YAMAHA NMAX 2015 Service Manual

Manufacturer: YAMAHA, Model Year: 2015, Model line: NMAX, Model: YAMAHA NMAX 2015Pages: 90, PDF Size: 3.56 MB

Page 41 of 90

Periodic maintenance an d a djustment

6-1

6

EAU17246

Periodic inspection, adjustment, and

lubrication will keep your vehicle in the

safest and most efficient condition

possible. Safety is an obligation of the

vehicle owner/operator. The most im-

portant points of vehicle inspection,

adjustment, and lubrication are ex-

plained on the following pages.

The intervals given in the periodic

maintenance charts should be simply

considered as a general guide under

normal riding conditions. However, de-

pending on the weather, terrain, geo-

graphical location, and individual use,

the maintenance intervals may need to

be shortened.

WARNING

EWA10322

Failure to properly maintain the vehi-

cle or performin g maintenance ac-

tivities incorrectly may increase

your risk of injury or death during

service or while usin g the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha d ealer perform

service.

WARNING

EWA15123

Turn off the en gine when performin g

maintenance unless otherwise

specified .

A runnin g en gine has movin g

parts that can catch on b ody

parts or clothin g an d electrical

parts that can cause shocks or

fires.

Runnin g the eng ine while ser-

vicin g can lead to eye injury,

b urns, fire, or car bon monoxi de

poisonin g – possi bly lea din g to

d eath. See pag e 1-3 for more in-

formation a bout car bon monox-

i d e.

WARNING

EWA15461

Brake discs, calipers, drums, an d

linin gs can b ecome very hot during

use. To avoi d possi ble burns, let

b rake components cool before

touching them.

EAU39692

Owner’s tool kitThe owner’s tool kit is located on the

bottom of the seat. (See page 3-15.)

The service information included in this

manual and the tools provided in the

owner’s tool kit are intended to assist

you in the performance of preventive

maintenance and minor repairs. How-

ever, additional tools such as a torque

wrench may be necessary to perform

certain maintenance work correctly.TIPIf you do not have the tools or experi-

ence required for a particular job, have

a Yamaha dealer perform it for you.1. Owner’s tool kit

1

U2DSE0E0.book Page 1 Thursday, March 19, 2015 10:34 AM

Page 42 of 90

Periodic maintenance an d a djustment

6-2

6

EAU46872

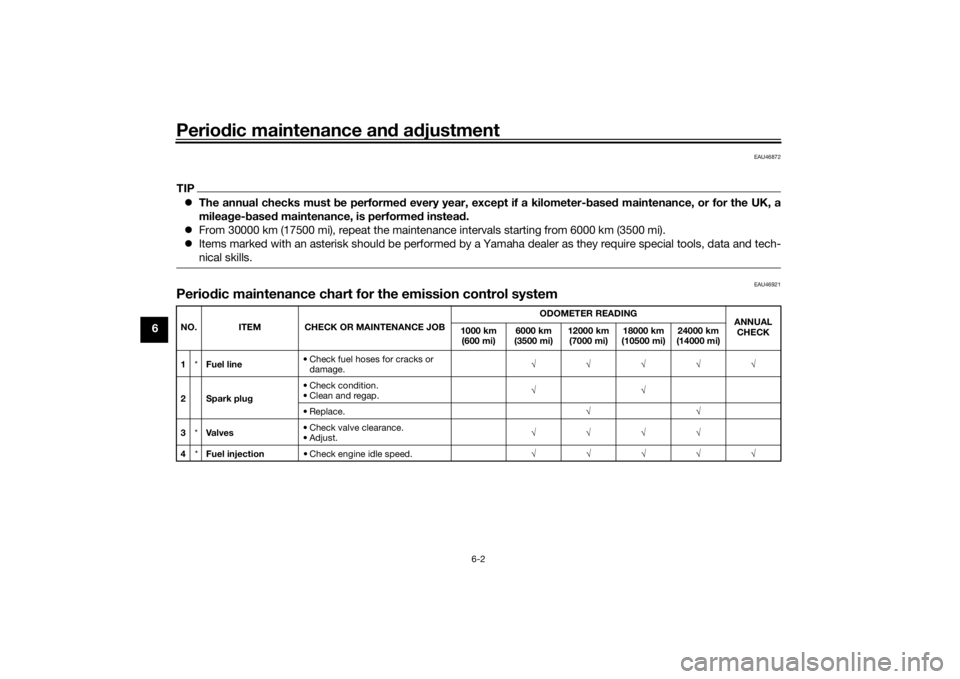

TIP The annual checks must b e performed every year, except if a kilometer- based maintenance, or for the UK, a

milea ge- base d maintenance, is performe d instead .

