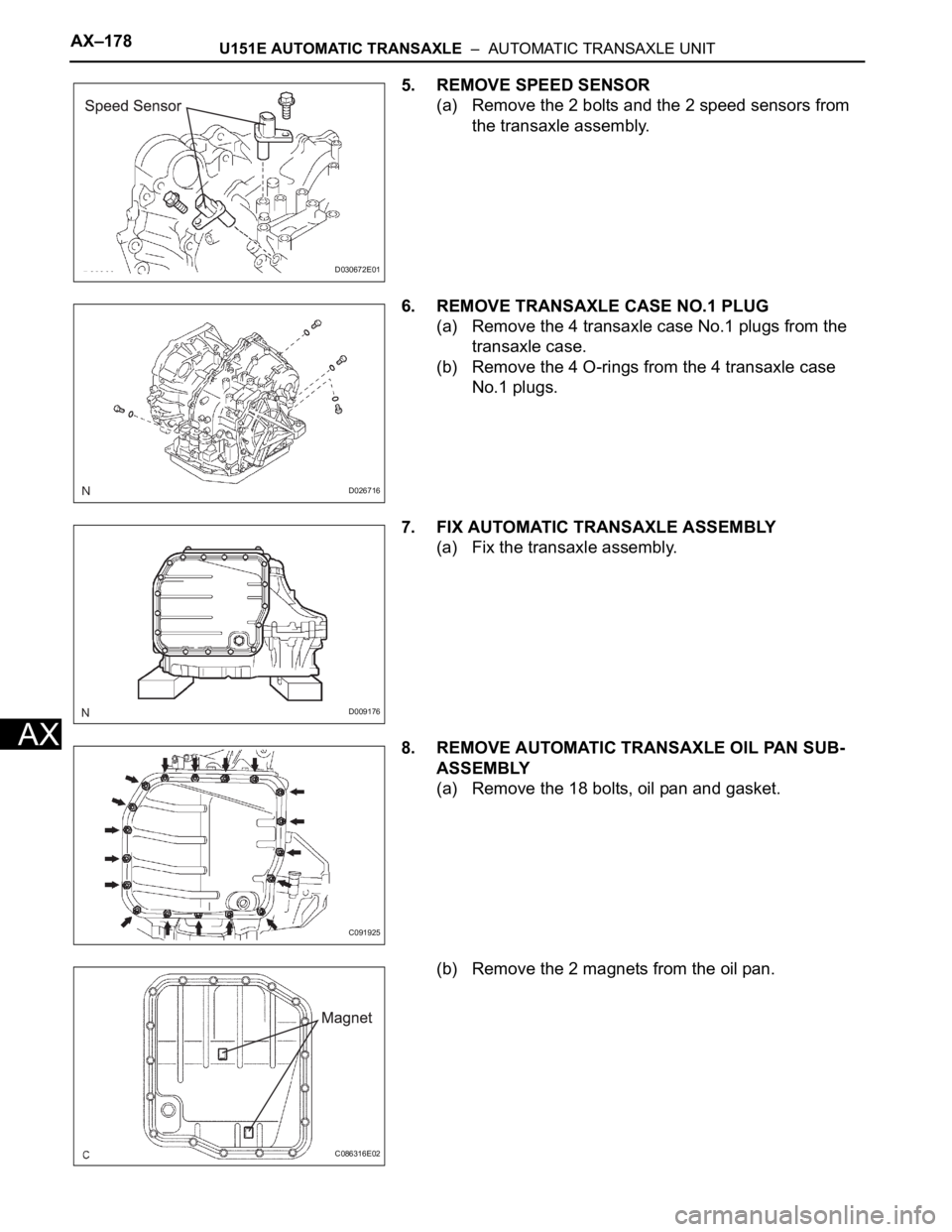

72. INSTALL SPEED SENSOR

(a) Coat 2 new O-rings with ATF and install them to the

2 sensors.

(b) Install the 2 sensors to the transaxle case with the 2

bolts.

Torque: 11.0 N*m (115 kgf*cm, 8 ft.*lbf)

