TOYOTA SUPRA 1986 Service Repair Manual

SUPRA 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57467/w960_57467-0.png

TOYOTA SUPRA 1986 Service Repair Manual

Trending: fuse box location, manual transmission fluid, engine oil, change time, air filter, ignition, diagram

Page 261 of 878

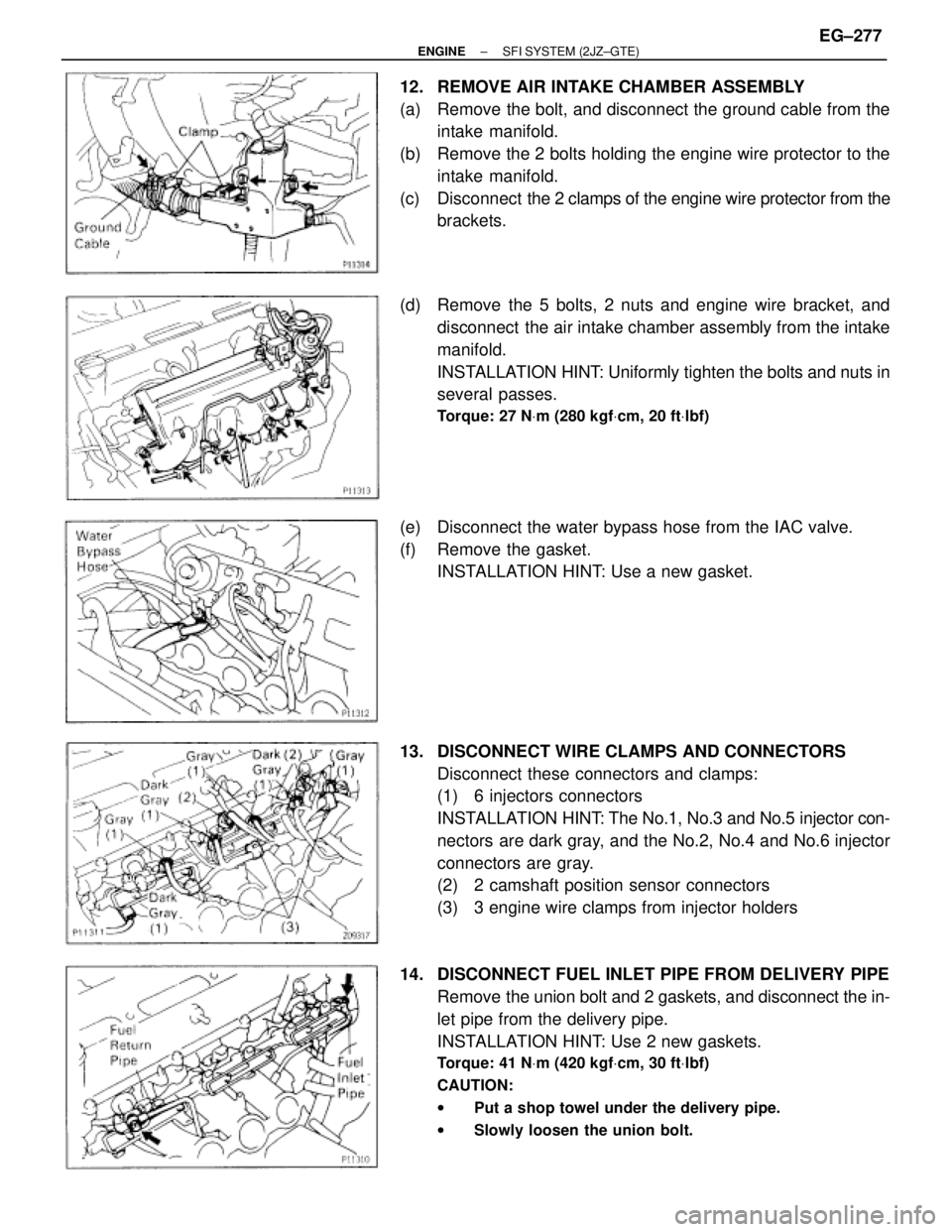

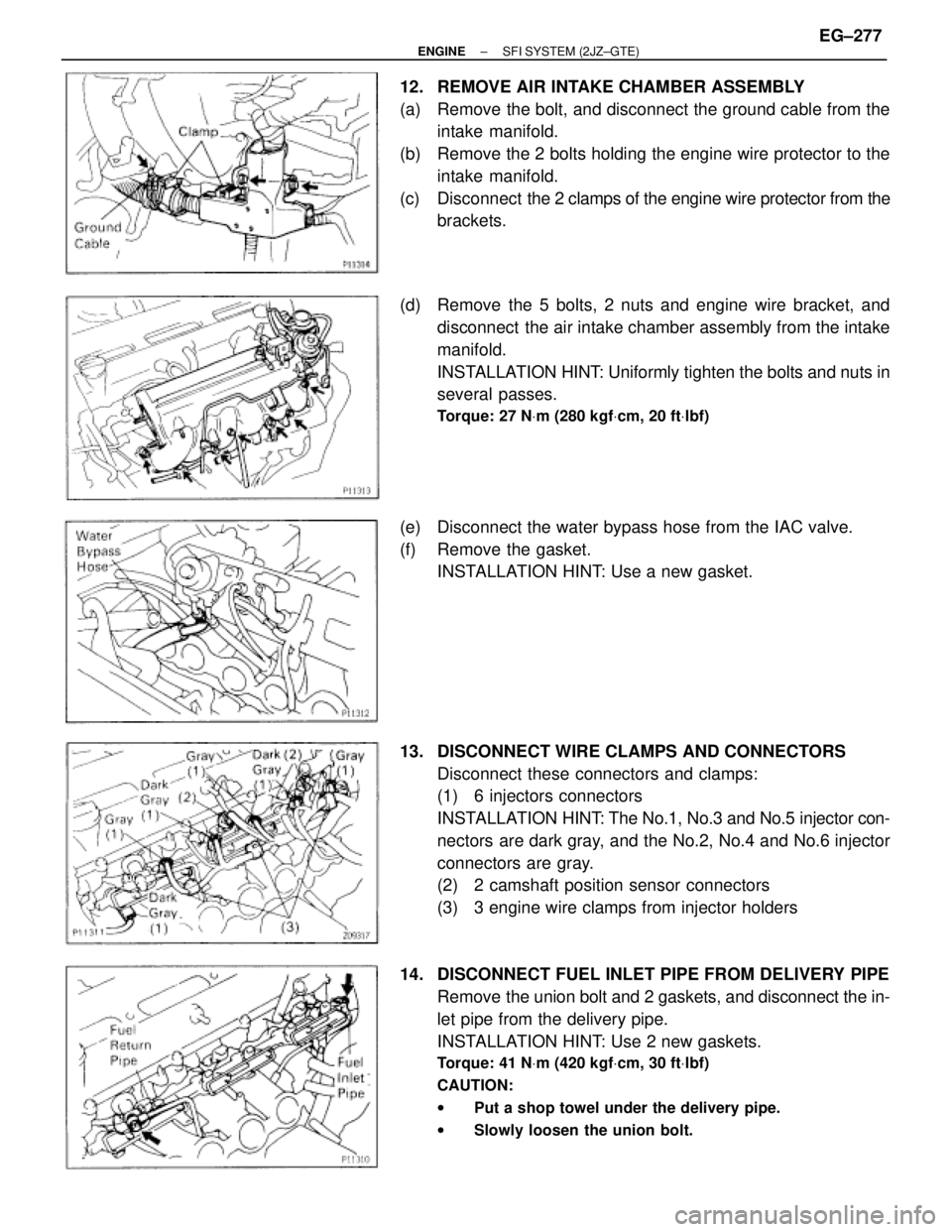

12. REMOVE AIR INTAKE CHAMBER ASSEMBLY

(a) Remove the bolt, and disconnect the ground cable from the

intake manifold.

(b) Remove the 2 bolts holding the engine wire protector to the

intake manifold.

(c) Disconnect the 2 clamps of the engine wire protector from the

brackets.

(d) Remove the 5 bolts, 2 nuts and engine wire bracket, and

disconnect the air intake chamber assembly from the intake

manifold.

INSTALLATION HINT: Uniformly tighten the bolts and nuts in

several passes.

Torque: 27 NVm (280 kgfVcm, 20 ftVlbf)

(e) Disconnect the water bypass hose from the IAC valve.

(f) Remove the gasket.

INSTALLATION HINT: Use a new gasket.

13. DISCONNECT WIRE CLAMPS AND CONNECTORS

Disconnect these connectors and clamps:

