VOLKSWAGEN CORRADO 1993 Repair Manual

Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 611 of 920

HOW TO USE SYSTEM WIRING DIAGRAMS

Article Text (p. 8)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

Power Top Relay(s) ........................... Power Convertible Top

Powertrain Control Module ....................... Engine Performance

Analog Instrument Panels

Cruise Control Systems

Data Link Connectors

Generators & Regulators

Starters

Power Window Motors .................................. Power Windows

Power Window Relay(s) ................................ Power Windows

Radiator Fan Motor(s) ........................ Electric Cooling Fans

Radiator Fan Relay(s) ........................... Engine Performance

Electric Cooling Fans

Rainsense Module .............................. Wiper/Washer Systems

Raise Relay .................................. Power Convertible Top

Remote Anti-Theft Personality (RAP) Module ....... Anti-Theft System

Starters

Warning Systems

Seat Belt Pretensioners ................... Air Bag Restraint System

Seat Belt Retractor Solenoid .................... Passive Restraints

Seat Belt Switch .......................... Air Bag Restraint System

Passive Restraints

Shift Interlock Solenoid ................... Shift Interlock Systems

Shift Lock Actuator ........................ Shift Interlock Systems

Side Marker Lights ................................. Exterior Lights

SIR Coil Assembly (Clockspring) ........... Air Bag Restraint System

Slip Ring (Clockspring) ................... Air Bag Restraint System

Steering Column Switches

SRS Control Module ........................ Air Bag Restraint System

Starter Motor ............................................. Starters

Starter Interrupt Relay ................................... Starters

Starter Solenoid .......................................... Starters

Starter Relay ............................................. Starters

Steering Wheel Position Sensor .................... Anti-Lock Brakes

Stoplights ......................................... Exterior Lights

Stoplight Switch ................................ Engine Performance

Cruise Control Systems

Anti-Lock Brakes

Sun Roof ECU ........................................ Power Sun Roof

Sun Roof Motor ...................................... Power Sun Roof

Sun Roof Position Sensor ............................ Power Sun Roof

Taillights ......................................... Exterior Lights

Throttle Position (TP) Sensor ................... Engine Performance

Torque Converter Clutch Solenoid/Switch ......... Engine Performance

Traction Control Switch ........................... Anti-Lock Brakes

Trailer Tow Connector .............................. Exterior Lights

Trailer Tow Relay .................................. Exterior Lights

Transmission/Transaxle .......................... Engine Performance

Transmission Control Module (TCM) ............... Engine Performance

Starters

Transmission Range Sensor ................................. Starters

Back-Up Lights

Engine Performance

Page 612 of 920

HOW TO USE SYSTEM WIRING DIAGRAMS

Article Text (p. 9)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

Transmission Range Switch ........................... Back-Up Lights

Engine Performance

Anti-Theft System

Turn Signal Flasher ................................ Exterior Lights

Turn Signal Lights ................................. Exterior Lights

Twilight Sentinel Switch ......................... Headlight Systems

Daytime Running Lights

Vapor Canister Leak Detection Pump .............. Engine Performance

Vehicle Control Module (VCM) .................... Engine Performance

Vehicle Dynamic Module ....................... Electronic Suspension

Vehicle Speed Control Servo ................. Cruise Control Systems

Vehicle Speed Sensor .......................... Data Link Connectors

Analog Instrument Panels

Cruise Control Systems

Electronic Suspension

Voltage Regulator .......................... Generators & Regulators

Water-In-Fuel Sensor ............................ Engine Performance

Analog Instrument Panels

Wheel Speed Sensors ............................... Anti-Lock Brakes

Window Timer Module .......................... Power Convertible Top

Windshield Intermittent Wiper Relay ........... Wiper/Washer Systems

Windshield Washer Motor ....................... Wiper/Washer Systems

Wiper Motor ................................... Wiper/Washer SystemsÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE

