TOYOTA TERCEL 1985 Repair Manual

TERCEL 1985

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57472/w960_57472-0.png

TOYOTA TERCEL 1985 Repair Manual

Trending: brake light, steering wheel, tire pressure, four wheel drive, oil viscosity, weight, ECU

Page 471 of 885

Page 472 of 885

Page 473 of 885

Page 474 of 885

Page 475 of 885

PR-1

PROPELLER SHAFT

(for 4WDl

PRECAUTIONS

TROUBLESHOOTING

PROPELLER SHAFT

Page

PR.2

PR-2

PR.2

ril:t'

ry*';'"'"s, 'f,'

$gu

Page 476 of 885

PR-z PROPELLER SHAFT - Precautions, Troubleshooting, Propeller Shaft

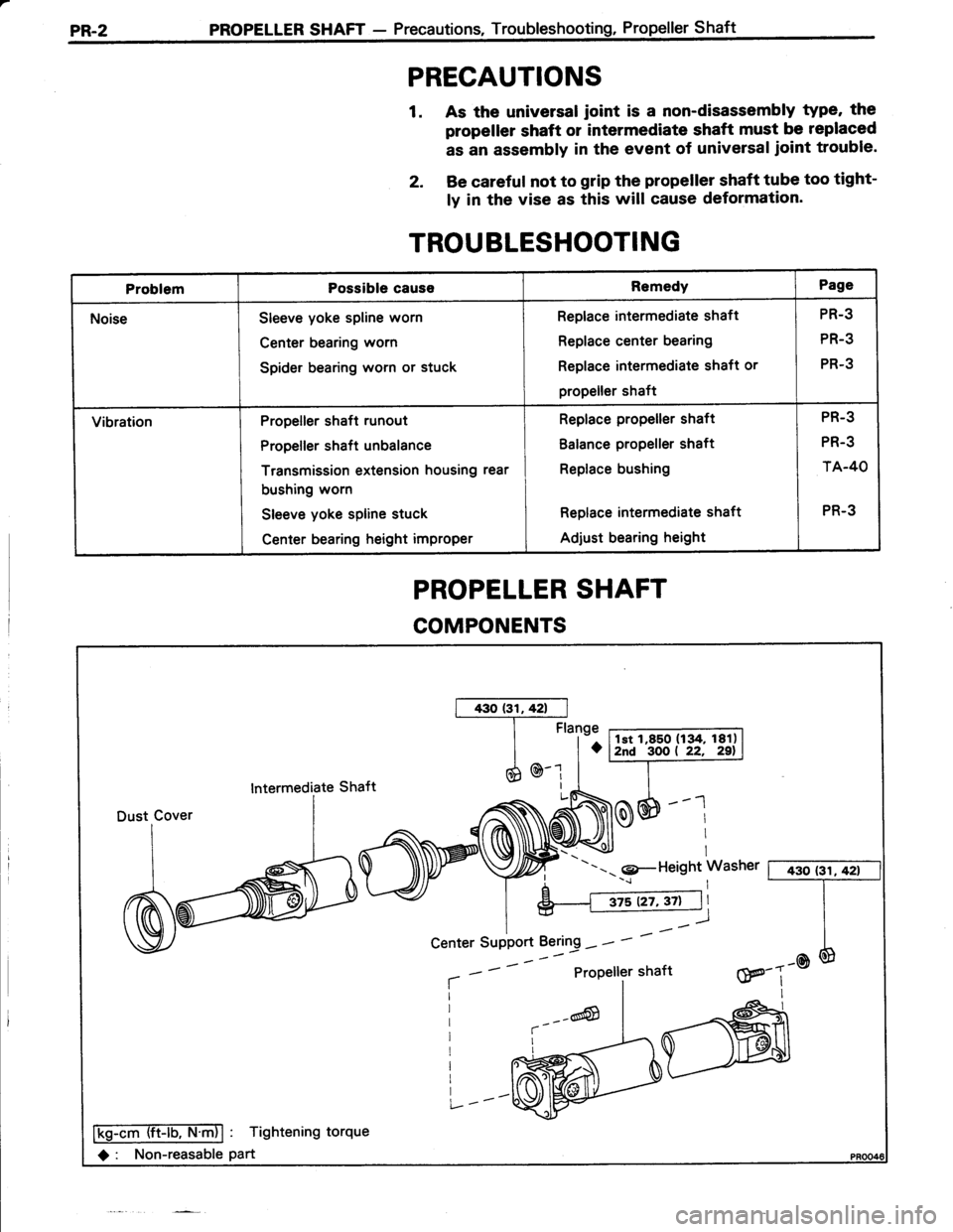

PRECAUTIONS

1. As the universal ioint is a non-disassembly type' the

propeller shaft or intermediate shaft must be replaced

as an assembly in the event of universalioint trouble.

