light YAMAHA SR400 2016 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: SR400, Model: YAMAHA SR400 2016Pages: 96, PDF Size: 2.52 MB

Page 72 of 96

Periodic maintenance and adjustment

6-34

1

2

3

4

5

6

7

8

9

10

11

12

13

14 If a fuse is blown, replace it as follows.

1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the seat. (See page 3-13.)

3. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher amperage

rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15132]

4. Turn the key to “ON” and turn on the electrical circuit in question to

check if the device operates.

5. If a fuse immediately blows again, have a Yamaha dealer check the

electrical system.

1. Fuse box

1. Headlight fuse

2. Signaling system fuse

3. Ignition fuse

4. Backup fuse

5. Fuel injection system fuse

6. Parking lighting fuse

7. Spare fuse

1

12

3 4

5

7

6

Specified fuses: Signaling system fuse:

15.0 A

Headlight fuse: 15.0 A

Ignition fuse: 10.0 A

Backup fuse:

7.5 A

Fuel injection system fuse: 7.5 A

Parking lighting fuse: 7.5 A

2RD-28199-E1.book 34 ページ 2015年9月3日 木曜日 午後3時42分

Page 73 of 96

Periodic maintenance and adjustment

6-35

1

2

3

4

5

6

7

8

9

10

11

12

13

14

EAU23799

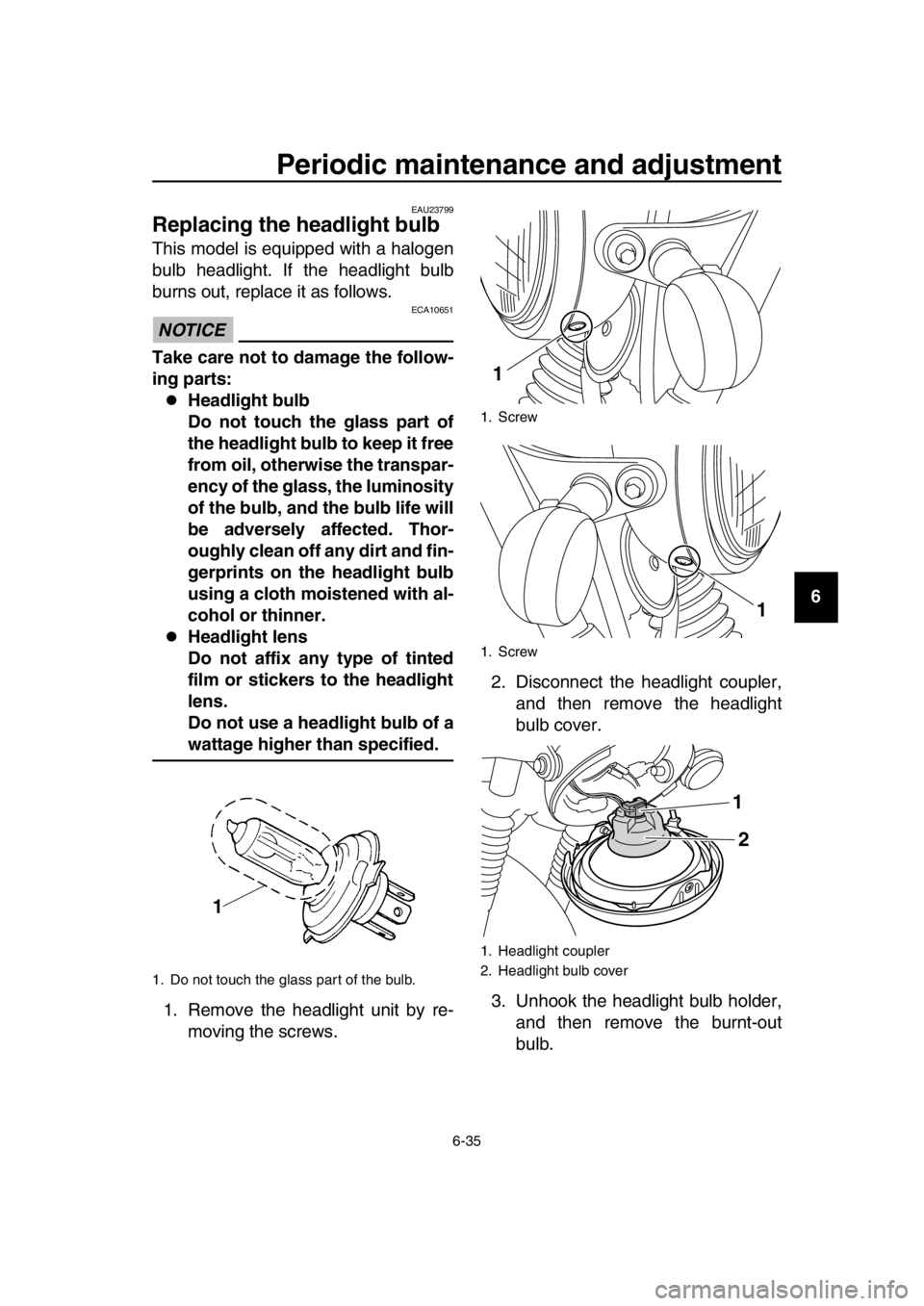

Replacing the headlight bulb

This model is equipped with a halogen

bulb headlight. If the headlight bulb

burns out, replace it as follows.

