VOLKSWAGEN CORRADO 1993 Repair Manual

Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 351 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 15)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

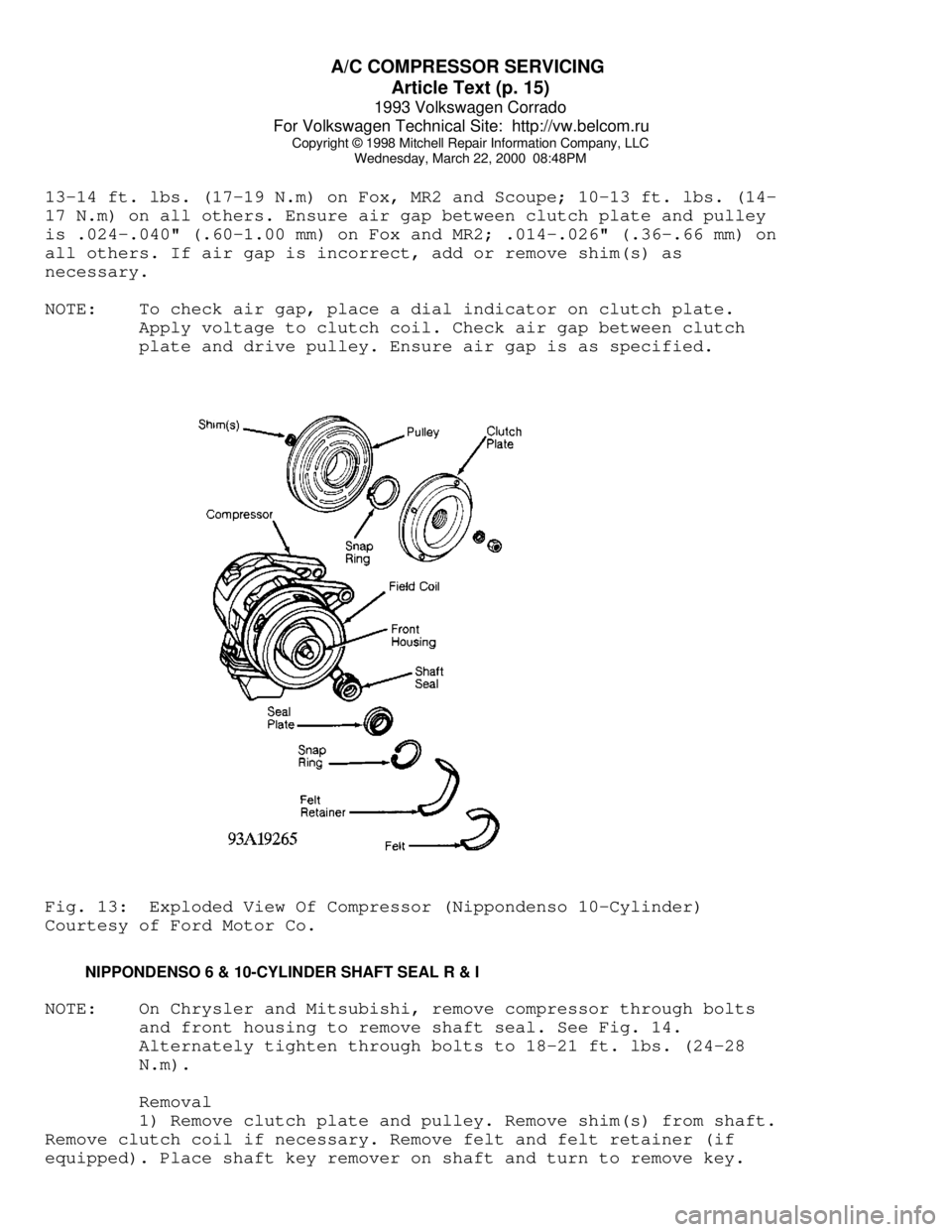

13-14 ft. lbs. (17-19 N.m) on Fox, MR2 and Scoupe; 10-13 ft. lbs. (14-

17 N.m) on all others. Ensure air gap between clutch plate and pulley

is .024-.040" (.60-1.00 mm) on Fox and MR2; .014-.026" (.36-.66 mm) on

all others. If air gap is incorrect, add or remove shim(s) as

necessary.

NOTE: To check air gap, place a dial indicator on clutch plate.

Apply voltage to clutch coil. Check air gap between clutch

plate and drive pulley. Ensure air gap is as specified.Fig. 13: Exploded View Of Compressor (Nippondenso 10-Cylinder)

Courtesy of Ford Motor Co.

NIPPONDENSO 6 & 10-CYLINDER SHAFT SEAL R & I

NOTE: On Chrysler and Mitsubishi, remove compressor through bolts

and front housing to remove shaft seal. See Fig. 14.

Alternately tighten through bolts to 18-21 ft. lbs. (24-28

N.m).

Removal

1) Remove clutch plate and pulley. Remove shim(s) from shaft.

Remove clutch coil if necessary. Remove felt and felt retainer (if

equipped). Place shaft key remover on shaft and turn to remove key.

Page 352 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 16)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