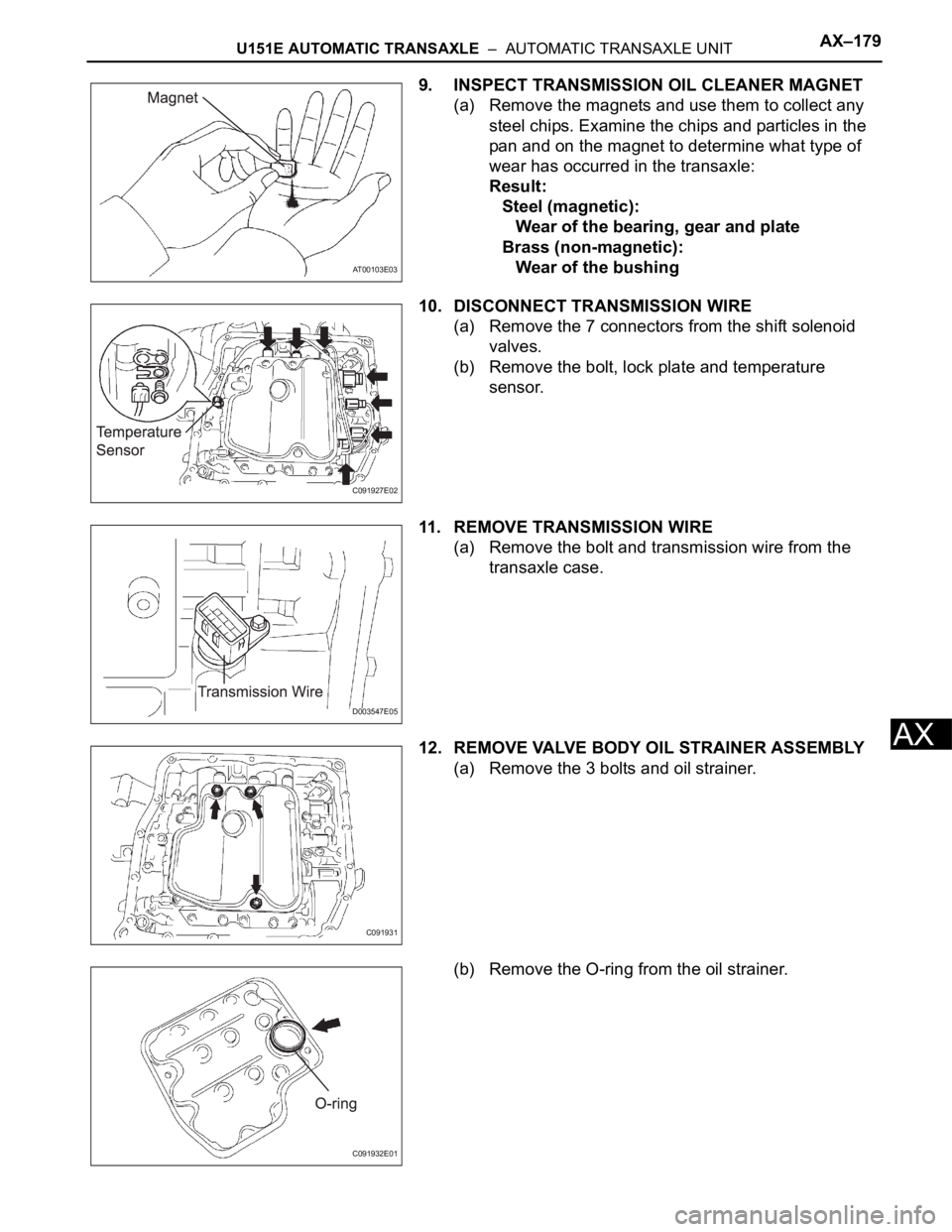

73. INSTALL OIL COOLER TUBE UNION (OUTLET OIL

COOLER UNION)

(a) Coat a new O-ring with ATF, and install it to the

elbow.

(b) Install the elbow to the transaxle case.

Torque: 27 N*m (276 kgf*cm, 20 ft.*lbf)

74. INSTALL OIL COOLER TUBE UNION (INLET OIL

COOLER UNION)

(a) Coat a new O-ring with ATF, and install it to the

union.

(b) Install the union to the transaxle case.

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

75. INSTALL BREATHER PLUG HOSE

(a) Install the breather plug hose to the transaxle case

firmly.

C091925

D026716

D030672E02

C083144E01

C083143E01

Page 1622 of 3000

AX–178U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

5. REMOVE SPEED SENSOR

(a) Remove the 2 bolts and the 2 speed sensors from

the transaxle assembly.

6. REMOVE TRANSAXLE CASE NO.1 PLUG

(a) Remove the 4 transaxle case No.1 plugs from the

transaxle case.

(b) Remove the 4 O-rings from the 4 transaxle case

No.1 plugs.

7. FIX AUTOMATIC TRANSAXLE ASSEMBLY

(a) Fix the transaxle assembly.

8. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Remove the 18 bolts, oil pan and gasket.

(b) Remove the 2 magnets from the oil pan.

D030672E01

D026716

D009176

C091925

C086316E02

Page 1623 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–179

AX

9. INSPECT TRANSMISSION OIL CLEANER MAGNET

(a) Remove the magnets and use them to collect any

steel chips. Examine the chips and particles in the

pan and on the magnet to determine what type of

wear has occurred in the transaxle:

Result:

Steel (magnetic):

Wear of the bearing, gear and plate

Brass (non-magnetic):

Wear of the bushing

10. DISCONNECT TRANSMISSION WIRE

(a) Remove the 7 connectors from the shift solenoid

valves.

(b) Remove the bolt, lock plate and temperature

sensor.

11. REMOVE TRANSMISSION WIRE

(a) Remove the bolt and transmission wire from the

transaxle case.

12. REMOVE VALVE BODY OIL STRAINER ASSEMBLY

(a) Remove the 3 bolts and oil strainer.

(b) Remove the O-ring from the oil strainer.

