VOLKSWAGEN CORRADO 1993 Repair Manual

Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 341 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

DIESEL KIKI 6-CYLINDER CLUTCH COIL R & I

NOTE: Due to variety of clutch and shaft seal configurations,

obtain appropriate A/C compressor service tools for

compressor being serviced.

Removal & Installation

1) Using Clutch Holder (J-33939) to prevent clutch disc from

rotating, remove shaft bolt. Using Clutch Disc Puller (J-33944-A) and

Forcing Bolt (J-33944-4), remove clutch disc. Remove shim(s) from

compressor drive shaft or clutch disc. See Fig. 5.

2) Remove snap ring, cover and pulley. With Puller Guide (J-

33943-A) in center of pulley, attach Crossbar (J-8433) to outside

diameter of pulley. Tighten crossbar bolt against puller guide to

remove pulley. Remove coil lead, screws, and coil.

3) To install, reverse removal procedure. Install cover snap

ring with beveled side facing out. Install clutch disc and tighten

center bolt to 133 INCH lbs. (15 N.m).

4) Using feeler gauge, ensure clearance between clutch disc

and pulley is .012-.024" (.30-.60 mm). If clearance is incorrect, add

or remove shim(s) as necessary.

DIESEL KIKI SHAFT SEAL R & I

Removal & Installation

1) Remove clutch coil. Remove and discard felt. Using Shaft

Seal Cover Remover/Installer (J-33942), push down and turn remover

clockwise to engage tangs to cover. Slowly remove seal cover from

bore.

2) Remove shaft seal snap ring. Use Shaft Seal Remover (J-

33942-B) to remove seal. Remove compressor through bolts, front head

and "O" ring. If necessary, replace front and rear valve plates, reed

valves, and "O" rings.

3) To install, reverse removal procedure. Coat "O" ring,

shaft seal and seal seat with refrigerant oil. Place Shaft Seal Guide

(J-34614) over end of compressor shaft. Ensure chamfered portion of

shaft seal retainer aligns with chamfered portion on compressor shaft.

4) Install front head and tighten compressor through bolts,

in a crisscross pattern, to 16 ft. lbs. (22 N.m). Install shaft seal

cover and felt. See Fig. 5. Rotate compressor drive shaft 2-3 times to

ensure compressor operates smoothly.

Page 342 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PMFig. 5: Exploded View Of Compressor (Diesel Kiki 6-Cylinder)

Courtesy of Isuzu Motor Co.