Page 613 of 920

I - SYSTEM/COMPONENT TESTS

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

ARTICLE BEGINNING

1993 ENGINE PERFORMANCE

System & Component Testing - Motronic

Corrado SLC

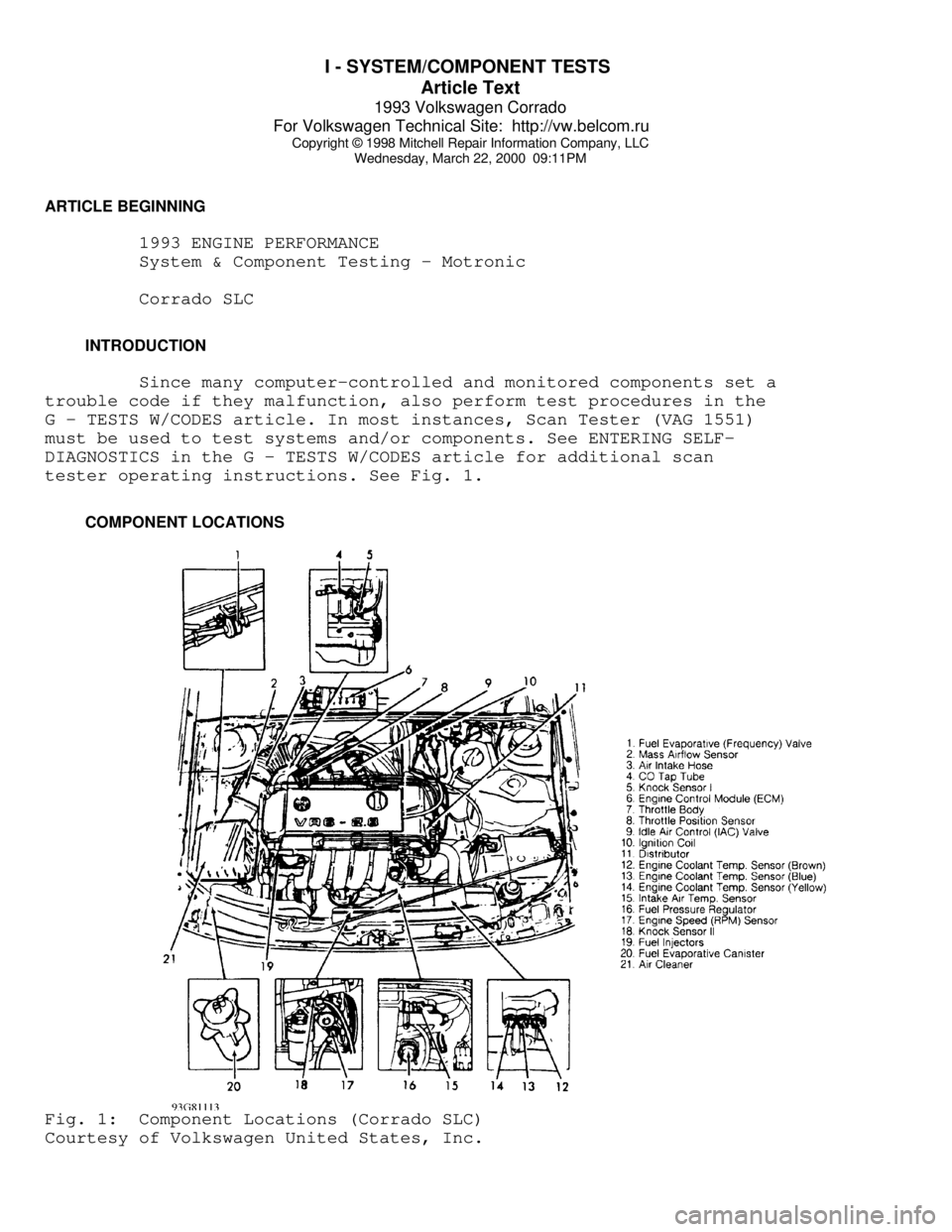

INTRODUCTION

Since many computer-controlled and monitored components set a

trouble code if they malfunction, also perform test procedures in the

G - TESTS W/CODES article. In most instances, Scan Tester (VAG 1551)

must be used to test systems and/or components. See ENTERING SELF-

DIAGNOSTICS in the G - TESTS W/CODES article for additional scan

tester operating instructions. See Fig. 1.

COMPONENT LOCATIONSFig. 1: Component Locations (Corrado SLC)

Courtesy of Volkswagen United States, Inc.

Page 614 of 920

I - SYSTEM/COMPONENT TESTS

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

COMPUTERIZED ENGINE CONTROLS

ELECTRONIC CONTROL MODULE (ECM)

Ground & Power Circuits

Check ECM ground and power circuits using the values in the

appropriate J - PIN VOLTAGE CHARTS article.

ENGINE SENSORS & SWITCHES

ENGINE COOLANT TEMPERATURE SENSOR

Corrado SLC (2.8L)

1) Ensure engine is cold. Connect Scan Tester (VAG 1551) to

Data Link Connectors (DLC) located in center console, in front of

shift lever. Start engine and allow it to idle.

2) With scan tester in READ TEST VALUE BLOCK function, select

group No. 01 and read coolant temperature value in field No. 2 of scan

tester. Temperature value must increase uniformly without

interruption. If value increases as specified, select END OUTPUT

function on scan tester.

