TOYOTA SUPRA 1986 Service Repair Manual

SUPRA 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57467/w960_57467-0.png

TOYOTA SUPRA 1986 Service Repair Manual

Trending: engine oil capacity, service indicator, engine overheat, brake light, transmission oil, bulb, checking oil

Page 221 of 878

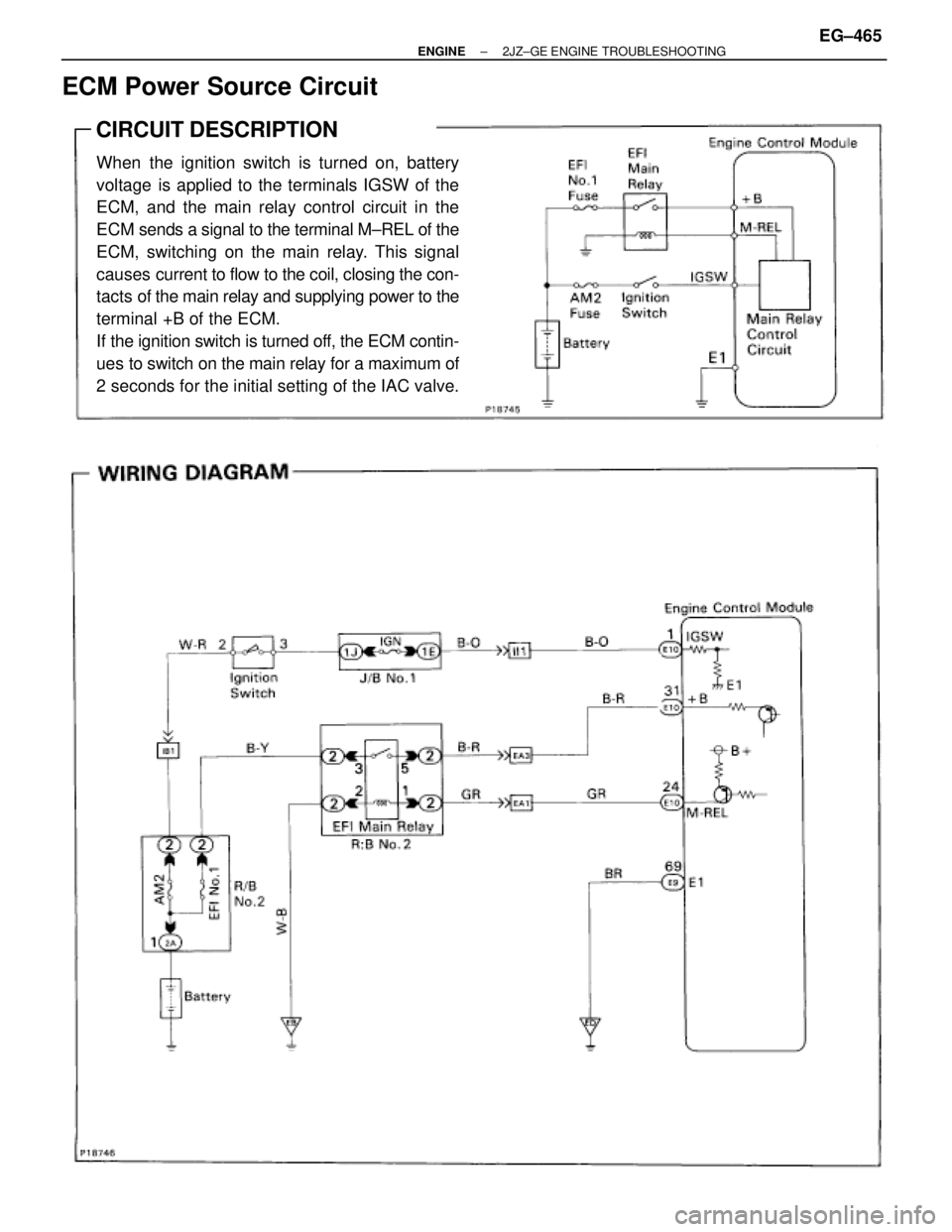

ECM Power Source Circuit

CIRCUIT DESCRIPTION

When the ignition switch is turned on, battery

voltage is applied to the terminals IGSW of the

ECM, and the main relay control circuit in the

ECM sends a signal to the terminal M±REL of the

ECM, switching on the main relay. This signal

causes current to flow to the coil, closing the con-

tacts of the main relay and supplying power to the

terminal +B of the ECM.

If the ignition switch is turned off, the ECM contin-

ues to switch on the main relay for a maximum of

2 seconds for the initial setting of the IAC valve.

± ENGINE2JZ±GE ENGINE TROUBLESHOOTINGEG±465

Page 222 of 878

(See page EG±404)

