maintenance YAMAHA GIGGLE50 2007 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: GIGGLE50, Model: YAMAHA GIGGLE50 2007Pages: 72, PDF Size: 1.05 MB

Page 6 of 72

1

2

3

4

5

6

7

8

9

EAU10210

TABLE OF CONTENTSSAFETY INFORMATION ................... 1-1

Fur ther safe-riding points ............... 1-4

DESCRIPTION ................................... 2-1

Left view ......................................... 2-1

Right view ....................................... 2-2

Controls and instruments ............... 2-3

INSTRUMENT AND CONTROL FUNC-

TIONS ................................................ 3-1

Main switch/steering lock ............... 3-1

Keyhole cover ................................. 3-2

Indicator and warning lights ........... 3-2

Speedometer unit ........................... 3-4

Fuel gauge ...................................... 3-4

Handlebar switches ........................ 3-5

Front brake lever ............................. 3-6

Rear brake lever ............................. 3-6

Fuel tank cap .................................. 3-6

Fuel .................................................3-7

Catalytic converter .......................... 3-8

Kickstarter....................................... 3-8

Seat ................................................3-9

Luggage hook ................................. 3-9

Helmet holder ................................. 3-9

Storage compartment ................... 3-10

PRE-OPERATION CHECKS ............. 4-1

Pre-operation check list .................. 4-2OPERATION AND IMPORTANT RIDING

POINTS .............................................. 5-1

Star ting the engine ......................... 5-1

Star ting off ...................................... 5-2

Acceleration and deceleration ........ 5-2

Braking........................................... 5-2

Engine break-in .............................. 5-3

Parking........................................... 5-3

PERIODIC MAINTENANCE AND MINOR

REPAIR .............................................. 6-1

Periodic maintenance and lubrication

chart............................................ 6-2

Removing and installing panels ..... 6-5

Checking the spark plug ................. 6-6

Engine oil and oil strainer ............... 6-7

Final transmission oil ...................... 6-9

Coolant......................................... 6-10

Replacing the air filter element ..... 6-12

Checking the throttle cable free

play............................................ 6-12

Valve clearance ............................ 6-12

Tires.............................................. 6-13

Cast wheels .................................. 6-15

Adjusting the brake lever free

play............................................ 6-15

Adjusting the rear brake lever free

play............................................ 6-16

Checking the front and rear brake

shoes......................................... 6-16Checking and lubricating the throttle

grip and cable ............................ 6-17

Lubricating the front and rear brake

levers......................................... 6-17

Checking and lubricating the

centerstand............................... 6-18

Checking the front fork ................. 6-18

Checking the steering ................... 6-19

Checking the wheel bearings ....... 6-19

Battery.......................................... 6-20

Replacing the fuse ........................ 6-21

Replacing the headlight bulb ........ 6-22

Replacing the tail/brake light bulb 6-23

Replacing a turn signal light bulb . 6-24

Troubleshooting............................ 6-24

Troubleshooting charts ................. 6-25

SCOOTER CARE AND STORAGE ... 7-1

Care ................................................ 7-1

Storage ........................................... 7-3

SPECIFICATIONS ............................. 8-1

CONSUMER INFORMATION ............ 9-1

Identification numbers .................... 9-1

15P-F8199-E0_ch0.pmd2007/06/13, 11:15 5

Page 8 of 72

1-1

1

2

3

4

5

6

7

8

9

EAU10220

Q QQ Q

Q

SAFETY INFORMATION

EAU10261

SCOOTERS ARE SINGLE TRACK VE-

HICLES. THEIR SAFE USE AND OP-

ERATION ARE DEPENDENT UPON

THE USE OF PROPER RIDING TECH-

NIQUES AS WELL AS THE EXPER-

TISE OF THE OPERATOR. EVERY

OPERATOR SHOULD KNOW THE FOL-

LOWING REQUIREMENTS BEFORE

RIDING THIS SCOOTER.

