lock VOLVO XC60 2009 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2009, Model line: XC60, Model: VOLVO XC60 2009Pages: 297, PDF Size: 21.16 MB

Page 239 of 297

06 Maintenance and specifications

Replacing bulbs06

}}

237Brake light

Backup light

Turn signal

Brake lights (LED)

NOTE

If an error message remains in the display

after a faulty bulb has been replaced, con-

tact an authorized Volvo workshop.

Brake lights and Taillights

The brake lights and taillights are replaced from

inside the cargo area.

NOTE Before starting to replace a bulb, see the

general information on page 232.

1. Open the panel.

2.

Remove the bulb holder by turning it coun-

terclockwise.

3. Remove the burned out bulb by pressing it

in and turning it counterclockwise.

4. Insert a new bulb, press it in and turn it clockwise.

5. Reinsert the bulb holder and turn it clock- wise.

License plate lighting 1. Remove the screws with a screwdriver.2. Carefully detach the entire bulb housing

and pull it out.

3. Replace the bulb.

4. Reinsert the entire bulb housing and screw

it into place.

Footwell lighting 1.

Insert a screwdriver at the short end of the

lens closest to the tunnel console (the cen-

ter of the vehicle) and turn gently so that

the lens comes loose. (Applies to both

lights).

2. Turn carefully until the lens comes loose.

3. Replace the bulb.

4. Press the lens back into place. G032485 G031940 G031941

Page 251 of 297

06 Maintenance and specifications

Fuses06

}}

* Option/accessory, for more information, see Introduction. 249

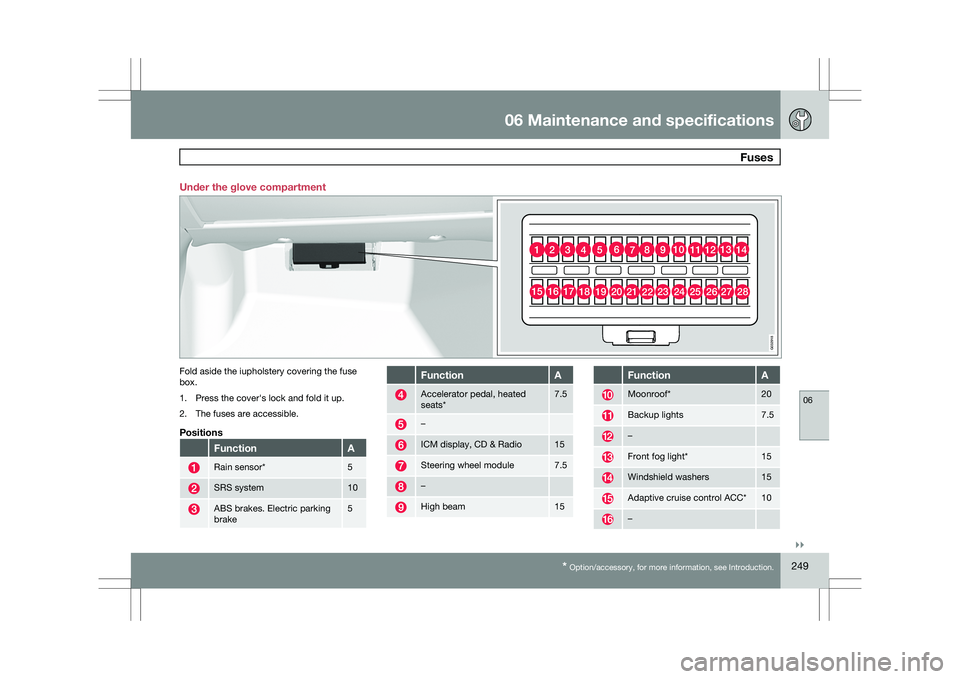

Under the glove compartment

Fold aside the iupholstery covering the fuse

box.