(1) 6 injectors connectors

INSTALLATION HINT: The No.1, No.3 and No.5 injector con-

nectors are dark gray, and the No.2, No.4 and No.6 injector

connectors are gray.

(2) 2 camshaft position sensor connectors

(3) 3 engine wire clamps from injector holders

14. DISCONNECT FUEL INLET PIPE FROM DELIVERY PIPE

Remove the union bolt and 2 gaskets, and disconnect the in-

let pipe from the delivery pipe.

INSTALLATION HINT: Use 2 new gaskets.

Torque: 41 NVm (420 kgfVcm, 30 ftVlbf)

CAUTION:

wPut a shop towel under the delivery pipe.

wSlowly loosen the union bolt.

± ENGINESFI SYSTEM (2JZ±GTE)EG±277

Page 262 of 878

15. DISCONNECT FUEL RETURN PIPE FROM FUEL

PRESSURE REGULATOR

Remove the union bolt and 2 gaskets, and disconnect the

fuel pipe from the pressure regulator.

INSTALLATION HINT: Use 2 new gaskets.

Torque: 27 NVm (280 kgfVcm, 20 ftVlbf)

CAUTION:

wPut a shop towel under the pressure regulator.

wSlowly loosen the union bolt.

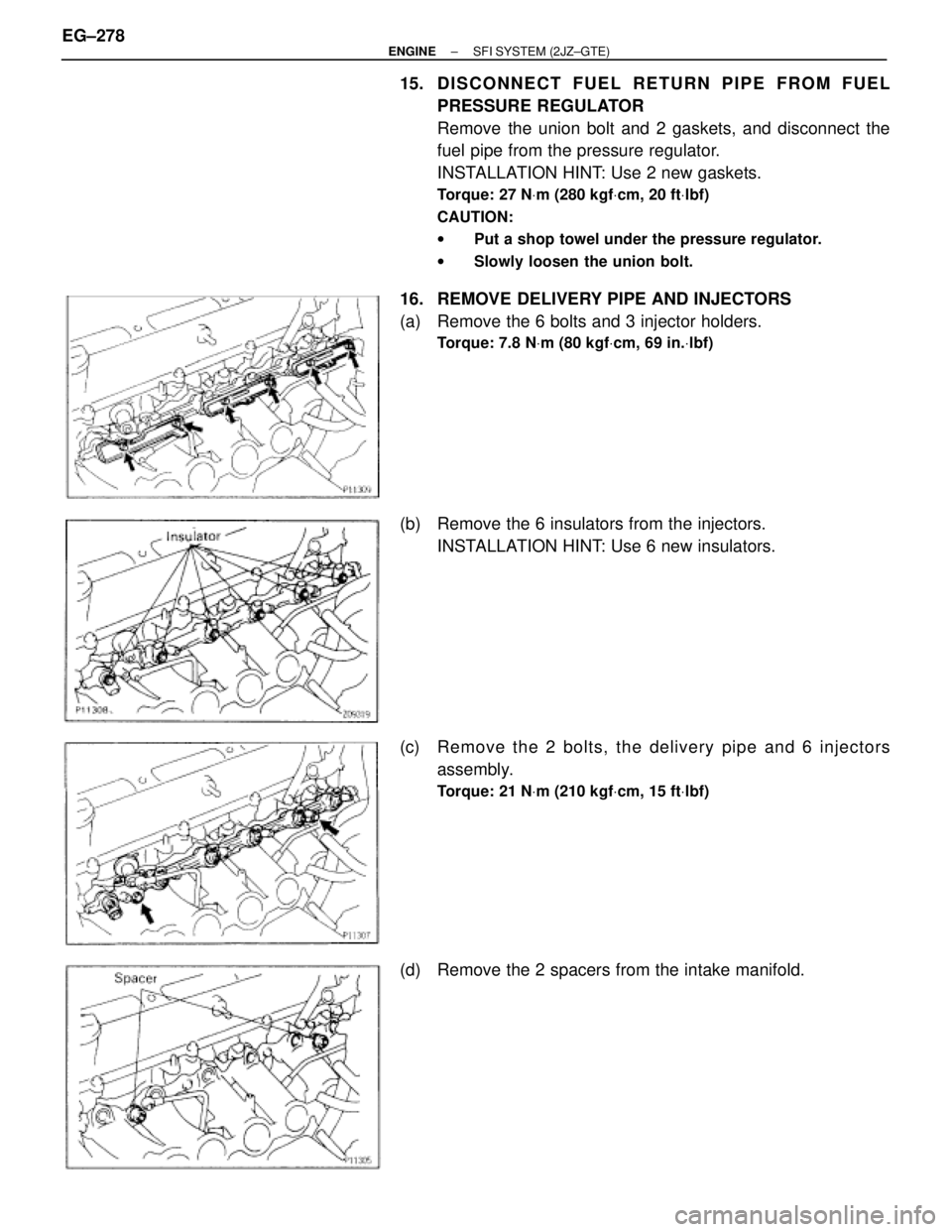

16. REMOVE DELIVERY PIPE AND INJECTORS

(a) Remove the 6 bolts and 3 injector holders.