HE OR SHE SHOULD:

8OBTAIN THOROUGH INSTRUC-

TIONS FROM A COMPETENT

SOURCE ON ALL ASPECTS OF

SCOOTER OPERATION.

8OBSERVE THE WARNINGS AND

MAINTENANCE REQUIRE-

MENTS IN THE OWNER’S

MANUAL.

8OBTAIN QUALIFIED TRAINING IN

SAFE AND PROPER RIDING

TECHNIQUES.

8OBTAIN PROFESSIONAL TECH-

NICAL SERVICE AS INDICATED

BY THE OWNER’S MANUAL AND/

OR WHEN MADE NECESSARY

BY MECHANICAL CONDITIONS.Safe riding

8Always make pre-operation checks.

Careful checks may help prevent

an accident.

8This scooter is designed to carry

the operator and passenger.

8The failure of motorists to detect

and recognize scooters in traffic is

the predominating cause of auto-

mobile/scooter accidents. Many

accidents have been caused by an

automobile driver who did not see

the scooter. Making yourself con-

spicuous appears to be very effec-

tive in reducing the chance of this

type of accident.

Therefore:

9Wear a brightly colored jacket.

9Use extra caution when ap-

proaching and passing through

intersections, since intersec-

tions are the most likely places

for scooter accidents to occur.

9Ride where other motorists can

see you. Avoid riding in another

motorist’s blind spot.8Many accidents involve inexperi-

enced operators. In fact, many op-

erators who have been involved in

accidents do not even have a cur-

rent driver’s license.

9Make sure that you are quali-

fied and that you only lend your

scooter to other qualified

operators.

9Know your skills and limits.

Staying within your limits may

help you to avoid an accident.

9We recommend that you

practice riding your scooter

where there is no traffic until

you have become thoroughly

familiar with the scooter and all

of its controls.

8Many accidents have been caused

by error of the scooter operator. A

typical error made by the operator

is veering wide on a turn due to

EXCESSIVE SPEED or

undercornering (insufficient lean

angle for the speed).