NOTICE

ECA10651

Take care not to damage the follow-

ing parts:

Headlight bulb

Do not touch the glass part of

the headlight bulb to keep it free

from oil, otherwise the transpar-

ency of the glass, the luminosity

of the bulb, and the bulb life will

be adversely affected. Thor-

oughly clean off any dirt and fin-

gerprints on the headlight bulb

using a cloth moistened with al-

cohol or thinner.

Headlight lens

Do not affix any type of tinted

film or stickers to the headlight

lens.

Do not use a headlight bulb of a

wattage higher than specified.

1. Remove the headlight unit by re- moving the screws. 2. Disconnect the headlight coupler,

and then remove the headlight

bulb cover.

3. Unhook the headlight bulb holder, and then remove the burnt-out

bulb.

1. Do not touch the glass part of the bulb.

1. Screw

1. Screw

1. Headlight coupler

2. Headlight bulb cover

1

1

1

2

2RD-28199-E1.book 35 ページ 2015年9月3日 木曜日 午後3時42分

Page 74 of 96

Periodic maintenance and adjustment

6-36

1

2

3

4

5

6

7

8

9

10

11

12

13

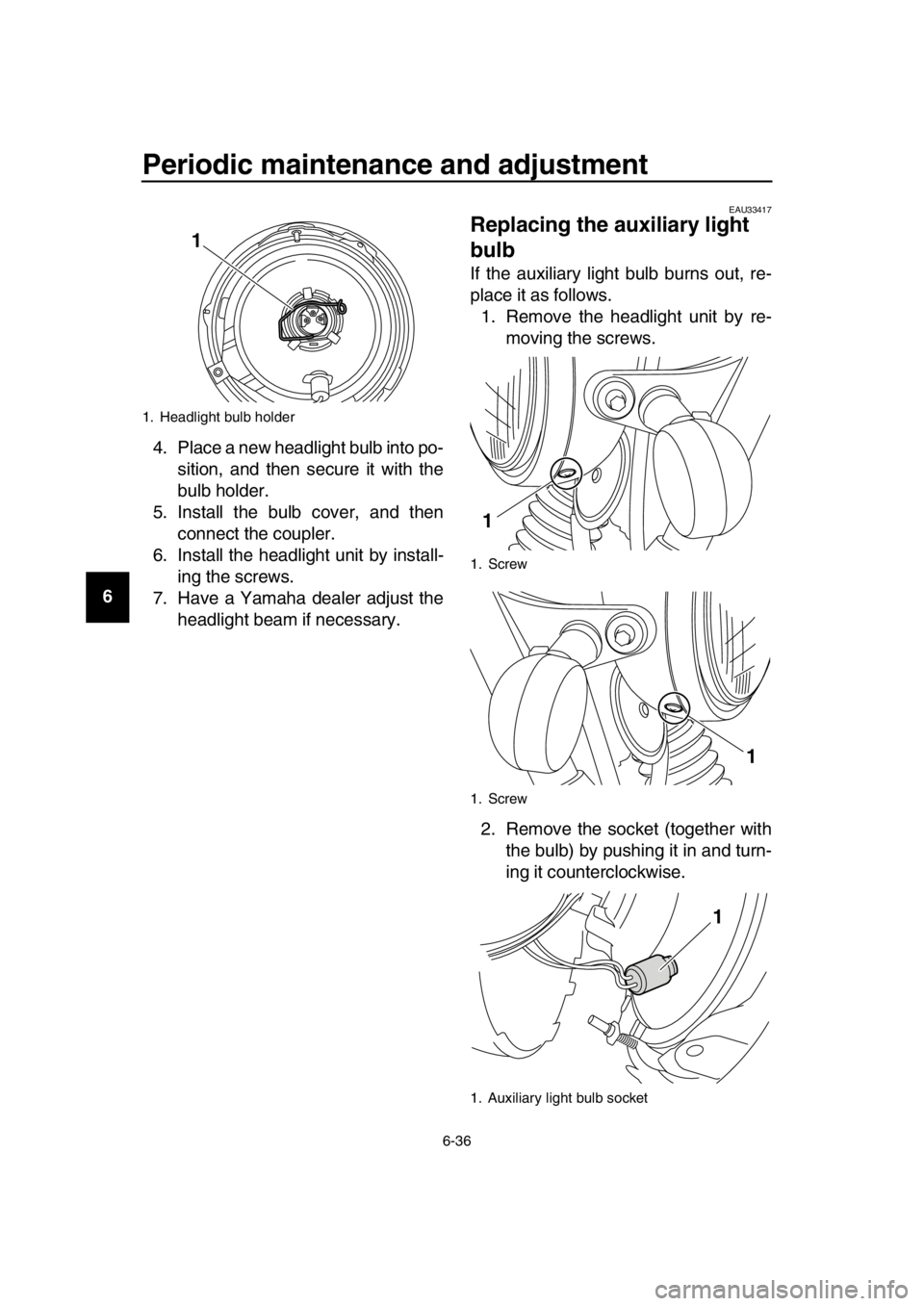

14 4. Place a new headlight bulb into po-

sition, and then secure it with the

bulb holder.

5. Install the bulb cover, and then connect the coupler.

6. Install the headlight unit by install- ing the screws.

7. Have a Yamaha dealer adjust the headlight beam if necessary.

EAU33417

Replacing the auxiliary light

bulb

If the auxiliary light bulb burns out, re-

place it as follows.1. Remove the headlight unit by re- moving the screws.

2. Remove the socket (together with the bulb) by pushing it in and turn-

ing it counterclockwise.

