light YAMAHA JOG50R 2008 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: JOG50R, Model: YAMAHA JOG50R 2008Pages: 72, PDF Size: 2.06 MB

Page 39 of 72

PERIODIC MAINTENANCE AND MINOR REPAIR

6-4

6

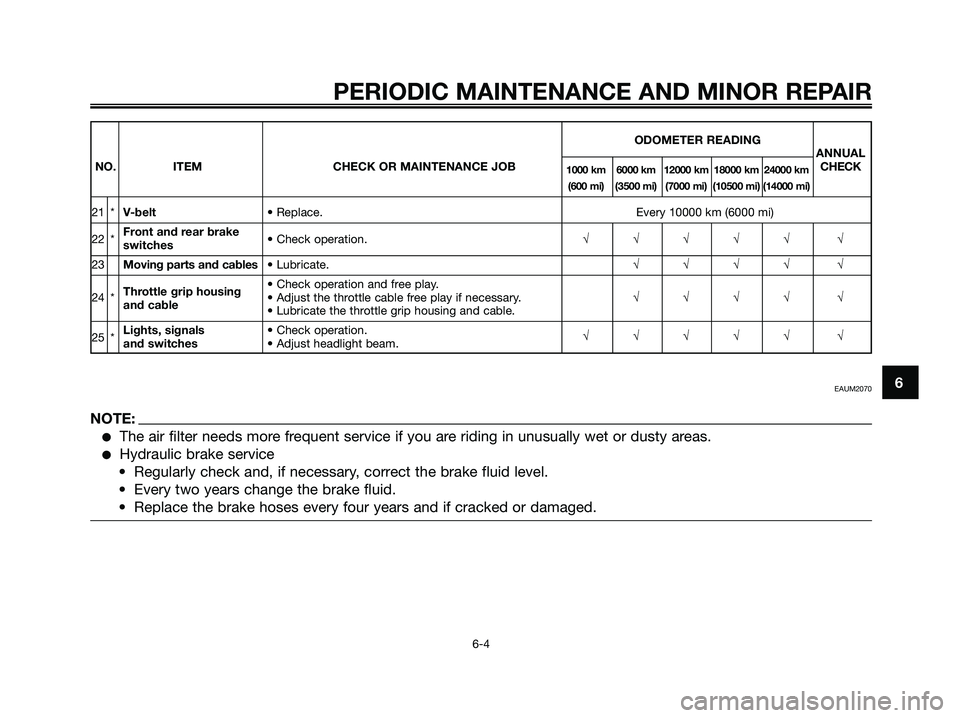

ODOMETER READING

ANNUAL

NO. ITEM CHECK OR MAINTENANCE JOB

1000 km 6000 km 12000 km 18000 km 24000 kmCHECK

(600 mi) (3500 mi) (7000 mi) (10500 mi) (14000 mi)

21 *V-belt• Replace. Every 10000 km (6000 mi)

22 *Front and rear brake

• Check operation.√√√√√ √

switches

23Moving parts and cables• Lubricate.√√√√ √

Throttle grip housing • Check operation and free play.

24 * • Adjust the throttle cable free play if necessary.√√√√ √

and cable

• Lubricate the throttle grip housing and cable.

25 *Lights, signals • Check operation.

and switches• Adjust headlight beam.√√√√√ √

EAUM2070

NOTE:

●The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

●Hydraulic brake service

• Regularly check and, if necessary, correct the brake fluid level.