9Always obey the speed limit

and never travel faster than

warranted by road and traffic

conditions. Safety information

EAU10220

Q QQ Q

Q

SAFETY INFORMATION

15P-F8199-E0_ch1.pmd2007/06/20, 14:20 1

Page 24 of 72

3-8

1

2

3

4

5

6

7

8

9

INSTRUMENT AND CONTROL FUNCTIONS

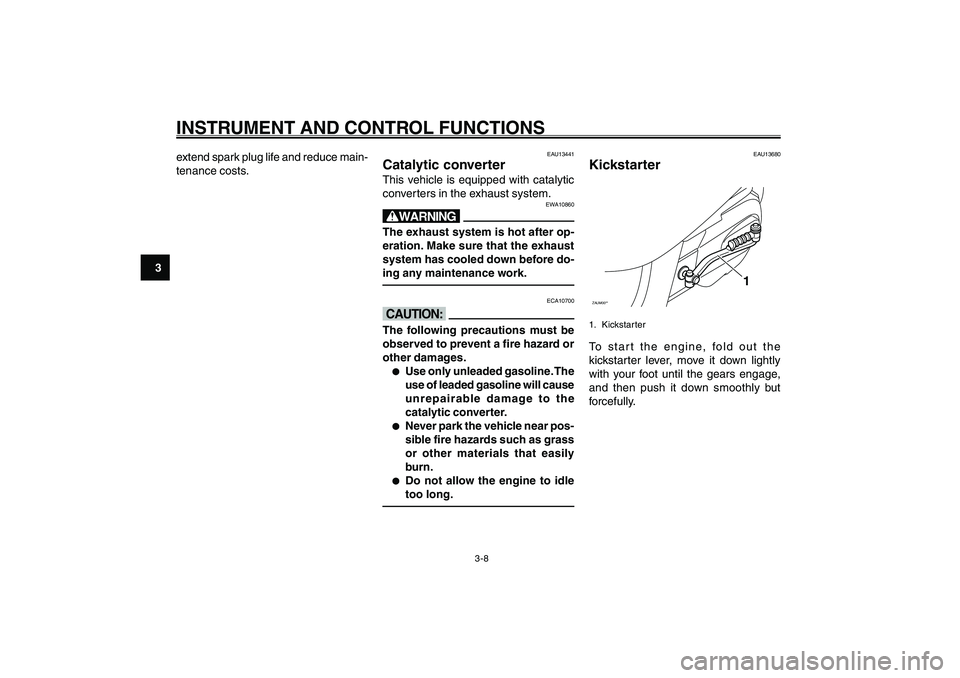

EAU13441

Catalytic converterThis vehicle is equipped with catalytic

converters in the exhaust system.

EWA10860

wThe exhaust system is hot after op-

eration. Make sure that the exhaust

system has cooled down before do-

ing any maintenance work.

ECA10700

cCThe following precautions must be

observed to prevent a fire hazard or

other damages.● ●● ●

●

Use only unleaded gasoline. The

use of leaded gasoline will cause

unrepairable damage to the

catalytic converter.

● ●● ●

●

Never park the vehicle near pos-

sible fire hazards such as grass

or other materials that easily

burn.

● ●● ●

●

Do not allow the engine to idle

too long.

Catalytic converter

Kickstarter

EAU13680

KickstarterZAUM00**

1

1. Kickstar terTo start the engine, fold out the

kickstarter lever, move it down lightly

with your foot until the gears engage,

and then push it down smoothly but

forcefully. extend spark plug life and reduce main-

tenance costs.

15P-F8199-E0_ch3.pmd2007/06/20, 14:21 8

Page 33 of 72

6-1

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIR

EAU17280

Safety is an obligation of the owner.

Periodic inspection, adjustment and lu-

brication will keep your vehicle in the

safest and most efficient condition pos-

sible. The most important points of in-

spection, adjustment, and lubrication

are explained on the following pages.

The intervals given in the periodic main-

tenance and lubrication chart should be

simply considered as a general guide

under normal riding conditions. How-

ever, DEPENDING ON THE

WEATHER, TERRAIN, GEOGRAPHI-

CAL LOCATION, AND INDIVIDUAL

USE, THE MAINTENANCE INTER-

VALS MAY NEED TO BE SHORT-

ENED.

EWA10320

wIf you are not familiar with mainte-

nance work, have a Yamaha dealer do

it for you.

EWA10330

wThis scooter is designed for use on

paved roads only. If this scooter is

operated in abnormally dusty, muddyor wet conditions, the air filter ele-

ment should be cleaned or replaced

more frequently, otherwise rapid en-

gine wear may result. Consult a

Yamaha dealer for proper mainte-

nance intervals.

