check engine YAMAHA DT125R 2002 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: DT125R, Model: YAMAHA DT125R 2002Pages: 96, PDF Size: 2.14 MB

Page 42 of 96

6-4

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU03884

NOTE:

8The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

8Hydraulic brake service

9Regularly check and, if necessary, correct the brake fluid level.

9Every two years replace the internal components of the brake master cylinders and calipers, and change the

brake fluid.

9Replace the brake hoses every four years and if cracked or damaged.21

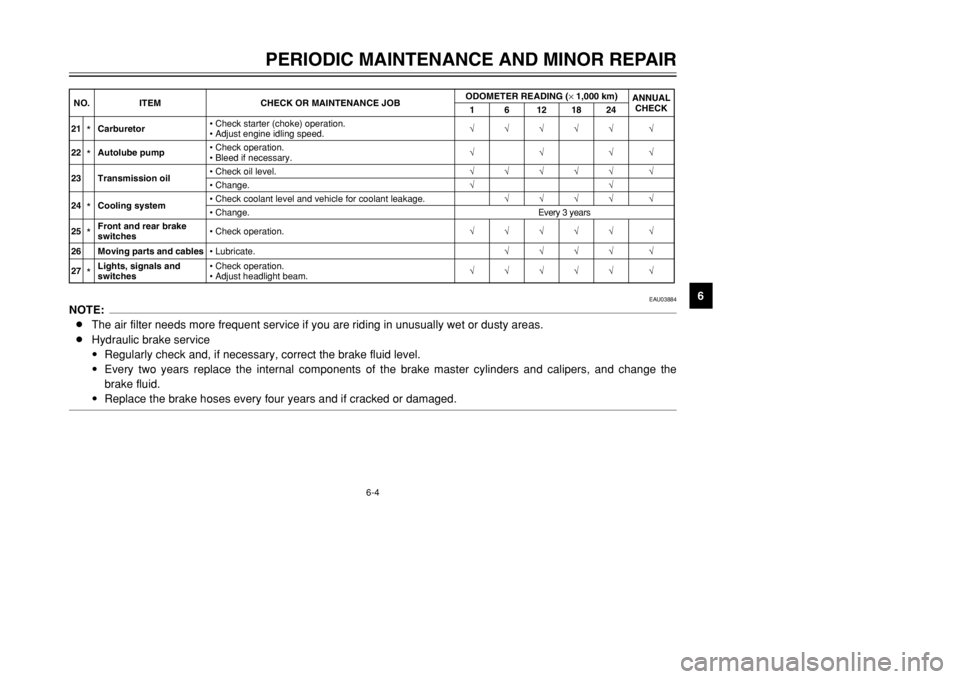

*Carburetor•Check starter (choke) operation.

•Adjust engine idling speed.√√√√√ √

22*Autolube pump•Check operation.

•Bleed if necessary.√√√√

23 Transmission oil•Check oil level.√√√√√ √

•Change.√√

24*Cooling system•Check coolant level and vehicle for coolant leakage.√√√√ √

•Change.Every 3 years

25*Front and rear brake

switches•Check operation.√√√√√ √

26 Moving parts and cables•Lubricate.√√√√ √

27*Lights, signals and

switches•Check operation.

•Adjust headlight beam.√√√√√ √ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (× 1,000 km)

ANNUAL

CHECK

1 6 12 18 24

3MB-9-E8 6/13/01 10:55 AM Page 41

Page 47 of 96

6-9

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU01833

Checking the spark plugThe spark plug is an important

engine component, which is easy to

check. Since heat and deposits will

cause any spark plug to slowly erode,

the spark plug should be removed

and checked in accordance with the

periodic maintenance and lubrication

chart. In addition, the condition of the

spark plug can reveal the condition of

the engine.