Torque: 7.8 NVm (80 kgfVcm, 69 in.Vlbf)

(b) Remove the 6 insulators from the injectors.

INSTALLATION HINT: Use 6 new insulators.

(c) Re mo ve th e 2 bo lts, th e de live ry pip e an d 6 in je cto rs

assembly.

Torque: 21 NVm (210 kgfVcm, 15 ftVlbf)

(d) Remove the 2 spacers from the intake manifold. EG±278

± ENGINESFI SYSTEM (2JZ±GTE)

Page 263 of 878

(e) Remove the 6 insulators from the delivery pipe.

INSTALLATION HINT: Use 6 new insulators.

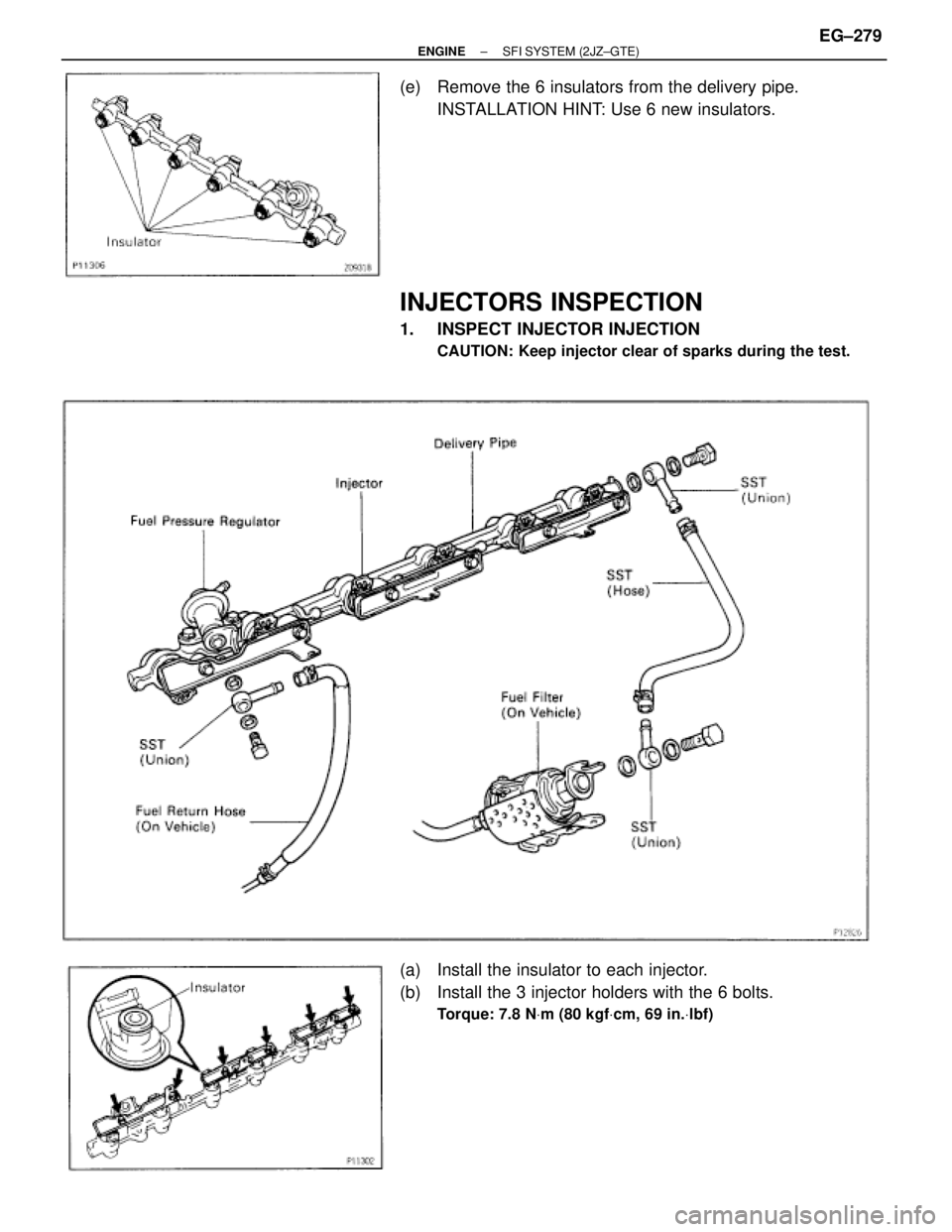

INJECTORS INSPECTION

1. INSPECT INJECTOR INJECTION

CAUTION: Keep injector clear of sparks during the test.

(a) Install the insulator to each injector.

(b) Install the 3 injector holders with the 6 bolts.

Torque: 7.8 NVm (80 kgfVcm, 69 in.Vlbf)