AT00103E03

C091927E02

D003547E05

C091931

C091932E01

Page 1704 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–21

AX

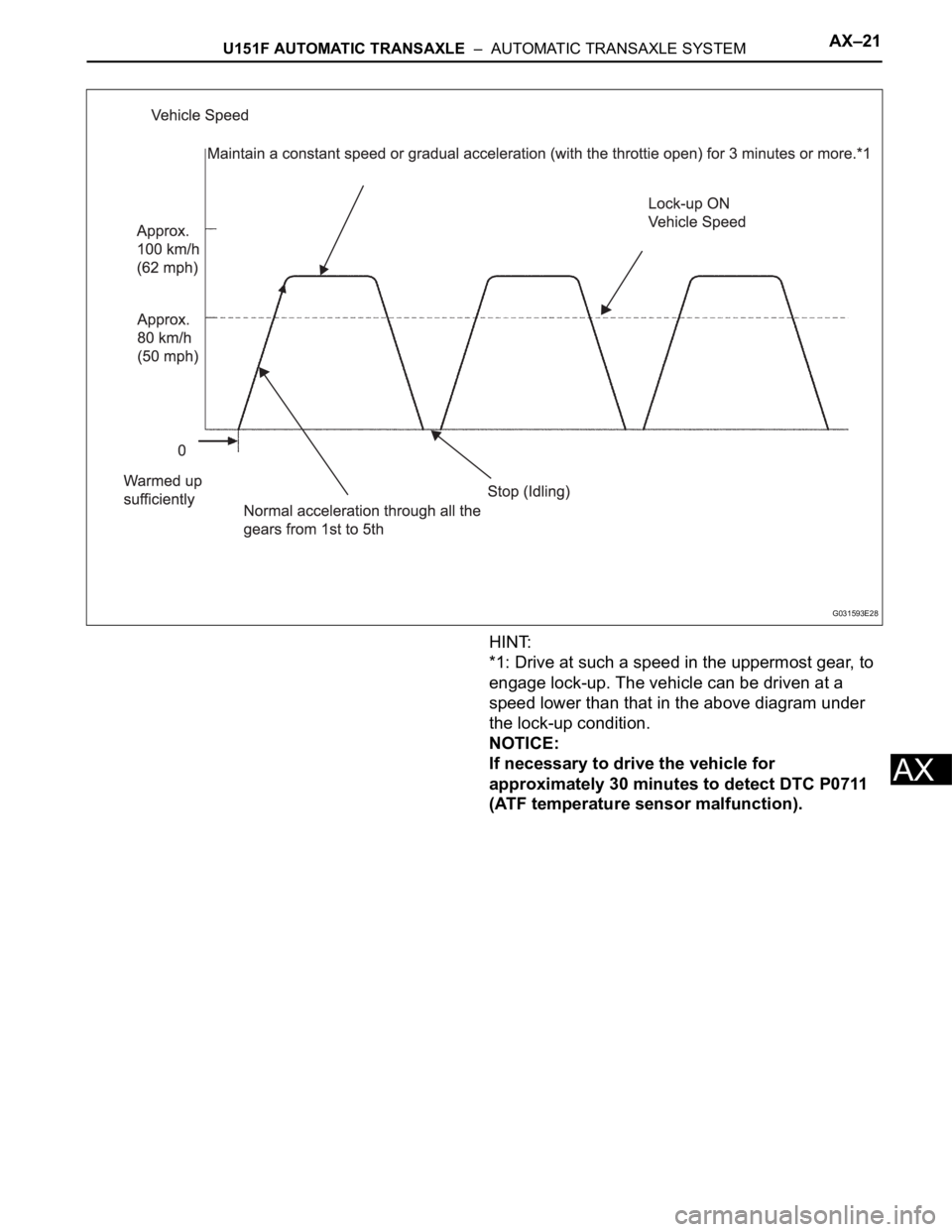

HINT:

*1: Drive at such a speed in the uppermost gear, to

engage lock-up. The vehicle can be driven at a

speed lower than that in the above diagram under

the lock-up condition.

NOTICE:

If necessary to drive the vehicle for

approximately 30 minutes to detect DTC P0711

(ATF temperature sensor malfunction).

G031593E28

Page 1705 of 3000

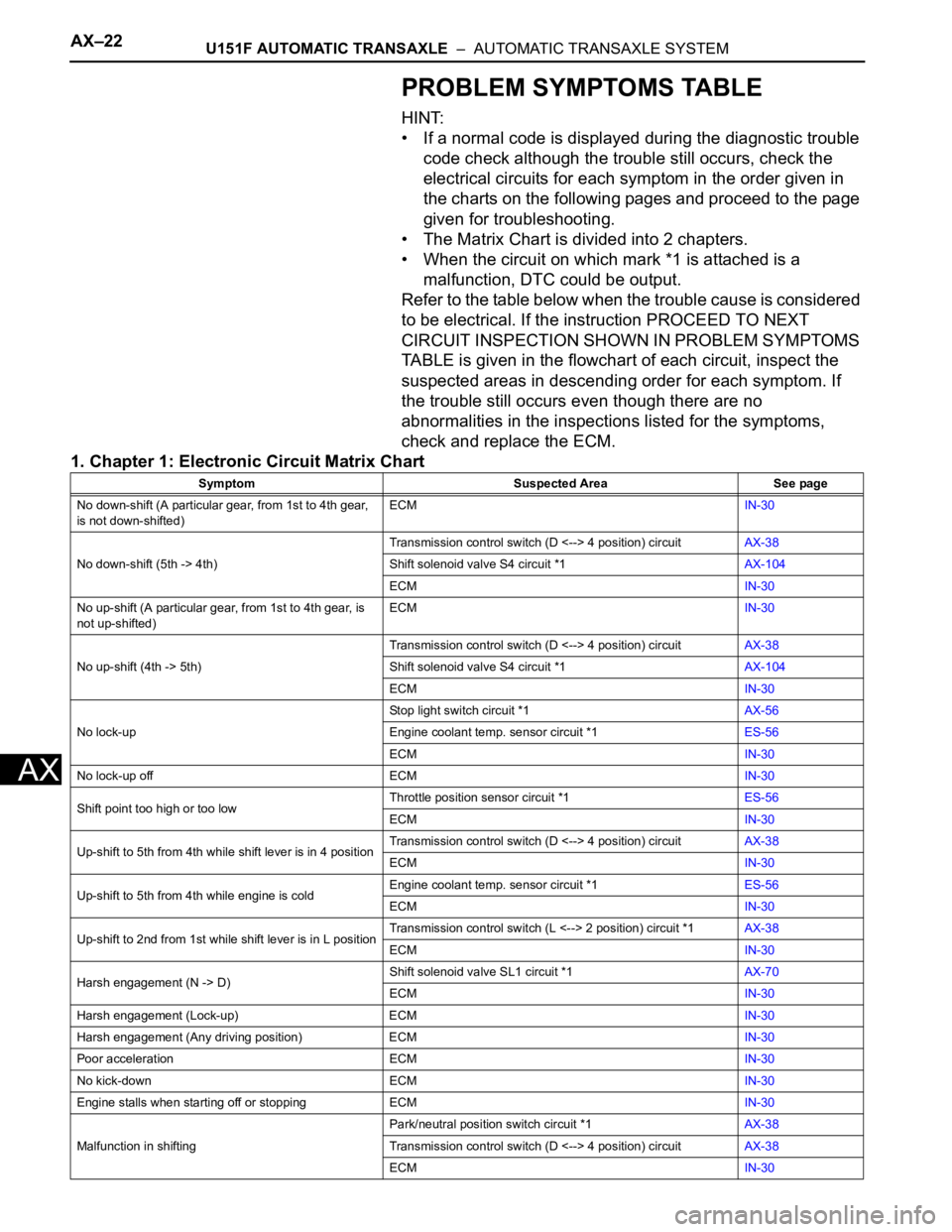

AX–22U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

PROBLEM SYMPTOMS TABLE

HINT:

• If a normal code is displayed during the diagnostic trouble

code check although the trouble still occurs, check the

electrical circuits for each symptom in the order given in

the charts on the following pages and proceed to the page

given for troubleshooting.