FORD FX-15 CLUTCH COIL R & I

Removal

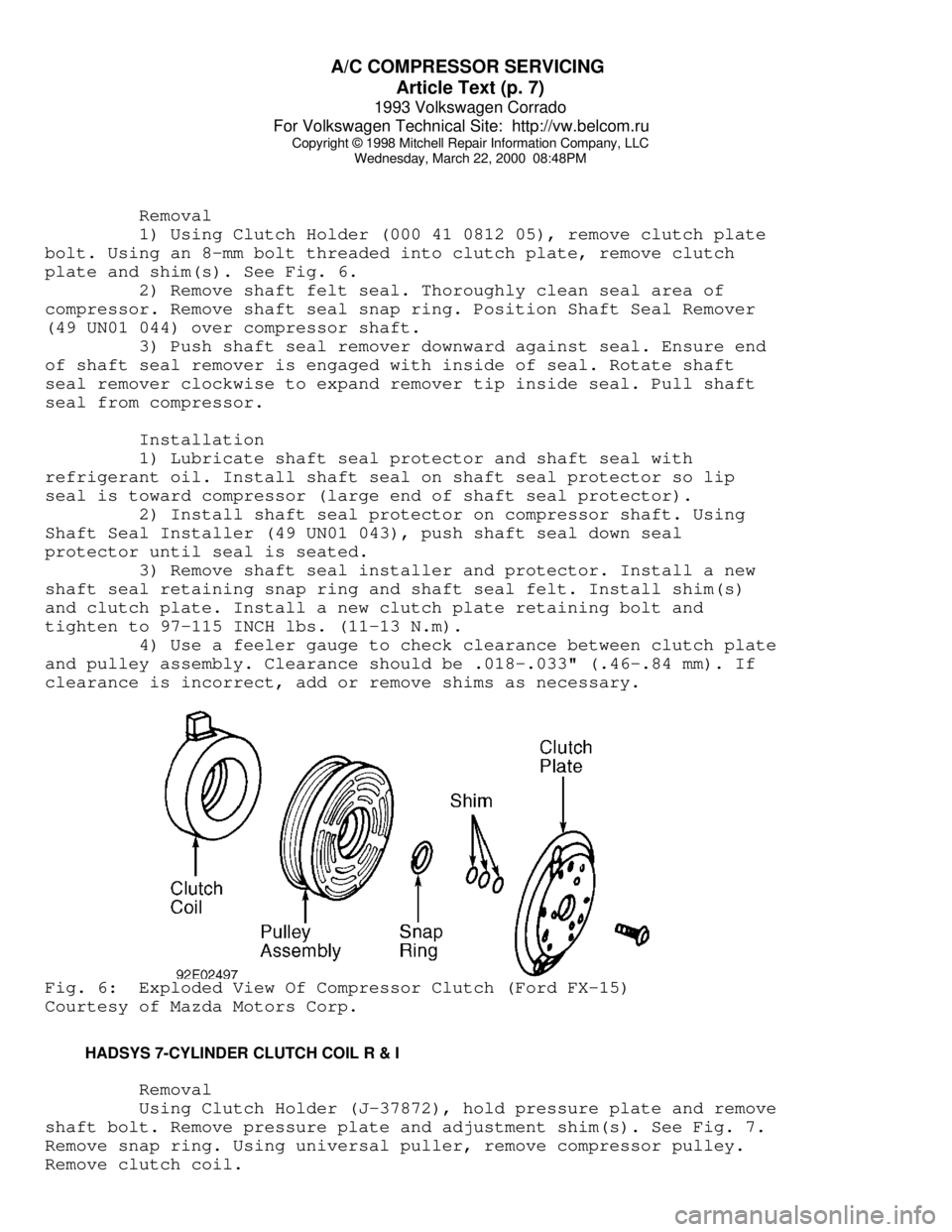

1) Using Clutch Holder (000 41 0812 05), remove clutch plate

bolt. Using an 8-mm bolt threaded into clutch plate, remove clutch

plate and shim(s). See Fig. 6.

2) Remove snap ring and pulley assembly. Install Shaft

Protector (49 UN01 047) over shaft seal opening. Use a 2-jaw puller to

remove clutch coil from compressor.

Installation

1) Ensure clutch coil mounting surface is clean. Use Coil

Installer (49 UN01 046) and 2-jaw puller engaged to rear side of

compressor front mounts to press coil into place.

2) Install pulley assembly. Install pulley assembly snap ring

with bevel side of snap ring facing out. Install shim(s) and clutch

plate. Install a new clutch plate bolt and tighten to 97-115 INCH lbs.

(11-13 N.m).

3) Use a feeler gauge to check clearance between clutch plate

and pulley assembly. Clearance should be .018-.033" (.46-.84 mm). If

clearance is incorrect, add or remove shims as necessary.

FORD FX-15 SHAFT SEAL R & I

Page 343 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

Removal

1) Using Clutch Holder (000 41 0812 05), remove clutch plate

bolt. Using an 8-mm bolt threaded into clutch plate, remove clutch

plate and shim(s). See Fig. 6.

2) Remove shaft felt seal. Thoroughly clean seal area of

compressor. Remove shaft seal snap ring. Position Shaft Seal Remover

(49 UN01 044) over compressor shaft.

3) Push shaft seal remover downward against seal. Ensure end

of shaft seal remover is engaged with inside of seal. Rotate shaft

seal remover clockwise to expand remover tip inside seal. Pull shaft

seal from compressor.

Installation

1) Lubricate shaft seal protector and shaft seal with

refrigerant oil. Install shaft seal on shaft seal protector so lip

seal is toward compressor (large end of shaft seal protector).

2) Install shaft seal protector on compressor shaft. Using

Shaft Seal Installer (49 UN01 043), push shaft seal down seal

protector until seal is seated.

3) Remove shaft seal installer and protector. Install a new

shaft seal retaining snap ring and shaft seal felt. Install shim(s)

and clutch plate. Install a new clutch plate retaining bolt and

tighten to 97-115 INCH lbs. (11-13 N.m).

4) Use a feeler gauge to check clearance between clutch plate

and pulley assembly. Clearance should be .018-.033" (.46-.84 mm). If

clearance is incorrect, add or remove shims as necessary.Fig. 6: Exploded View Of Compressor Clutch (Ford FX-15)

Courtesy of Mazda Motors Corp.