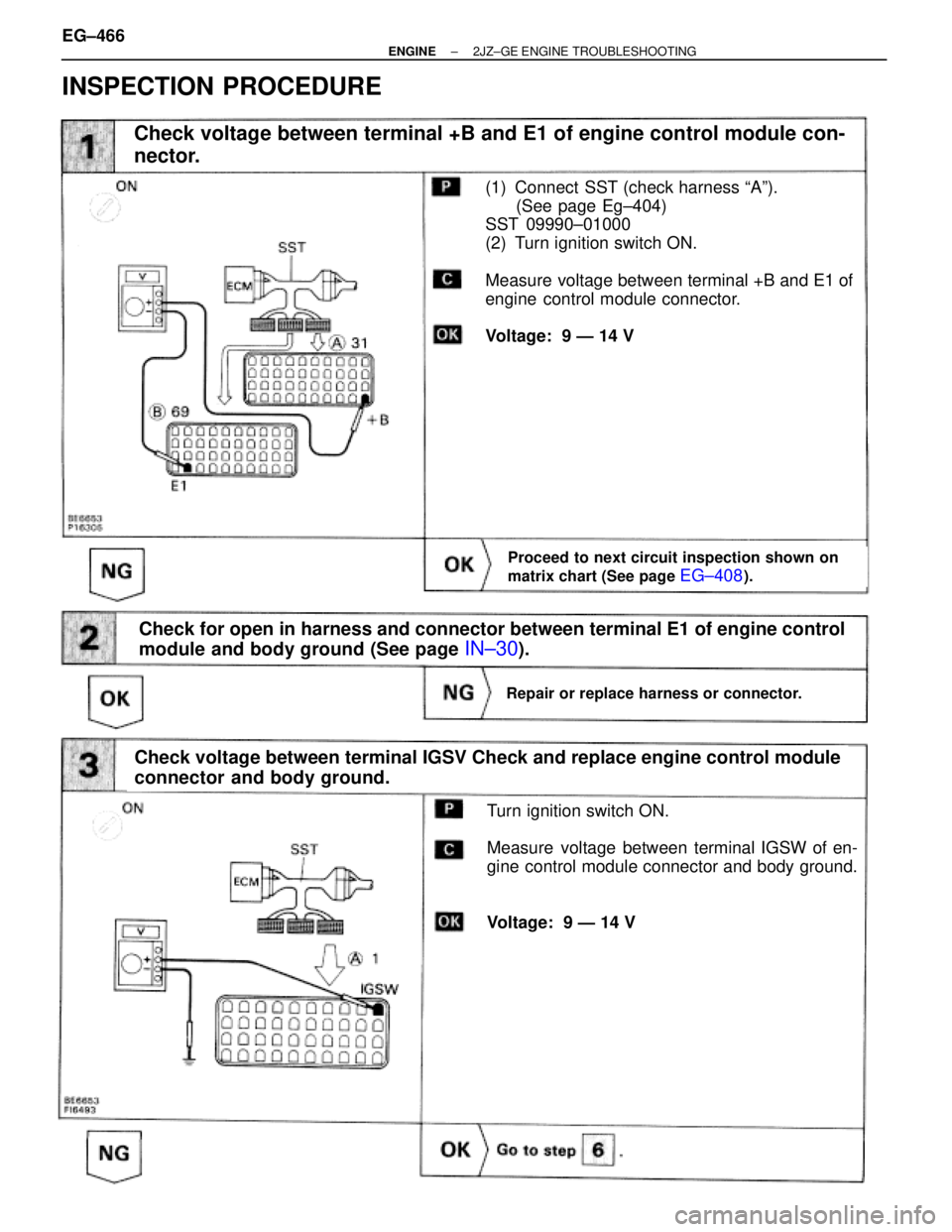

Check voltage between terminal +B and E1 of engine control module con-

nector.

(1) Connect SST (check harness ªAº).

(See page Eg±404)

SST 09990±01000

(2) Turn ignition switch ON.

Measure voltage between terminal +B and E1 of

engine control module connector.

Voltage: 9 Ð 14 V

Check and replace engine control module.

Repair or replace harness or connector.

Check voltage between terminal IGSV Check and replace engine control module

connector and body ground.

Proceed to next circuit inspection shown on

matrix chart (See page

EG±408).

Check for open in harness and connector between terminal E1 of engine control

module and body ground (See page

IN±30).

Turn ignition switch ON.

Measure voltage between terminal IGSW of en-

gine control module connector and body ground.