• The Matrix Chart is divided into 2 chapters.

• When the circuit on which mark *1 is attached is a

malfunction, DTC could be output.

Refer to the table below when the trouble cause is considered

to be electrical. If the instruction PROCEED TO NEXT

CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE is given in the flowchart of each circuit, inspect the

suspected areas in descending order for each symptom. If

the trouble still occurs even though there are no

abnormalities in the inspections listed for the symptoms,

check and replace the ECM.

1. Chapter 1: Electronic Circuit Matrix Chart

Symptom Suspected Area See page

No down-shift (A particular gear, from 1st to 4th gear,

is not down-shifted)ECMIN-30

No down-shift (5th -> 4th)Transmission control switch (D <--> 4 position) circuitAX-38

Shift solenoid valve S4 circuit *1AX-104

ECMIN-30

No up-shift (A particular gear, from 1st to 4th gear, is

not up-shifted)ECMIN-30

No up-shift (4th -> 5th)Transmission control switch (D <--> 4 position) circuitAX-38

Shift solenoid valve S4 circuit *1AX-104

ECMIN-30

No lock-upStop light switch circuit *1AX-56

Engine coolant temp. sensor circuit *1ES-56

ECMIN-30

No lock-up off ECMIN-30

Shift point too high or too lowThrottle position sensor circuit *1ES-56

ECMIN-30

Up-shift to 5th from 4th while shift lever is in 4 positionTransmission control switch (D <--> 4 position) circuitAX-38

ECMIN-30

Up-shift to 5th from 4th while engine is coldEngine coolant temp. sensor circuit *1ES-56

ECMIN-30

Up-shift to 2nd from 1st while shift lever is in L positionTransmission control switch (L <--> 2 position) circuit *1AX-38

ECMIN-30

Harsh engagement (N -> D)Shift solenoid valve SL1 circuit *1AX-70

ECMIN-30

Harsh engagement (Lock-up) ECMIN-30

Harsh engagement (Any driving position) ECMIN-30

Poor acceleration ECMIN-30

No kick-down ECMIN-30

Engine stalls when starting off or stopping ECMIN-30

Malfunction in shiftingPark/neutral position switch circuit *1AX-38

Transmission control switch (D <--> 4 position) circuitAX-38

ECMIN-30

Page 1712 of 3000

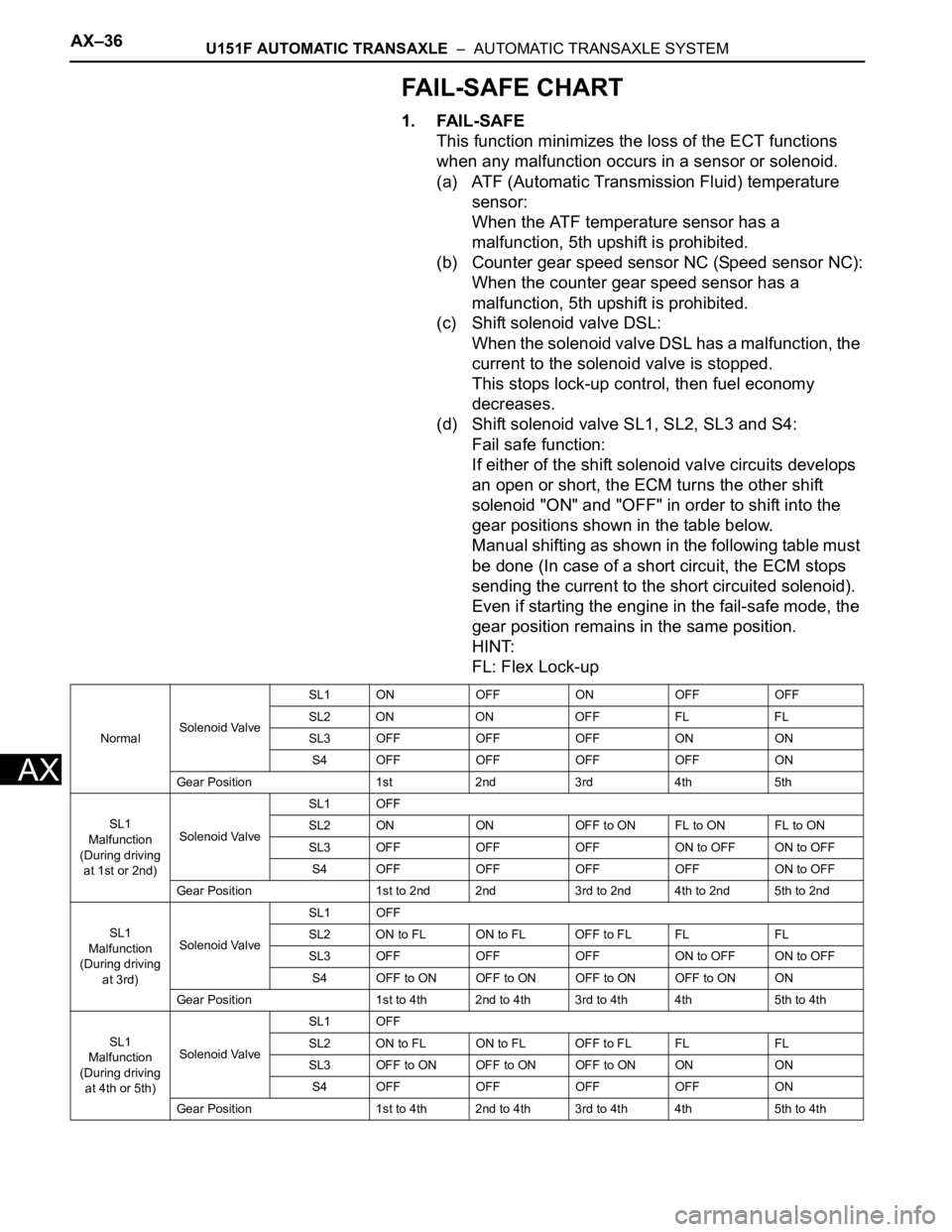

AX–36U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

FAIL-SAFE CHART

1. FAIL-SAFE

This function minimizes the loss of the ECT functions

when any malfunction occurs in a sensor or solenoid.