• Every two years change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

5RW-F8199-E4.QXD 19/11/07 08:01 Página 39

Page 40 of 72

EAU18740

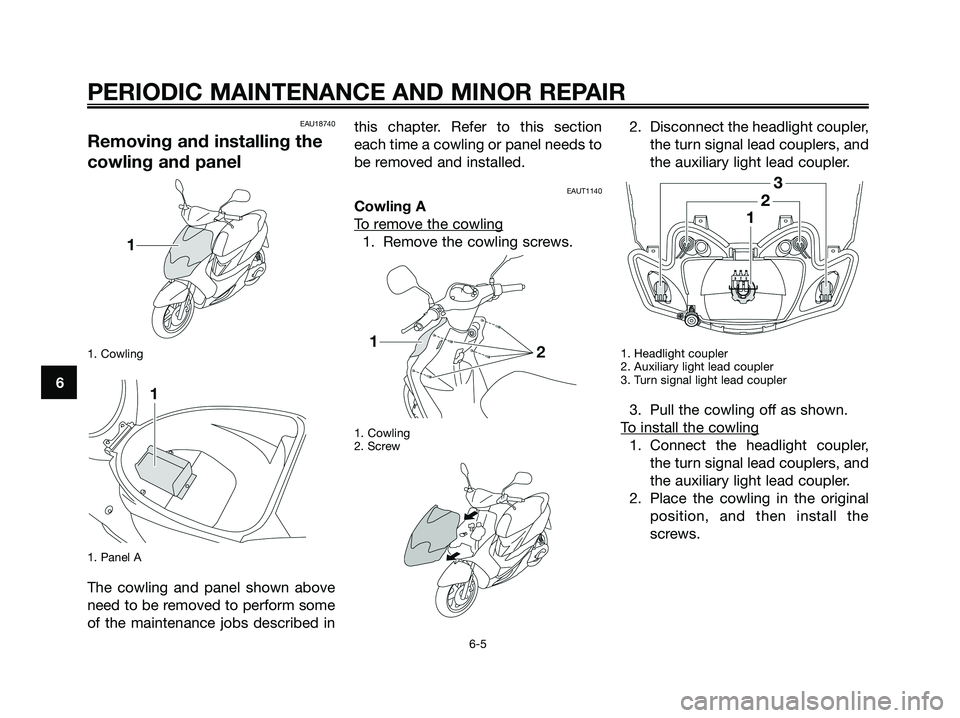

Removing and installing the

cowling and panel

1. Cowling

1. Panel A

The cowling and panel shown above

need to be removed to perform some

of the maintenance jobs described inthis chapter. Refer to this section

each time a cowling or panel needs to

be removed and installed.

EAUT1140

Cowling A

T

o remove the cowling

1. Remove the cowling screws.

1. Cowling

2. Screw

2. Disconnect the headlight coupler,

the turn signal lead couplers, and

the auxiliary light lead coupler.

1. Headlight coupler

2. Auxiliary light lead coupler

3. Turn signal light lead coupler

3. Pull the cowling off as shown.

T

o install the cowling

1. Connect the headlight coupler,

the turn signal lead couplers, and

the auxiliary light lead coupler.

2. Place the cowling in the original

position, and then install the

screws.

PERIODIC MAINTENANCE AND MINOR REPAIR

6-5

6

5RW-F8199-E4.QXD 19/11/07 08:01 Página 40

Page 41 of 72

EAUM1250

Panel A

T

o remove the panel

1. Open the storage compartment.

(See page 3-11.)

2. Remove the screw, and then take

the panel off.

1. Screw

2. Panel

To install the panel

1. Place the panel in the original

position, and then install the

screw.

2. Close the storage compartment.

EAU19621

Checking the spark plug

1. Spark plug gap

The spark plug is an important engine

component, which should be chec-

ked periodically, preferably by a

Yamaha dealer. Since heat and depo-

sits will cause any spark plug to

slowly erode, it should be removed

and checked in accordance with the

periodic maintenance and lubrication

chart. In addition, the condition of the

spark plug can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of the spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is riddennormally). If the spark plug shows a

distinctly different color, the engine

could be operating improperly. Do not

attempt to diagnose such problems

yourself. Instead, have a Yamaha

dealer check the vehicle.

If the spark plug shows signs of elec-

trode erosion and excessive carbon

or other deposits, it should be repla-

ced.

Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the

spark plug threads.

Spark plug gap:

0.6-0.7 mm (0.024-0.028 in)

Specified spark plug:

BR8HS/NGK (for CS50 CS50Z)

BPR4HS/NGK (for CS50M)

1

ZAUM0037

PERIODIC MAINTENANCE AND MINOR REPAIR

6-6

6

5RW-F8199-E4.QXD 19/11/07 08:01 Página 41

Page 43 of 72

EWA11310

s s

WARNING

●Make sure that no foreign

material enters the final trans-

mission case.