Voltage: 9 Ð 14 V

INSPECTION PROCEDURE

EG±466± ENGINE2JZ±GE ENGINE TROUBLESHOOTING

Page 223 of 878

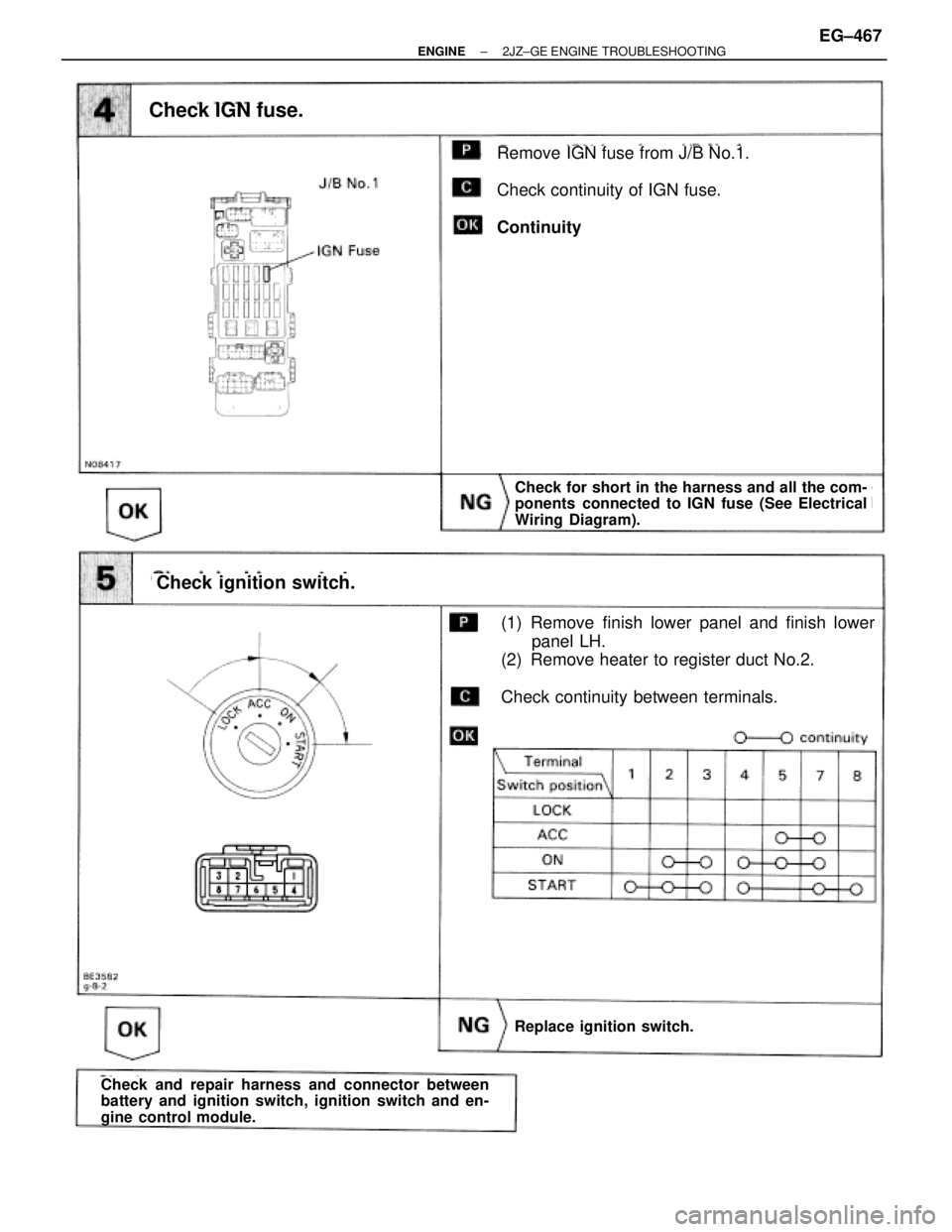

Check IGN fuse.

Remove IGN fuse from J/B No.1.

Check continuity of IGN fuse.

Continuity

Check for short in the harness and all the com-

ponents connected to IGN fuse (See Electrical

Wiring Diagram).

Check ignition switch.

(1) Remove finish lower panel and finish lower

panel LH.

(2) Remove heater to register duct No.2.

Check continuity between terminals.

Replace ignition switch.

Check and repair harness and connector between

battery and ignition switch, ignition switch and en-

gine control module.

± ENGINE2JZ±GE ENGINE TROUBLESHOOTINGEG±467

Page 224 of 878

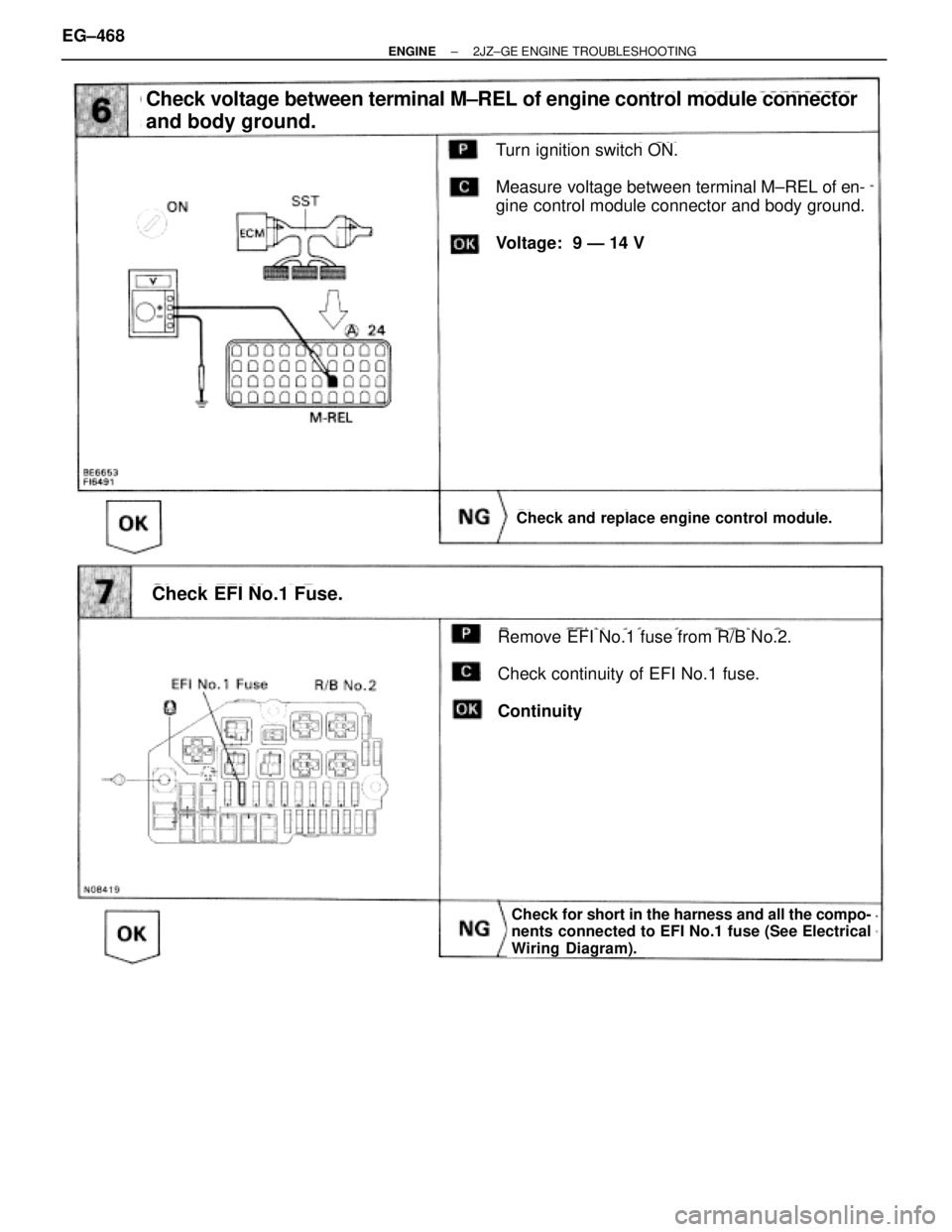

Check voltage between terminal M±REL of engine control module connector

and body ground.