From 30000 km (17500 mi), repeat the maintenance intervals starting from 6000 km (3500 mi).

Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and tech-

nical skills.

EAU46921

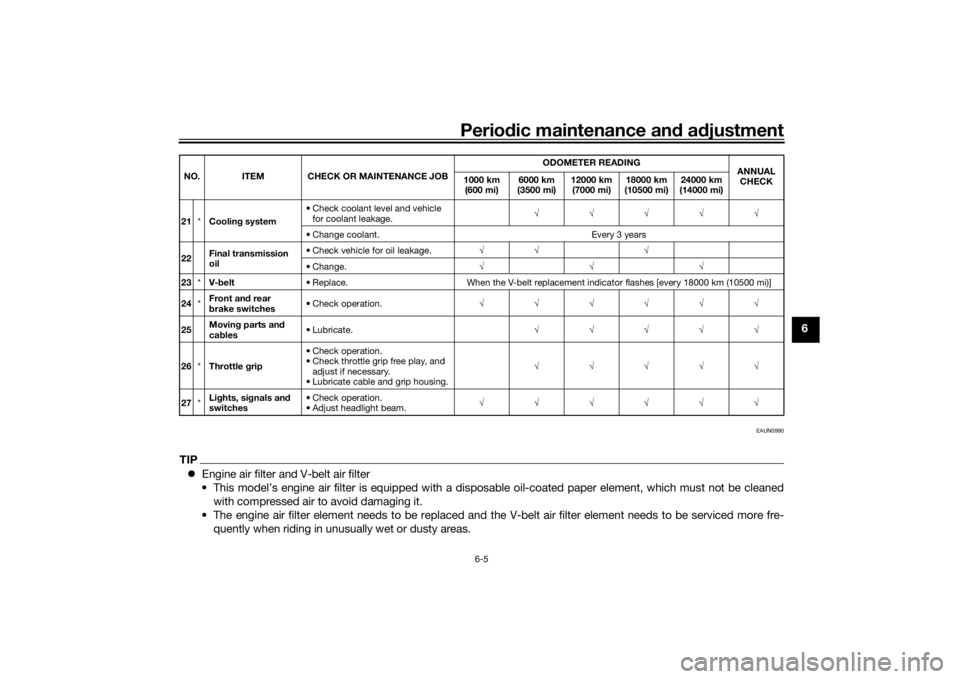

Perio dic maintenance chart for the emission control systemNO. ITEM CHECK OR MAINTENANCE JOB ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 6000 km

(3500 mi) 12000 km

(7000 mi) 18000 km

(10500 mi) 24000 km

(14000 mi)

1 *Fuel line • Check fuel hoses for cracks or

damage. √√√√√

2Spark plu g• Check condition.

• Clean and regap.

√√

• Replace. √√

3 *Va l ve s • Check valve clearance.

•Adjust.