(a) ATF (Automatic Transmission Fluid) temperature

sensor:

When the ATF temperature sensor has a

malfunction, 5th upshift is prohibited.

(b) Counter gear speed sensor NC (Speed sensor NC):

When the counter gear speed sensor has a

malfunction, 5th upshift is prohibited.

(c) Shift solenoid valve DSL:

When the solenoid valve DSL has a malfunction, the

current to the solenoid valve is stopped.

This stops lock-up control, then fuel economy

decreases.

(d) Shift solenoid valve SL1, SL2, SL3 and S4:

Fail safe function:

If either of the shift solenoid valve circuits develops

an open or short, the ECM turns the other shift

solenoid "ON" and "OFF" in order to shift into the

gear positions shown in the table below.

Manual shifting as shown in the following table must

be done (In case of a short circuit, the ECM stops

sending the current to the short circuited solenoid).

Even if starting the engine in the fail-safe mode, the

gear position remains in the same position.

HINT:

FL: Flex Lock-up

NormalSolenoid ValveSL1 ON OFF ON OFF OFF

SL2 ON ON OFF FL FL

SL3 OFF OFF OFF ON ON

S4 OFF OFF OFF OFF ON

Gear Position 1st 2nd 3rd 4th 5th

SL1

Malfunction

(During driving

at 1st or 2nd)Solenoid ValveSL1 OFF

SL2 ON ON OFF to ON FL to ON FL to ON

SL3 OFF OFF OFF ON to OFF ON to OFF

S4 OFF OFF OFF OFF ON to OFF

Gear Position 1st to 2nd 2nd 3rd to 2nd 4th to 2nd 5th to 2nd

SL1

Malfunction

(During driving

at 3rd)Solenoid ValveSL1 OFF

SL2 ON to FL ON to FL OFF to FL FL FL

SL3 OFF OFF OFF ON to OFF ON to OFF

S4 OFF to ON OFF to ON OFF to ON OFF to ON ON

Gear Position 1st to 4th 2nd to 4th 3rd to 4th 4th 5th to 4th

SL1

Malfunction

(During driving

at 4th or 5th)Solenoid ValveSL1 OFF

SL2 ON to FL ON to FL OFF to FL FL FL

SL3 OFF to ON OFF to ON OFF to ON ON ON

S4 OFF OFF OFF OFF ON

Gear Position 1st to 4th 2nd to 4th 3rd to 4th 4th 5th to 4th

Page 1714 of 3000

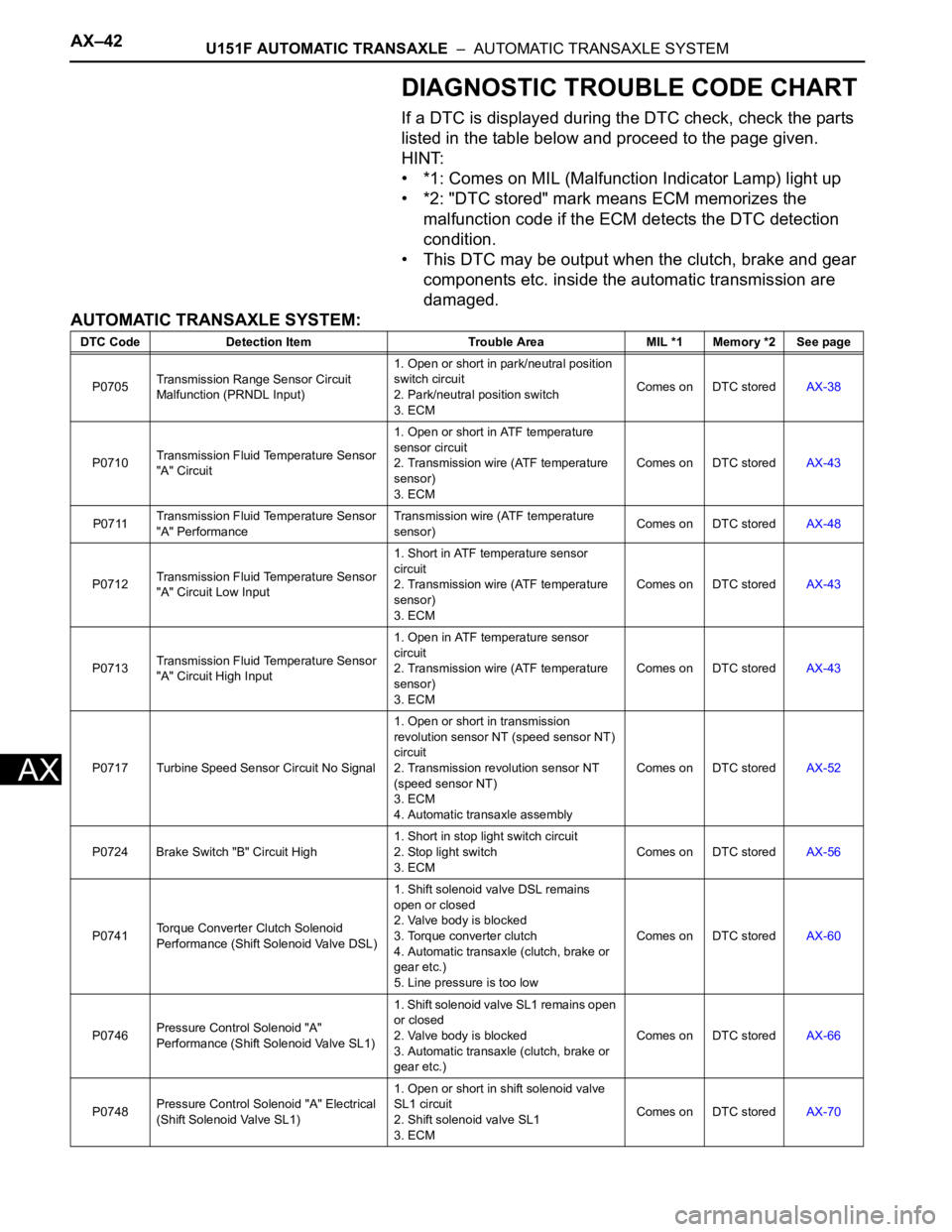

AX–42U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

DIAGNOSTIC TROUBLE CODE CHART