2. Be careful not to grip the propeller shaft tube too tight-

ly in the vise as this will cause deformation.

TROUBLESHOOTING

ProblemPossible causeRemedyPage

NoiseSleeve yoke spline worn

Center bearing worn

Spider bearing worn or stuck

Replace intermediate shaft

Replace center bearing

Replace intermediate shaft or

propeller shaft

PR-3

PR-3

PR-3

VibrationPropeller shaft runout

Propeller shaft unbalance

Transmission extension housing rear

bushing worn

Sleeve yoke spline stuck

Center bearing height imProPer

Replace propeller shaft

Balance propeller shaft

Replace bushing

Replace intermediate shaft

Adjust bearing height

PR-3

PR-3

TA.4O

PR-3

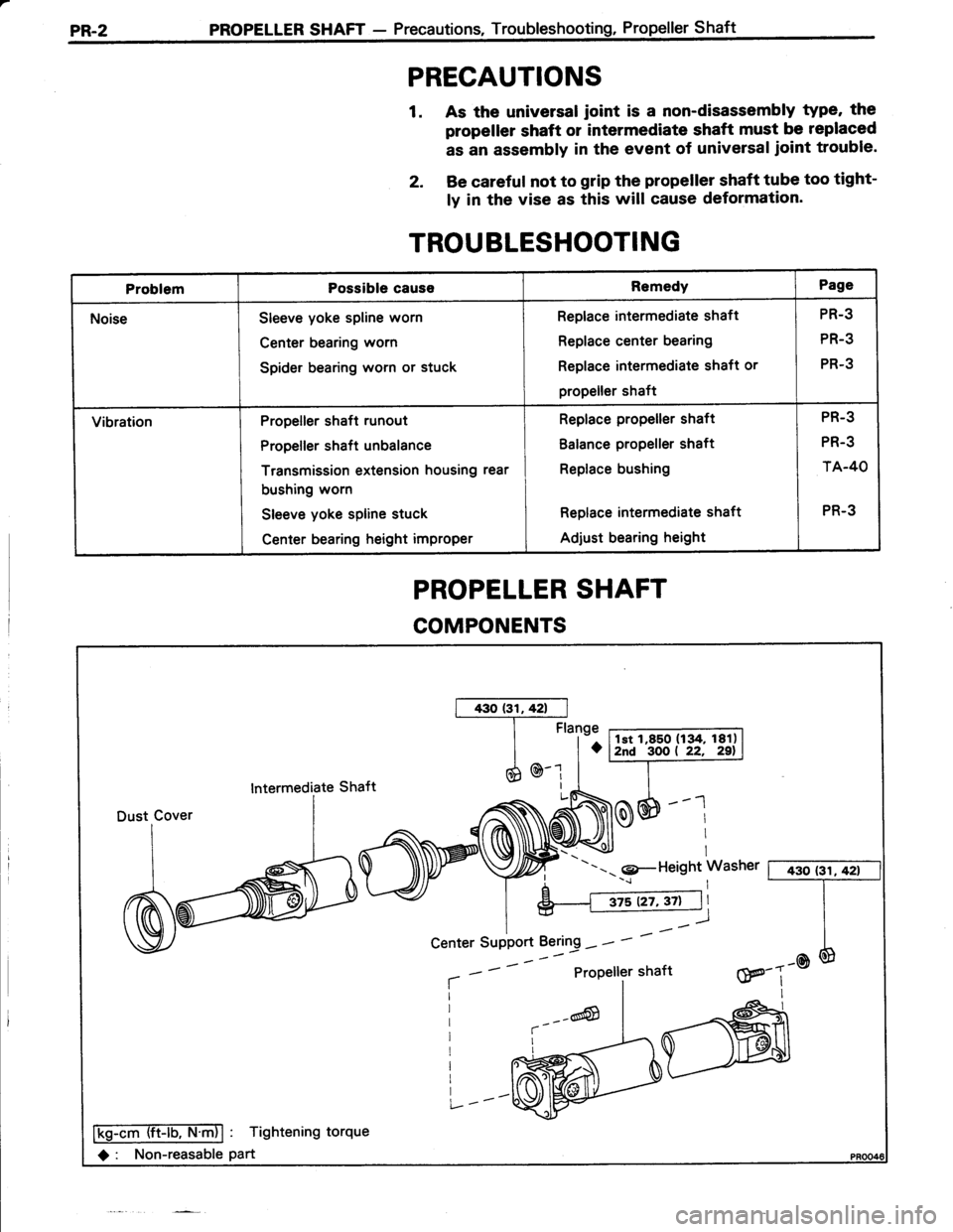

PROPELLER SHAFT

COMPONENTS

lntermediate Shaft

---- 9-Height Washer [ 430 (3il42t

aProPeller shaftw---@III

Ffiffiiib-ntnl : Tightening torque

O : Non-reasable part

Center SuPPort Bering - -

Page 477 of 885

PROPELLER SHAFT - Propeller ShaftPR.3

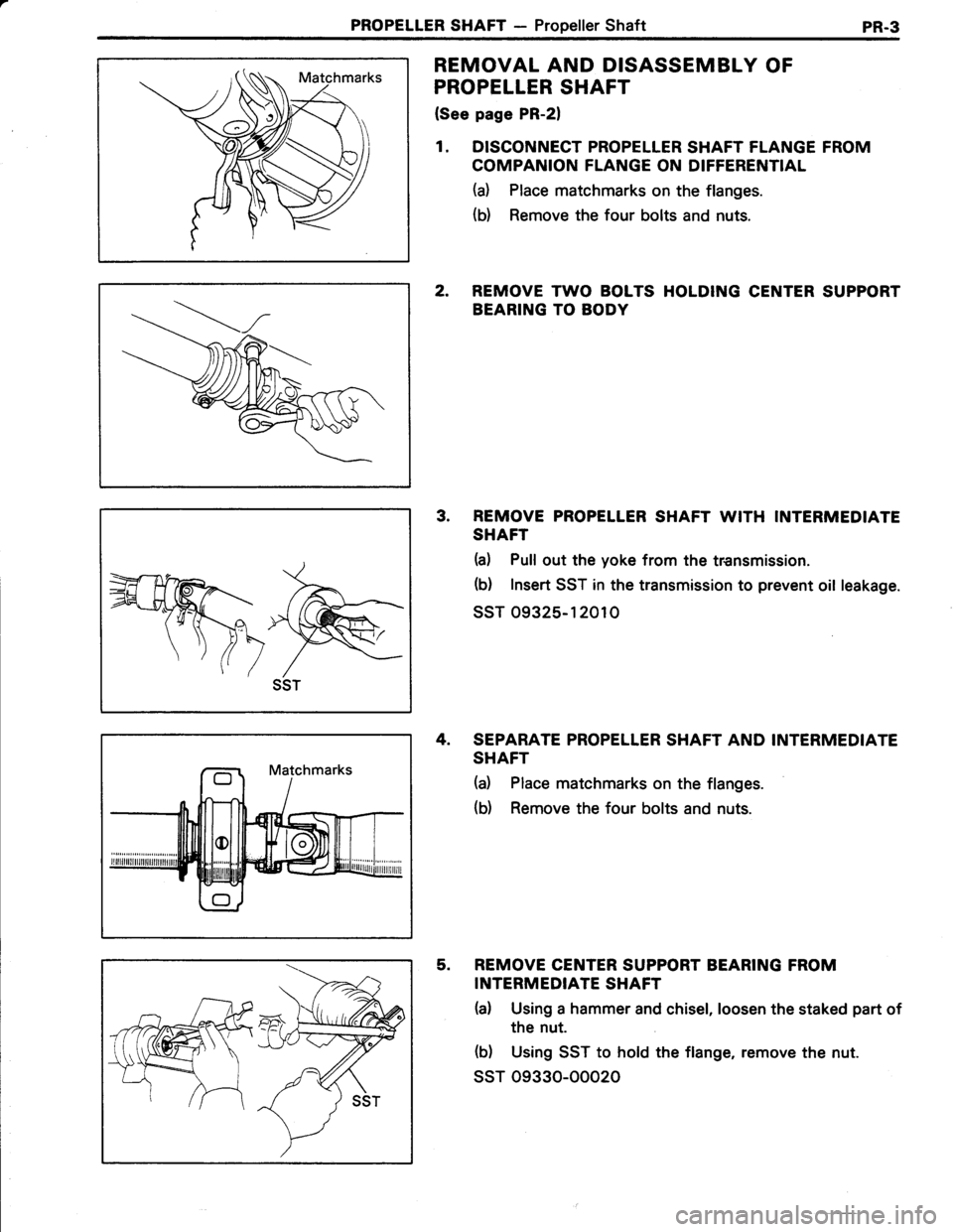

REMOVAL AND DISASSEMBLY OF

PROPELLER SHAFT

(See page PR-21

1. DISCONNECT PROPELLER SHAFT FLANGE FROM

COMPANION FLANGE ON DIFFERENTIAL

(a) Place matchmarks on the flanges.

(b) Remove the four bolts and nuts.

2. REMOVE TWO BOLTS HOLDING CENTER SUPPORT

BEARING TO BODY

3. REMOVE PROPELLER SHAFT WITH INTERMEDIATE

SHAFT

h) Pull out the yoke from the transmission.

(b) Insert SST in the transmission to prevent oil leakage.

ssT 09325-1 20rO

4. SEPARATE PROPELLER SHAFT AND INTERMEDIATE

SHAFT

(a) Place matchmarks on the flanges.

(b) Remove the four bolts and nuts.

5. REMOVE CENTER SUPPORT BEARING FROM

INTERMEDIATE SHAFT

(a) Using a hammer and chisel, loosen the staked part of

the nut.

(b) Using SST to hold the flange, remove the nut.