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIR

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 1

Page 34 of 72

6-2

1

2

3

4

5

6

7

8

9

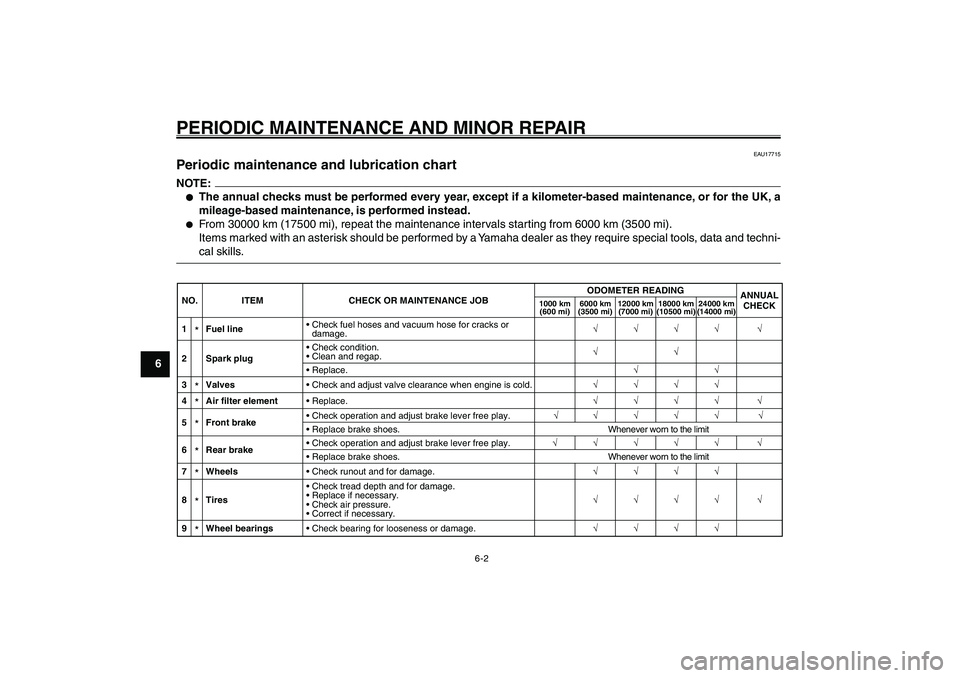

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIRPeriodic maintenance and lubrication chart

ANNUAL

CHECK

1000 km

(600 mi)6000 km

(3500 mi)12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

1

*Fuel line• Check fuel hoses and vacuum hose for cracks or

damage.�—�—�—�— �—

2 Spark plug• Check condition.

• Clean and regap.�—�—

• Replace.�—�—

3*Valves• Check and adjust valve clearance when engine is cold.�—�—�—�—

4*Air filter element• Replace.�—�—�—�— �—

5*Front brake• Check operation and adjust brake lever free play.�—�— �— �— �— �—

• Replace brake shoes. Whenever worn to the limit

6*Rear brake• Check operation and adjust brake lever free play.�—�—�—�—�— �—

• Replace brake shoes. Whenever worn to the limit

7*Wheels• Check runout and for damage.�—�—�—�—

8*Tires• Check tread depth and for damage.

• Replace if necessary.

• Check air pressure.

• Correct if necessary.�—�—�—�— �—

9*Wheel bearings• Check bearing for looseness or damage.�—�—�—�—

EAU17715

Periodic maintenance and lubrication chartNOTE:● ●● ●

●

The annual checks must be performed every year, except if a kilometer-based maintenance, or for the UK, a

mileage-based maintenance, is performed instead.

●

From 30000 km (17500 mi), repeat the maintenance intervals starting from 6000 km (3500 mi).

Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and techni-

cal skills.

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 2

Page 35 of 72

6-3

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIR

10

*Steering bearings• Check bearing assemblies for looseness.

• Moderately repack with lithium-soap-based grease

every 12000 km (7000 mi) or 24 months.�—�—Repack.�—Repack.�—

11*Chassis fasteners• Make sure that all nuts, bolts and screws are properly

tightened.�—�—�—�— �—

12Front brake lever

pivot shaft• Lubricate with lithium-soap-based grease.�—�—�—�— �—

13Rear brake lever pivot

shaft• Lubricate with lithium-soap-based grease.�—�—�—�— �—

14 Centerstand• Check operation.

• Lubricate.�—�—�—�— �—

15*Front fork• Check operation and for oil leakage.�—�—�—�—

16*Shock absorber

assembly• Check operation and shock absorber for oil leakage.�—�—�—�—

17*Fuel injection• Check engine idle speed.�—�—�—�—�— �—

18Engine oil• Change. (See page 6-7.)