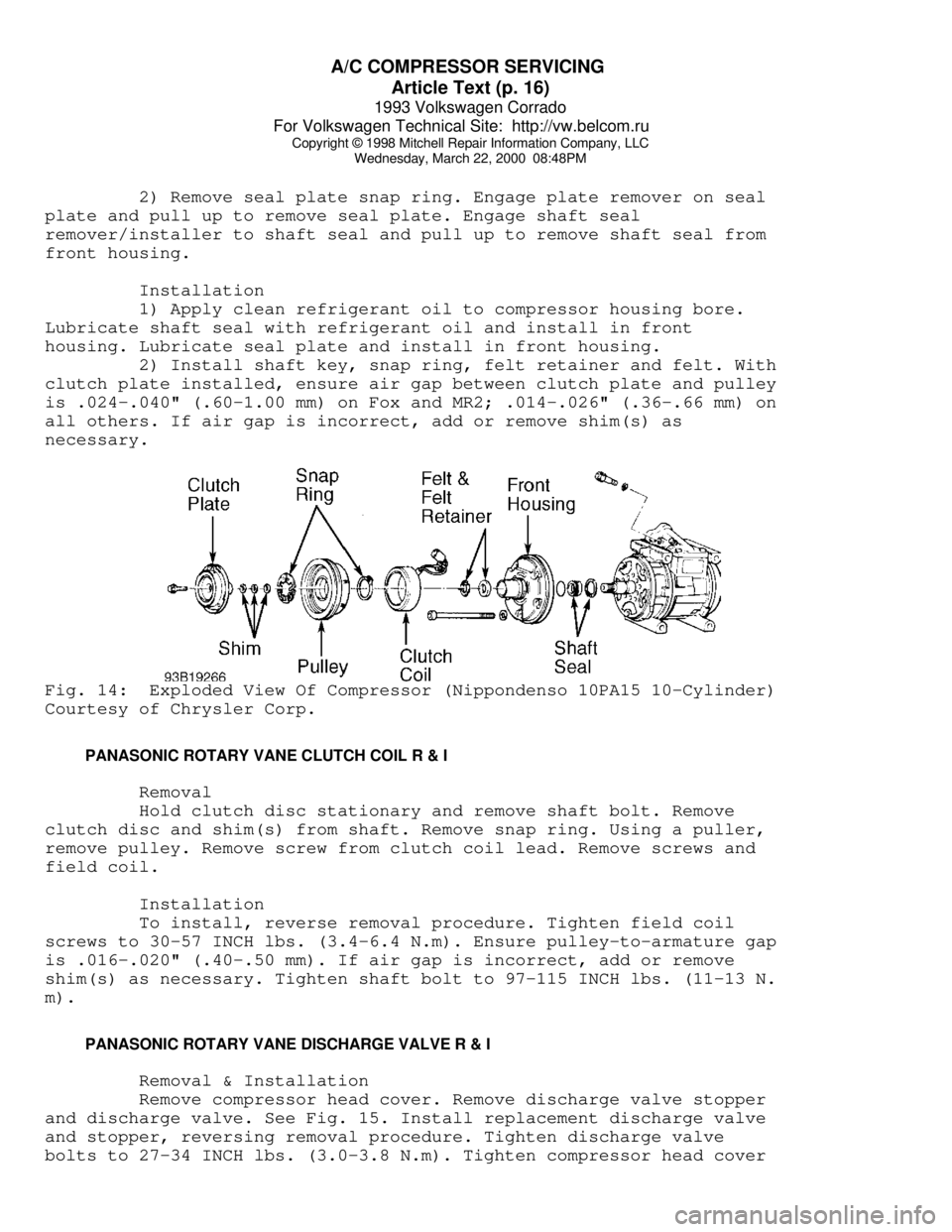

2) Remove seal plate snap ring. Engage plate remover on seal

plate and pull up to remove seal plate. Engage shaft seal

remover/installer to shaft seal and pull up to remove shaft seal from

front housing.

Installation

1) Apply clean refrigerant oil to compressor housing bore.

Lubricate shaft seal with refrigerant oil and install in front

housing. Lubricate seal plate and install in front housing.

2) Install shaft key, snap ring, felt retainer and felt. With

clutch plate installed, ensure air gap between clutch plate and pulley

is .024-.040" (.60-1.00 mm) on Fox and MR2; .014-.026" (.36-.66 mm) on

all others. If air gap is incorrect, add or remove shim(s) as

necessary.Fig. 14: Exploded View Of Compressor (Nippondenso 10PA15 10-Cylinder)

Courtesy of Chrysler Corp.

PANASONIC ROTARY VANE CLUTCH COIL R & I

Removal

Hold clutch disc stationary and remove shaft bolt. Remove

clutch disc and shim(s) from shaft. Remove snap ring. Using a puller,

remove pulley. Remove screw from clutch coil lead. Remove screws and

field coil.

Installation

To install, reverse removal procedure. Tighten field coil

screws to 30-57 INCH lbs. (3.4-6.4 N.m). Ensure pulley-to-armature gap

is .016-.020" (.40-.50 mm). If air gap is incorrect, add or remove

shim(s) as necessary. Tighten shaft bolt to 97-115 INCH lbs. (11-13 N.

m).