1. Press the cover\fs lock and fold it up.

2. The fuses are accessible.

Positions

Function A

Rain sensor* 5

SRS system 10

ABS brakes. Electric parking

brake 5 Function A

Accelerator pedal, heated

seats* 7.5

–

ICM display, CD & Radio 15

Steering wheel module 7.5

–

High beam 15 Function A

Moonroof* 20

Backup lights 7.5

–

Front fog light* 15

Windshield washers 15

Adaptive cruise control ACC* 10

– 1011121314123456789

2322212019181716152425262728

G032918

Page 252 of 297

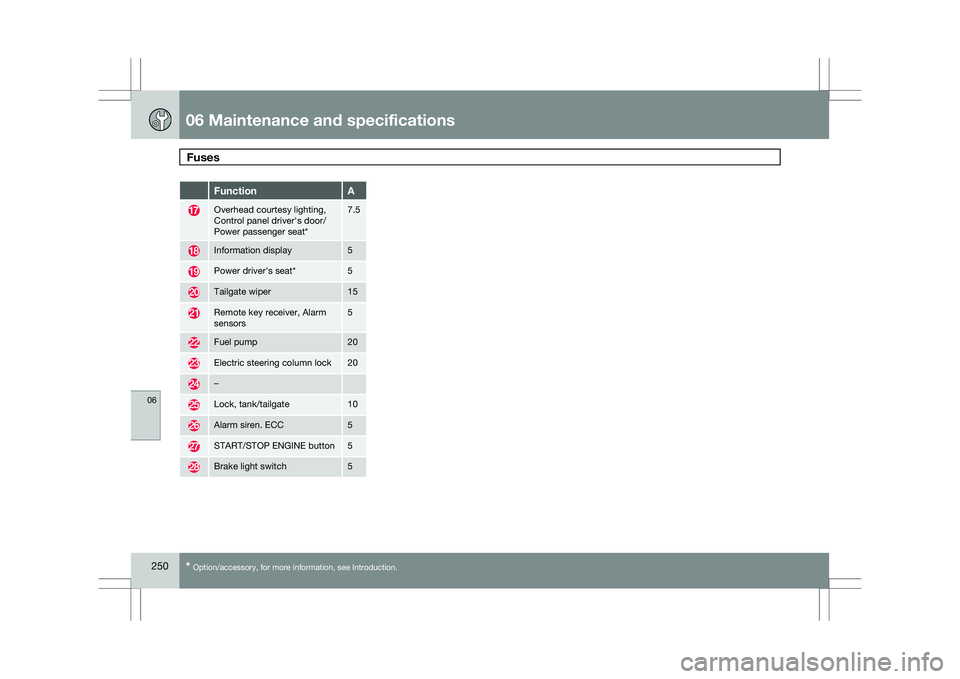

06 Maintenance and specificationsFuses 06

250

* Option/accessory, for more information, see Introduction. Function A

Overhead courtesy lighting,

Control panel driver\fs door/

Power passenger seat* 7.5

Information display 5

Power driver\fs seat* 5

Tailgate wiper 15

Remote key receiver, Alarm

sensors 5

Fuel pump 20

Electric steering column lock 20

–

Lock, tank/tailgate 10

Alarm siren. ECC 5

START/STOP ENGINE button 5

Brake light switch 5

Page 265 of 297

06 Maintenance and specifications

Wheels and tires06

}}

263

chains in some cases CANNOT be used.

Sufficient clearances between chains and

brakes, suspension and body components

must be maintained.

\b Some strap-on type chains will interfere

with brake components and therefore

CANNOT be used.

\b All Wheel Drive models: Snow chains

should only be installed on the front

wheels. Only chains adapted for AWD

models should be used.

Consult your Volvo retailer for additional snow

chain information.

CAUTION \b

Check local regulations regarding the

use of snow chains before installing.

\b Use single-sided snow chains only.

\b Always follow the chain manufacturer\fs

installation instructions carefully. Install

chains as tightly as possible and

retighten periodically.

\b Never exceed the chain manufacturer\fs

specified maximum speed limit. (Under

no circumstances should you exceed

31 mph (50 km/h).

\b Avoid bumps, holes or sharp turns

when driving with snow chains.

\b The handling of the vehicle can be

adversely affected when driving with

chains. Avoid fast or sharp turns as well

as locked wheel braking.

Snow tires, studded tires 2

Tires for winter use:

\b Owners who live in or regularly commute

through areas with sustained periods of

snow or icy driving conditions are strongly

advised to fit suitable winter tires to help

retain the highest degree of traction.