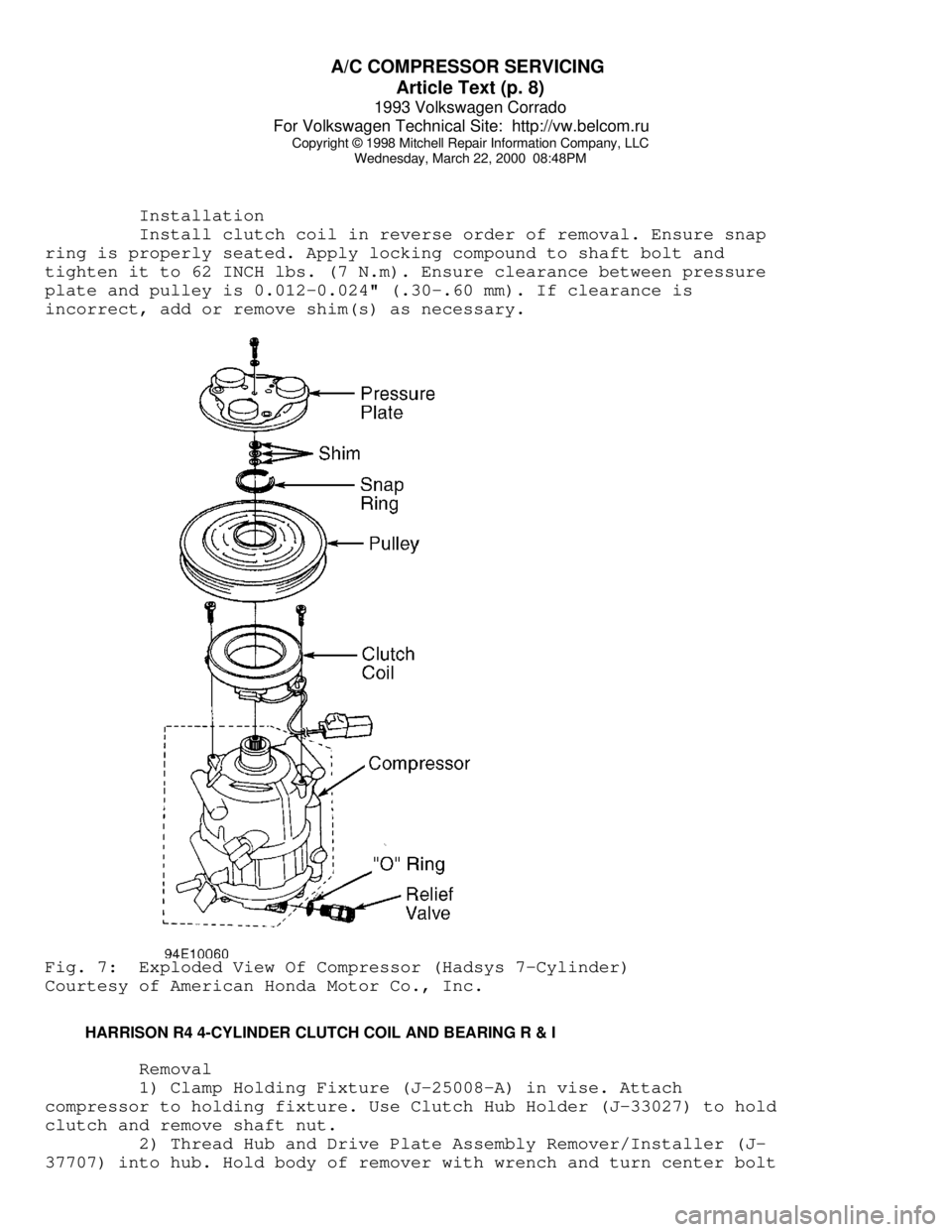

HADSYS 7-CYLINDER CLUTCH COIL R & I

Removal

Using Clutch Holder (J-37872), hold pressure plate and remove

shaft bolt. Remove pressure plate and adjustment shim(s). See Fig. 7.

Remove snap ring. Using universal puller, remove compressor pulley.

Remove clutch coil.