± ENGINESFI SYSTEM (2JZ±GTE)EG±279

Page 264 of 878

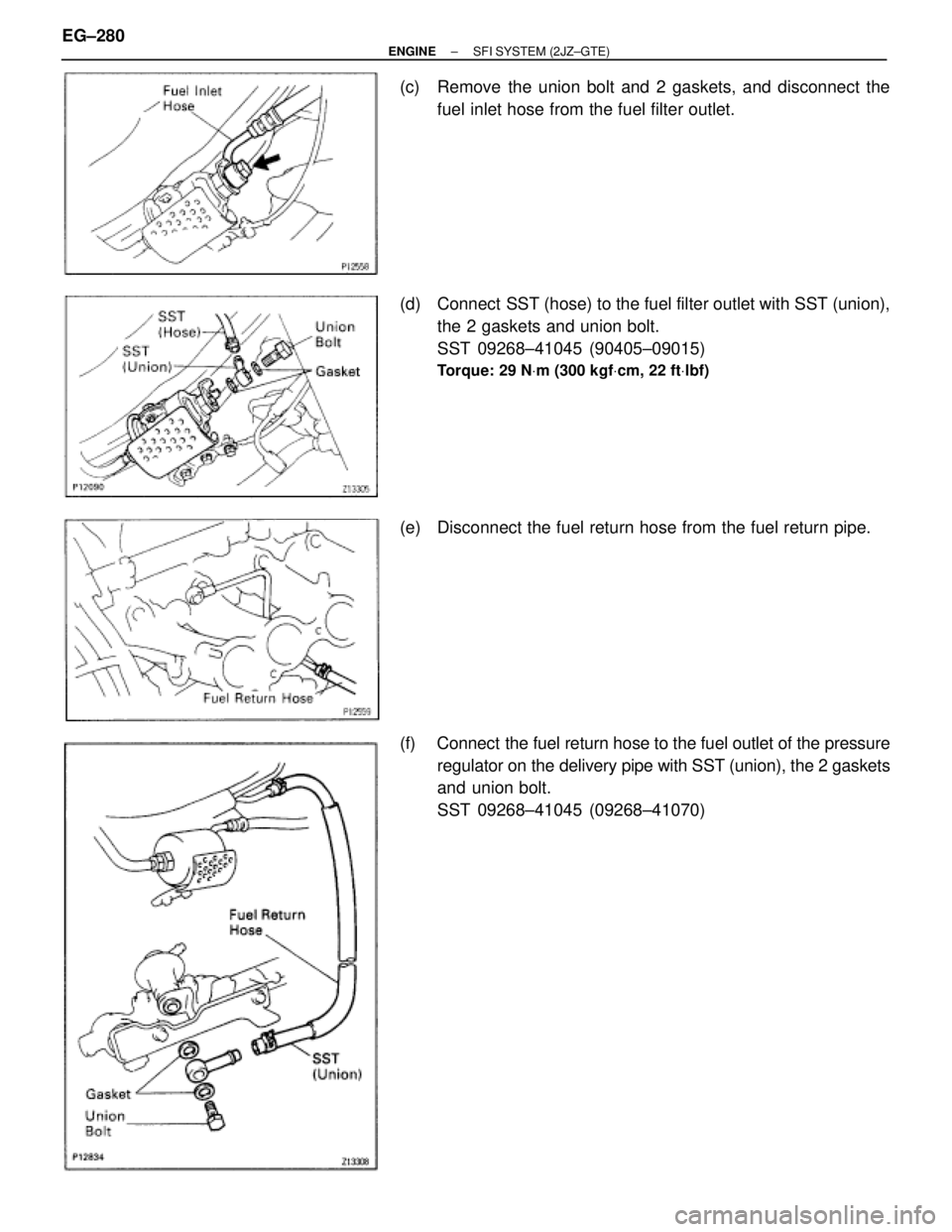

(c) Remove the union bolt and 2 gaskets, and disconnect the

fuel inlet hose from the fuel filter outlet.

(d) Connect SST (hose) to the fuel filter outlet with SST (union),

the 2 gaskets and union bolt.

SST 09268±41045 (90405±09015)

Torque: 29 NVm (300 kgfVcm, 22 ftVlbf)

(e) Disconnect the fuel return hose from the fuel return pipe.

(f) Connect the fuel return hose to the fuel outlet of the pressure

regulator on the delivery pipe with SST (union), the 2 gaskets

and union bolt.

SST 09268±41045 (09268±41070) EG±280

± ENGINESFI SYSTEM (2JZ±GTE)