If a DTC is displayed during the DTC check, check the parts

listed in the table below and proceed to the page given.

HINT:

• *1: Comes on MIL (Malfunction Indicator Lamp) light up

• *2: "DTC stored" mark means ECM memorizes the

malfunction code if the ECM detects the DTC detection

condition.

• This DTC may be output when the clutch, brake and gear

components etc. inside the automatic transmission are

damaged.

AUTOMATIC TRANSAXLE SYSTEM:

DTC Code Detection Item Trouble Area MIL *1 Memory *2 See page

P0705Transmission Range Sensor Circuit

Malfunction (PRNDL Input)1. Open or short in park/neutral position

switch circuit

2. Park/neutral position switch

3. ECMComes on DTC storedAX-38

P0710Transmission Fluid Temperature Sensor

"A" Circuit1. Open or short in ATF temperature

sensor circuit

2. Transmission wire (ATF temperature

sensor)

3. ECMComes on DTC storedAX-43

P0711Transmission Fluid Temperature Sensor

"A" PerformanceTransmission wire (ATF temperature

sensor)Comes on DTC storedAX-48

P0712Transmission Fluid Temperature Sensor

"A" Circuit Low Input1. Short in ATF temperature sensor

circuit

2. Transmission wire (ATF temperature

sensor)

3. ECMComes on DTC storedAX-43

P0713Transmission Fluid Temperature Sensor

"A" Circuit High Input1. Open in ATF temperature sensor

circuit

2. Transmission wire (ATF temperature

sensor)

3. ECMComes on DTC storedAX-43

P0717 Turbine Speed Sensor Circuit No Signal1. Open or short in transmission

revolution sensor NT (speed sensor NT)

circuit

2. Transmission revolution sensor NT

(speed sensor NT)

3. ECM

4. Automatic transaxle assemblyComes on DTC storedAX-52

P0724 Brake Switch "B" Circuit High1. Short in stop light switch circuit

2. Stop light switch

3. ECMComes on DTC storedAX-56

P0741Torque Converter Clutch Solenoid

Performance (Shift Solenoid Valve DSL)1. Shift solenoid valve DSL remains

open or closed

2. Valve body is blocked

3. Torque converter clutch

4. Automatic transaxle (clutch, brake or

gear etc.)

5. Line pressure is too lowComes on DTC storedAX-60

P0746Pressure Control Solenoid "A"