PANASONIC ROTARY VANE DISCHARGE VALVE R & I

Removal & Installation

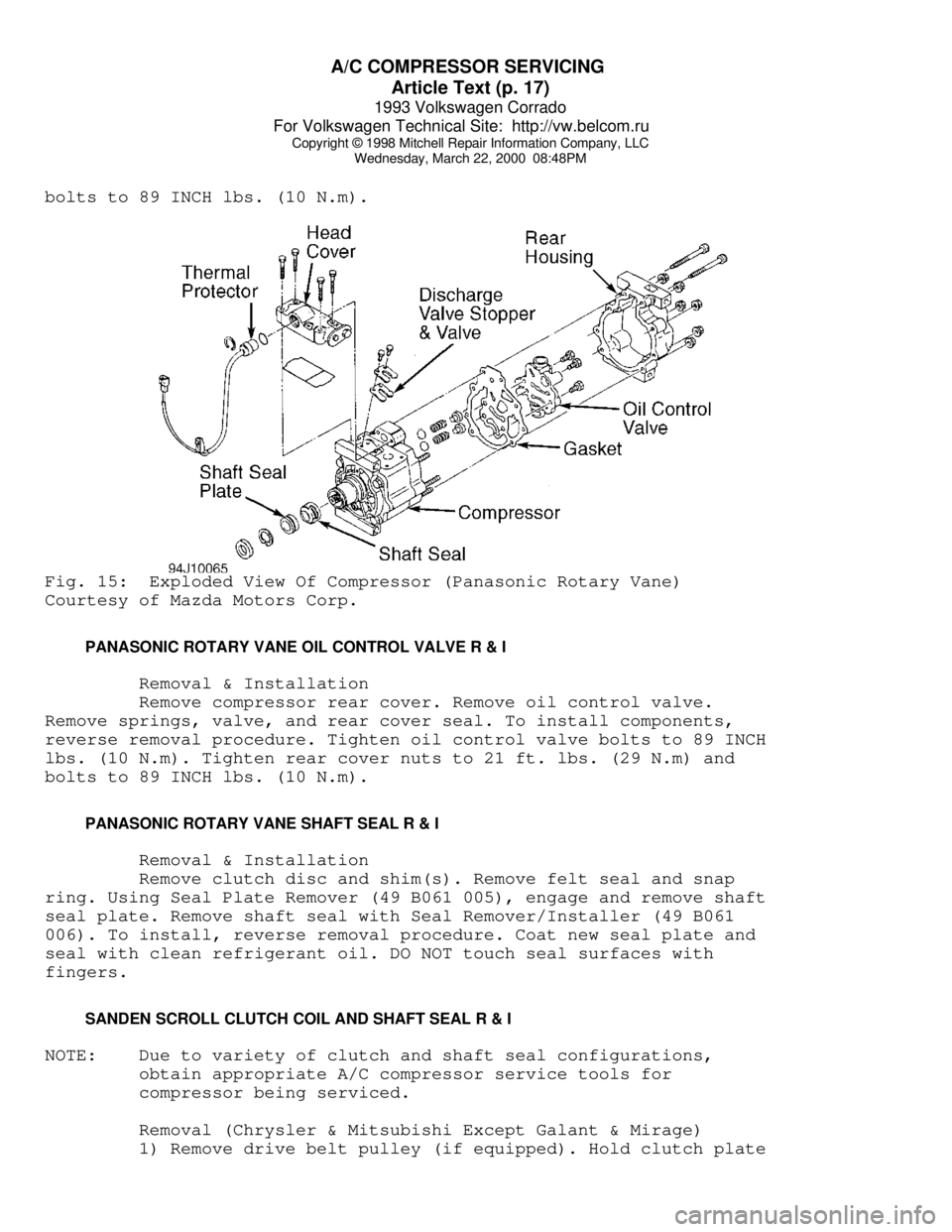

Remove compressor head cover. Remove discharge valve stopper

and discharge valve. See Fig. 15. Install replacement discharge valve

and stopper, reversing removal procedure. Tighten discharge valve

bolts to 27-34 INCH lbs. (3.0-3.8 N.m). Tighten compressor head cover

Page 353 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 17)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

bolts to 89 INCH lbs. (10 N.m).Fig. 15: Exploded View Of Compressor (Panasonic Rotary Vane)

Courtesy of Mazda Motors Corp.

PANASONIC ROTARY VANE OIL CONTROL VALVE R & I

Removal & Installation

Remove compressor rear cover. Remove oil control valve.

Remove springs, valve, and rear cover seal. To install components,

reverse removal procedure. Tighten oil control valve bolts to 89 INCH

lbs. (10 N.m). Tighten rear cover nuts to 21 ft. lbs. (29 N.m) and

bolts to 89 INCH lbs. (10 N.m).

PANASONIC ROTARY VANE SHAFT SEAL R & I

Removal & Installation

Remove clutch disc and shim(s). Remove felt seal and snap

ring. Using Seal Plate Remover (49 B061 005), engage and remove shaft

seal plate. Remove shaft seal with Seal Remover/Installer (49 B061

006). To install, reverse removal procedure. Coat new seal plate and

seal with clean refrigerant oil. DO NOT touch seal surfaces with

fingers.

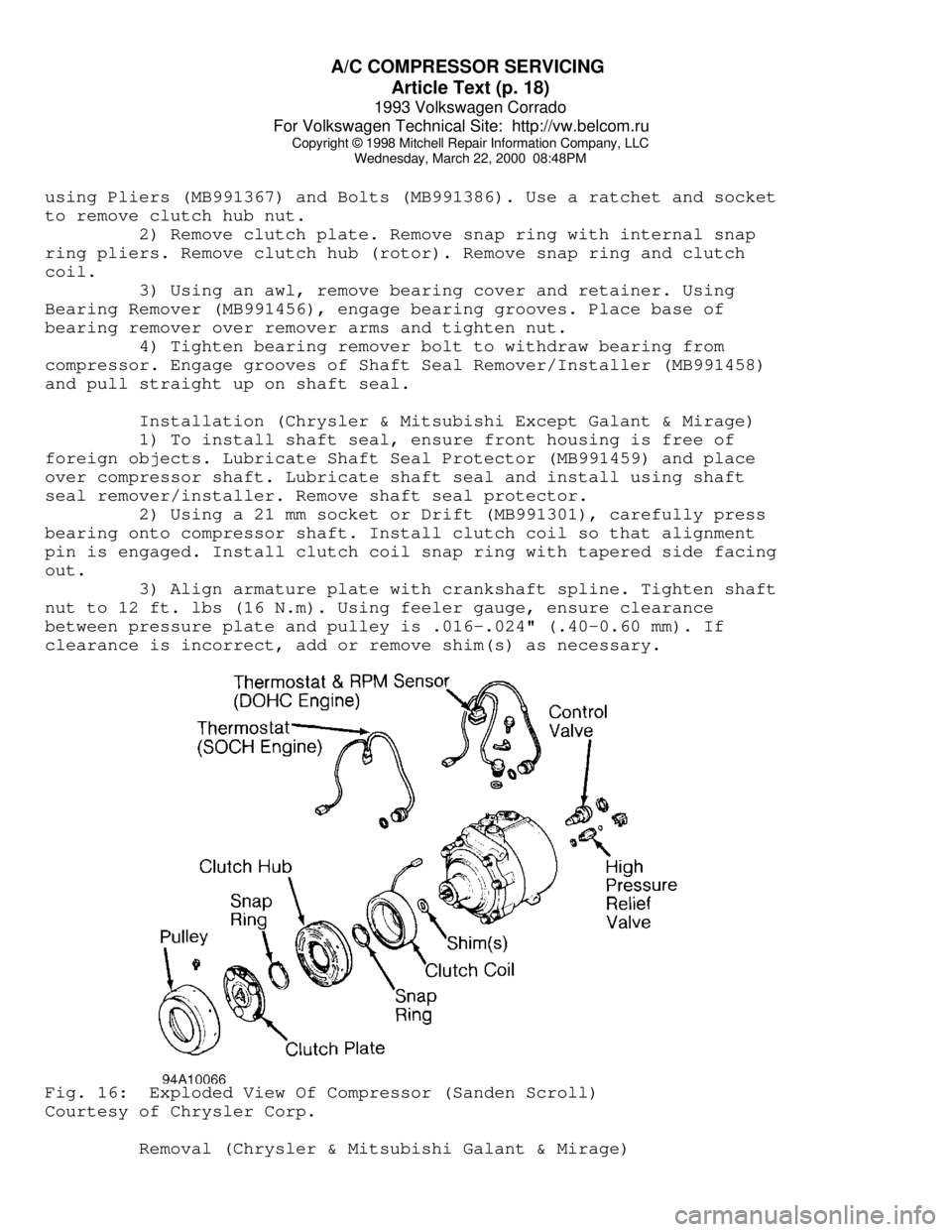

SANDEN SCROLL CLUTCH COIL AND SHAFT SEAL R & I

NOTE: Due to variety of clutch and shaft seal configurations,

obtain appropriate A/C compressor service tools for

compressor being serviced.