Page 344 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 8)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

Installation

Install clutch coil in reverse order of removal. Ensure snap

ring is properly seated. Apply locking compound to shaft bolt and

tighten it to 62 INCH lbs. (7 N.m). Ensure clearance between pressure

plate and pulley is 0.012-0.024" (.30-.60 mm). If clearance is

incorrect, add or remove shim(s) as necessary.Fig. 7: Exploded View Of Compressor (Hadsys 7-Cylinder)

Courtesy of American Honda Motor Co., Inc.

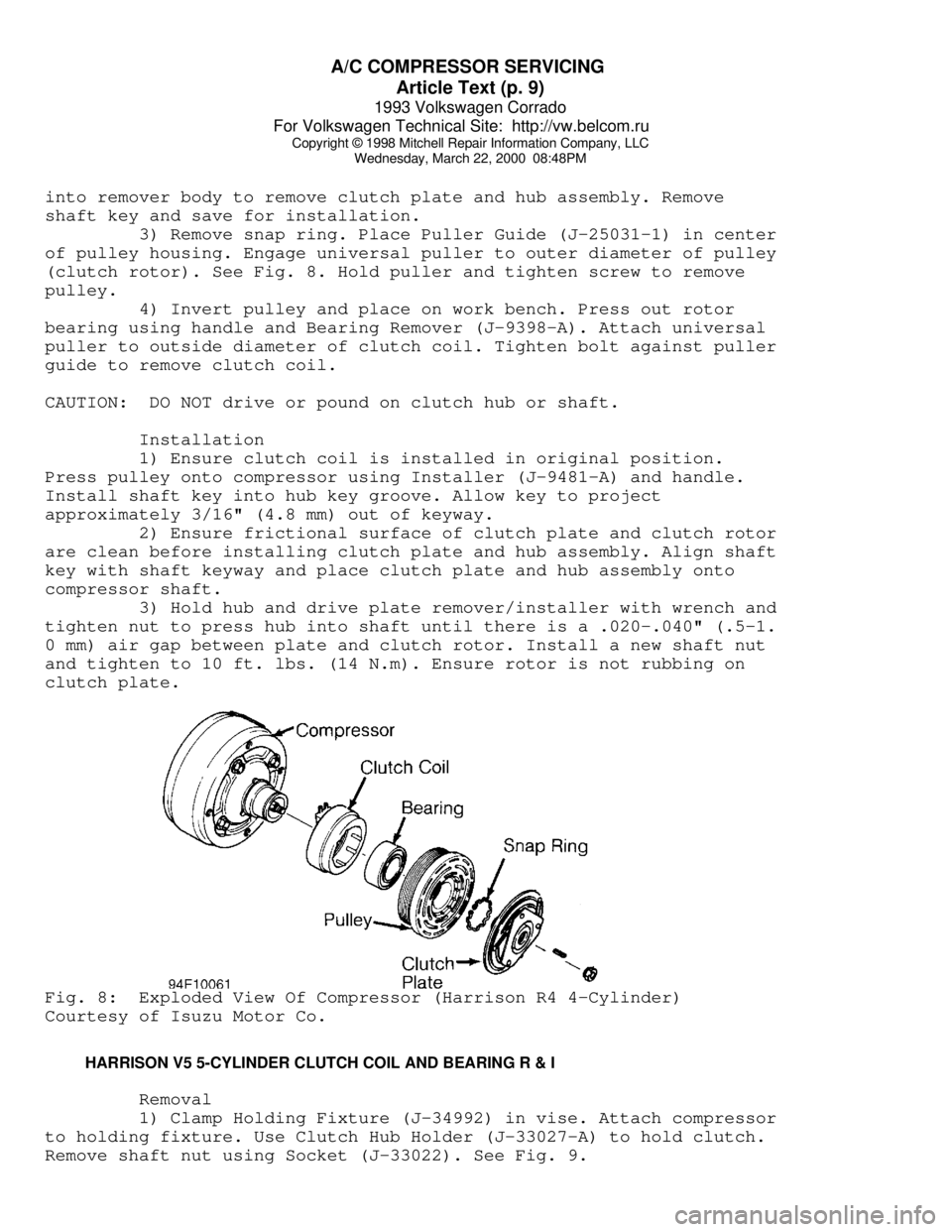

HARRISON R4 4-CYLINDER CLUTCH COIL AND BEARING R & I

Removal

1) Clamp Holding Fixture (J-25008-A) in vise. Attach

compressor to holding fixture. Use Clutch Hub Holder (J-33027) to hold

clutch and remove shaft nut.