Turn ignition switch ON.

Measure voltage between terminal M±REL of en-

gine control module connector and body ground.

Voltage: 9 Ð 14 V

Check and replace engine control module.

Check EFI No.1 Fuse.

Remove EFI No.1 fuse from R/B No.2.

Check continuity of EFI No.1 fuse.

Continuity

Check for short in the harness and all the compo-

nents connected to EFI No.1 fuse (See Electrical

Wiring Diagram).

EG±468± ENGINE2JZ±GE ENGINE TROUBLESHOOTING

Page 225 of 878

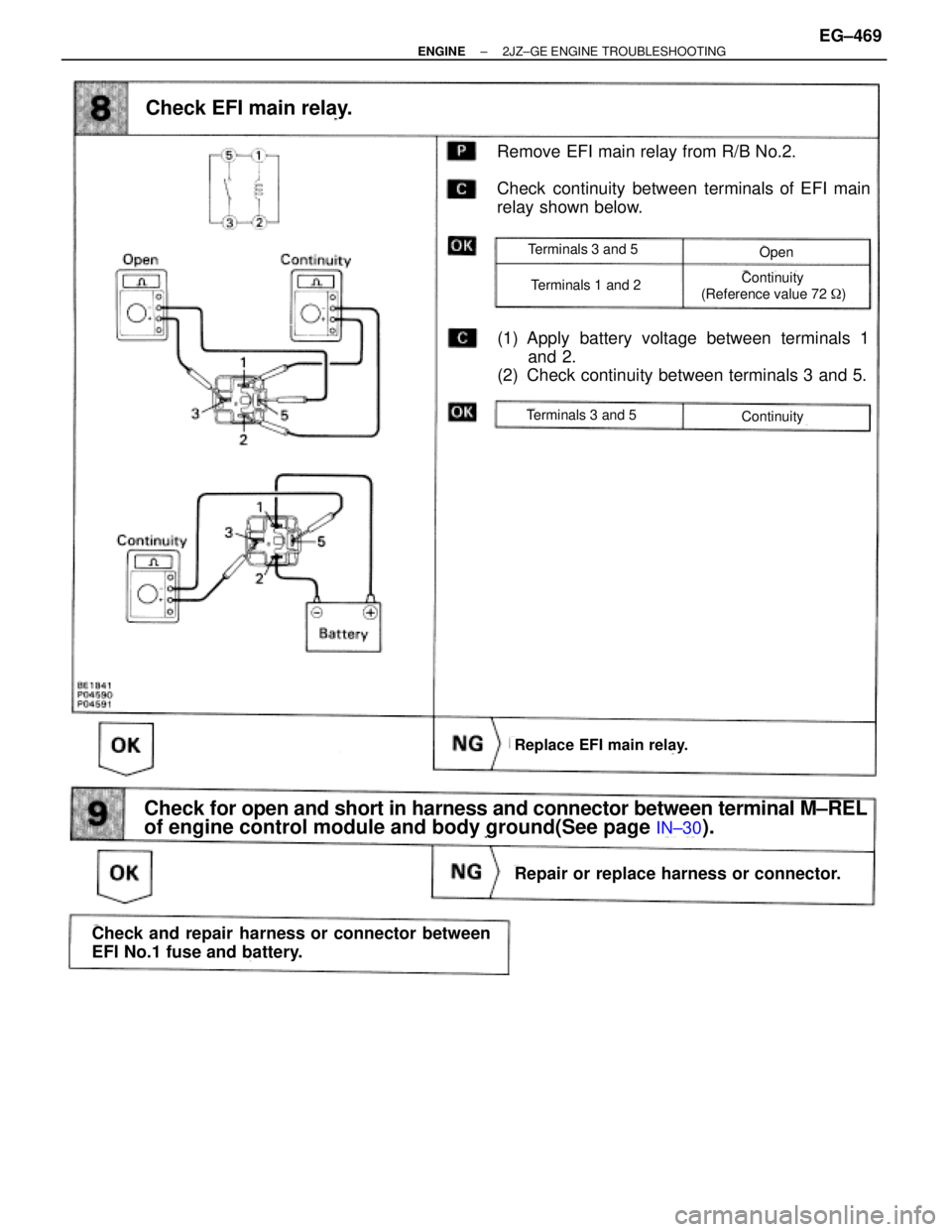

Check EFI main relay.

Remove EFI main relay from R/B No.2.

Check continuity between terminals of EFI main

relay shown below.

Replace EFI main relay.

(1) Apply battery voltage between terminals 1

and 2.

(2) Check continuity between terminals 3 and 5.

Repair or replace harness or connector.

Check and repair harness or connector between

EFI No.1 fuse and battery.

Check for open and short in harness and connector between terminal M±REL

of engine control module and body ground(See page

IN±30).