Removal (Chrysler & Mitsubishi Except Galant & Mirage)

1) Remove drive belt pulley (if equipped). Hold clutch plate

Page 354 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 18)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

using Pliers (MB991367) and Bolts (MB991386). Use a ratchet and socket

to remove clutch hub nut.

2) Remove clutch plate. Remove snap ring with internal snap

ring pliers. Remove clutch hub (rotor). Remove snap ring and clutch

coil.

3) Using an awl, remove bearing cover and retainer. Using

Bearing Remover (MB991456), engage bearing grooves. Place base of

bearing remover over remover arms and tighten nut.

4) Tighten bearing remover bolt to withdraw bearing from

compressor. Engage grooves of Shaft Seal Remover/Installer (MB991458)

and pull straight up on shaft seal.

Installation (Chrysler & Mitsubishi Except Galant & Mirage)

1) To install shaft seal, ensure front housing is free of

foreign objects. Lubricate Shaft Seal Protector (MB991459) and place

over compressor shaft. Lubricate shaft seal and install using shaft

seal remover/installer. Remove shaft seal protector.

2) Using a 21 mm socket or Drift (MB991301), carefully press

bearing onto compressor shaft. Install clutch coil so that alignment

pin is engaged. Install clutch coil snap ring with tapered side facing

out.

3) Align armature plate with crankshaft spline. Tighten shaft

nut to 12 ft. lbs (16 N.m). Using feeler gauge, ensure clearance

between pressure plate and pulley is .016-.024" (.40-0.60 mm). If

clearance is incorrect, add or remove shim(s) as necessary.Fig. 16: Exploded View Of Compressor (Sanden Scroll)

Courtesy of Chrysler Corp.

Removal (Chrysler & Mitsubishi Galant & Mirage)

Page 355 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 19)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

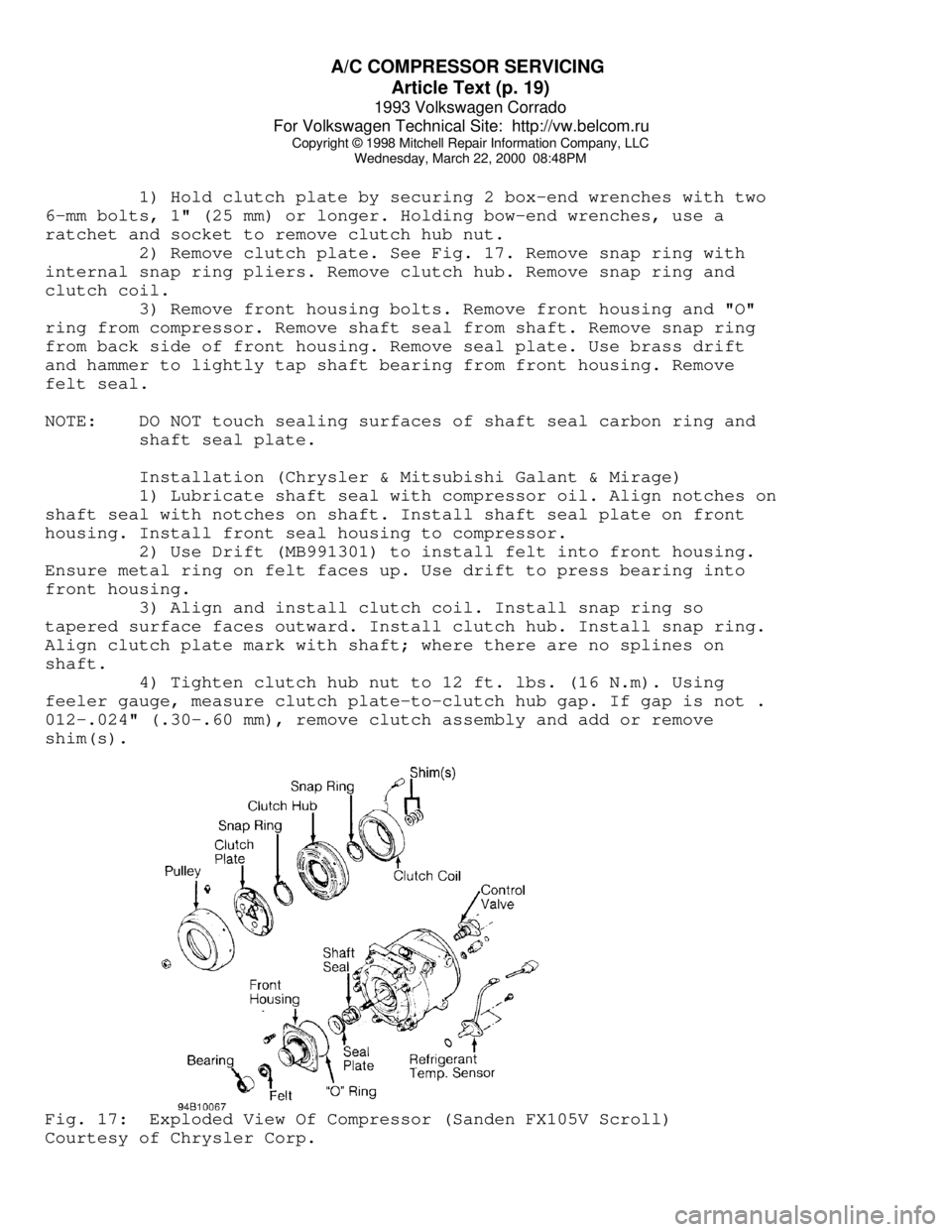

1) Hold clutch plate by securing 2 box-end wrenches with two

6-mm bolts, 1" (25 mm) or longer. Holding bow-end wrenches, use a

ratchet and socket to remove clutch hub nut.

2) Remove clutch plate. See Fig. 17. Remove snap ring with

internal snap ring pliers. Remove clutch hub. Remove snap ring and

clutch coil.

3) Remove front housing bolts. Remove front housing and "O"

ring from compressor. Remove shaft seal from shaft. Remove snap ring

from back side of front housing. Remove seal plate. Use brass drift

and hammer to lightly tap shaft bearing from front housing. Remove

felt seal.

NOTE: DO NOT touch sealing surfaces of shaft seal carbon ring and

shaft seal plate.