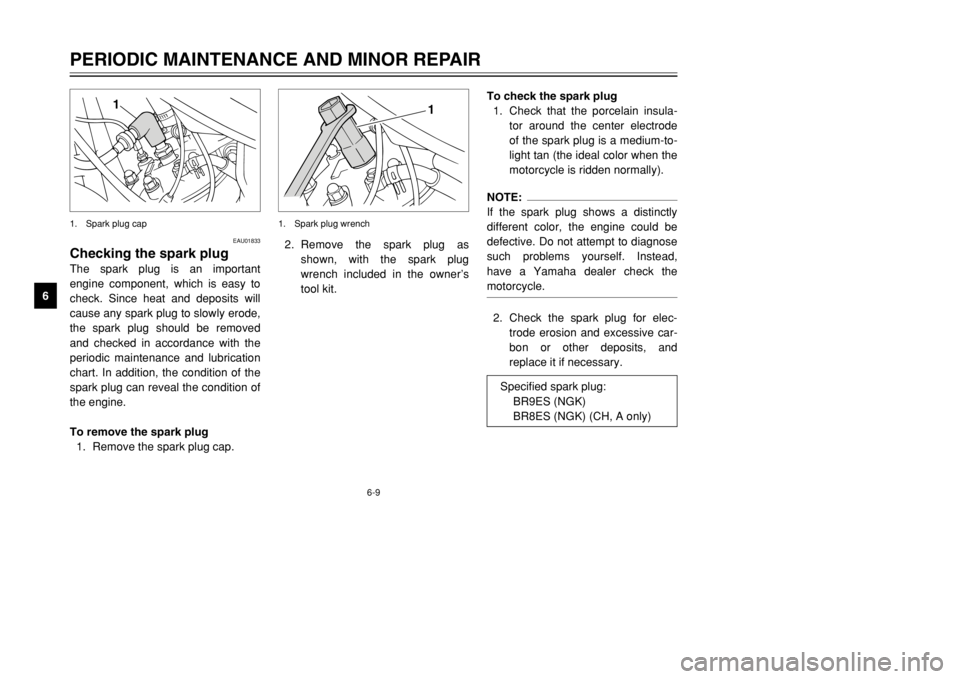

To remove the spark plug

1. Remove the spark plug cap.

1

1. Spark plug cap

To check the spark plug

1. Check that the porcelain insula-

tor around the center electrode

of the spark plug is a medium-to-

light tan (the ideal color when the

motorcycle is ridden normally).NOTE:

If the spark plug shows a distinctly

different color, the engine could be

defective. Do not attempt to diagnose

such problems yourself. Instead,

have a Yamaha dealer check the

motorcycle.2. Check the spark plug for elec-

trode erosion and excessive car-

bon or other deposits, and

replace it if necessary. 2. Remove the spark plug as

shown, with the spark plug

wrench included in the owner’s

tool kit.

1

1. Spark plug wrench

Specified spark plug:

BR9ES (NGK)

BR8ES (NGK) (CH, A only)