Page 265 of 878

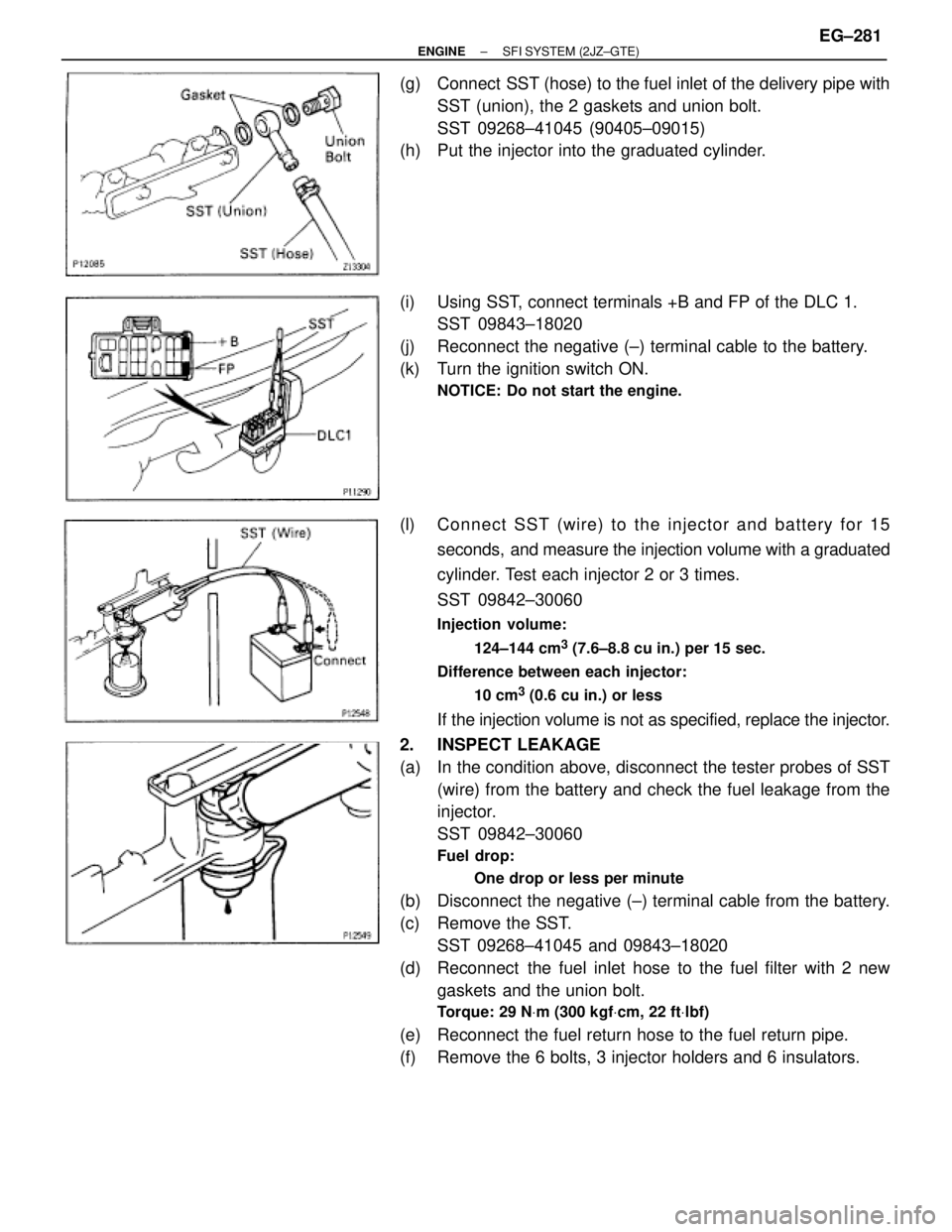

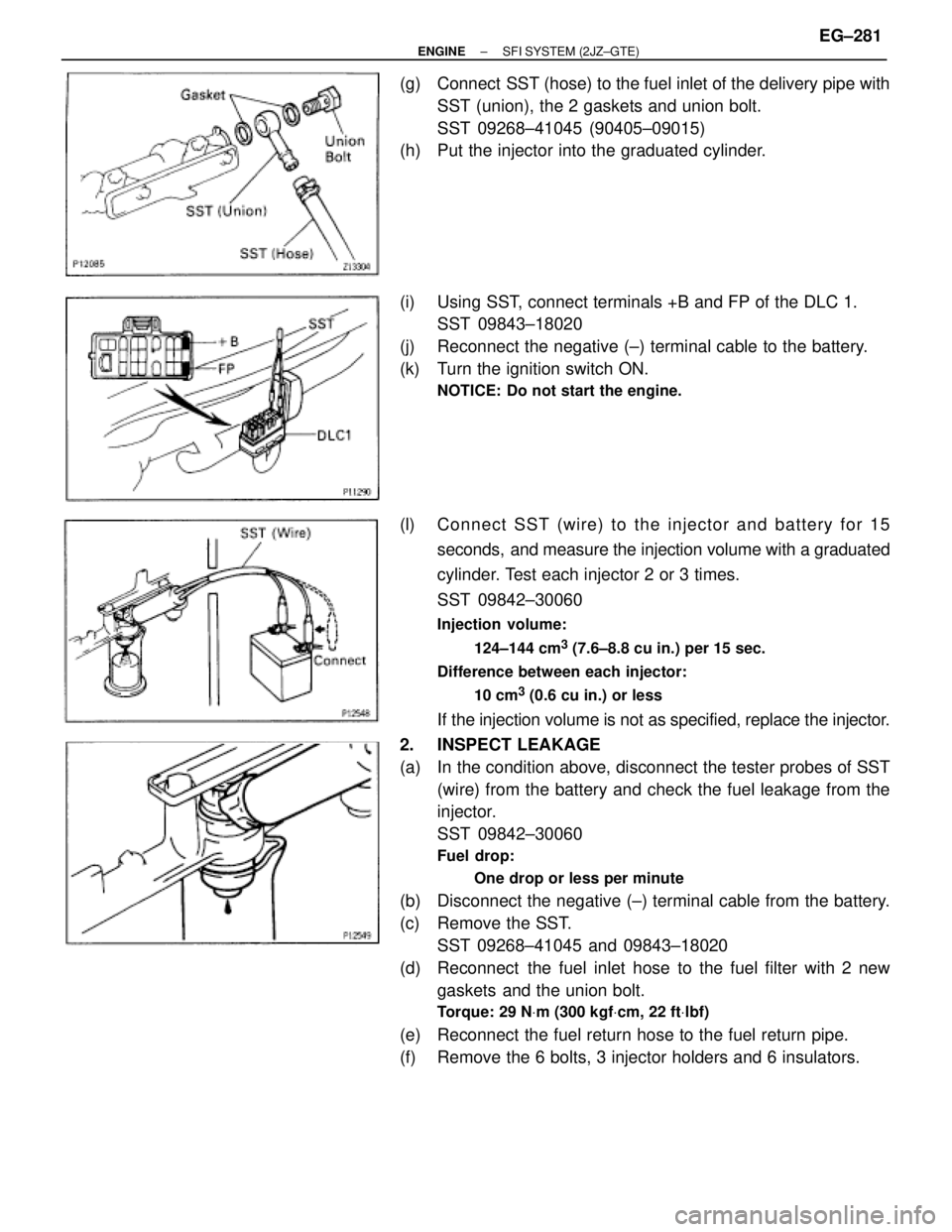

(g) Connect SST (hose) to the fuel inlet of the delivery pipe with

SST (union), the 2 gaskets and union bolt.

SST 09268±41045 (90405±09015)

(h) Put the injector into the graduated cylinder.

(i) Using SST, connect terminals +B and FP of the DLC 1.

SST 09843±18020

(j) Reconnect the negative (±) terminal cable to the battery.

(k) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(l) Connect SST (wire) to the injector and battery for 15

seconds, and measure the injection volume with a graduated

cylinder. Test each injector 2 or 3 times.

SST 09842±30060

Injection volume:

124±144 cm

3 (7.6±8.8 cu in.) per 15 sec.

Difference between each injector:

10 cm

3 (0.6 cu in.) or less

If the injection volume is not as specified, replace the injector.

2. INSPECT LEAKAGE

(a) In the condition above, disconnect the tester probes of SST

(wire) from the battery and check the fuel leakage from the

injector.

SST 09842±30060

Fuel drop:

One drop or less per minute

(b) Disconnect the negative (±) terminal cable from the battery.

(c) Remove the SST.

SST 09268±41045 and 09843±18020

(d) Reconnect the fuel inlet hose to the fuel filter with 2 new

gaskets and the union bolt.

Torque: 29 NVm (300 kgfVcm, 22 ftVlbf)

(e) Reconnect the fuel return hose to the fuel return pipe.

(f) Remove the 6 bolts, 3 injector holders and 6 insulators.