√√√√

4 *Fuel injection • Check engine idle speed. √√√√√

U2DSE0E0.book Page 2 Thursday, March 19, 2015 10:34 AM

Page 43 of 90

Periodic maintenance an d a djustment

6-3

6

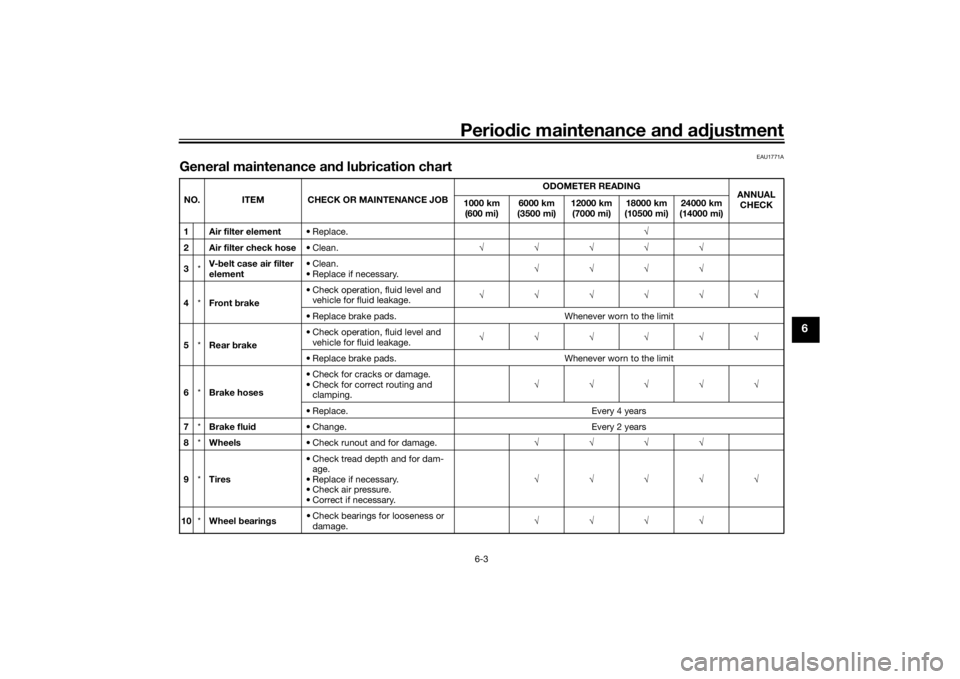

EAU1771A

General maintenance an d lu brication chartNO. ITEM CHECK OR MAINTENANCE JOB ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 6000 km

(3500 mi) 12000 km

(7000 mi) 18000 km

(10500 mi) 24000 km

(14000 mi)

1 Air filter element •Replace. √

2 Air filter check hose • Clean. √√√√√

3 *V-

belt case air filter

element • Clean.

• Replace if necessary.

√√√√

4 *Front brake • Check operation, fluid level and

vehicle for fluid leakage. √√√√√√

• Replace brake pads. Whenever worn to the limit

5 *Rear brake • Check operation, fluid level and

vehicle for fluid leakage. √√√√√√

• Replace brake pads. Whenever worn to the limit

6 *Brake hoses • Check for cracks or damage.

• Check for correct routing and

clamping. √√√√√

• Replace. Every 4 years

7 *Brake flui d • Change. Every 2 years

8 *Wheels • Check runout and for damage. √√√√

9 *Tires • Check tread depth and for dam-

age.

• Replace if necessary.

• Check air pressure.