●Make sure that no oil gets on

the tire or wheel.

7. Check the final transmission case

for oil leakage. If oil is leaking,

check for the cause.

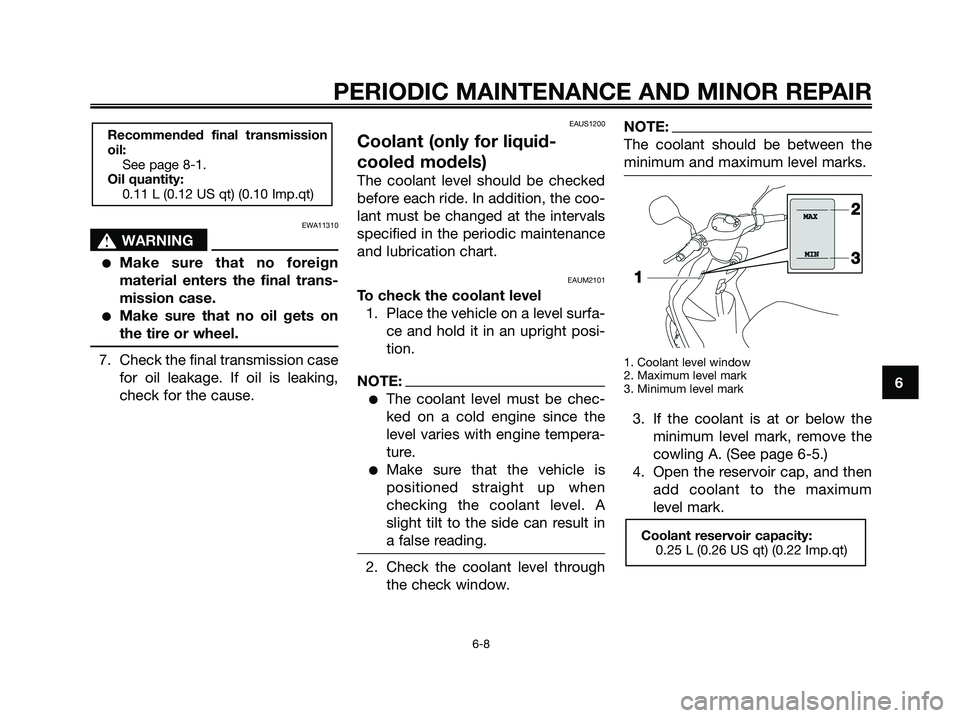

EAUS1200

Coolant (only for liquid-

cooled models)

The coolant level should be checked

before each ride. In addition, the coo-

lant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAUM2101

To check the coolant level

1. Place the vehicle on a level surfa-

ce and hold it in an upright posi-

tion.

NOTE:

●The coolant level must be chec-

ked on a cold engine since the

level varies with engine tempera-

ture.

●Make sure that the vehicle is

positioned straight up when

checking the coolant level. A

slight tilt to the side can result in

a false reading.

2. Check the coolant level through

the check window.

NOTE:

The coolant should be between the

minimum and maximum level marks.

1. Coolant level window

2. Maximum level mark

3. Minimum level mark

3. If the coolant is at or below the

minimum level mark, remove the

cowling A. (See page 6-5.)

4. Open the reservoir cap, and then

add coolant to the maximum

level mark.

Coolant reservoir capacity:

0.25 L (0.26 US qt) (0.22 Imp.qt)

Recommended final transmission

oil:

See page 8-1.

Oil quantity:

0.11 L (0.12 US qt) (0.10 Imp.qt)

PERIODIC MAINTENANCE AND MINOR REPAIR

6-8

6

5RW-F8199-E4.QXD 19/11/07 08:01 Página 43

Page 56 of 72

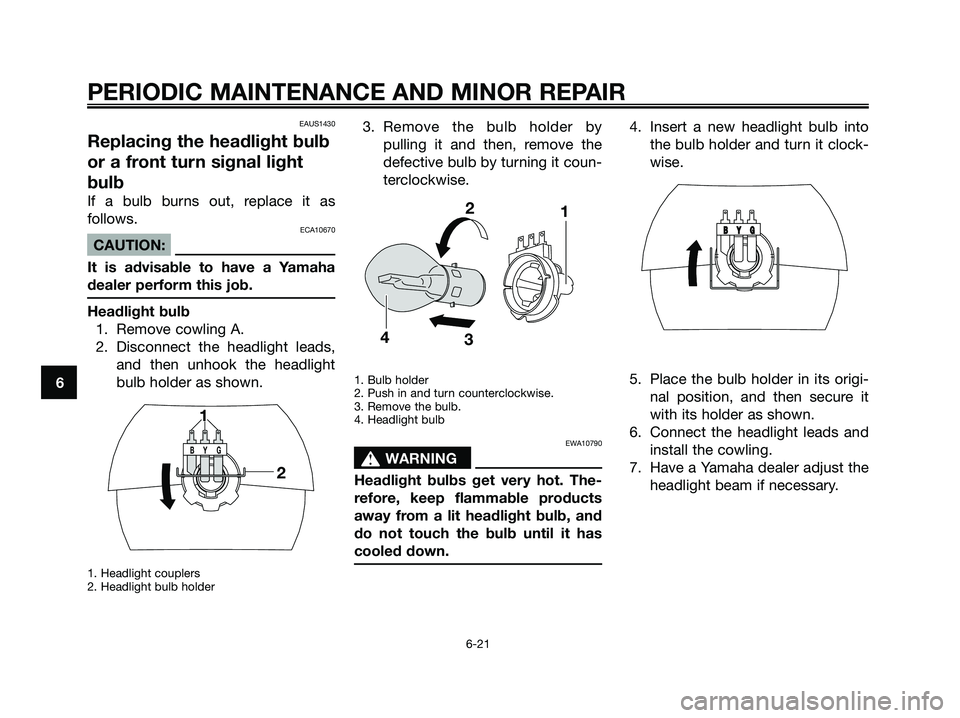

EAUS1430

Replacing the headlight bulb

or a front turn signal light

bulb

If a bulb burns out, replace it as

follows.

ECA10670

CAUTION:

It is advisable to have a Yamaha

dealer perform this job.

Headlight bulb

1. Remove cowling A.

2. Disconnect the headlight leads,

and then unhook the headlight

bulb holder as shown.

1. Headlight couplers

2. Headlight bulb holder

3. Remove the bulb holder by

pulling it and then, remove the

defective bulb by turning it coun-

terclockwise.

1. Bulb holder

2. Push in and turn counterclockwise.

3. Remove the bulb.

4. Headlight bulb

EWA10790

s s

WARNING

Headlight bulbs get very hot. The-

refore, keep flammable products

away from a lit headlight bulb, and

do not touch the bulb until it has

cooled down.

4. Insert a new headlight bulb into

the bulb holder and turn it clock-

wise.

5. Place the bulb holder in its origi-

nal position, and then secure it

with its holder as shown.

6. Connect the headlight leads and

install the cowling.

7. Have a Yamaha dealer adjust the

headlight beam if necessary.