ssT 09330-00020

Page 478 of 885

PR-4PROPELLER SHAFT - Propeller Shaft

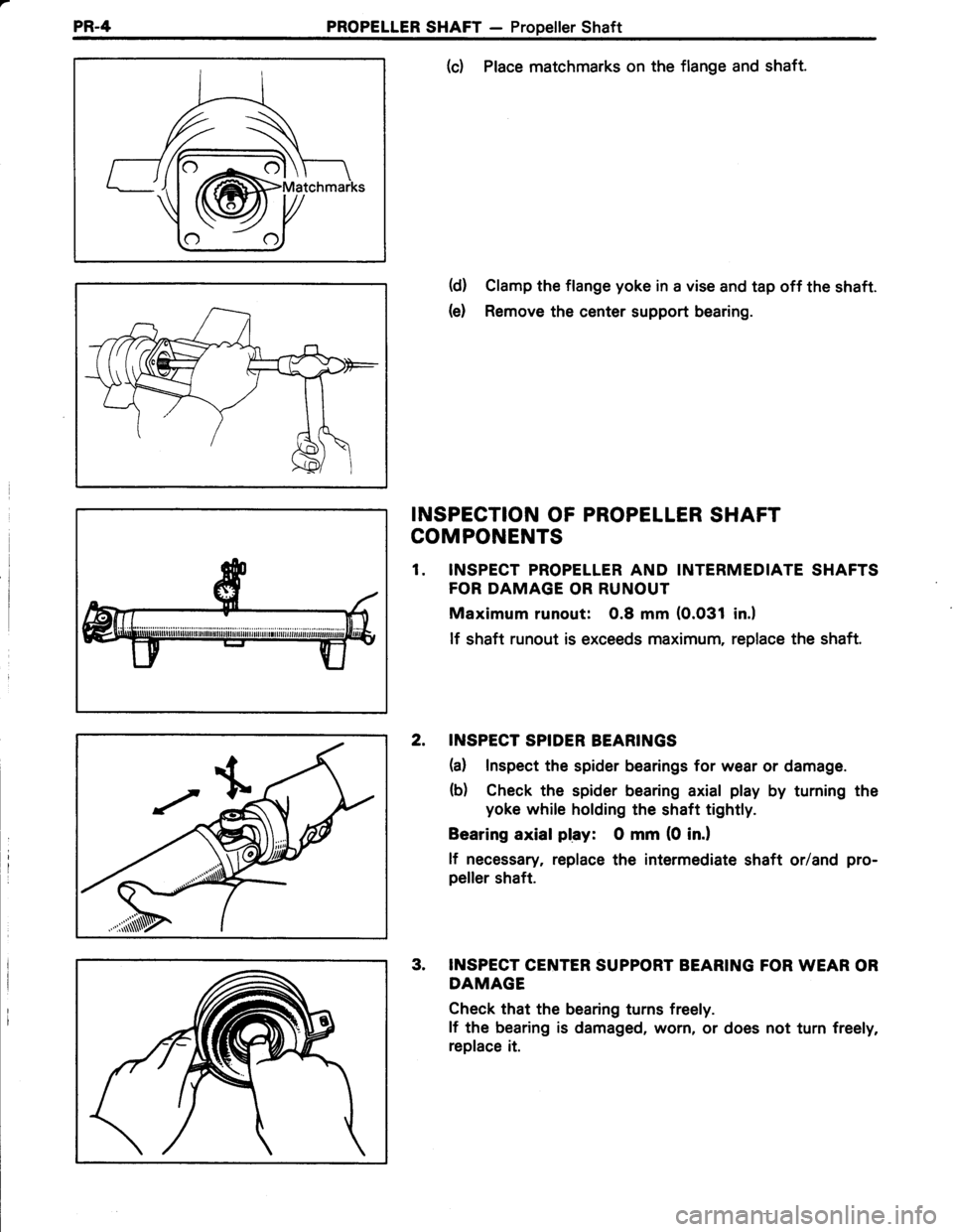

(c) Place matchmarks on the flange and shaft.

(d) Clamp the flange yoke in a vise and tap off the shaft.

(e) Remove the center support bearing.

INSPECTION OF PROPELLER SHAFT

COMPONENTS

1. INSPECT PROPELLER AND INTERMEDIATE SHAFTS

FOR DAMAGE OR RUNOUT

Maximum runout: 0.8 mm (0.031 in.l

lf shaft runout is exceeds maximum, replace the shaft.

2. INSPECT SPIDER BEARINGS

(a) Inspect the spider bearings for wear or damage.

(b) Check the spider bearing axial play by turning the

yoke while holding the shaft tightly.

Bearing axial play: O mm (0 in.l

lf necessary, replace the intermediate shaft orland pro-

peller shaft.

3. INSPECT CENTER SUPPORT BEARING FOR WEAR OR

DAMAGE

Check that the bearing turns freely.

lf the bearing is damaged, worn, or does not turn freely,

replace it.