• Check oil level and vehicle for oil leakage.�—Every 3000 km (1750 mi)

19

*Engine oil strainer•Clean.�—Every 6000 km (3500 mi)

20*Cooling system• Check coolant level and vehicle for coolant leakage.�—�—�—�— �—

• Change. Every 3 years

21 Final transmission oil• Check vehicle for oil leakage.�—�— �—

• Change.�—�—�—�—�—

22*V-belt• Replace. Every 10000 km (6000 mi)

23*Front and rear brake

switches• Check operation.�—�—�—�—�— �—

24Moving parts and

cables• Lubricate.�—�—�—�— �— NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi)6000 km

(3500 mi)12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 3

Page 36 of 72

6-4

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIR25

*Throttle grip housing

and cable• Check operation and free play.

• Adjust the throttle cable free play if necessary.

• Lubricate the throttle grip housing and cable.�—�—�—�— �—

26*Air induction system• Check the air cut-off valve, reed valve, and hose for

damage.

• Replace the entire air induction system if necessary.�—�—�—�— �—

27*Lights, signals and

switches• Check operation.

• Adjust headlight beam.�—�—�—�—�— �— NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi)6000 km

(3500 mi)12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 4

Page 37 of 72

6-5

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIR

EAU18771

Removing and installing pan-

elsThe panels shown need to be removed

to perform some of the maintenance

jobs described in this chapter. Refer to

this section each time a panel needs to

be removed and installed.ZAUM00**

3

1

2

1. Panel A

2. Panel B

3. Panel CPanels, removing and installing

EAUT2100

Panel ATo remo

ve the panel

Slide the panel backward, and then pull

it out as shown.

ZAUM00**

1

1. Panel ATo install the panel

Place and slide the panel into the origi-

nal position.Panel B

To remo

ve the panel

Remove the screw, and then take the

panel off.

ZAUM00**

1

1. Panel BTo install the panel

Place the panel in the original position,

and then install the screw.

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 5

Page 38 of 72

6-6

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIRPanel CTo remo

ve the panel

ZAUM00**

1

1. Panel C1. Open the seat. (See page 3-9.)

2. Remove the screws, and then take

the panel off.To install the panel

Place the panel in the original position,

and then install the screws.

EAUT2070

Checking the spark plugThe spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic main-

tenance and lubrication chart. In addi-

tion, the condition of the spark plug can

reveal the condition of the engine.

To remove the spark plug

1. Remove panel A. (See page 6-5.)

2. Remove the spark plug cap.ZAUM00**

1

1. Spark plug wrench

Spark plug, checking

3. Remove the spark plug as shown,

with a spark plug wrench available

at a Yamaha dealer.

To check the spark plug

1. Check that the porcelain insulator

around the center electrode of the

spark plug is a medium-to-light tan

(the ideal color when the vehicle is

ridden normally).

NOTE:

If the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to di-

agnose such problems yourself. In-

stead, have a Yamaha dealer check the

vehicle.2. Check the spark plug for electrode

erosion and excessive carbon or

other deposits, and replace it if

necessary.Specified spark plug:

CR7E (NGK)

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 6

Page 39 of 72

6-7

1

2

3

4

5

6

7

8

9

EAU17226

PERIODIC MAINTENANCE AND MINOR REPAIR

To install the spark plug

1. Measure the spark plug gap with a

wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation.Spark plug gap:

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)2. Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the

spark plug threads.

3. Install the spark plug with the spark

plug wrench, and then tighten it to

the specified torque.Tightening torque:

Spark plug:

NOTE:

If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4~1/2 turn past

finger tight. However, the spark plug

should be tightened to the specified

torque as soon as possible.

4. Install the spark plug cap.

5. Install the panel.

EAUT1460

Engine oil and oil strainerThe engine oil level should be checked

before each ride. In addition, the oil must

be changed and the oil strainer cleaned

at the intervals specified in the periodic

maintenance and lubrication chart.

To check the engine oil level

1. Place the vehicle on the

centerstand.NOTE:

Make sure that the vehicle is positioned

straight up when checking the oil level.

A slight tilt to the side can result in a

false reading.2. Start the engine, warm it up for sev-

eral minutes, and then turn it off. Engine oil

15P-F8199-E0_ch6.pmd2007/06/21, 11:09 7