Terminals 3 and 5

Terminals 3 and 5

Terminals 1 and 2

Open

Continuity

Continuity

(Reference value 72 �)

± ENGINE2JZ±GE ENGINE TROUBLESHOOTINGEG±469

Page 226 of 878

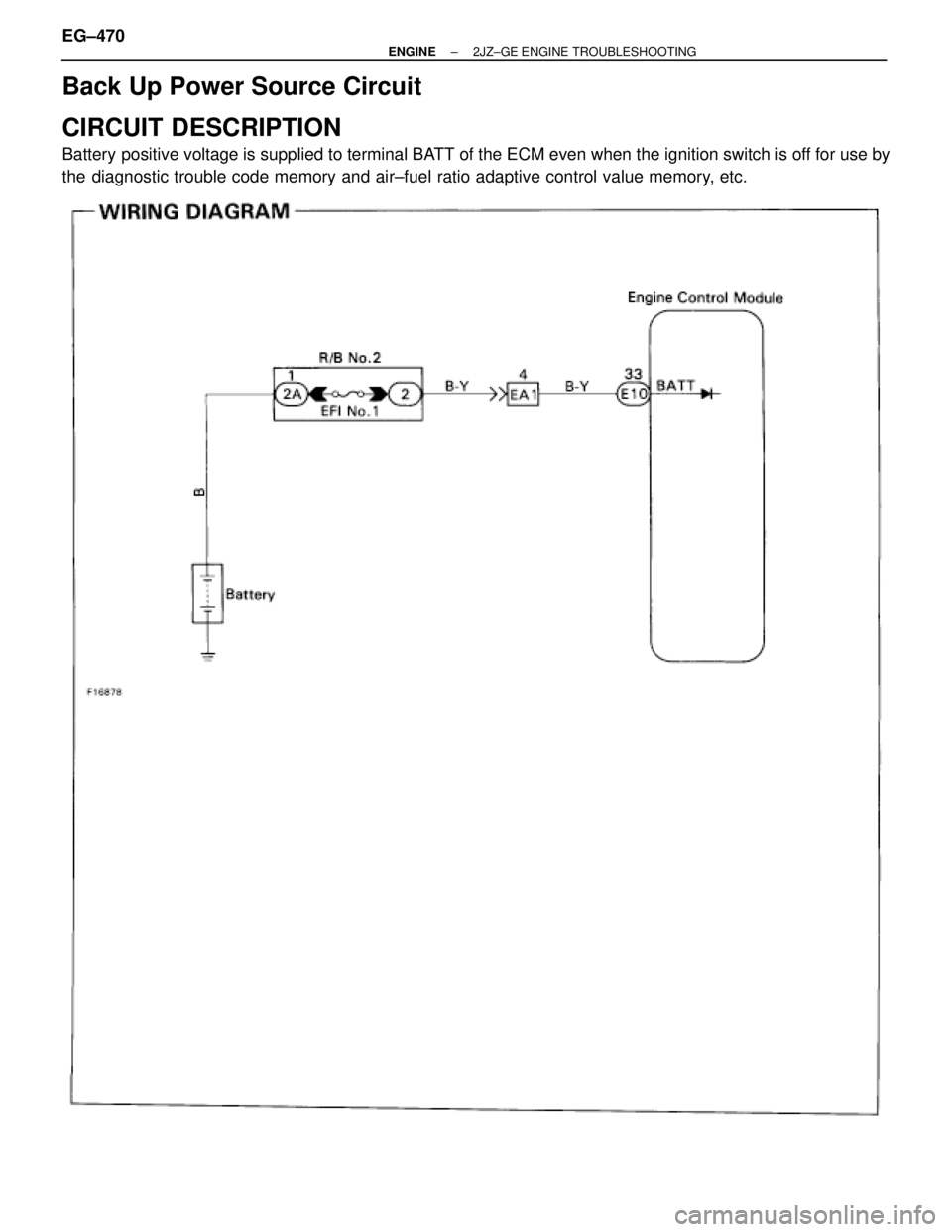

Back Up Power Source Circuit

CIRCUIT DESCRIPTION

Battery positive voltage is supplied to terminal BATT of the ECM even when the ignition switch is off for use by

the diagnostic trouble code memory and air±fuel ratio adaptive control value memory, etc.