\b It is important to install winter tires on all

four wheels to help retain traction during cornering, braking, and accelerating. Fail-

ure to do so could reduce traction to an

unsafe level or adversely affect handling.

\b Do not mix tires of different design as this

could also negatively affect overall tire road

grip.

\b Winter tires wear more quickly on dry roads

in warm weather. They should be removed

when the winter driving season has ended.

\b Studded tires should be run-in

300 – 600 miles (500 – 1000 km) during

which the vehicle should be driven as

smoothly as possible to give the studs the

opportunity to seat properly in the tires.

The tires should have the same rotational

direction throughout their entire lifetime.

NOTE Please consult state or provincial regula-

tions restricting the use of studded winter

tires before installing such tires.

2

Where permitted

Page 266 of 297

06 Maintenance and specificationsWheels and tires 06

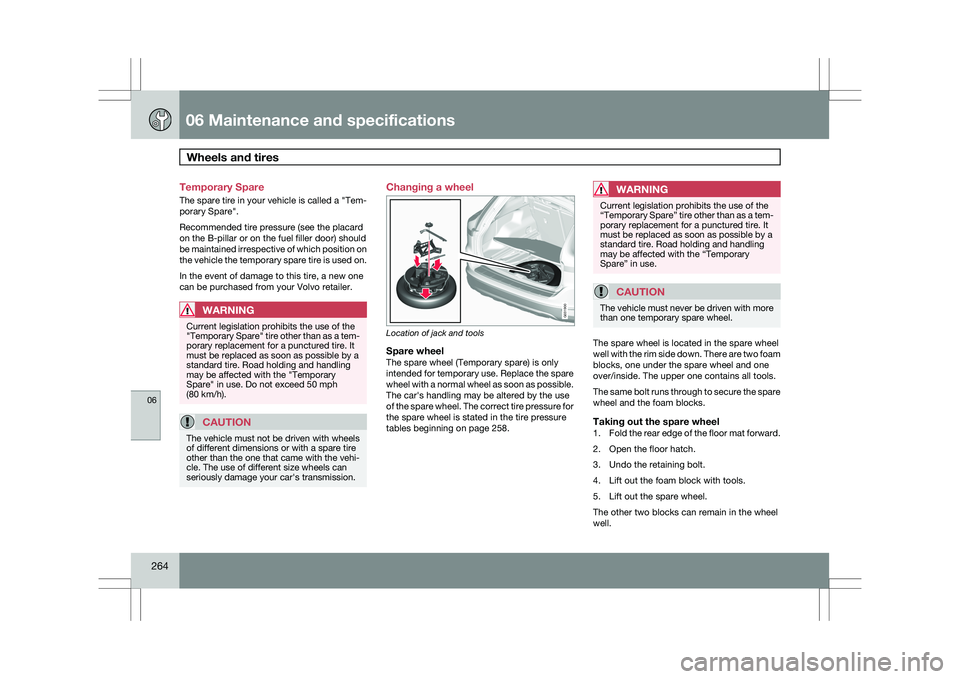

264 Temporary Spare

The spare tire in your vehicle is called a "Tem-

porary Spare".

Recommended tire pressure (see the placard

on the B-pillar or on the fuel filler door) should

be maintained irrespective of which position on

the vehicle the temporary spare tire is used on.

In the event of damage to this tire, a new one

can be purchased from your Volvo retailer.

WARNING

Current legislation prohibits the use of the

"Temporary Spare" tire other than as a tem-

porary replacement for a punctured tire. It

must be replaced as soon as possible by a

standard tire. Road holding and handling

may be affected with the "Temporary

Spare" in use. Do not exceed 50 mph

(80 km/h).

CAUTION

The vehicle must not be driven with wheels

of different dimensions or with a spare tire

other than the one that came with the vehi-

cle. The use of different size wheels can

seriously damage your car\fs transmission. Changing a wheel

Location of jack and tools

Spare wheelThe spare wheel (Temporary spare) is only

intended for temporary use. Replace the spare

wheel with a normal wheel as soon as possible.