3MB-9-E8 6/13/01 10:55 AM Page 46

Page 48 of 96

6-10

PERIODIC MAINTENANCE AND MINOR REPAIR

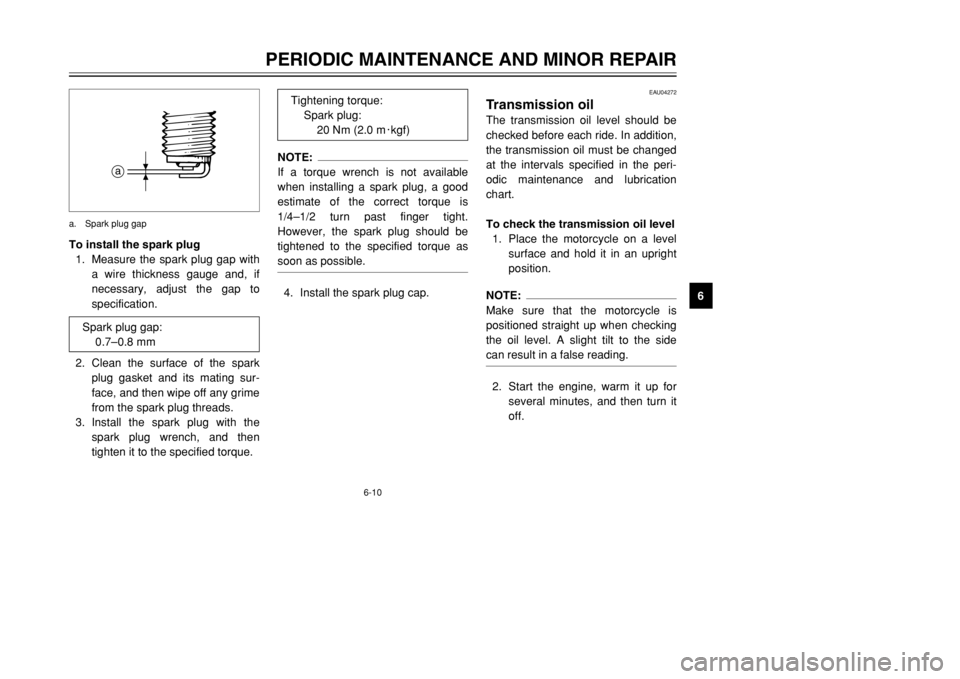

6 To install the spark plug

1. Measure the spark plug gap with

a wire thickness gauge and, if

necessary, adjust the gap to

specification.

2. Clean the surface of the spark

plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

3. Install the spark plug with the

spark plug wrench, and then

tighten it to the specified torque.

a

a. Spark plug gap

EAU04272

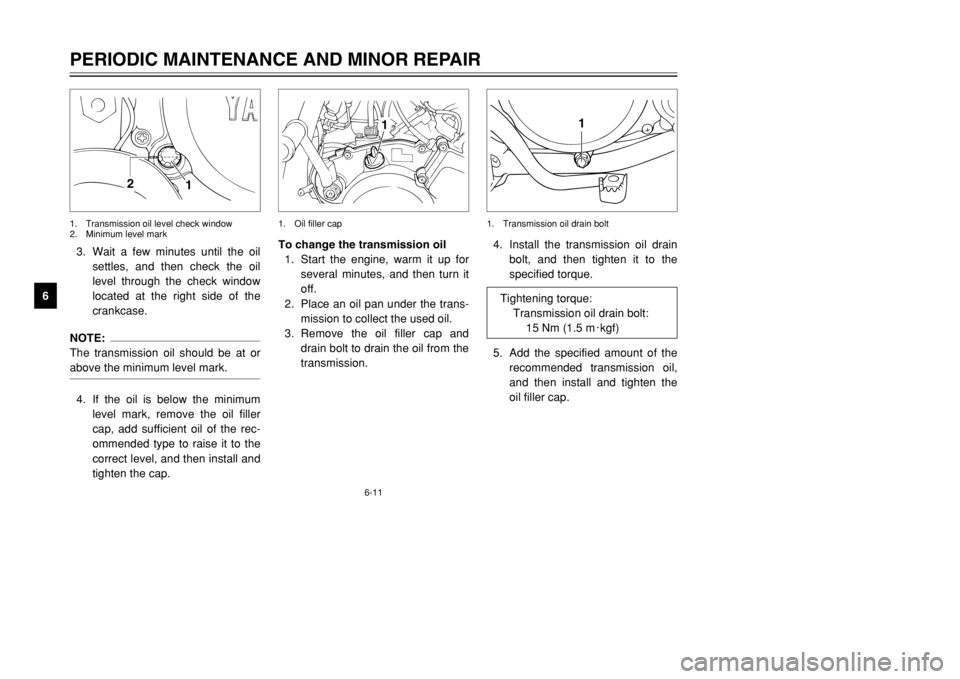

Transmission oilThe transmission oil level should be

checked before each ride. In addition,

the transmission oil must be changed

at the intervals specified in the peri-

odic maintenance and lubrication

chart.

To check the transmission oil level

1. Place the motorcycle on a level

surface and hold it in an upright

position.NOTE:

Make sure that the motorcycle is

positioned straight up when checking

the oil level. A slight tilt to the side

can result in a false reading.2. Start the engine, warm it up for

several minutes, and then turn it

off.

NOTE:

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is

1/4–1/2 turn past finger tight.

However, the spark plug should be

tightened to the specified torque as

soon as possible.4. Install the spark plug cap.

Spark plug gap:

0.7–0.8 mmTightening torque:

Spark plug:

20 Nm (2.0 m0kgf)

3MB-9-E8 6/13/01 10:55 AM Page 47

Page 49 of 96

6-11

PERIODIC MAINTENANCE AND MINOR REPAIR

63. Wait a few minutes until the oil

settles, and then check the oil

level through the check window

located at the right side of the

crankcase.