EG±470± ENGINE2JZ±GE ENGINE TROUBLESHOOTING

Page 227 of 878

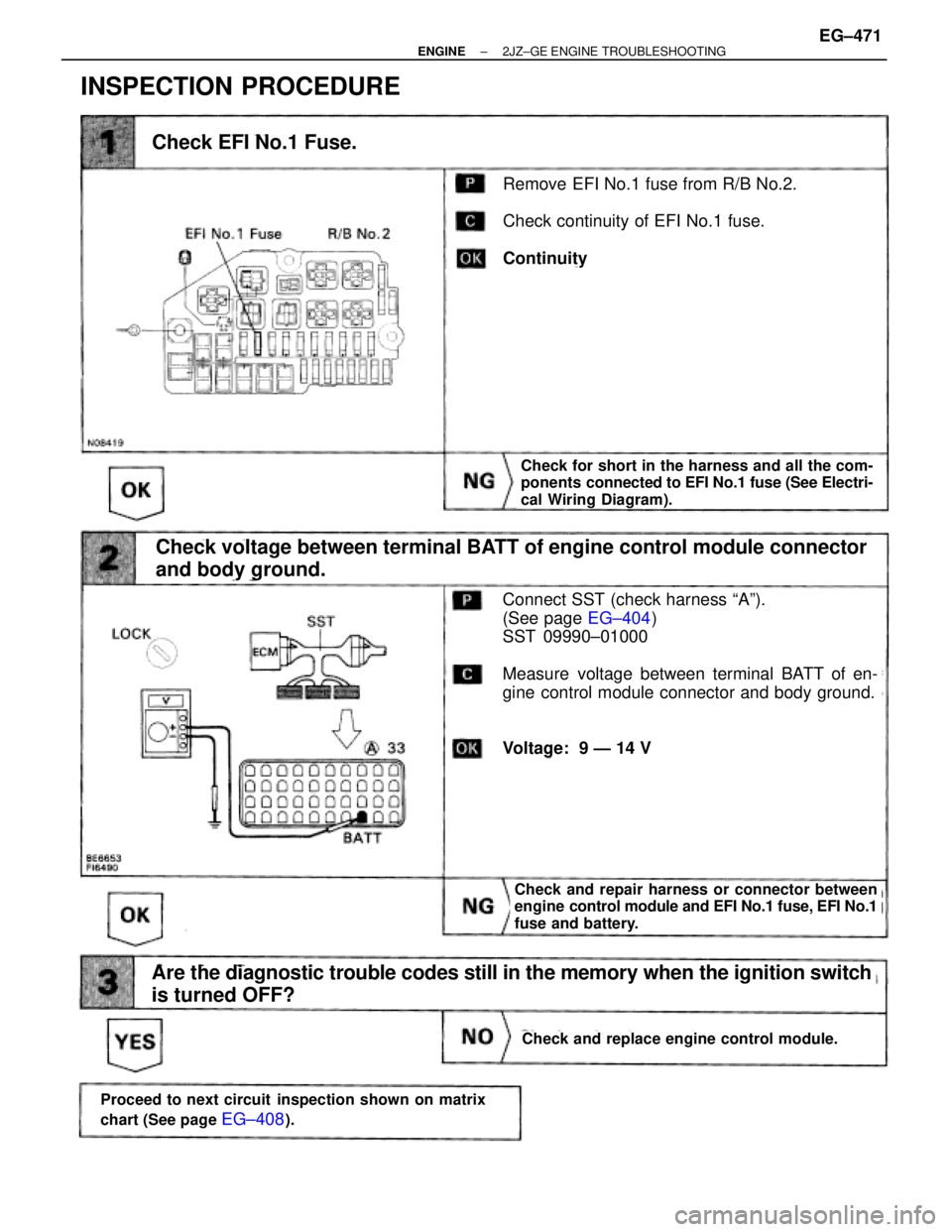

INSPECTION PROCEDURE

Check EFI No.1 Fuse.

Remove EFI No.1 fuse from R/B No.2.

Check continuity of EFI No.1 fuse.

Continuity

Check for short in the harness and all the com-

ponents connected to EFI No.1 fuse (See Electri-

cal Wiring Diagram).

Connect SST (check harness ªAº).

(See page EG±404)

SST 09990±01000

Measure voltage between terminal BATT of en-

gine control module connector and body ground.

Voltage: 9 Ð 14 V

Check and replace engine control module.

Check and repair harness or connector between

engine control module and EFI No.1 fuse, EFI No.1

fuse and battery.

Proceed to next circuit inspection shown on matrix

chart (See page

EG±408).

Check voltage between terminal BATT of engine control module connector

and body ground.

Are the diagnostic trouble codes still in the memory when the ignition switch

is turned OFF?