GGYYBB

1 2

3

4

GYB

1

2

PERIODIC MAINTENANCE AND MINOR REPAIR

6-21

6

5RW-F8199-E4.QXD 19/11/07 08:01 Página 56

Page 57 of 72

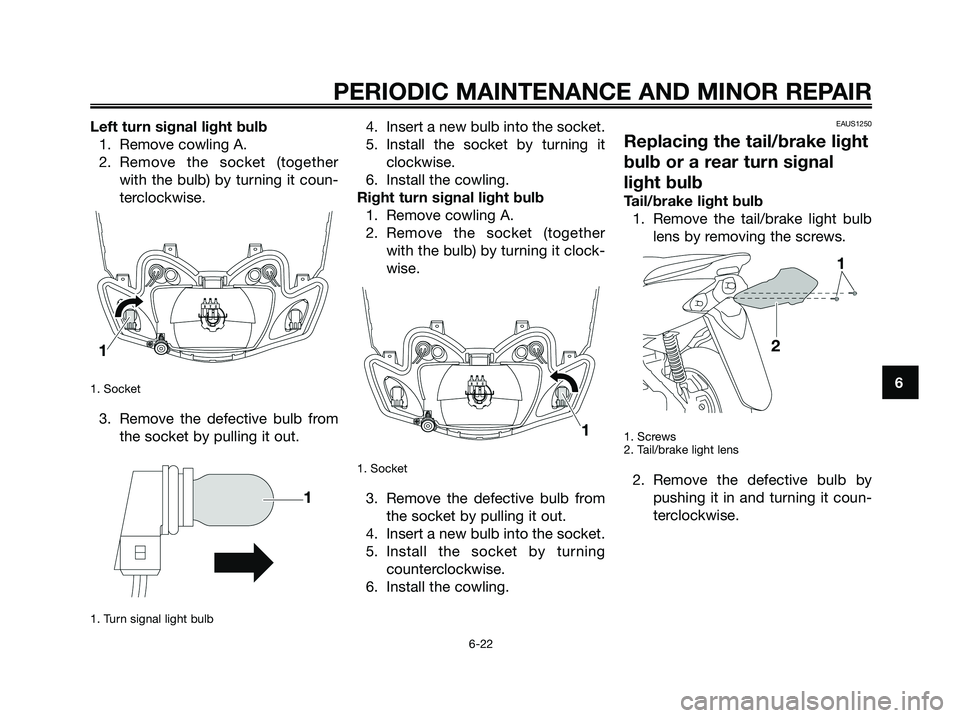

Left turn signal light bulb

1. Remove cowling A.

2. Remove the socket (together

with the bulb) by turning it coun-

terclockwise.

1. Socket

3. Remove the defective bulb from

the socket by pulling it out.

1. Turn signal light bulb

4. Insert a new bulb into the socket.

5. Install the socket by turning it

clockwise.

6. Install the cowling.

Right turn signal light bulb

1. Remove cowling A.

2. Remove the socket (together

with the bulb) by turning it clock-

wise.

1. Socket

3. Remove the defective bulb from

the socket by pulling it out.

4. Insert a new bulb into the socket.

5. Install the socket by turning

counterclockwise.

6. Install the cowling.

EAUS1250

Replacing the tail/brake light

bulb or a rear turn signal

light bulb

Tail/brake light bulb

1. Remove the tail/brake light bulb

lens by removing the screws.

1. Screws

2. Tail/brake light lens

2. Remove the defective bulb by

pushing it in and turning it coun-

terclockwise.

PERIODIC MAINTENANCE AND MINOR REPAIR

6-22

6

5RW-F8199-E4.QXD 19/11/07 08:01 Página 57

Page 58 of 72

1. Tail/brake light bulb

3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the

screws.

Rear turn signal light bulb

1. Remove the tail/brake light lens

by removing the screw.

2. Remove the turn signal light bulb

lens by removing the screw.

1. Screw

2. Rear turn signal light bulb lens

3. Rear turn signal light bulb

3. Remove the defective bulb by

pushing it in and turning it coun-

terclockwise.

4. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

5. Install the turn signal light bulb

lens by installing the screw.

6. Install the tail/brake light bulb

lens by installing the screw.

ECA10680

CAUTION:

Do not overtighten the screws,

otherwise the lens may break.

EAUS1410

Replacing an auxiliary light

bulb

This model is equipped with two auxi-

liary lights. If an auxiliary light bulb

burns out, replace it as follows.

1. Remove cowling A. (See page

6-5.)

2. Remove the auxiliary light socket

(together with the bulb) by pulling

it out.

1. Auxiliary light bulb socket

3. Remove the defective bulb by

pulling it out.

PERIODIC MAINTENANCE AND MINOR REPAIR

6-23

6

5RW-F8199-E4.QXD 19/11/07 08:01 Página 58

Page 59 of 72

1. Auxiliary light bulb

4. Insert a new bulb into the socket.

5. Install the auxiliary light socket

(together with the bulb) by pus-

hing it in.