• Correct if necessary. √√√√√

10 *Wheel bearin gs • Check bearings for looseness or

damage. √√√√

U2DSE0E0.book Page 3 Thursday, March 19, 2015 10:34 AM

Page 44 of 90

Periodic maintenance an d a djustment

6-4

6

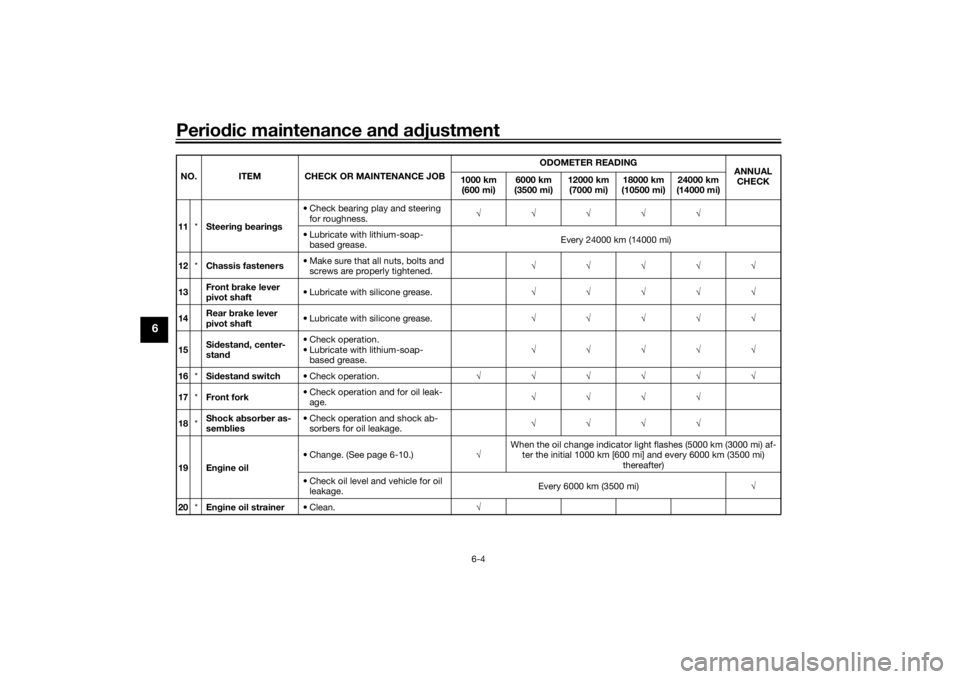

11 *Steerin g b earin gs • Check bearing play and steering

for roughness. √√√√√

• Lubricate with lithium-soap- based grease. Every 24000 km (14000 mi)

12 *Chassis fasteners • Make sure that all nuts, bolts and

screws are properly tightened. √√√√√

13 Front

brake lever

pivot shaft • Lubricate with silicone grease.

√√√√√

14 Rear

brake lever

pivot shaft • Lubricate with silicone grease.

√√√√√

15 Si

destan d, center-

stan d • Check operation.

• Lubricate with lithium-soap-

based grease. √√√√√

16 *Sidestan d switch • Check operation. √√√√√√

17 *Front fork • Check operation and for oil leak-

age. √√√√

18 *Shock a

bsor ber as-

sem blies • Check operation and shock ab-

sorbers for oil leakage. √√√√

19 En gine oil • Change. (See page 6-10.)

√When the oil change indicator lig

ht flashes (5000 km (3000 mi) af-

ter the initial 1000 km [600 mi] and every 6000 km (3500 mi) thereafter)

• Check oil level and vehicle for oil leakage. Every 6000 km (3500 mi)

√

20 *Engine oil strainer • Clean. √

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 6000 km

(3500 m

i)12000 km

(7000 mi) 18000 km

(10500 mi) 24000 km

(14000 mi)

U2DSE0E0.book Page 4 Thursday, March 19, 2015 10:34 AM

Page 45 of 90

Periodic maintenance an d a djustment

6-5

6

EAUN0990

TIP Engine air filter and V-belt air filter

• This model’s engine air filter is equipped with a disposable oil-coated paper element, which must not be cleaned with compressed air to avoid damaging it.

• The engine air filter element needs to be replaced and the V-belt air filter element needs to be serviced more fre-

quently when riding in unusually wet or dusty areas.21 *Coolin g system • Check coolant level and vehicle

for coolant leakage. √√√√√

• Change coolant. Every 3 years

22 Final transmission

oil • Check vehicle for oil leakage.

√√ √

• Change. √√√

23 *V-belt • Replace. When the V-belt replacement indicator flashes [every 18000 km (10500 mi)]

24 *Front an

d rear

b rake switches • Check operation.

√√√√√√

25 Movin

g parts an d

ca bles • Lubricate.

√√√√√

26 *Throttle g rip • Check operation.

• Check throttle grip free play, and

adjust if necessary.

• Lubricate cable and grip housing. √√√√√

27 *Li

ghts, si gnals an d

switches • Check operation.

• Adjust headlight beam.

√√√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 6000 km

(3500 mi) 12000 km

(7000 mi) 18000 km

(10500 mi) 24000 km

(14000 mi)

U2DSE0E0.book Page 5 Thursday, March 19, 2015 10:34 AM

Page 46 of 90

Periodic maintenance an d a djustment

6-6

6

Hydraulic brake service

• After disassembling the brake master cylinders and calipers, always change the fluid. Regularly check the brake fluid levels and fill the reservoirs as required.