± ENGINE2JZ±GE ENGINE TROUBLESHOOTINGEG±471

Page 228 of 878

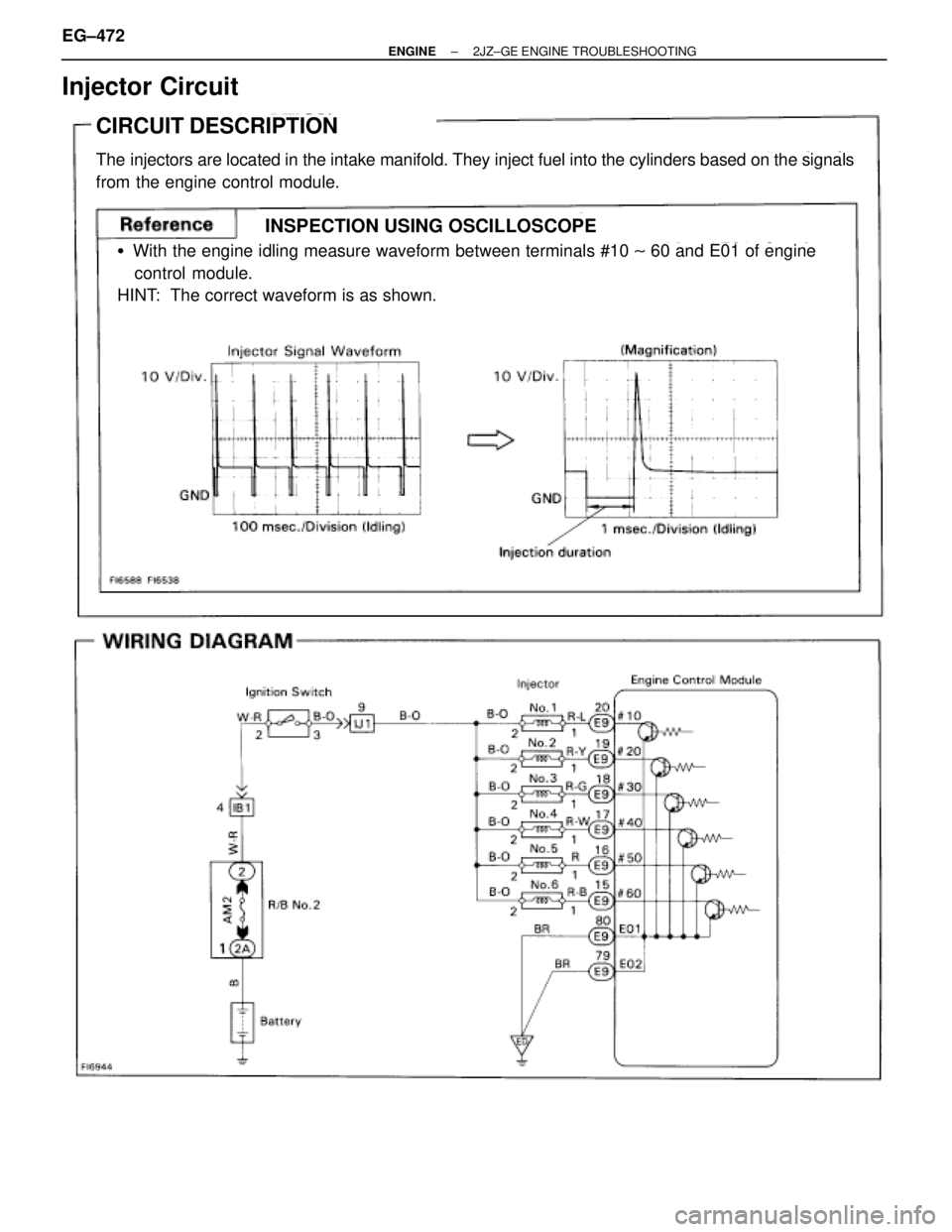

Injector Circuit

CIRCUIT DESCRIPTION

The injectors are located in the intake manifold. They inject fuel into the cylinders based on the signals

from the engine control module.

INSPECTION USING OSCILLOSCOPE

�With the engine idling measure waveform between terminals #10 ~ 60 and E01 of engine

control module.

HINT: The correct waveform is as shown.

EG±472± ENGINE2JZ±GE ENGINE TROUBLESHOOTING

Page 229 of 878

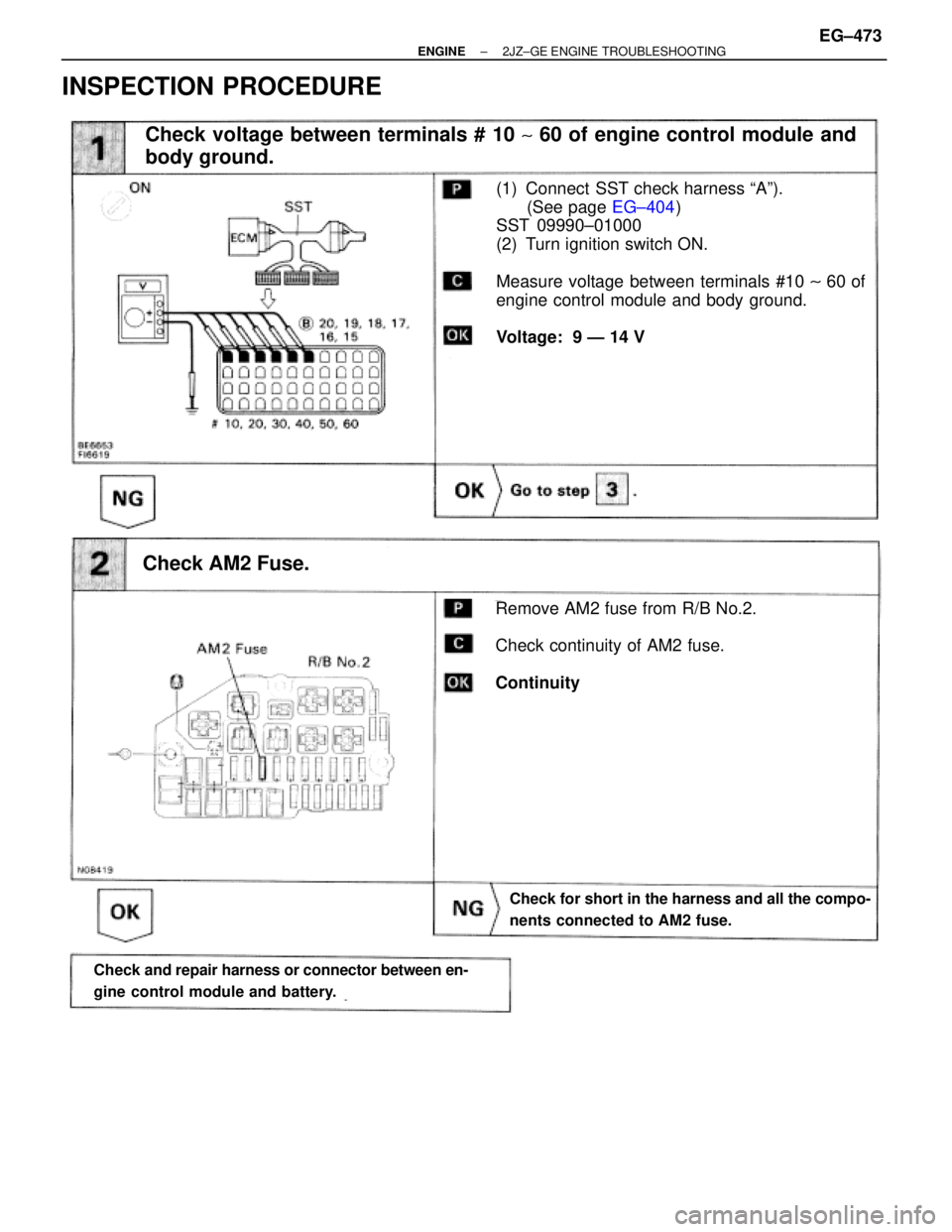

INSPECTION PROCEDURE

(See page EG±404)

Check voltage between terminals # 10 ~ 60 of engine control module and

body ground.