± ENGINESFI SYSTEM (2JZ±GTE)EG±281

Page 266 of 878

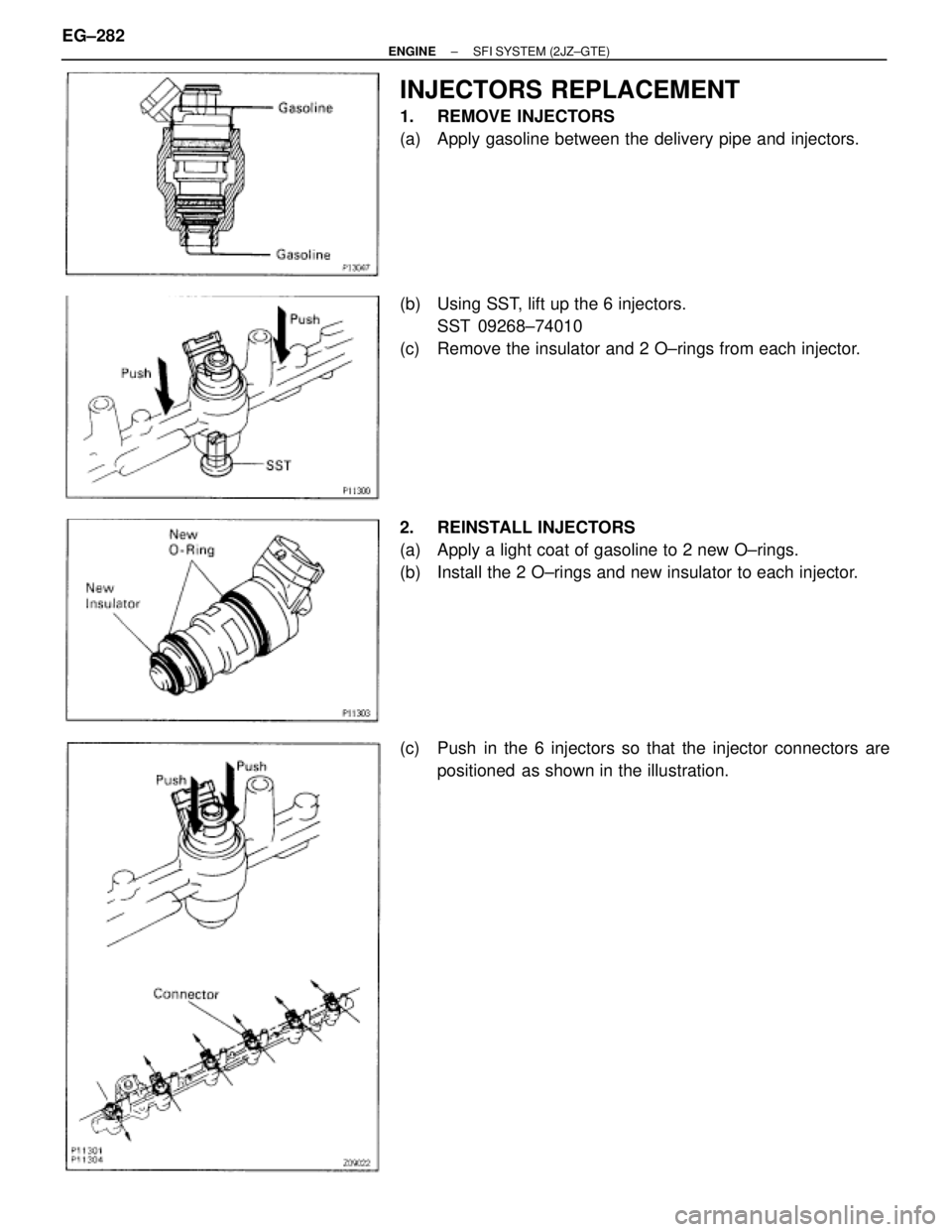

INJECTORS REPLACEMENT

1. REMOVE INJECTORS

(a) Apply gasoline between the delivery pipe and injectors.

(b) Using SST, lift up the 6 injectors.

SST 09268±74010

(c) Remove the insulator and 2 O±rings from each injector.

2. REINSTALL INJECTORS

(a) Apply a light coat of gasoline to 2 new O±rings.

(b) Install the 2 O±rings and new insulator to each injector.

(c) Push in the 6 injectors so that the injector connectors are

positioned as shown in the illustration. EG±282

± ENGINESFI SYSTEM (2JZ±GTE)

Page 267 of 878

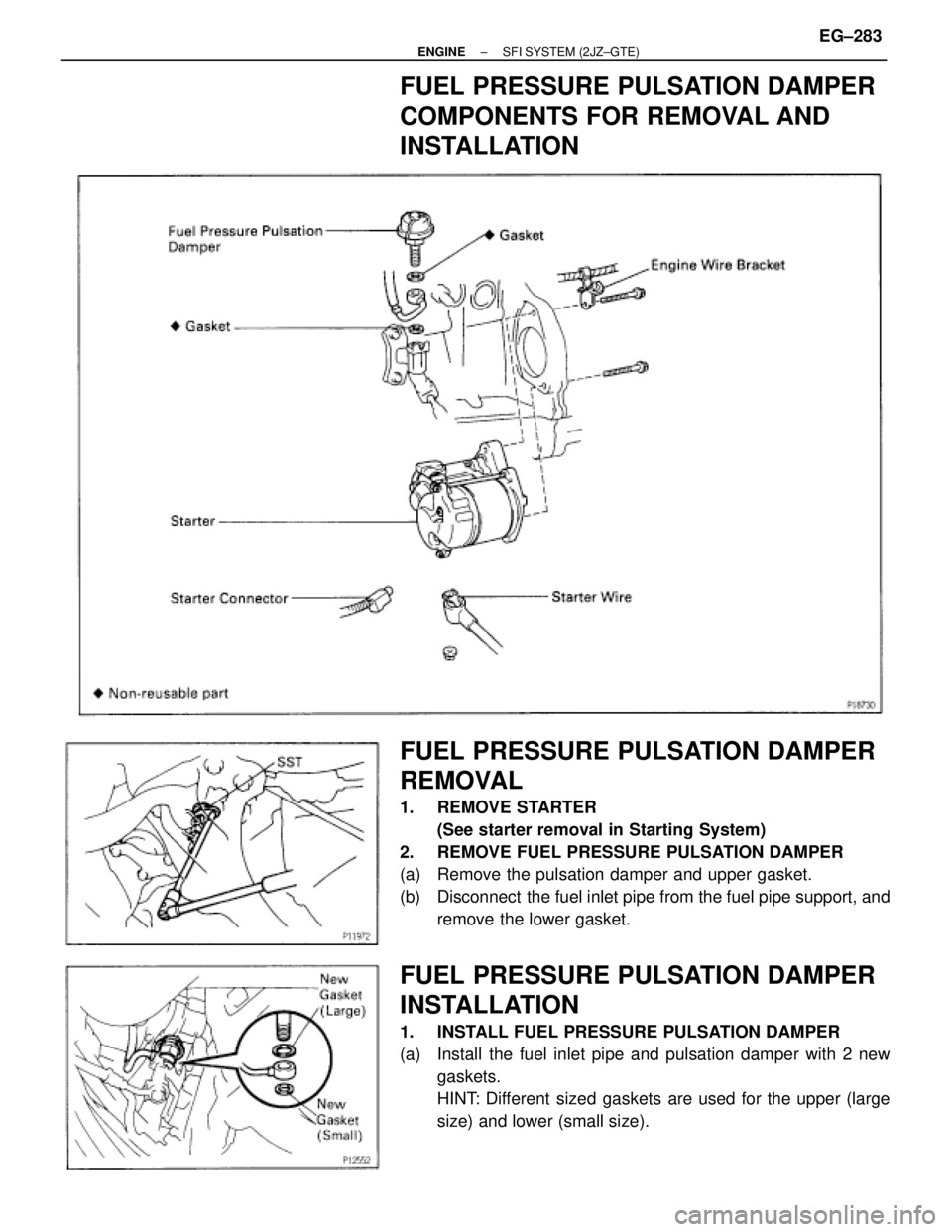

FUEL PRESSURE PULSATION DAMPER

COMPONENTS FOR REMOVAL AND

INSTALLATION

FUEL PRESSURE PULSATION DAMPER

REMOVAL

1. REMOVE STARTER

(See starter removal in Starting System)

2. REMOVE FUEL PRESSURE PULSATION DAMPER

(a) Remove the pulsation damper and upper gasket.