3) If displayed value does not change or if engine

malfunctions during certain temperature ranges, turn ignition off and

measure engine coolant temperature sensor resistance. See ENGINE

COOLANT TEMPERATURE SENSOR RESISTANCE table.

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTemperature

øF (øC) Ohms

68 (20) ......................... 3000-2000

86 (30) ......................... 2000-1500

104 (40) ........................ 1500-1000

122 (50) ......................... 1000-800

140 (60) .......................... 700-500

158 (70) .......................... 500-375

176 (80) .......................... 375-275

194 (90) .......................... 275-225

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ INTAKE AIR TEMPERATURE SENSOR

Corrado SLC (2.8L)

1) Turn ignition off. Disconnect intake air temperature

sensor. Remove sensor from intake manifold and plug opening in

manifold. Reconnect sensor to wiring harness.

2) Connect Scan Tester (VAG 1551) to Data Link Connectors

(DLC) located in center console, in front of shift lever. Start engine

and allow it to idle. With scan tester in READ TEST VALUE BLOCK

function, select group 03 and read intake air temperature sensor value

in field No. 4 of scan tester.

3) Spray sensor with cooling spray and observe value on scan

Page 615 of 920

I - SYSTEM/COMPONENT TESTS

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

tester. Scan tester value must decrease. If temperature value does not

change, repair intake air temperature sensor circuit or replace sensor

as necessary. After repairs, erase Diagnostic Trouble Code (DTC)

memory (if applicable) and select END OUTPUT function.

HALL EFFECT SENSOR

Corrado SLC (2.8L)

Testing information is not available from manufacturer. These

vehicles are equipped with a distributorless ignition system.

FUEL SYSTEM

ACCELERATION/FULL THROTTLE ENRICHMENT & DECELERATION FUEL

CUT-OFF

Corrado SLC (2.8L)

1) Ensure engine coolant temperature is at least 176øF

(80

øC). Connect Scan Tester (VAG 1551) to Data Link Connectors (DLC)

located in center console, in front of shift lever.

2) Start engine and allow it to idle. With scan tester in

READ TEST VALUE BLOCK function, select group No. 04 and read value in

field No. 4 of scan tester. Display value must be 00010 at idle.

3) Using accelerator pedal, increase engine speed to 3000 RPM

and observe scan tester. Display value in field No. 4 of scan tester

must briefly be 10100. Release accelerator pedal and observe scan

tester.

4) Display value in field No. 4 of scan tester must briefly

be 00011, then return to 00010 at idle. If values are not as

specified, see THROTTLE POSITION (TP) SENSOR ADJUSTMENT procedures in

the D - ADJUSTMENTS article. If values are as specified, select END

OUTPUT function on scan tester.

FUEL INJECTORS & CIRCUIT

Corrado SLC (2.8L)