2) Thread Hub and Drive Plate Assembly Remover/Installer (J-

37707) into hub. Hold body of remover with wrench and turn center bolt

Page 345 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 9)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

into remover body to remove clutch plate and hub assembly. Remove

shaft key and save for installation.

3) Remove snap ring. Place Puller Guide (J-25031-1) in center

of pulley housing. Engage universal puller to outer diameter of pulley

(clutch rotor). See Fig. 8. Hold puller and tighten screw to remove

pulley.

4) Invert pulley and place on work bench. Press out rotor

bearing using handle and Bearing Remover (J-9398-A). Attach universal

puller to outside diameter of clutch coil. Tighten bolt against puller

guide to remove clutch coil.

CAUTION: DO NOT drive or pound on clutch hub or shaft.

Installation

1) Ensure clutch coil is installed in original position.

Press pulley onto compressor using Installer (J-9481-A) and handle.

Install shaft key into hub key groove. Allow key to project

approximately 3/16" (4.8 mm) out of keyway.

2) Ensure frictional surface of clutch plate and clutch rotor

are clean before installing clutch plate and hub assembly. Align shaft

key with shaft keyway and place clutch plate and hub assembly onto

compressor shaft.

3) Hold hub and drive plate remover/installer with wrench and

tighten nut to press hub into shaft until there is a .020-.040" (.5-1.

0 mm) air gap between plate and clutch rotor. Install a new shaft nut

and tighten to 10 ft. lbs. (14 N.m). Ensure rotor is not rubbing on

clutch plate.Fig. 8: Exploded View Of Compressor (Harrison R4 4-Cylinder)

Courtesy of Isuzu Motor Co.

HARRISON V5 5-CYLINDER CLUTCH COIL AND BEARING R & I

Removal

1) Clamp Holding Fixture (J-34992) in vise. Attach compressor

to holding fixture. Use Clutch Hub Holder (J-33027-A) to hold clutch.

Remove shaft nut using Socket (J-33022). See Fig. 9.

Page 346 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 10)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

2) Thread Clutch Plate and Hub Assembly Remover (J-33013-B)

into hub. Hold body of remover with wrench and turn center bolt to

remove clutch plate and hub assembly. Remove snap ring. Remove shaft

key and save for installation.

3) Place Puller Guide (J-33023-A) in center of pulley

housing. Engage Rotor/Bearing Puller (J-33020) to inner circle of

slots in pulley (rotor). Hold rotor/bearing puller in place and

tighten screw to remove pulley.

4) Remove screw from rotor/bearing puller. Invert assembly

and place on work bench with rotor/bearing puller still engaged.

Remove hub bearing using handle and Bearing Remover (J-9398-A).

5) With puller guide in place, attach Crossbar (J-8433-1) and

Puller (J-33025) to outside diameter of clutch coil. Tighten crossbar

Bolt (J-8433-3) against puller guide to remove clutch coil.

Installation

1) Ensure clutch coil is installed in original position.

Press coil into position using crossbar, clutch Coil Installer (J-

33024) and Through Bolts (J-34992-2). Stake compressor housing 120

degrees apart to secure coil.

2) Position Rotor/Bearing Installer (J-33017) and puller

guide over inner race of bearing. Using through bolts, assemble

crossbar over puller pilot and tighten through bolts onto holding

fixture. Tighten crossbar bolt to press pulley/bearing assembly onto

compressor.

3) Install shaft key into hub key groove. Allow key to

project approximately 1/8" (3.2 mm) out of keyway. Align shaft key

with shaft keyway and place clutch plate and hub assembly onto

compressor shaft.

CAUTION: Do not drive or pound on clutch hub or compressor shaft, as

compressor could be damaged internally.

4) Hold hex portion of Hub Installer (J-33013) with a wrench.

Tighten center screw to press hub into shaft until there is .020-.030"

(.50-.76 mm) air gap between frictional plate and clutch rotor.

5) Install new shaft nut with small diameter boss of nut

against crankshaft shoulder. Use Socket (J-33022) and Clutch Hub

Holder (J-33027-A). Tighten shaft nut to 12 ft. lbs. (16 N.m). Ensure

pulley does not rub on clutch plate. See Fig. 9.