(b) Disconnect the fuel inlet pipe from the fuel pipe support, and

remove the lower gasket.

FUEL PRESSURE PULSATION DAMPER

INSTALLATION

1. INSTALL FUEL PRESSURE PULSATION DAMPER

(a) Install the fuel inlet pipe and pulsation damper with 2 new

gaskets.

HINT: Different sized gaskets are used for the upper (large

size) and lower (small size).

± ENGINESFI SYSTEM (2JZ±GTE)EG±283

Page 268 of 878

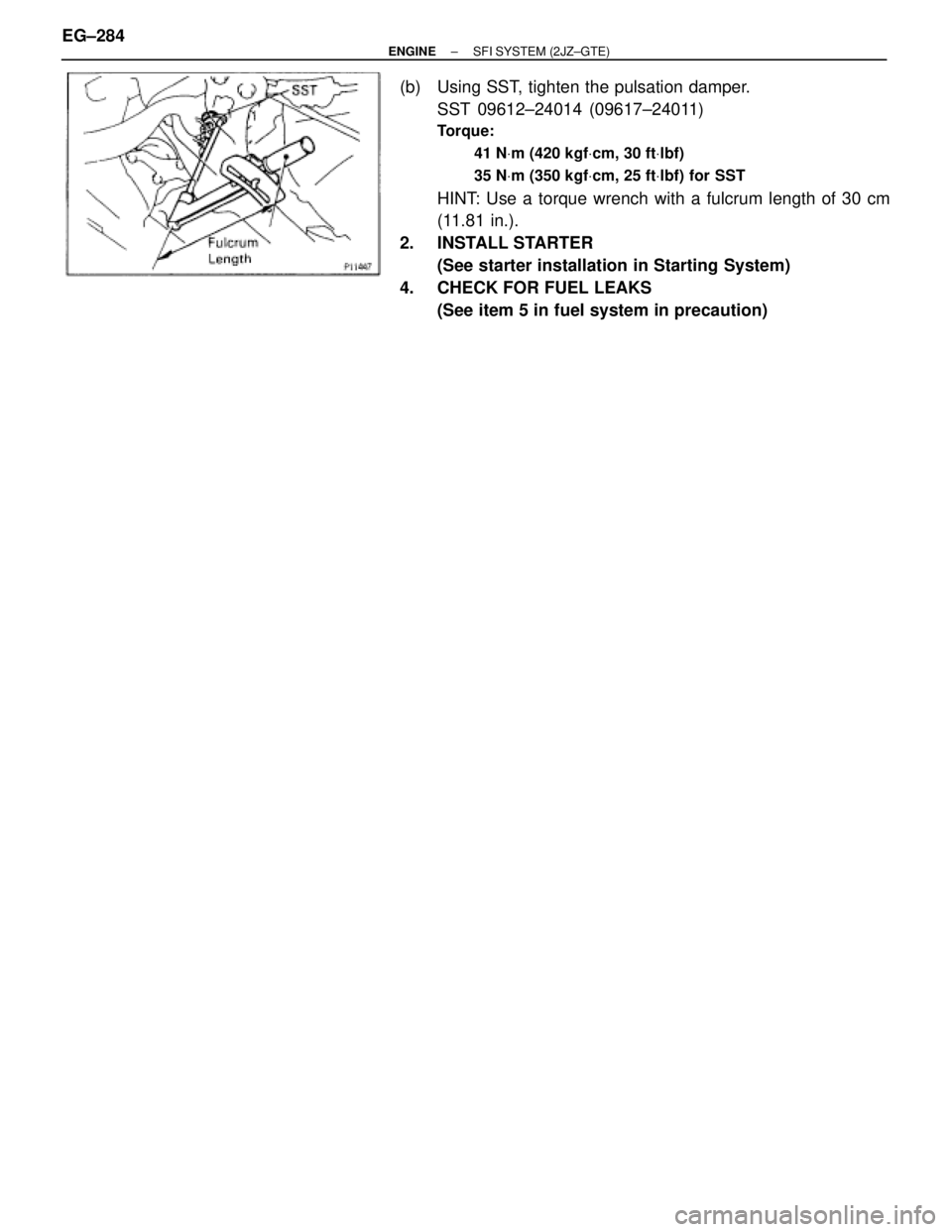

(b) Using SST, tighten the pulsation damper.

SST 09612±24014 (09617±24011)

Torque:

41 NVm (420 kgfVcm, 30 ftVlbf)

35 NVm (350 kgfVcm, 25 ftVlbf) for SST

HINT: Use a torque wrench with a fulcrum length of 30 cm

(11.81 in.).

2. INSTALL STARTER

(See starter installation in Starting System)

4. CHECK FOR FUEL LEAKS

(See item 5 in fuel system in precaution) EG±284

± ENGINESFI SYSTEM (2JZ±GTE)