Installation (Chrysler & Mitsubishi Galant & Mirage)

1) Lubricate shaft seal with compressor oil. Align notches on

shaft seal with notches on shaft. Install shaft seal plate on front

housing. Install front seal housing to compressor.

2) Use Drift (MB991301) to install felt into front housing.

Ensure metal ring on felt faces up. Use drift to press bearing into

front housing.

3) Align and install clutch coil. Install snap ring so

tapered surface faces outward. Install clutch hub. Install snap ring.

Align clutch plate mark with shaft; where there are no splines on

shaft.

4) Tighten clutch hub nut to 12 ft. lbs. (16 N.m). Using

feeler gauge, measure clutch plate-to-clutch hub gap. If gap is not .

012-.024" (.30-.60 mm), remove clutch assembly and add or remove

shim(s).Fig. 17: Exploded View Of Compressor (Sanden FX105V Scroll)

Courtesy of Chrysler Corp.

Page 356 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 20)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

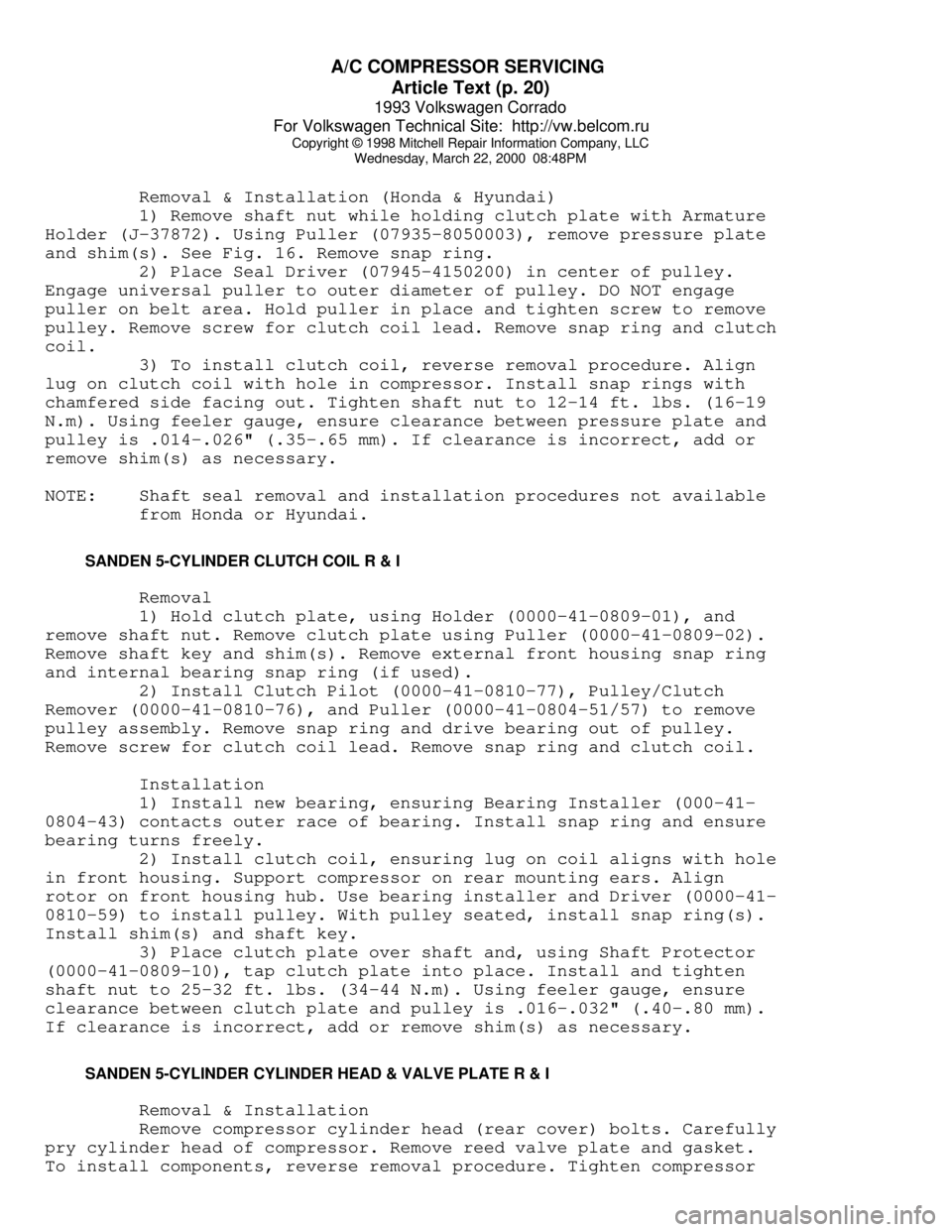

Removal & Installation (Honda & Hyundai)

1) Remove shaft nut while holding clutch plate with Armature

Holder (J-37872). Using Puller (07935-8050003), remove pressure plate

and shim(s). See Fig. 16. Remove snap ring.

2) Place Seal Driver (07945-4150200) in center of pulley.

Engage universal puller to outer diameter of pulley. DO NOT engage

puller on belt area. Hold puller in place and tighten screw to remove

pulley. Remove screw for clutch coil lead. Remove snap ring and clutch

coil.

3) To install clutch coil, reverse removal procedure. Align

lug on clutch coil with hole in compressor. Install snap rings with

chamfered side facing out. Tighten shaft nut to 12-14 ft. lbs. (16-19

N.m). Using feeler gauge, ensure clearance between pressure plate and

pulley is .014-.026" (.35-.65 mm). If clearance is incorrect, add or

remove shim(s) as necessary.

NOTE: Shaft seal removal and installation procedures not available

from Honda or Hyundai.

SANDEN 5-CYLINDER CLUTCH COIL R & I

Removal

1) Hold clutch plate, using Holder (0000-41-0809-01), and

remove shaft nut. Remove clutch plate using Puller (0000-41-0809-02).

Remove shaft key and shim(s). Remove external front housing snap ring

and internal bearing snap ring (if used).

2) Install Clutch Pilot (0000-41-0810-77), Pulley/Clutch

Remover (0000-41-0810-76), and Puller (0000-41-0804-51/57) to remove

pulley assembly. Remove snap ring and drive bearing out of pulley.

Remove screw for clutch coil lead. Remove snap ring and clutch coil.

Installation

1) Install new bearing, ensuring Bearing Installer (000-41-

0804-43) contacts outer race of bearing. Install snap ring and ensure

bearing turns freely.