Performance (Shift Solenoid Valve SL1)1. Shift solenoid valve SL1 remains open

or closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC storedAX-66

P0748Pressure Control Solenoid "A" Electrical

(Shift Solenoid Valve SL1)1. Open or short in shift solenoid valve

SL1 circuit

2. Shift solenoid valve SL1

3. ECMComes on DTC storedAX-70

Page 1715 of 3000

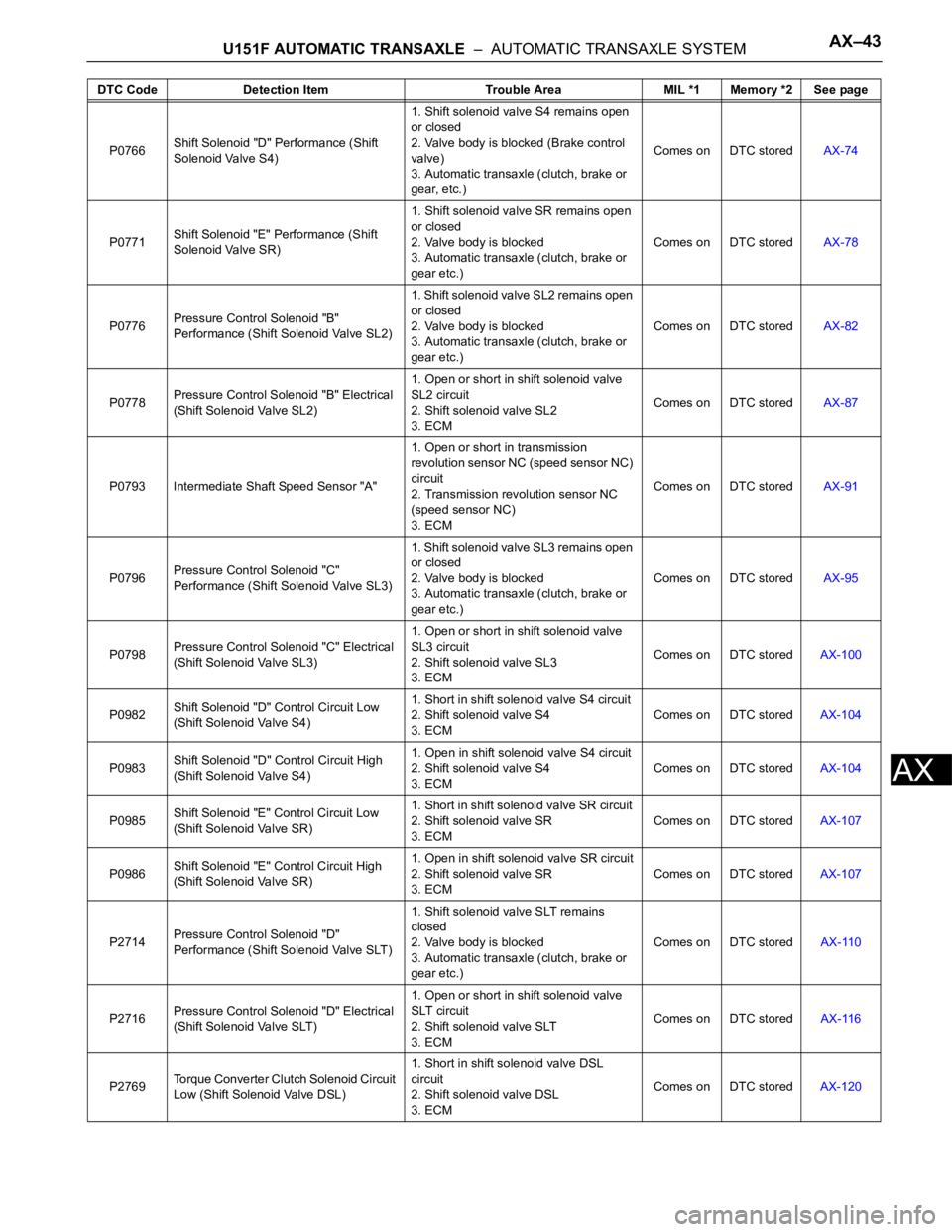

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–43

AX

P0766Shift Solenoid "D" Performance (Shift

Solenoid Valve S4)1. Shift solenoid valve S4 remains open

or closed

2. Valve body is blocked (Brake control

valve)

3. Automatic transaxle (clutch, brake or

gear, etc.)Comes on DTC storedAX-74

P0771Shift Solenoid "E" Performance (Shift

Solenoid Valve SR)1. Shift solenoid valve SR remains open

or closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC storedAX-78

P0776Pressure Control Solenoid "B"

Performance (Shift Solenoid Valve SL2)1. Shift solenoid valve SL2 remains open

or closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC storedAX-82

P0778Pressure Control Solenoid "B" Electrical

(Shift Solenoid Valve SL2)1. Open or short in shift solenoid valve

SL2 circuit

2. Shift solenoid valve SL2

3. ECMComes on DTC storedAX-87

P0793 Intermediate Shaft Speed Sensor "A"1. Open or short in transmission

revolution sensor NC (speed sensor NC)

circuit

2. Transmission revolution sensor NC

(speed sensor NC)

3. ECMComes on DTC storedAX-91

P0796Pressure Control Solenoid "C"

Performance (Shift Solenoid Valve SL3)1. Shift solenoid valve SL3 remains open

or closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC storedAX-95

P0798Pressure Control Solenoid "C" Electrical

(Shift Solenoid Valve SL3)1. Open or short in shift solenoid valve

SL3 circuit

2. Shift solenoid valve SL3

3. ECMComes on DTC storedAX-100

P0982Shift Solenoid "D" Control Circuit Low

(Shift Solenoid Valve S4)1. Short in shift solenoid valve S4 circuit

2. Shift solenoid valve S4

3. ECMComes on DTC storedAX-104

P0983Shift Solenoid "D" Control Circuit High

(Shift Solenoid Valve S4)1. Open in shift solenoid valve S4 circuit

2. Shift solenoid valve S4

3. ECMComes on DTC storedAX-104

P0985Shift Solenoid "E" Control Circuit Low

(Shift Solenoid Valve SR)1. Short in shift solenoid valve SR circuit

2. Shift solenoid valve SR

3. ECMComes on DTC storedAX-107

P0986Shift Solenoid "E" Control Circuit High

(Shift Solenoid Valve SR)1. Open in shift solenoid valve SR circuit

2. Shift solenoid valve SR

3. ECMComes on DTC storedAX-107

P2714Pressure Control Solenoid "D"

Performance (Shift Solenoid Valve SLT)1. Shift solenoid valve SLT remains

closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC stored

AX-110

P2716Pressure Control Solenoid "D" Electrical

(Shift Solenoid Valve SLT)1. Open or short in shift solenoid valve

SLT circuit

2. Shift solenoid valve SLT

3. ECMComes on DTC storedAX-116

P2769Torque Converter Clutch Solenoid Circuit

Low (Shift Solenoid Valve DSL)1. Short in shift solenoid valve DSL

circuit

2. Shift solenoid valve DSL

3. ECMComes on DTC storedAX-120 DTC Code Detection Item Trouble Area MIL *1 Memory *2 See page

Page 1717 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–45

AX

DESCRIPTION

The park/neutral position switch detects the shift lever position and sends signals to the ECM.

MONITOR DESCRIPTION

These DTCs indicate a problem with the park/neutral position switch and the wire harness in the park/

neutral position switch circuit.

The park/neutral position switch detects the shift lever position and sends a signal to the ECM.

For security, the park/neutral position switch detects the shift lever position so that engine can be started

only when the shift lever is in the P or N position

The park/neutral position switch sends a signal to the ECM according to the shift position (P, R, N or D).

The ECM determines that there is a problem with the switch or related parts if in receives more than 1

position signal simultaneously. The ECM will turn on the MIL and store the DTC.

MONITOR STRATEGY

DTC P0705Transmission Range Sensor Circuit Malfunc-

tion (PRNDL Input)

DTC No. DTC Detection Condition Trouble Area

P0705(A) Any 2 or more signals of the following are ON

simultaneously (2-trip detection logic)

• P input signal is ON.

• N input signal is ON.

• R input signal is ON.

• D input signal is ON.

• 3 input signal is ON.

• 2 input signal is ON.

(B) Any 2 or more signals of the following are ON

simultaneously (2-trip detection logic)

• NSW (STAR) input signal is ON.

• R input signal is ON.

• D input signal is ON.

• 3 input signal is ON.