HARRISON V5 5-CYLINDER SHAFT SEAL R & I

Removal

Remove clutch plate and hub assembly. Remove shaft seal snap

ring. Thoroughly clean inside of compressor neck area around shaft and

seal. Engage tangs of Seal Remover/Installer (J-23128-A) into recessed

portion of seal and remove seal. Remove and discard "O" ring from

compressor neck. Thoroughly clean inside of compressor neck and "O"

ring groove.

Installation

Page 347 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 11)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

1) Coat new "O" ring with refrigerant oil and install on "O"

Ring Installer (J-33011). Install "O" ring into groove in compressor

neck. Attach new seal to seal remover/installer. Dip shaft seal in

clean refrigerant oil.

2) Place Seal Protector (J-34614) over compressor shaft. Push

new seal over shaft protector. Install new seal snap ring with flat

side against seal. Install clutch plate assembly.Fig. 9: Exploded View Of Compressor (Harrison V5 5-Cylinder)

Courtesy of General Motors Corp.

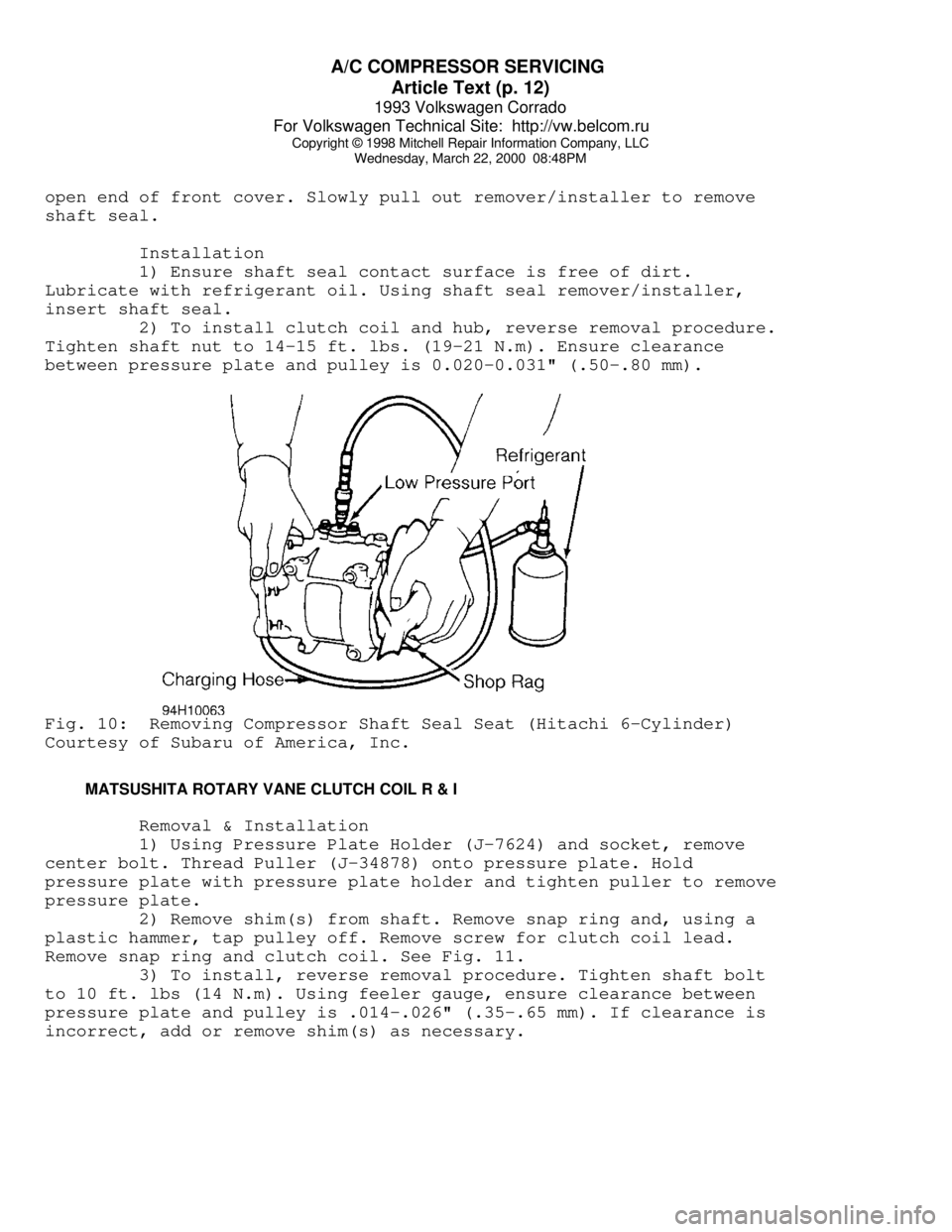

HITACHI 6-CYLINDER CLUTCH COIL AND SEAL R & I

Removal

1) Hold clutch hub with Clutch Tightener (925770000). Remove

shaft nut from shaft. Using Clutch Hub Remover (926130000), remove

clutch hub. Use snap ring pliers to remove inner snap ring.