2) Install clutch coil, ensuring lug on coil aligns with hole

in front housing. Support compressor on rear mounting ears. Align

rotor on front housing hub. Use bearing installer and Driver (0000-41-

0810-59) to install pulley. With pulley seated, install snap ring(s).

Install shim(s) and shaft key.

3) Place clutch plate over shaft and, using Shaft Protector

(0000-41-0809-10), tap clutch plate into place. Install and tighten

shaft nut to 25-32 ft. lbs. (34-44 N.m). Using feeler gauge, ensure

clearance between clutch plate and pulley is .016-.032" (.40-.80 mm).

If clearance is incorrect, add or remove shim(s) as necessary.

SANDEN 5-CYLINDER CYLINDER HEAD & VALVE PLATE R & I

Removal & Installation

Remove compressor cylinder head (rear cover) bolts. Carefully

pry cylinder head of compressor. Remove reed valve plate and gasket.

To install components, reverse removal procedure. Tighten compressor

Page 357 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 21)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

cylinder head bolts, in a crisscross pattern, to 21-29 ft. lbs. (29-39

N.m).

SANDEN 5-CYLINDER SHAFT SEAL R & I

Removal

Remove shaft nut and clutch plate. Remove shaft key and

shim(s). Carefully remove felt ring. Remove shaft seal seat snap ring.

Using Seal Seat Remover/Installer (0000-41-0810-73), carefully remove

seal seat. Using Shaft Seal Remover/Installer (0000-41-0812-11),

carefully remove shaft seal.

Installation

1) Install Seal Protector (0000-41-0812-13) over shaft. Place

new seal on remover/installer. DO NOT touch carbon sealing surface

with fingers. Dip seal in refrigerant oil and install. Remove seal

installer by turning counterclockwise.

2) Coat seal seat with refrigerant oil. Install seal seat

using remover/installer. Install seal seat snap ring (with flat side

down). Install shim(s), felt ring and shaft key. Install shaft nut and

clutch plate. Ensure clearance between clutch plate and pulley is .

016-.032" (.40-.80 mm). If clearance is incorrect, add or remove

shim(s) as necessary.

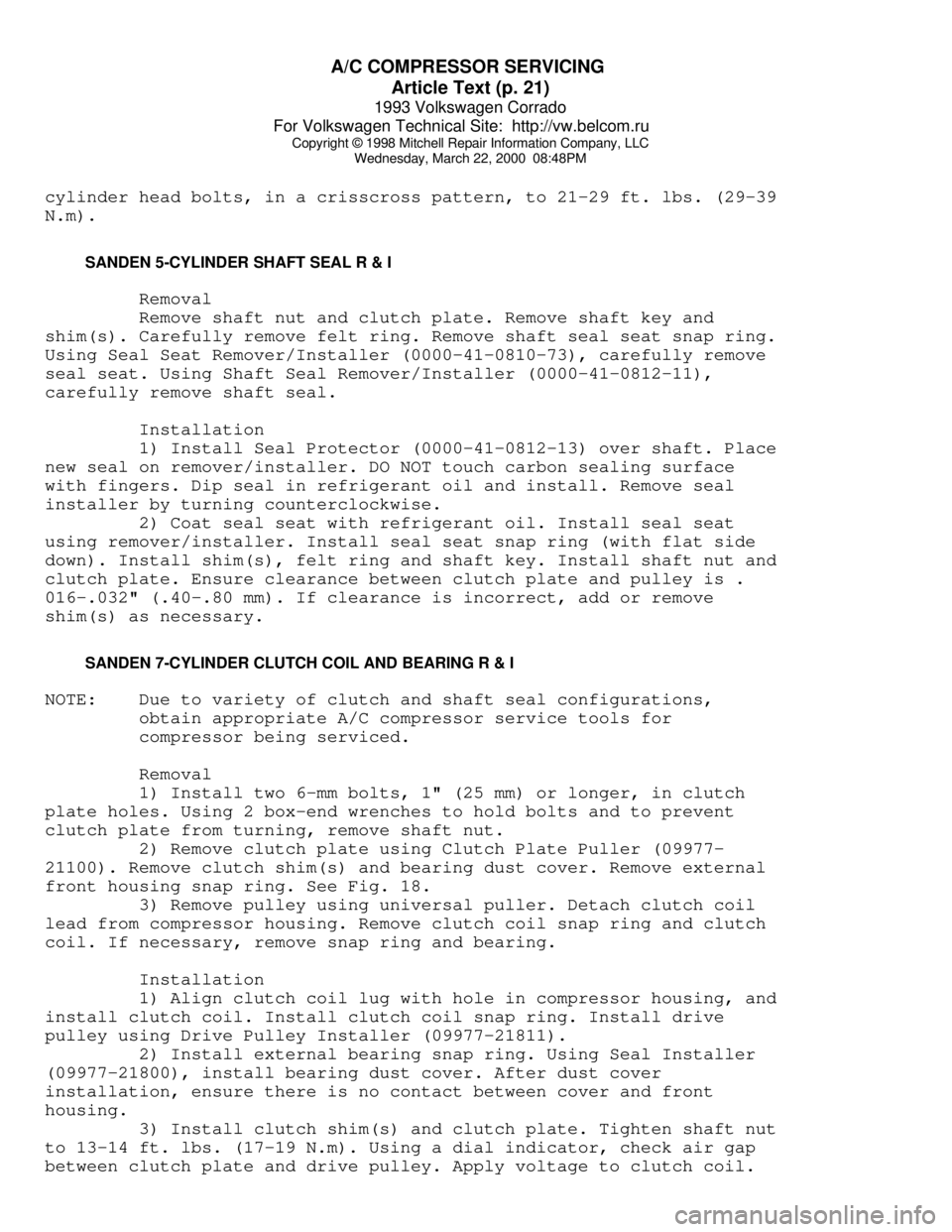

SANDEN 7-CYLINDER CLUTCH COIL AND BEARING R & I

NOTE: Due to variety of clutch and shaft seal configurations,

obtain appropriate A/C compressor service tools for

compressor being serviced.

Removal

1) Install two 6-mm bolts, 1" (25 mm) or longer, in clutch

plate holes. Using 2 box-end wrenches to hold bolts and to prevent

clutch plate from turning, remove shaft nut.