1. Headlight bulb holder

1

1. Screw

1. Screw

1. Auxiliary light bulb socket

1

1

1

2RD-28199-E1.book 36 ページ 2015年9月3日 木曜日 午後3時42分

Page 75 of 96

Periodic maintenance and adjustment

6-37

1

2

3

4

5

6

7

8

9

10

11

12

13

14

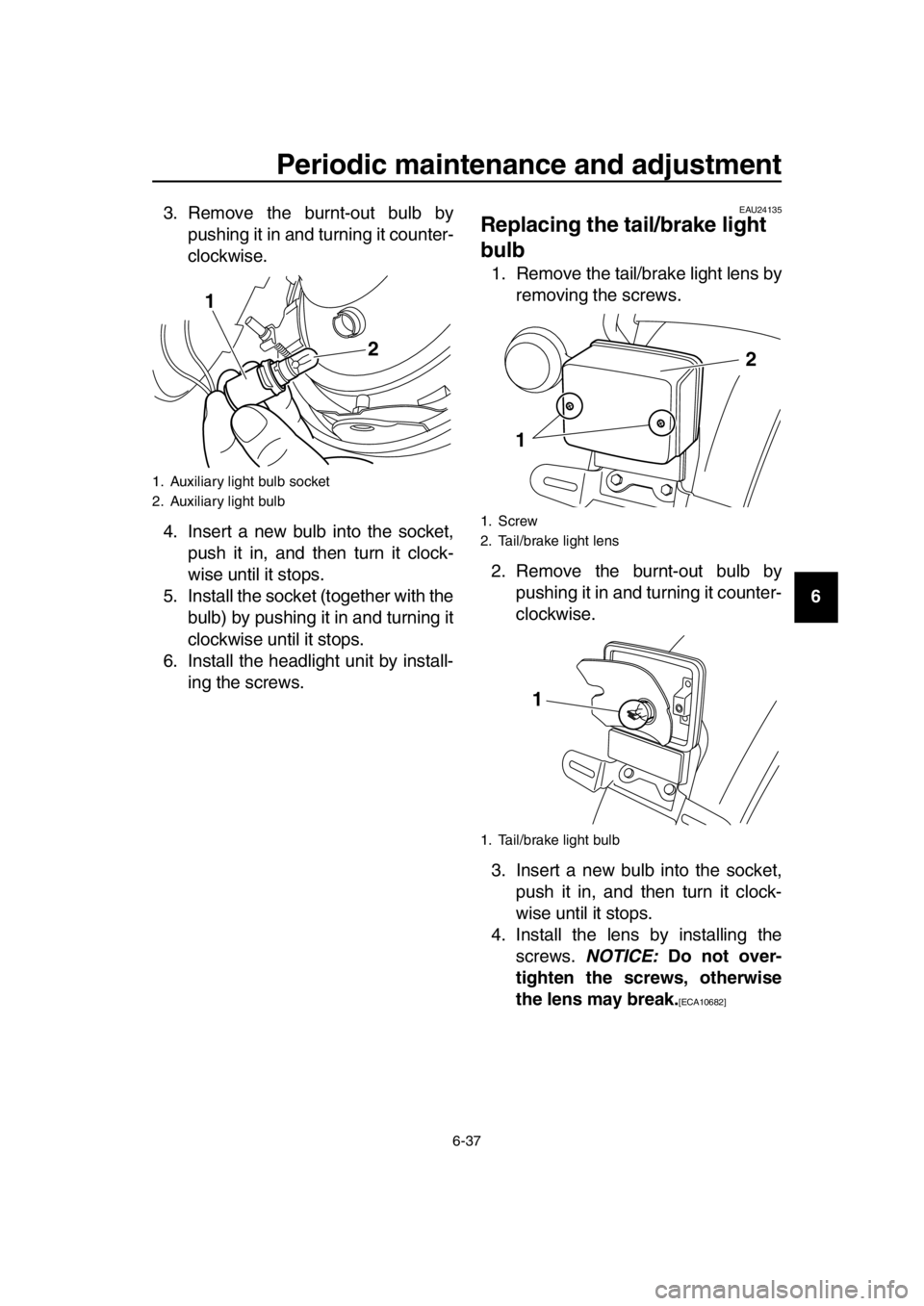

3. Remove the burnt-out bulb by

pushing it in and turning it counter-

clockwise.

4. Insert a new bulb into the socket, push it in, and then turn it clock-

wise until it stops.

5. Install the socket (together with the bulb) by pushing it in and turning it

clockwise until it stops.

6. Install the headlight unit by install- ing the screws.

EAU24135

Replacing the tail/brake light

bulb

1. Remove the tail/brake light lens byremoving the screws.

2. Remove the burnt-out bulb by pushing it in and turning it counter-

clockwise.

3. Insert a new bulb into the socket, push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the screws. NOTICE: Do not over-

tighten the screws, otherwise

the lens may break.

[ECA10682]