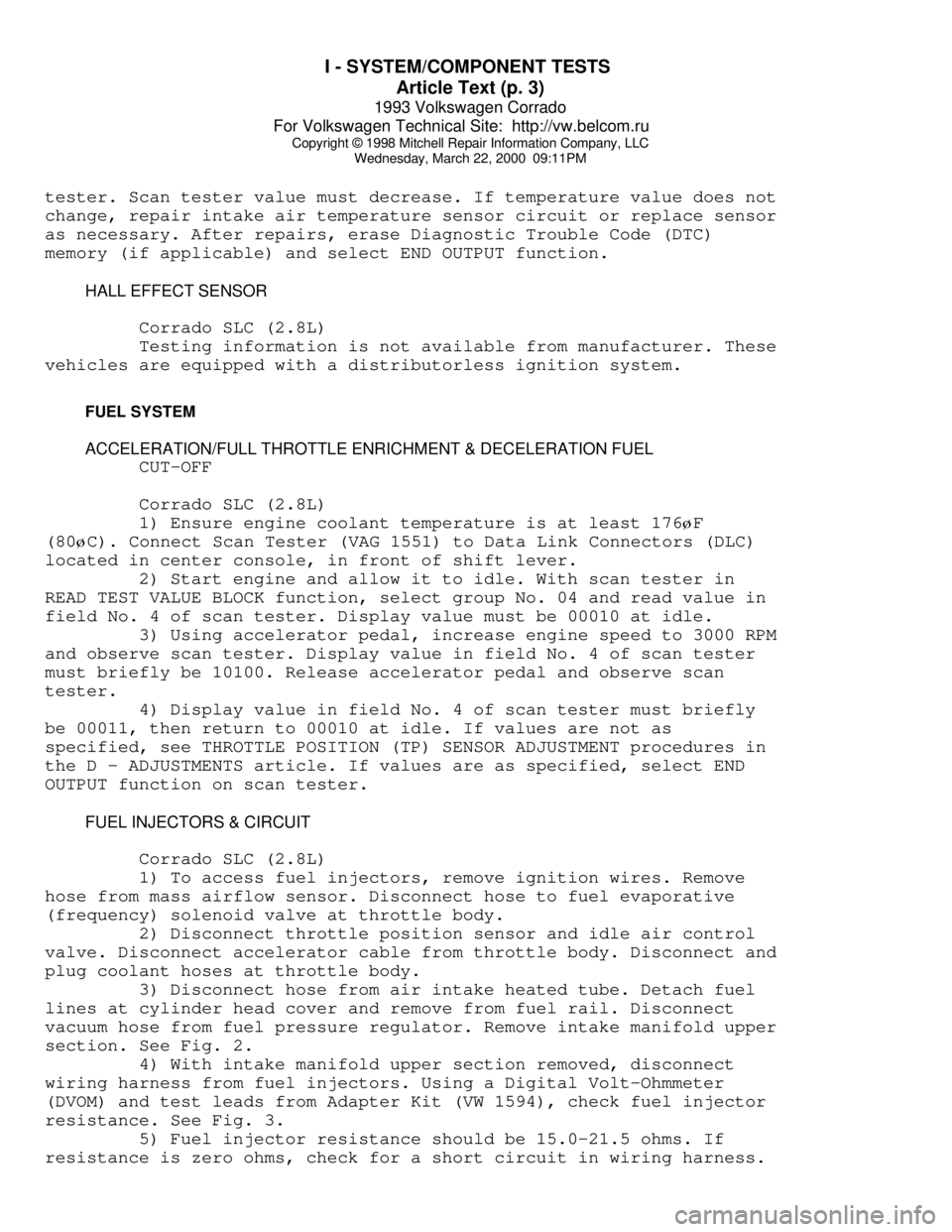

1) To access fuel injectors, remove ignition wires. Remove

hose from mass airflow sensor. Disconnect hose to fuel evaporative

(frequency) solenoid valve at throttle body.

2) Disconnect throttle position sensor and idle air control

valve. Disconnect accelerator cable from throttle body. Disconnect and

plug coolant hoses at throttle body.

3) Disconnect hose from air intake heated tube. Detach fuel

lines at cylinder head cover and remove from fuel rail. Disconnect

vacuum hose from fuel pressure regulator. Remove intake manifold upper

section. See Fig. 2.