NOTE:

The transmission oil should be at or

above the minimum level mark.4. If the oil is below the minimum

level mark, remove the oil filler

cap, add sufficient oil of the rec-

ommended type to raise it to the

correct level, and then install and

tighten the cap.

1

2

1. Transmission oil level check window

2. Minimum level mark

4. Install the transmission oil drain

bolt, and then tighten it to the

specified torque.

5. Add the specified amount of the

recommended transmission oil,

and then install and tighten the

oil filler cap.

1

1. Transmission oil drain bolt

To change the transmission oil

1. Start the engine, warm it up for

several minutes, and then turn it

off.

2. Place an oil pan under the trans-

mission to collect the used oil.

3. Remove the oil filler cap and

drain bolt to drain the oil from the

transmission.

1

1. Oil filler cap

Tightening torque:

Transmission oil drain bolt:

15 Nm (1.5 m0kgf)

3MB-9-E8 6/13/01 10:55 AM Page 48

Page 50 of 96

6-12

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EC000077

cC8In order to prevent clutch slip-

page (since the transmission

oil also lubricates the clutch),

do not mix any chemical addi-

tives with the oil.

8Make sure that no foreign

material enters the transmis-

sion.6. Start the engine, and then let it

idle for several minutes while

checking the transmission for oil

leakage. If oil is leaking, immedi-

ately turn off the engine and

check for the cause.

EAU01808

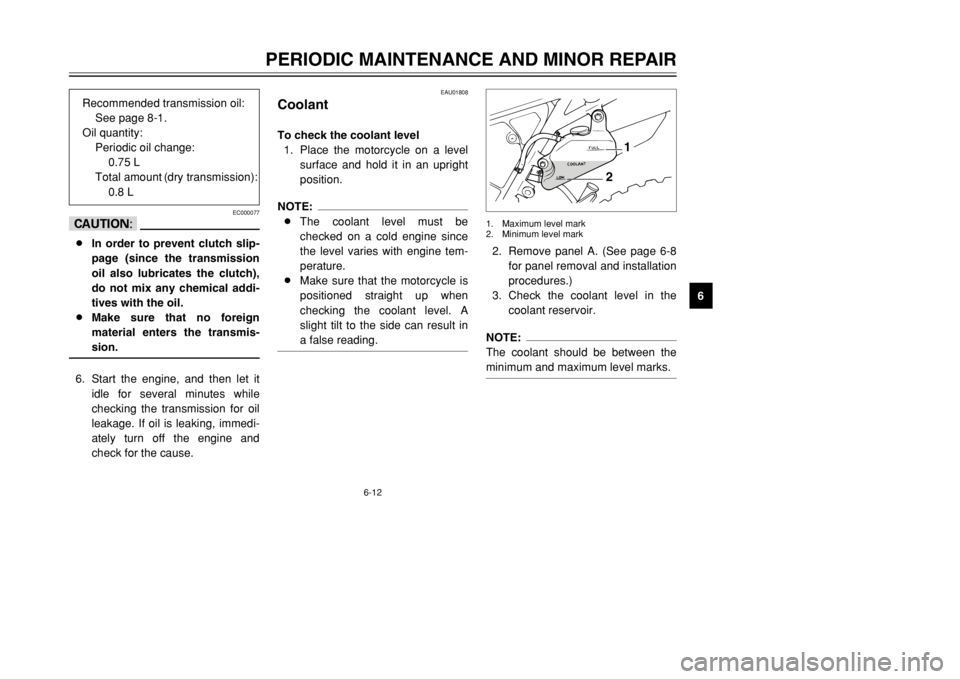

CoolantTo check the coolant level

1. Place the motorcycle on a level

surface and hold it in an upright

position.NOTE:

8The coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

8Make sure that the motorcycle is

positioned straight up when

checking the coolant level. A

slight tilt to the side can result in

a false reading.

2. Remove panel A. (See page 6-8

for panel removal and installation

procedures.)

3. Check the coolant level in the

coolant reservoir.NOTE:

The coolant should be between the

minimum and maximum level marks.

2

1

1. Maximum level mark

2. Minimum level mark

Recommended transmission oil:

See page 8-1.