The car\fs handling may be altered by the use

of the spare wheel. The correct tire pressure for

the spare wheel is stated in the tire pressure

tables beginning on page 258.

WARNING Current legislation prohibits the use of the

“Temporary Spare” tire other than as a tem-

porary replacement for a punctured tire. It

must be replaced as soon as possible by a

standard tire. Road holding and handling

may be affected with the “Temporary

Spare” in use.

CAUTION

The vehicle must never be driven with more

than one temporary spare wheel.

The spare wheel is located in the spare wheel

well with the rim side down. There are two foam

blocks, one under the spare wheel and one

over/inside. The upper one contains all tools.

The same bolt runs through to secure the spare

wheel and the foam blocks.

Taking out the spare wheel1.

Fold the rear edge of the floor mat forward.

2. Open the floor hatch.

3. Undo the retaining bolt.

4. Lift out the foam block with tools.

5. Lift out the spare wheel.

The other two blocks can remain in the wheel

well. G031900

Page 267 of 297

06 Maintenance and specifications

Wheels and tires06

}}

265

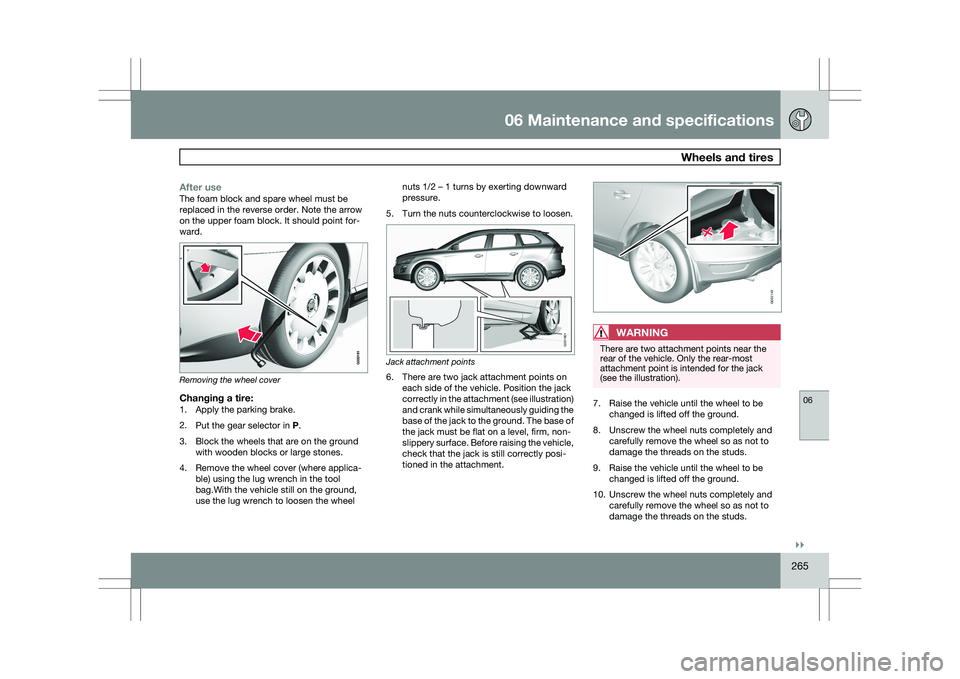

After useThe foam block and spare wheel must be

replaced in the reverse order. Note the arrow

on the upper foam block. It should point for-

ward.Removing the wheel cover

Changing a tire:1. Apply the parking brake.

2.

Put the gear selector in P.

3. Block the wheels that are on the ground with wooden blocks or large stones.

4. Remove the wheel cover (where applica- ble) using the lug wrench in the tool

bag.With the vehicle still on the ground,

use the lug wrench to loosen the wheel nuts 1/2 – 1 turns by exerting downward

pressure.

5. Turn the nuts counterclockwise to loosen. Jack attachment points

6. There are two jack attachment points on

each side of the vehicle. Position the jack

correctly in the attachment (see illustration)

and crank while simultaneously guiding the

base of the jack to the ground. The base of

the jack must be flat on a level, firm, non-

slippery surface. Before raising the vehicle,

check that the jack is still correctly posi-

tioned in the attachment.