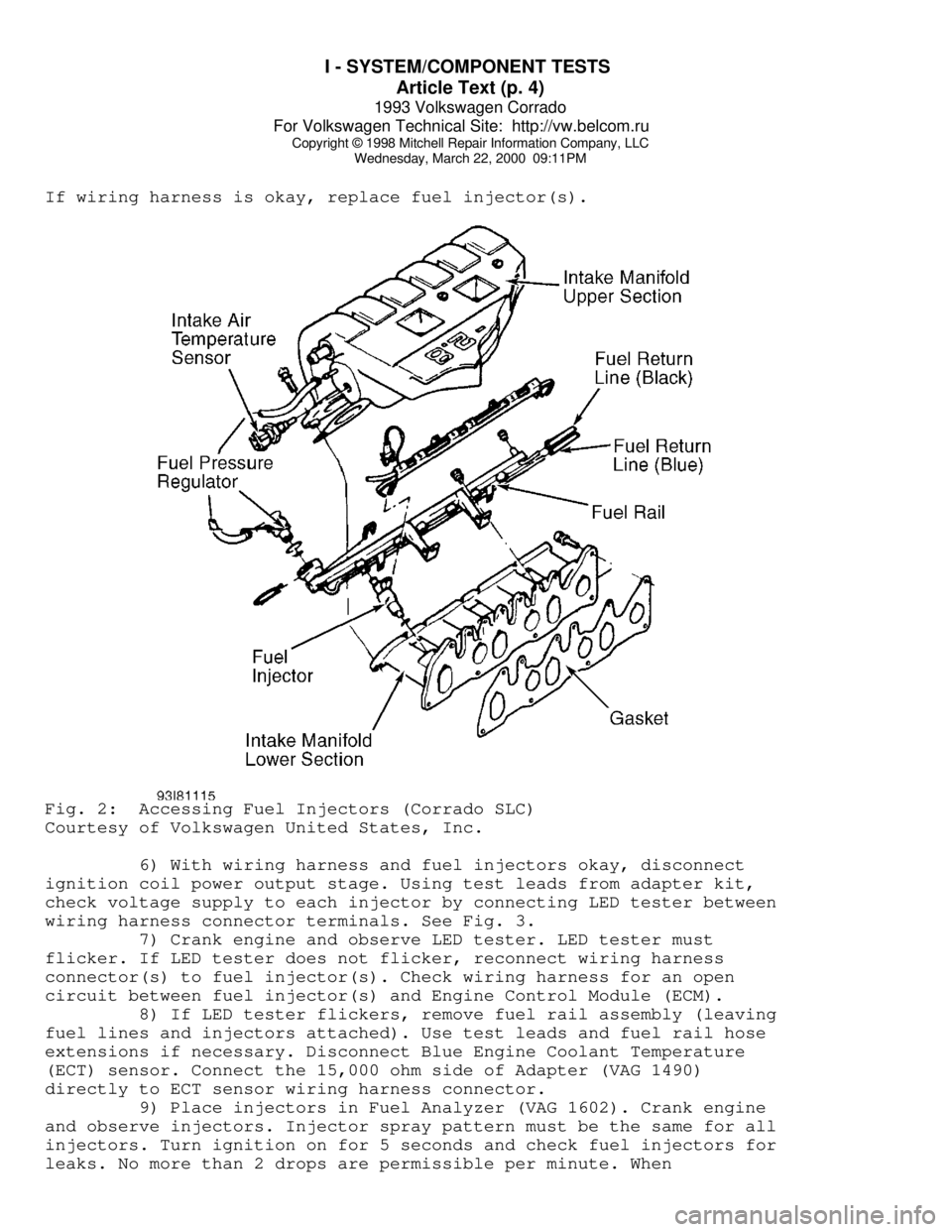

4) With intake manifold upper section removed, disconnect

wiring harness from fuel injectors. Using a Digital Volt-Ohmmeter

(DVOM) and test leads from Adapter Kit (VW 1594), check fuel injector

resistance. See Fig. 3.

5) Fuel injector resistance should be 15.0-21.5 ohms. If

resistance is zero ohms, check for a short circuit in wiring harness.

Page 616 of 920

I - SYSTEM/COMPONENT TESTS

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

If wiring harness is okay, replace fuel injector(s).Fig. 2: Accessing Fuel Injectors (Corrado SLC)

Courtesy of Volkswagen United States, Inc.

6) With wiring harness and fuel injectors okay, disconnect

ignition coil power output stage. Using test leads from adapter kit,

check voltage supply to each injector by connecting LED tester between

wiring harness connector terminals. See Fig. 3.

7) Crank engine and observe LED tester. LED tester must

flicker. If LED tester does not flicker, reconnect wiring harness

connector(s) to fuel injector(s). Check wiring harness for an open

circuit between fuel injector(s) and Engine Control Module (ECM).

8) If LED tester flickers, remove fuel rail assembly (leaving

fuel lines and injectors attached). Use test leads and fuel rail hose

extensions if necessary. Disconnect Blue Engine Coolant Temperature

(ECT) sensor. Connect the 15,000 ohm side of Adapter (VAG 1490)

directly to ECT sensor wiring harness connector.

9) Place injectors in Fuel Analyzer (VAG 1602). Crank engine

and observe injectors. Injector spray pattern must be the same for all

injectors. Turn ignition on for 5 seconds and check fuel injectors for

leaks. No more than 2 drops are permissible per minute. When

Page 617 of 920

I - SYSTEM/COMPONENT TESTS

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

reinstalling fuel rail, ensure that "O" rings are not damaged.Fig. 3: Testing Fuel Injectors & Circuit (Corrado SLC)

Courtesy of Volkswagen United States, Inc.