Oil quantity:

Periodic oil change:

0.75 L

Total amount (dry transmission):

0.8 L

3MB-9-E8 6/13/01 10:55 AM Page 49

Page 51 of 96

6-13

PERIODIC MAINTENANCE AND MINOR REPAIR

64. If the coolant is at or below the

minimum level mark, open the

reservoir cap, add coolant to the

maximum level mark, and then

close the reservoir cap.

EW000067

wNever attempt to remove the radia-

tor cap when the engine is hot.5. Install the panel.NOTE:

If the engine overheats, see page

6-45 for further instructions.

EC000080

cC8If coolant is not available, use

distilled water or soft tap water

instead. Do not use hard water

or salt water since it is harmful

to the engine.

8If water has been used instead

of coolant, replace it with

coolant as soon as possible,

otherwise the engine may not

be sufficiently cooled and the

cooling system will not be pro-

tected against frost and corro-

sion.

8If water has been added to the

coolant, have a Yamaha dealer

check the antifreeze content of

the coolant as soon as possi-

ble, otherwise the effective-

ness of the coolant will be

reduced.

Coolant reservoir capacity:

0.35 L

3MB-9-E8 6/13/01 10:55 AM Page 50

Page 53 of 96

6-15

PERIODIC MAINTENANCE AND MINOR REPAIR

68. Install the reservoir tank hose.

9. Pour the recommended coolant

into the radiator until it is full.10. Install the radiator cap.

11. Run the engine several minutes.

Stop the engine and recheck the

coolant level in the radiator. If it

is low, add more coolant until it

reaches the top of the radiator.

12. Install the radiator cap stopper

bolt.

13. Fill the reservoir tank with

coolant up to maximum level.

14. Install the reservoir tank cap and

check for coolant leakage.

NOTE:

If any leakage is found, ask a

Yamaha dealer to inspect the cooling

system.15. Install the cowling and the panel.

EC000080

cC8If coolant is not available, use

distilled water or soft tap water

instead. Do not use hard water

or salt water since it is harmful

to the engine.

8If water has been used instead

of coolant, replace it with

coolant as soon as possible,

otherwise the engine may not

be sufficiently cooled and the

cooling system will not be pro-

tected against frost and corro-

sion.

8If water has been added to the

coolant, have a Yamaha dealer

check the antifreeze content of

the coolant as soon as possi-

ble, otherwise the effective-

ness of the coolant will be

reduced.

Recommended antifreeze:

High quality ethylene glycol

antifreeze containing corrosion

inhibitors for aluminum engines.

Antifreeze and water mixing ratio:

1:1

Total amount:

1.05 L

Reservoir tank capacity:

0.35 L

3MB-9-E8 6/13/01 10:55 AM Page 52

Page 55 of 96

6-17

PERIODIC MAINTENANCE AND MINOR REPAIR

67. Pull the sponge material over the

frame.

8. Install the air filter element onto

the guide, and then tighten the

wing nut.

9. Insert the air filter element into

the case.

10. Install the air filter case cover by

installing the screws.

11. Install the panel.

EC000082

cC8Make sure that the air filter ele-

ment is properly seated in the

air filter case.

8The engine should never be

operated without the air filter

element installed, otherwise

the piston and/or cylinder may

become excessively worn.