WARNING There are two attachment points near the

rear of the vehicle. Only the rear-most

attachment point is intended for the jack

(see the illustration).

7. Raise the vehicle until the wheel to be

changed is lifted off the ground.

8. Unscrew the wheel nuts completely and carefully remove the wheel so as not to

damage the threads on the studs.

9. Raise the vehicle until the wheel to be changed is lifted off the ground.

10. Unscrew the wheel nuts completely and carefully remove the wheel so as not to

damage the threads on the studs. G031901 G032149

Page 268 of 297

06 Maintenance and specificationsWheels and tires 06

266

* Option/accessory, for more information, see Introduction.

WARNING \b

The jack must correctly engage the jack

attachment.

\b Be sure the jack is on a firm, level, non-

slippery surface.

\b Never allow any part of your body to be

extended under a vehicle supported by

a jack.

\b Use the jack intended for the vehicle

when changing a tire. For any other job,

use stands to support the vehicle.

\b Apply the parking brake and put the

gear selector in the Park (

P) position.

\b Block the wheels standing on the

ground, use rigid wooden blocks or

large stones.

\b The jack should be kept well-greased

and clean, and should not be damaged.

\b No objects should be placed between

the base of jack and the ground, or

between the jack and the attachment

bar on the vehicle.

Re-installing the wheel1. Clean the contact surfaces on the wheel

and hub.

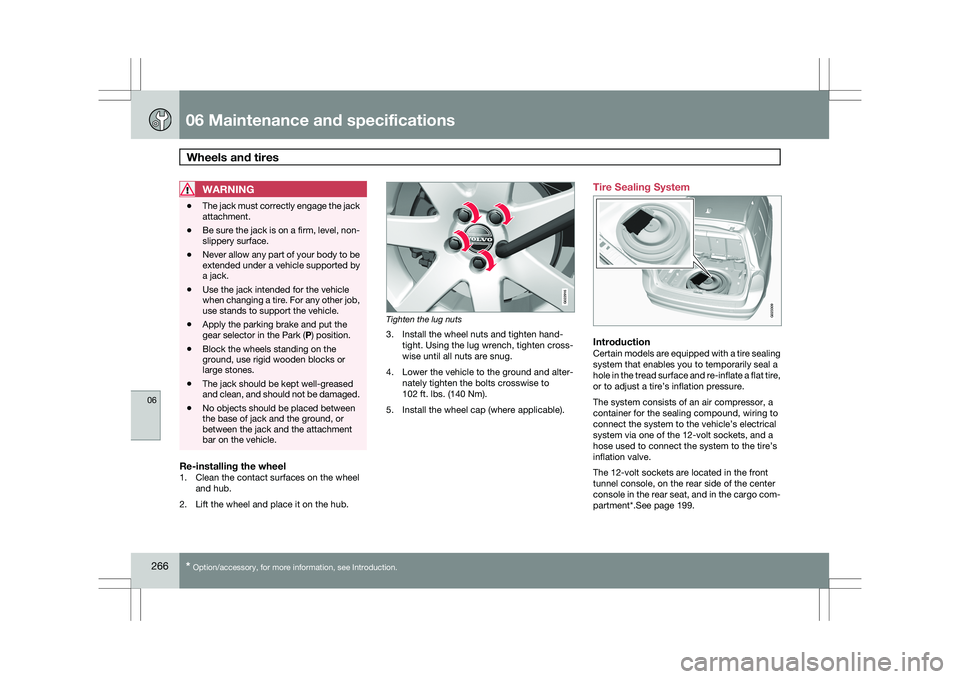

2. Lift the wheel and place it on the hub. Tighten the lug nuts

3. Install the wheel nuts and tighten hand-

tight. Using the lug wrench, tighten cross-

wise until all nuts are snug.

4. Lower the vehicle to the ground and alter- nately tighten the bolts crosswise to

102 ft. lbs. (140 Nm).

5. Install the wheel cap (where applicable). Tire Sealing System

IntroductionCertain models are equipped with a tire sealing

system that enables you to temporarily seal a

hole in the tread surface and re-inflate a flat tire,

or to adjust a tire’s inflation pressure.