2) Remove pulley and bearing assembly. Remove screws securing

clutch coil lead. Remove inner snap ring from clutch coil. Remove

clutch coil from front cover.

3) Remove shaft key. Use snap ring pliers to remove shaft

seal snap ring. Wrap a rag around compressor shaft. Using Injector

Needle (92619000) and refrigerant can, slowly pressurize compressor at

low pressure (suction) service port. See Fig. 10. Catch shaft seal

seat in rag.

4) Insert Shaft Seal Remover/Installer (926120000) through

Page 348 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 12)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

open end of front cover. Slowly pull out remover/installer to remove

shaft seal.

Installation

1) Ensure shaft seal contact surface is free of dirt.

Lubricate with refrigerant oil. Using shaft seal remover/installer,

insert shaft seal.

2) To install clutch coil and hub, reverse removal procedure.

Tighten shaft nut to 14-15 ft. lbs. (19-21 N.m). Ensure clearance

between pressure plate and pulley is 0.020-0.031" (.50-.80 mm).Fig. 10: Removing Compressor Shaft Seal Seat (Hitachi 6-Cylinder)

Courtesy of Subaru of America, Inc.

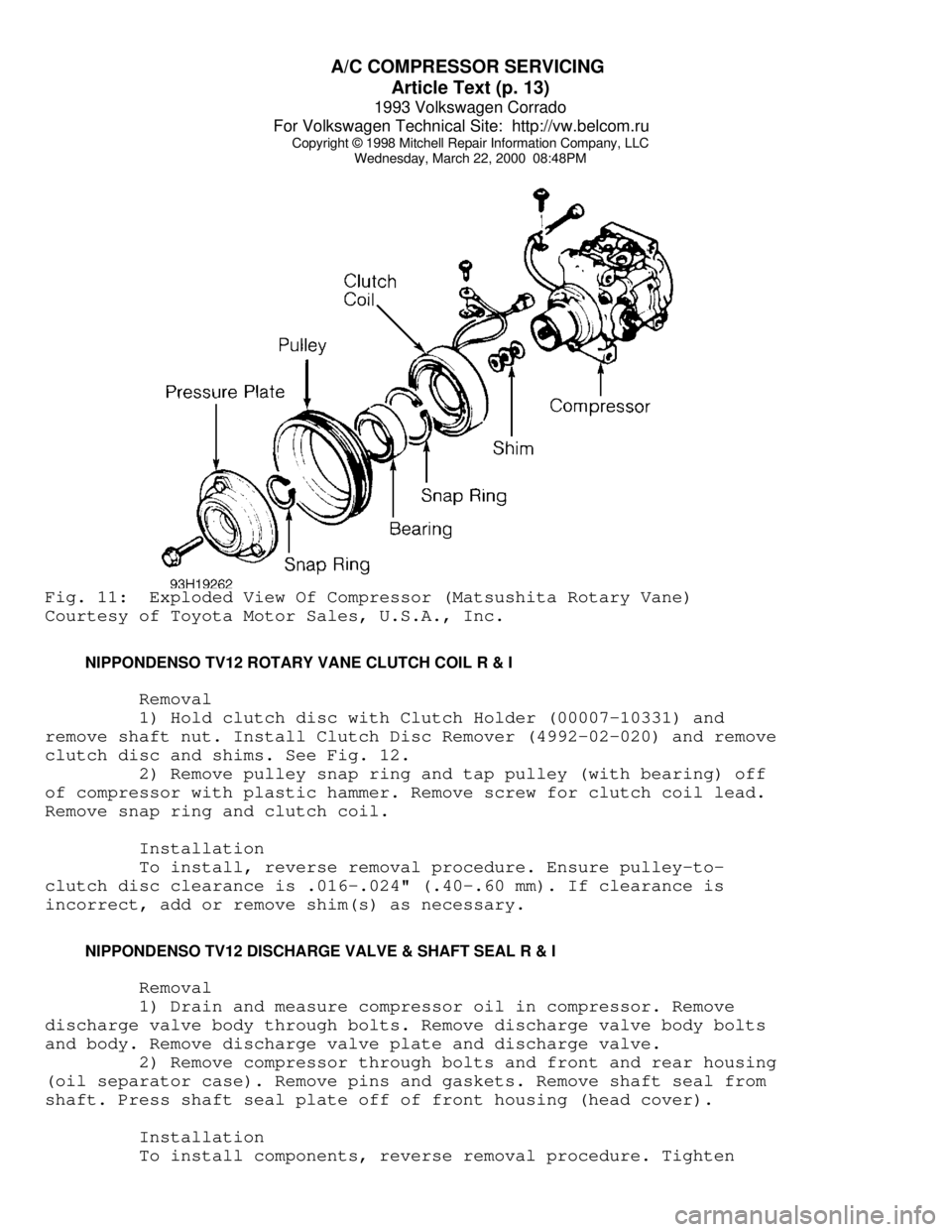

MATSUSHITA ROTARY VANE CLUTCH COIL R & I

Removal & Installation

1) Using Pressure Plate Holder (J-7624) and socket, remove

center bolt. Thread Puller (J-34878) onto pressure plate. Hold

pressure plate with pressure plate holder and tighten puller to remove

pressure plate.

2) Remove shim(s) from shaft. Remove snap ring and, using a

plastic hammer, tap pulley off. Remove screw for clutch coil lead.

Remove snap ring and clutch coil. See Fig. 11.

3) To install, reverse removal procedure. Tighten shaft bolt

to 10 ft. lbs (14 N.m). Using feeler gauge, ensure clearance between

pressure plate and pulley is .014-.026" (.35-.65 mm). If clearance is

incorrect, add or remove shim(s) as necessary.

Page 349 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 13)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PMFig. 11: Exploded View Of Compressor (Matsushita Rotary Vane)

Courtesy of Toyota Motor Sales, U.S.A., Inc.

NIPPONDENSO TV12 ROTARY VANE CLUTCH COIL R & I

Removal