OXYGEN SENSOR CONTROL

IDLE CONTROL SYSTEM

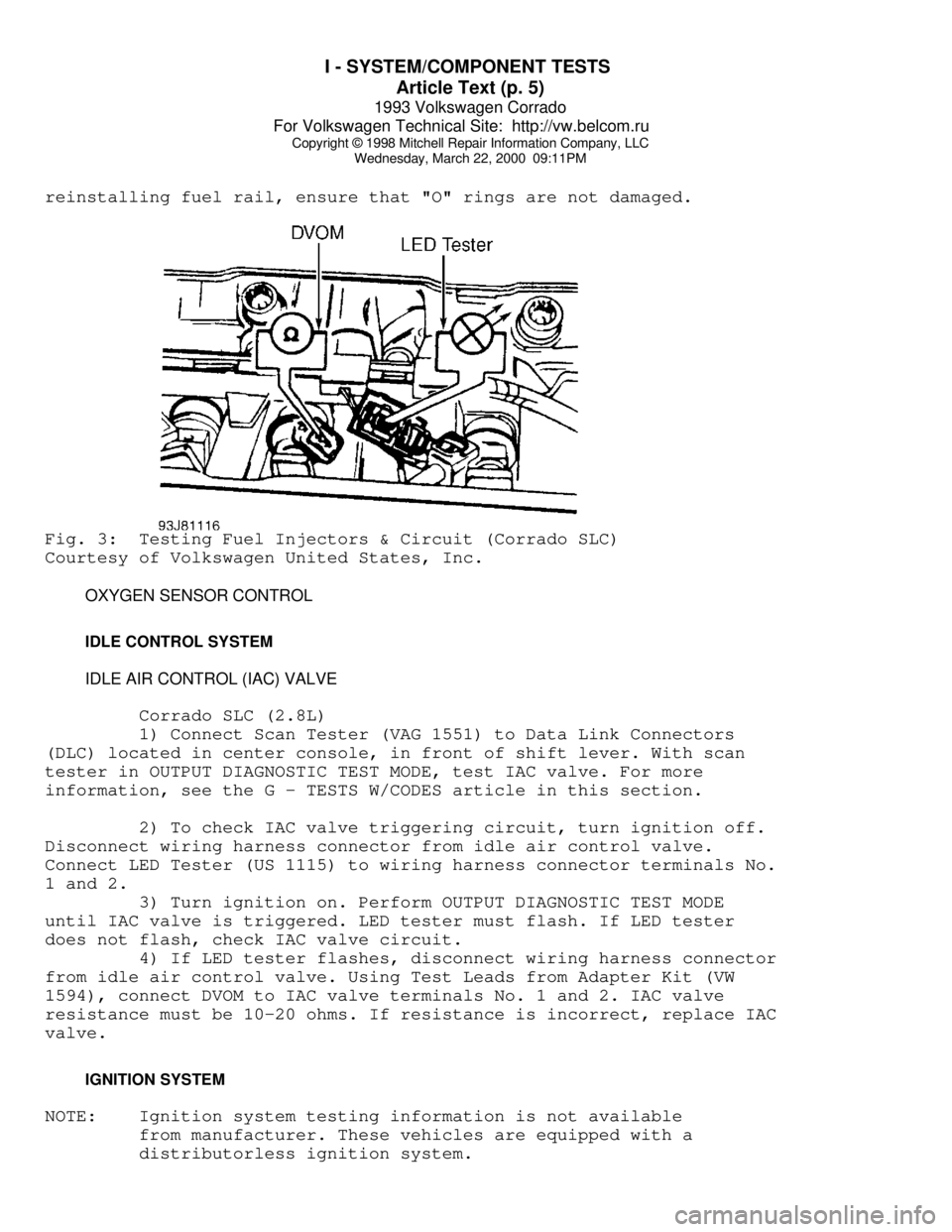

IDLE AIR CONTROL (IAC) VALVE

Corrado SLC (2.8L)

1) Connect Scan Tester (VAG 1551) to Data Link Connectors

(DLC) located in center console, in front of shift lever. With scan

tester in OUTPUT DIAGNOSTIC TEST MODE, test IAC valve. For more

information, see the G - TESTS W/CODES article in this section.

2) To check IAC valve triggering circuit, turn ignition off.

Disconnect wiring harness connector from idle air control valve.

Connect LED Tester (US 1115) to wiring harness connector terminals No.

1 and 2.

3) Turn ignition on. Perform OUTPUT DIAGNOSTIC TEST MODE

until IAC valve is triggered. LED tester must flash. If LED tester

does not flash, check IAC valve circuit.

4) If LED tester flashes, disconnect wiring harness connector

from idle air control valve. Using Test Leads from Adapter Kit (VW

1594), connect DVOM to IAC valve terminals No. 1 and 2. IAC valve

resistance must be 10-20 ohms. If resistance is incorrect, replace IAC

valve.

IGNITION SYSTEM

NOTE: Ignition system testing information is not available

from manufacturer. These vehicles are equipped with a

distributorless ignition system.

Page 618 of 920

I - SYSTEM/COMPONENT TESTS

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

IGNITION COIL

EMISSION SYSTEMS & SUB-SYSTEMS

NOTE: Other than EGR system, additional emission systems and

sub-system component testing information is not available

from manufacturer.