• 2 input signal is ON.

(C) All switches are OFF simultaneously for

NSW(STAR), P, R, N, D, 3, 2 positions (2-trip detection

logic).

(D) Both 1 and 2 conditions are met (2-trip detection

logic)

1. One of the following conditions are met

(a) NSW (STAR) input signal is ON.

(b) P input signal is ON.

(c) N input signal is ON.

(d) R input signal is ON.

2. One of the following conditions are met

(a) 4 input signal is ON.

(b) L input signal is ON.• Short in park/neutral position switch circuit

• Park/neutral position switch

•ECM

Related DTCs P0705: Park/neutral position switch/Verify switch input

Required sensors/Components Park/neutral position switch

Frequency of operation Continuous

DurationCondition (A), (B), (D)

2 sec.

Condition (C)

60 sec.

MIL operation 2 driving cycles

Sequence of operation None

Page 1722 of 3000

AX–50U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

DESCRIPTION

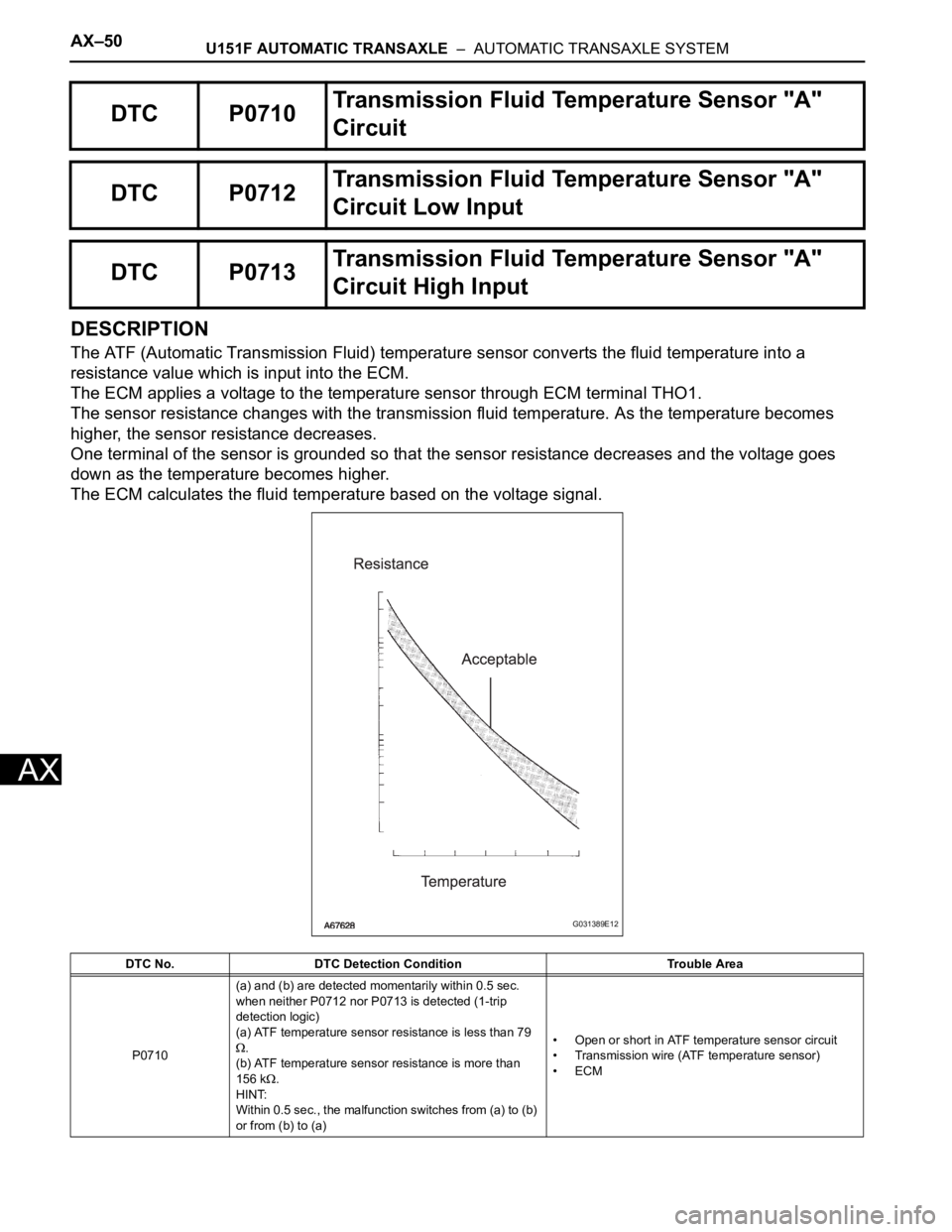

The ATF (Automatic Transmission Fluid) temperature sensor converts the fluid temperature into a

resistance value which is input into the ECM.

The ECM applies a voltage to the temperature sensor through ECM terminal THO1.

The sensor resistance changes with the transmission fluid temperature. As the temperature becomes

higher, the sensor resistance decreases.

One terminal of the sensor is grounded so that the sensor resistance decreases and the voltage goes

down as the temperature becomes higher.

The ECM calculates the fluid temperature based on the voltage signal.

DTC P0710Transmission Fluid Temperature Sensor "A"

Circuit

DTC P0712Transmission Fluid Temperature Sensor "A"

Circuit Low Input

DTC P0713Transmission Fluid Temperature Sensor "A"

Circuit High Input

DTC No. DTC Detection Condition Trouble Area

P0710(a) and (b) are detected momentarily within 0.5 sec.

when neither P0712 nor P0713 is detected (1-trip

detection logic)

(a) ATF temperature sensor resistance is less than 79

.

(b) ATF temperature sensor resistance is more than

156 k

.

HINT:

Within 0.5 sec., the malfunction switches from (a) to (b)

or from (b) to (a)• Open or short in ATF temperature sensor circuit

• Transmission wire (ATF temperature sensor)

•ECM

G031389E12