1. Auxiliary light bulb socket

2. Auxiliary light bulb

1

2

1. Screw

2. Tail/brake light lens

1. Tail/brake light bulb

1 2

1

2RD-28199-E1.book 37 ページ 2015年9月3日 木曜日 午後3時42分

Page 76 of 96

Periodic maintenance and adjustment

6-38

1

2

3

4

5

6

7

8

9

10

11

12

13

14

EAU60010

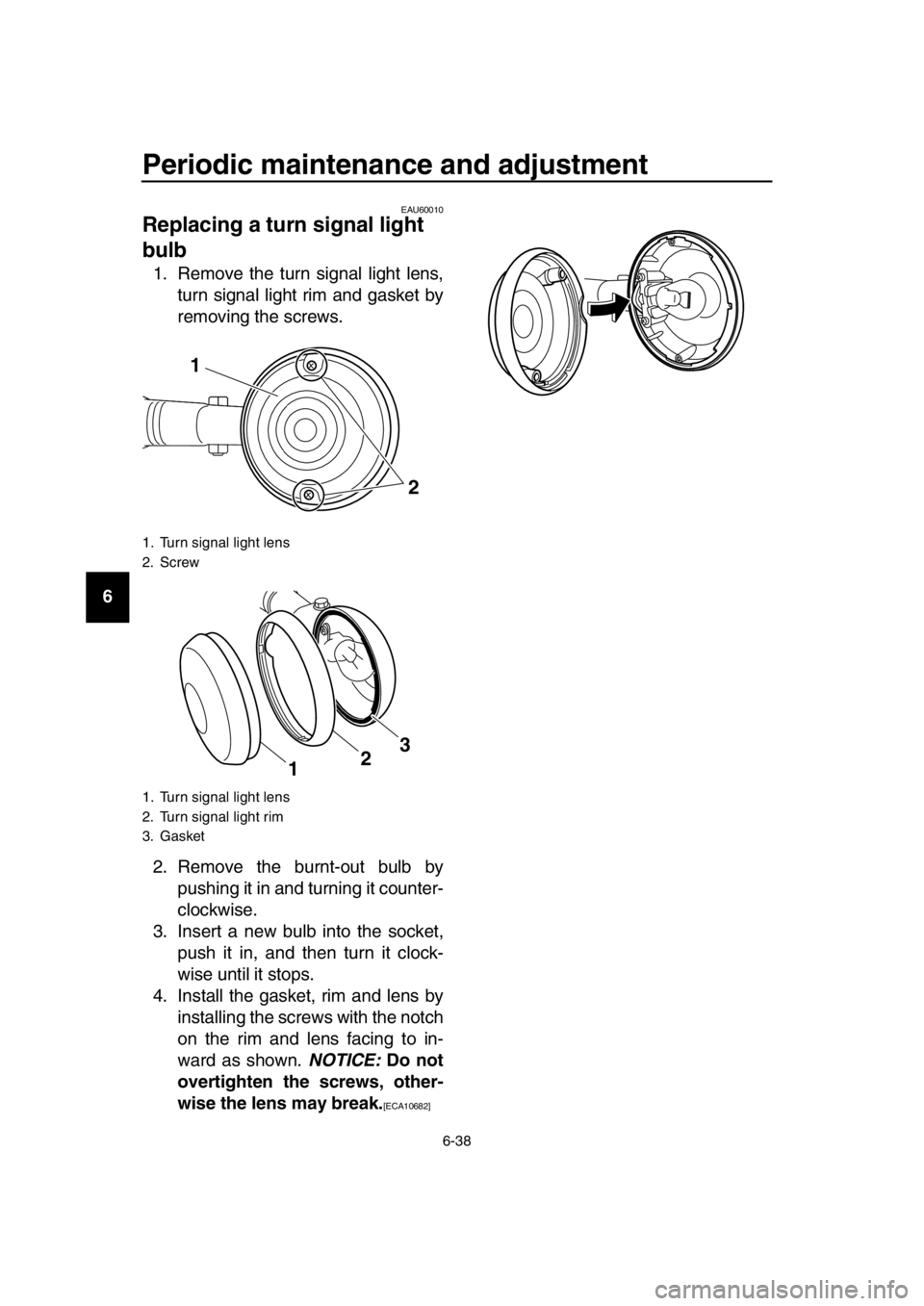

Replacing a turn signal light

bulb

1. Remove the turn signal light lens, turn signal light rim and gasket by

removing the screws.

2. Remove the burnt-out bulb by pushing it in and turning it counter-

clockwise.

3. Insert a new bulb into the socket, push it in, and then turn it clock-

wise until it stops.

4. Install the gasket, rim and lens by installing the screws with the notch

on the rim and lens facing to in-

ward as shown. NOTICE: Do not

overtighten the screws, other-

wise the lens may break.

[ECA10682]