• Every two years replace the internal components of the brake master cylinders and calipers, and change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

U2DSE0E0.book Page 6 Thursday, March 19, 2015 10:34 AM

Page 47 of 90

Periodic maintenance an d a djustment

6-7

6

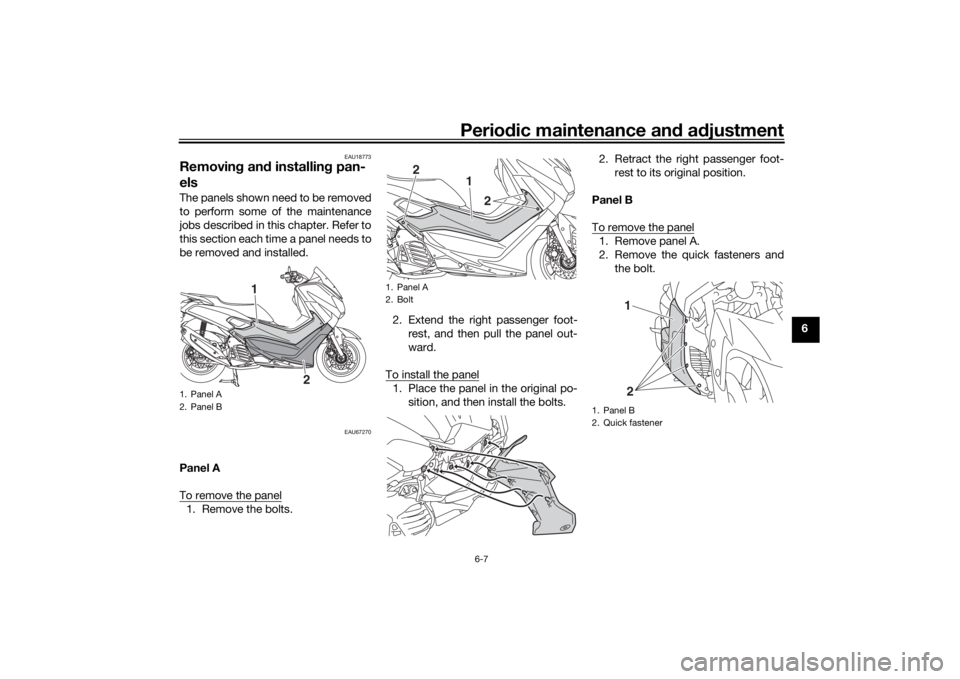

EAU18773

Removin g an d installin g pan-

elsThe panels shown need to be removed

to perform some of the maintenance

jobs described in this chapter. Refer to

this section each time a panel needs to

be removed and installed.

EAU67270

Panel A

To remove the panel1. Remove the bolts. 2. Extend the right passenger foot-

rest, and then pull the panel out-

ward.

To install the panel

1. Place the panel in the original po- sition, and then install the bolts. 2. Retract the right passenger foot-

rest to its original position.