EAU00632

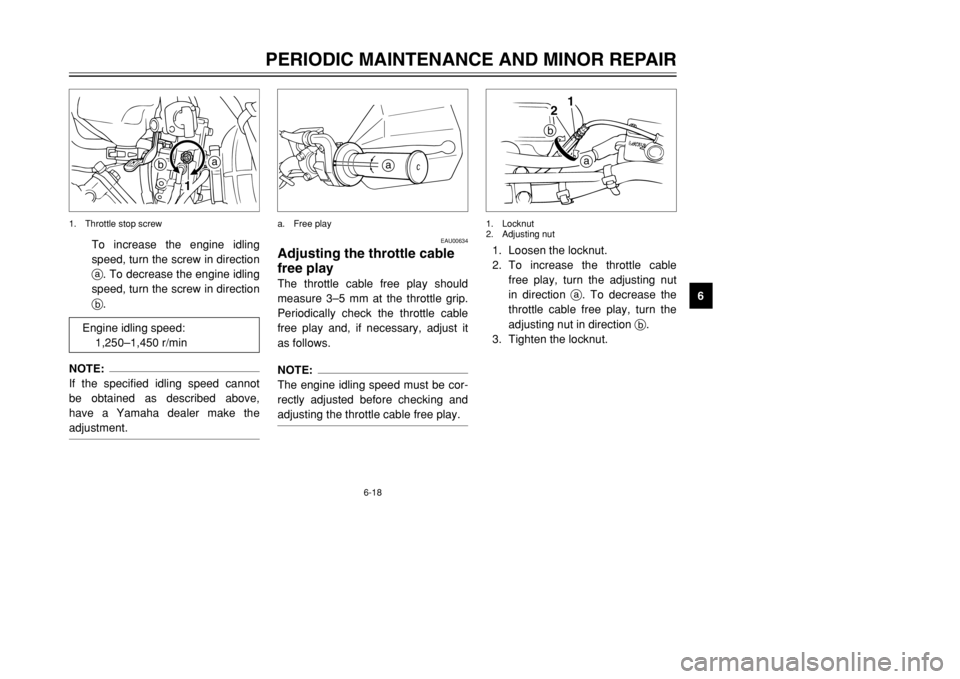

Adjusting the engine idling

speedThe engine idling speed must be

checked and, if necessary, adjusted

as follows at the intervals specified in

the periodic maintenance and lubrica-

tion chart.

1. Start the engine and warm it up

for several minutes at 1,000–

2,000 r/min while occasionally

revving it to 4,000–5,000 r/min.NOTE:

The engine is warm when it quickly

responds to the throttle.2. Check the engine idling speed

and, if necessary, adjust it to

specification by turning the throt-

tle stop screw.

EAU00629

Adjusting the carburetorThe carburetor is an important part of

the engine and requires very sophisti-

cated adjustment. Therefore, most

carburetor adjustments should be left

to a Yamaha dealer, who has the

necessary professional knowledge

and experience. The adjustment

described in the following section,

however, may be serviced by the

owner as part of routine mainte-

nance.

EC000094

cCThe carburetor has been set and

extensively tested at the Yamaha

factory. Changing these settings

without sufficient technical knowl-

edge may result in poor perfor-

mance of or damage to the engine.

Recommended oil:

2-stroke engine oil

3MB-9-E8 6/13/01 10:55 AM Page 54

Page 56 of 96

6-18

PERIODIC MAINTENANCE AND MINOR REPAIR

6

b

a

1

1. Throttle stop screw

To increase the engine idling

speed, turn the screw in direction

a. To decrease the engine idling

speed, turn the screw in direction

b.

NOTE:

If the specified idling speed cannot

be obtained as described above,

have a Yamaha dealer make the

adjustment.

EAU00634

Adjusting the throttle cable

free playThe throttle cable free play should

measure 3–5 mm at the throttle grip.

Periodically check the throttle cable

free play and, if necessary, adjust it

as follows.NOTE:

The engine idling speed must be cor-

rectly adjusted before checking and

adjusting the throttle cable free play.

a

a. Free play

Engine idling speed:

1,250–1,450 r/min

1. Loosen the locknut.

2. To increase the throttle cable

free play, turn the adjusting nut

in direction a. To decrease the

throttle cable free play, turn the

adjusting nut in direction b.

3. Tighten the locknut.

2

1

b

a

1. Locknut

2. Adjusting nut

3MB-9-E8 6/13/01 10:55 AM Page 55

Page 67 of 96

6-29

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU04034

Checking and lubricating the

throttle grip and cableThe operation of the throttle grip

should be checked before each ride.

In addition, the cable should be lubri-

cated or replaced at the intervals

specified in the periodic maintenance

chart.

EAU02962

Checking and lubricating the

cablesThe operation of all control cables

and the condition of the cables

should be checked before each ride,

and the cables and cable ends

should be lubricated if necessary. If a

cable is damaged or does not move

smoothly, have a Yamaha dealer

check or replace it.

EW000112

wDamage to the outer sheath may

interfere with proper cable opera-

tion and will cause the inner cable

to rust. Replace a damaged cable

as soon as possible to prevent

unsafe conditions.

Recommended lubricant:

Engine oil

3MB-9-E8 6/13/01 10:55 AM Page 66