1. Turn signal light lens

2. Screw

1. Turn signal light lens

2. Turn signal light rim

3. Gasket

1

2

3

2

1

2RD-28199-E1.book 38 ページ 2015年9月3日 木曜日 午後3時42分

Page 79 of 96

Periodic maintenance and adjustment

6-41

1

2

3

4

5

6

7

8

9

10

11

12

13

14

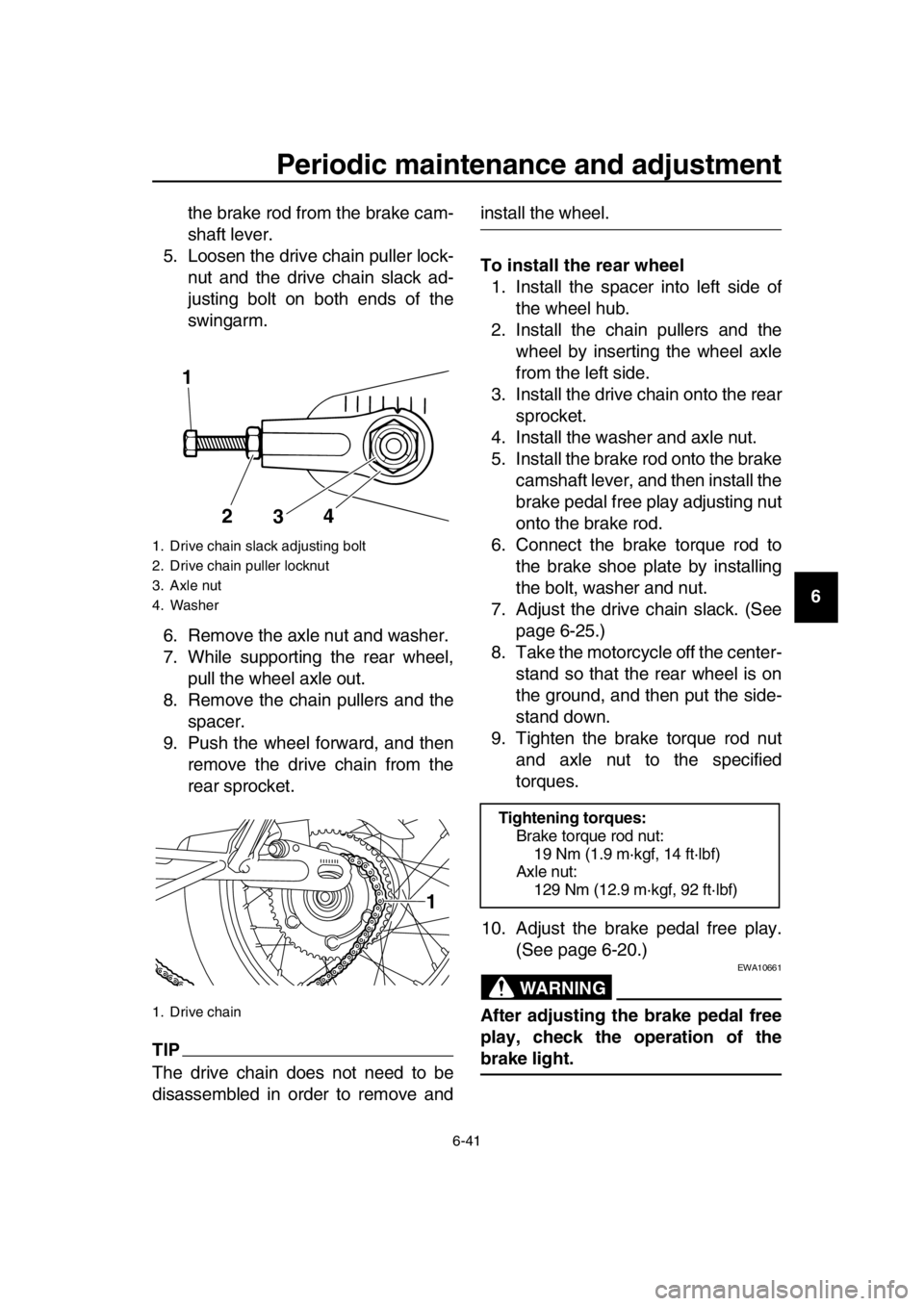

the brake rod from the brake cam-

shaft lever.

5. Loosen the drive chain puller lock- nut and the drive chain slack ad-

justing bolt on both ends of the

swingarm.

6. Remove the axle nut and washer.

7. While supporting the rear wheel, pull the wheel axle out.

8. Remove the chain pullers and the spacer.

9. Push the wheel forward, and then remove the drive chain from the

rear sprocket.