6. Install the cowling.

EAU25880

Troubleshooting

Although Yamaha scooters receive a

thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition sys-

tems, for example, can cause poor

starting and loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your scooter

require any repair, take it to a Yamaha

dealer, whose skilled technicians

have the necessary tools, experience,

and know-how to service the scooter

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

PERIODIC MAINTENANCE AND MINOR REPAIR

6-24

6

5RW-F8199-E4.QXD 19/11/07 08:01 Página 59

Page 62 of 72

EAU37833

Matte color cautionECA15192

CAUTION:

Some models are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

advice on what products to use

before cleaning the vehicle.Using a

brush, harsh chemical products or

cleaning compounds when clea-

ning these parts will scratch or

damage their surface. Wax also

should not be applied to any matte

colored finished parts.

EAU26091

Care

While the open design of a scooter

reveals the attractiveness of the tech-

nology, it also makes it more vulnera-

ble. Rust and corrosion can develop

even if high-quality components are

used. A rusty exhaust pipe may go

unnoticed on a car, however, it

detracts from the overall appearance

of a scooter. Frequent and proper

care does not only comply with the

terms of the warranty, but it will also

keep your scooter looking good,

extend its life and optimize its perfor-

mance.

Before cleaning

1. Cover the muffler outlet with a

plastic bag after the engine has

cooled down.

2. Make sure that all caps and

covers as well as all electrical

couplers and connectors, inclu-

ding the spark plug cap, are

tightly installed.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such pro-ducts onto seals, gaskets and

wheel axles. Always rinse the dirt

and degreaser off with water.

Cleaning

ECA10781

CAUTION:

●Avoid using strong acidic whe-

el cleaners, especially on spo-

ked wheels. If such products

are used on hard-to-remove

dirt, do not leave the cleaner on

the affected area any longer

than instructed. Also, tho-

roughly rinse the area off with

water, immediately dry it, and

then apply a corrosion protec-

tion spray.

●Improper cleaning can damage

plastic parts such as cowlings,

panels, windshields, headlight

lenses, meter lenses, etc. Use

only a soft, clean cloth or spon-

ge with mild detergent and

water to clean plastic.

●Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

SCOOTER CARE AND STORAGE

7-1

7

5RW-F8199-E4.QXD 19/11/07 08:01 Página 62

Page 63 of 72

cleaning products, solvent or

thinner, fuel (gasoline), rust

removers or inhibitors, brake

fluid, antifreeze or electrolyte.

●Do not use high-pressure was-

hers or steam-jet cleaners sin-

ce they cause water seepage

and deterioration in the follo-

wing areas: seals (of wheel and

swingarm bearings, fork and

brakes), electric components

(couplers, connectors, instru-

ments, switches and lights),

breather hoses and vents.

●For scooters equipped with a

windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or scrat-

ching. Some cleaning com-

pounds for plastic may leave

scratches on the windshield.

Test the product on a small hid-

den part of the windshield to

make sure that it does not lea-

ve any marks. If the windshield

is scratched, use a quality

plastic polishing compound

after washing.

After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottle-

brush for hard-to-reach areas. Stub-

born dirt and insects will come off

more easily if the area is covered with

a wet cloth for a few minutes before

cleaning.

After riding in the rain, near the sea or

on salt-sprayed roads

Since sea salt or salt sprayed on the

roads during winter are extremely

corrosive in combination with water,

carry out the following steps after

each ride in the rain, near the sea or

on salt-sprayed roads.

NOTE:

Salt sprayed on roads in the winter

may remain well into spring.

1. Clean the scooter with cold water

and a mild detergent after the

engine has cooled down.

ECA10790

CAUTION:

Do not use warm water since it

increases the corrosive action of

the salt.

2. Apply a corrosion protection

spray on all metal, including

chrome- and nickel-plated, surfa-

ces to prevent corrosion.

After cleaning

1. Dry the scooter with a chamois or

an absorbing cloth.

2. Use a chrome polish to shine

chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally indu-

ced discoloring of stainless-steel

exhaust systems can be removed

through polishing.)

3. To prevent corrosion, it is recom-

mended to apply a corrosion pro-

tection spray on all metal, inclu-

ding chrome- and nickel-plated,

surfaces.

4. Use spray oil as a universal clea-

ner to remove any remaining dirt.

5. Touch up minor paint damage

caused by stones, etc.

SCOOTER CARE AND STORAGE

7-2

7

5RW-F8199-E4.QXD 19/11/07 08:01 Página 63