1) Hold clutch disc with Clutch Holder (00007-10331) and

remove shaft nut. Install Clutch Disc Remover (4992-02-020) and remove

clutch disc and shims. See Fig. 12.

2) Remove pulley snap ring and tap pulley (with bearing) off

of compressor with plastic hammer. Remove screw for clutch coil lead.

Remove snap ring and clutch coil.

Installation

To install, reverse removal procedure. Ensure pulley-to-

clutch disc clearance is .016-.024" (.40-.60 mm). If clearance is

incorrect, add or remove shim(s) as necessary.

NIPPONDENSO TV12 DISCHARGE VALVE & SHAFT SEAL R & I

Removal

1) Drain and measure compressor oil in compressor. Remove

discharge valve body through bolts. Remove discharge valve body bolts

and body. Remove discharge valve plate and discharge valve.

2) Remove compressor through bolts and front and rear housing

(oil separator case). Remove pins and gaskets. Remove shaft seal from

shaft. Press shaft seal plate off of front housing (head cover).

Installation

To install components, reverse removal procedure. Tighten

Page 350 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 14)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

compressor through bolts to 19 ft. lbs. (26 N.m). Tighten discharge

valve bolts to 41 INCH lbs. (4.6 N.m). Tighten discharge valve body

and body through bolts to 96 INCH lbs. (10.8 N.m).Fig. 12: Exploded View Of Compressor (Nippondenso TV12 Rotary Vane)

Courtesy of Mazda Motors Corp.

NIPPONDENSO 6 & 10-CYLINDER CLUTCH COIL AND BEARING R & I

NOTE: Due to variety of clutch and shaft seal configurations,

obtain appropriate A/C compressor service tools for

compressor being serviced.

Removal

1) Hold clutch plate stationary and remove shaft bolt (or

nut). Remove clutch plate using puller. Remove shim(s) from shaft and

snap ring. Tap pulley off shaft with plastic hammer. If pulley cannot

be removed by hand, use commercially available puller.

2) Remove snap ring, bearing, and seal (if equipped) from

pulley. See Fig. 13. Remove screw for clutch coil lead. Remove snap

ring and clutch coil.

Installation

To install, reverse removal procedure. Ensure snap rings are

installed with beveled side facing out. Tighten shaft bolt (or nut) to