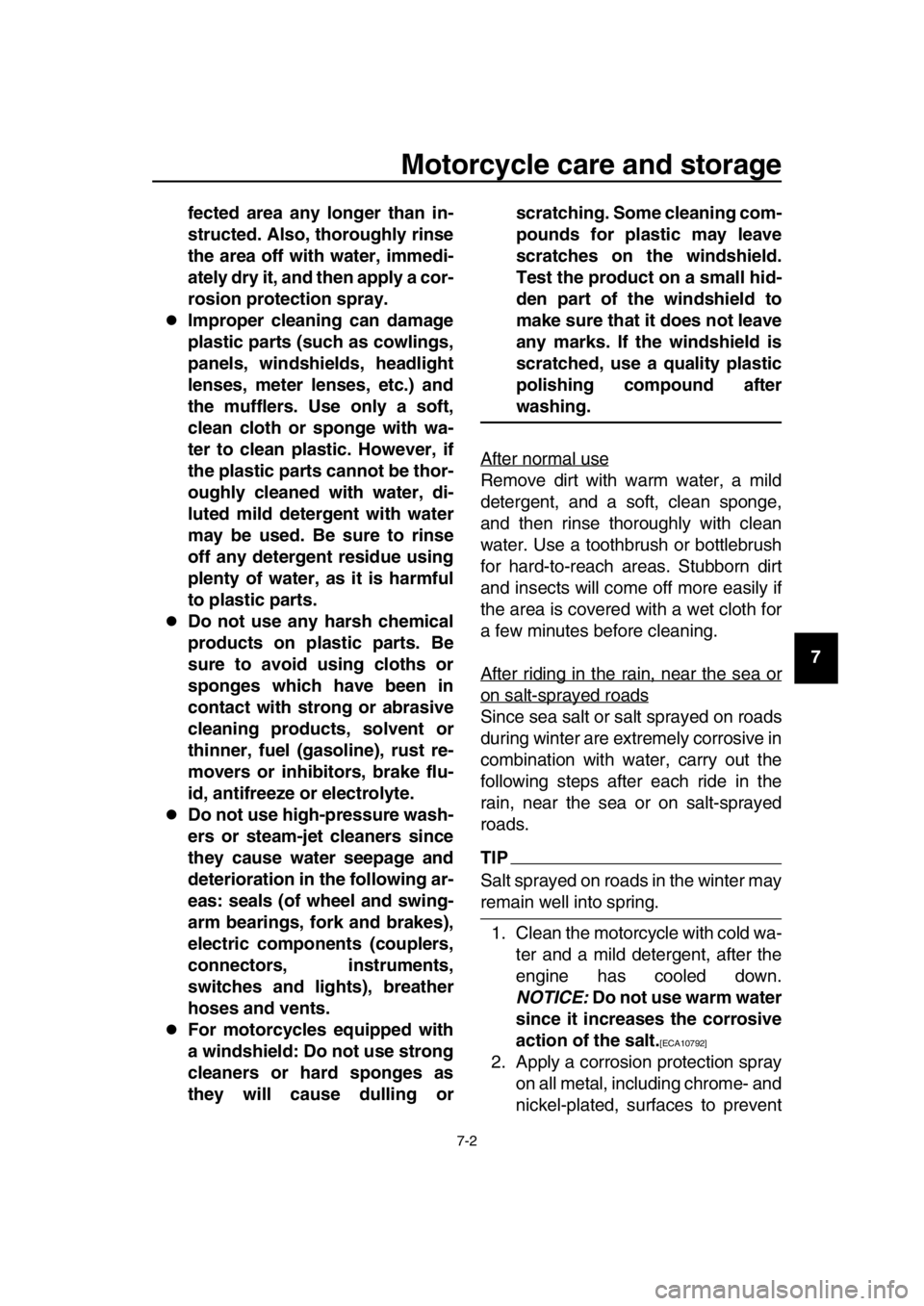

TIP

The drive chain does not need to be

disassembled in order to remove and

install the wheel.

To install the rear wheel1. Install the spacer into left side of the wheel hub.

2. Install the chain pullers and the wheel by inserting the wheel axle

from the left side.

3. Install the drive chain onto the rear sprocket.

4. Install the washer and axle nut.

5. Install the brake rod onto the brake camshaft lever, and then install the

brake pedal free play adjusting nut

onto the brake rod.

6. Connect the brake torque rod to the brake shoe plate by installing

the bolt, washer and nut.

7. Adjust the drive chain slack. (See page 6-25.)

8. Take the motorcycle off the center- stand so that the rear wheel is on

the ground, and then put the side-

stand down.

9. Tighten the brake torque rod nut and axle nut to the specified

torques.

10. Adjust the brake pedal free play. (See page 6-20.)

WARNING

EWA10661

After adjusting the brake pedal free

play, check the operation of the

brake light.

1. Drive chain slack adjusting bolt

2. Drive chain puller locknut

3. Axle nut

4. Washer

1. Drive chain

3

2

14

1

Tightening torques:

Brake torque rod nut: 19 Nm (1.9 m·kgf, 14 ft·lbf)

Axle nut: 129 Nm (12.9 m·kgf, 92 ft·lbf)

2RD-28199-E1.book 41 ページ 2015年9月3日 木曜日 午後3時42分

Page 80 of 96

Periodic maintenance and adjustment

6-42

1

2

3

4

5

6

7

8

9

10

11

12

13

14

EAU25852

Troubleshooting

Although Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur dur-

ing operation. Any problem in the fuel,

compression, or ignition systems, for

example, can cause poor starting and

loss of power.

The following troubleshooting chart

represents a quick and easy procedure

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look like

Yamaha parts, but they are often inferi-

or, have a shorter service life and can

lead to expensive repair bills.

WARNING

EWA15142

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from water