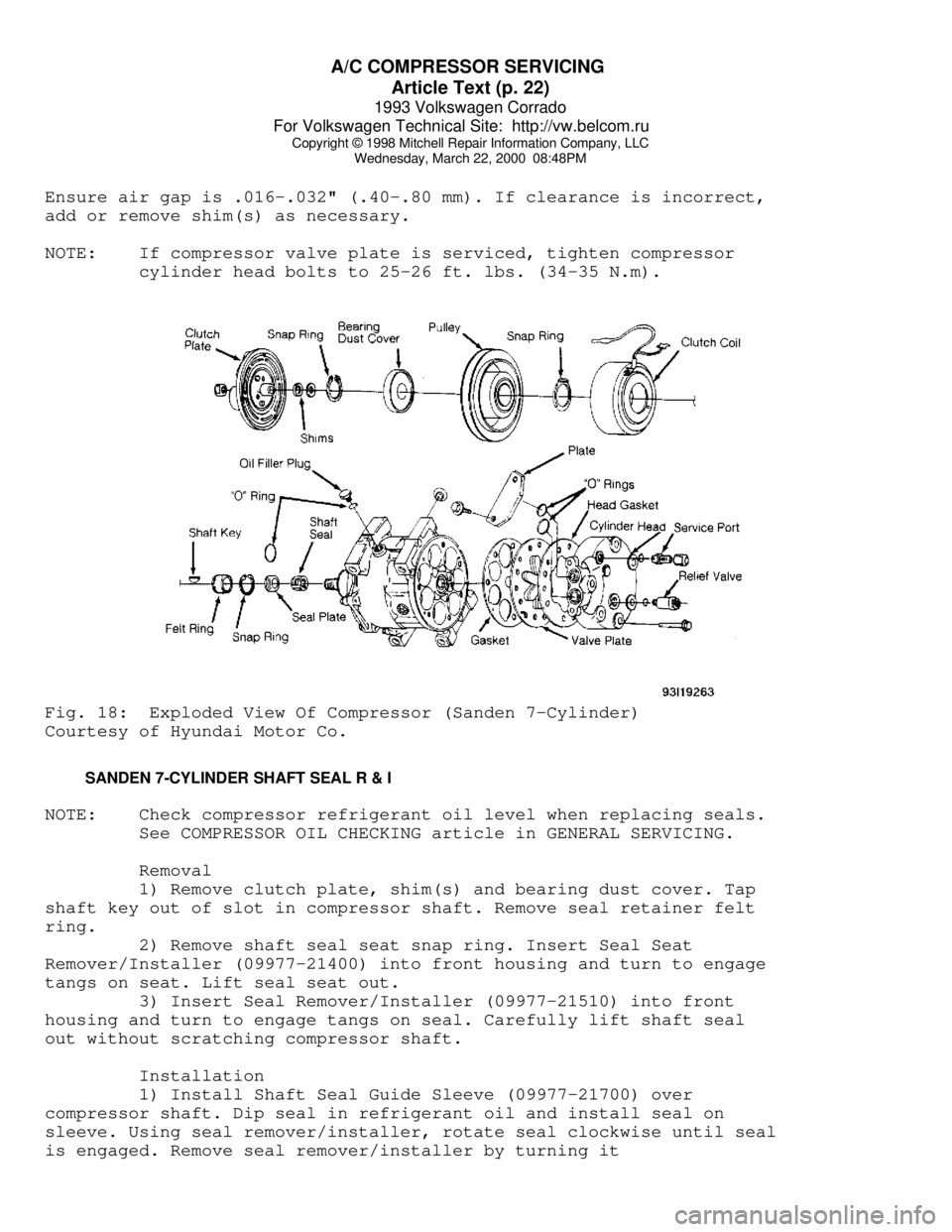

2) Remove clutch plate using Clutch Plate Puller (09977-

21100). Remove clutch shim(s) and bearing dust cover. Remove external

front housing snap ring. See Fig. 18.

3) Remove pulley using universal puller. Detach clutch coil

lead from compressor housing. Remove clutch coil snap ring and clutch

coil. If necessary, remove snap ring and bearing.

Installation

1) Align clutch coil lug with hole in compressor housing, and

install clutch coil. Install clutch coil snap ring. Install drive

pulley using Drive Pulley Installer (09977-21811).

2) Install external bearing snap ring. Using Seal Installer

(09977-21800), install bearing dust cover. After dust cover

installation, ensure there is no contact between cover and front

housing.

3) Install clutch shim(s) and clutch plate. Tighten shaft nut

to 13-14 ft. lbs. (17-19 N.m). Using a dial indicator, check air gap

between clutch plate and drive pulley. Apply voltage to clutch coil.

Page 358 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 22)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

Ensure air gap is .016-.032" (.40-.80 mm). If clearance is incorrect,

add or remove shim(s) as necessary.

NOTE: If compressor valve plate is serviced, tighten compressor

cylinder head bolts to 25-26 ft. lbs. (34-35 N.m).Fig. 18: Exploded View Of Compressor (Sanden 7-Cylinder)

Courtesy of Hyundai Motor Co.

SANDEN 7-CYLINDER SHAFT SEAL R & I

NOTE: Check compressor refrigerant oil level when replacing seals.

See COMPRESSOR OIL CHECKING article in GENERAL SERVICING.

Removal

1) Remove clutch plate, shim(s) and bearing dust cover. Tap

shaft key out of slot in compressor shaft. Remove seal retainer felt

ring.

2) Remove shaft seal seat snap ring. Insert Seal Seat

Remover/Installer (09977-21400) into front housing and turn to engage

tangs on seat. Lift seal seat out.

3) Insert Seal Remover/Installer (09977-21510) into front

housing and turn to engage tangs on seal. Carefully lift shaft seal

out without scratching compressor shaft.

Installation

1) Install Shaft Seal Guide Sleeve (09977-21700) over

compressor shaft. Dip seal in refrigerant oil and install seal on

sleeve. Using seal remover/installer, rotate seal clockwise until seal

is engaged. Remove seal remover/installer by turning it

Page 359 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 23)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

counterclockwise.

2) Coat seal seat with refrigerant oil and install seal with

seal seat remover/installer. Remove shaft seal guide sleeve. Install

snap ring with beveled edge facing out. Install seal retainer felt

ring using seal seat remover/installer.

3) Install shaft key and clutch plate. Tighten shaft nut to

13-14 ft. lbs. (17-19 N.m). Using a dial indicator, check air gap

between clutch plate and drive pulley. Apply voltage to clutch coil.