Panel B

To remove the panel

1. Remove panel A.

2. Remove the quick fasteners and the bolt.

1. Panel A

2. Panel B

1

2

1. Panel A

2. Bolt

1

2

2

1. Panel B

2. Quick fastener

21

U2DSE0E0.book Page 7 Thursday, March 19, 2015 10:34 AM

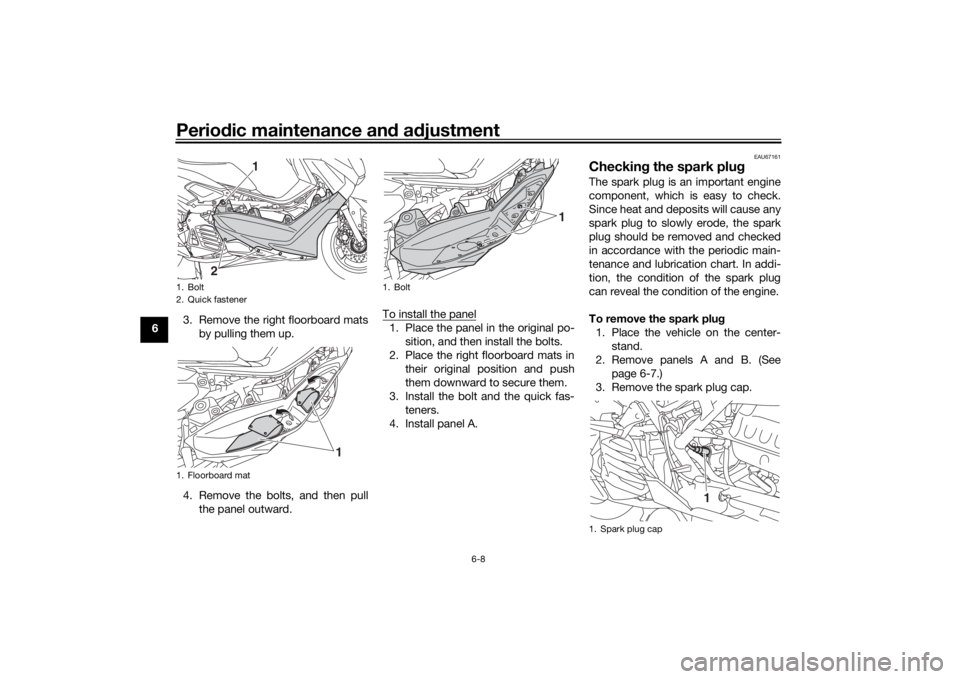

Page 48 of 90

Periodic maintenance an d a djustment

6-8

6 3. Remove the right floorboard mats

by pulling them up.

4. Remove the bolts, and then pull the panel outward. To install the panel

1. Place the panel in the original po-

sition, and then install the bolts.

2. Place the right floorboard mats in their original position and push

them downward to secure them.

3. Install the bolt and the quick fas- teners.

4. Install panel A.

EAU67161

Checkin g the spark plu gThe spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic main-

tenance and lubrication chart. In addi-

tion, the condition of the spark plug

can reveal the condition of the engine.

To remove the spark plu g

1. Place the vehicle on the center- stand.

2. Remove panels A and B. (See page 6-7.)

3. Remove the spark plug cap.

1. Bolt

2. Quick fastener

1. Floorboard mat

1

2

1

1. Bolt

1

1. Spark plug cap

1

U2DSE0E0.book Page 8 Thursday, March 19, 2015 10:34 AM

Page 49 of 90

Periodic maintenance an d a djustment

6-9

6

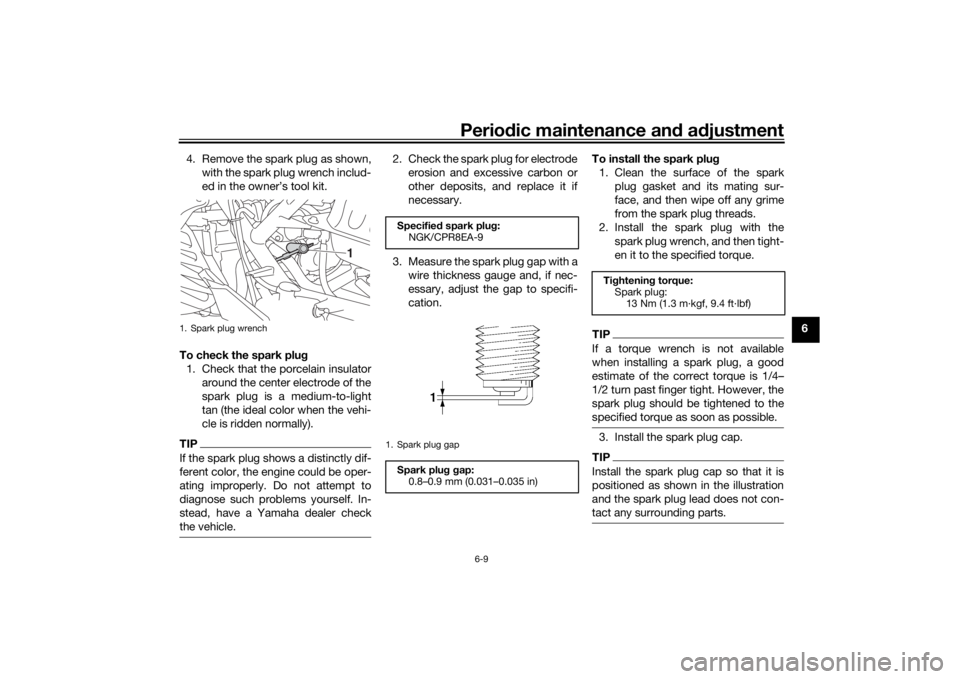

4. Remove the spark plug as shown,

with the spark plug wrench includ-

ed in the owner’s tool kit.

To check the spark plu g

1. Check that the porcelain insulator around the center electrode of the

spark plug is a medium-to-light

tan (the ideal color when the vehi-

cle is ridden normally).