heaters or furnaces. Gasoline or

gasoline vapors can ignite or ex-

plode, causing severe injury or

property damage.

2RD-28199-E1.book 42 ページ 2015年9月3日 木曜日 午後3時42分

Page 83 of 96

Motorcycle care and storage

7-2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

fected area any longer than in-

structed. Also, thoroughly rinse

the area off with water, immedi-

ately dry it, and then apply a cor-

rosion protection spray.

Improper cleaning can damage

plastic parts (such as cowlings,

panels, windshields, headlight

lenses, meter lenses, etc.) and

the mufflers. Use only a soft,

clean cloth or sponge with wa-

ter to clean plastic. However, if

the plastic parts cannot be thor-

oughly cleaned with water, di-

luted mild detergent with water

may be used. Be sure to rinse

off any detergent residue using

plenty of water, as it is harmful

to plastic parts.

Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust re-

movers or inhibitors, brake flu-

id, antifreeze or electrolyte.

Do not use high-pressure wash-

ers or steam-jet cleaners since

they cause water seepage and

deterioration in the following ar-

eas: seals (of wheel and swing-

arm bearings, fork and brakes),

electric components (couplers,

connectors, instruments,

switches and lights), breather

hoses and vents.

For motorcycles equipped with

a windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or scratching. Some cleaning com-

pounds for plastic may leave

scratches on the windshield.

Test the product on a small hid-

den part of the windshield to

make sure that it does not leave

any marks. If the windshield is

scratched, use a quality plastic

polishing compound after

washing.

After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain, near the sea or

on salt-sprayed roads

Since sea salt or salt sprayed on roads

during winter are extremely corrosive in

combination with water, carry out the

following steps after each ride in the

rain, near the sea or on salt-sprayed

roads.