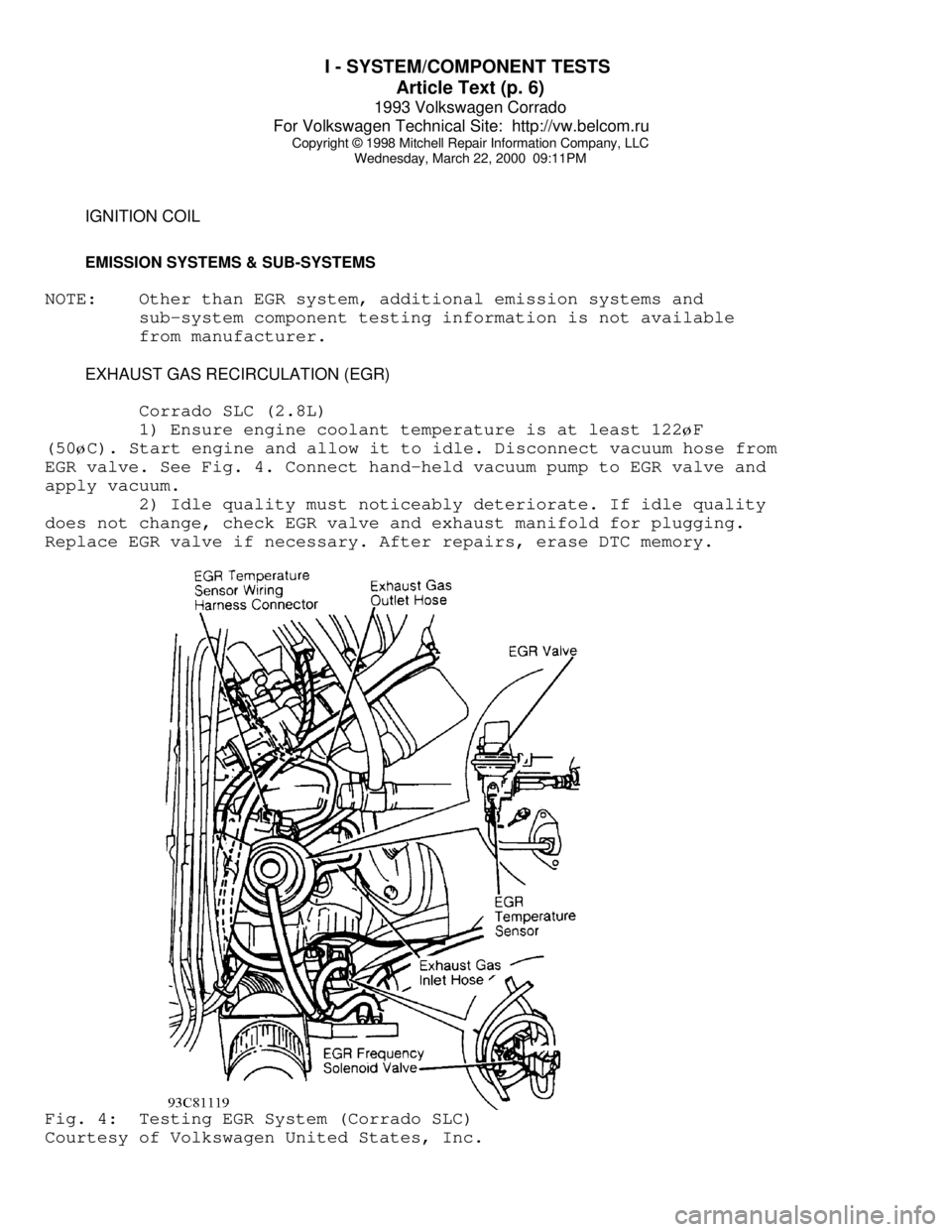

EXHAUST GAS RECIRCULATION (EGR)

Corrado SLC (2.8L)

1) Ensure engine coolant temperature is at least 122øF

(50

øC). Start engine and allow it to idle. Disconnect vacuum hose from

EGR valve. See Fig. 4. Connect hand-held vacuum pump to EGR valve and

apply vacuum.

2) Idle quality must noticeably deteriorate. If idle quality

does not change, check EGR valve and exhaust manifold for plugging.

Replace EGR valve if necessary. After repairs, erase DTC memory.Fig. 4: Testing EGR System (Corrado SLC)

Courtesy of Volkswagen United States, Inc.

Page 619 of 920

I - SYSTEM/COMPONENT TESTS

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

END OF ARTICLE

Page 620 of 920

INSTRUMENT PANEL

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:12PM

ARTICLE BEGINNING

1993 ACCESSORIES & EQUIPMENT

Volkswagen Instrument Panel

Corrado SLC

DESCRIPTION & OPERATION

Instrument cluster for most models includes speedometer, fuel

gauge and temperature gauge. Optional instruments include clock,

tachometer, voltmeter and oil temperature gauge. See Figs. 3.

Printed circuit provides voltage to gauges. A voltage

regulator attached to printed circuit controls voltage to fuel and

temperature gauges. Most warning lights are a Light Emitting Diode

(LED). To replace diode, pull from printed circuit socket.