Page 269 of 878

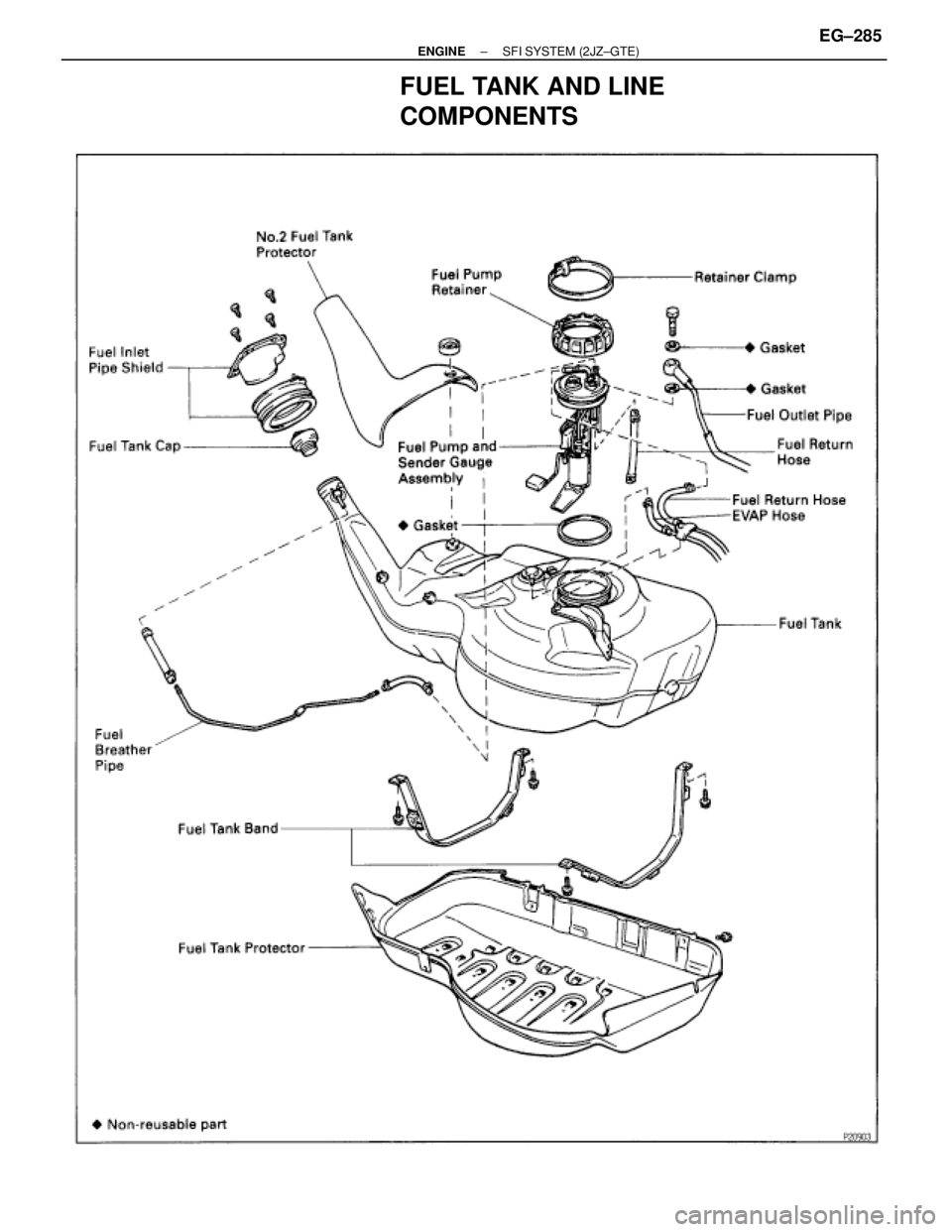

FUEL TANK AND LINE

COMPONENTS

± ENGINESFI SYSTEM (2JZ±GTE)EG±285

Page 270 of 878

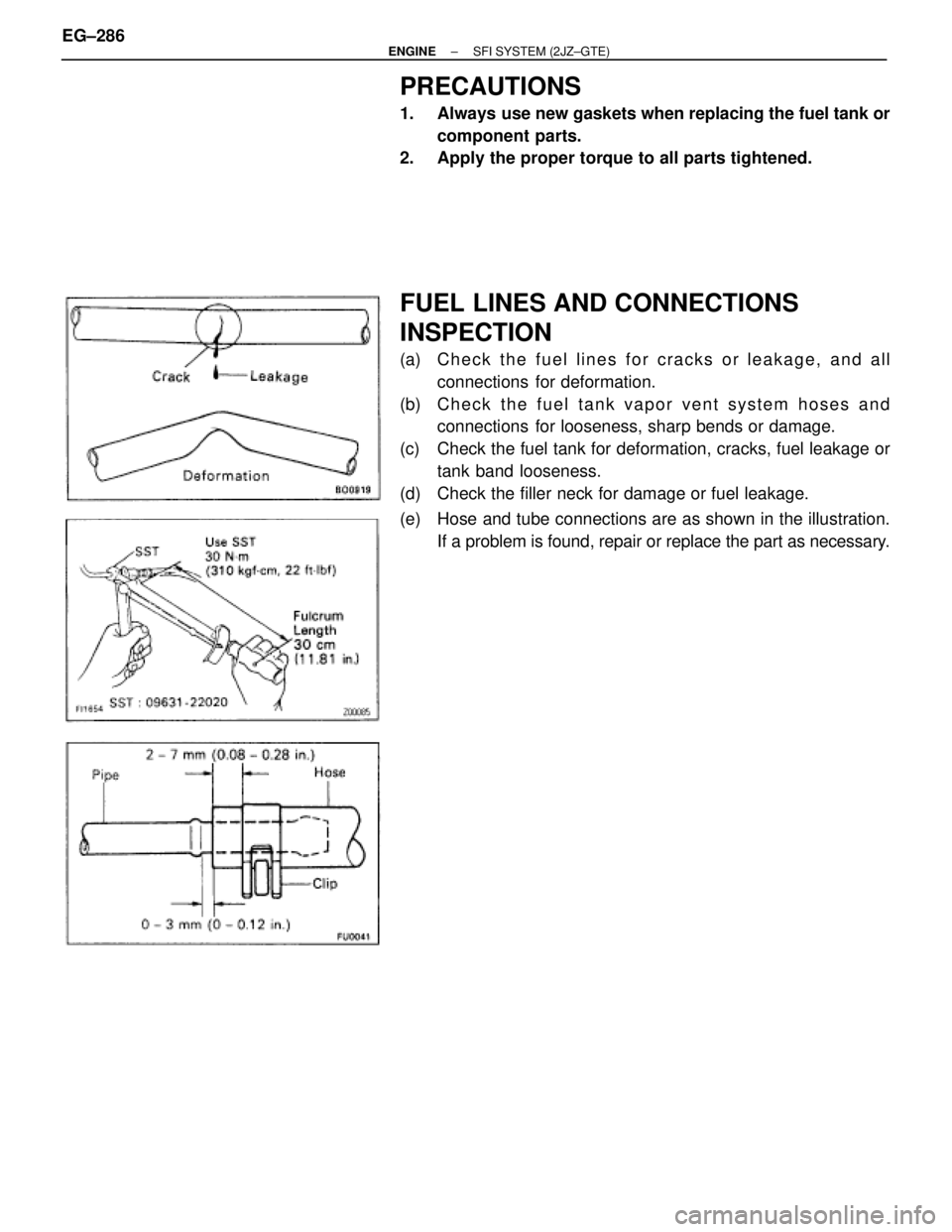

PRECAUTIONS

1. Always use new gaskets when replacing the fuel tank or

component parts.

2. Apply the proper torque to all parts tightened.

FUEL LINES AND CONNECTIONS

INSPECTION

(a) Check the fuel lines for cracks or leakage, and all

connections for deformation.

(b) C h e c k t h e f u e l t a n k vapor vent system hoses and

connections for looseness, sharp bends or damage.

(c) Check the fuel tank for deformation, cracks, fuel leakage or

tank band looseness.

(d) Check the filler neck for damage or fuel leakage.

(e) Hose and tube connections are as shown in the illustration.

If a problem is found, repair or replace the part as necessary. EG±286

± ENGINESFI SYSTEM (2JZ±GTE)

Trending: maintenance, bulb, oil reset, wheel, key, turn signal, remote start