The system consists of an air compressor, a

container for the sealing compound, wiring to

connect the system to the vehicle’s electrical

system via one of the 12-volt sockets, and a

hose used to connect the system to the tire’s

inflation valve.

The 12-volt sockets are located in the front

tunnel console, on the rear side of the center

console in the rear seat, and in the cargo com-

partment*.See page 199. G022916 G023309

Page 269 of 297

06 Maintenance and specifications

Wheels and tires06

}}

267

Accessing the tire sealing systemThe tire sealing system is stowed under the

floor of the cargo area. To access it:

1.

Fold up or remove any protective floor cov-

ering or carpet.

2. Open the floor hatch.

3. Remove the retaining screws.

4. Lift out the foam plastic block holding the jack and lug wrench.

5. Lift out the tire sealing system.

NOTE \b

The tire sealing system is only intended

to seal holes on the tire’s tread area, not

the sidewall.

\b Tires with large holes or tears cannot be

repaired with the tire sealing system.

WARNING \b

After using the tire sealing system, the

vehicle should not be driven farther than

approximately 120 miles (200 km).

\b Have the tire inspected by a trained and

qualified Volvo service technician as

soon as possible to determine if it can

be permanently repaired or must be

replaced.

\b The vehicle should not be driven faster

than 50 mph (80 km/h) while using a tire

that has been temporarily repaired with

the tire sealing system.

\b After using the tire sealing system, drive

carefully and avoid abrupt steering

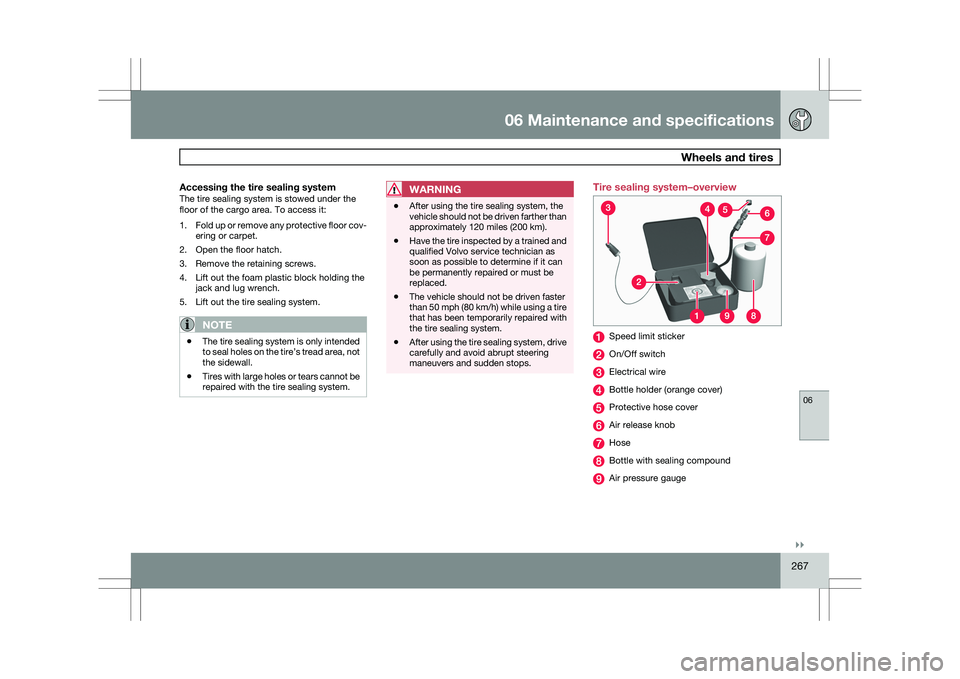

maneuvers and sudden stops. Tire sealing system–overview

Speed limit sticker

On/Off switch

Electrical wire

Bottle holder (orange cover)

Protective hose cover

Air release knob

Hose

Bottle with sealing compound

Air pressure gauge

Page 272 of 297

06 Maintenance and specificationsWheels and tires 06

270

CAUTION The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

WARNING

If the pressure remains below 22 psi

(1.8 bar) after approximately seven minutes,

turn off the compressor. In this case, the

hole is too large to be sealed and the vehicle

should not be driven.