(1) Connect SST check harness ªAº).

(See page EG±404)

SST 09990±01000

(2) Turn ignition switch ON.

Measure voltage between terminals #10

~ 60 of

engine control module and body ground.

Voltage: 9 Ð 14 V

Check for short in the harness and all the compo-

nents connected to AM2 fuse.

Remove AM2 fuse from R/B No.2.

Check continuity of AM2 fuse.

Continuity

Check and repair harness or connector between en-

gine control module and battery.

Check AM2 Fuse.

± ENGINE2JZ±GE ENGINE TROUBLESHOOTINGEG±473

Page 230 of 878

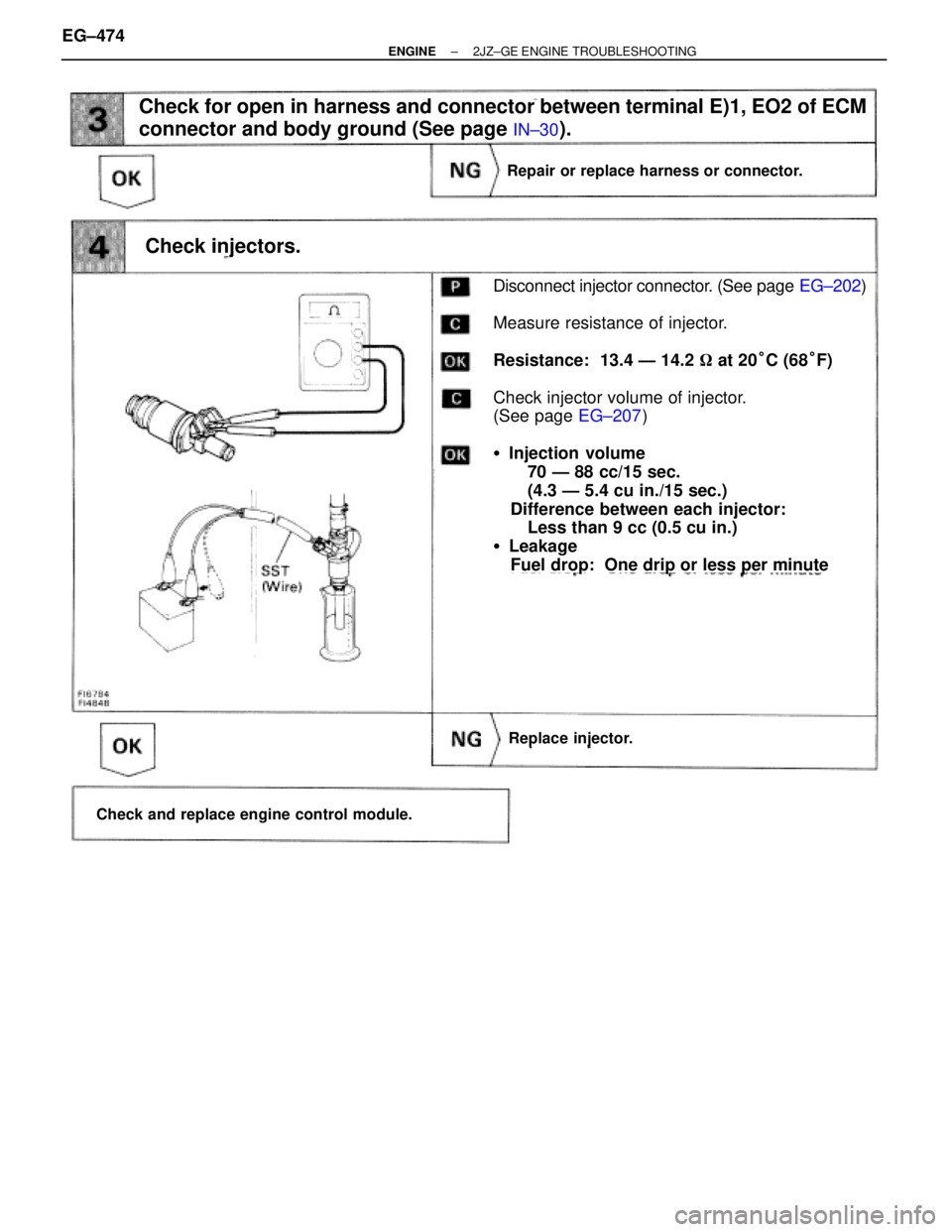

(See page

EG±202)

Check for open in harness and connector between terminal E)1, EO2 of ECM

connector and body ground (See page

IN±30).

Disconnect injector connector. (See page EG±202)

Measure resistance of injector.

Resistance: 13.4 Ð 14.2 � at 20°C (68°F)

Check injector volume of injector.

(See page EG±207)

�Injection volume

70 Ð 88 cc/15 sec.

(4.3 Ð 5.4 cu in./15 sec.)

Difference between each injector:

Less than 9 cc (0.5 cu in.)

�Leakage

Fuel drop: One drip or less per minute

Replace injector.

Check and replace engine control module.

Check injectors.

Repair or replace harness or connector.

Replace injector.

Check and replace engine control module.

EG±474± ENGINE2JZ±GE ENGINE TROUBLESHOOTING

Trending: air suspension, water pump, check transmission fluid, catalytic converter, fuel filter, stop start, cooling