TESTING

VOLTAGE REGULATOR TEST

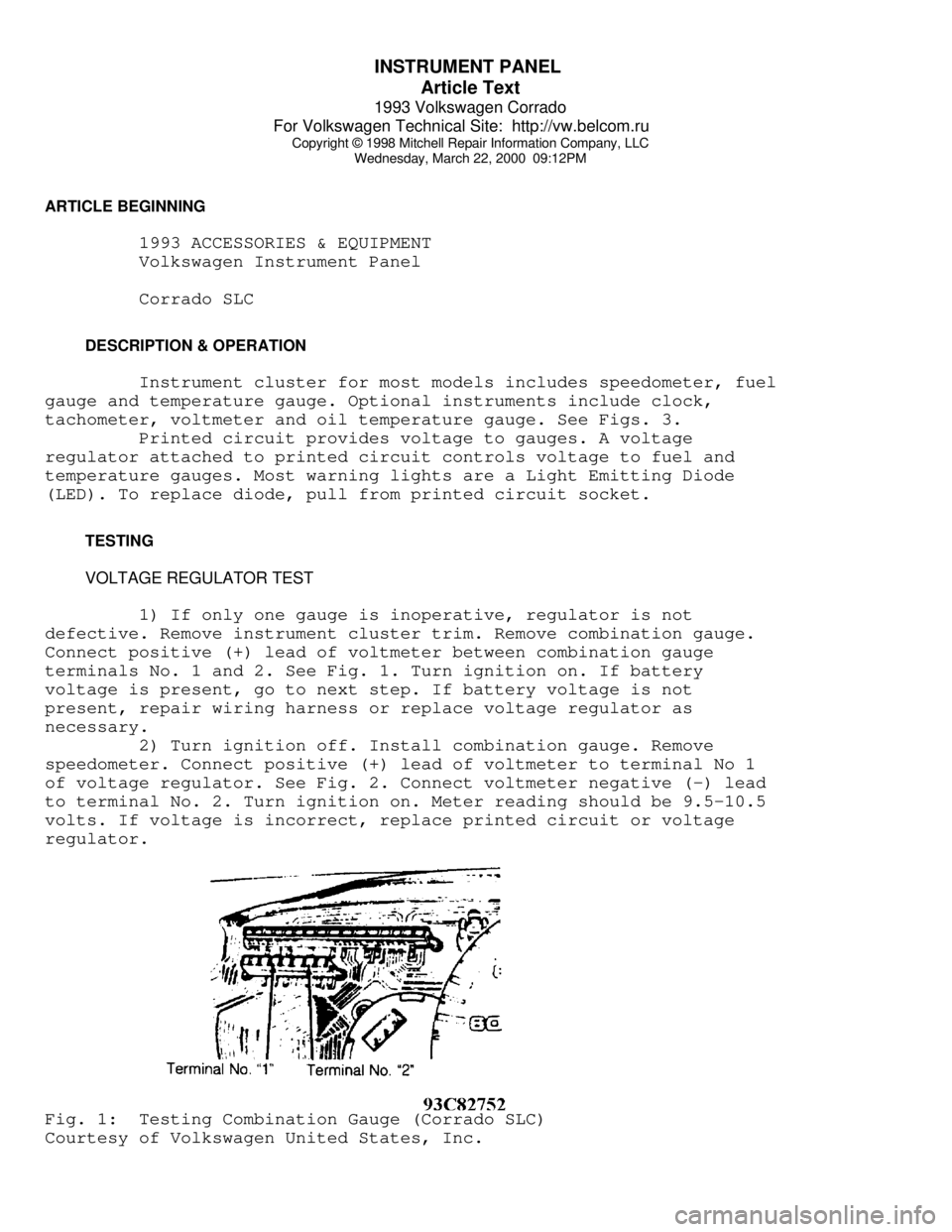

1) If only one gauge is inoperative, regulator is not

defective. Remove instrument cluster trim. Remove combination gauge.

Connect positive (+) lead of voltmeter between combination gauge

terminals No. 1 and 2. See Fig. 1. Turn ignition on. If battery

voltage is present, go to next step. If battery voltage is not

present, repair wiring harness or replace voltage regulator as

necessary.

2) Turn ignition off. Install combination gauge. Remove

speedometer. Connect positive (+) lead of voltmeter to terminal No 1

of voltage regulator. See Fig. 2. Connect voltmeter negative (-) lead

to terminal No. 2. Turn ignition on. Meter reading should be 9.5-10.5

volts. If voltage is incorrect, replace printed circuit or voltage

regulator.Fig. 1: Testing Combination Gauge (Corrado SLC)

Courtesy of Volkswagen United States, Inc.