Page 479 of 885

PROPELLER SHAFT - Propeller ShaftPR.5

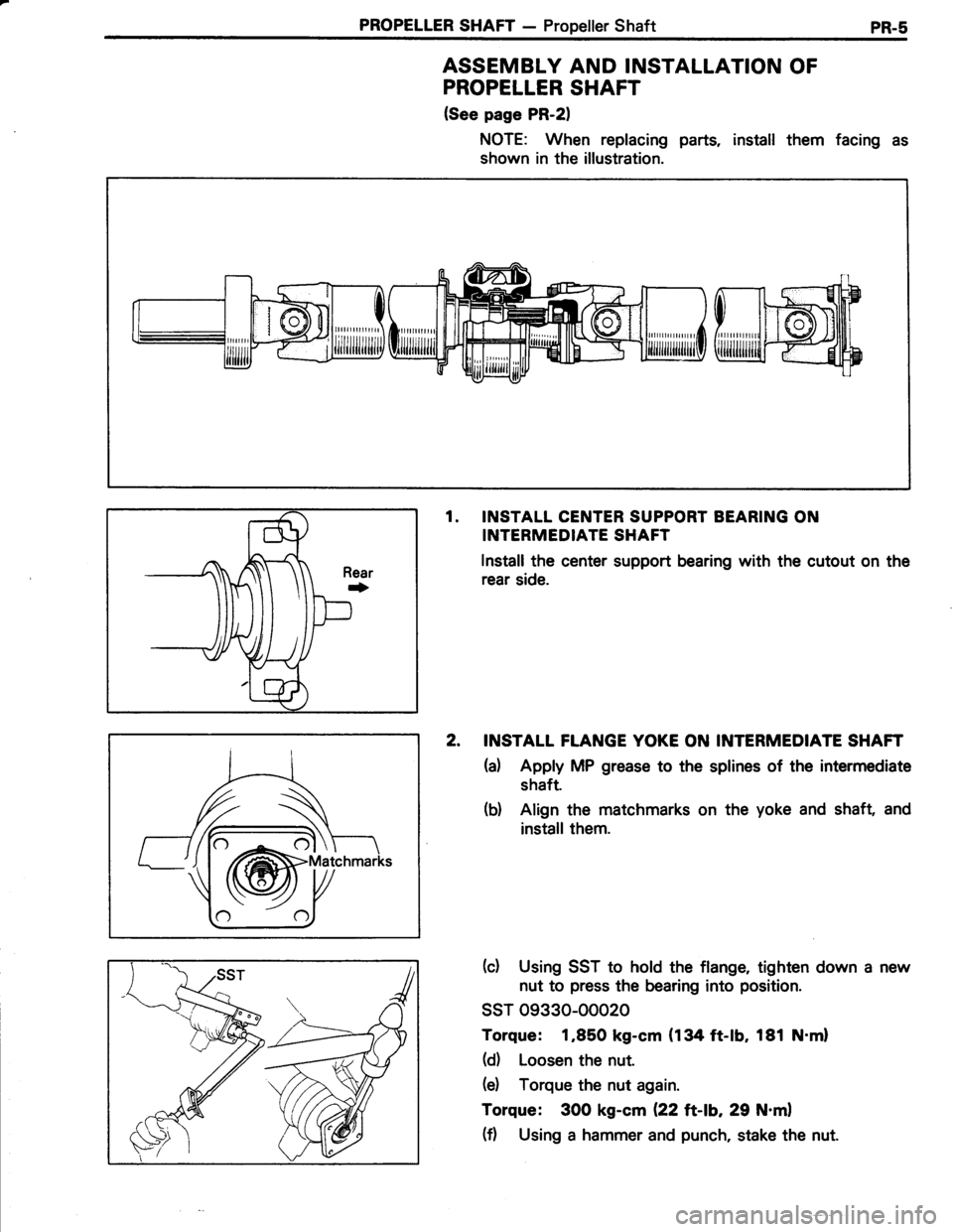

ASSEMBLY AND INSTALLATION OF

PROPELLER SHAFT

(See page PR-21

NOTE: When replacing parts, install them facing as

shown in the illustration.

fl

rthffihP

tuldi€?ih

1. INSTALL CENTER SUPPORT BEARING ON

INTERMEDIATE SHAFT

lnstall the center support bearing with the cutout on the

rear side.

2. INSTALL FTANGE YOKE ON INTERMEDIATE SHAFT

ta) Apply MP grease to the splines of the intermediate

shaft.

(b) Align the matchmarks on the yoke and shaft and

install them.

(c) Using SST to hold the flange, tighten down a

nut to press the bearing into position.

ssT 09330-ooo20

Torque: 1,850 kg-cm (134 ft-lb, 181 N.ml

(d) Loosen the nut.

(e) Torque the nut again.

Torque: 300 kg-cm (22 ft-\b,29 N.ml

(f) Using a hammer and punch, stake the nut.