TIPIf the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to

diagnose such problems yourself. In-

stead, have a Yamaha dealer check

the vehicle.

2. Check the spark plug for electrodeerosion and excessive carbon or

other deposits, and replace it if

necessary.

3. Measure the spark plug gap with a wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation. To install the spark plu

g

1. Clean the surface of the spark plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

2. Install the spark plug with the spark plug wrench, and then tight-

en it to the specified torque.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.3. Install the spark plug cap.TIPInstall the spark plug cap so that it is

positioned as shown in the illustration

and the spark plug lead does not con-

tact any surrounding parts.

1. Spark plug wrench

1

Specified spark plu g:

NGK/CPR8EA-9

1. Spark plug gap

Spark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 13 Nm (1.3 m·kgf, 9.4 ft·lbf)

U2DSE0E0.book Page 9 Thursday, March 19, 2015 10:34 AM

Page 50 of 90

Periodic maintenance an d a djustment

6-10

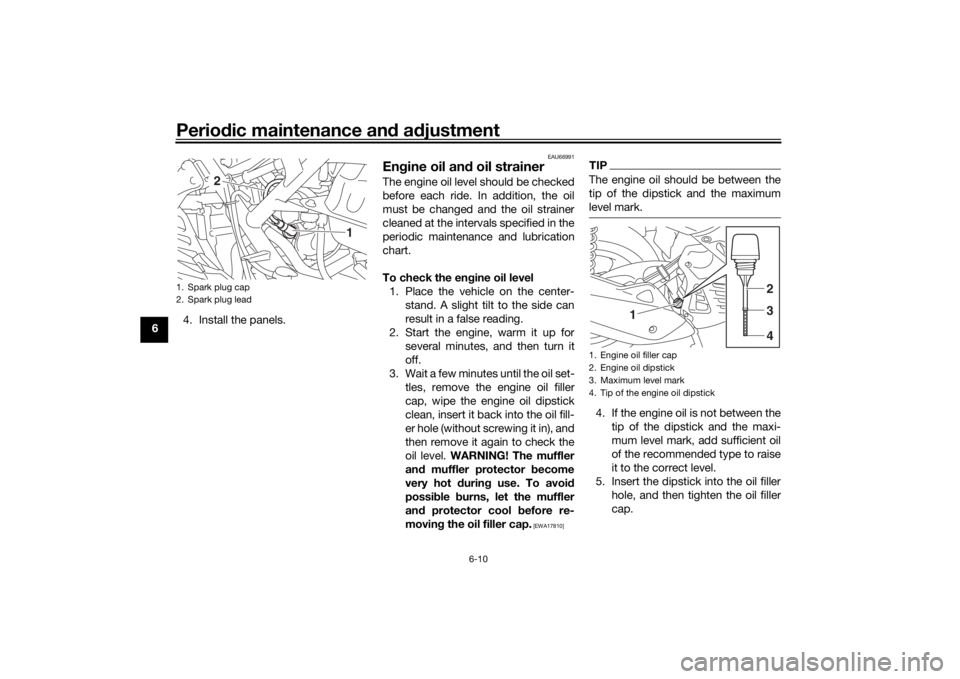

6 4. Install the panels.

EAU66991

En

gine oil an d oil strainerThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil strainer

cleaned at the intervals specified in the

periodic maintenance and lubrication

chart.

To check the en gine oil level

1. Place the vehicle on the center- stand. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles, remove the engine oil filler

cap, wipe the engine oil dipstick

clean, insert it back into the oil fill-

er hole (without screwing it in), and

then remove it again to check the

oil level. WARNING! The muffler

an d muffler protector become

very hot d uring use. To avoi d

possi ble burns, let the muffler

an d protector cool before re-

movin g the oil filler cap.

[EWA17810]

TIPThe engine oil should be between the

tip of the dipstick and the maximum

level mark.4. If the engine oil is not between the

tip of the dipstick and the maxi-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Insert the dipstick into the oil filler hole, and then tighten the oil filler

cap.

1. Spark plug cap

2. Spark plug lead

1

2

1. Engine oil filler cap

2. Engine oil dipstick

3. Maximum level mark

4. Tip of the engine oil dipstick

1

234

U2DSE0E0.book Page 10 Thursday, March 19, 2015 10:34 AM