11.

Switch off the compressor and disconnect

the electrical wire from the 12-volt

socket.

12. Unscrew the hose from the tire’s inflation valve and reinstall the valve cap.

13. Immediately drive the vehicle for approxi- mately 2 miles (3 km) at a maximum speed

of 50 mph (80 km/h) to distribute the seal-

ing compound in the tire.

NOTE \b

Safely stow the tire sealing system in a

convenient place as it will soon be used

again to check the tire’s inflation pres-

sure.

\b The empty bottle of sealing compound

cannot be removed from the bottle

holder. Consult a trained and qualified

Volvo service technician to have the

bottle removed and properly disposed

of.

WARNING If heavy vibrations, unsteady steering

behavior, or noises should occur while driv-

ing, reduce speed and park the vehicle in a

safe place. Recheck the tire for bumps,

cracks, or other visible damage, and

recheck its inflation pressure. If the pressure

is below 19 psi (1.3 bar), do not continue

driving. Have the vehicle towed to a trained

and qualified Volvo service technician.

Stage 2: Checking inflation pressure1. Connect the tire sealing system as descri-

bed in stage 1.

2. Refer to the inflation pressure tablesfor the

correct inflation pressure. If the tire needs

to be inflated, start the tire sealing system’s compressor. If necessary, release air from

the tire by turning the air release knob

counterclockwise.

CAUTION The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

WARNING

If you interrupt your trip for more than 1

hour, check the inflation pressure in the

damaged tire again before continuing.

Replacing the sealing compound

container

The sealing compound container must be

replaced if:

\b

the tire sealing system has been used to

repair a tire

\b the container’s expiration date has passed

(see the date on decal).

Page 273 of 297

06 Maintenance and specifications

Wheels and tires06

}}

271

NOTE\b

After use, the sealing compound bottle,

the hose, and certain other system

components must be replaced. Please

consult your Volvo retailer for replace-

ment parts.

\b If the sealing compound bottle’s expi-

ration date has passed, please take it to

a Volvo retailer or a recycling station

that can properly dispose of harmful

substances. Inflating tires

The tire sealing system can be used to inflate

the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off.

Ensure that the on/off switch is in position

0 (the 0 side of the switch should be

pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire’s infla-

tion valve and screw the hose connector

onto the valve as tightly as possible by

hand.

5. Connect the electrical wire to the nearest 12-volt socket in the vehicle. 6. Start the vehicle’s engine.

WARNING \b

The vehicle’s engine should be running

when the tire sealing system is used to

avoid battery drain. Therefore, be sure

the vehicle is parked in a well ventilated

place, or outdoors, before using the sys-

tem.

\b Children should never be left unattended

in the vehicle when the engine is running. 7. Check the tire’s inflation pressure on the

gauge. Switch off the compressor briefly to

get a clear reading from the pressure

gauge.

8. Refer to the tire inflation tables for the cor-

rect inflation pressure. If the tire needs to

be inflated, start the tire sealing system’s

compressor (press the on/off switch to

position I). If necessary, release air from the

tire by turning the air release knob coun-

terclockwise.

CAUTION The compressor should not be used for

more than 10 minutes at a time to avoid

overheating. 9. Turn off the compressor (press the on/off

switch to position 0) when the correct infla-

tion pressure has been reached.

10. Unscrew the hose from the tire’s inflation valve and reinstall the valve cap.

11. Disconnect the electrical wire from the 12-volt socket.

Tire Pressure Monitoring System

(TPMS)–U.S models only

NOTE USA – FCC ID: KR5S122780002

This device complies with part 15 of the

FCC rules. Operation is subject to the fol-

lowing conditions: (1) This device may not

cause harmful interference, and (2) this

device must accept any interference

received, including interference that may

cause undesired operation.

The tire pressure monitoring system uses sen-

sors mounted in the tire valves to check infla-

tion pressure levels. When the vehicle is mov-

ing at a speed of approximately 20 mph

(30 km/h) or faster, these sensors transmit

inflation pressure data to a receiver located in

the vehicle.