Page 480 of 885

PR-6 PROPELLER SHAFT - Propeiler Shaft

SST

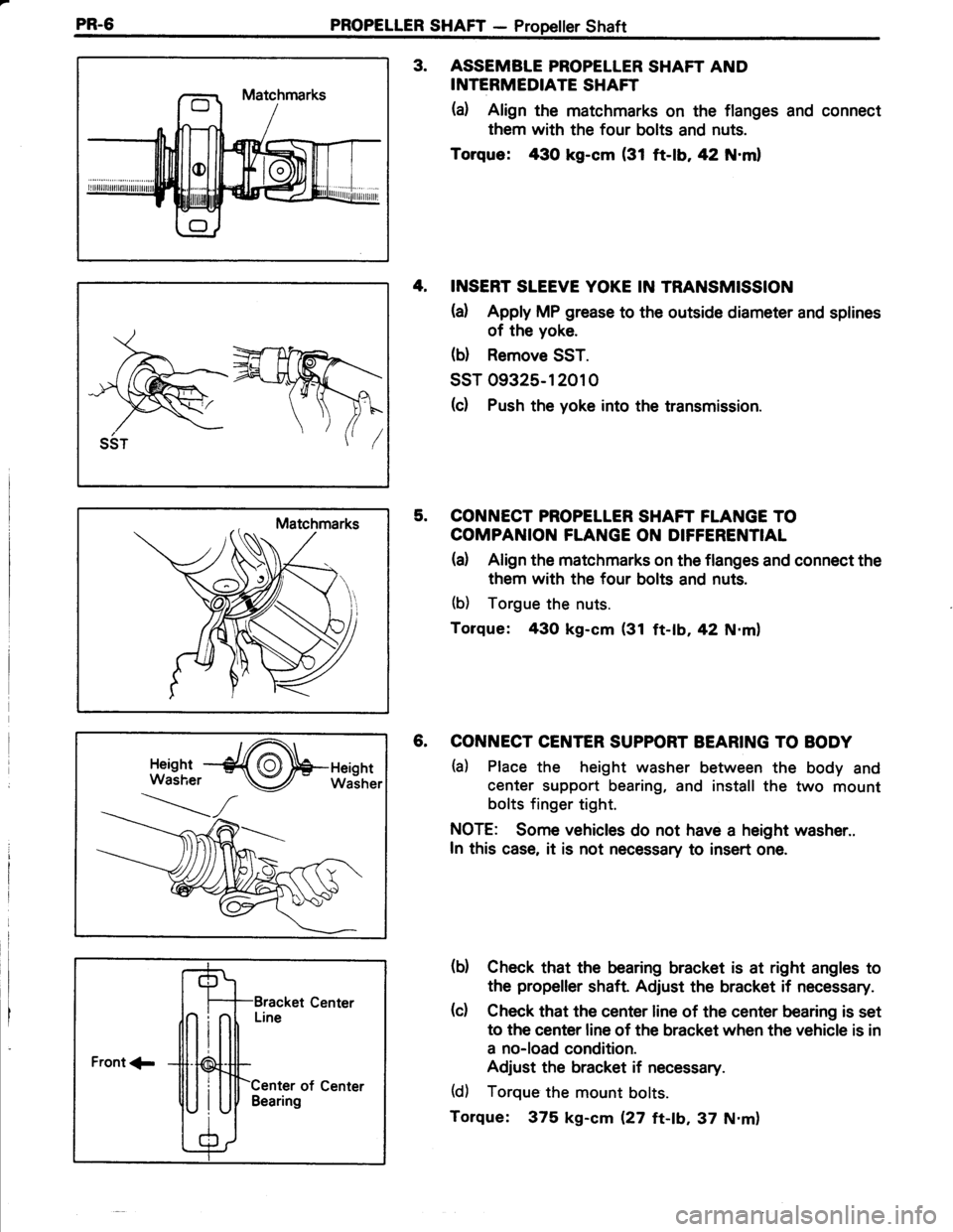

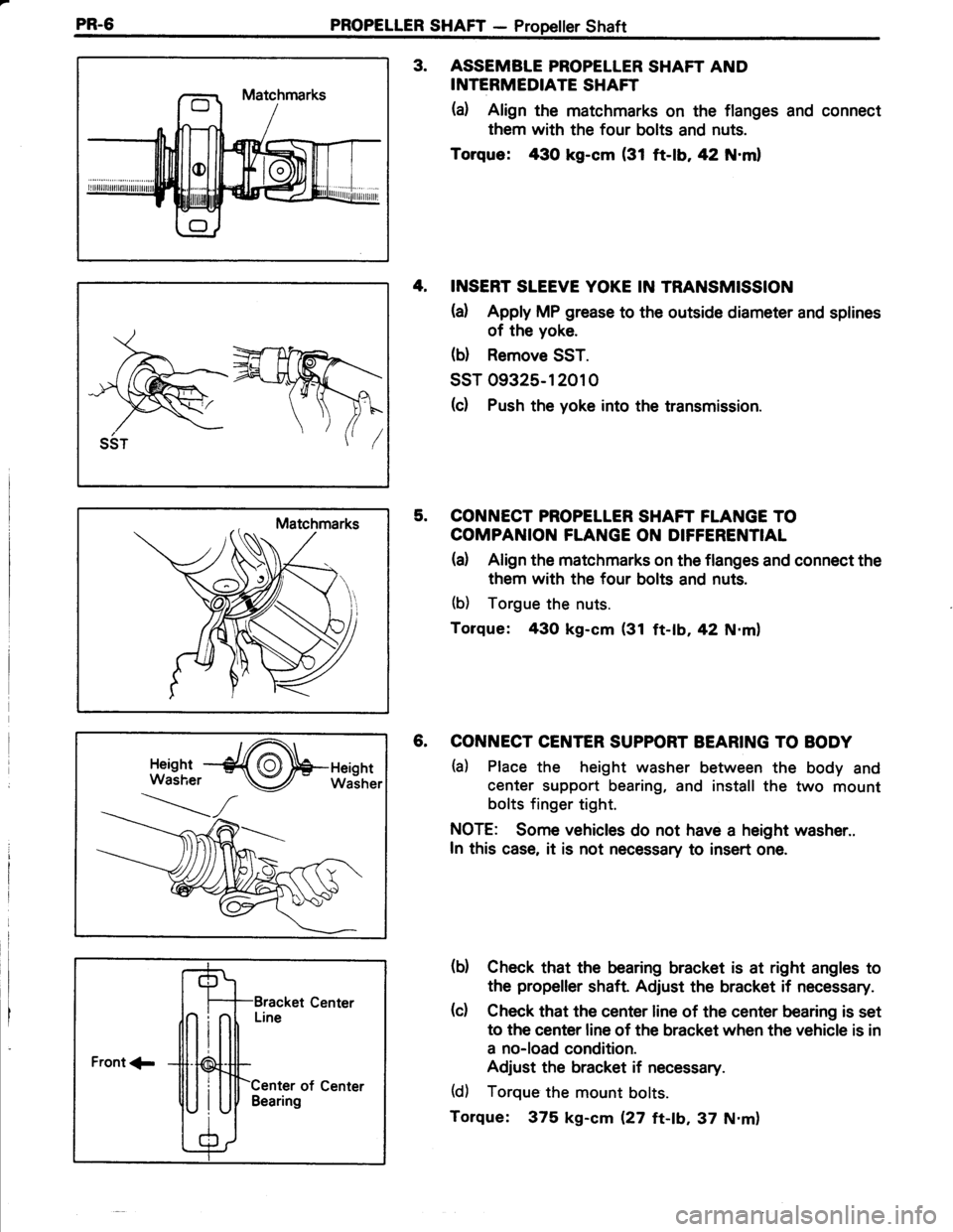

3. ASSEMBTE PROPELLER SHAFT AND

INTERMEDIATE SHAFT

(a) Align the matchmarks on the flanges and connect

them with the four bolts and nuts.

Torque: 430 kg-cm (31 ft-|b,42 N.ml

4, INSERT SLEEVE YOKE IN TRANSMISSION

{a) Apply MP grease to the outsade diameter and splines

of the yoke.

(b) Remove SST.

ssT 09325-12010

(c) Push the yoke into the transmission.

5. CONNECT PROPELLER SHAFT FLANGE TO

COMPANION FLANGE ON DIFFERENTIAL

(a) Align the matchmarks on the flanges and connect the

them with the four bolts and nuts.

(b) Torgue the nuts.

Torque: 43O kg-cm (31 ft-tb,42 N.m)

6. CONNECT CENTER SUPPORT BEARING TO BODY

ta) Place the height washer between the body and

center support bearing, and install the two mount

bolts finger tight.

NOTE: Some vehicles do not have a height washer..

In this case, it is not necessary to insert one.

(b) Check that the bearing bracket is at right angles to

the propeller shaft Adjust the bracket if necessary.

(c) Check that the center line of the center bearing is set

to the center line of the bracket when the vehicle is in

a no-load condition.

Adjust the bracket if necessary.

(d) Torque the mount bolts.

Torque: 375 kg-cm Q7 tt-ab,37 N.m)

Front 1-

Center of CenterBearing

Trending: boot, torque, heater, engine, 4WD, lock, wheel alignment