TIP

Salt sprayed on roads in the winter may

remain well into spring. 1. Clean the motorcycle with cold wa- ter and a mild detergent, after the

engine has cooled down.

NOTICE: Do not use warm water

since it increases the corrosive

action of the salt.

[ECA10792]

2. Apply a corrosion protection sprayon all metal, including chrome- and

nickel-plated, surfaces to prevent

2RD-28199-E1.book 2 ページ 2015年9月3日 木曜日 午後3時42分

Page 84 of 96

Motorcycle care and storage

7-3

1

2

3

4

5

6

7

8

9

10

11

12

13

14 corrosion.

After cleaning 1. Dry the motorcycle with a chamois

or an absorbing cloth.

2. Immediately dry the drive chain and lubricate it to prevent it from

rusting.

3. Use a chrome polish to shine chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally in-

duced discoloring of stainless-

steel exhaust systems can be re-

moved through polishing.)

4. To prevent corrosion, it is recom- mended to apply a corrosion pro-

tection spray on all metal,

including chrome- and nickel-plat-

ed, surfaces.

5. Use spray oil as a universal clean- er to remove any remaining dirt.

6. Touch up minor paint damage caused by stones, etc.

7. Wax all painted surfaces.

8. Let the motorcycle dry completely before storing or covering it.

WARNING

EWA11132

Contaminants on the brakes or tires

can cause loss of control.

Make sure that there is no oil or

wax on the brakes or tires.

If necessary, clean the brake

discs and brake linings with a

regular brake disc cleaner or ac-

etone, and wash the tires with

warm water and a mild deter-

gent. Before riding at higher

speeds, test the motorcycle’s

braking performance and cor-

nering behavior.

NOTICE

ECA10801

Apply spray oil and wax spar-

ingly and make sure to wipe off

any excess.

Never apply oil or wax to any

rubber and plastic parts, but

treat them with a suitable care

product.

Avoid using abrasive polishing

compounds as they will wear

away the paint.

TIP

Consult a Yamaha dealer for ad-

vice on what products to use.

Washing, rainy weather or humid

climates can cause the headlight

lens to fog. Turning the headlight

on for a short period of time will

help remove the moisture from the

lens.

2RD-28199-E1.book 3 ページ 2015年9月3日 木曜日 午後3時42分

Page 88 of 96

Specifications

8-2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Front tire:

Type: With tube

Size: 90/100-18M/C 54S

Manufacturer/model:

BRIDGESTONE/BT-45F

Rear tire:

Type:With tube

Size:

110/90-18M/C 61S

Manufacturer/model: BRIDGESTONE/BT-45R

Loading:

Maximum load:

150 kg (331 lb)

* (Total weight of rider, passenger, cargo and accessories)

Tire air pressure (measured on cold

tires):

Up to 90 kg (198 lb) load:Front:

175 kPa (1.75 kgf/cm

2, 25 psi)

Rear: 200 kPa (2.00 kgf/cm

2, 29 psi)

90 kg (198 lb) lo ad - maximum load:

Front: 200 kPa (2.00 kgf/cm

2, 29 psi)

Rear: 225 kPa (2.25 kgf/cm

2, 33 psi)

Front wheel:

Wheel type:Spoke wheel

Rim size: 18 x 1.85

Rear wheel:

Wheel type:Spoke wheel

Rim size: 18 x 2.15

Front brake:

Type:Hydraulic disc brake

Specified brake fluid:

DOT 4

Rear brake:

Type:Mechanical leading tr ailing drum brake

Front suspension:

Type:

Telescopic fork

Spring: Coil spring

Shock absorber:

Hydraulic damper

Wheel travel: 150 mm (5.9 in)

Rear suspension:

Type:

Swingarm

Spring: Coil spring

Shock absorber: Hydraulic damper

Wheel travel:

105 mm (4.1 in)

Electrical system:

System voltage:12 V

Ignition system:

TCI

Charging system: AC magneto

Battery:

Model:

GT4B-5

Voltage, capacity: 12 V, 2.5 Ah (10 HR)

Headlight:

Bulb type:

Halogen bulb

Bulb wattage quantity:

Headlight:

H4, 60.0 W/55.0 W x 1

Brake/tail light:

21.0 W/5.0 W 1

Front turn signal light: 21.0 W 2

Rear turn signal light:

21.0 W 2

Auxiliary light: 4.0 W 1

Meter lighting: 1.7 W 4

Neutral indicator light:

1.7 W 1

High beam indicator light: 1.7 W 1

2RD-28199-E1.book 2 ページ 2015年9月3日 木曜日 午後3時42分