Ensure air gap is .016-.032" (.40-.80 mm). If clearance is incorrect,

add or remove shim(s) as necessary.

SEIKO-SEIKI ROTARY VANE

NOTE: Volvo Seiko-Seiki compressor servicing procedure is not

available from manufacturer.

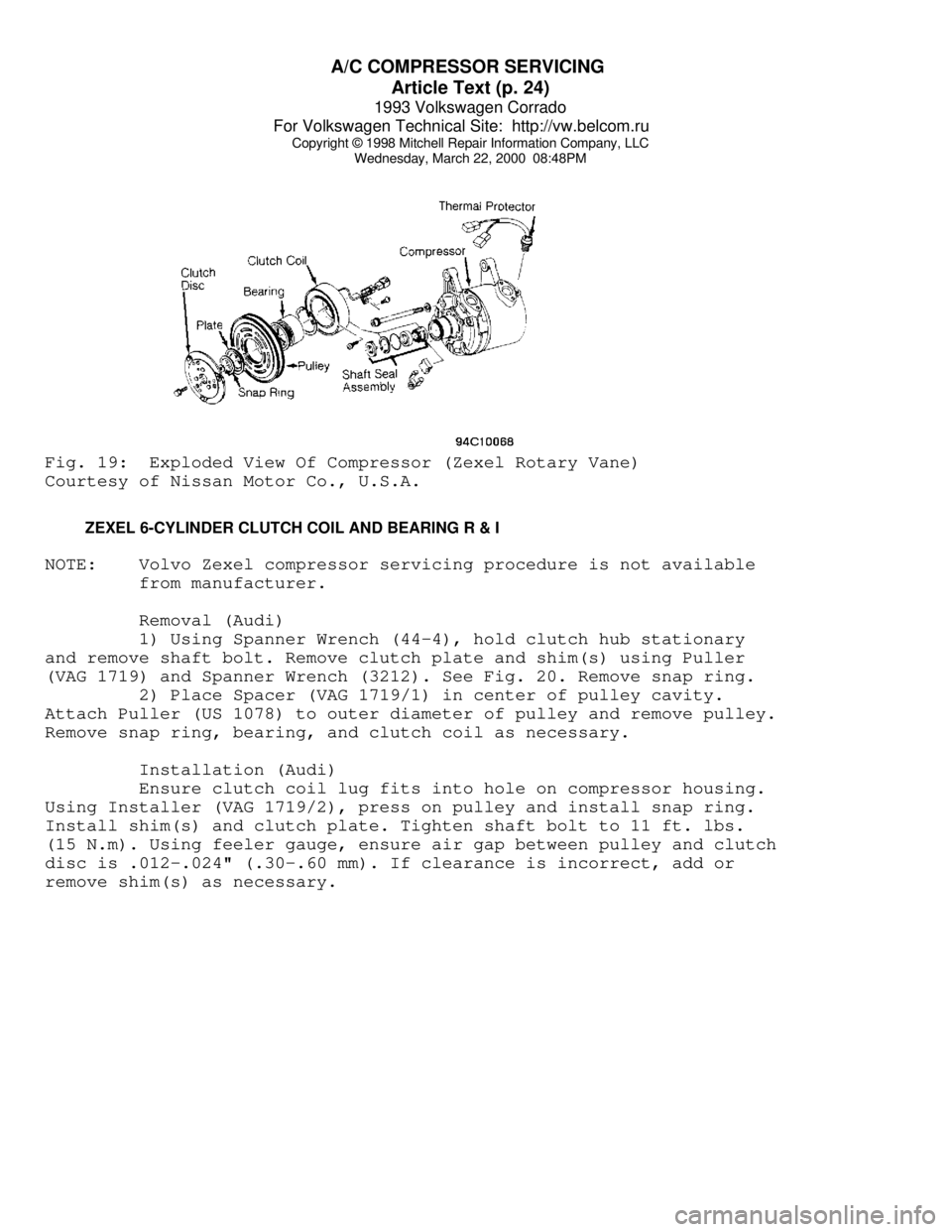

ZEXEL ROTARY VANE CLUTCH COIL AND BEARING R & I

Removal

1) Hold clutch disc using Clutch Disc Wrench (KV99231260) and

remove center bolt. Using Clutch Disc Puller (KV99232340), remove

drive plate and adjustment shim(s).

2) Remove snap ring. Remove pulley using Pilot (J-39023) and

universal puller. Remove clutch coil. If necessary, remove snap ring

and bearing. See Fig. 19.

Installation

1) Ensure coil lead is installed in original position.

Install and tighten coil screws. Press pulley onto compressor using

Pulley Installer (J-33940). Install snap ring and adjustment shim(s).

2) Install clutch disc and tighten center bolt to 11-13 ft.

lbs. (15-18 N.m). Using feeler gauge, ensure clearance between clutch

disc and pulley is .012-.024" (.30-.60 mm). If clearance is incorrect,

add or remove shim(s) as necessary. Break-in clutch by engaging and

disengaging clutch 30 times.

NOTE: Shaft seal assembly servicing procedure is not available

from manufacturer. Use exploded view as a guide. See

Fig. 19. Tighten thermal protector, if removed, to

11-13 ft.lbs. (15-18 N.m).

Page 360 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 24)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PMFig. 19: Exploded View Of Compressor (Zexel Rotary Vane)

Courtesy of Nissan Motor Co., U.S.A.

ZEXEL 6-CYLINDER CLUTCH COIL AND BEARING R & I

NOTE: Volvo Zexel compressor servicing procedure is not available

from manufacturer.

Removal (Audi)

1) Using Spanner Wrench (44-4), hold clutch hub stationary

and remove shaft bolt. Remove clutch plate and shim(s) using Puller

(VAG 1719) and Spanner Wrench (3212). See Fig. 20. Remove snap ring.

2) Place Spacer (VAG 1719/1) in center of pulley cavity.

Attach Puller (US 1078) to outer diameter of pulley and remove pulley.

Remove snap ring, bearing, and clutch coil as necessary.

Installation (Audi)

Ensure clutch coil lug fits into hole on compressor housing.

Using Installer (VAG 1719/2), press on pulley and install snap ring.

Install shim(s) and clutch plate. Tighten shaft bolt to 11 ft. lbs.

(15 N.m). Using feeler gauge, ensure air gap between pulley and clutch

disc is .012-.024" (.30-.60 mm). If clearance is incorrect, add or

remove shim(s) as necessary.